Environmental Impact Assessment of Transportation Infrastructure in the Life Cycle: Case Study of a Fast Track Transportation Project in China

Abstract

:1. Introduction

2. Literature Review

2.1. Environmental Impact Assessment (EIA) of Transportation Infrastructure

2.2. Application of LCA Method in Environmental Impact Assessment

2.3. Gaps in Knowledge

3. Research Methodology

4. Data analysis

4.1. Input Data

4.2. Results

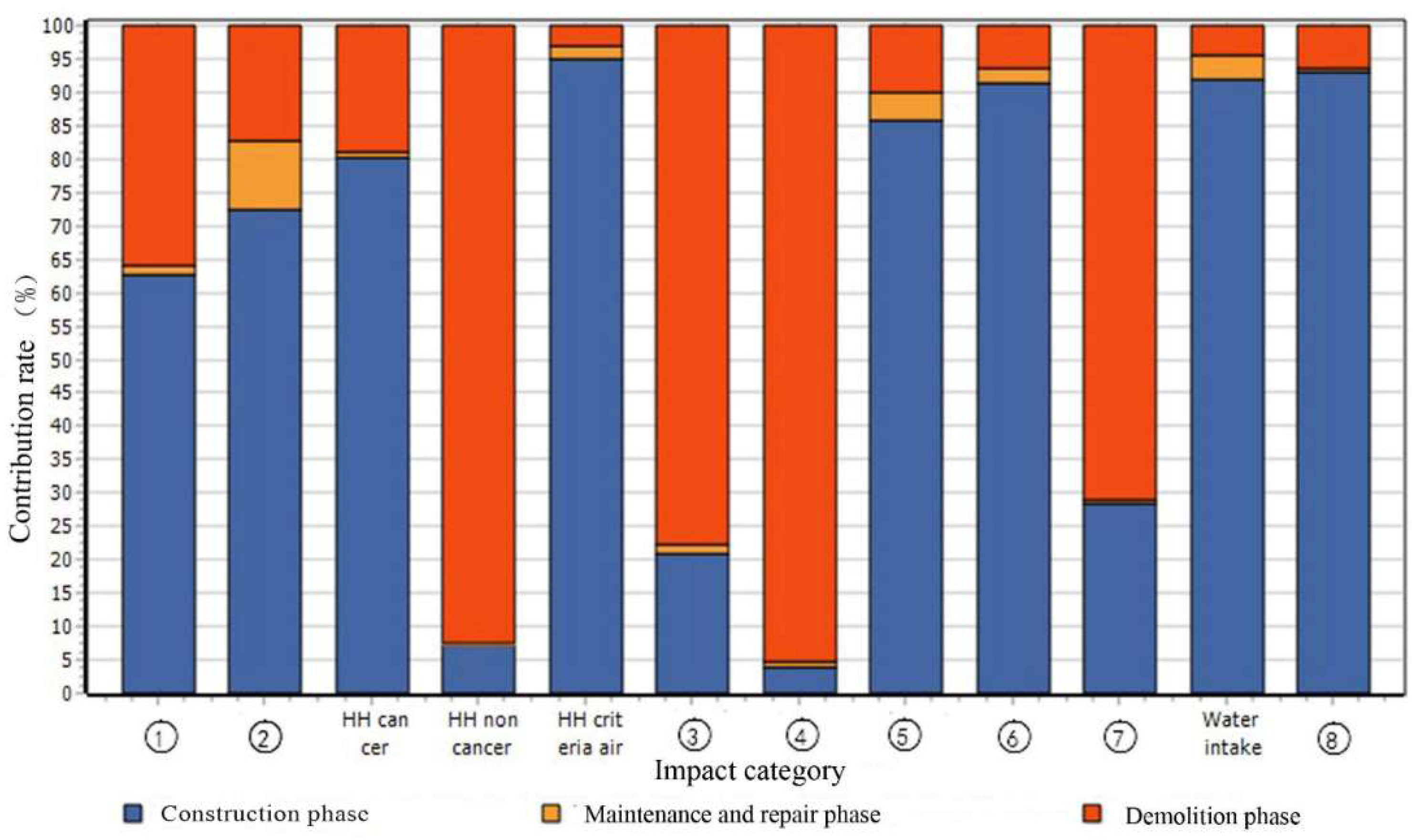

4.2.1. EIA in the Life Cycle

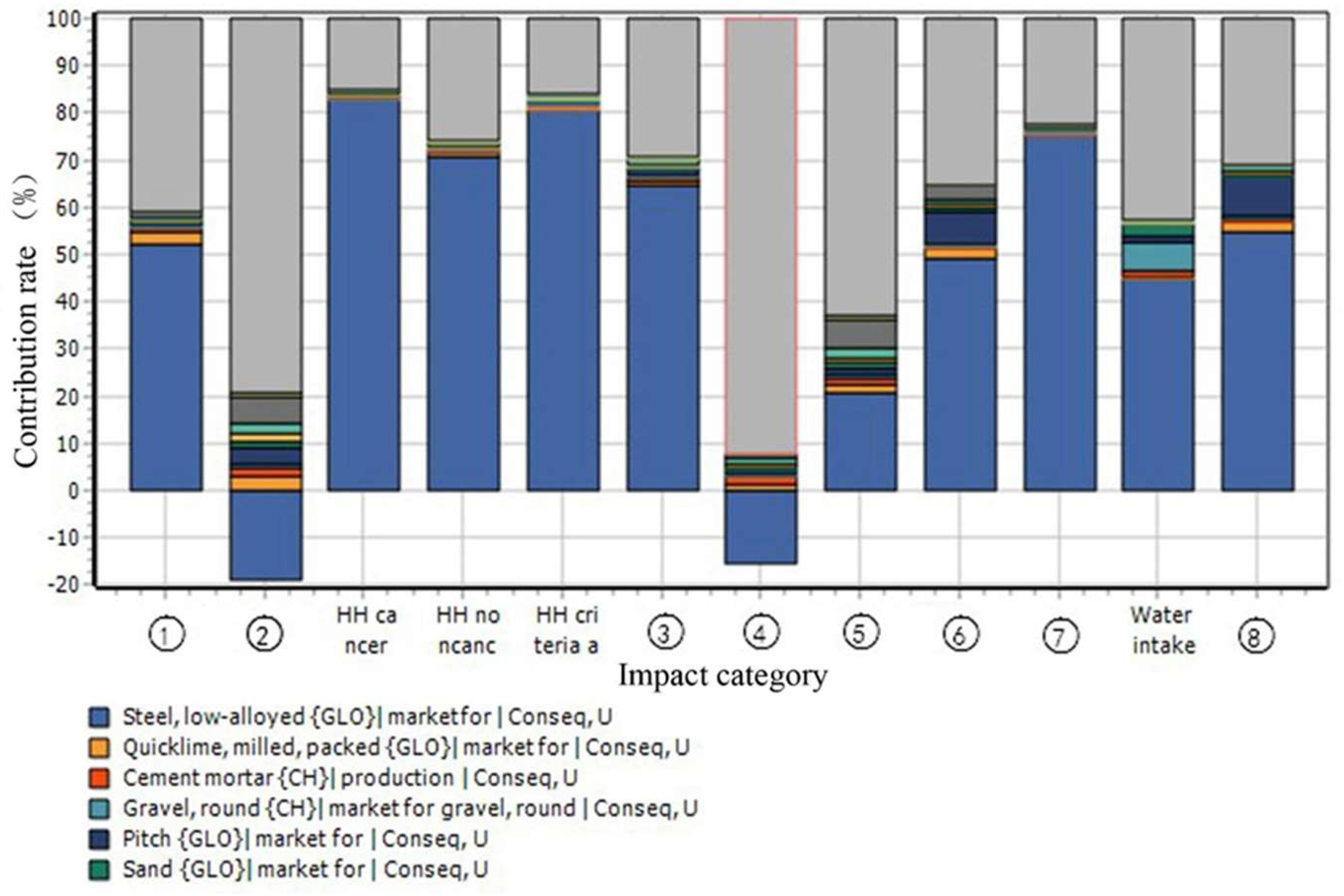

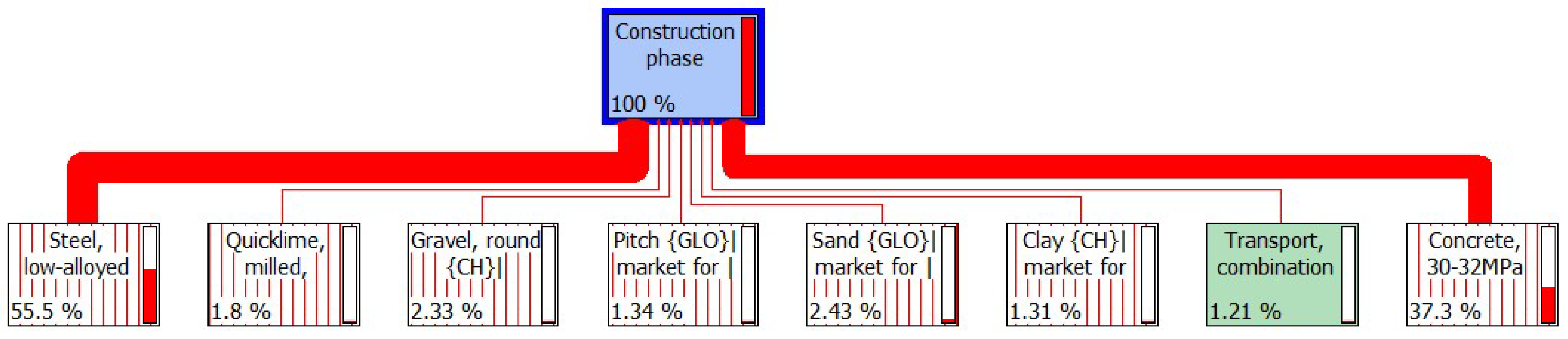

4.2.2. EIA in Construction Phase

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chakrabarti, S. Can highway development promote employment growth in India? Transp. Policy 2018, 69, 1–9. [Google Scholar] [CrossRef]

- Li, X.; Fan, Y.L.; Wu, L. CO2 emissions and expansion of railway, road, airline and in-land waterway networks over the 1985–2013 period in China: A time series analysis. Transp. Res. Part D Transp. Environ. 2017, 57, 130–140. [Google Scholar] [CrossRef]

- Transport Industry Development Statistics Bulletin from Ministry of Transport of the People’s Republic of China. Available online: http://zizhan.mot.gov.cn/zfxxgk/bnssj/zhghs/201803/t20180329_3005087.html (accessed on 2 June 2018).

- Cellura, M.; Cusenza, M.A.; Longo, S. Energy-related GHG emissions balances: IPCC versus LCA. Sci. Total Environ. 2018, 628, 1328–1339. [Google Scholar] [CrossRef] [PubMed]

- VanderZaag, A.C. On the systematic underestimation of methane conversion factors in IPCC guidance. Waste Manag. 2018, 75, 499–502. [Google Scholar] [CrossRef]

- Climate Change 2014: Mitigation of Climate Change. Available online: http://www.ipcc.ch/report/ar5/wg3/ (accessed on 26 June 2018).

- Mustapa, S.I.; Bekhet, H.A. Analysis of CO2 emissions reduction in the Malaysian transportation sector: An optimisation approach. Energy Policy 2016, 89, 171–183. [Google Scholar] [CrossRef]

- Monghasemi, S.; Abdallah, M.; Tawfik, A.; Clevenger, C. Time-Environmental Impacts Tradeoff Analysis for Businesses Commuters; ASCE—American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 628–638.

- Yin, X.; Chen, W.; Eom, J.; Clarke, L.E.; Kim, S.H.; Patel, P.L.; Yu, S.; Kyle, G.P. China’s transportation energy consumption and CO2 emissions from a global perspective. Energy Policy 2015, 82, 233–248. [Google Scholar] [CrossRef]

- Ahmed, K.; Ahmed, S. A predictive analysis of CO2 emissions, environmental policy stringency, and economic growth in China. Environ. Sci. Pollut. Res. 2018, 25, 16091–16100. [Google Scholar] [CrossRef]

- Meng, X.; Han, J. Roads, economy, population density, and CO2: A city-scaled causality analysis. Resour. Conserv. Recycl. 2018, 128, 508–515. [Google Scholar] [CrossRef]

- Guo, Z.; Hu, D.; Zhang, Z.; Zhang, P.; Zhang, X. Material metabolism and lifecycle GHG emissions of urban road system (URS). J. Clean. Prod. 2017, 165, 243–253. [Google Scholar] [CrossRef]

- Lin, B.L.; Liu, C.; Wang, H.J.; Lin, R.X. Modeling the railway network design problem: A novel approach to considering carbon emissions reduction. Transp. Res. Part D Transp. Environ. 2017, 56, 95–109. [Google Scholar] [CrossRef]

- Dimoula, V.; Kehagia, F.; Tsakalidis, A. A Holistic Approach for Estimating Carbon Emissions of Road and Rail Transport Systems. Aerosol Air Qual. Res. 2016, 16, 61–68. [Google Scholar] [CrossRef]

- Peng, B.; Cai, C.; Hu, R. Energy consumption and carbon emission evaluation of expressway asphalt pavement. J. Chang’An Univ. Nat. Sci. Ed. 2016, 36, 8–15. [Google Scholar]

- Liu, K.; Bai, Y.; Wang, C.; Zhang, X.; Zhang, C. Study on the Comprehensive Carbon-emission Assessment of Infrastructure Projects. Environ. Sci. Technol. 2017, 40, 185–190. [Google Scholar]

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4, 024008. [Google Scholar] [CrossRef] [Green Version]

- Ren, J.; Gao, L.; Feng, Y. Discussion on the traffic carbon emission structure and development strategy of low carbon transportation in Tianjin. Environ. Pollut. Control 2015, 37, 96–99. [Google Scholar]

- Thaveewatanaseth, K.; Limjirakan, S. Key factors of low carbon development strategy for sustainable transport. IOP Conf. Ser. Earth Environ. Sci. 2018, 117, 012003. [Google Scholar] [CrossRef] [Green Version]

- Shen, B.; Lepech, M.D. Probabilistic Design of Environmentally Sustainable Reinforced-Concrete Transportation Infrastructure Incorporating Maintenance Optimization. J. Infrastruct. Syst. 2017, 23, 10. [Google Scholar] [CrossRef]

- Hammervold, J.; Reenaas, M.; Brattebo, H. Environmental Life Cycle Assessment of Bridges. J. Bridge Eng. 2013, 18, 153–161. [Google Scholar] [CrossRef]

- O’Born, R. Life cycle assessment of large scale timber bridges: A case study from the world’s longest timber bridge design in Norway. Transp. Res. Part D Transp. Environ. 2018, 59, 301–312. [Google Scholar] [CrossRef]

- Babaee, S.; Loughlin, D.H. Exploring the role of natural gas power plants with carbon capture and storage as a bridge to a low-carbon future. Clean Technol. Environ. Policy 2018, 20, 379–391. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y.Q.; Liu, Y.Y.; Feng, S.; Wang, D.W. Estimating Life-Cycle CO2 Emissions from Freeway Greening Engineering; ASCE—American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 796–805.

- Sohn, H.; Seong, T.-R.; Kim, I.-G. Special issue on “ICT Bridge Technology for Life-span Extension and Carbon Emission Mitigation” Preface. Smart Struct. Syst. 2016, 17, I. [Google Scholar]

- Liu, Y.; Wang, Y.; Li, D. Estimation and uncertainty analysis on carbon dioxide emissions from construction phase of real highway projects in China. J. Clean. Prod. 2017, 144, 337–346. [Google Scholar] [CrossRef]

- Wang, X.; Duan, Z.; Wu, L.; Yang, D. Estimation of carbon dioxide emission in highway construction: A case study in southwest region of China. J. Clean. Prod. 2015, 103, 705–714. [Google Scholar] [CrossRef]

- Sun, X.Y.; Dong, W.W.; Wang, H.L.; Wang, J. Multi-Level Fuzzy Comprehensive Evaluation of Bridge Carbon Intensity Based on Life-Cycle Carbon Emission Model. Adv. Mater. Res. 2012, 374–377, 1685–1689. [Google Scholar] [CrossRef]

- Shi, F.; Huang, T.; Tanikawa, H.; Han, J.; Hashimoto, S.; Moriguchi, Y. Toward a Low Carbon-Dematerialization Society Measuring the Materials Demand and CO2 Emissions of Building and Transport Infrastructure Construction in China. J. Ind. Ecol. 2012, 16, 493–505. [Google Scholar] [CrossRef]

- Zhao, K.; Xu, X.; Yang, G.; Wu, S.; Jiang, F. Impacts of highway construction and operation on carbon footprint in China: A case study of Jiangsu Province. Environ. Prog. Sustain. Energy 2016, 35, 1468–1475. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Tseng, M.L.; Wong, W.P. Sustainable product design and development: A review of tools, applications and research prospects. Resour. Conserv. Recycl. 2018, 132, 49–61. [Google Scholar] [CrossRef]

- Itoya, E.; El-Hamalawi, A.; Ison, S.G.; Frost, M.W.; Hazell, K. Development and Implementation of a Lifecycle Carbon Tool for Highway Maintenance. J. Transp. Eng. 2015, 141, 04014092. [Google Scholar] [CrossRef]

- Dos Santos, J.M.O.; Thyagarajan, S.; Keijzer, E.; Flores, R.F.; Flintsch, G. Comparison of Life-Cycle Assessment Tools for Road Pavement Infrastructure. Transp. Res. Rec. 2017, 2646, 28–38. [Google Scholar] [CrossRef] [Green Version]

- Peñaloza, D.; Erlandsson, M.; Pousette, A. Climate impacts from road bridges: Effects of introducing concrete carbonation and biogenic carbon storage in wood. Struct. Infrastruct. Eng. 2018, 14, 56–67. [Google Scholar] [CrossRef]

- Manzo, S.; Salling, K.B. Integrating life-cycle assessment into transport cost-benefit analysis. In Transport Research Arena Tra2016; Rafalski, L., Zofka, A., Eds.; Elsevier Science BV: Amsterdam, The Netherlands, 2016; Volume 14, pp. 273–282. [Google Scholar]

- Manzo, S.; Dong, Y.; Miraglia, S.; Salling, K.B. How the inclusion of life cycle impacts affects transport cost-benefit analysis. Eur. J. Transp. Infrastruct. Res. 2018, 18, 372–388. [Google Scholar]

- Xie, H.B.; Wu, W.J.; Wang, Y.F. Life-time reliability based optimization of bridge maintenance strategy considering LCA and LCC. J. Clean. Prod. 2018, 176, 36–45. [Google Scholar] [CrossRef]

- Coston-Guarini, J.; Guarini, J.M.; Hinz, S.; Wilson, J.; Chauvaud, L. A roadmap for a quantitative ecosystem-based environmental impact assessment. ICES J. Mar. Sci. 2016, 74, 2012–2023. [Google Scholar] [CrossRef]

- Ali, M.; Marvuglia, A.; Geng, Y.; Chaudhry, N.; Khokhar, S. Emergy based carbon footprinting of household solid waste management scenarios in Pakistan. Resour. Conserv. Recycl. 2018, 131, 283–296. [Google Scholar] [CrossRef]

- Batouli, M.; Bienvenu, M.; Mostafavi, A. Putting sustainability theory into roadway design practice: Implementation of LCA and LCCA analysis for pavement type selection in real world decision making. Transp. Res. Part D Transp. Environ. 2017, 52, 289–302. [Google Scholar] [CrossRef]

- Bachawati, M.E.; Manneh, R.; Belarbi, R.; Dandres, T.; Nassab, C.; Zakhem, H.E. Cradle-to-gate Life Cycle Assessment of traditional gravel ballasted, white reflective, and vegetative roofs: A Lebanese case study. J. Clean. Prod. 2016, 137, 833–842. [Google Scholar] [CrossRef]

- Starostka-Patyk, M. New Products Design Decision Making Support by SimaPro Software on the Base of Defective Products Management. Procedia Comput. Sci. 2015, 65, 1066–1074. [Google Scholar] [CrossRef] [Green Version]

- Tam, W.Y.V.; Le, K.N.; Tran, C.N.N.; Wang, J.Y. A review on contemporary computational programs for Building’s life-cycle energy consumption and greenhouse-gas emissions assessment: An empirical study in Australia. J. Clean. Prod. 2018, 172, 4220–4230. [Google Scholar] [CrossRef]

- Luijten, C.J.L.M.; Gijt, J.G.D.; Said, M.; Bouwheer, C.H.J. From LCA to LCC in Infrastructure Reducing CO2 Emissions in Infrastructure; LCC: Delft, The Netherlands, 2016. [Google Scholar]

- Morales-Mendoza, L.F.; Azzaro-Pantel, C. Bridging LCA data gaps by use of process simulation for energy generation. Clean Technol. Environ. Policy 2017, 19, 1535–1546. [Google Scholar] [CrossRef]

- Penades-Pla, V.; Marti, J.V.; Garcia-Segura, T.; Yepes, V. Life-Cycle Assessment: A Comparison between Two Optimal Post-Tensioned Concrete Box-Girder Road Bridges. Sustainability 2017, 9, 1864. [Google Scholar] [CrossRef]

- Tang, H.; Kuai, H.; Huang, X. Energy consumption model for highway maintenance based on life cycle assessment. J. Southeast Univ. Nat. Sci. Ed. 2016, 46, 629–634. [Google Scholar]

- Streimikiene, D.; Balezentis, T.; Balezentiene, L. Comparative assessment of road transport technologies. Renew. Sustain. Energy Rev. 2013, 20, 611–618. [Google Scholar] [CrossRef]

- Barsan, L.; Barsan, A. Some Aspects Concerning the Design for Recycling and Waste Minimisation; World Scientific and Engineering Acad and Soc: Athens, Greece, 2009; pp. 274–277. [Google Scholar]

- Li, H.; Deng, Q.X.; Zhang, J.X.; Xia, B.; Skitmore, M. Assessing the life cycle CO2 emissions of reinforced concrete structures: Four cases from China. J. Clean. Prod. 2019, 210, 1496–1506. [Google Scholar] [CrossRef]

- Di Maria, A.; Eyckmans, J.; Van Acker, K. Downcycling versus recycling of construction and demolition waste: Combining LCA and LCC to support sustainable policy making. Waste Manag. 2018, 75, 3–21. [Google Scholar] [CrossRef] [PubMed]

- Gudukeya, L.; Mbohwa, C. Life cycle assessment of steel balls. In Proceedings of the 2015 International Conference on Industrial Engineering and Operation Management (IEOM), Dubai, UAE, 3–5 March 2015; p. 8. [Google Scholar]

- Ye, H.; Ren, Q.; Hu, X.; Lin, T.; Shi, L.; Zhang, G.; Li, X. Modeling energy-related CO2 emissions from office buildings using general regression neural network. Resour. Conserv. Recycl. 2018, 129, 168–174. [Google Scholar] [CrossRef]

- Kumanayake, R.; Luo, H.B.; Paulusz, N. Assessment of material related embodied carbon of an office building in Sri Lanka. Energy Build. 2018, 166, 250–257. [Google Scholar] [CrossRef]

- Anthonissen, J.; Troyen, D.V.; Braet, J.; Bergh, W.V.D. Using carbon dioxide emissions as a criterion to award road construction projects: A pilot case in Flanders. J. Clean. Prod. 2015, 102, 96–102. [Google Scholar] [CrossRef]

- Su, F. Green Development Mode of the Suburban Steel Plant. J. Eng. Stud. 2017, 9, 85–98. [Google Scholar]

- Krantz, J.; Lu, W.; Johansson, T.; Olofsson, T. Analysis of alternative road construction staging approaches to reduce carbon dioxide emissions. J. Clean. Prod. 2017, 143, 980–988. [Google Scholar] [CrossRef]

- Babbitt, C.W.; Lindner, A.S. A life cycle comparison of disposal and beneficial use of coal combustion products in Florida: Part 2: Imapact assessment of disposal and beneficial use options. Int. J. Life Cycle Assess. 2008, 13, 555–563. [Google Scholar] [CrossRef]

- Buekers, J.; Deutsch, F.; Veldeman, N.; Janssen, S.; Panis, L.I. Fine atmospheric particles from agricultural practices in Flanders: From emissions to health effects and limit values. Outlook Agric. 2014, 43, 39–44. [Google Scholar] [CrossRef]

- Morshed, A.; Shao, Y.X. Optimized process window for fresh concrete carbonation curing. Can. J. Civ. Eng. 2014, 41, 986–994. [Google Scholar] [CrossRef]

| Materials | Amount |

|---|---|

| Steel (kg/m2) | 261.02 |

| Concrete (m3/m2) | 1.89 |

| Quicklime (kg/m2) | 32.72 |

| Cement mortar (kg/m2) | 72.68 |

| Gravel (kg/m2) | 714.70 |

| Pitch (kg/m2) | 11.21 |

| Sand (kg/m2) | 340.82 |

| Fly ash (kg/m2) | 0.30 |

| Clay brick (kg/m2) | 29.55 |

| Clay (kg/m2) | 678.24 |

| Construction Phase | Materials/Assemblies | Amount | Unit |

|---|---|---|---|

| Steel | 261.02 | kg | |

| Concrete | 1.89 | m3 | |

| Quicklime | 32.72 | kg | |

| Cement mortar | 72.68 | kg | |

| Gravel | 714.70 | kg | |

| Pitch | 11.21 | kg | |

| Sand | 340.82 | kg | |

| Fly ash | 0.30 | kg | |

| Clay brick | 29.55 | kg | |

| Clay | 678.24 | kg | |

| Processes | Amount | Unit | |

| Transport, combination truck, average fuel mix | 199.33 | tkm | |

| Diesel, burned in agricultural machinery | 13.11 | MJ | |

| Maintenance and repair phase | The energy consumption | Amount | Unit |

| Electricity, low voltage | 71.1 | kWh | |

| Demolition phase | The energy consumption | Amount | Unit |

| Electricity, low voltage | 8.4 | kWh | |

| Waste specification | Amount | Unit | |

| Construction waste | 6644.21 | kg | |

| Disposal scenario | Percentage | ||

| Municipal solid waste (waste scenario) (Treatment of municipal solid waste, landfill) | 100% | ||

| Impact Category | Construction Phase | Maintenance and Repair Phase | Demolition Phase |

|---|---|---|---|

| ① Global warming | 61.82 | 1.48 | 36.70 |

| ② Acidification | 72.50 | 10.20 | 17.30 |

| ③ Eutrophication | 21.00 | 1.20 | 77.80 |

| ④ Ecotoxicity | 3.98 | 0.62 | 95.40 |

| ⑤ Smog | 85.80 | 4.06 | 10.10 |

| ⑥ Natural resource depletion | 91.40 | 2.26 | 6.30 |

| ⑦ Habitat alteration | 28.30 | 0.65 | 71.10 |

| ⑧ Ozone depletion | 93.20 | 0.32 | 6.51 |

| Impact Category | Steel | Concrete | Quicklime | Cement Mortar | Pitch | Sand | Clay Brick | Clay |

|---|---|---|---|---|---|---|---|---|

| ① Global warming | 52.20 | 40.80 | 2.65 | - | - | 0.27 | - | - |

| ② Acidification | −19.00 | 79.20 | 2.83 | 1.80 | 3.40 | 1.30 | 1.76 | 2.26 |

| ③ Eutrophication | 64.80 | 29.50 | 0.61 | 1.06 | 1.43 | 0.36 | 0.59 | 1.04 |

| ④ Ecotoxicity | −15.70 | 92.10 | 1.34 | 1.53 | 0.89 | 0.46 | 0.72 | 1.48 |

| ⑤ Smog | 20.80 | 62.90 | 1.60 | 1.30 | 1.27 | 1.06 | 1.16 | 1.89 |

| ⑥ Natural resource depletion | 49.20 | 35.20 | 2.14 | - | 6.9 | 0.54 | 1.10 | 0.98 |

| ⑦ Habitat alteration | 75.40 | 22.40 | 0.25 | - | - | 0.30 | 0.30 | 0.68 |

| ⑧ Ozone depletion | 54.60 | 30.90 | 2.51 | 0.31 | 8.37 | 0.60 | 0.73 | 1.06 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Deng, Q.; Zhang, J.; Olubunmi Olanipekun, A.; Lyu, S. Environmental Impact Assessment of Transportation Infrastructure in the Life Cycle: Case Study of a Fast Track Transportation Project in China. Energies 2019, 12, 1015. https://doi.org/10.3390/en12061015

Li H, Deng Q, Zhang J, Olubunmi Olanipekun A, Lyu S. Environmental Impact Assessment of Transportation Infrastructure in the Life Cycle: Case Study of a Fast Track Transportation Project in China. Energies. 2019; 12(6):1015. https://doi.org/10.3390/en12061015

Chicago/Turabian StyleLi, Hui, Quanxue Deng, Jingxiao Zhang, Ayokunle Olubunmi Olanipekun, and Sainan Lyu. 2019. "Environmental Impact Assessment of Transportation Infrastructure in the Life Cycle: Case Study of a Fast Track Transportation Project in China" Energies 12, no. 6: 1015. https://doi.org/10.3390/en12061015

APA StyleLi, H., Deng, Q., Zhang, J., Olubunmi Olanipekun, A., & Lyu, S. (2019). Environmental Impact Assessment of Transportation Infrastructure in the Life Cycle: Case Study of a Fast Track Transportation Project in China. Energies, 12(6), 1015. https://doi.org/10.3390/en12061015