Numerical Study on Heat Transfer Performance in Packed Bed

Abstract

:1. Introduction

2. Mathematical Model

2.1. Governing Equations for Solid Particles

2.2. Governing Equations for Gas Phase

2.3. Heat Transfer Models

2.4. Entransy Dissipation

3. Simulation Conditions

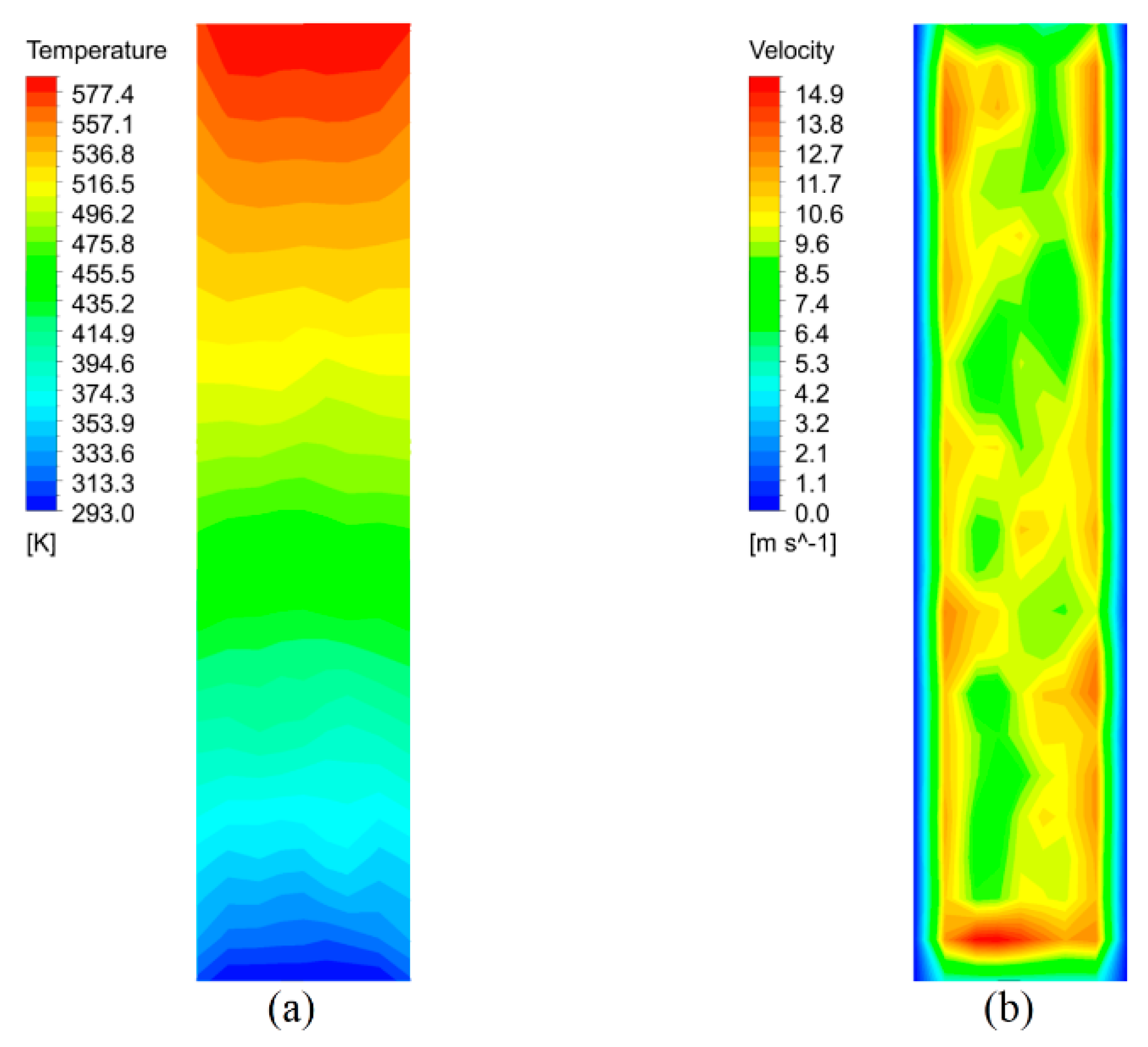

4. Results and Discussion

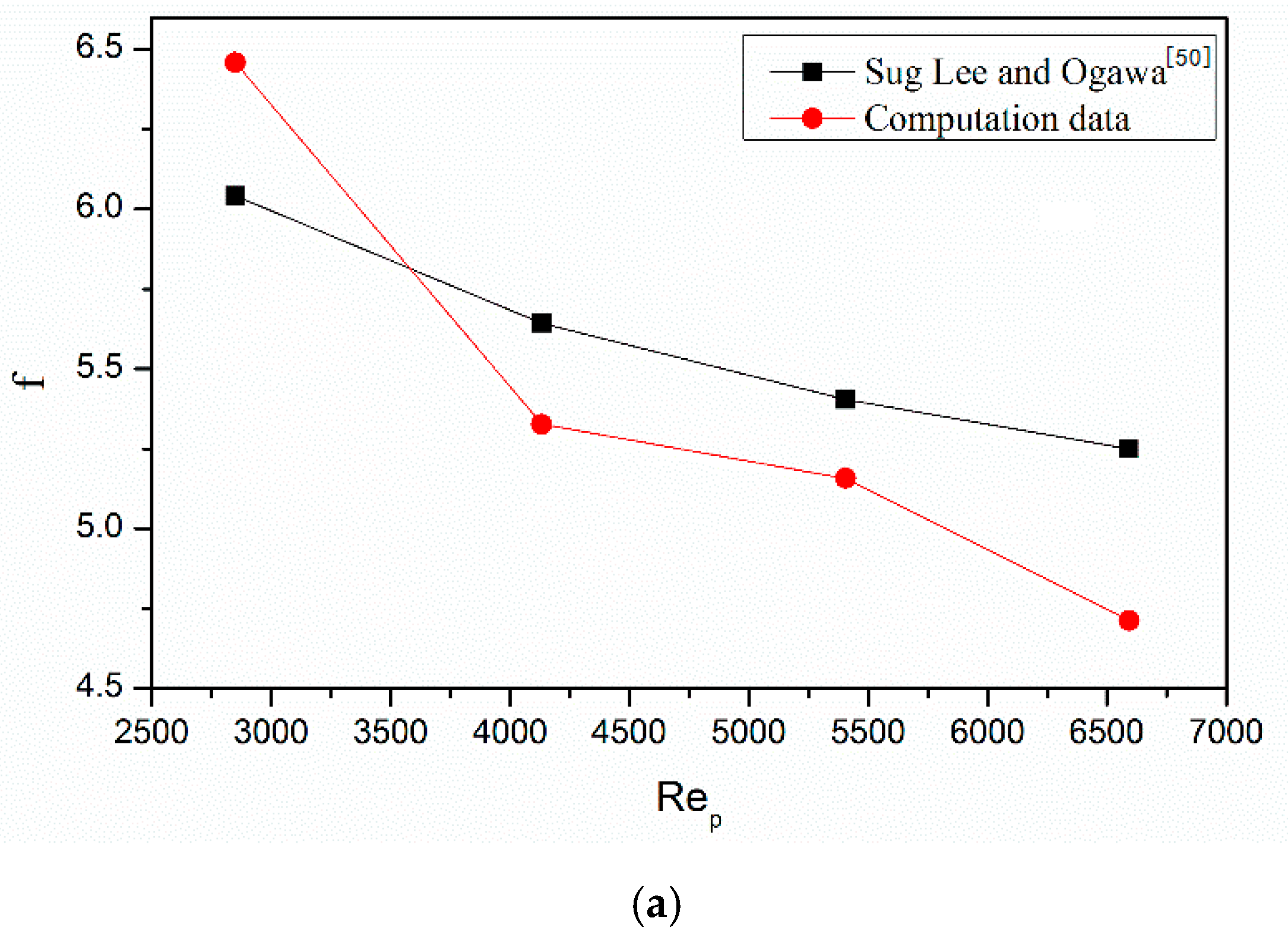

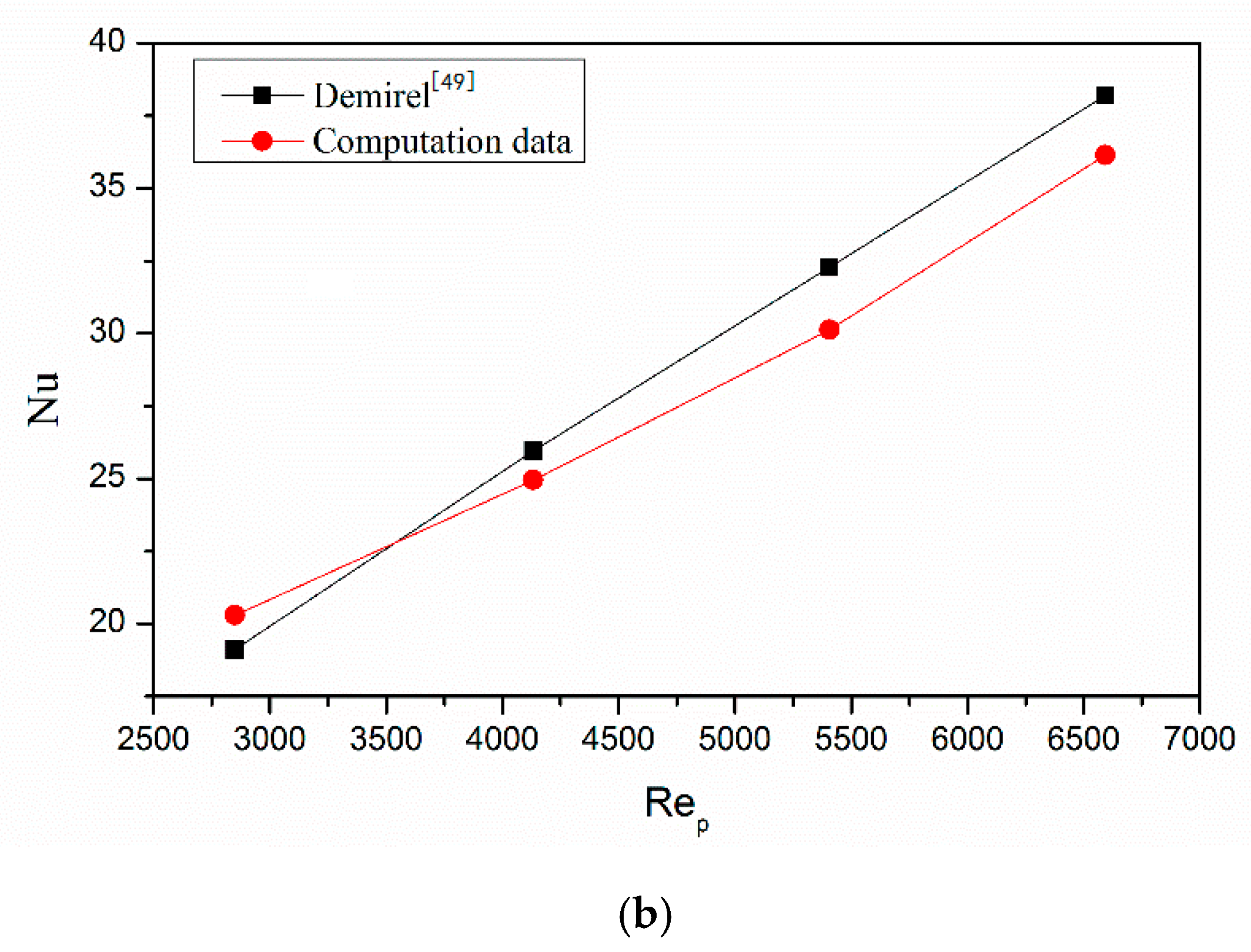

4.1. Model Validation

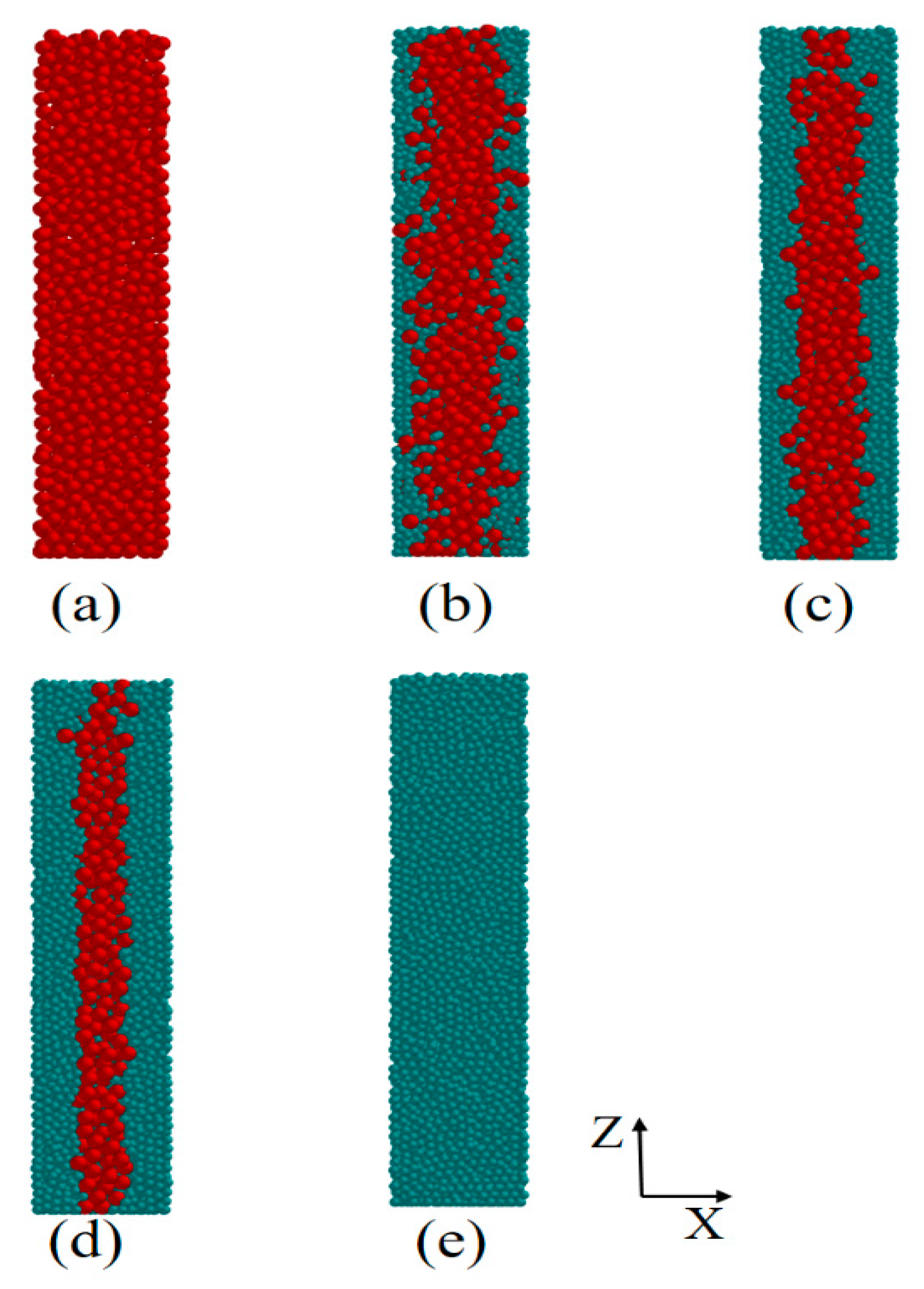

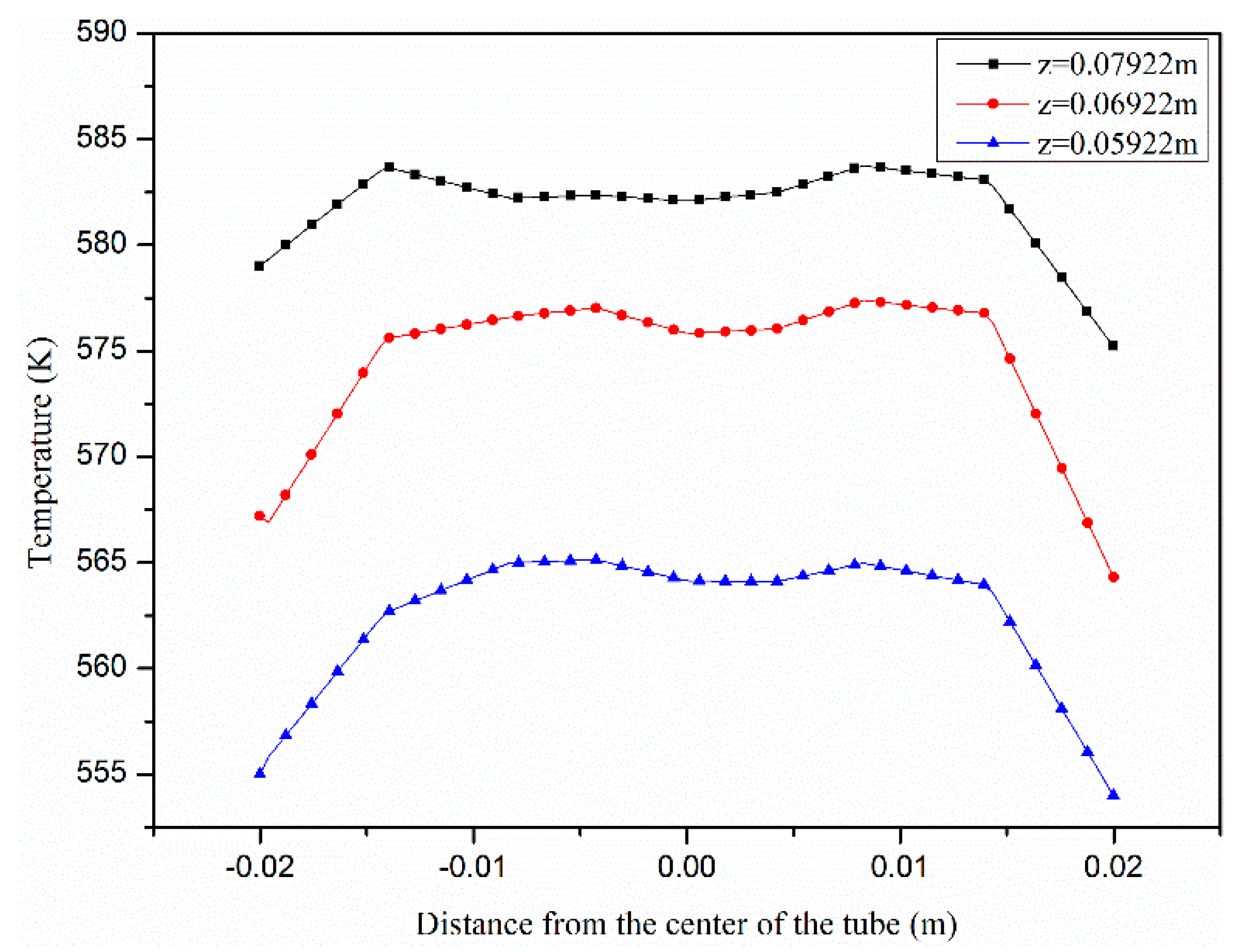

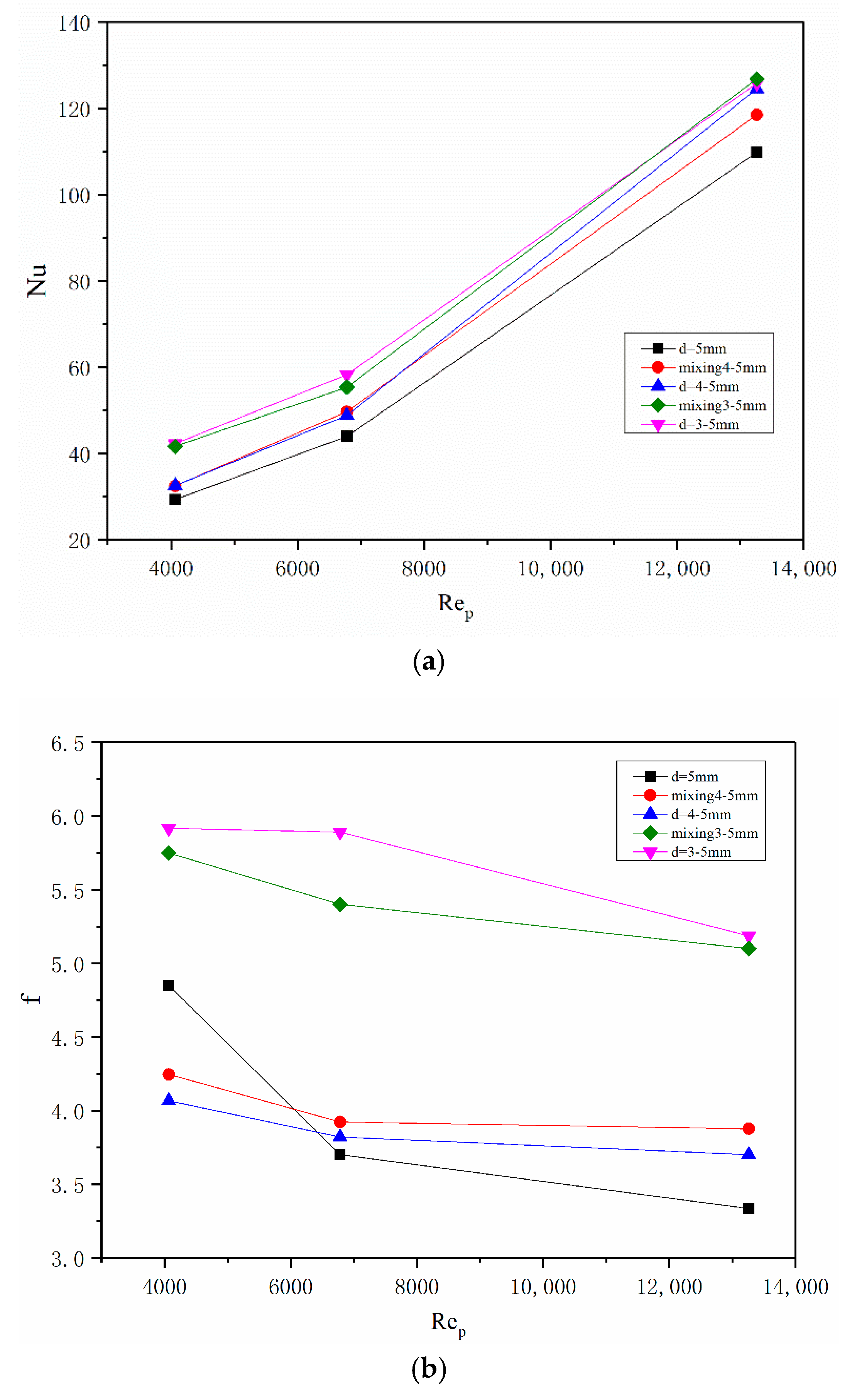

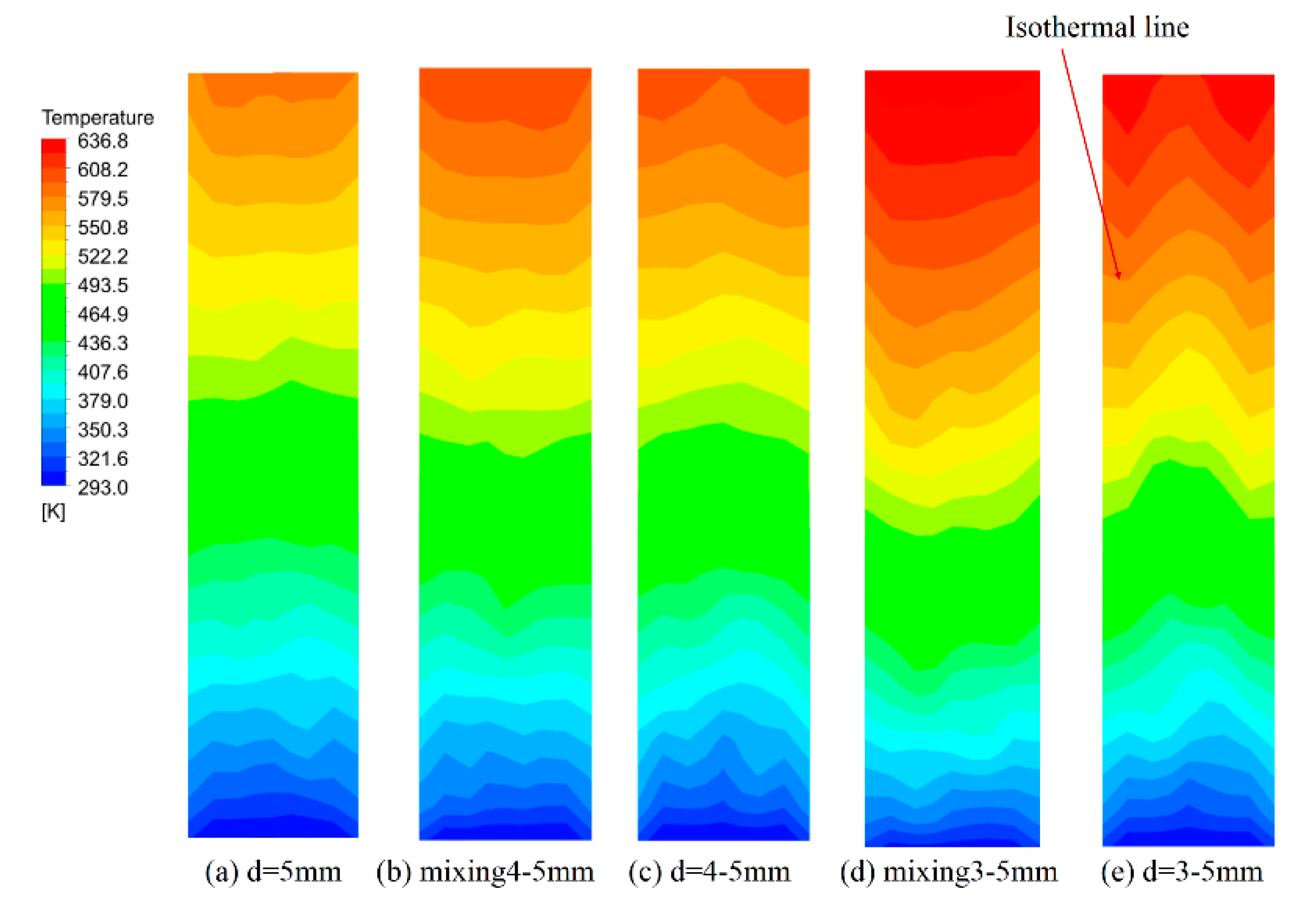

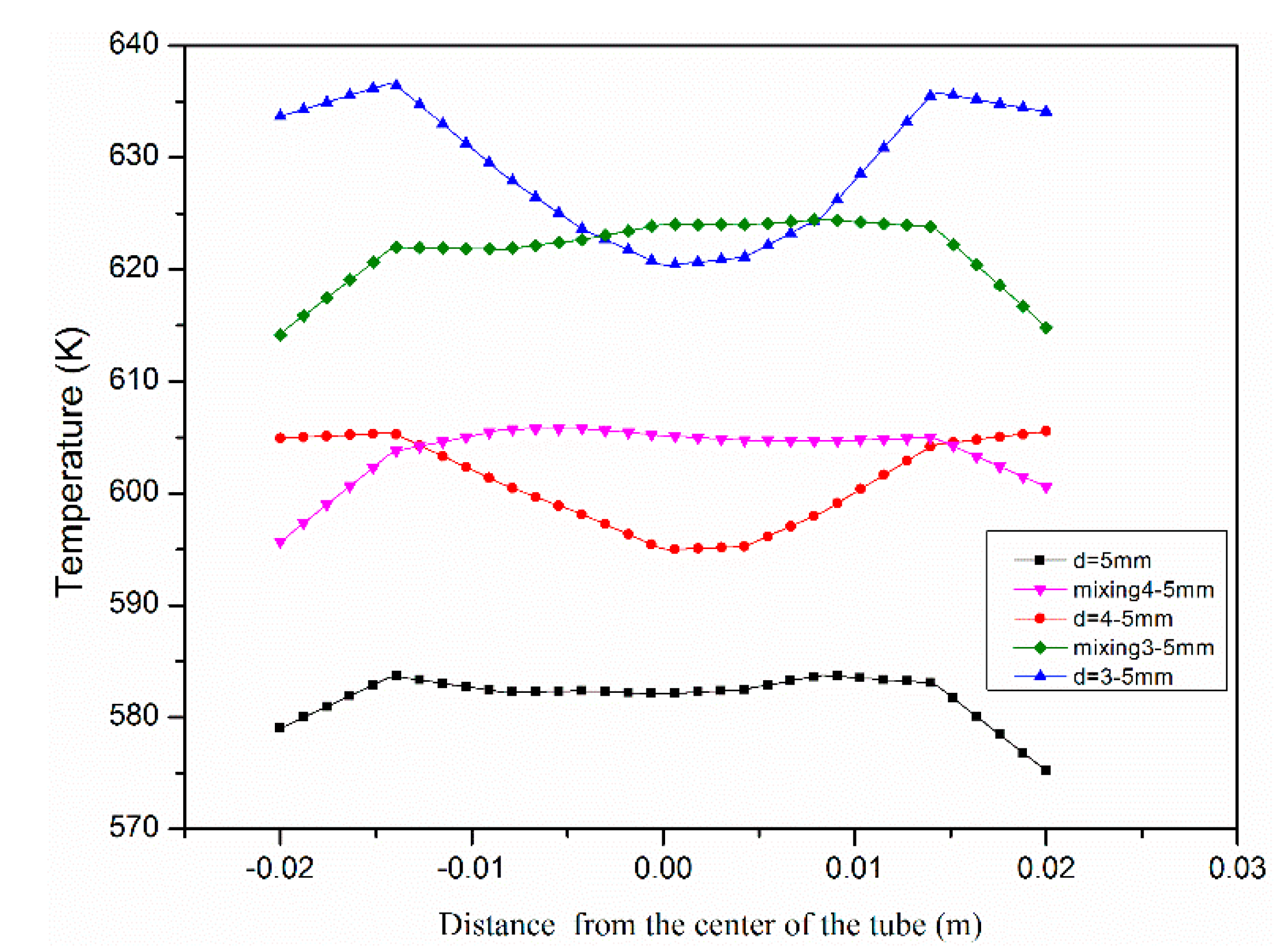

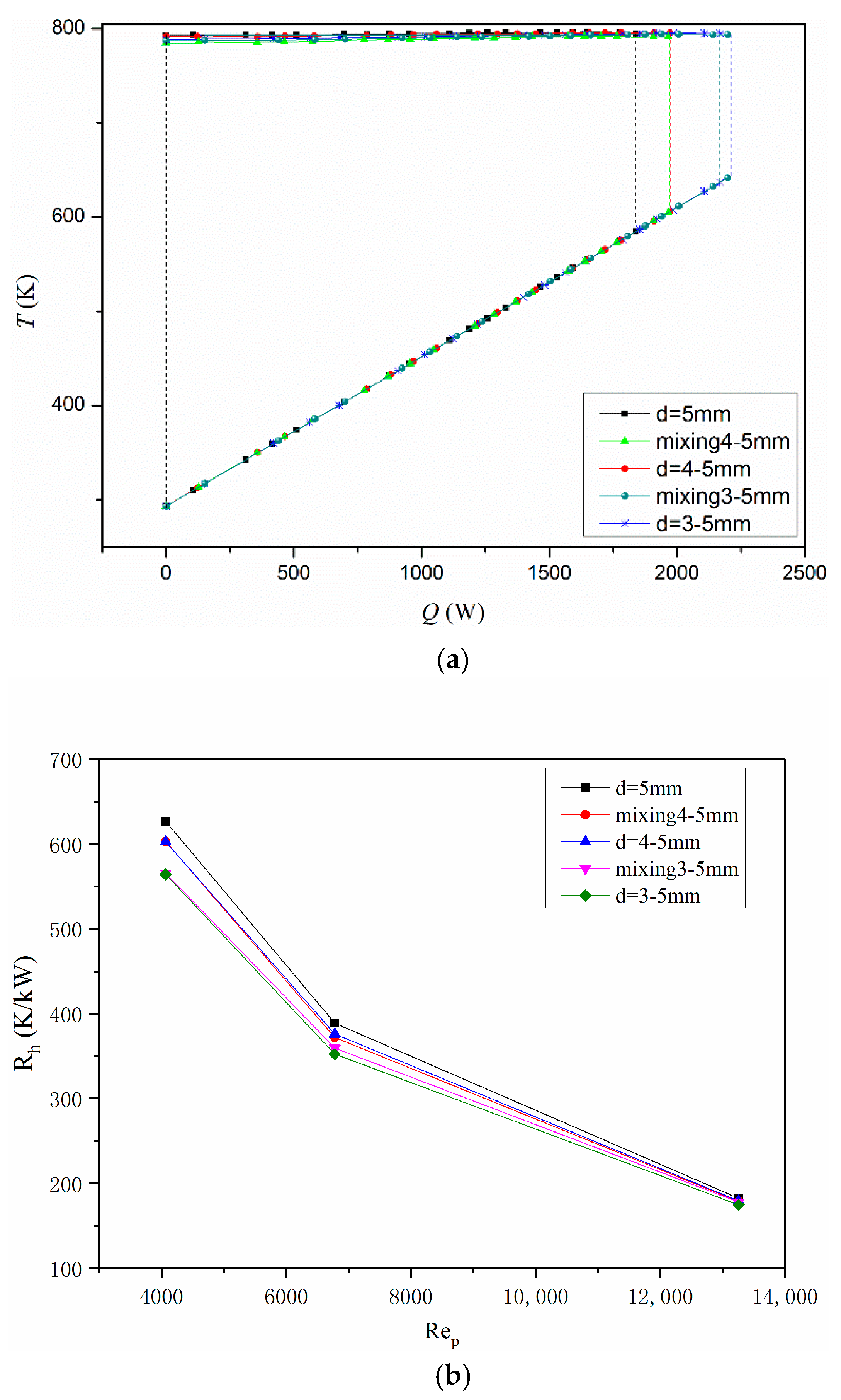

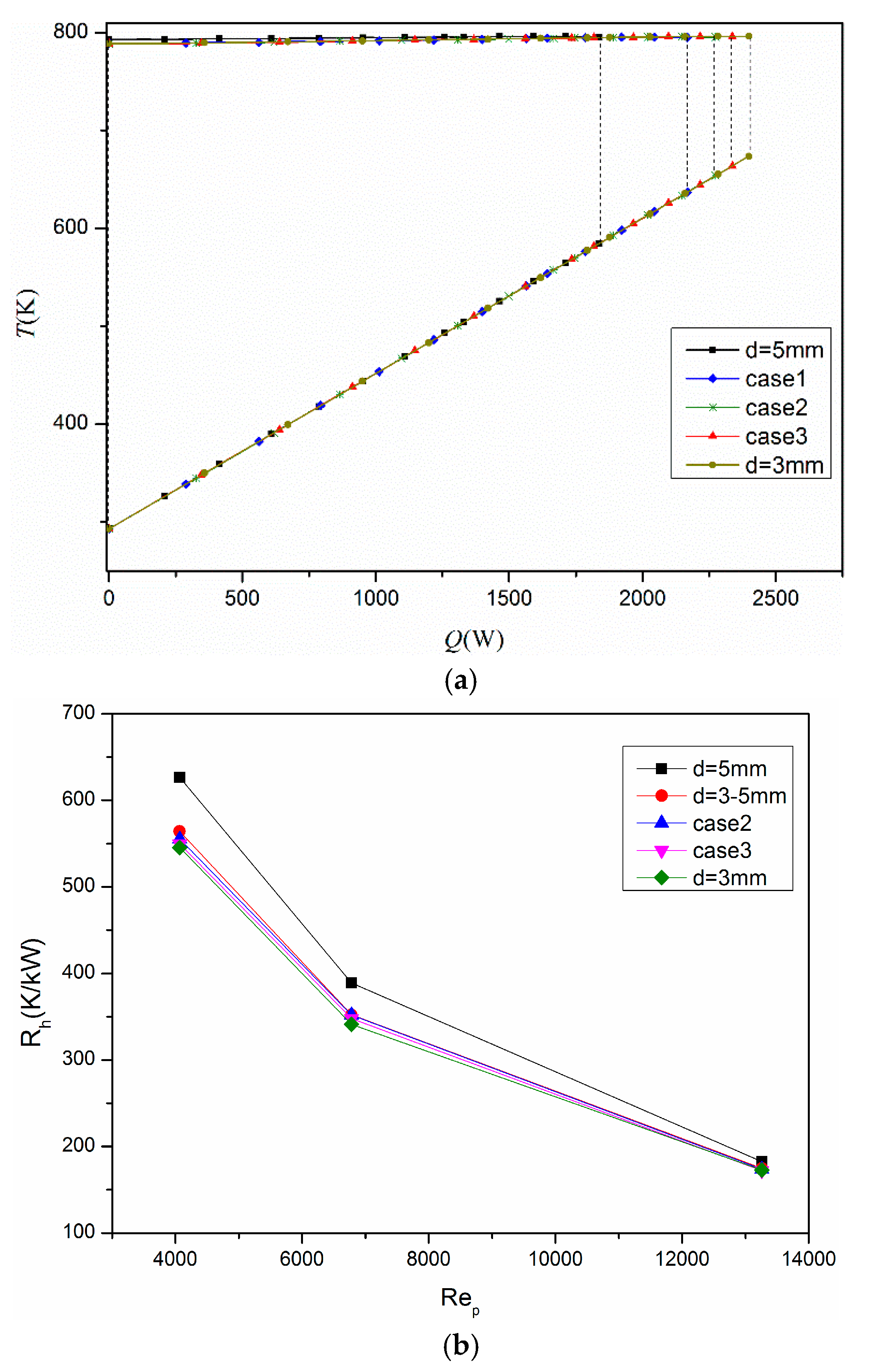

4.2. The Effect of Particle Diameter Distribution

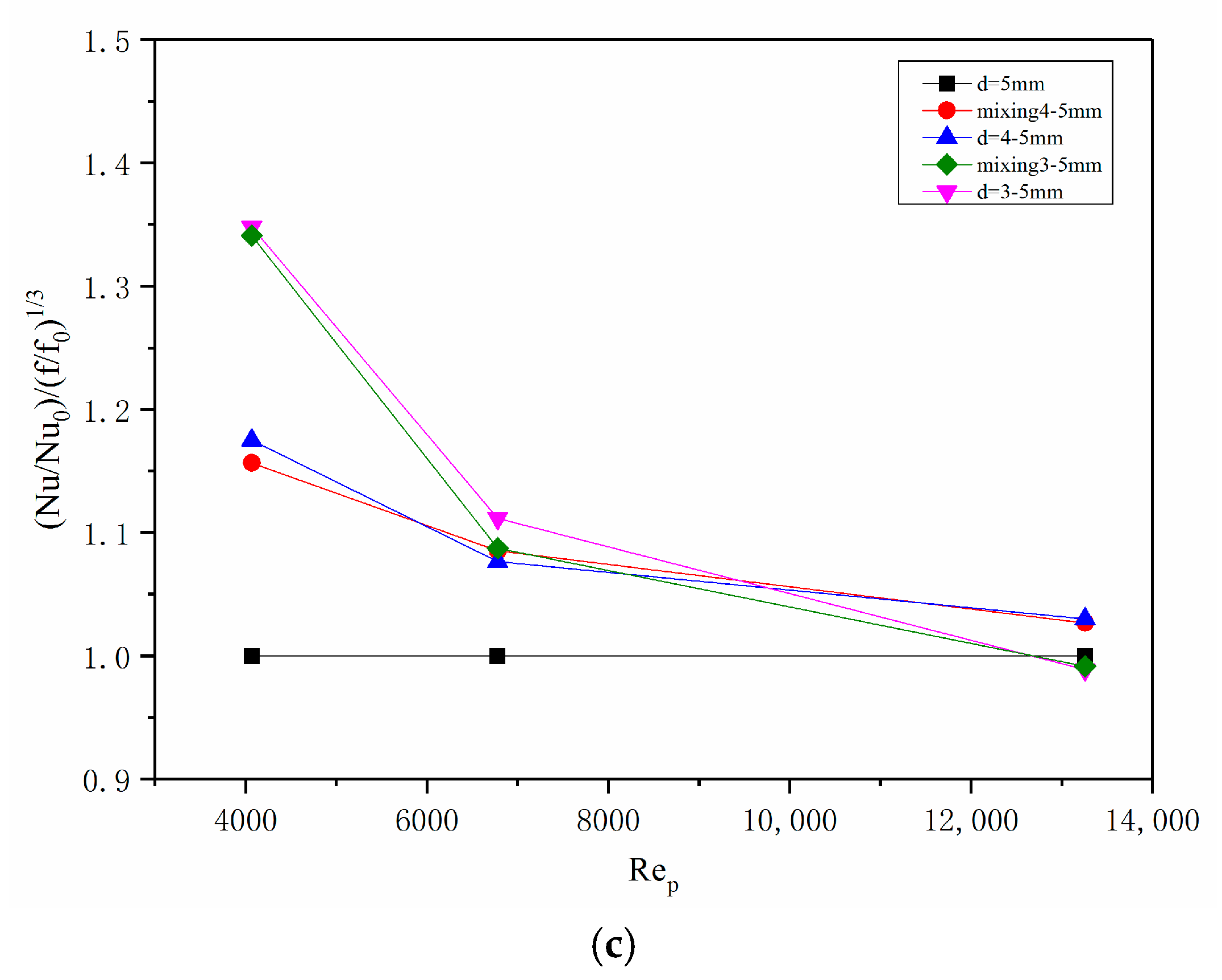

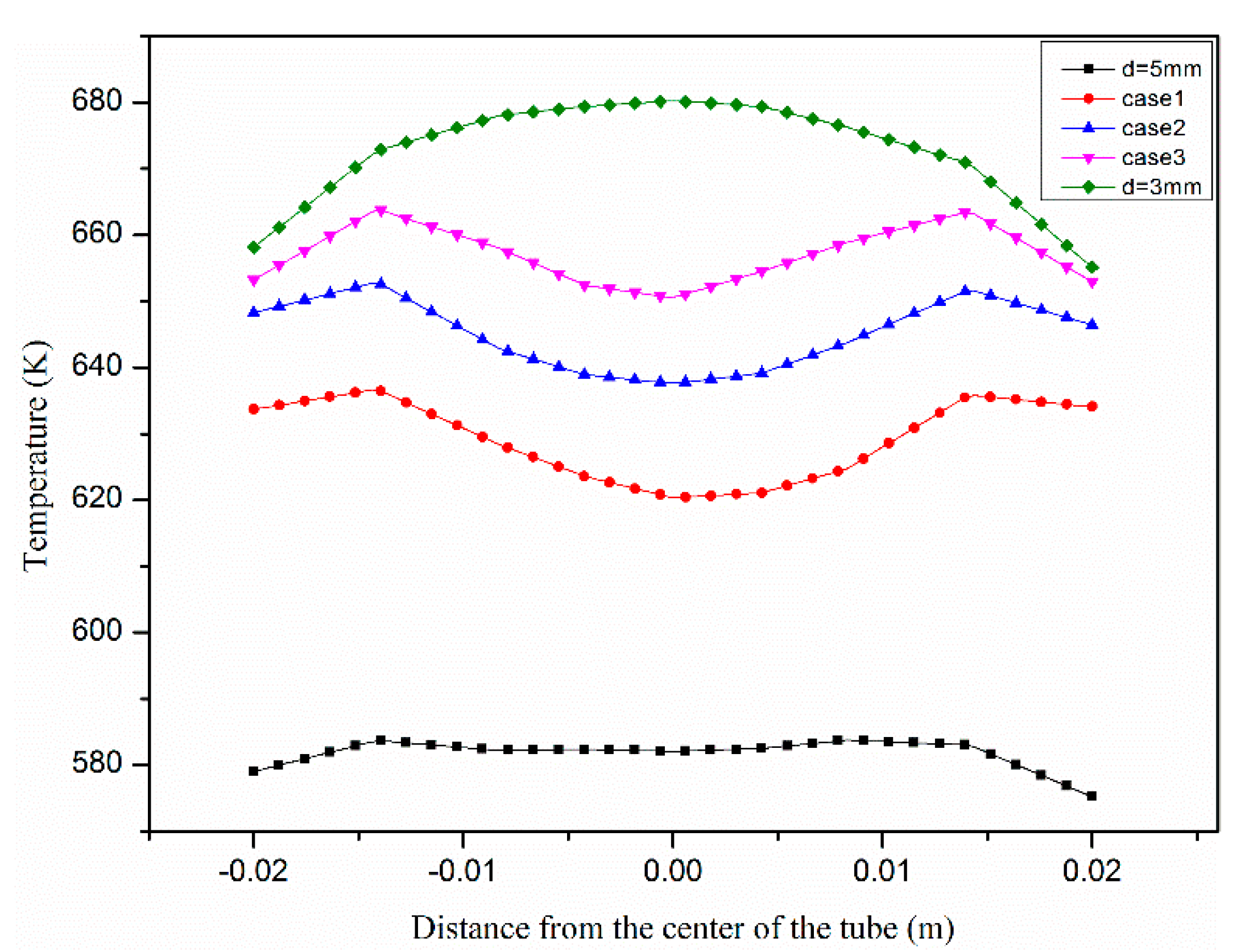

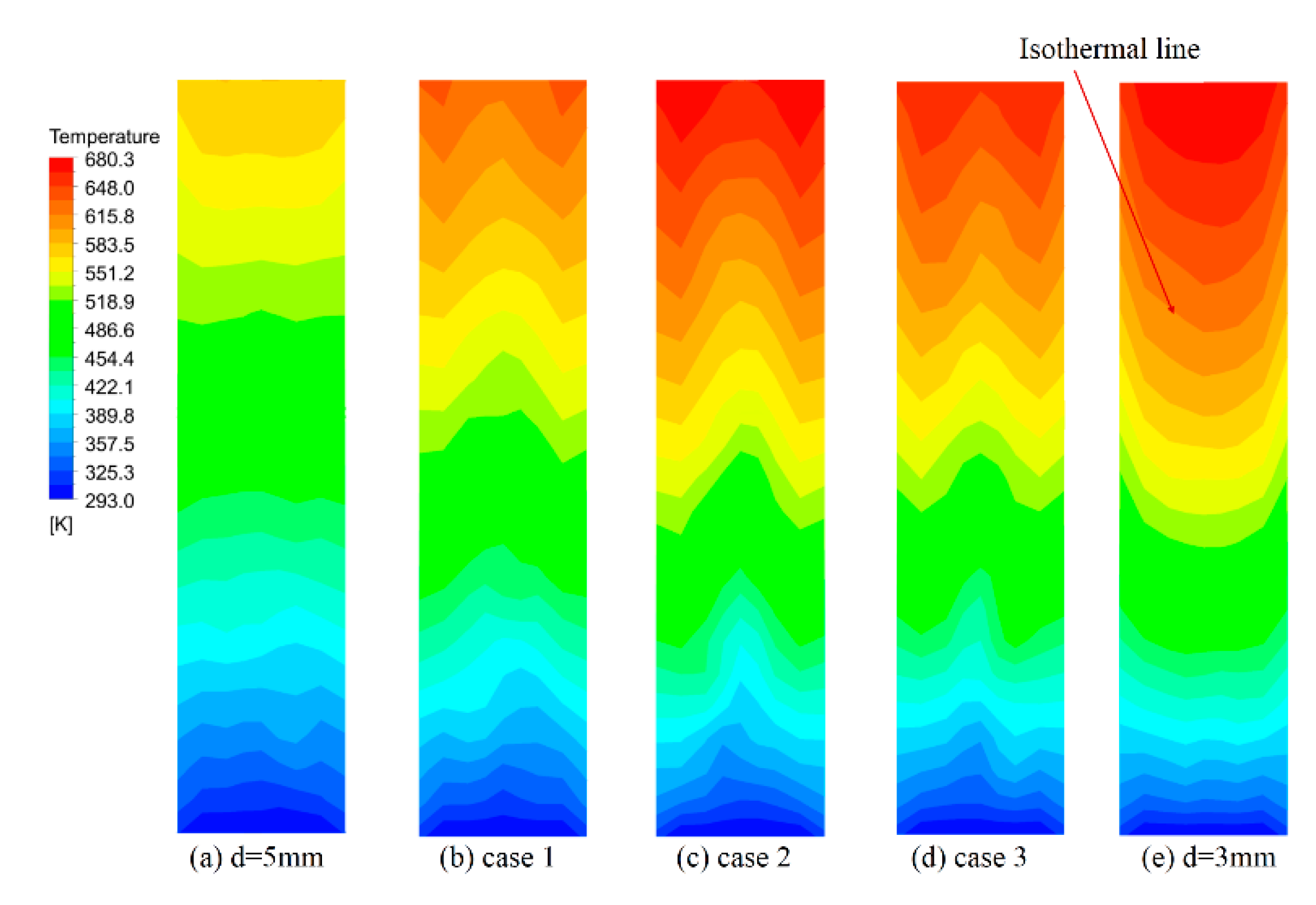

4.3. The Effect of Distribution Thickness

5. Conclusions

- By changing the radial distribution of the particle size in the bed the velocity distribution and temperature distribution in the bed can be effectively improved, the wall effects are well restrained, and the heat transfer ability between the gas and solid is utilized in the greatest extent.

- The range of wall effects is just one particle diameter (5 mm) away from the wall, and the heat transfer performance can be obviously improved by filling small particles in the near wall region.

- The increase of distribution thickness can obviously improve the heat transfer effects, and the equivalent thermal resistance is reduced compared to the uniform size distribution.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Surface area of particle (m2) | |

| Specific heat capacity of gas (J/kg/K) | |

| Specific heat capacity of particle i (J/kg/K) | |

| D | The diameter of bed (m) |

| pore scale hydraulic diameter (m) | |

| Particle diameter (m) | |

| f | Friction factor |

| G | Entransy (W.K) |

| Moment of inertia of particle i (kg/m2) | |

| L1 | The length of extended domain (m) |

| L2 | The length of particle domain (m) |

| Mas of particle i (kg) | |

| Angular velocity of particle i (rad/s) | |

| p | Pressure of gas (Pa) |

| Q | Heat flow (J/s) |

| equivalent thermal resistance (K/W) | |

| Temperature of gas (T) | |

| Temperature of particle i (T) | |

| Volume of particle (m3) | |

| Velocity of particle i (m/s) | |

| Energy source | |

| Momentum source | |

| Density of gas (kg/m3) | |

| Porosity of bed | |

| entransy dissipation (W.K) | |

| Temperature difference (K) | |

| Temperature gradient (K/m) | |

| k | Thermal conductivity |

References

- Bu, S.S.; Yang, J.; Zhou, M.; Li, S.Y.; Wang, Q.W.; Guo, Z.X. On contact point modifications for forced convective heat transfer analysis in a structured packed bed of spheres. Nucl. Eng. Des. 2014, 270, 21–33. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Bu, S.S.; Zeng, M.; Wang, Q.W.; Nakayama, A. Experimental analysis of forced convective heat transfer in novel structured packed beds of particles. Chem. Eng. 2012, 71, 126–137. [Google Scholar] [CrossRef]

- Dixon, A.G.; Di Constanzo, M.A.; Soucy, B.A. Fluid-phase radial transport in packed beds of low tube-to-particle diameter ratio. Heat Mass Transf. 1984, 27, 1701–1713. [Google Scholar] [CrossRef]

- Dixon, A.G. Heat transfer in fixed beds at very low (<4) tube-to-particle diameter ratio. Eng. Chem. Res. 1997, 36, 3053–3064. [Google Scholar]

- Borkink, J.G.H.; Westerterp, K.R. Influence of tube and particle diameter on heat transfer in packed beds. AIChE J. 1992, 38, 703–715. [Google Scholar] [CrossRef]

- Gunn, D.J.; Ahmad, M.M.; Sabri, M.N. Radial heat transfer to fixed beds of particles. Chem. Eng. Sci. 1987, 42, 2163–2171. [Google Scholar] [CrossRef]

- Ge, Y.; Liu, Z.C.; Liu, W. Multi-objective genetic optimization of the heat transfer for tube inserted with porous media. Int. J. Heat Mass Transf. 2016, 101, 981–987. [Google Scholar] [CrossRef]

- Zheng, N.; Liu, P.; Shan, F.; Liu, Z.; Liu, W. Effects of rib arrangements on the flow pattern and heat transfer in an internally ribbed heat exchanger tube. Int. J. Therm. Sci. 2016, 101, 93–105. [Google Scholar] [CrossRef]

- Reddy, R.K.; Joshi, J.B. CFD modeling of pressure drop and drag coefficient in fixed beds: Wall effects. Particuology 2010, 8, 37–43. [Google Scholar] [CrossRef]

- Muller, G.E. Radial void fraction distribution in randomly packed fixed beds of uniformly sized spheres in cylindrical containers. Powder Technol. 1992, 72, 269–275. [Google Scholar] [CrossRef]

- McGreavy, C.; Foumeny, E.A.; Javed, K.H. Characterization of transport properties for fixed bed in terms of local bed structure and flow distribution. Chem. Eng. Sci. 1986, 41, 787–797. [Google Scholar] [CrossRef]

- De Beer, M.; Du Toit, C.G.; Rousseau, P.G. A methodology to investigate the contribution of conduction and radiation heat transfer to the effective thermal conductivity of packed graphite pebble beds, including the wall effect. Nucl. Eng. Des. 2017, 314, 67–81. [Google Scholar] [CrossRef]

- Coberly, C.A.; Marshall, W.R. Temperature gradient in gas stream flowing through fixed granular beds. Chem. Eng. Prog. 1951, 47, 141–150. [Google Scholar]

- Ferreira, L.M.; Castro, J.A.M.; Rodrigues, A.E. An analytical and experimental study of heat transfer in fixed bed. Int. J. Heat Mass Transf. 2002, 45, 951–961. [Google Scholar] [CrossRef] [Green Version]

- Collier, A.P.; Hayhurst, A.N.; Richardson, J.L.; Scott, S.A. The heat transfer coefficient between a particle and a bed (packed of fluidized) of much larger particles. Chem. Eng. Sci. 2004, 59, 4613–4620. [Google Scholar] [CrossRef]

- Nijemeisland, M.; Dixon, A.G. CFD study of fluid flow and wall heat transfer in a fixed bed of spheres. AIChE J. 2004, 50, 906–921. [Google Scholar] [CrossRef]

- Yang, J.; Wu, J.Q.; Zhou, L.; Wang, Q.W. Computational study of fluid flow and heat transfer in composite packed beds of spheres with low tube to particle diameter ratio. Nucl. Eng. Des. 2016, 300, 85–96. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Q.W.; Zeng, M.; Nakayama, A. Computational study of forced convective heat transfer in structured packed beds with spherical or ellipsoidal particles. Chem. Eng. Sci. 2010, 65, 726–738. [Google Scholar] [CrossRef]

- Guardo Coussirat, M.; ALarrayoz, M.; Recasens, F.; Egusquiza, E. Influence of the turbulence model in CFD modeling of wall-to-fluid heat transfer in packed beds. Chem. Eng. Sci. 2005, 60, 1733–1742. [Google Scholar] [CrossRef]

- Zhu, H.P.; Zhou, Z.Y.; Yang, R.Y.; Yu, A.B. Discrete particle simulation of particulate systems: Theoretical developments. Chem. Eng. Sci. 2003, 62, 3378–3396. [Google Scholar] [CrossRef]

- Li, Y.; Ji, W. Acceleratio of coupled granular flow and fluid flow simulations in pebble bed energy systems. Nucl. Eng. Des. 2013, 258, 275–283. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, M.; Lium, Y.; Zheng, J. Particle-scale simulation of the flow and heat transfer behaviors in fluidized bed with immersed tube. AIChE J. 2009, 55, 3109–3124. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47. [Google Scholar] [CrossRef]

- Zhong, W.; Yu, A.B.; Zhou, C.; Xie, J.; Zhang, H. CFD simulation of dense particulate reaction system: Approaches, recent advances and applications. Chem. Eng. Sci. 2016, 140, 16–43. [Google Scholar] [CrossRef]

- Chu, K.W.; Yu, A.B. Numerical simulation of complex particle–fluid flows. Powder Technol. 2008, 179, 104–114. [Google Scholar] [CrossRef]

- Gui, N.; Fan, J.R.; Luo, K. DEM–LES study of 3-D bubbling fluidized bed with immersed tubes. Chem. Eng. Sci. 2008, 63, 3654–3663. [Google Scholar] [CrossRef]

- Zhou, H.; Flamant, G.; Gauthier, D.; Flitris, Y. Simulation of coal combustion in a bubbling fluidized bed by distinct element method. Chem. Eng. Res. Des. 2003, 81, 1144–1149. [Google Scholar] [CrossRef]

- Li, J.T.; Mason, D.J. Application of the discrete element modelling in air drying of particulate solids. Dry. Technol. 2002, 20, 255–282. [Google Scholar] [CrossRef]

- Natsui, S.; Nogami, H.; Ueda, U.; Kano, J.; Inoue, R.; Ariyama, T. Simultaneous threedimensional analysis of gas-solid flow in blast furnace by combining discrete element method and computational fluid dynamics. ISIJ Int. 2011, 51, 41–50. [Google Scholar] [CrossRef]

- Yang, W.J.; Zhou, Z.Y.; Yu, A.B. Particle scale studies of heat transfer in a moving bed. Powder Technol. 2015, 281, 99–111. [Google Scholar] [CrossRef]

- Wu, H.; Gui, N.; Yang, X.T.; Tu, J.Y.; Jiang, S.Y. Numerical simulation of heat transfer in packed pebble beds: CFD-DEM coupled with particle thermal radiation. Int. J. Heat Mass Transf. 2017, 110, 393–405. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Li, D.Y.; Wang, B.X. A novel concept for convective heat transfer enhancement. Int. J. Heat Mass Transf. 1998, 41, 2221–2225. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Tao, W.Q.; Shah, R. The field synergy (coordination) principle and its applications in enhancing single phase convective heat transfer. Int. J. Heat Mass Transf. 2005, 48, 1797–1807. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Z.C.; Guo, Z.Y. Physical quantity synergy in laminar flow field of convective heat transfer and analysis of heat transfer enhancement. Chin. Sci. Bull. 2009, 54, 3579–3586. [Google Scholar] [CrossRef]

- Liu, W.; Liu, P.; Dong, Z.M.; Yang, K.; Liu, Z.C. A study on the multi-field synergy principle of convective heat and mass transfer enhancement. Int. J. Heat Mass Transf. 2019, 134, 722–734. [Google Scholar] [CrossRef]

- Sun, H.N.; Ge, Y.; Liu, W.; Liu, Z.C. Geometric optimization of two-stage thermoelectric generator using genetic algorithm and thermodynamic analysis. Energy 2019, 171, 37–48. [Google Scholar] [CrossRef]

- Ge, Y.; Shan, F.; Liu, Z.C.; Liu, W. Optimal structural design of a heat sink with laminar single-phase flow using computational fluid dynamics based multi-objective genetic algorithm. J. Heat Transfer 2018, 9, 13–18. [Google Scholar] [CrossRef]

- Ge, Y.; Liu, Z.C.; Sun, H.N.; Liu, W. Optimal design of a segmented thermoelectric generator based on three-dimensional numerical simulation and multi-objective genetic algorithm. Energy 2018, 147, 1060–1069. [Google Scholar] [CrossRef]

- Ge, Y.; Wang, S.C.; Liu, Z.C.; Liu, W. Optimal shape design of a minichannel heat sink applying multi-objective optimization algorithm and three-dimensional numerical method. Appl. Thermal Eng. 2019, 148, 120–128. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Zhu, H.Y.; Liang, X.G. Entransy-A physical quantity describing heat transfer ability. Heat Mass Transf. 2007, 50, 2545–2556. [Google Scholar] [CrossRef]

- Chen, Q.; Zhu, H.Y.; Pan, N.; Guo, Z.Y. An alternative criterion heat transfer optimization. Math. Phys. Eng. Sci. 2011, 467, 1012–1028. [Google Scholar] [CrossRef]

- Chen, Q.; Liang, X.G.; Guo, Z.Y. Entransy Theory for the optimization of heat transfer—A review and update. Heat Mass Transf. 2013, 63, 65–81. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, M.; Pan, N.; Guo, Z.-Y. Optimization principles for convective heat transfer. Energy 2009, 34, 1199–1206. [Google Scholar] [CrossRef]

- Malone, F.; Xu, B.H. Particle-scale simulation of heat transfer in liquid-fluidized beds. Powder Technol. 2008, 184, 189–204. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Yu, A.B.; Zulli, P. Particle scale study of heat transfer in packed and bubbling fluidized beds. AIChE J. 2009, 55, 868–884. [Google Scholar] [CrossRef]

- Wang, J.; Liu, W.; Liu, Z. The application of exergy destruction minimization in convective heat transfer optimization. Appl. Therm. Eng. 2015, 88, 384–390. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Z.; Jia, H. Entransy expression of the second law of thermodynamics and its application to optimization in heat transfer process. Int. J. Heat Transf. 2011, 54, 3049–3059. [Google Scholar] [CrossRef]

- Cheng, X.G.; Li, Z.X.; Guo, Z.Y. Variational principles in heat conduction. J. Eng. Thermophys. 2004, 25, 457–459. [Google Scholar]

- Demirel, Y.; Sharma, R.N.; Al-Ali, H.H. On the effective heat transfer parameters in a packed bed. Int. J. Heat Mass Transf. 2000, 43, 327–332. [Google Scholar] [CrossRef]

- Sug Lee, J.; Ogawa, K. Pressure drop through packed beds. J. Chem. Eng. Jpn. 1974, 27, 691–693. [Google Scholar]

| Bed Geometry | Diameter D (mm) | 40 |

|---|---|---|

| Particle domain L2 (mm) | 180 | |

| Extended domain L1(mm) | 90 | |

| Particle | diameter d (mm) | 3/4/5 |

| Density (kg/m3) | 4540 | |

| thermal conductivity (W/(m.K) | 24.6 | |

| thermal capacity Cp (J/(kg.K) | 630 | |

| initial temperature (K) | 800 | |

| Gas | Density (kg/m3) | 0.9944 |

| Thermal conductivity (W/(m.K) | 0.03066 | |

| thermal capacity Cp (J/(kg.K) | 1009 | |

| initial velocity (m/s) | 5 | |

| Initial temperature (K) | 293 | |

| dynamic viscosity (m2/s) | 2.13e-05 | |

| Contact parameter | Poisson ratio | 0.3 |

| Young’s modulus (Mpa) | 64.52 | |

| rolling friction coefficient | 0.01 | |

| static friction coefficient | 0.545 | |

| restitution coefficient | 0.2 |

| 2849.9 | 4132.4 | 5405.3 | 6592.8 | ||

| Nu | Sug Lee and Ogawa [50] | 19.108 | 25.962 | 32.270 | 38.200 |

| Computation data | 20.290 | 24.950 | 30.124 | 36.148 | |

| Deviation | 6.2% | 3.9% | 6.6% | 5.4% | |

| f | Demirel [49] | 6.041 | 5.642 | 5.404 | 5.249 |

| Computation data | 6.459 | 5.326 | 5.157 | 4.712 | |

| Deviation (%) | 6.9% | 5.6% | 4.5% | 10.2% | |

| Particle Size Distribution | d = 5 mm | Mixing 4–5 mm | d = 4–5 mm | Mixing 3–5 mm | d = 3–5 mm (Case1) | Case2 | Case3 | d = 3 mm |

|---|---|---|---|---|---|---|---|---|

| Outlet temperature (K) | 584.4 | 605.1 | 606.8 | 624.2 | 636.3 | 652.4 | 662.2 | 672.1 |

| Average porosity | 0.4397 | 0.4177 | 0.4177 | 0.4127 | 0.4127 | 0.4114 | 0.589 | 0.41 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Xu, C.; Liu, W.; Liu, Z. Numerical Study on Heat Transfer Performance in Packed Bed. Energies 2019, 12, 414. https://doi.org/10.3390/en12030414

Wang S, Xu C, Liu W, Liu Z. Numerical Study on Heat Transfer Performance in Packed Bed. Energies. 2019; 12(3):414. https://doi.org/10.3390/en12030414

Chicago/Turabian StyleWang, Shicheng, Chenyi Xu, Wei Liu, and Zhichun Liu. 2019. "Numerical Study on Heat Transfer Performance in Packed Bed" Energies 12, no. 3: 414. https://doi.org/10.3390/en12030414