Constellation of Condensation and Raindrops and Its Effect on the DC Flashover Voltage of Inclined Silicone Insulation

Abstract

:1. Introduction

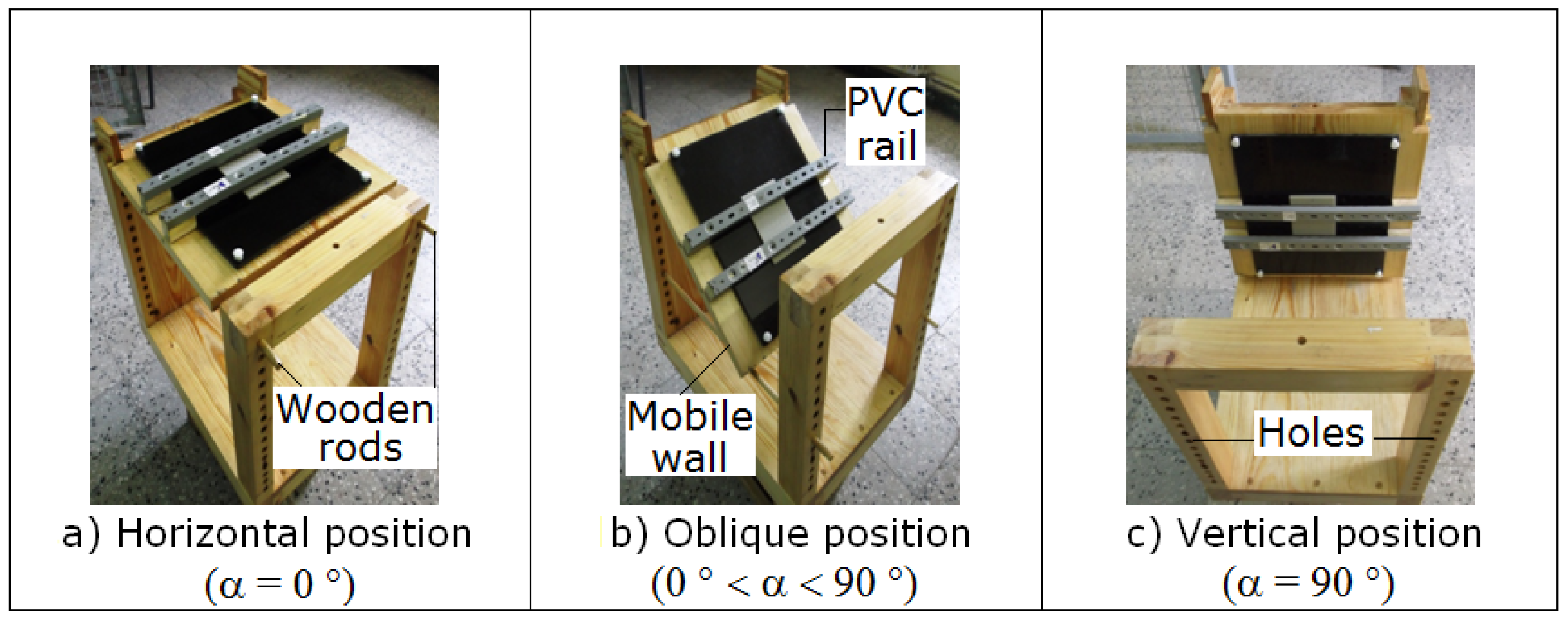

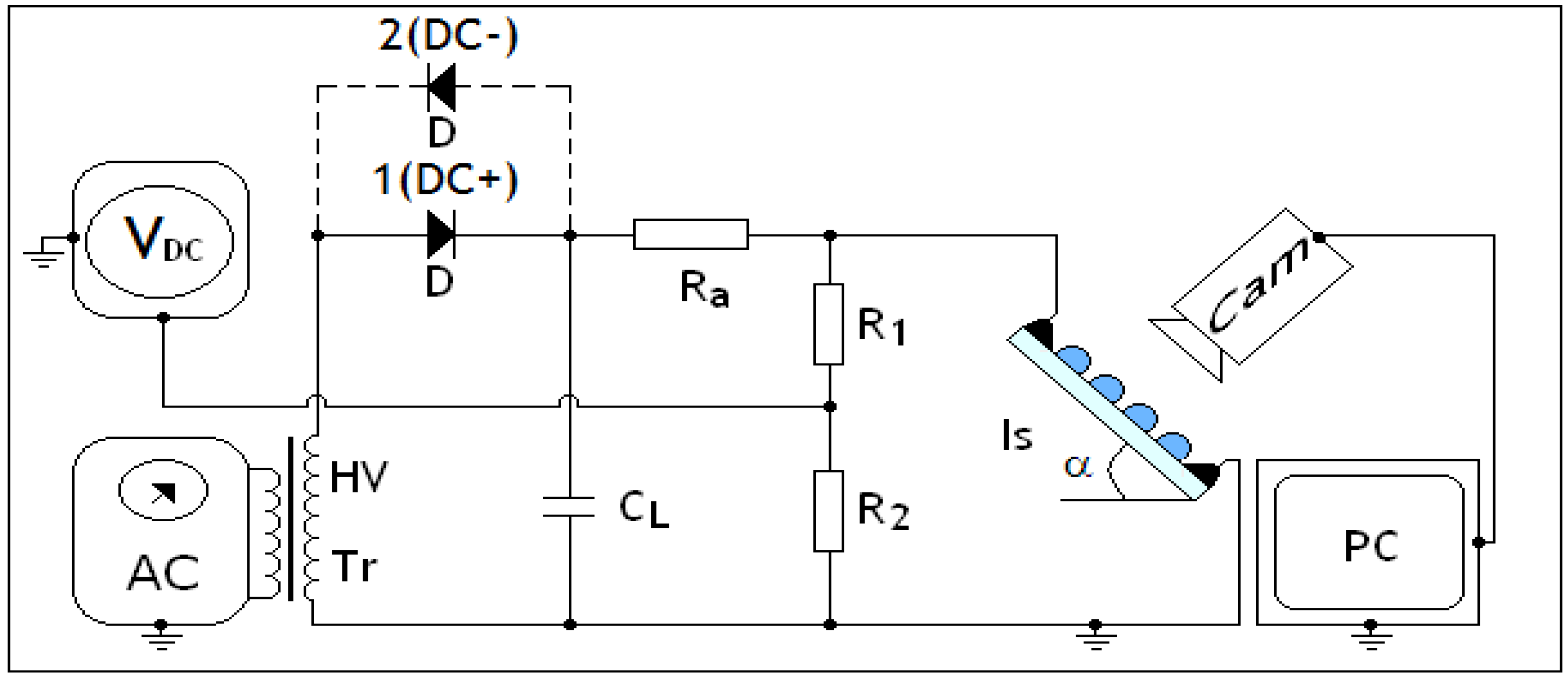

2. On-Site and Laboratory Experimental Devices and Measurement Techniques

3. Results and Discussion

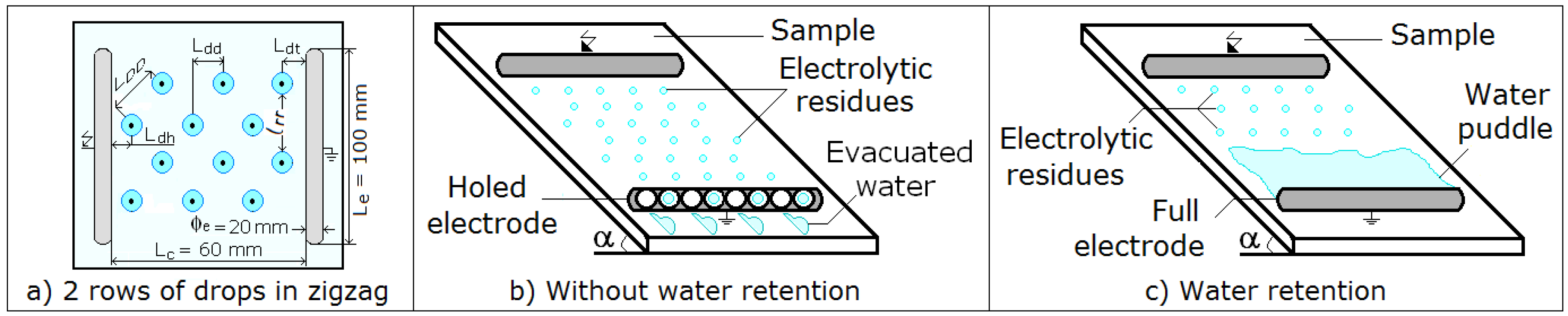

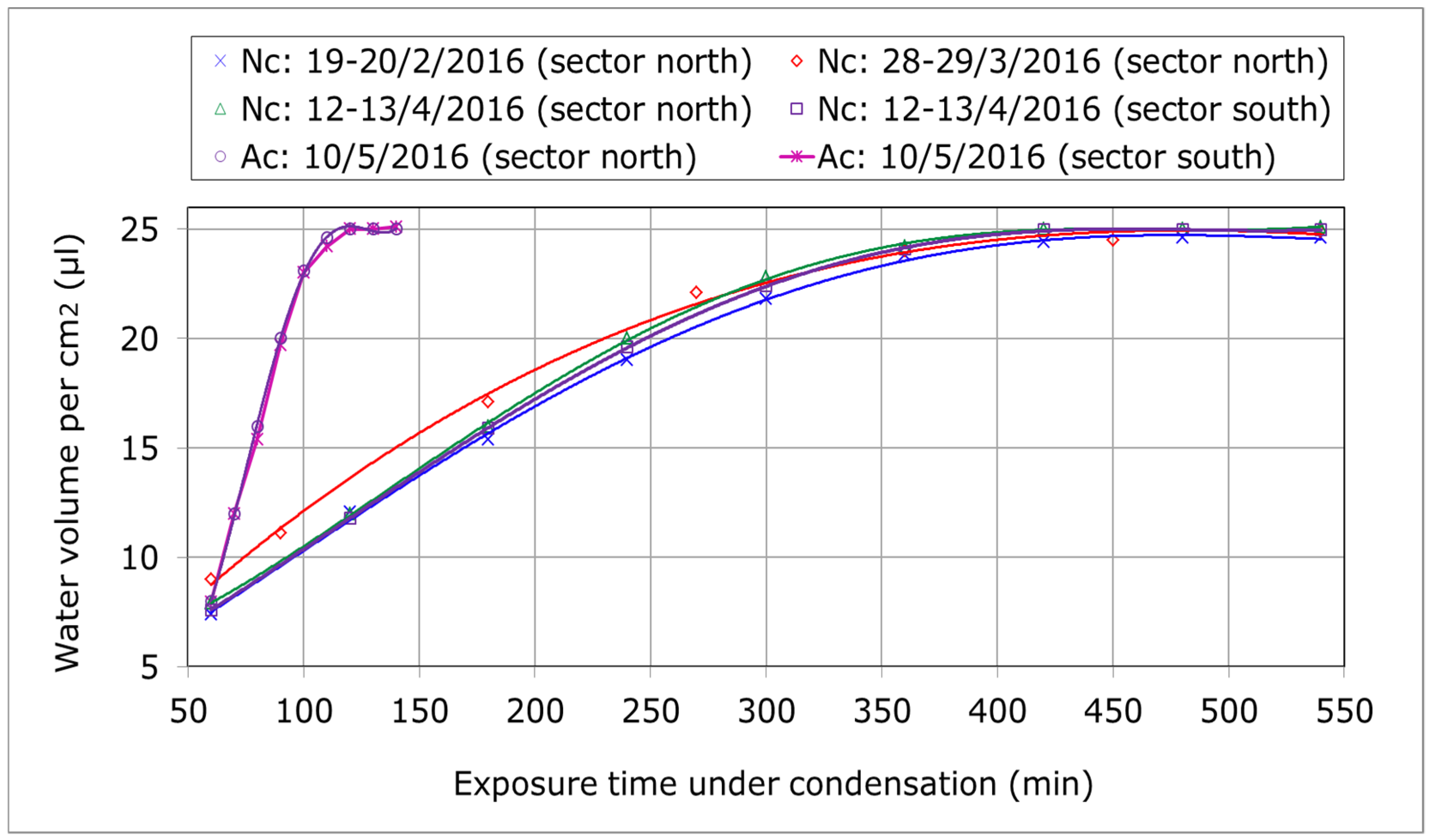

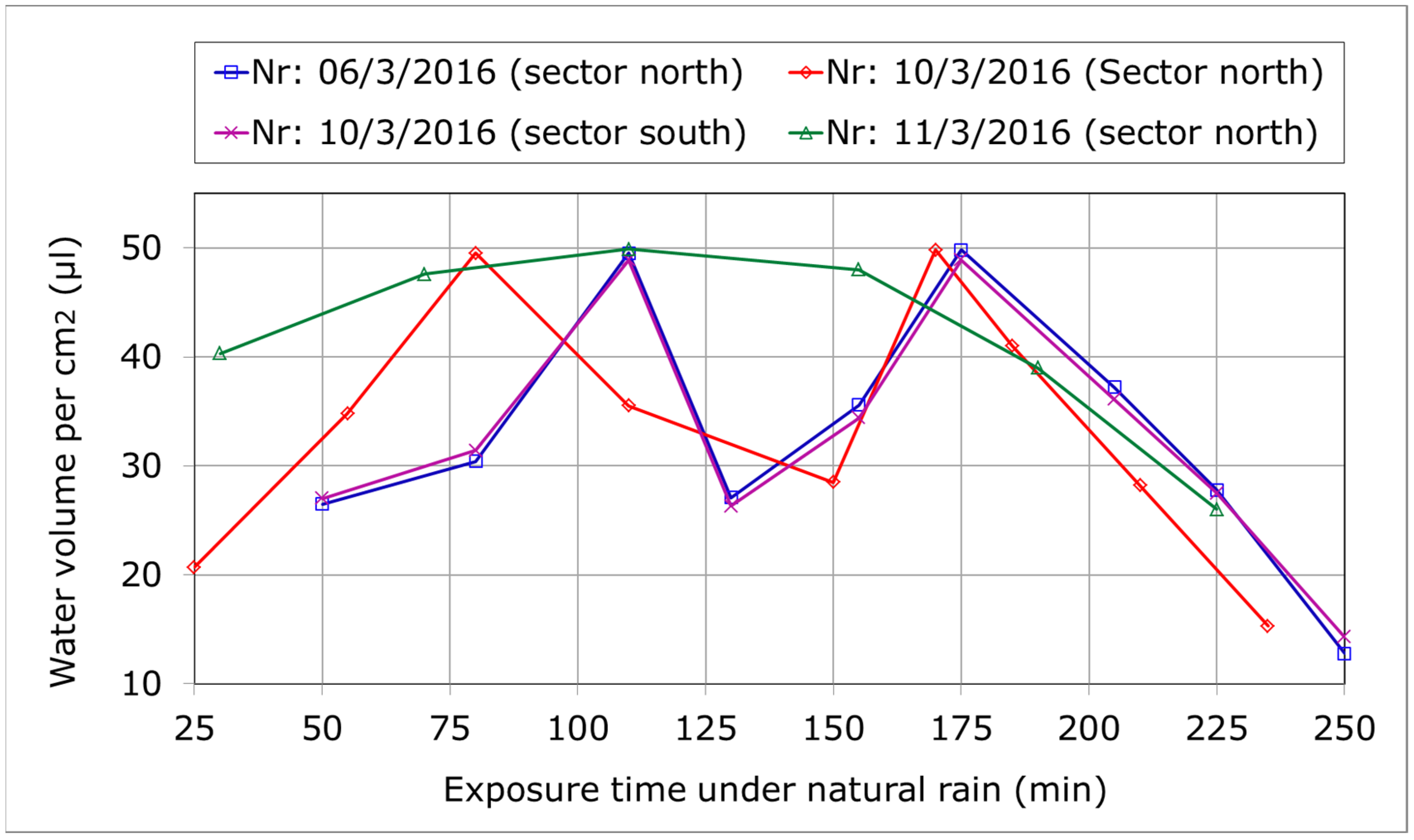

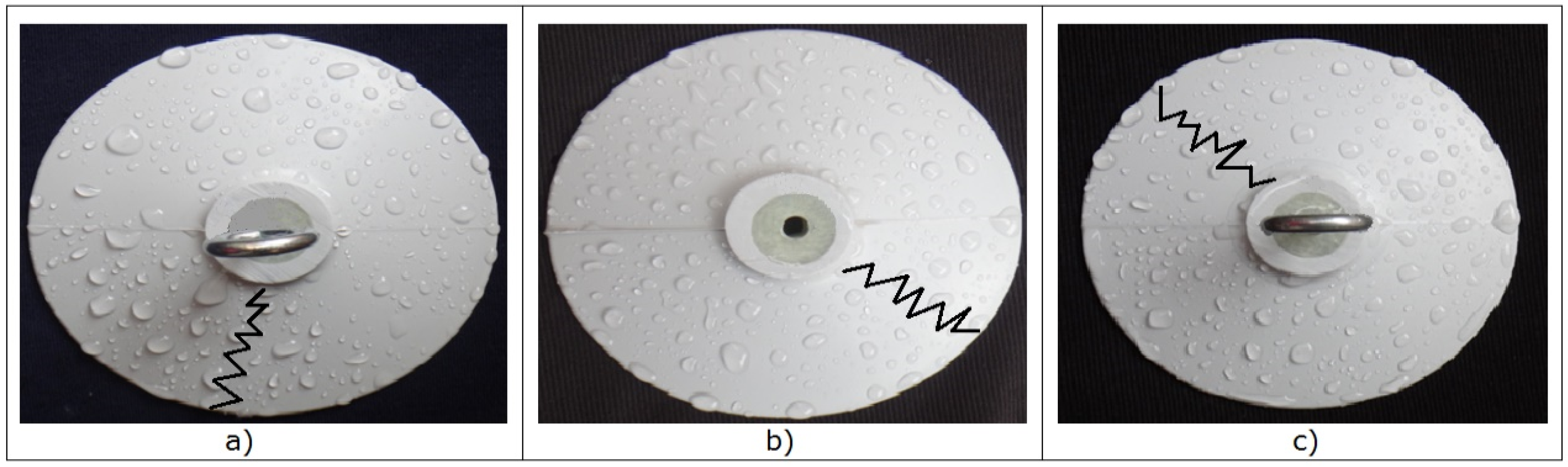

3.1. Constellation and Volume of Condensation and Rain Drops

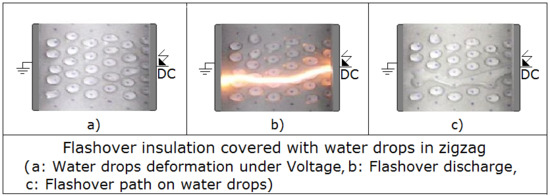

3.2. Effect of the Zigzag Arrangement of Water Drops on the Flashover of Silicone Insulation

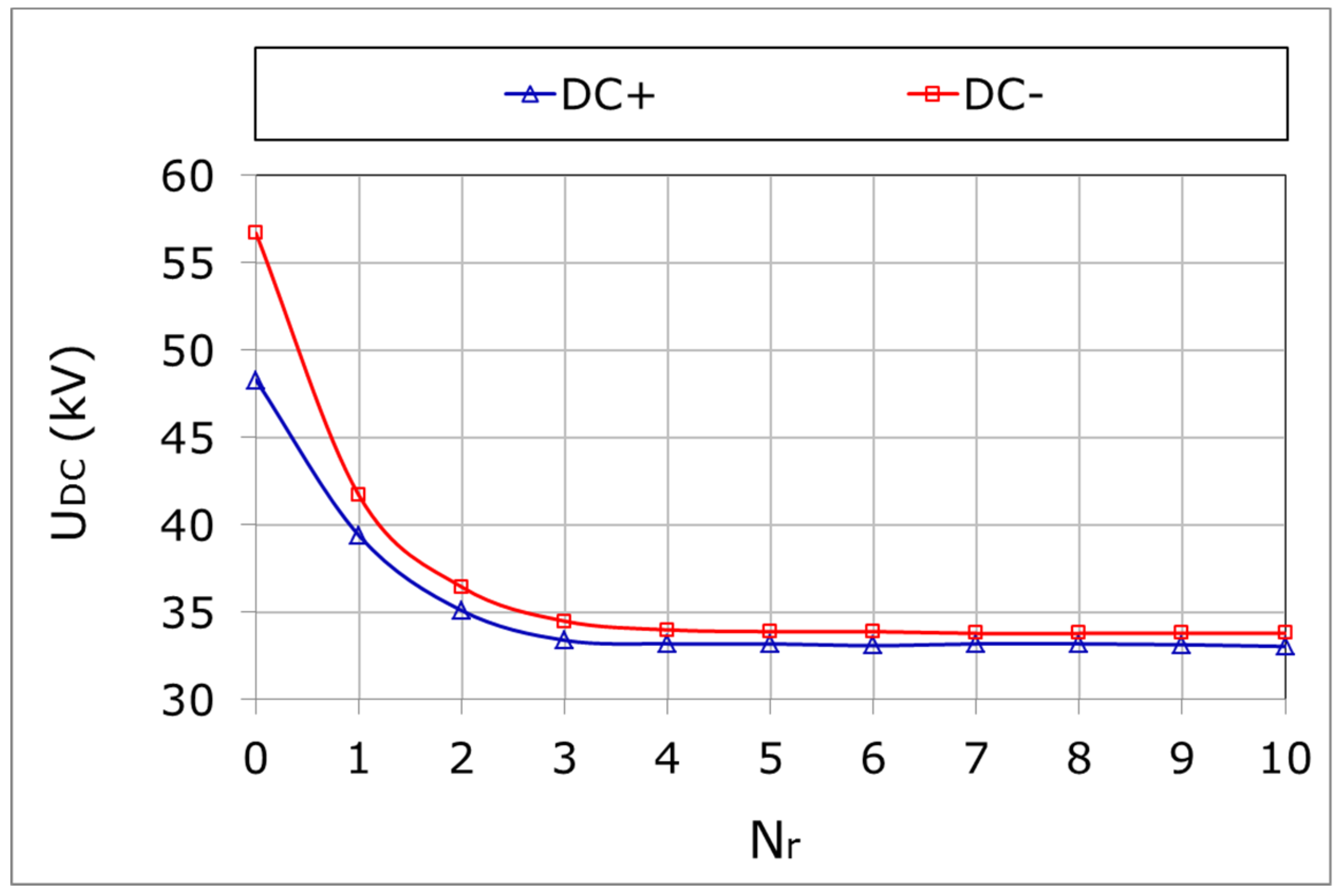

3.2.1. Number of Rows of Water Drops

- (i)

- The first zone showing a rapid decline in the flashover voltage of the material from the value obtained in the absence of water droplets on its surface up to a minimum value. This one is obtained for a number of rows of drops of the order of 4 to 5, regardless of the polarity of the applied voltage.

- (ii)

- The second zone characterizing the constancy of the minimum flashover voltage of the insulation regardless of the number of additional rows added on its surface.

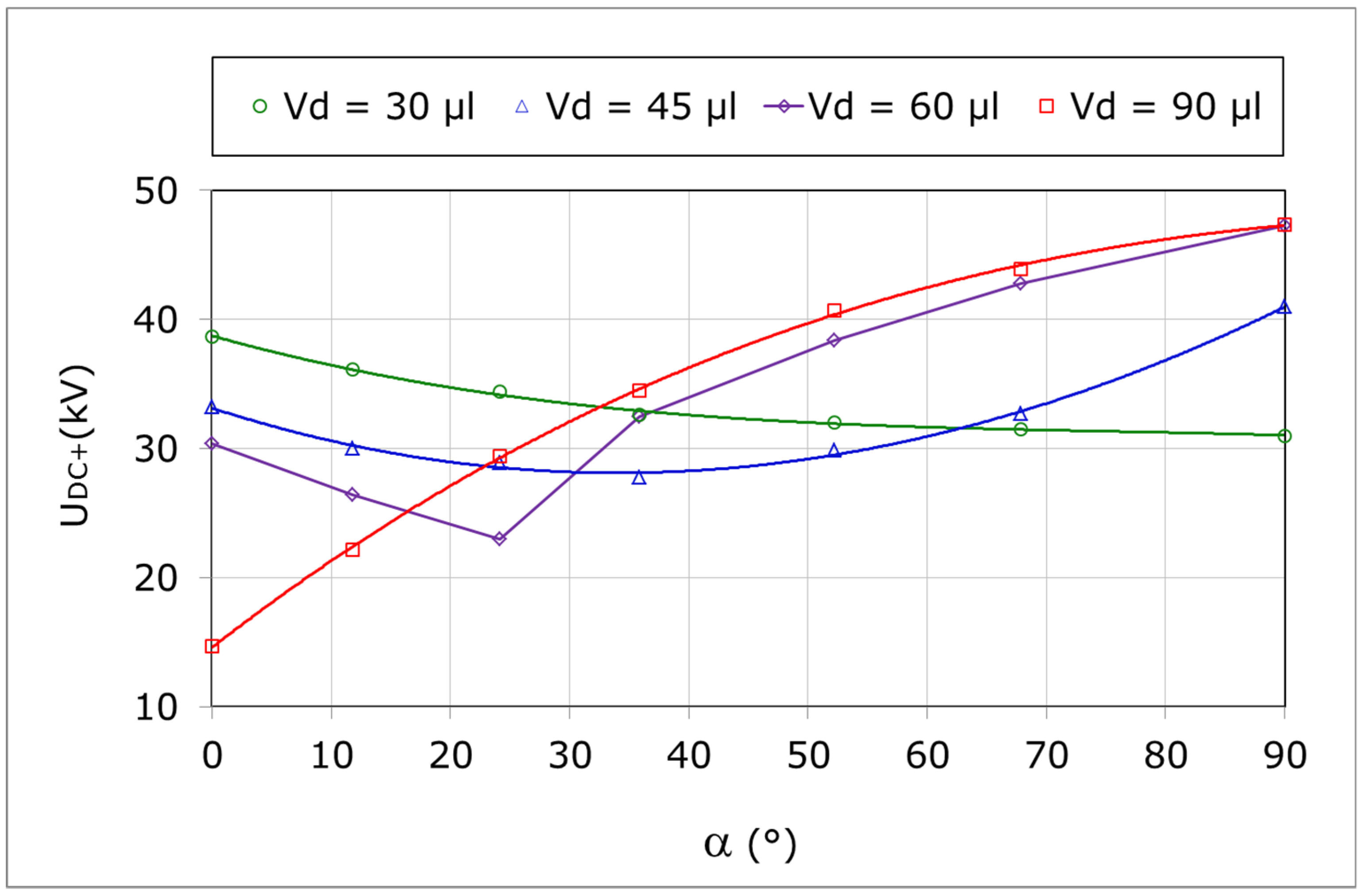

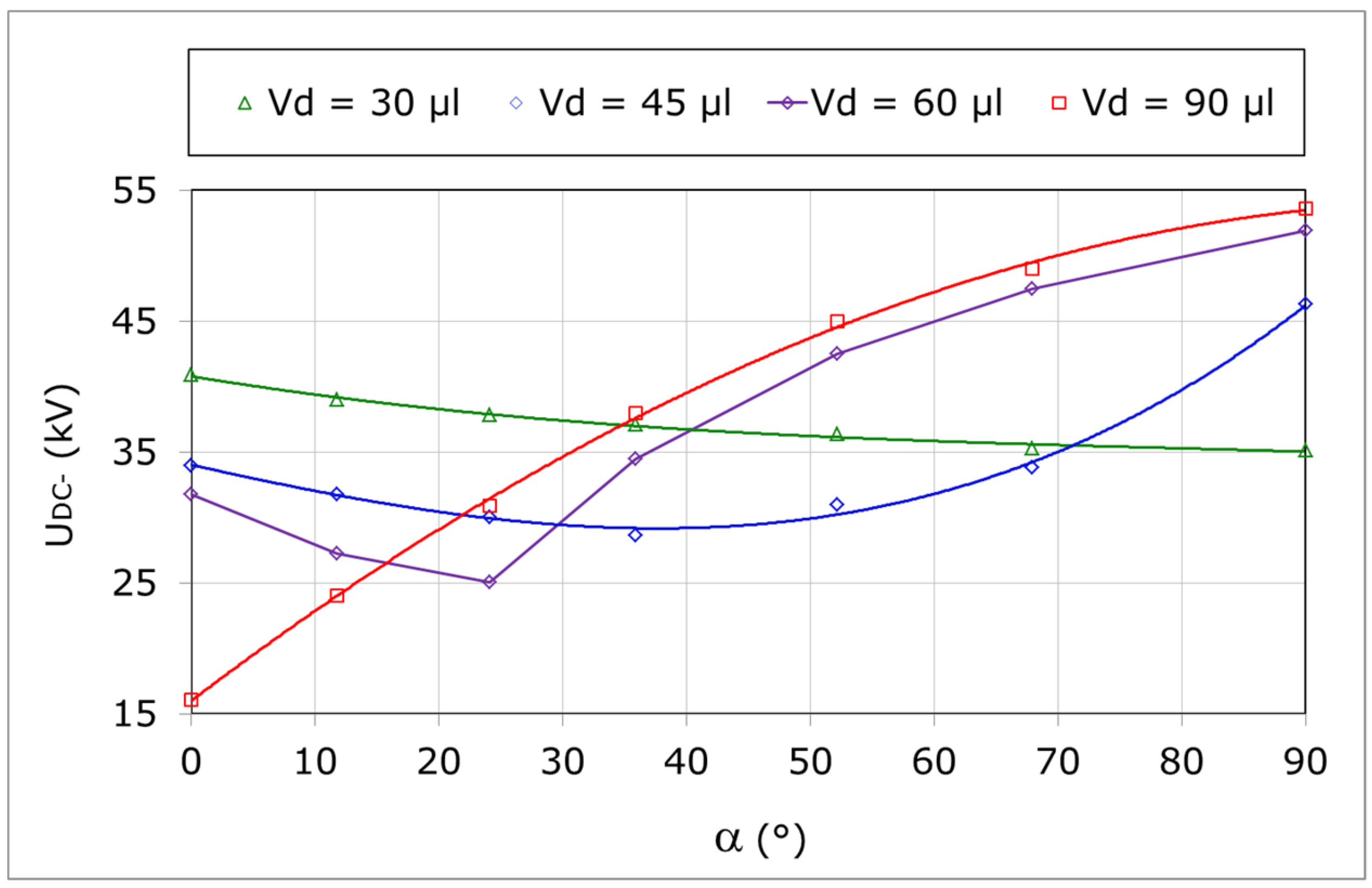

3.2.2. Inclination Angle of Insulation and Volume of Water Droplets

- (1)

- (2)

- When 30 µL < Vd < 90 µL, the curve of the insulation’s flashover voltage as a function of its inclination angle has a minimum regardless of the polarity of the voltage applied to the considered insulation (Figure 12 and Figure 13). The position of this minimum moves toward lower angles of inclination of the insulation with the growth of the size of the water droplets (0° < α < 50°). The value of this minimum decreases as the insulation’s angle of inclination approaches 0°, regardless of the polarity of the applied voltage.

- (3)

- When Vd = 90 μL, the shape of the characteristic UDC = f(α) is strictly increasing for both polarities (Figure 12 and Figure 13). For α = 0°, the value of the ratio ℜu is the lowest. It is of the order of 30% in DC+ (Figure 12) and 28% in DC− (Figure 13). This is due to the greater shortening of the dry leakage path of the insulation by voluminous water droplets. For α = 90°, the very bulky drops leave the surface well before the arrival of the insulation at this position. Under the effect of the resultant electric forces, friction, and gravitation, these give up their place to electrolytic residues. The variation of their volume is closely related to the angle of inclination and, consequently, the number and the frequency of the bump between the initial droplets of water belonging to the extreme row located in the immediate vicinity of the electrode under voltage and the residual droplets of the following rows.

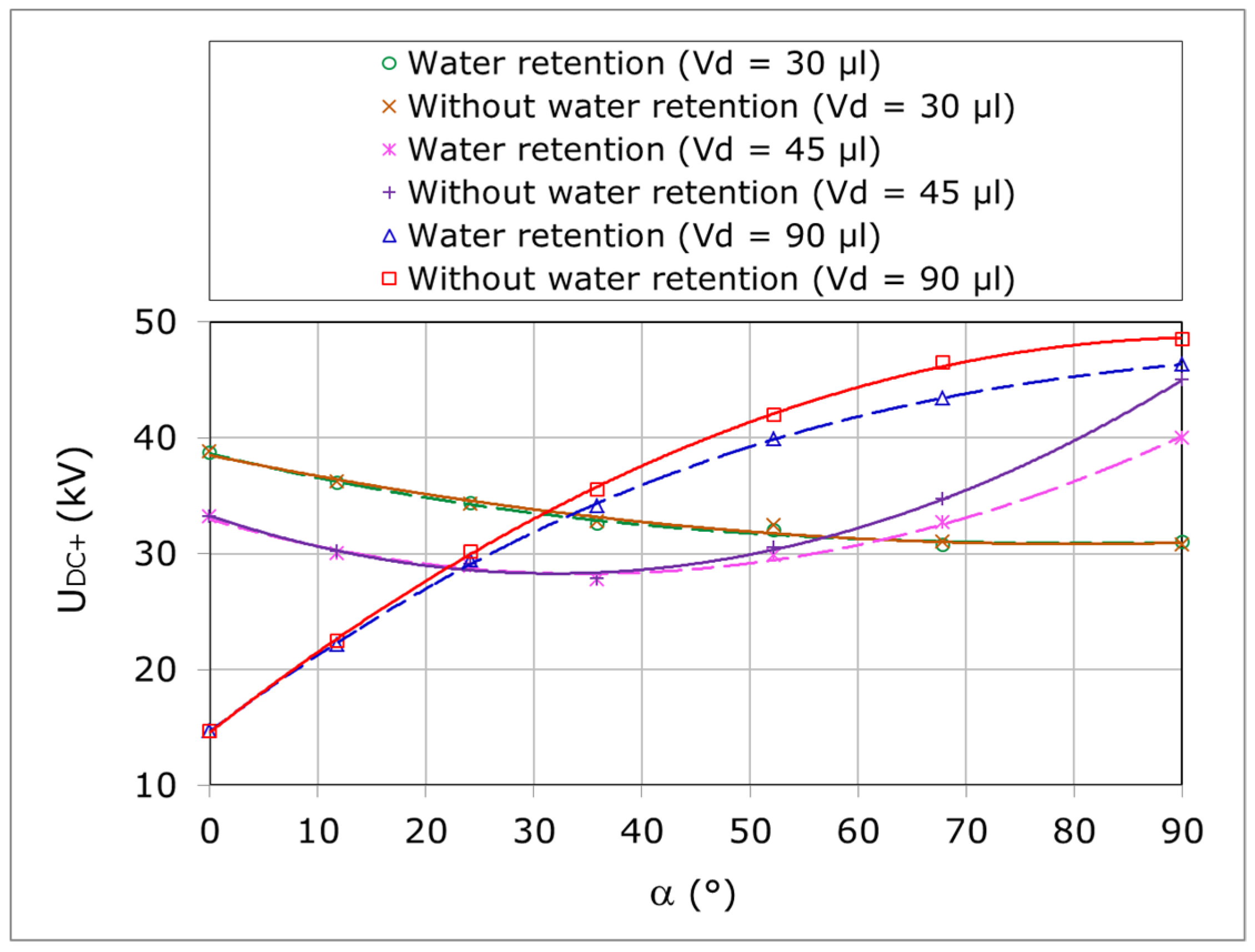

3.2.3. Evacuation of Water through the Holey Ground Electrode

4. Conclusions

- -

- The surface of a shed is covered with a combination of large, medium, and small droplets of water obeying to a constellation much closer to an asymmetric zigzag arrangement than a straight line.

- -

- The maximum volume of natural rainwater, collected per square centimeter of the surface of this insulation, is almost twice that resulting from natural or artificial condensation. Therefore, the leakage path of the natural rain insulation is reduced by almost half only under the effect of condensation, so the risk of flashover is higher, in this case, and the degradation of the material is higher as well.

- -

- The reproduction in the laboratory of a symmetrical zigzag arrangement of several rows of water droplets, manually deposited on silicone insulation with variable inclination and under DC voltage, led to the following essential results.

- -

- Under a zero inclination, five rows of six water drops of 45 μL of volume and 200 μS/cm of electrical conductivity, are sufficient to lower the insulation’s flashover voltage to a maximum of 40% compared to that obtained without these drops. Under these conditions, the volume of water droplets plays a very important role, since its elevation of 45 to 90 μL results in a reduction of the flashover voltage of the insulation of the order of 72% compared to the case without water droplets.

- -

- The interval of the insulation’s most favorable angle of inclination for such an arrangement of water droplets ranging between 60 and 90 µL, is between 50° and 90°. In the case of water retention at the ground electrode, it tolerates a maximum drop of 17% of the flashover voltage of the insulation compared to what was obtained without these droplets. On the other hand, if the water is evacuated through the perforated ground electrode, the maximum loss of the insulation’s flashover voltage is only about 13%. The volume of the residual micro-droplets is much less than 15 μL. The micro-discharges and the flashover become very rare. Therefore, such a profile of the sheds of a silicone insulator is highly recommended for reasons of its very low retention of water droplets and, therefore, a very slow electrical aging of this one.

- -

- On the other hand, under the same arrangement of water droplets varying between 45 and 60 μL, the interval of inclination’s angle of the insulation 0° < α < 50° is unfavorable, since it causes a reduction in the insulation’s flashover voltage of more than 48% compared to the case without water droplets. In addition, because of the strong adhesion of voluminous droplets on the surface of the insulation under voltage, the frequency of occurrence of electric discharges is very high and, therefore, the electrical aging of this one is greatly accelerated.

- -

- Lastly, a zero inclination’s angle of the insulation with such an arrangement is favorable only when it is under the effect of the phenomenon of condensation when the volume of water droplets remains well below 30 µL.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jia, Z.; Chen, C.; Wang, X.; Lu, H.; Yang, C.; Li, T. Leakage Current Analysis on RTV Coated Porcelain Insulators during Long Term Fog Experiments. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1547–1553. [Google Scholar]

- Dong, B.B.; Jiang, X.L.; Zhang, Z.J.; Hu, J.L.; Hu, Q.; Shu, L.C. Effect of Environment Factors on AC Flashover Performance of 3 Units of Polluted Insulator Strings Under Natural Fog Condition. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1926–1932. [Google Scholar] [CrossRef]

- Li, Y.; Jin, H.; Nie, S.; Tong, C.; Gao, N. Effect of superhydrophobicity on flashover characteristics of silicone rubber under wet conditions. AIP Adv. 2018, 8, 015313. [Google Scholar] [CrossRef]

- Nekahi, A.; McMeekin, S.G.; Farzaneh, M. Flashover Characteristics of Silicone Rubber Sheets under Various Environmental Conditions. Energies 2016, 9, 683. [Google Scholar] [CrossRef]

- Bouchelga, F.; Boudissa, R. Effect of the Development of Electrical Parallel Discharges on Performance of Polluted Insulators under DC Voltage. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2224–2233. [Google Scholar] [CrossRef]

- Li, L.; Gu, Y.; Hao, Y. Shed Parameters Optimization of Composite Post Insulators for UHVDC Flashover Voltages at High Altitudes. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 169–176. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, D.; You, J.; Zhao, J.; Jiang, X. Study on the DC Flashover Performance of Various Types of Insulators With Fan-shaped Non-uniform Pollution. IEEE Trans. Power Deliv. 2015, 30, 1871–1879. [Google Scholar] [CrossRef]

- Abbasi, A.; Shayegani, A.; Niayesh, K. Contribution of Design Parameters of SiR Insulators to Their DC Pollution Flashover Performance. IEEE Trans. Power Deliv. 2014, 29, 1814–1821. [Google Scholar] [CrossRef]

- Boudissa, R.; Bayadi, A.; Baersch, R. Effect of Pollution Distribution Class on Insulators Flashover under AC Voltage. Electr. Power Syst. Res. 2013, 104, 176–182. [Google Scholar] [CrossRef]

- Yang, L.; Hao, Y.; Li, L.; Zhao, Y. Comparison of Pollution Flashover Performance of Porcelain Long Rod, Disc Type and composite UHVDC Insulators at High Altitudes. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1053–1059. [Google Scholar] [CrossRef]

- Wieczoreck, K.; Fleszynski, J.; Bretuj, W. Effect of Shape of Insulator Housings and Positions of Composite Insulators on Ageing Resistance Under High Voltage and Precipitation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1044–1052. [Google Scholar] [CrossRef]

- Bo, L.; Gorur, R.S. Modeling Flashover of AC Outdoor Insulators under Contaminated Conditions with Dry Band Formation and Arcing. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1037–1043. [Google Scholar] [CrossRef]

- Aydogmus, Z.; Cebeci, M. A New Flashover Dynamic Model of Polluted HV Insulators. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 577–584. [Google Scholar] [CrossRef]

- Baer, C.; Baersch, R.; Hergert, A.; Kindersberger, J. Evaluation of the Retention and Recovery of the hydrophobicity of Insulating Materials in High Voltage Outdoor Applications under AC and DC Stresses With the Dynamic Drop Test. IEEE Trans. Dielectr. Electr. Insul. 2015, 23, 294–303. [Google Scholar] [CrossRef]

- Ghunem, R.; Ghunem, A. Using the Inclined-Plane Test to Evaluate the Resistance of Outdoor Polymer Insulating Materials to Electrical Tracking and Erosion. IEEE Electr. Insul. Mater. 2015, 31, 16–22. [Google Scholar] [CrossRef]

- Cherney, E.A.; Gorur, R.S.; Krivda, A.; Jayaram, S.H.; Rowland, S.M.; Li, S.; Marzinotto, M.; Ghunem, R.A.; Ramirez, I. DC inclined-plane tracking and erosion test of insulating materials. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 211–217. [Google Scholar] [CrossRef]

- Chandrasekar, S.; Sarathi, R.; Danikas, M.G. Analysis of surface degradation of silicone rubber insulation due to tracking under different voltage profiles. Electr. Eng. 2007, 89, 489–501. [Google Scholar] [CrossRef]

- Liu, Y.; Du, B.X.; Farzaneh, M. Characteristics of Induced Discharge on a Polymer Insulator Surface under Electro-wetting Conditions. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2958–2967. [Google Scholar] [CrossRef]

- Boudissa, R.; Belhoul, T.; Haim, K.D.; Kornhuber, S. Effect of Inclination Angle of Hydrophobic Silicone Insulation Covered by Water Drops on its DC Performance. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2890–2900. [Google Scholar] [CrossRef]

- De La O, A.; Gorur, R.S. Flashover of Contaminated Nonceramic Outdoor Insulators in a Wet Atmosphere. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 814–823. [Google Scholar] [CrossRef]

- Braunsberger, T.; Kurrat, M. Cyclic Water Drop Corona on silicone Rubber Samples. In Proceedings of the 15th International Symposium on High Voltage Engineering, University of Ljublijana, Elktroinstitut Milan Widmar, Ljublijana, Slovenia, 27–31 August 2007; pp. 33–34. [Google Scholar]

- Slimani, S.; Bouatia, N.; Belhoul, T.; Boudissa, R.; Kornhuber, S.; Haim, K.D. Effet de l’angle d’inclinaison sur le nombre et le volume des gouttes d´eau résiduelles recouvrant la surface d´une isolation en silicone mise hors ou sous tension alternative. In Proceedings of the 11th Conference of French Society of Electrostatics, Grenoble, France, 29–31 August 2018. [Google Scholar]

| Parameter | εr | Tanδ | ρv (Ωm) | Rs (Ω) |

|---|---|---|---|---|

| Value | 3.2 | 0.11 | 6.8 × 1011 | 4 × 1010 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boudissa, R.; Bouchelga, F.; Kornhuber, S.; Haim, K.D. Constellation of Condensation and Raindrops and Its Effect on the DC Flashover Voltage of Inclined Silicone Insulation. Energies 2019, 12, 3549. https://doi.org/10.3390/en12183549

Boudissa R, Bouchelga F, Kornhuber S, Haim KD. Constellation of Condensation and Raindrops and Its Effect on the DC Flashover Voltage of Inclined Silicone Insulation. Energies. 2019; 12(18):3549. https://doi.org/10.3390/en12183549

Chicago/Turabian StyleBoudissa, Rabah, Fatma Bouchelga, Stefan Kornhuber, and Klaus Dieter Haim. 2019. "Constellation of Condensation and Raindrops and Its Effect on the DC Flashover Voltage of Inclined Silicone Insulation" Energies 12, no. 18: 3549. https://doi.org/10.3390/en12183549