Heat Transfer Characteristics of High-Temperature Dusty Flue Gas from Industrial Furnaces in a Granular Bed with Buried Tubes

Abstract

:1. Introduction

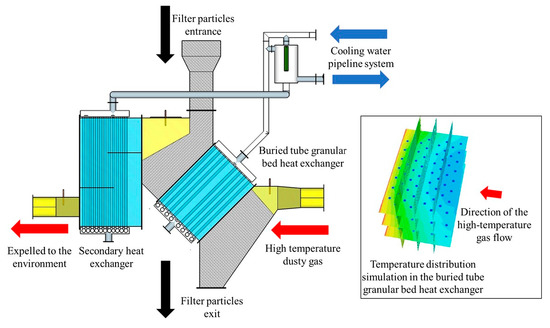

2. Mathematical Model

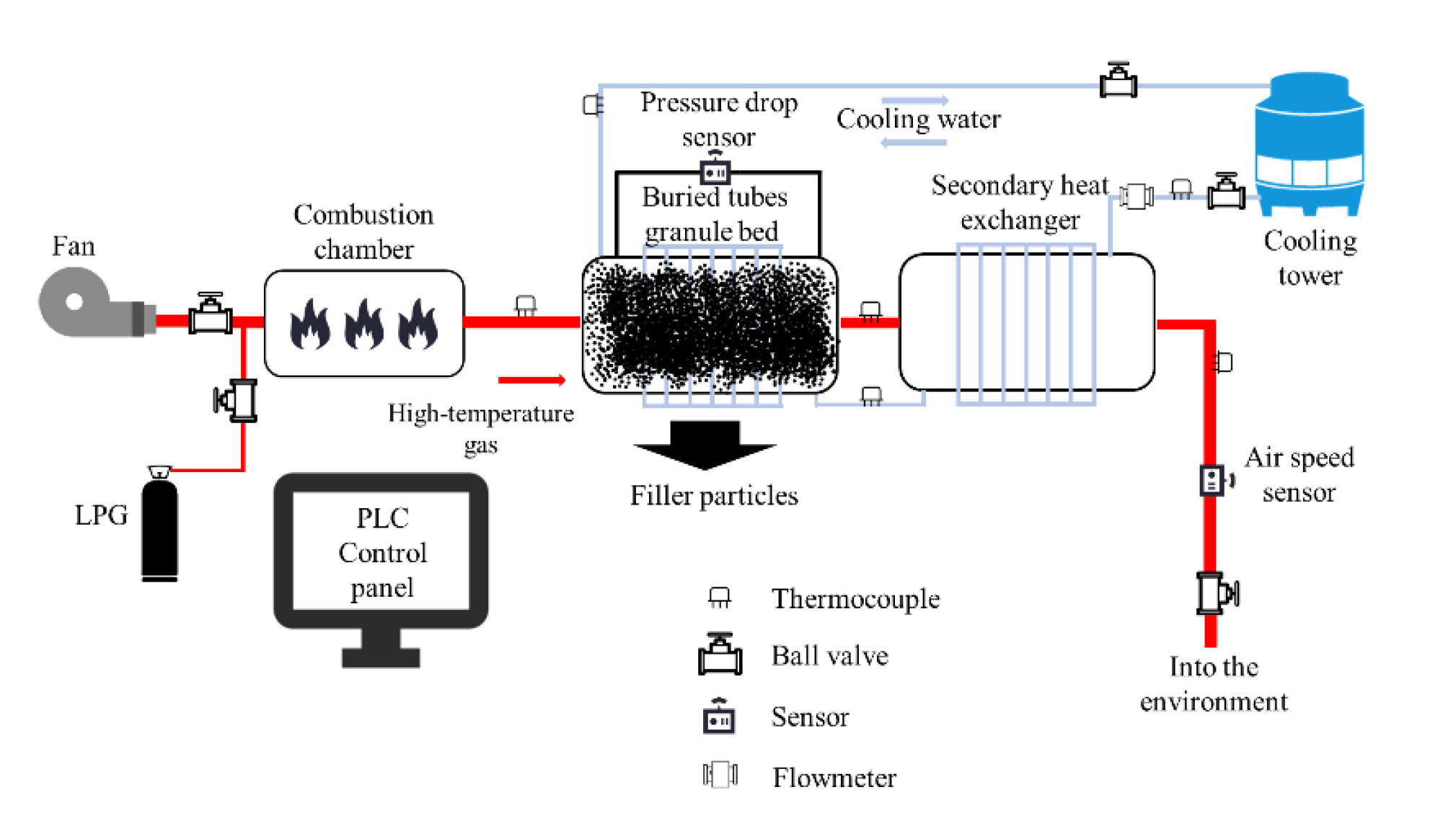

3. Experimental Design

4. Experiment and Result Analysis

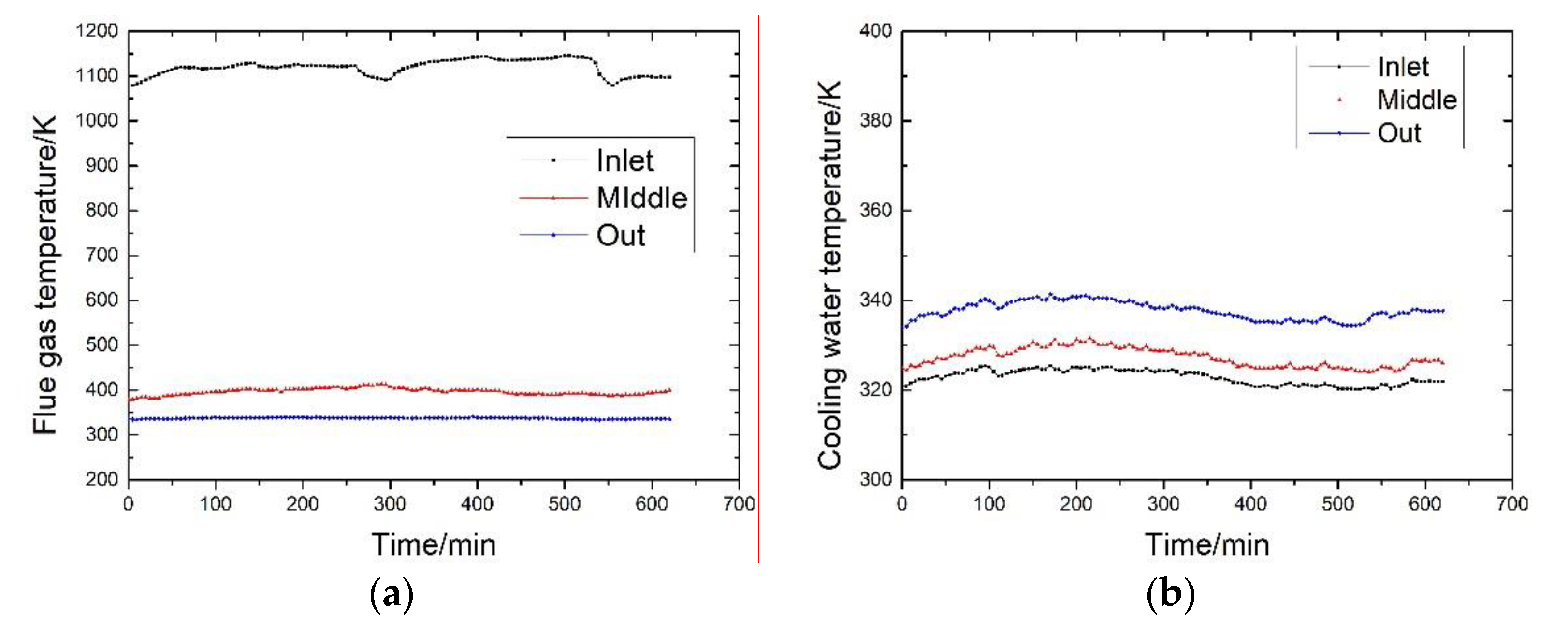

4.1. Analysis of Heat Transfer Experimental Results

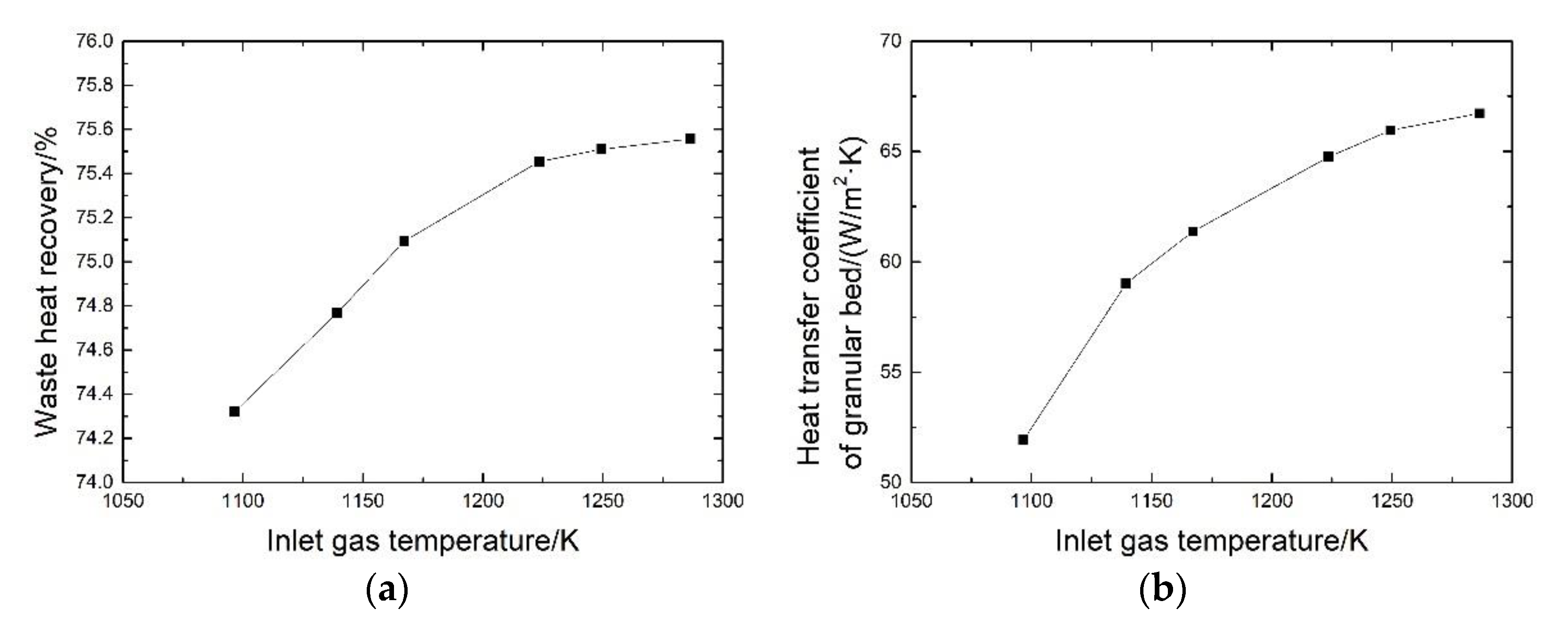

4.2. Influence of Inlet Flue Gas Temperature on Waste Heat Recovery

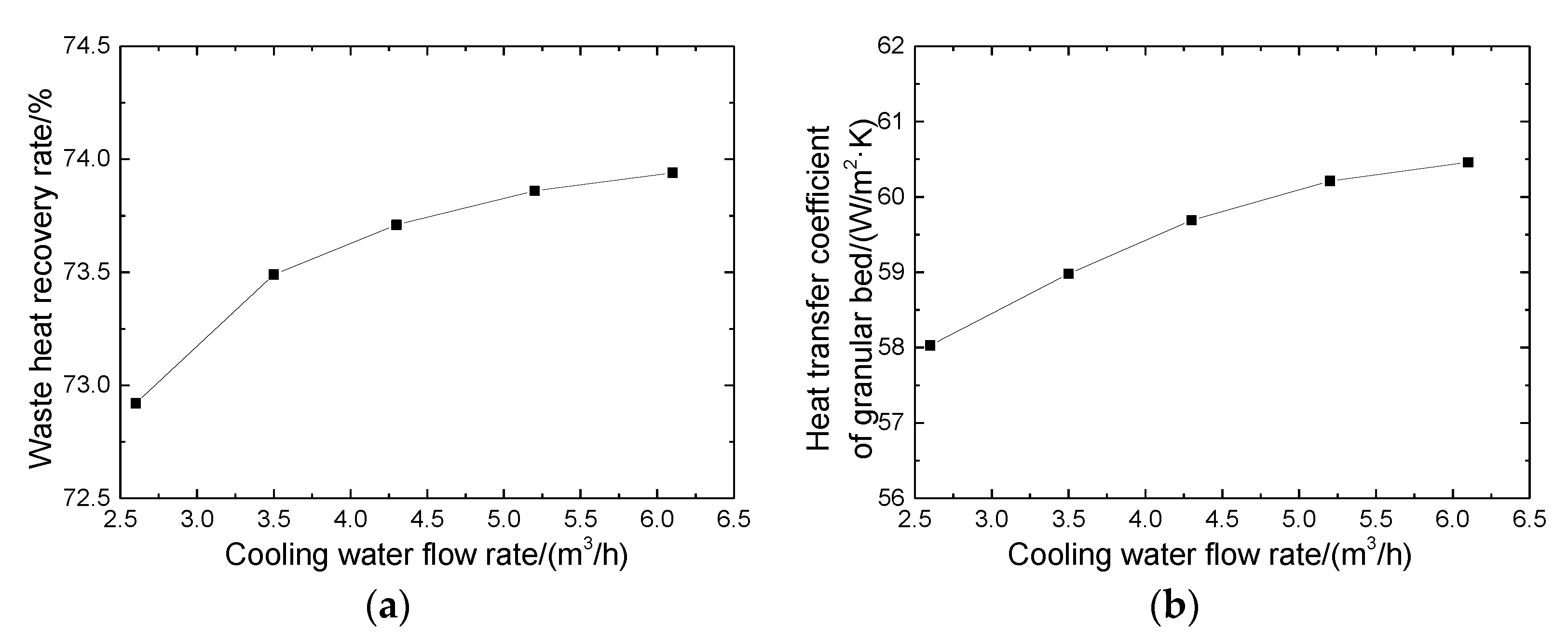

4.3. Influence of Cooling Water Flow on Waste Heat Recovery

5. Numerical Simulation and Analysis

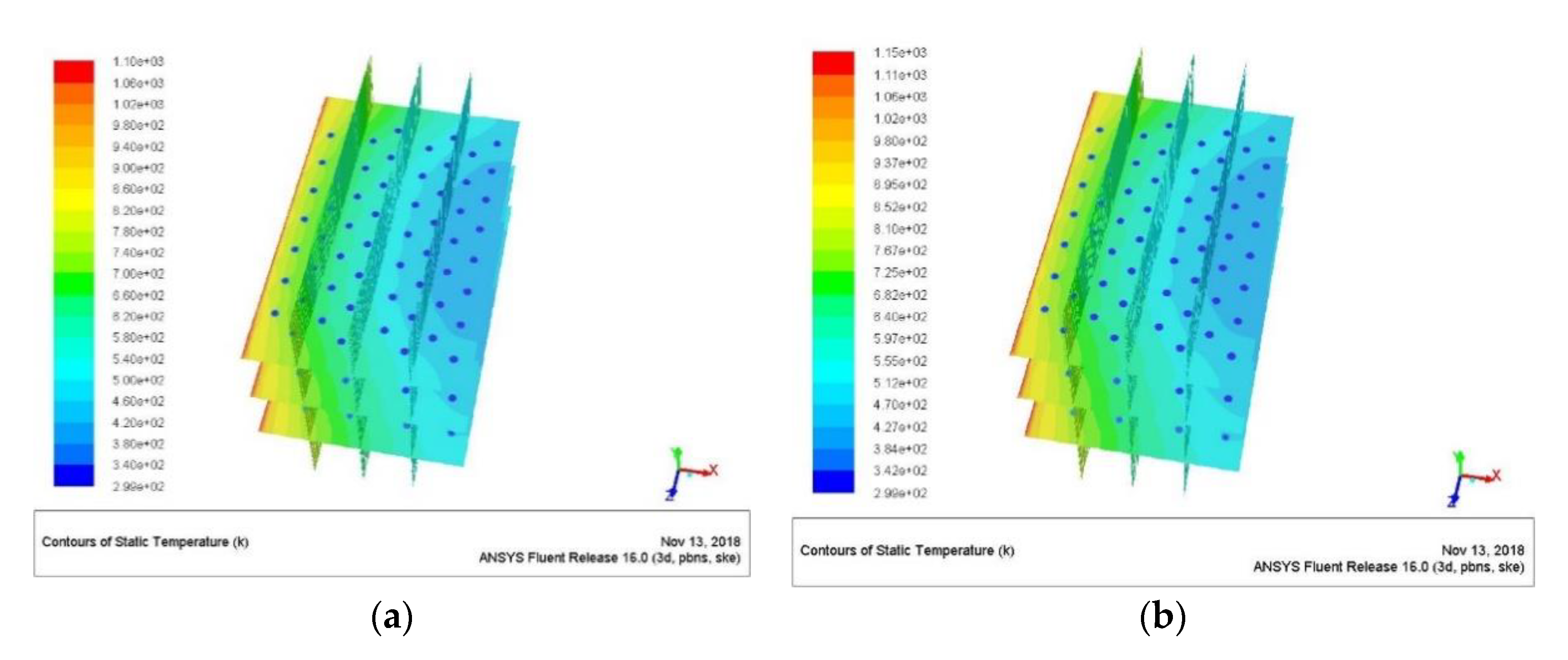

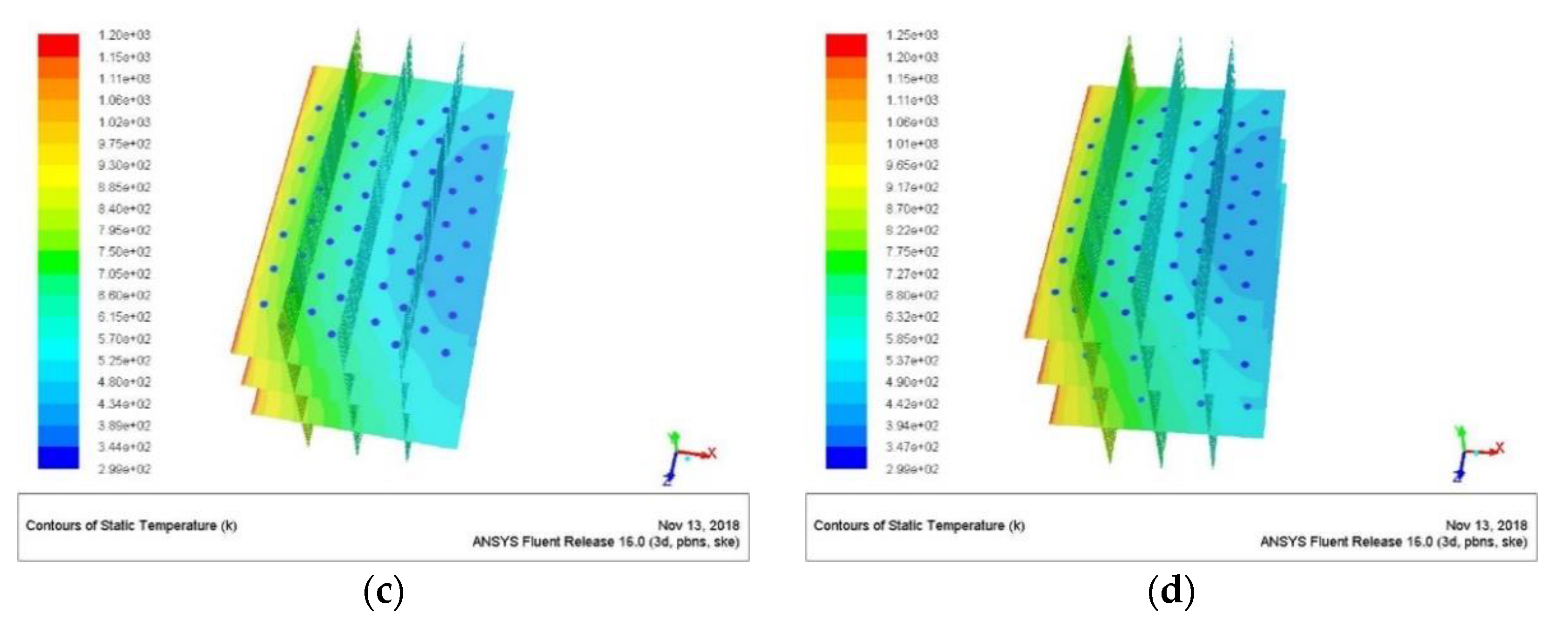

5.1. Heat Transfer under Different Inlet Flue Gas Temperatures

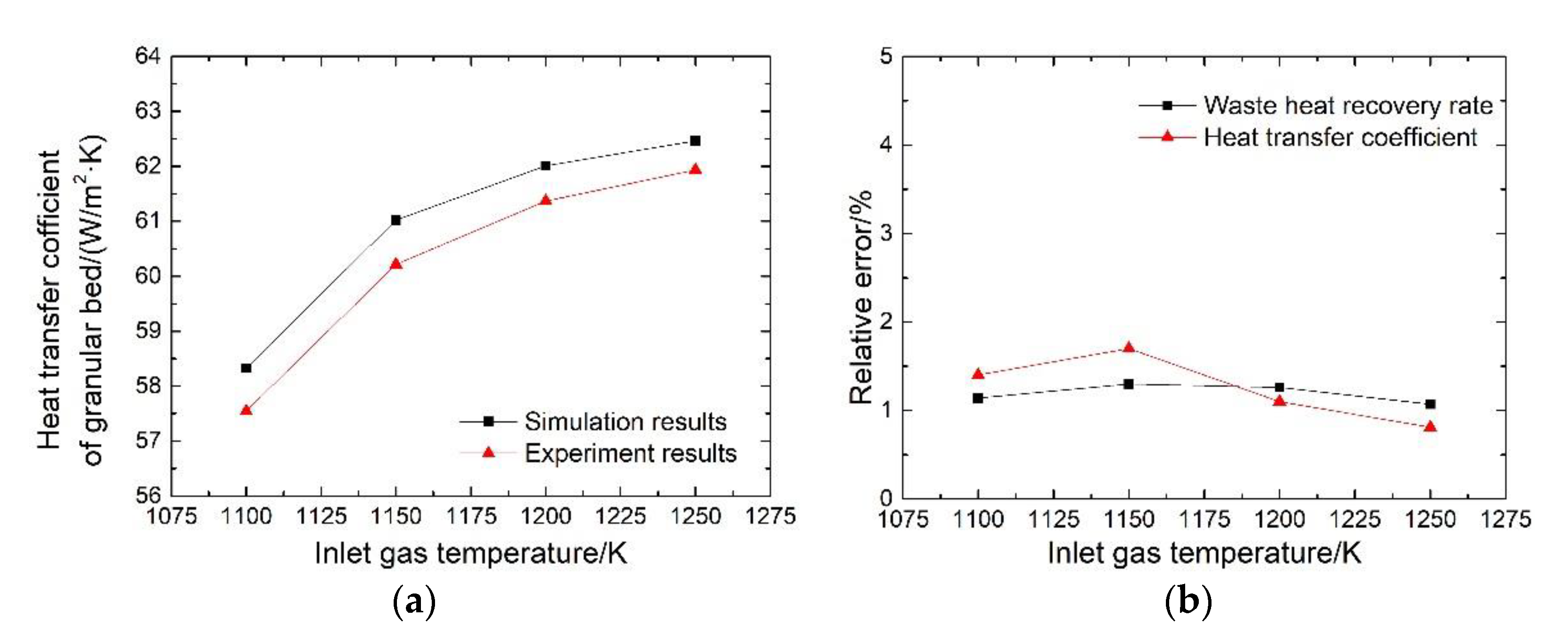

5.2. Heat Transfer under Different Cooling Water Flow Rates

6. Conclusions

- (1)

- The experimental equipment operated stably at 1073.15 K. The waste heat recovery rate increased gradually when the heat and the recovery rate stored in the particles stabilized at higher than 72% after storage.

- (2)

- The waste heat recovery rate of the equipment increased by 1.7%, and the heat transfer coefficient of the granular bed increased by 26.6% with the variation in the inlet gas temperature from 1096.65 K to 1286.45 K. The experimental correlation of the heat transfer coefficient of the granular bed with the inlet gas temperature was proposed.

- (3)

- The waste heat recovery rate of the equipment increased by 1.9%, and the heat transfer coefficient of the granular bed increased by 4.4% with the variation in the cooling water flow rate from 2.6 m3/h to 5.1 m3/h. The experimental correlation of the heat transfer coefficient of the granular bed with the cooling water flow rate was proposed. With the increase of cooling water flow rate and flue gas inlet temperature, the increase rate of waste heat recovery rate and heat transfer coefficient of granular bed slowed down.

- (4)

- The heat transfer in the granular bed was simulated. The influence of gas temperature on the heat transfer in the granular bed was studied, and the relative error between the experimental and simulation results was less than 2%.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Name | Significance |

| Total heat transfer coefficient of the granular bed, W/(m2·K) | |

| Total heat transfer area, m2 | |

| Logarithmic mean temperature difference, K | |

| c | Specific heat capacity of cooling water, J/(kg·K) |

| Cooling water mass flow rate, kg/s | |

| Temperature of inlet cooling water, K | |

| Temperature of outlet cooling water, K | |

| Inlet gas temperature, K | |

| Outlet gas temperature, K | |

| n | Number of heat exchange tubes in the granular bed |

| d | Diameter of heat exchange tubes, m |

| l | Length of a single heat exchange tube, m |

| m | Total mass of the filled particles in the granular bed, kg |

| Mass of a single filled particle, kg | |

| r | Radius of a single filled particle, m |

| σ | Blackbody radiation constant, W/(m2·K4) |

| Contact thermal resistance between particles, m2·K/W | |

| Gas blackness in porous media | |

| Density of particles, kg/m3 | |

| r | Radius of a single filled particle, m |

References

- Nasr, K.; Ramadhyani, S.; Viskanta, R. An Experimental Investigation on Forced Convection Heat Transfer from a Cylinder Embedded in a Packed Bed. J. Heat Transf. 1994, 116, 73–80. [Google Scholar] [CrossRef]

- Pivem, A.C.; Marcelo, J.S. Laminar Heat Transfer in a Moving Porous Bed Reactor Simulated with a Macroscopic Two-energy Equation Model. Int. J. Heat Mass Transf. 2012, 55, 1922–1930. [Google Scholar] [CrossRef]

- Zumbrunnen, D.A.; Viskanta, R.; Incropera, F.P. Heat transfer through granular beds at high temperature. Wärme-und Stoffübertrag. 1984, 18, 221–226. [Google Scholar] [CrossRef]

- Dayal, R.; Gambaryan-Roisman, T. A novel numerical method for radiation exchange in granular medium. Heat Mass Transf. 2016, 52, 2587–2591. [Google Scholar] [CrossRef]

- Shen, C.; Yang, S.L.; Zhang, D.W.; Yu, P.; Yang, J.Z. Experimental Research on Heat Transfer Performance of Parallel Flow Heat Pipe Exchanges. J. Eng. Thermophys. 2018, 39, 1339–1343. [Google Scholar]

- Zhang, Z.F.; Ma, T.Z.; Zhao, J.Q.; Huo, X.H. Studies on Heat Transfer from a Vertical Immersed Tube in a Large Particle Fluidized Bed. J. Eng. Thermophys. 1988, 9, 156–160. [Google Scholar]

- Royston, D. Heat transfer in the flow of solids in gas suspensions through a packed bed. Ind. Eng. Chem. Process. Des. Dev. 1971, 10, 145–150. [Google Scholar] [CrossRef]

- Doherty, J.A.; Verma, R.S.; Shrivastava, S. Heat transfer from immersed horizontal tubes of different diameter in a gas-fluidized bed. Energy 1986, 11, 773–783. [Google Scholar] [CrossRef]

- Zhang, S.C.; Wang, Z.F. Experimental and Numerical Investigations on the Fluidized Heat Absorption inside Quartz Glass and Metal Tubes. Energies 2019, 12, 806. [Google Scholar] [CrossRef] [Green Version]

- Cong, T.N.; He, Y.R.; Chen, H.S.; Ding, Y.L.; Wen, D.S. Heat transfer of gas-solid two-phase mixtures flowing through a packed bed under constant wall heat. Chem. Eng. J. 2007, 130, 1–10. [Google Scholar] [CrossRef]

- Grewal, N.S.; Saxena, S.C. Maximum heat transfer coefficient between a horizontal tube and a gas-solid fluidized bed. Ind. Eng. Chem. Process. Des. Dev. 1981, 20, 108–116. [Google Scholar] [CrossRef]

- Yin, S.W.; Li, J.; Shi, G.S.; Xue, F.Y.; Wang, L. Experiment Study on Heat Transfer Characteristics of Dusty Gas Flowing through a Granular Bed with Buried Tubes. Appl. Therm. Eng. 2019, 146, 296–404. [Google Scholar] [CrossRef]

- Chen, J.L.; Li, X.F.; Huai, X.L.; Wang, Y.W.; Zhou, J.Z. Numerical Study of Collection Efficiency and Heat-Transfer Characteristics of Packed Granular Filter. Particuology 2019, 46, 75–82. [Google Scholar] [CrossRef]

- Yin, S.W.; Shi, Y.L.; Tong, L.G.; Wang, L.; Ding, Y.L. Performance Simulation and Benefit Analysis of Ammonia Absorption Cooling and Heating Dual-Supply System Based on Off-Peak Electricity Heat Storage. Energies 2019, 12, 2298. [Google Scholar] [CrossRef] [Green Version]

- Yin, S.W.; Xue, F.Y.; Wang, X.; Wang, L.; Tong, L.G. Experimental Study on Purification and Waste Heat Recovery Characteristics of Dusty Gas in Buried Tube Granular Bed. J. Eng. Thermophys. 2019, 40, 1928–1935. [Google Scholar]

- Wang, N.H.; Meng, F.Z. Influence of Logarithmic Mean Temperature Difference on Heat Transfer Area of Heat Exchanges. Petro-Chem. Equip. 1999, 28, 13–15. [Google Scholar]

| Parameter/Unit | Value |

|---|---|

| Hydraulic diameter/mm | 16 |

| Turbulence intensity/% | 13 |

| Material equivalent diameter/mm | 5 |

| Viscous resistance coefficient of porous media | 4551.54 |

| Inertial resistance coefficient of porous media | 18,148.15 |

| Thermal conductivity of porous media/W/(m2·K) | 39.59 |

| Grid Sizes | Inlet Gas Temperature/K | Outlet Gas Temperature/K | Relative Error/% |

|---|---|---|---|

| 80,342 | 800 | 665.32 | |

| 2,764,566 | 800 | 664.21 | 1.67 |

| 4,537,529 | 800 | 663.83 | 2.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Xue, F.; Wang, X.; Tong, L.; Wang, L.; Ding, Y. Heat Transfer Characteristics of High-Temperature Dusty Flue Gas from Industrial Furnaces in a Granular Bed with Buried Tubes. Energies 2020, 13, 3589. https://doi.org/10.3390/en13143589

Yin S, Xue F, Wang X, Tong L, Wang L, Ding Y. Heat Transfer Characteristics of High-Temperature Dusty Flue Gas from Industrial Furnaces in a Granular Bed with Buried Tubes. Energies. 2020; 13(14):3589. https://doi.org/10.3390/en13143589

Chicago/Turabian StyleYin, Shaowu, Feiyang Xue, Xu Wang, Lige Tong, Li Wang, and Yulong Ding. 2020. "Heat Transfer Characteristics of High-Temperature Dusty Flue Gas from Industrial Furnaces in a Granular Bed with Buried Tubes" Energies 13, no. 14: 3589. https://doi.org/10.3390/en13143589