The Emission Characteristics of a Diesel Engine During Start-Up Process at Different Altitudes

Abstract

:1. Introduction

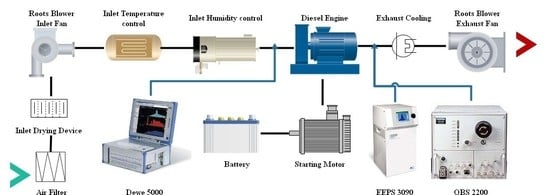

2. Apparatus and Methodology

2.1. Experimental Apparatus

2.2. Start Process Definition

- (a)

- Cranking process: the diesel engine crankshaft was driven by an external force and started to rotate until the speed rose steadily.

- (b)

- Start-up process: the engine began to run steadily until the speed rose to its idle speed.

- (c)

- Idle process: the engine’s speed ran steadily at an idle speed.

2.3. Experiment Procedure

2.4. Analysis Procedure

3. Start-Up Performance

4. Result and Analysis

4.1. CO Emission

4.2. CO2 Emission

4.3. THC Emission

4.4. NOX Emissions

4.5. PN Emission

4.6. PM Emission

4.7. VOC Emission

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kockelman, M.S.R.K.M. The problem of cold starts: A closer look at mobile source emissions levels. Transp. Res. Part D Transp. Environ. 2016, 43, 123–132. [Google Scholar] [Green Version]

- Williams, M.; Minjares, R. A technical summary of Euro 6/VI vehicle emission standards. Int. Counc. Clean Transp. (ICCT) 2016. Available online: https://theicct.org/publications/technical-summary-euro-6vi-vehicle-emission-standards (accessed on 10 July 2017).

- Vressner, A.; Gabrielsson, P.; Gekas, I.; Senar-Serra, E. Meeting the EURO VI NOx Emission Legislation using a EURO IV Base Engine and a SCR/ASC/DOC/DPF Configuration in the World Harmonized Transient Cycle. SAE Tech. Pap. 2010. [Google Scholar] [CrossRef]

- Pacaud, P.; Perrin, H.; Laget, O. Cold start on diesel engine: Is low compression ratio compatible with cold start requirements? SAE Int. J. Engines 2008, 1, 831–849. [Google Scholar] [CrossRef]

- Tan, P.; Zhang, X.; Hu, Z.; Lou, D. Effects of DOC+CDPF on particulate emission from a diesel engine with biodiesel fuel. China Environ. Sci. 2015, 35, 2978–2984. [Google Scholar]

- John, D.; Gajarlawar, N. Experiences in cold start optimization of a multi-purpose vehicle equipped with 2.2 L common rail diesel engine. SAE Tech. Pap. 2011. [Google Scholar] [CrossRef]

- Kumar, D.; Murugesan, L.; Nagarajan, M.; Kakde, N.; Mahesh, P. Experimental investigation of six cylinder turbocharged Di-diesel engine cold startability. SAE Tech. Pap. 2014. [Google Scholar] [CrossRef]

- La Rocca, A.; MacMillan, D.; Shayler, P.; Murphy, M.; Pegg, I. CFD investigation on the influence of in-cylinder mixture distribution from multiple pilot injections on cold idle behaviour of a light duty diesel engine. SAE Tech. Pap. 2014. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, H.; Wyszynski, M.L.; Tian, J.; Xu, H. Experimental study on diesel fuel injection characteristics under cold start conditions with single and split injection strategies. Fuel Process. Technol. 2015, 131, 213–222. [Google Scholar] [CrossRef]

- Chaichan, M.T. Effect of injection timing and coolant temperatures of DI diesel engine on cold and hot engine startability and emissions. IOSR J. Mech. Civ. Eng. (IOSRJMCE) 2016, 13, 62–70. [Google Scholar]

- Phatak, R.; Nakamura, T. Cold startability of open-chamber direct-injection diesel engines—Part I: Measurement technique and effects of compression ratio. SAE Trans. 1983, 92, 1031–1040. [Google Scholar]

- Han, Z.; Henein, N.; Nitu, B.; Bryzik, W. Diesel engine cold start combustion instability and control strategy. SAE Tech. Pap. 2001. [Google Scholar] [CrossRef]

- Mathis, U.; Mohr, M.; Forss, A. Comprehensive particle characterization of modern gasoline and diesel passenger cars at low ambient temperatures. Atmos. Environ. 2005, 39, 107–117. [Google Scholar] [CrossRef]

- Weilenmann, M.; Soltic, P.; Saxer, C.; Forss, A.M.; Heeb, N. Regulated and nonregulated diesel and gasoline cold start emissions at different temperatures. Atmos. Environ. 2005, 39, 2433–2441. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Maroon, O.K.; Abaas, K.I. The effect of diesel engine cold start period on the emitted emissions. Int. J. Sci. Eng. Res. 2016, 7, 749–753. [Google Scholar]

- Cârulescu, S.; Şoica, A.; Cârulescu, R. Emission level approximation at cold start for diesel vehicles. Combustion 2015, 51, 5. [Google Scholar]

- Roy, M.M.; Calder, J.; Wang, W.; Mangad, A.; Diniz, F.C.M. Cold start idle emissions from a modern Tier-4 turbo-charged diesel engine fueled with diesel-biodiesel, diesel-biodiesel-ethanol, and diesel-biodiesel-diethyl ether blends. Appl. Energy 2016, 180, 52–65. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Xu, H. Cold start particle number, size and mass emissions from a CRDI diesel engine running on biodiesel blends in a cold environment. Biofuels 2016, 7, 353–363. [Google Scholar] [CrossRef]

- Cárdenas, M.D.; Gómez, A.; Armas, O. Pollutant emissions from starting a common rail diesel engine fueled with different biodiesel fuels. J. Energy Eng. 2016, 142, E4015012. [Google Scholar] [CrossRef]

- Wang, X.; Ge, Y.; Yu, L.; Feng, X. Comparison of combustion characteristics and brake thermal efficiency of a heavy-duty diesel engine fueled with diesel and biodiesel at high altitude. Fuel 2013, 107, 852–858. [Google Scholar] [CrossRef]

- Yu, L.; Ge, Y.; Tan, J.; He, C.; Wang, X.; Liu, H.; Zhao, W.; Gou, J.; Fu, G.; Feng, X.; et al. Experimental investigation of the impact of biodiesel on the combustion and emission characteristics of a heavy duty diesel engine at various altitudes. Fuel 2014, 115, 220–226. [Google Scholar] [CrossRef]

- He, C.; Ge, Y.; Ma, C.; Tan, J.; Liu, Z.; Wang, C.; Yu, L.; Ding, Y. Emission characteristics of a heavy-duty diesel engine at simulated high altitudes. Sci. Total Environ. 2011, 409, 3138–3143. [Google Scholar] [CrossRef]

- Ambrozik, A.; Ambrozik, T.; Lagowski, P. Fuel impact on emissions of harmful components of the exhaust gas from the CI engine during cold start-up. Eksploat. Niezawodn. 2015, 17, 95–99. [Google Scholar] [CrossRef]

- Kan, Z.; Hu, Z.; Lou, D.; Tan, P.; Cao, Z.; Yang, Z. Effects of altitude on combustion and ignition characteristics of speed-up period during cold start in a diesel engine. Energy 2018, 150, 164–175. [Google Scholar] [CrossRef]

- Kan, Z.C.; Lou, D.M.; Cao, Z.Z.; Hu, Z.Y.; Liu, S.; Yang, Z.H. Effects of altitude on combustion characteristic during cold start of heavy-duty diesel engine. Int. J. Automot. Technol. 2017, 18, 209–217. [Google Scholar] [CrossRef]

- Kobayashi, A.; Kurashima, A.; Endo, S. Analysis of cold start combustion in a direct injection diesel engine. SAE Tech. Pap. 1984. [Google Scholar] [CrossRef]

- Kan, Z.C.; Hu, Z.Y.; Lou, D.M.; Cao, Z.Y.; Cao, J. Effect of the altitude on the combustion characteristics of a low-compression-ratio diesel engine during the start-up process. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 231, 1838–1847. [Google Scholar] [CrossRef]

- Wu, B. The composing mechanism of NOx in combustion. Electr. Power Environ. Prot. 2003, 19, 9–12. [Google Scholar]

- Jimenez, J.L.; Canagaratna, M.R.; Donahue, N.M.; Prevot, A.S.H.; Zhang, Q.; Kroll, J.H.; DeCarlo, P.F.; Allan, J.D.; Coe, H.; Ng, N.L.; et al. Evolution of organic aerosols in the atmosphere. Science 2009, 326, 1525–1529. [Google Scholar] [CrossRef]

| Item | Value | Item | Value |

|---|---|---|---|

| Cylinders | 6 Symmetrical | Fuel supply system | EIL |

| Displacement | 15.9 L | Compression ratio | 14.25 |

| Bore | 150 mm | Intake system | TCI |

| Stroke | 160 mm | Valve per cylinder | 4 |

| Rod length | 300 mm | Nozzle | 10 |

| Cylinder angle | 60° | Idle speed | 800 r/min |

| Simulation Altitude (m) | Intake/Exhaust Pressure (kPa) |

|---|---|

| 0 | 101.3 |

| 1000 | 90.1 |

| 2000 | 79.2 |

| 3000 | 70.1 |

| 3750 | 63.5 |

| 4500 | 57.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, L.; Lou, D.; Hu, Z.; Tan, P. The Emission Characteristics of a Diesel Engine During Start-Up Process at Different Altitudes. Energies 2019, 12, 3556. https://doi.org/10.3390/en12183556

Fang L, Lou D, Hu Z, Tan P. The Emission Characteristics of a Diesel Engine During Start-Up Process at Different Altitudes. Energies. 2019; 12(18):3556. https://doi.org/10.3390/en12183556

Chicago/Turabian StyleFang, Liang, Diming Lou, Zhiyuan Hu, and Piqiang Tan. 2019. "The Emission Characteristics of a Diesel Engine During Start-Up Process at Different Altitudes" Energies 12, no. 18: 3556. https://doi.org/10.3390/en12183556