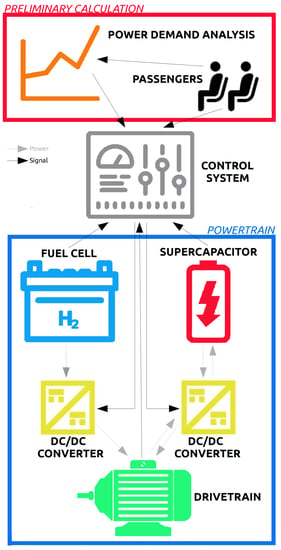

2.1. Preliminary Calculation

In this paper, a fuel cell hybrid tramway is tested on a real route. Typically, a tramway power demand is the most appropriate for the fuel cell use among rail applications, since its parameters assume moderate values. However, tramway rapid power variations do not recommend a powertrain constituted by a fuel cell stack only; the energy storage system use is mandatory, to avoid rapid fuel cell deterioration. Therefore, the fuel cell and energy storage characteristics and their sizing are strictly correlated with the vehicle demands and they can be very variable since there is not a canonical powertrain for every tramway [

13]. The power demand prediction results crucial in a preliminary phase, in order to select a suitable configuration for the line tested. The input parameters are the track morphology, the vehicle drive-cycle, and the tramway physical characteristics. To calculate the power demand, Equation (1) is used, where the traction power depends on: the mass times acceleration term; the resistive power, that considers the vehicle frictions in relation to air and rail; the track slope, useful for ascent and descent phases. All the terms are explained in the Nomenclature. The resistive power can be evaluated by the Davis equation, where A, B, and C terms depend on vehicle characteristics. It should be underlined that each term used for the power demand is a function of the passenger number.

During the sizing test, all the losses caused by the powertrain components have to be considered; although they cannot be known a priori, an efficiency estimation for each component, is needed to select suitable energy source sizes.

2.2. Energy Management System

Fuel cell systems achieve good performance and long lifespan when they operate in quasi-steady-state conditions, without working as power variation providers, avoiding starvation issues; thusly, the proper fuel cell behavior is guaranteed, avoiding premature damages, e.g., starvation issues. For this reason, a vehicle powered only by fuel cells is often not recommended; on the contrary, fuel cell hybrid systems can be a high-performing solution for different applications in the transport field. However, the introduction of new degrees of freedom, namely the power-rate choice of different energy sources, inevitably leads to higher complex systems. The power-sharing of fuel cell hybrid vehicles constitutes a sensitive issue, that affects the system response, efficiency, and lifespan.

The control system implementation needs a deep knowledge of the vehicle components and transport application to be managed; better performance can be reached when the control system is implemented ad-hoc for specific uses, considering features and peculiarities of the energy sources and vehicle drive-cycle. Compared to other transportation uses, railways are designed for a specific travel route; therefore, the speed and track morphology are always the same and the power and energy demand mainly change according to the train weight, namely the number of passengers and/or goods transported.

For these reasons, an equivalent consumption minimization strategy (ECMS), weighted for rail passenger number, is considered for the case study analyzed. The ECMS, designed by Paganelli et al. [

14], is a strategy based on optimization algorithms, operating in real-time, with a moderate computational burden. In the present case study, it is used to calculate the optimal power that the fuel cell system should supply, according to the fuel cell and energy storage system parameters.

The reference power output is achieved by solving the objective function minimization, reported in Equation (2), that represents the instantaneous hydrogen consumption of the vehicle.

The fuel cell consumption is indicated with

cFC, achieved through a polynomial fit, that emulates the hydrogen consumption of the fuel cell model. The equivalent hydrogen consumption, owing to the supercapacitor,

ceq,SC, is calculated considering the average fuel cell consumption, the fuel cell, and the supercapacitor powers, as reported in Equation (3).

A particular focus is on the equivalence factor (

keq), shown in Equation (4), since the power calculation is very sensitive to this parameter that correlates fuel cell and supercapacitor outputs. In addition, the equivalence factor, conveniently calibrated, allows the correct role of the supercapacitor as a power variations provider, guaranteeing an energy consumption equal to 0 kWh at the end of the cycle.

As a matter of fact, the SC state of charge (SOC) is considered to avoid supercapacitor improper operations; the fuel cell power output is varied according to the ratio between initial and current SOC, using a proper supercapacitor comparative factor (kSC) that assumes different values for charging and discharging mode.

Another important parameter is k1, useful for taking into account the drive cycle characteristics; in equivalent consumption minimization strategies, better performance can be reached if some drive cycle features are implemented in the control system. For this reason, the k1 calculation is obtained by means of an iterative approach: during the first instants, k1 is varied in order to achieve the average drive cycle power as output of the control strategy; once the suitable value is reached, k1 is maintained constant for the whole drive cycle time.

The key factor of the innovative strategy presented is kpass, which depends on the passenger number and it is updated after every stop. Its characterization is achieved for a specific journey simulated and vehicle typology used; thusly, it is possible to predict the power variations due to the weight change with good accuracy.

After the fuel cell power calculation, the supercapacitor is managed using simple power equilibriums, considering the drive cycle, fuel cell, and regenerative braking power, as shown in Equations (5) and (6), for acceleration and deceleration modes, respectively. The fuel cell and supercapacitor powers, reported in Equations (2), (5), and (6), are elaborated and, by means of the ratio between reference powers and real-time device voltage, shown in Equations (7) and (8), the reference currents are calculated.

2.3. Energy Sources

The energy and power demands are provided by the energy sources. In detail, according to the control strategy implemented, the energy of the whole cycle is supplied by the fuel cell, by means of the electrochemical reaction that uses the chemical energy of hydrogen. Therefore, the amount of hydrogen stored in the onboard train tanks fulfills the vehicle demands and electric recharges are not needed. According to the drive-cycle characteristics, the supercapacitor results are suitable for tramway demands, achieving high performance. It is useful for providing power and energy variations, but its energy consumption at the end of the cycle is 0 kWh, thanks to the control system. In other words, the SC state of charge assumes the same value at the start and end of the drive-cycle.

2.3.1. Fuel Cell

The core of the whole powertrain is the fuel cell stack, capable of transforming the hydrogen chemical energy into an electrical one and having water and heat as byproducts. Among fuel cells, proton exchange membrane (PEM) fuel cells are the most used for transport applications and also for some other stationary uses; this is due to their low operating temperature, high power density, specific energy, and fast start-up time [

15]. As a matter of fact, fuel cell operative temperatures are about 80–100 °C, given by the high electrolyte performance at low temperatures, that leads to fast start-up time. In addition, it can reach a high power level with compact dimensions; the high specific energy is an indirect feature, owing to the hydrogen storage type [

16].

The fuel cell stack is numerically modeled in dynamic conditions through numerous relations linked to electrical, thermodynamic, and chemical processes. Its model has been formalized and later implemented ad hoc, in order to accurately study the PEM performance in the advanced application presented [

7]. Nevertheless, several simplifications have been considered, such as the supply manifold neglecting and ideal humidifier behavior, thus achieving a satisfying accuracy for the case study analyzed. The PEM model is based on the equivalent circuit, where the electrochemical model plays a pivotal role. The Nernst voltage, namely the ideal voltage, is the first term of Equations (9)–(10) and is the input of the voltage source. A particular focus is on the partial pressures, obtained by the derivative of the gas law, solved through the Laplace transformation [

7].

The PEM current is imposed by the DC/DC converter, according to the control strategy decisions, while the real voltage is achieved by the difference between the Nernst voltage and the activation (Vact), ohmic (Vohm), and concentration losses (Vconc), as shown in Equations (9)–(10). The former are due to the slow kinetics of the reactions and they are good represented by the Tafel equation, calculated as the logarithm of the ratio between fuel cell (IFC) and exchange current (I0). The ohmic losses are caused by the internal resistance of the system, achieved using Ohm’s law. The latter, namely the concentration losses, occur at high currents, for the gradient of the reactant concentration; this phenomenon is approximated by the last terms of Equations (9)–(10), function of the operative and maximum (Imax) fuel cell currents.

It should be underlined that, among the losses parameter calculations, the exchange current and charge transfer coefficient (

αFC) are obtained by means of an iterative process. The electrochemical model allows for acquiring all the main PEM parameters, including efficiency and hydrogen mass flow rate.

The hydrogen mass flow rate is crucial for the control strategy used, and its calculation is shown in Equation (11), depending on the cell number (

Nc), fuel cell current and utilization factor (

Uf). Regarding the fuel cell efficiency, it is calculated in Equation (12) as the ratio between output and input powers, respectively the fuel cell output and the chemical power contained in the hydrogen mass flow rate consumed. The main constant used in the model is listed in

Table 1.

2.3.2. Supercapacitor

Among the electrical energy sources, supercapacitors occupy an intermediate position between battery and capacitor, owing to their characteristics. They are suitable for responding to high-frequency power demands, both in charge and discharge operations. Compared to batteries with the same size, it could provide higher power amounts, up to a hundred times, with lower energy density, between 3 and 30 times. The vehicle and drive cycle features are fundamental to properly use the supercapacitor as an energy storage system, since the increase of vehicle weight and occupied space and the power and energy demand trends need to be considered. For these reasons, supercapacitors are not widely used in transports.

Usually, rail drive cycles have sudden power components, that can be well managed by supercapacitors. An electric double-layer capacitor (EDLC) supercapacitor is used for this transport application. Several assumptions are considered, such as neglecting the aging and temperature effect and, also, the cell balancing. As with the PEM fuel cell, an equivalent circuit is used, constituted of a voltage source and an equivalent resistance, that is considered constant for both charge and discharge phases. The value of the voltage source is achieved by means of the Stern equation, expressed in Equation (13) [

17]. Among the main outputs, particular focus is oriented on the state of charge which is an important parameter in the control strategy; the SOC calculation is shown in Equation (14) [

17].

2.4. DC/DC Converters

The energy sources are connected to the drivetrain subsystem by means of DC/DC converters, mainly to manage them, imposing the power rate by means of strategy decisions, and protect them from sudden voltage variations that can lead to premature damages [

18].

A unidirectional boost converter, shown in

Figure 1a, is selected to link the fuel cell and the drivetrain system; it is useful for increasing the PEM voltage to the 800 V DC bus one.

Regarding the supercapacitor, a bi-directional buck-boost converter is used, mainly to store the regenerative energy in the storage system, shown in

Figure 1b.

These power electronics devices are modeled using all their electrical components, not by means of electrical correlations. They are satisfyingly controlled according to the fuel cell and supercapacitor current demands. In detail, the DC/DC converter duty cycle is managed by evaluating the current error, namely the difference between the reference current value, calculated by means of the control system (Equations (7) and (8)), and the real current value, the one measured at the DC/DC converter. Operating on the on-off periods of the DC/DC converter switches, the error achieved is changed with the aim of reducing the difference between the real and reference currents.

2.5. Drivetrain

The energy sources used are in parallel and are connected to an 800 V DC bus. Therefore, the voltage obtained is direct and single-phase. Since an AC motor is used, owing to its good performance, an inverter connects the DC bus to the motor. It can convert the single-phase and direct current in the sinusoidal and three-phase one, allowing the voltage control, in terms of amplitude and phase shift angle, managing the motor outputs.

The terminal part of the electric system is the motor and it converts the electric power into mechanical power. Nowadays, among the motor types, the permanent magnet synchronous motor (PMSM) is the most used in vehicle applications because of its characteristics, i.e., high specific power, torque, and higher efficiency compared to the other motor typologies [

19].

The motor torque and speed are converted in those needed at the wheels by means of the gearbox, which is a mechanical component, useful for connecting driveshaft and motor. In electric railways, one gear ratio can be used, with higher efficiency compared to more complex systems.

Inverters, motors, and gearboxes are bidirectional devices because the power can flow in both directions and, consequently, the motor can work as a generator, during deceleration phases, and as a motor, during acceleration phases. Thusly, a regenerative braking strategy can be implemented in the control strategy, leading to an overall efficiency improvement. The detailed modeling of the drivetrain components is beyond the scope of the present paper, but they are taken into account considering energy losses and, hence, component efficiencies, which are listed in

Table 2.