Trade-Offs in Net Life Cycle Energy Balance and Water Consumption in California Almond Orchards

Abstract

:1. Introduction

2. Materials and Methods

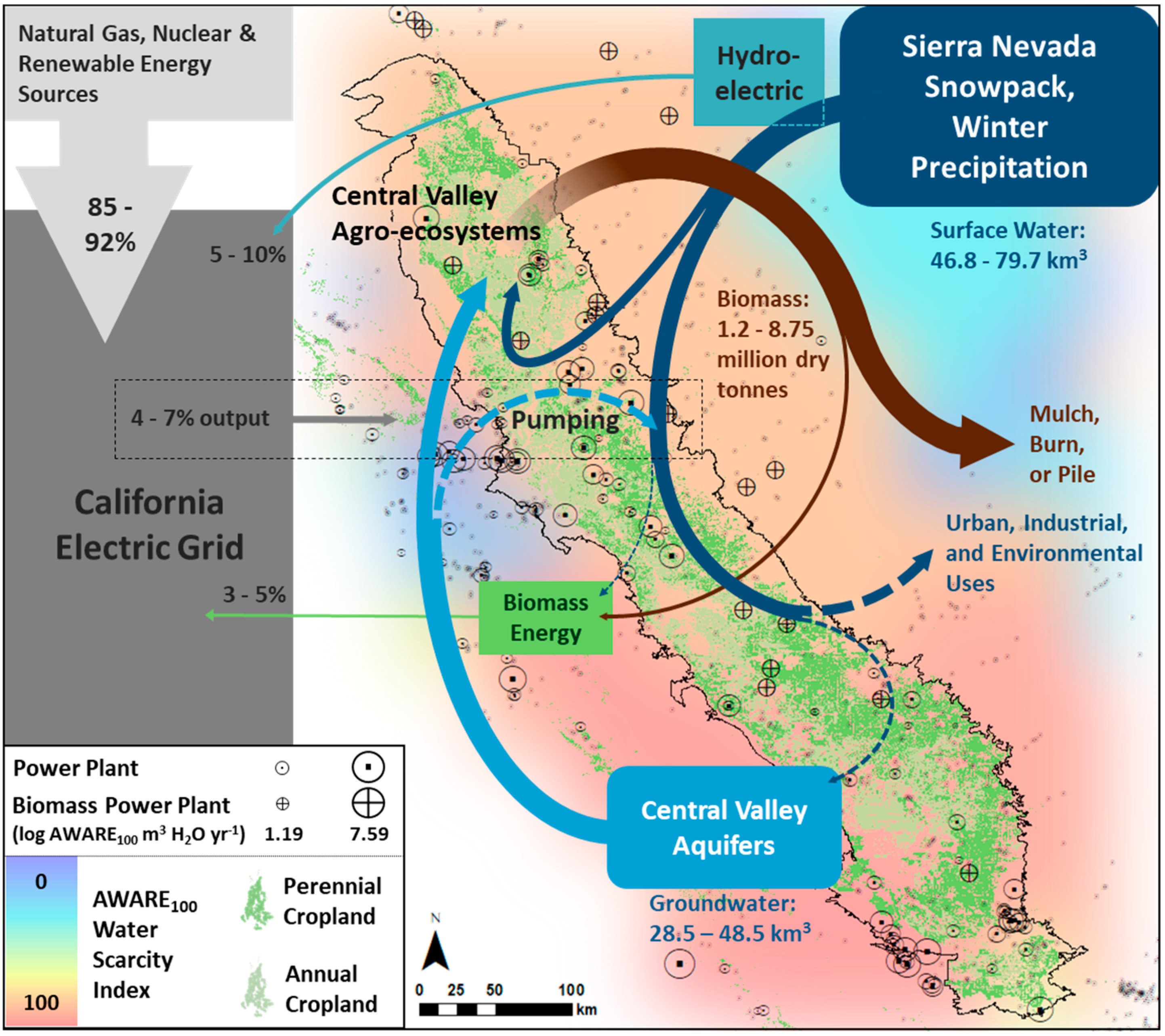

2.1. Model Structure and Development

2.2. System Definition and Boundaries

2.3. Scenario Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Name | Gross Generation (MWh yr−1) | Reported Water Use (m3 MWh−1) | Estimated Water Use (m3 MWh−1) | Water Use (m3 yr−1) | Biomass Fuel Type * |

|---|---|---|---|---|---|

| SPI—Lincoln | 108,289 | -- | 3.324 | 359,908 | A/S |

| Burney Forest Products | 220,403 | 3.720 | -- | 819,856 | F/S |

| Merced Power | 74,997 | -- | 3.324 | 249,259 | U/A |

| Chowchilla II Biomass | 79,062 | -- | 3.324 | 262,770 | U/A |

| Collins Pine Co Project | 15,398 | -- | 3.324 | 51,177 | F/S |

| Desert View Power | 386,443 | 1.471 | -- | 568,618 | U/A |

| DG Fairhaven Power Plant | 44,702 | -- | 3.324 | 148,571 | S |

| SPI—Sonora | 33,794 | -- | 3.324 | 112,317 | A/F/S |

| HL Power Company | 209,349 | 3.779 | -- | 791,084 | F/S |

| Scotia | 153,954 | 3.589 | -- | 552,481 | F/S |

| SPI—Burney | 89,565 | -- | 3.324 | 297,677 | F/S |

| SPI—Quincy | 123,657 | -- | 3.324 | 410,985 | F/S |

| Wheelabrator Shasta | 312,613 | -- | 3.324 | 1,038,998 | U/A/F/S |

| Rio Bravo Fresno | 215,749 | 3.532 | -- | 762,088 | U/A |

| Rio Bravo Rocklin | 200,299 | 2.441 | -- | 488,889 | U/A/F/S |

| Pacific Ultrapower Chinese | 163,846 | -- | 3.324 | 544,557 | U/A/F/S |

| Wadham | 186,264 | 0.003 | -- | 548 | A |

| Woodland Biomass Power Ltd | 211,860 | -- | 3.324 | 704,136 | U/A |

| Roseburg Forest Products | 59,298 | -- | 3.324 | 197,082 | F/S |

| SPI—Anderson 2 | 166,180 | -- | 3.324 | 552,314 | A/F/S |

References

- United States Department of Agriculture National Agriculture Statistics Service (USDA NASS). CropScape—Cropland Data Layer. Available online: https://nassgeodata.gmu.edu/CropScape/ (accessed on 18 September 2019).

- United States Department of Agriculture Foreign Agricultural Service (USDA FAS). Tree Nuts: World Markets and Trade. Washington, DC, USA; 2017. Available online: downloads.usda.library.cornell.edu/usda-esmis/files/tm70mv16z/2b88qc65d/f4752h181/treenutwm-02-17-2017.pdf (accessed on 15 June 2020).

- Goldhamer, D.A.; Fereres, E. Establishing an almond water production function for California using long term yield response to variable irrigation. Irrig. Sci. 2017, 35, 169–179. [Google Scholar] [CrossRef]

- Pope, K.S.; Lightle, D.M.; Buchner, R.P.; Niederholzer, F.; Klonsky, K.; Sumner, D.A.; Gutierrez, C.A. Sample Costs to Establish an Orchard and Produce Almonds: Sacramento Valley Micro-Sprinkler Irrigation; University of California Cooperative Extension: Davis, CA, USA, 2016. [Google Scholar]

- Yaghmour, M.; Haviland, D.R.; Fichtner, E.J.; Sanden, B.L.; Viveros, M.; Sumner, D.A.; Stewart, D.; Culumber, M. Sample Costs to Establish an Orchard and Produce Almonds: San Joaquin Valley South Double-Line Drip Irrigation; University of California Cooperative Extension: Davis, CA, USA, 2016. [Google Scholar]

- Duncan, R.A.; Holtz, B.A.; Doll, D.A.; Klonsky, K.; Sumner, D.A.; Gutierrez, C.A.; Stewart, D.E. Sample Costs to Establish an Orchard and Produce Almonds: San Joaquin Valley North Micro Sprinkler Irrigation; University of California Cooperative Extension: Davis, CA, USA, 2016. [Google Scholar]

- California Natural Resources Agency. Open Data. Periodic Groundwater Level Measurements. Available online: https://data.cnra.ca.gov/dataset/periodic-groundwater-level-measurements (accessed on 25 November 2019).

- Kendall, A.M.; Marvinney, E.M.; Zhu, W.; Brodt, S.B. Life Cycle–based Assessment of energy use and greenhouse gas emissions in almond production, Part I: Analytical framework and baseline results. J. Ind. Ecol. 2015, 19, 1008–1018. [Google Scholar] [CrossRef]

- Wittwer, G. From Almond Shaming to Water Trading: CGE Insights into Managing California’s Drought; Centre of Policy Studies: Melbourne, VIC, Australia, 2015. [Google Scholar]

- California Energy Commission (CEC). California Electricity Data, Facts, and Statistics. California Electrical Energy Generation. Available online: www.energy.ca.gov/almanac/electricity_data/electricity_generation.html (accessed on 15 June 2020).

- University of California Agriculture and Natural Resources (UCANR). Woody Biomass Utilization. The Resource. Available online: https://ucanr.edu/sites/WoodyBiomass/Woody_Biomass_Library/The_Resource/ (accessed on 24 October 2019).

- Public Policy Institute of California (PPIC). Publications. Available online: https://www.ppic.org/publication/water-use-in-california/ (accessed on 24 October 2019).

- Medellín-Azuara, J.; Howitt, R.E.; MacEwan, D.J.; Lund, J.R. Economic impacts of climate-related changes to California agriculture. Clim. Change 2011, 109 (Suppl. 1), S387–S405. [Google Scholar] [CrossRef]

- Margulis, S.A.; Cortés, G.; Girotto, M.; Huning, L.S.; Li, D.; Durand, M. Characterizing the extreme 2015 snowpack deficit in the Sierra Nevada (USA) and the implications for drought recovery. Geophys. Res. Lett. 2016, 43, 6341–6349. [Google Scholar] [CrossRef]

- Vine, E. Adaptation of California’s electricity sector to climate change. Clim. Change 2012, 111, 75–99. [Google Scholar] [CrossRef]

- Hyles, T. The Water-Electricity Nexus in California: Drought-Induced Risk to Thermal Electricity Generation. Master’s Thesis, Humboldt State University, Arcata, CA, USA, 2017. [Google Scholar]

- Wilson, T.S.; Sleeter, B.M.; Cameron, R.D. Mediterranean California’s water use future under multiple scenarios of developed and agricultural land use change. PLoS ONE 2017, 12, E0187181. [Google Scholar] [CrossRef] [Green Version]

- Notarnicola, B.; Sala, S.; Assumpcio, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The role of life cycle assessment in supporting sustainable agri-food system: A review of the challenges. J. Clean Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef] [Green Version]

- Bessou, C.; Basset-Mens, C.; Tran, T.; Benoist, A. LCA applied to perennial cropping systems: A review focused on the farm stage. Int. J. Life Cycle Assess. 2012, 18, 340–361. [Google Scholar] [CrossRef] [Green Version]

- Heller, M.C.; Keoleian, G.A. Assessing the sustainability of the US food system: A life cycle perspective. Agric. Syst. 2003, 76, 1007–1041. [Google Scholar] [CrossRef]

- Heller, M.C.; Willits-Smith, A.; Meyer, R.; Keoleian, G.A.; Rose, D. Greenhouse gas emissions and energy use associated with production of individual self-selected US diets. Environ. Res. Lett. 2018, 13, 044004. [Google Scholar] [CrossRef] [PubMed]

- Bartzas, G.; Komnitsas, K. Life cycle analysis of pistachio production in Greece. Sci. Total Environ. 2017, 595, 13–24. [Google Scholar] [CrossRef] [PubMed]

- Rosa, D.; Figueiredo, F.; Castanheira, É.; Freire, F. Life-cycle assessment of fresh and frozen chestnut. J. Clean Prod. 2017, 140, 742–752. [Google Scholar] [CrossRef]

- Volpe, R.; Messineo, S.; Volpe, M.; Messineo, A. Carbon footprint of tree nuts-based consumer products. Sustainability 2015, 7, 14917–14934. [Google Scholar] [CrossRef] [Green Version]

- Bartzas, G.; Vamvuka, D.; Komnitsas, K. Comparative life cycle assessment of pistachio, almond and apple production. Inform. Proc. Agric. 2017, 4, 188–198. [Google Scholar] [CrossRef]

- Bessou, C.; Basset-Mens, C.; Latunussa, C.; Velu, A.; Heitz, H.; Vanniere, H.; Caliman, J.-P. Partial modelling of the perennial crop cycle misleads LCA results in two contrasted case studies. Int. J. Life Cycle Assess. 2016, 21, 297–310. [Google Scholar] [CrossRef]

- Giudice, A.; Mbohwa, C.; Clasadonte, M.T.; Ingrao, C. Environmental assessment of the citrus fruit production in Sicily using LCA. Ital. J. Food. Sci. 2013, 25, 202–212. [Google Scholar]

- Nicolò, B.; De Salvo, M.; Ramirez-Sanz, C.; Estruch, V.; Sanjuan, N.; Falcone, G.; Strano, A. Life cycle assessment applied to different citrus farming systems in Spain and Italy. Agroecol. Sust. Food 2018, 42, 1092–1105. [Google Scholar]

- Vinyes, E.; Asin, L.; Alegre, S.; Muñoz, P.; Boschmonart, J.; Gasol, C. Life cycle assessment of apple and peach production, distribution and consumption in Mediterranean fruit sector. J. Clean Prod. 2017, 149, 313–320. [Google Scholar] [CrossRef]

- Ingrao, C.; Matarazzo, A.; Tricase, C.; Clasadonte, M.T.; Huisingh, D. Life cycle assessment for highlighting environmental hotspots in Sicilian peach production systems. J. Clean Prod. 2015, 92, 109–120. [Google Scholar] [CrossRef]

- Lofman, D.; Petersen, M.; Bower, A. Water, energy and environment nexus: The California experience. Water Res. Dev. 2002, 18, 73–85. [Google Scholar] [CrossRef]

- Hamdy, A.; Driouech, N.; Hmid, A. The water-energy-food security nexus in the Mediterranean: Challenges and opportunities. In Proceedings of the Fifth International Scientific Agricultural Symposium, Pale, Bosnia and Herzegovina, 23–26 October 2014. [Google Scholar]

- Albrecht, T.R.; Crootof, A.; Scott, C.A. The Water-Energy-Food Nexus: A systematic review of methods for nexus assessment. Environ. Res. Lett. 2018, 13, 043002. [Google Scholar] [CrossRef]

- International Standards Organization (ISO). Environmental Management—Life Cycle Assessment—Principles and Framework. ISO/TC 207/SC 5; International Standards Organization: Geneva, Switzerland, 2016. [Google Scholar]

- Alaphilippe, A.; Boissy, J.; Simon, S.; Godard, C. Environmental impact of intensive versus semi-extensive apple orchards: Use of a specific methodological framework for Life Cycle Assessments (LCA) in perennial crops. J. Clean Prod. 2016, 127, 555–561. [Google Scholar] [CrossRef]

- Fazio, S.; Monti, A. Life cycle assessment of different bioenergy production systems including perennial and annual crops. Biomass Bioenergy 2011, 35, 4868–4878. [Google Scholar] [CrossRef]

- Monti, A.; Fazio, S.; Venturi, G. Cradle-to-farm gate life cycle assessment in perennial energy crops. Eur. J. Agron. 2009, 31, 77–84. [Google Scholar] [CrossRef]

- Water Use in Life Cycle Assessment (WULCA). AWARE: Consensus-Based Method Development to Assess Water Use in LCA. Available online: http://www.wulca-waterlca.org/aware.html (accessed on 19 October 2019).

- Marvinney, E.M.; Kendall, A.M.; Brodt, S.B. Life Cycle-based assessment of energy use and greenhouse gas emissions in almond production, Part II: Scenario and sensitivity analysis. J. Ind. Ecol. 2015, 19, 1019–1029. [Google Scholar] [CrossRef]

- Egea, G.; Nortes, P.A.; Gonzalez-Real, M.M.; Baille, A.; Domingo, R. Agronomic response and water productivity of almond trees under contrasted deficit irrigation regimes. Agric. Water Manag. 2010, 97, 171–181. [Google Scholar] [CrossRef]

- Burt, C.; Howes, D.; Wilson, G. California Agricultural Water Electrical Energy Requirements; Irrigation Training and Research Center; California Polytechnic State University: San Luis Obispo, CA, USA, 2003. [Google Scholar]

- Klein, G.; Krebs, M.; Hall, V.; O’Brien, T.; Blevins, B.B. California’s Water—Energy Relationship. Prepared in Support of the 2005 Integrated Energy Policy Report Proceeding (04-IEPR-01E); California Energy Commission: Sacramento, CA, USA, 2005. [Google Scholar]

- Goulds Water Technology. Turbine Catalog: Performance Curves. Available online: http://goulds.com/turbine-catalog/ (accessed on 24 May 2019).

- Kimmelshue, J.E.; Heilmann, M.H.; Wang, Z.; Mulder, S.; Stall, C. Almond Industry Maps: A Comprehensive, Living Map of California Almonds. Available online: https://www.almonds.com/growers/resources/crop-forecasts/tc-almond-industry-maps (accessed on 18 January 2019).

- California Air Resources Board (CARB). CARB Pollution Mapping Tool. Available online: https://ww3.arb.ca.gov/ei/tools/pollution_map/ (accessed on 7 November 2018).

- California Air Resources Board (CARB). OFF ROAD 2007; Mobile Source Emissions Inventory Program: Sacramento, CA, USA, 2007. [Google Scholar]

- United States Environmental Protection Agency (USEPA). Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI). Available online: https://www.epa.gov/chemical-research/tool-reduction-and-assessment-chemicals-and-other-environmental-impacts-traci (accessed on 20 January 2017).

- Boulay, A.-M.; Bare, J.; Benini, L.; Berger, M.; Lathuillière, M.J.; Manzardo, A.; Margni, M.; Motoshita, M.; Núñez, M.; Pastor, A.V.; et al. The WULCA consensus characterization model for water scarcity footprints: Assessing impacts of water consumption based on available water remaining (AWARE). Int. J. Life Cycle Assess. 2018, 23, 368–378. [Google Scholar] [CrossRef] [Green Version]

- Schmied, H.M.; Eisner, S.; Franz, D.; Wattenbach, M.; Portmann, F.T.; Flörke, M.; Döll, P. Sensitivity of simulated global-scale freshwater fluxes and storages to input data, hydrological model structure, human water use and calibration. Hydrol. Earth Sys. Sci. 2014, 18, 3511–3538. [Google Scholar] [CrossRef] [Green Version]

- Almond Board of California (ABC). California Almond Sustainability Program. Available online: https://www.sustainablealmondgrowing.org/ (accessed on 24 July 2019).

- United States Department of Agriculture National Agriculture Statistics Service (USDA NASS). Statistics by State. Available online: www.nass.usda.gov/Statistics_by_State/California/Publications/AgComm/index.php (accessed on 4 May 2019).

- Macknick, J.; Newmark, R.; Heath, G.; Hallett, K. Operational water consumption and withdrawal factors for electricity generating technologies: A review of existing literature. Env. Res. Lett. 2012, 7, 045802. [Google Scholar] [CrossRef]

| Baseline Scenario | Description |

|---|---|

| Business-as-Usual (BaU) | Almond orchard water use, irrigation energy demand, and biomass energy feedstock production/utilization parameters represent estimates of typical regional practices and infrastructure conditions [4,5,6,51]. |

| 2018 Time-Sensitive Snapshot | Orchard planting date distribution data [42] is used to weight orchard water use, energy demand, and biomass energy feedstock production/utilization by orchard age in year 2018. |

| Maximum Bioenergy Feedstock | As in BaU scenario, except 100% of almond biomass co-product is assumed to be utilized for energy production. |

| Surface Water Only | As in BaU scenario, except 100% of irrigation water is assumed to be delivered via regional surface water sources. |

| Maximum Bioenergy + Surface Water | As in BaU scenario, 100% of almond biomass co-product is assumed to be utilized for energy production and 100% of irrigation water is assumed to be delivered via regional surface water sources. |

| Region | Baseline Scenario | Freshwater Use (Ml ha−1 yr−1) | Available Water (AWARE)100 Water Scarcity (Ml ha−1 yr−1) | Energy Use (GJ ha−1 yr−1) | Biomass Production (tonne ha−1 yr−1) | Biomass Electricity Production (GJ ha−1 yr−1) |

|---|---|---|---|---|---|---|

| Central Valley Aggregate Mean | BaU | 11.53 | 895.95 | 138.1 | 1.76 | 34.5 |

| 2018 Time-Sensitive Snapshot | 11.95 | 930.78 | 121.6 | 1.50 | 26.1 | |

| Maximum Bioenergy Feedstock | 11.51 | 895.94 | 149.5 | 4.78 | 88.3 | |

| Surface Water Only | 11.51 | 895.94 | 85.6 | 1.76 | 34.5 | |

| Max Bioenergy + Surface Water | 11.50 | 895.93 | 97.0 | 4.78 | 88.3 | |

| San Joaquin Valley | BaU | 9.69 | 686.18 | 94.5 | 2.01 | 45.0 |

| 2018 Time-Sensitive Snapshot | 9.68 | 686.04 | 51.4 | 1.59 | 32.2 | |

| Maximum Bioenergy Feedstock | 9.68 | 686.17 | 100.8 | 4.40 | 80.5 | |

| Surface Water Only | 9.68 | 686.18 | 66.5 | 2.01 | 45.0 | |

| Max Bioenergy + Surface Water | 9.67 | 686.17 | 72.8 | 4.40 | 80.5 | |

| Tulare Lake | BaU | 14.13 | 1178.22 | 189.4 | 1.66 | 27.7 |

| 2018 Time-Sensitive Snapshot | 14.96 | 1247.51 | 192.4 | 1.49 | 22.8 | |

| Maximum Bioenergy Feedstock | 14.11 | 1178.21 | 205.3 | 5.23 | 97.5 | |

| Surface Water Only | 14.11 | 1178.20 | 100.8 | 1.66 | 27.7 | |

| Max Bioenergy + Surface Water | 14.09 | 1178.19 | 116.7 | 5.23 | 97.5 | |

| Sacramento Valley | BaU | 8.71 | 616.46 | 100.7 | 1.46 | 27.7 |

| 2018 Time-Sensitive Snapshot | 9.04 | 640.04 | 94.1 | 1.24 | 20.7 | |

| Maximum Bioenergy Feedstock | 8.69 | 616.44 | 112.0 | 4.43 | 81.3 | |

| Surface Water Only | 8.70 | 616.45 | 89.9 | 1.46 | 27.7 | |

| Max Bioenergy + Surface Water | 8.69 | 616.44 | 101.1 | 4.43 | 81.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marvinney, E.; Ro, J.W.; Kendall, A. Trade-Offs in Net Life Cycle Energy Balance and Water Consumption in California Almond Orchards. Energies 2020, 13, 3195. https://doi.org/10.3390/en13123195

Marvinney E, Ro JW, Kendall A. Trade-Offs in Net Life Cycle Energy Balance and Water Consumption in California Almond Orchards. Energies. 2020; 13(12):3195. https://doi.org/10.3390/en13123195

Chicago/Turabian StyleMarvinney, Elias, Jin Wook Ro, and Alissa Kendall. 2020. "Trade-Offs in Net Life Cycle Energy Balance and Water Consumption in California Almond Orchards" Energies 13, no. 12: 3195. https://doi.org/10.3390/en13123195