Energy and Nutrients’ Recovery in Anaerobic Digestion of Agricultural Biomass: An Italian Perspective for Future Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Analysis

2.2. Analytical Methods

2.3. Biomethane Potential of Substrates

2.4. Definition of the Hydrolysis Rate

3. Results and Discussion

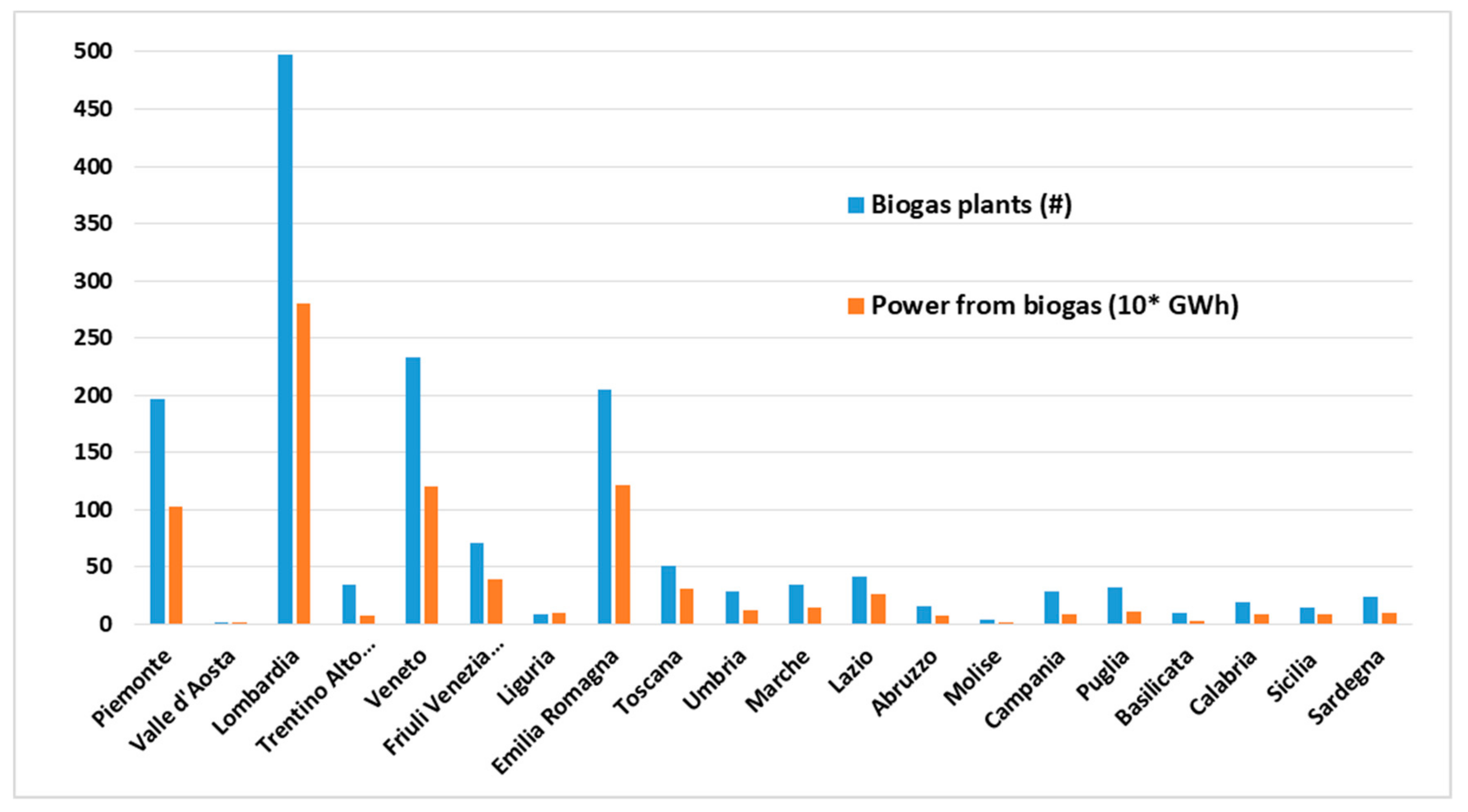

3.1. The Actual Italian Scenario for Biogas Production

3.2. Typical Feedstocks for the Actual Italian Scenario

3.3. Actual Use of Digestate

4. Future Perspective for the Biogas Sector in Italy

4.1. Future Feedstocks

4.2. Recovery of Nutrients from Digestate

4.3. Biogas, Power to Gas and Added-Value Biobased Compounds

5. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Poeschl, M.; Ward, S.; Owende, P. Evaluation of energy efficiency of various biogas production and utilization pathways. Appl. Energy 2010, 87, 3305–3321. [Google Scholar] [CrossRef]

- Wall, D.M.; O’Kiely, P.; Murphy, J.D. The potential for biomethane from grass and slurry to satisfy renewable energy targets. Bioresour. Tech. 2014, 149, 425–431. [Google Scholar] [CrossRef] [PubMed]

- Arthurson, V. Closing the global energy and nutrient cycles through application of biogas residue to agricultural land–Potential benefits and drawbacks. Energies 2009, 2, 226–242. [Google Scholar] [CrossRef]

- Czyrnek-Deletre, M.M.; Smyth, B.M.; Murphy, J.D. Beyond carbon and energy: The challenge in setting guidelines for life cycle assessment of biofuel systems. Renew. Energy 2017, 105, 436–448. [Google Scholar] [CrossRef] [Green Version]

- Del Pablo-Romero, M.; Sánchez-Braza, A.; Salvador-Ponce, J.; Sánchez-Labrador, N. An overview of feed-in tariffs, premiums and tenders to promote electricity from biogas in the EU-28. Renew. Sustain. Energy Rev. 2017, 73, 1366–1379. [Google Scholar] [CrossRef]

- Scheftelowitz, M.; Becker, R.; Thran, D. Improved power provision from biomass: A retrospective on the impacts of German energy policy. Biomass Bioenergy 2018, 111, 1–12. [Google Scholar] [CrossRef]

- European Biogas Association. Annual Report. 2015. Available online: http://european-biogas.eu/2015/12/16/biogasreport2015/ (accessed on 28 May 2019).

- Gruda, N.; Bisbis, M.; Tanny, J. Impacts of protected vegetable cultivation on climate change and adaptation strategies for cleaner production—A review. J. Clean. Prod. 2019, 225, 324–339. [Google Scholar] [CrossRef]

- Hamelin, L.; Naroznova, I.; Wenzel, H. Environmental consequences of different carbon alternatives for increased manure-based biogas. Appl. Energy 2014, 114, 774–782. [Google Scholar] [CrossRef]

- Theuerl, S.; Herrmann, C.; Heiermann, M.; Grundmann, P.; Landwehr, N.; Kreidenweis, U.; Prochnow, A. The Future Agricultural Biogas Plant in Germany: A Vision. Energies 2019, 12, 306. [Google Scholar] [CrossRef]

- Cobuloglu, H.I.; Büyüktahtakin, I.E. Food vs. biofuel: An optimization approach to the spatio-temporal analysis of land-use competition and environmental impacts. Appl. Energy 2015, 140, 418–434. [Google Scholar] [CrossRef]

- Garcia, N.H.; Mattioli, A.; Gil, A.; Frison, N.; Battista, F.; Bolzonella, D. Evaluation of the methane potential of different agricultural and food processing substrates for improved biogas production in rural areas. Renew. Sustain. Energy Rev. 2019, 112, 1–10. [Google Scholar] [CrossRef]

- Battista, F.; Bolzonella, D. Exploitation of Solar Energy for Ammonium Sulfate Recovery from Anaerobic Digestate of Different Origin. Waste Biomass Valoris. 2019. [Google Scholar] [CrossRef]

- Lal, R. Digging deeper: A wholistic perspective of factors affecting Soil Organic Carbon sequestration. Glob. Change Biol. 2018, 24, 3285–3301. [Google Scholar] [CrossRef] [PubMed]

- Mehta, C.M.; Khunjar, W.O.; Nguyen, V.; Tait, S.; Batstone, D.J. Technologies to recover nutrients from waste streams: A critical review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 385–427. [Google Scholar] [CrossRef]

- Moller, K.; Müller, T. Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Vaneeckhaute, C.; Darveau, O.; Meers, E. Fate of micronutrients and heavy metals in digestate processing using vibrating reversed osmosis as resource recovery technology. Sep. Purif. Technol. 2019, 223, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Bernet, N.; Beline, F. Challenges and innovations on biological treatment of livestock effluents. Bioresour. Technol. 2009, 100, 5431–5436. [Google Scholar] [CrossRef] [PubMed]

- Fuchs, W.; Drosg, B. Assessment of the state of the art of technologies for the processing of digestate residue from anaerobic digesters. Water Sci. Technol. 2013, 67, 1984–1993. [Google Scholar] [CrossRef] [Green Version]

- Drosg, B.; Fuchs, W.; Al Seadi, T.; Madsen, M.; Linke, B. Nutrient Recovery by Biogas Digestate Processing; IEA Bioenergy: Paris, France, 2015; ISBN 978-1-910154-15-1. [Google Scholar]

- Bolzonella, D.; Fatone, F.; Gottardo, M.; Frison, N. Nutrients recovery from anaerobic digestate of agro-waste: Techno-economic assessment of full scale applications. J. Environ. Manag. 2018, 216, 111–119. [Google Scholar] [CrossRef]

- Gontard, N.; Sonesson, U.; Birkved, M.; Majone, M.; Bolzonella, D.; Celli, A.; Angellier-Coussy, H.; Jang, G.W.; Verniquet, A.; Broeze, J.; et al. A research challenge vision regarding management of agricultural waste in a circular bio-based economy. Crit. Rev. Environ. Sci. Technol. 2018, 48, 614–654. [Google Scholar] [CrossRef] [Green Version]

- Consorzio Italiano Biogas. 2019. Available online: https://www.consorziobiogas.it/ (accessed on May 2019).

- Gestore Servizi Energetici. Rapporto Statistico: Energia da Fonti Rinnovabili in Italia. Anno 2016. 2018. Available online: https://www.gse.it/documenti_site/Documenti%20GSE/Rapporti%20statistici/Rapporto%20statistico%20GSE%20-%202016.pdf (accessed on 28 May 2019).

- ISAAC. Increasing Social Awareness and Acceptance of Biogas and Biomethane. Available online: http://www.isaac-project.it/ (accessed on 28 May 2019).

- Agristat, Istituto Nazionale di Statistica per l’Agricoltura e la Zootecnia. Available online: http://agri.istat.it/ (accessed on 28 May 2019).

- American Public Health Association, American Water Works Association and Water Pollution Control Federation. APHA, AWWA & WPCF Standard Methods for the Examination of Water and Wastewater, 17th ed.; American Public Health Association, American Water Works Association and Water Pollution Control Federation: Washington, DC, USA, 1989.

- Angelidaki, I.; Alves, M.; Bolzonella, D.; Borzacconi, L.; Campos, J.L.; Guwy, A.J.; Kalyuzhnyi, S.; Jenicek, P.; van Lier, J.B. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: A proposed protocol for batch assays. Water Sci. Technol. 2009, 59, 927–934. [Google Scholar] [CrossRef] [PubMed]

- Holliger, C.; Alves, M.; Andrade, D.; Angelidaki, I.; Astals, S.; Baier, U.; Bougrier, C.; Buffière, P.; Carballa, M.; De Wilde, V.; et al. Towards a standardization of biomethane potential tests. Water Sci. Technol. 2016, 74, 2515–2522. [Google Scholar] [CrossRef] [PubMed]

- Benato, A.; Macor, A. Italian Biogas Plants: Trend, Subsidies, Cost, Biogas Composition and Engine Emissions. Energies 2019, 12, 979. [Google Scholar] [CrossRef]

- Ragazzoni, A. Analisi della Redditività Degli Impianti per la Produzione di Biogas alla Luce delle Nuove Tariffe Incentivanti 2013. Available online: http://www.crpa.it/media/documents/crpa_www/Convegni/20130314_BiogasBiometano_RA/Ragazzoni_RA_14-3-2013.pdf (accessed on 28 May 2019).

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 2010. 85, 849–860. [Google Scholar] [CrossRef]

- Beggio, G.; Schievano, A.; Bonato, T.; Hennebert, P.; Pivato, A. Statistical analysis for the quality assessment of digestates from separately collected organic fraction of municipal solid waste (OFMSW) and agro-industrial feedstock. Should input feedstock to anaerobic digestion determine the legal status of digestate? Waste Manag. 2019, 87, 546–558. [Google Scholar] [CrossRef] [PubMed]

- Council of the European Union. Proposal for a Regulation of the European Parliament and of the Council Laying Down Rules on the Making Available on the Market of CE Marked Fertilising Products and Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009. 2018. Available online: http://data.consilium.europa.eu/doc/document/ST-15103-2018-INIT/en/pdf (accessed on 28 May 2019).

- Tambone, F.; Scaglia, B.; D’Imporzano, G.; Schievano, A.; Orzi, V.; Salati, S.; Adani, F. Assessing amendment and fertilizing properties of digestates from anaerobic digestion through a comparative study with digested sludge and compost. Chemosphere 2010, 81, 577–583. [Google Scholar] [CrossRef]

- Grigatti, M.; Boanini, E.; Bolzonella, D.; Sciubba, L.; Mancarella, S.; Ciavatta, C.; Marzadori, C. Organic wastes as alternative sources of phosphorus for plant nutrition in a calcareous soil. Waste Manag. 2019, 93, 34–46. [Google Scholar] [CrossRef] [PubMed]

- Gazzetta Ufficiale della Repubblica Italiana. Decreto 2 marzo 2018. Promozione Dell’uso del Biometano e Degli Altri Biocarburanti Avanzati Nel Settore dei Trasporti. 2018. Available online: https://www.gazzettaufficiale.it/eli/id/2018/03/19/18A01821/SG (accessed on 28 May 2019).

- SNAM. Available online: http://www.snam.it/en/Natural-gas/green-energy/biomethane (accessed on 28 May 2019).

- Schievano, A.; D’Imporzano, G.; Adani, F. Substituting energy crops with organic wastes and agro-industrial residues for biogas production. J. Environ. Manag. 2009, 90, 2537–2541. [Google Scholar] [CrossRef] [PubMed]

- Giuliano, A.; Bolzonella, D.; Pavan, P.; Cavinato, C.; Cecchi, F. Co-digestion of livestock effluents, energy crops and agro-waste: Feeding and process optimization in mesophilic and thermophilic conditions. Bioresour. Technol. 2013, 128, 612–618. [Google Scholar] [CrossRef]

- De Menna, F.; Malagnino, R.A.; Vittuari, M.; Molari, G.; Seddaiu, G.; Deligios, P.A.; Solinas, S.; Ledda, L. Potential Biogas Production from Artichoke Byproducts in Sardinia, Italy. Energies 2016, 9, 92. [Google Scholar] [CrossRef]

- Battista, F.; Ruggeri, B.; Fino, D.; Erriquens, F.; Rutigliano, L.; Mescia, D. Toward the scale-up of agro-food feed mixture for biogas production. J. Environ. Chem. Eng. 2013, 1, 1223–1230. [Google Scholar] [CrossRef]

- Valenti, F.; Porto, S.M.C.; Selvaggi, R.; Pecorino, B. Evaluation of biomethane potential from by-products and agricultural residues co-digestion in southern Italy. J. Environ. Manag. 2018, 223, 834–840. [Google Scholar] [CrossRef] [PubMed]

- Selvaggi, R.; Pappalardo, G.; Chinnici, G.; Fabbri, C.I. Assessing land efficiency of biomethane industry: A case study of Sicily. Energy Policy 2018, 119, 689–695. [Google Scholar] [CrossRef]

- Vaneeckhaute, C.; Lebuf, V.; Michels, E.; Belia, E.; Vanrolleghem, P.A.; Tack, F.M.G.; Meers, E. Nutrient recovery from digestate: Systematic technology review and product classification. Waste Biomass Valor. 2017, 8, 21–40. [Google Scholar] [CrossRef]

- Kertesz, S.; Beszedes, S.; Laszlo, Z.; Szabo, G.; Hodur, C. Nanofiltration and reverse osmosis of pig manure: Comparison of results from vibratory and classical modules. Desalin. Water Treat. 2010, 14, 233–238. [Google Scholar] [CrossRef] [Green Version]

- Battista, F.; Frison, N.; Pavan, P.; Cavinato, C.; Gottardo, M.; Fatone, F.; Eusebi, A.L.; Majone, M.; Zeppilli, M.; Valentino, F.; et al. Food wastes and sewage sludge as feedstock for an urban biorefinery producing biofuels and added-value bioproducts. J. Chem. Technol. Biotechnol. 2019, in press. [Google Scholar] [CrossRef]

- Agler, M.T.; Wrenn, B.A.; Zinder, S.H.; Angenent, L.T. Waste to bioproduct conversion with undefined mixed cultures: The carboxylate platform. Trends Biotechnol. 2011, 29, 70–78. [Google Scholar] [CrossRef] [PubMed]

- Hahn, H.; Krautkremer, B.; Hartmann, K.; Wachendorf, M. Review of concepts for a demand-driven biogas supply for flexible power generation. Rrenew. Sustain. Energy Rev. 2014, 29, 383–393. [Google Scholar] [CrossRef]

| NORTH ITALY | CENTRAL ITALY | SOUTH ITALY | |||||

|---|---|---|---|---|---|---|---|

| Crops, Fruits (Tons) | Veneto | Lombardia | Toscana | Lazio | Puglia | Campania | Italy |

| Wheat (common + durum) | 709,795 | 410,952 | 318,658 | 194,560 | 1,026,600 | 246,863 | 7,054,799 |

| Chickpea | 843 | 3828 | 7580 | 1190 | 3032 | 534 | 47,438 |

| Beans and string beans | 6018 | 6830 | 1698 | 3220 | 7670 | 46,893 | 151,452 |

| Onions | 30,592 | 10,227 | 5757 | 2190 | 39,650 | 34,155 | 382,634 |

| Carrots | 30,021 | Low | 1143 | 88,180 | 33,370 | 4620 | 480,824 |

| Fennel | 557 | 88 | 2430 | 17,260 | 146,400 | 63,819 | 537,444 |

| Lettuce | 9390 | 18,493 | 1547 | 16,750 | 100,480 | 33,139 | 349,017 |

| Fresh fruits (apples, pears, apricots, cherries) | 405,819 | 66,154 | 35,744 | 13,528 | 72,274 | 172,199 | 3,516,837 |

| Olive oil | 24,371 | 4987 | 120,364 | 88,434 | 565,100 | 112,926 | 1,867,662 |

| Wine (DOP *, IGP **, table wine) | 1,015,801 | 148,833 | 270,830 | 131,961 | 955,257 | 132,749 | 5,043,610 |

| Citrus fruits (oranges, tangerines, lemons) | Low | Low | 122 | 3411 | 115,023 | 49,700 | 2,080,377 |

| Substrates (Tons) | NORTH ITALY | CENTRAL ITALY | SOUTH ITALY | ||||

|---|---|---|---|---|---|---|---|

| Farm Animals’ Categories (#) | Veneto | Lombardia | Toscana | Lazio | Puglia | Campania | ITALY |

| Ovines | 11,178 | 81,356 | 199,300 | 511,088 | 170,950 | 151,369 | 2,984,336 |

| Bovines | 546,171 | 542,209 | 36,484 | 26,203 | 60,867 | 195,862 | 2,651,010 |

| Swines | 437,428 | 4,265,523 | 272,445 | 93,999 | 70,698 | 195,383 | 11,380,546 |

| Poultries and Rabbits | 108,841,000 | 66,043,108 | 6,145,918 | 414,186 | 18,770,251 | 114,747 | 606,062,235 |

| Equines | 12,382 | 3497 | 225 | 2589 | 31,144 | 679 | 67,005 |

| Total Solids (%) | Total Volatile Solids (%) | TVS/TS (%) | COD (g·kg−1) | TKN (g·kg−1) | TP (g·kg−1) | |

|---|---|---|---|---|---|---|

| Energy Crops | ||||||

| Millet—Panicum Miliaceum L. | 21.8 | 20.1 | 92.0 | - | - | - |

| Barley—Hordeum distichon L. | 25.8–66.3 | 25.1–59.1 | 89.3–97.2 | 517 | 7.0–19.9 | 0.8–3.9 |

| Maize—Zea mays L. | 40–66.50 | 38.3–64.0 | 90.7–96.5 | 293–304 | 4.0–4.8 | 0.3–0.6 |

| Sorghum—Sorghum spp. | 28.6–39.6 | 25.5–35.4 | 89.3–94.0 | 302–353 | 3.2–13.0 | 0.5 |

| Triticale—Triticum aestivum L. | 30–30.8 | 27.9 | 90.4–93.1 | 296 | 13.5 | 0.7 |

| Vegetables and fruits by products | ||||||

| Carrot Leaves—Daucus carota L. | 14.8 | 12.3 | 83.6 | 258 | 3.1 | - |

| Radicchio Leaves—Red Cichorium L. | 10.4 | 9.3 | 89.0 | 38.1 | 0.9 | 0.3 |

| Potato Peels—Solanum tuberosum L. | 11.8 | 10.7 | 90.6 | 186 | 4.8 | 0.5 |

| Apple Pomace—Malus domestica L. | 50.2 | 47.9 | 95.6 | 580 | 4.2 | - |

| Tomato Pomace—Solanum lycopersicum L. | 30.1 | 29.0 | 96.1 | 380 | 7.7 | - |

| Grape Marcs—Vitis vinifera. L. | 29.6–36.7 | 27.8–34.3 | 93.1–93.7 | 312–347 | 5.7–9.2 | 2.8–3.3 |

| Grape Vinasse—Vitis vinifera. L. | 35.6–64.2 | 28.5–53.1 | 80.0–82.7 | 178–324 | 17.6–37.4 | - |

| Lemon Pomace—Citrus lemon L. | 12.6–85.5 | 12.0–64.3 | 75.1–95.3 | 127–692 | 1.7–6.1 | 0.3–0.4 |

| Livestock effluents | ||||||

| Bovine Slurry | 4.9–14.5 | 3.6–12.2 | 72.5–100 | 48.0–128 | 2.1–6.2 | 0.3–1.2 |

| Bovine Manure | 15.6–47.7 | 13.5–32.1 | 48.7–99.8 | 135–291 | 3.2–7.1 | 0.2–1.5 |

| Pig Manure | 36.1 | 35.9 | 99.3 | 381 | - | - |

| Pig Slurry | 0.7–6.4 | 0.5–5.3 | 75.0–82.7 | 5.2–46.6 | 0.2–5.0 | 0.1–1.5 |

| Poultry Manure | 31.5–78.3 | 21.3–51.7 | 44.7–84.1 | 235–586 | 2.3–38.9 | 5.2–15.3 |

| Kh (d−1) | T-50 (d) | CH4 Yield (LCH4·kg TVS−1) | |

|---|---|---|---|

| Energy Crops | |||

| Millet—Panicum miliaceum L. | 0.080 | 13.1 | 253 |

| Barley—Hordeum distichon L. | 0.097 | 8.1 | 290 ± 83 |

| Maize—Zea mays L. | 0.135 ± 0.06 | 6.2 | 289 ± 86 |

| Sorghum—Sorghum spp. | 0.091 ± 0.06 | 10.6 | 313 ± 73 |

| Triticale—Triticum aestivum L. | 0.154 ± 0.07 | 10.3 | 351 ± 5 |

| Vegetables and Fruits by-Products | |||

| Carrot Leaves—Daucus carota L. | 0.096 | 7.0 | 312 |

| Radicchio Leaves—Red Cichorium L. | 0.185 | 3.0 | 431 |

| Potato Peels—Solanum tuberosum. L. | 0.063 | 3.9 | 446 |

| Onion Peels—Allium cepa L. | 0.213 | 3.0 | 455 |

| Apple Pomace—Malus domestica L. | 0.148 | 0.0 | 204 |

| Tomato Pomace—Solanum lycopersicum L. | 0.068 | 10.9 | 239 |

| Grape Marcs—Vitis vinifera. L. | 0.103 ± 0.04 | 11.4 | 248 ± 48 |

| Grape Vinasse—Vitis vinifera. L. | 0.162 | 5.3 | 274 ± 123 |

| Lemon Pomace—Citrus lemon L. | 0.226 ± 0.06 | 4.3 | 355 ± 10 |

| Livestock Effluents | |||

| Bovine Slurries | 0.039 ± 0.02 | 14.1 | 35.2 ± 4.3 |

| Bovine Manure | 0.038 ± 0.02 | 12.3 | 97.5 ± 9.3 |

| Pig Manure | 0.090 | 8.0 | 128 |

| Pig Slurries | 0.120 | 8.0 | 187 ± 89 |

| Poultry Manure | 0.098 ± 0.03 | 6.8 | 208 ± 103 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Battista, F.; Frison, N.; Bolzonella, D. Energy and Nutrients’ Recovery in Anaerobic Digestion of Agricultural Biomass: An Italian Perspective for Future Applications. Energies 2019, 12, 3287. https://doi.org/10.3390/en12173287

Battista F, Frison N, Bolzonella D. Energy and Nutrients’ Recovery in Anaerobic Digestion of Agricultural Biomass: An Italian Perspective for Future Applications. Energies. 2019; 12(17):3287. https://doi.org/10.3390/en12173287

Chicago/Turabian StyleBattista, Federico, Nicola Frison, and David Bolzonella. 2019. "Energy and Nutrients’ Recovery in Anaerobic Digestion of Agricultural Biomass: An Italian Perspective for Future Applications" Energies 12, no. 17: 3287. https://doi.org/10.3390/en12173287