3.2.1. Scenarios’ Performance Comparison

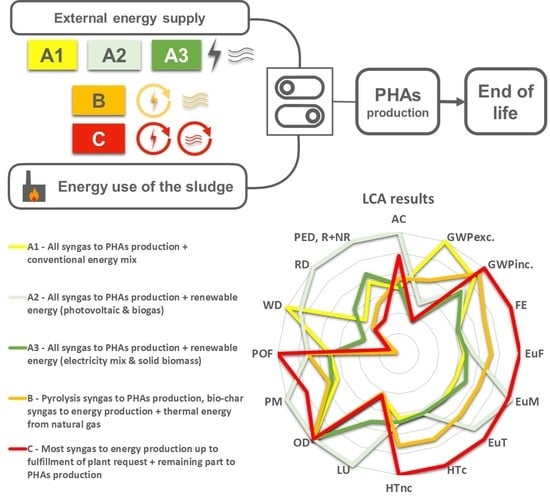

Table 6 shows the total impact scores of the 5 analyzed scenarios over the 17 chosen impact categories. A clear pattern emerges from the data when considering the number of impact categories in which each scenario shows better results than the others or, in other words, when all 17 impact categories are considered equivalent. From this point of view, scenario A1—ConvE performs better than the other ones but only slightly better than scenario A3—RE/Mix+SB. In more detail, scenario A1 scores best in six categories (AC, EuF, EuM, POF, PM, HTnc), and in four more categories, it is first on an equal footing (EuT, FE, HTc, and OD). Scenario A3 shows the best results in two categories (GWPinc. and IR), and in five more categories, it is first on an equal footing (EuT, FE, GWPexc., HTc, and OD), four of them with scenario A1, and is the second best in six categories (AC, EuF, EuM, POF, PM, HTnc, the latest on an equal footing). Moreover, A1 outperforms scenario A3 in nine categories, including PED, R+NR, and RD, while scenario A3 outperforms scenario A1 in four categories, including GWPexc. and GWPinc. Scenario B—CharSyn2E has medium performances, showing the best results in two categories (LU and WD); in another one, it is first on an equal footing with all the other scenarios (OD), and it never shows the worst results. Scenario A2—RE/Pv+Bg shows the worst results in six categories (AC, EuM, LU, PM, RD, PED, R+NR) and the best in three categories (FE, HTc, and OD), all of them on an equal footing with other scenarios. Scenario C—MostSyn2E shows the worst performances in seven categories (GWPinc., EuF, EuT, FE, HTc, HTnc, POF) but also the best in the other four, even if in two of them (GWPexc. and OD) on an equal footing. It is worth noting that three of the impact categories where it shows the best results are GWPexc., PED, R+NR, and RD, which is the main impacts—often the only ones—considered when comparing the environmental performances of plastics and/or bioplastics. These categories can be considered on a global scale, since the impact measured by the midpoint indicator, e.g., the global warming potential, has an effect on a global scale. On the other hand, it is possible to state that scenario C generally shows higher values than the A-based scenarios in the impact categories AC, EuF, EuM, EuT, FE, HTc, HTnc, PM, and POF. These categories can be considered on the local and regional scale, since the impact measured by the midpoint indicator, e.g., the acidifying or eutrophicating potentials, has an effect on a local or regional scale. Therefore, the results exclude that scenarios A1 and A3 are superior to scenario 3 when considering only a small number of impact categories, or when their relative importance is also taken into account. In other words, the results cannot establish in a straightforward way whether one scenario prevails over the others, as the ranking depends on the method adopted to establish it. An insight into the reasons and origins of this trade-off is given in the following

Section 3.2.2, after analyzing in detail the impacts in relevant categories.

The only category equally impacted in all five scenarios is ozone depletion (2.3 × 10−8 kg CFC-11 eq.). This finding can be easily explained since the impact derives almost completely from the PHAs extraction process that is the same for each scenario. In particular, the impact is attributable to the emission into the atmosphere of organic halogenates, mainly bromochlorodifluoromethane (Halon 1211), deriving from the methanol production process that is the base-chemical of DMC synthesis.

The differences among the results of the five scenarios are high for many impact categories, even one order of magnitude. Generally, differences are higher than ±50%; apart from the OD category, climate change included biogenic carbon is the one showing the lowest percent differences.

3.2.2. Detailed Analysis of Relevant Impact Categories Results

As explained in

Section 2.3.5, results were also calculated using the Environmental Footprint 2.0 method in order to determine relevant impact categories, i.e., those cumulatively accounting for 80% of the total impact score. Applying the normalization and weighting factors proposed by PEFCR guidance [

75], the identified categories are (in decreasing order): GWP, WD, RD, EuF, POF, and respiratory inorganics.

Considering this, the analysis of the relative contribution of the processes was focused on the following impact categories: GWPexc., EuF, WD, POF, PM (as proxy for “respiratory inorganics”), and RD. The PED, R+NR impact category is also discussed.

Figure 3 shows the relative contributions of PyAD, PHAs-enriched biomass production, PHAs extraction, and PHAs EoL phases.

Differences among the five scenarios for the primary energy demand from renewable and non-renewable resources are high. The energy recovered in the EoL phase is the same for every scenario, while energy required in PHAs production varies widely (see

Table 4) as a function of both the energy source and the input feedstock, which increases from scenarios A to scenario B, and from scenario B to scenario C. In fact, a greater quantity of processed ADSS is progressively used, until energy independence is reached in scenario C. It must be remembered that in the LCA analysis, the input ADSS is considered as “zero-burden”, i.e., without any associated environmental impact, in accordance with what is generally applied in life cycle analyses of waste. This implies that the PED, R+NR value of ADSS is zero. On the contrary, external sources supplying energy in A-based scenarios and in scenario B have positive PED, R+NR values, i.e., they have associated environmental impacts. For this reason, the PED, R+NR decreases as the processed ADSS increases. The results for A-based scenarios clearly show that the PED, R+NR values for external renewable sources are not lower than those of fossil sources; quite obviously, their high value mainly derives from the renewable part of the indicator, while that of the fossil sources mainly derives from the non-renewable part. This is in accordance also with the findings from the analysis of energy performance indicators (see

Section 3.1).

In scenarios A1, A2, A3, and B, the life cycle phase causing the greatest impacts in terms of PED, R+NR is PyAD, and in particular the pertraction system, due to its high energy consumption. In scenario C, the phase responsible for the greatest impacts is PHAs extraction, due to the background process of DMC production, an energy-intensive process. Thanks to the energy recovery from the bioplastic products, the EoL phase leads to environmental credits. These credits, together with the energy self-sufficiency of the process, lead to the negative PED, R+NR value for scenario C.

Differences among the five scenarios for the climate change, excluded biogenic carbon category, are high, in some cases even more than one order of magnitude. The contributions to climate change scores are mainly due to PyAD and PHAs-enriched biomass production in scenario A1; to PyAD and PHAs EoL in scenarios A2, B, and C; and to PHAs extraction and PHAs EoL in scenario A3. Relevant flows analysis indicates that the carbon dioxide emissions due to thermal energy and electricity production processes are key contributors in every scenario. Generally, the lower the non-renewable energy use, the better the results for GWPexc. In scenarios A3 and C, i.e., the two best performing scenarios, carbon dioxide savings are due to credits for energy production in the PHAs EoL phase. These credits are subtracted from the emissions due to the other life cycle phases, resulting in an overall environmental benefit for this impact category.

Differences among the five scenarios for eutrophication of freshwater are less than one order of magnitude. EuF is mainly related to PyAD in every scenario. In particular, it is related to the phosphorous emissions to freshwater deriving from WWTP and related sludge agricultural spreading, and to phosphate emissions to freshwater from biochar gasification ash disposal. Coherently, the impact increases as the amount of input ADSS to be processed increases.

As regards water depletion, scenarios are grouped into three clusters: The highest impact values are observed for A1 and A2, and the lowest ones for B and C, while A3 shows intermediate values. The relevant processes related to water depletion are different for the various scenarios. In scenario A1, this impact is roughly equally distributed among the different processes and PHAs EoL leads to a water saving of about 30%. In scenario A2, the contribution of PHAs extraction and PHAs-enriched biomass production decreases, while that of PyAD increases, as well as the percentage saving due to EoL. In scenario A3, the contribution of PyAD and PHAs-enriched biomass production decreases substantially, while that of PHAs extraction increases slightly; however, credits obtained from PHAs EoL lead to an overall environmental benefit. In scenarios B and C, WD is an “avoided impact” too, and for more than 50%, thanks to PHAs EoL. These savings are due to credits for energy production through plastics incineration, while the impacts in the other life cycle stages in every scenario are always due to electricity consumption from the grid mix.

Resources depletion shows a very similar pattern to that of water depletion for scenario A1, where the non-renewable elements and energy resource consumption for energy production have a high impact. The impact grows further in scenarios A3 and A2, in particular for the PyAD and PHAs-enriched biomass production phases, even if in these scenarios are due to the consumption of renewable energy sources. PyAD in scenario B and both PyAD and PHAs-enriched biomass production in scenario C show negative scores. This is due to credits obtained for the use in agriculture of WWTP sludge deriving from process water treatment, which implies an avoided consumption of phosphate ore for chemical fertilizer production. In scenarios B and C, the negative score is also due to the avoided consumption of non-renewable elements and energy resources for energy production. There are other impacts coming from non-renewable elements and resource consumption for methanol production in the PHAs extraction phase in all scenarios.

As mentioned above, two other relevant impact categories are POF and respiratory inorganics. Differences among the five scenarios for photochemical ozone formation are less than one order of magnitude and the results show a pattern similar to the eutrophication of freshwater. Impacts are mainly related to PyAD, in particular to nitrogen oxide emissions from syngas CHP and the boiler used for electricity and thermal energy production in scenarios B and C, and from biogas combustion in scenario A2. Coherently, the impact increases as the amount of syngas and biogas used to produce energy increases. As a proxy for respiratory inorganics, not present among the ILCD-recommended impact categories, it is possible to analyze the impact category of particulate matter. Additionally, for this category, the differences among the five scenarios are less than one order of magnitude, and the impact score is primarily due to PyAD, in particular to PM2.5, i.e. PM with a diameter of 2.5 μm or less, and nitrogen oxides emissions from syngas CHP and the boiler used for electricity and thermal energy production in scenarios B and C, and from thermal energy production through biogas combustion in scenario A2. In this case, biogas combustion causes a greater impact than syngas combustion.

Summarizing the contributions analysis, it is possible to claim that PyAD is generally the most relevant phase for each scenario and each relevant impact category, and that when there are exceptions, they are related to the avoided impacts obtained by PHAs EoL. The environmental impacts of PyAD in all scenarios are essentially due to the energy production processes, both from fossil and renewable sources, and also from the syngas CHP and boiler when present. Among the processes with the highest energy needs is the pertraction system used to transfer VFAs from dilute streams of anaerobic digestion into a VFAs-rich stream for PHAs production. The temperature difference between mesophilic anaerobic digestion with sporogenic bacteria and PHAs production with MMC results in a high thermal energy demand in the pertraction system because of the cooling of large volumes of liquid from AAF, which must be heated again to a mesophilic temperature before being recirculated back to AAF. As demonstrated by comparing the different scenarios, and in particular the A-based ones, the replacement of fossil energy sources with renewable energy sources does not allow ipso facto for a reduction of the environmental impacts due to this process in all the analyzed impact categories, but there is a trade-off between global and local impacts.

Generally, renewable energy sources cause lower fossil carbon emissions and a lower use of fossil primary energy and fossil resources, that is, lower impact values in global-scale categories; however, their total primary energy and their resource use is higher when renewable energies and resources are taken into account, but this is not the case when organic waste, such as ADSS, which is considered “impact free”, i.e., without any associated environmental impact, is used as an energy source. On the other hand, renewable energy production and particularly the production and combustion of biomass shows higher scores in regional- and local-scale impact categories; this is mainly due to the fact that biomass production requires vast agricultural areas and intensive cultivation methods, including the use of chemical fertilizers, and that biomass combustion is often less efficient than fossil fuel combustion, generating emissions and waste with high acidifying and eutrophicating potential, and with toxic effects.

However, it is possible to note that the A3—RE/Mix+SB scenario generally has good performances both on global impacts, such as climate change, thanks to the use of renewable resources, and on local ones, such as the water depletion, particulate matter emission, and eutrophication categories. The latter is thanks to the fact that the combustion processes of solid biomass (consisting mainly of by-products) have lower impacts compared to the combustion of biogas produced from ad hoc grown biomass (A2—RE/Pv+Bg), and that the renewable electricity mix has lower impacts than the electricity mix used in the “conventional energy” scenario (A1—ConvE).

The modelled end-of-life phase leads to environmental credits being obtained. In fact, electricity and thermal energy is produced from both PHAs’ direct combustion in waste-to-energy plants and the combustion of recovered biogas generated by PHAs’ degradation in landfills. Thanks to this energy production, an equivalent amount of energy production from non-renewable resources, with greater environmental impact, is avoided.

An undeniable advantage of PHAs is their biodegradability, which at the moment is not fully considered and evaluated within the LCA methodology. While methodological research in this field shall go on, in the near future, a different end-of-life for these polymers is foreseeable as their diffusion increases, that is, their collection together with organic waste, followed by the recovery of the carbon content through composting or anaerobic digestion. At that stage, it will be appropriate and interesting to assess which end-of-life of the polymer will bring the greatest benefits.

3.2.3. Comparison with PHAs Literature and Other Polymers’ Results

In terms of environmental performance, in general, bio-based products tend to compare poorly against their respective conventional counterparts on impact categories, such as eutrophication, an impact typically caused by fertilizers during biomass cultivation [

76,

77]. Mixed results have been reported for other categories, including acidification and tropospheric ozone formation. Claims of environmental benefits for bioproducts often rely on reduced greenhouse gas (GHG) emissions and non-renewable energy use. In any case, the wide ranges of objectives, scopes, methodological choices, and results of LCA studies on bio-based products makes it difficult not only to infer a general trend on their environmental impacts but also to suggest a widely applicable way to reduce their impacts [

76]. However, as regards PHAs production specifically, and as it is shown in the following comparison with the literature, the choice of feedstock and the use of residues and co-products for energy production can reduce the environmental impacts of this process [

12,

31,

33,

34,

36,

40,

41].

In

Figure 4, the values of non-biogenic GHGs emissions per kilogram of PHAs obtained by various authors are compared; data are in chronological order and the whole range of results found in each paper, including this study, is represented when available.

Figure 4 shows also the values for four other polymers with which the PHAs are compared with, two of them are fossil-based (PET and PP) and two bio-based (bio-PP and PLA).

Generally, values range from 0.5 to 5 kg of CO

2-equivalent per kilogram of PHAs. The results of the present study fall within this range. However, great variability exists among the studies. A potential impact up to about 25 kg CO

2-equivalent per kg of PHAs was assessed by Pietrini and coauthors [

32] and an avoided impact of up to about 6 kg CO

2-equivalent per kg of PHAs was evaluated by Rostkowski and coauthors [

35]. Higher values were reported by Pietrini and coauthors [

32], Kendall [

36], and Posen and coauthors [

38] and they correspond to sugar cane- and corn-derived polyhydroxybutyrate (PHB). Lower values (i.e., below 0.5 kg CO

2-equivalent emitted per kilogram of biopolymer) were reported by studies that account for carbon uptake during biomass growth, thereby considering carbon storage in the bio-based polymer [

26,

27,

28,

30] or when the only carbon source is a waste [

12,

41]. Negative impacts were reported when the energy source [

33] or also when waste streams from PHAs production are used for energy recovery [

35].

In

Figure 5, the fossil energy requirement for PHAs production reported by various authors is compared; data are in chronological order and the whole range of results found in each paper, including this study, are represented when available.

Figure 5 shows also the values for four other polymers with which the PHAs are compared; two of them are fossil-based (PET and PP) and two bio-based (bio-PP and PLA).

Data range from 320 to −12 MJ per kilogram of PHAs, with median values spanning between 20 to 80 MJ per kilogram of biopolymer. The present work shows values ranging from about 80 to −10 MJ per kg of PHAs, depending on the considered scenarios. The highest values were reported by Pietrini and coauthors [

32] and Sakamoto [

37], where carbon sources are from dedicated crops and the whole life cycle of PHB-based end products is considered. The lowest values were reported in studies where the use of organic residues as fuel to generate electricity and steam is assumed [

26,

29].

As regards the comparison of PHAs from ADSS with other polymers, first of all, it can be noted that the bio-based polymers tend to have both lower non-biogenic GHGs emissions and lower fossil energy demand values than the fossil-based polymers, as expected. For both indicators, the PHAs’ range of values overlaps the range of other polymers’ values, being wider. PHAs’ average value is only slightly higher than that of bio-PP and PLA, and falls within the range of fossil-based PET and PP.

In summary, the performances of PHAs produced from sewage sludge of the agro-industry analyzed in this study are of the same order of magnitude as those of other PHAs production processes found in the literature, in terms of both non-biotic GHG emissions and energy demand. Moreover, their performances also overlap with those of other fossil-based and bio-based polymers. This is a good omen, considering that there is still room for improvement for this process and that no primary data is available at the industrial scale yet.