Solar Water Heating Systems Applied to High-Rise Buildings—Lessons from Experiences in China

Abstract

:1. Introduction

2. Methodology

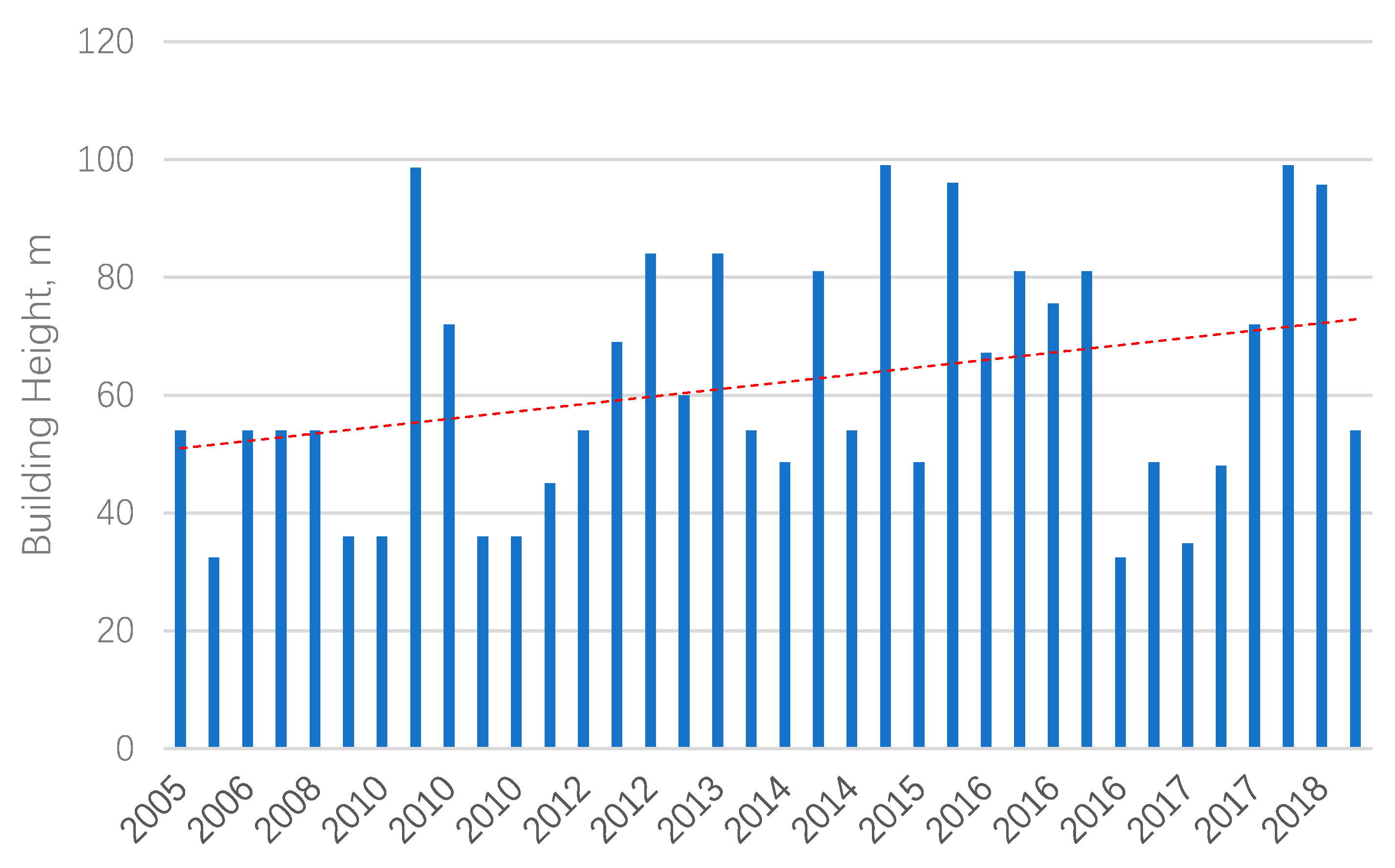

3. Results

3.1. Three Basic Principles

(1). Safety

(2). Aesthetics

(3). Functionality

3.2. Hot Water Usage and Storage Tank Capacity

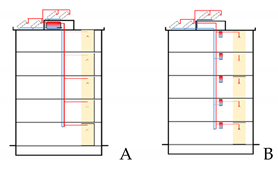

3.3. System Types

3.4. Collector Types

- is the collector efficiency;

- η0 is the peak collector efficiency;

- is the incidence angle modifier;

- is the incidence angle for radiation in °;

- is the heat loss coefficient of a collector at ambient temperature in W/(m2K);

- is the temperature dependence of the heat loss coefficient of a collector in W/(m2K2);

- is the mean solar collector fluid temperature in °C;

- is the ambient temperature in °C; and

- is the solar irradiance on the collector in W/m2.

- is the power produced by the solar collector in W; and

- is the gross area of the solar collector in m2.

3.5. System Components

3.6. Installations

(1) Roofs

(2) Walls

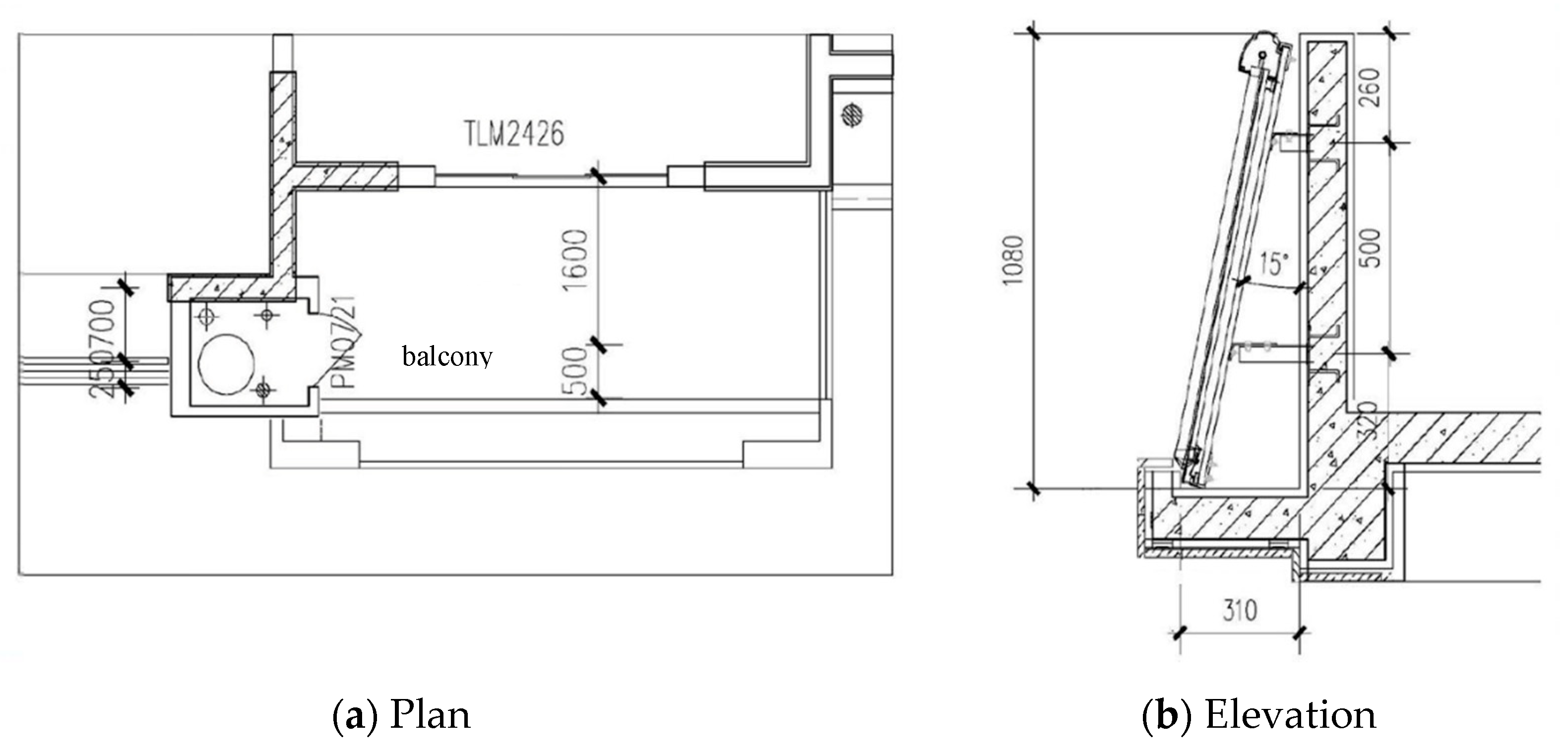

(3) Balconies

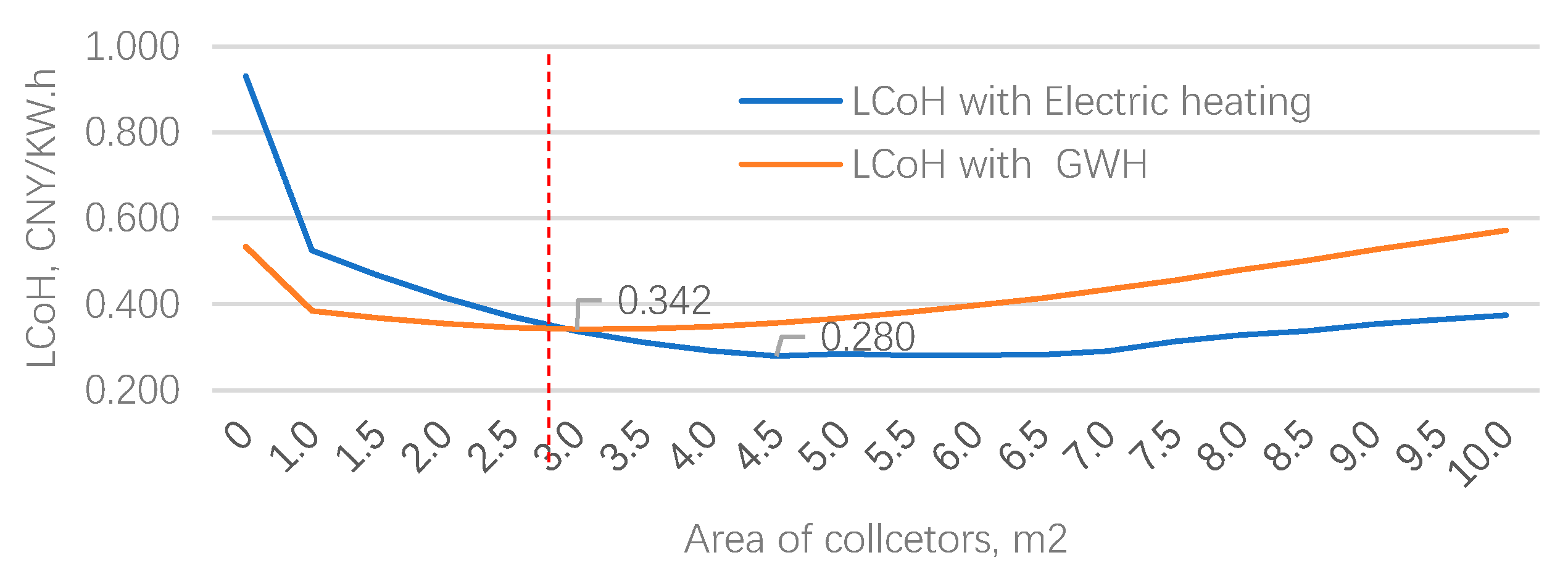

3.7. Auxiliary Heat Sources

3.8. Economic Performance

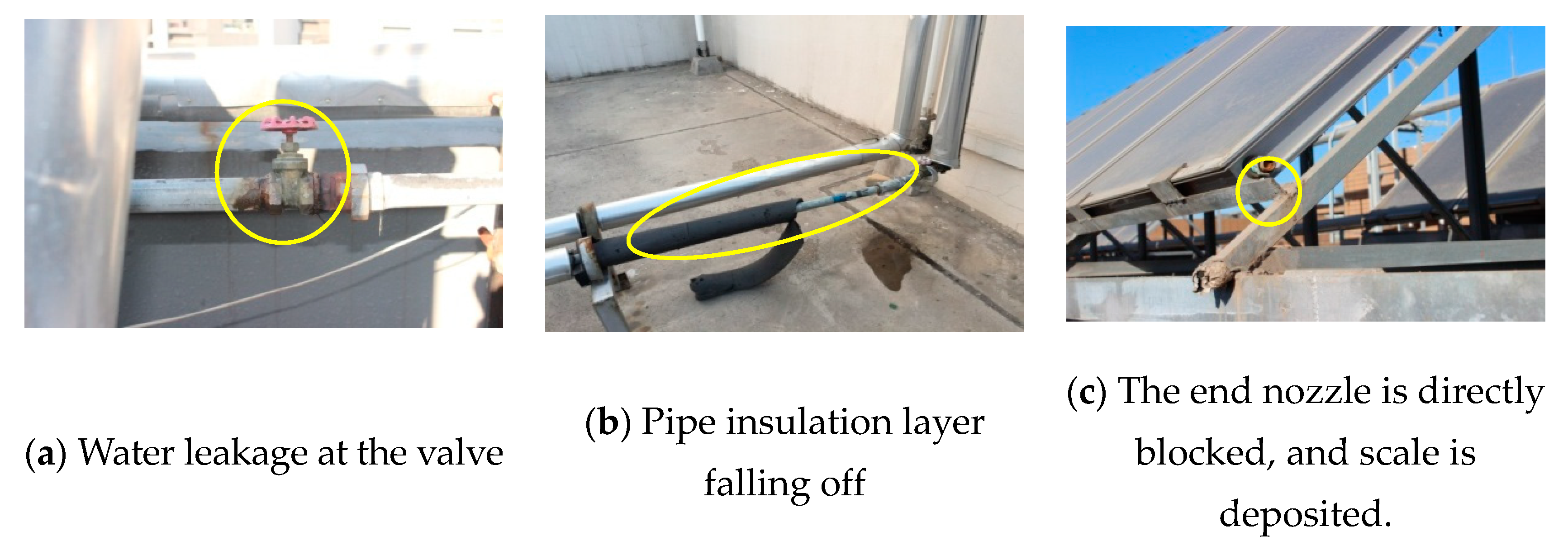

3.9. Operation and Maintenance

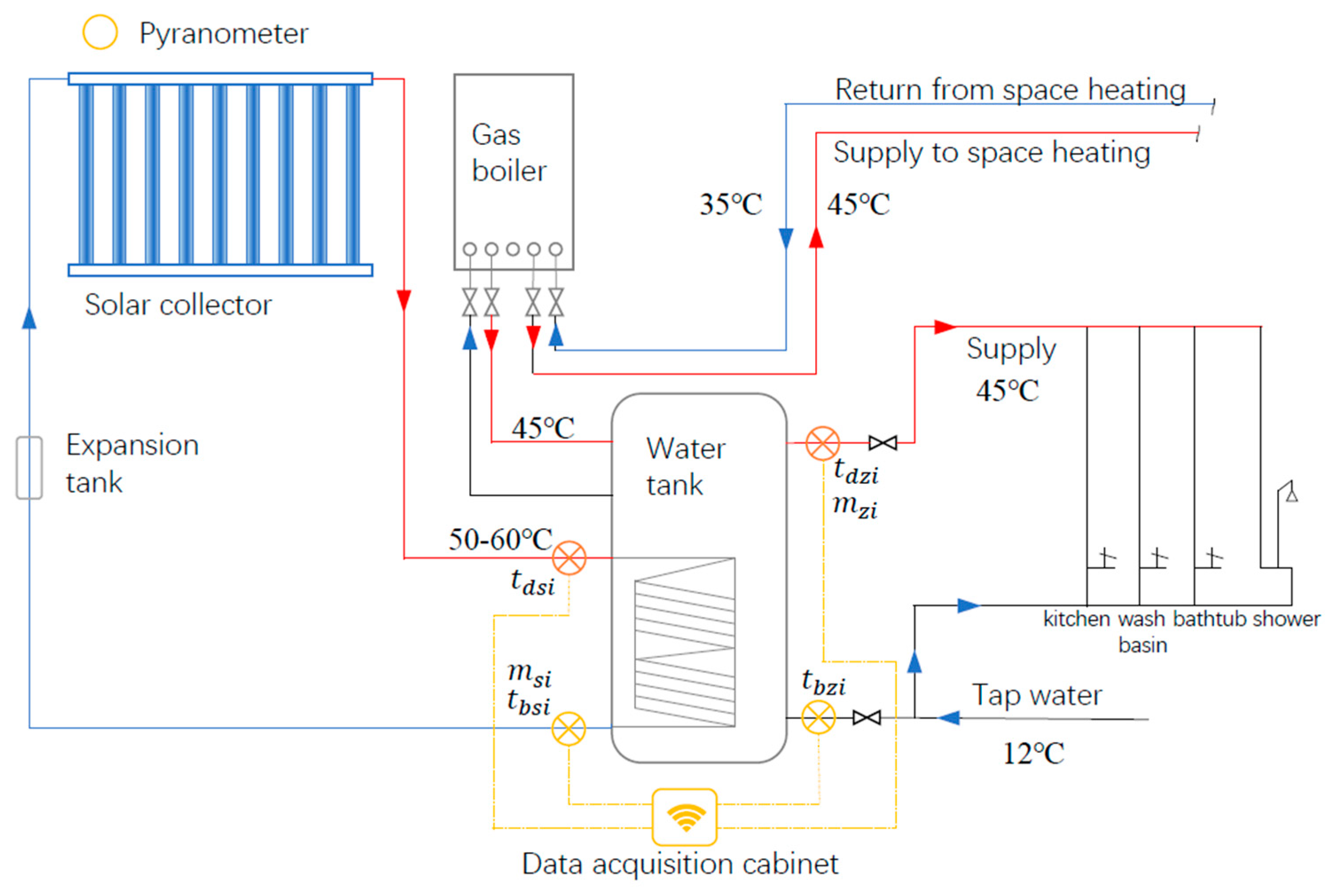

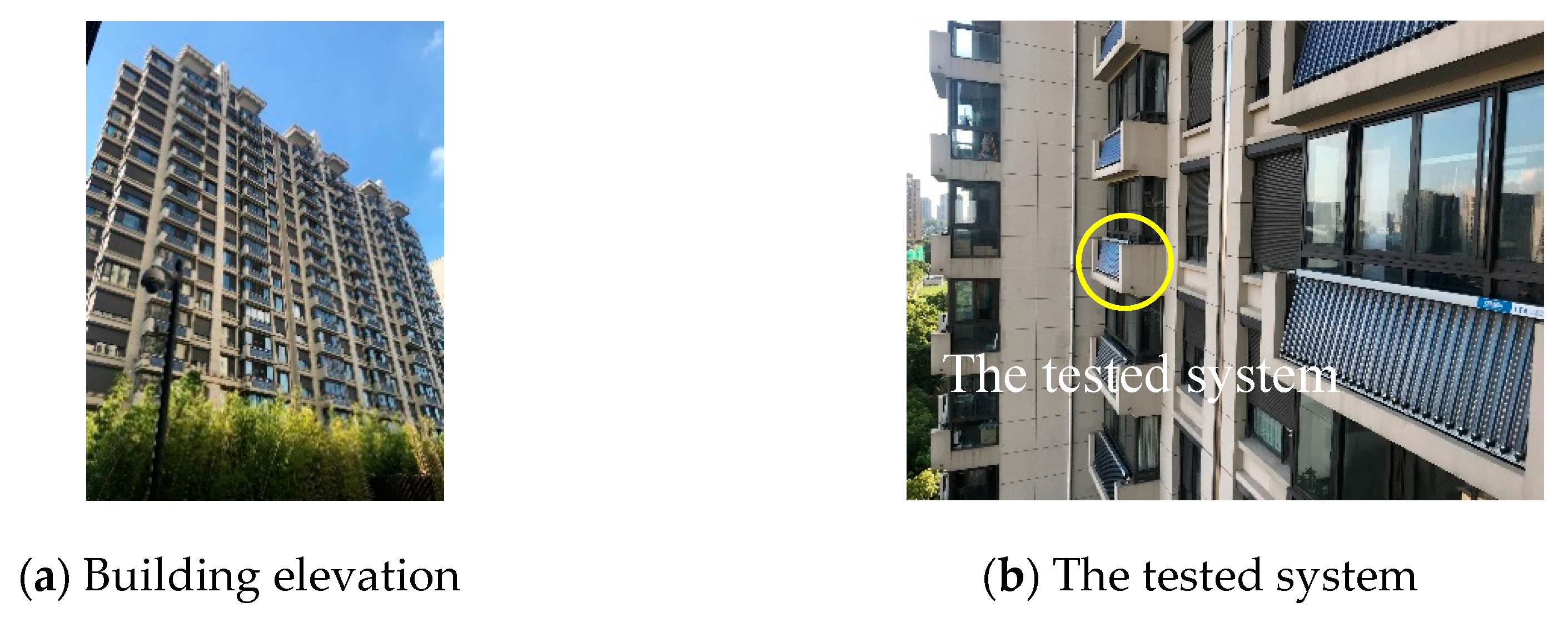

4. Case Study

- LCoH is the levelized cost of heat in CNY/kWh;

- is the initial investment in CNY;

- is subsidies and incentives in CNY;

- is operation and maintenance costs (year t) in CNY;

- is saved final energy (year t) in kWh;

- is the discount rate in %; The discount rate is defined as the weighted average cost of capital (WACC). According to the National Bureau of Statistics of China, 3% was used in the study. and

- is a period of analysis in the year. 15 was used for solar collectors and ASHPs, and 8 was used for gas boilers in the study.

5. Discussion

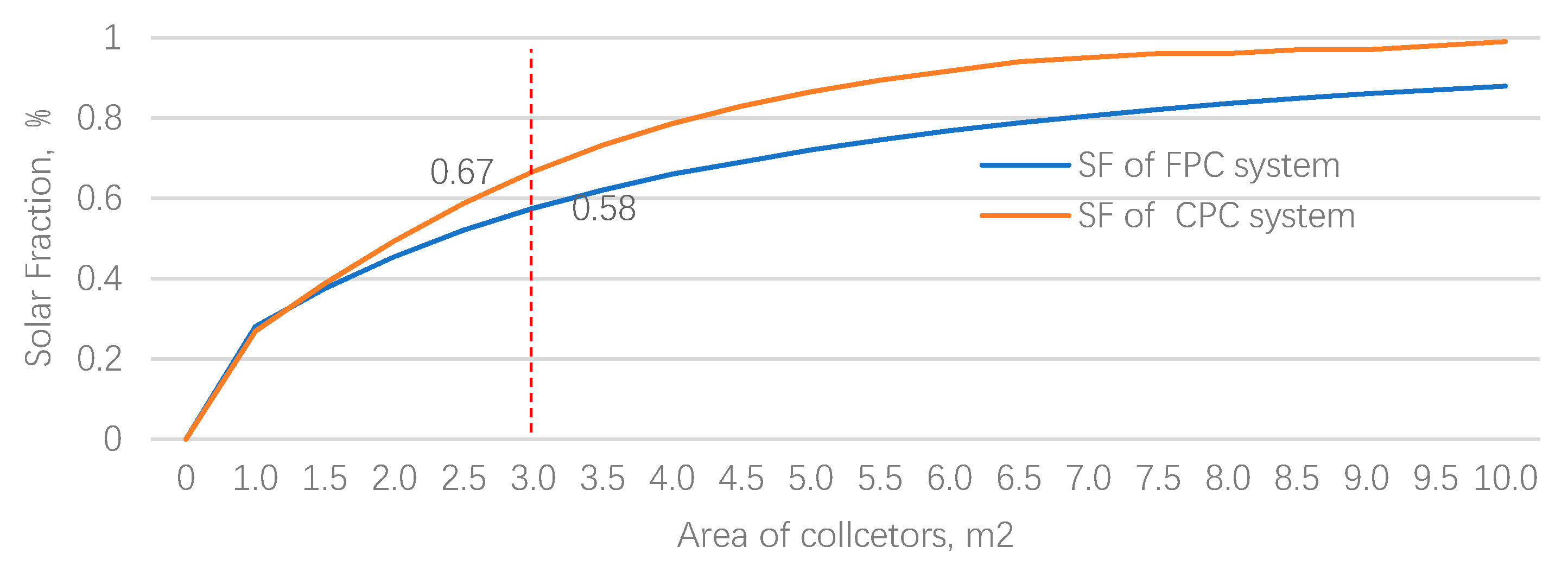

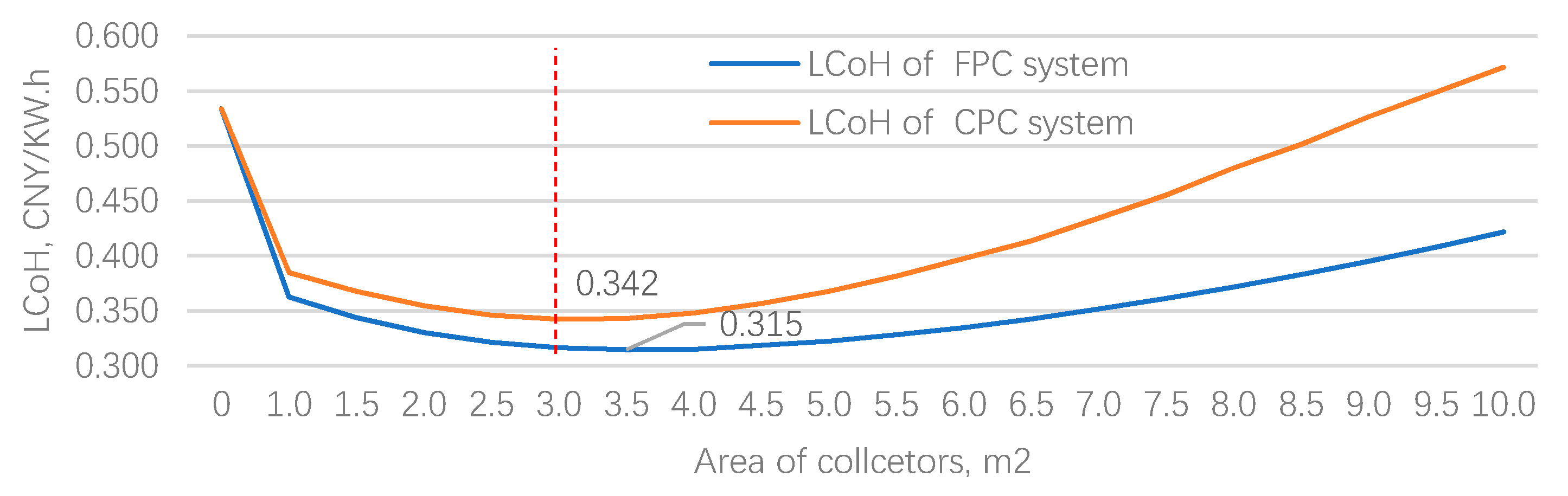

5.1. Performance Comparison of Different Systems

5.2. Limitations of this Study and Future Work

6. Conclusions

- The installation of SWH systems in high-rise buildings is feasible and reliable with careful design, construction, operation and maintenance. Insufficient hot water in winter (29%), water leakage (21%), lack of professional operation and maintenance personnel (10%) are the three major problems in the operation of SWH systems.

- Mutual occlusion between buildings will significantly reduce the efficiency of SWH systems. Usually, the aperture area of the collector is half-blocked, and the energy consumption of the auxiliary heat source is correspondingly doubled.

- An individual household system (61%) is better than a centralized system (25%) in high-rise buildings in terms of the system efficiency, higher solar fraction for single households, and assurance of the installation area for solar collectors.

- The average area of solar collectors per household was 2.17 /household, the average design solar fraction was 52%.

- FPCs are most suitable for the integration with SWH systems in high-rise buildings in terms of system security and reliability. However, when considering the system efficiency, CPCs are better with higher SFs, but the installation of CPC in high-rise buildings requires strict supervision and reliable technical support to ensure safety and security. The system requires fewer CPCs, compared to FPCs, to reach the lowest LCoH.

- When solar collectors are installed on roofs, a floating board is the best installation method to integrate solar collectors with roofs to ensure adequate installation space and minimize the impact on the architectural design. If solar collectors have to be installed on walls, a pallet should be designed to support collectors. Wind loads need to be considered during the structural design of the pallet.

- Electric heating elements (89%) were the most common auxiliary heat sources for SWH systems, followed by gas water heaters and air source heat pumps.

- The cost of SWH systems per m2 of a building area, including the equipment expense and the installation fees, was between 22 CNY/m2 to 75 CNY/m2. The average percentage was 0.3% of the total building construction cost; it is acceptable for developers and residents when considering the energy cost savings from solar thermal.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AGETC | All-glass evacuated tubular solar collector |

| ASHP | Air source heat pump |

| BIST | Building integrated solar thermal |

| CNY | Chinese Yuan |

| CPC | A compound parabolic collector with a U-shaped copper pipe inside |

| ETC | Evacuated tubular collector |

| EWH | Electric water heater |

| FPC | Flat plate collector |

| GWH | Gas water heater |

| HPETC | An evacuated tubular collector with a heat pipe inside |

| LCoH | Levelized cost of heat |

| SF | Solar fraction |

| SWH | Solar water heating |

| UPETC | An evacuated tubular collector with a U-shaped copper pipe inside |

| Symbols | |

| the gross area of the solar collector, m2 | |

| the heat loss coefficient of a collector at ambient temperature, W/(m2K) | |

| the temperature dependence of the heat loss coefficient of a collector, W/(m2K2) | |

| operation and maintenance costs (year t), CNY | |

| the specific heat capacity of water, J/(kg·K) | |

| the specific heat capacity of a collector fluid, J/(kg·K) | |

| the saved final energy (in year t), kWh | |

| the solar fraction obtained in short-term tests under specific solar radiation conditions, % | |

| the calculated annual solar fraction of the system, % | |

| the solar irradiance on the collector, W/m2 | |

| the initial investment, CNY | |

| the incidence angle modifier | |

| the hot water flow rate recorded in i-th test, m3/s | |

| the working fluid flow rate in the heat collection system recorded in i-th test, m3/s | |

| the total energy consumption of the solar water heating system, MJ | |

| the total heat gain of solar collectors, MJ | |

| the discount rate, % | |

| subsidies and incentives, CNY | |

| the period of analysis, year | |

| the hot water temperature recorded in i-th test, °C | |

| the cold water temperature recorded in i-th test, °C | |

| the collector fluid temperature at the outlet recorded in i-th test, °C | |

| the collector fluid temperature at the inlet recorded in i-th test, °C | |

| the time step, s | |

| the time step, s | |

| the peak collector efficiency | |

| the incidence angle for radiation, ° | |

| the density of hot water, kg/m3 | |

| the density of collector fluid, kg/m3 | |

References

- Sawin, J.L.; Rutovitz, J.; Sverrisson, F. Renewables 2018 Gobal Status Report; REN21: Paris, France, 2018. [Google Scholar]

- Weiss, W.; Spörk-Dür, M. Solar Heat Worldwide 2018; AEE—Institute for Sustainable Technologies: Gleisdorf, Austria, 2018. [Google Scholar]

- Huang, J.; Tian, Z.; Fan, J. A comprehensive analysis on development and transition of the solar thermal market in China with more than 70% market share worldwide. Energy 2019, 174, 611–624. [Google Scholar] [CrossRef]

- Vieira, A.S.; Stewart, R.A.; Lamberts, R.; Beal, C.D. Residential solar water heaters in Brisbane, Australia: Key performance parameters and indicators. Renew. Energy 2018, 116, 120–132. [Google Scholar] [CrossRef] [Green Version]

- Benli, H. Potential application of solar water heaters for hot water production in Turkey. Renew. Sustain. Energy Rev. 2016, 54, 99–109. [Google Scholar] [CrossRef]

- Bano, F.; Sehgal, V. Evaluation of energy-efficient design strategies: Comparison of the thermal performance of energy-efficient office buildings in composite climate, India. Sol. Energy 2018, 176, 506–519. [Google Scholar] [CrossRef]

- Hoffman, L.A.; Ngo, T.T. Affordable solar thermal water heating solution for rural Dominican Republic. Renew. Energy 2018, 115, 1220–1230. [Google Scholar] [CrossRef]

- Lee, J.M.; Braham, W.W. Building emergy analysis of Manhattan: Density parameters for high-density and high-rise developments. Ecol. Modell. 2017, 363, 157–171. [Google Scholar] [CrossRef]

- Maurer, C.; Cappel, C.; Kuhn, T.E. Progress in building-integrated solar thermal systems. Sol. Energy 2017, 154, 158–186. [Google Scholar] [CrossRef]

- Takebayashi, H.; Ishii, E.; Moriyama, M.; Sakaki, A. Study to examine the potential for solar energy utilization based on the relationship between urban morphology and solar radiation gain on building rooftops and wall surfaces. Sol. Energy 2015, 119, 362–369. [Google Scholar] [CrossRef]

- Shi, J.; Su, W.; Zhu, M.; Chen, H.; Pan, Y.; Wan, S.; Wang, Y. Solar water heating system integrated design in high-rise apartment in China. Energy Build. 2013, 58, 19–26. [Google Scholar] [CrossRef]

- He, G.; Zheng, Y.; Wu, Y.; Cui, Z.; Qian, K. Promotion of building-integrated solar water heaters in urbanized areas in China: Experience, potential, and recommendations. Renew. Sustain. Energy Rev. 2015, 42, 643–656. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; He, B.; Xu, W.; Jin, G.; Zhang, X. Application and suitability analysis of the key technologies in nearly zero energy buildings in China. Renew. Sustain. Energy Rev. 2019, 101, 329–345. [Google Scholar] [CrossRef]

- Tsalikis, G.; Martinopoulos, G. Solar energy systems potential for nearly net zero energy residential buildings. Sol. Energy 2015, 115, 743–756. [Google Scholar] [CrossRef]

- Raji, B.; Tenpierik, M.J.; Van Den Dobbelsteen, A. An assessment of energy-saving solutions for the envelope design of high-rise buildings in temperate climates: A case study in the Netherlands. Energy Build. 2016, 124, 210–221. [Google Scholar] [CrossRef]

- Colmenar-Santos, A.; Vale-Vale, J.; Borge-Diez, D.; Requena-Pérez, R. Solar thermal systems for high rise buildings with high consumption demand: Case study for a 5 star hotel in Sao Paulo, Brazil. Energy Build. 2014, 69, 481–489. [Google Scholar] [CrossRef]

- Balter, J.; Ganem, C.; Discoli, C. On high-rise residential buildings in an oasis-city: Thermal and energy assessment of different envelope materiality above and below tree canopy. Energy Build. 2016, 113, 61–73. [Google Scholar] [CrossRef]

- Yoo, J. Evaluation of solar hot water heating system applications to high-rise multi-family housing complex based on three years of system operation. Energy Build. 2015, 101, 54–63. [Google Scholar] [CrossRef]

- Pan, W.; Pan, M. A dialectical system framework of zero carbon emission building policy for high-rise high-density cities: Perspectives from Hong Kong. J. Clean. Prod. 2018, 205, 1–13. [Google Scholar] [CrossRef]

- Chow, T.T.; Fong, K.F.; Chan, A.L.S.; Lin, Z. Potential application of a centralized solar water-heating system for a high-rise residential building in Hong Kong. Appl. Energy 2006, 83, 42–54. [Google Scholar] [CrossRef]

- Wong, L.T.; Mui, K.W.; Guan, Y. Shower water heat recovery in high-rise residential buildings of Hong Kong. Appl. Energy 2010, 87, 703–709. [Google Scholar] [CrossRef]

- Lotfabadi, P. High-rise buildings and environmental factors. Renew. Sustain. Energy Rev. 2014, 38, 285–295. [Google Scholar] [CrossRef]

- Sadati, S.; Edwards, R. Incorporating solar energy sources in low energy buildings in two major cities in Iran. Energy Procedia 2019, 156, 85–89. [Google Scholar] [CrossRef]

- Alves, T.; Machado, L.; Gonçalves, R.; Souza, D.; De Wilde, P. Assessing the energy saving potential of an existing high-rise office building stock. Energy Build. 2018, 173, 547–561. [Google Scholar] [CrossRef]

- Lotfabadi, P. Solar considerations in high-rise buildings. Energy Build. 2015, 89, 183–195. [Google Scholar] [CrossRef]

- Thi, P.; Ha, H. A Concept for Energy-Efficient High-Rise Buildings in Hanoi and a Calculation Method for Building Energy Efficiency Factor. Procedia Eng. 2016, 142, 154–160. [Google Scholar] [CrossRef] [Green Version]

- Xie, M.; Chenyu, L.; Ying, W.; Wang, J. Comprehensive utilization of renewable energy for new civil buildings in Shanghai. Energy Procedia 1997, 152, 336–341. [Google Scholar] [CrossRef]

- Hu, S.; Yan, D.; Guo, S.; Cui, Y.; Dong, B. A survey on energy consumption and energy usage behavior of households and residential building in urban China. Energy Build. 2017, 148, 366–378. [Google Scholar] [CrossRef]

- Ahmad, T.; Aibinu, A.; Jamaluddin, M. The effects of high-rise residential construction on sustainability of housing systems. Procedia Eng. 2017, 180, 1695–1704. [Google Scholar] [CrossRef]

- Souliotis, M.; Panaras, G.; Fokaides, P.A.; Papaefthimiou, S.; Kalogirou, A.S. Solar water heating for social housing: Energy analysis and Life Cycle Assessment. Energy Build. 2018, 169, 157–171. [Google Scholar] [CrossRef]

- Aelenei, L.; Smyth, M.; Platzer, W.; Norton, B.; Kennedy, D.; Kalogirou, S.; Maurer, C. Solar Thermal Systems—Towards a Systematic Characterization of Building Integration. Energy Procedia 2016, 91, 897–906. [Google Scholar] [CrossRef]

- Maurer, C.; Cappel, C.; Kuhn, T.E. Simple models for building-integrated solar thermal systems. Energy Build. 2015, 103, 118–123. [Google Scholar] [CrossRef]

- O’Hegarty, R.; Kinnane, O.; McCormack, S.J. Review and analysis of solar thermal facades. Sol. Energy 2016, 135, 408–422. [Google Scholar] [CrossRef]

- Lamnatou, C.; Mondol, J.D.; Chemisana, D.; Maurer, C. Modelling and simulation of Building-Integrated solar thermal systems: Behaviour of the coupled building/system configuration. Renew. Sustain. Energy Rev. 2015, 48, 178–191. [Google Scholar] [CrossRef]

- Zhang, R.; Shen, G.Q.P.; Ni, M.; Wong, J.K.W. Techno-economic feasibility of solar water heating system: Overview and meta-analysis. Sustain. Energy Technol. Assess. 2018, 30, 164–173. [Google Scholar] [CrossRef]

- Abd-ur-rehman, M.; Al-sulaiman, F.A.; Mehmood, A. The potential of energy savings and the prospects of cleaner energy production by solar energy integration in the residential buildings of Saudi Arabia. J. Clean. Prod. 2018, 183, 1122–1130. [Google Scholar] [CrossRef]

- Hu, R. Research on Mandatory Installation Policy of Solar Water Heater for Civil Buildings. Constr. Sci. Technol. 2008, 61–63. [Google Scholar] [CrossRef]

- Hu, R.; Li, J. Global Solar Thermal Industry Incentive Policy and Its Enlightenment to China. Energy China 2007, 29, 27–31. [Google Scholar]

- Li, J.; Huang, J. Policies and technical suggestions on the mandatory installation of building integrated solar water heating systems. Hous. Ind. 2010, 7, 20–23. (In Chinese) [Google Scholar]

- He, Z. Solar Water Heating Systems Applied in High-rise Residential Buildings in China. Energy Procedia 2016, 91, 408–414. [Google Scholar] [CrossRef] [Green Version]

- Hongbing, C.; Xilin, C. Study on the performance of residential centralized solar hot water System. Energy Procedia 2019, 158, 223–228. [Google Scholar] [CrossRef]

- Li, D.; Liu, G.; Liao, S. Solar potential in urban residential buildings. Sol. Energy 2015, 111, 225–235. [Google Scholar] [CrossRef]

- Louvet, Y.; Fischer, S.; Furbo, S.; Giovanetti, F.; Mauthner, F.; Mugnier, D.; Philippen, D. Guideline for Levelized Cost of Heat (LCoH) Calculations for Solar Thermal Applications; International Energy Agency: Paris, France, 2017. [Google Scholar]

- Munari Probst, M.C.; Roecker, C. Designing solar thermal systems for Architecture integration -criteria and guidelines for product and system developers. In Proceedings of the 3rd IGCP 591 Annual Meeting, Lund, Sweden, 9–19 June 2013. [Google Scholar]

- Wall, M.; Cristina, M.; Probst, M.; Roecker, C. Achieving solar energy in architecture—IEA SHC Task 41. Energy Procedia 2012, 30, 1250–1260. [Google Scholar] [CrossRef]

- Hachem-vermette, C. Multistory building envelope: Creative design and enhanced performance. Sol. Energy 2018, 159, 710–721. [Google Scholar] [CrossRef]

- Sánchez-pantoja, N.; Vidal, R.; Pastor, M.C. Aesthetic impact of solar energy systems. Renew. Sustain. Energy Rev. 2018, 98, 227–238. [Google Scholar] [CrossRef]

- Visa, I.; Moldovan, M.; Comsit, M.; Neagoe, M.; Duta, A. Facades integrated solar-thermal collectors—Challenges and solutions. Energy Procedia 2017, 112, 176–185. [Google Scholar] [CrossRef]

- Technical Code for Solar Water Heating System of Civil Buildings (GB 50364–2005); China Building Industry Press: Beijing, China, 2005.

- Luo, S.; Li, H.; Mao, Y.; Yang, C. Experimental research on a novel sun shading & solar energy collecting coupling device for inpatient building in hot summer and cold winter climate zone in China. Appl. Therm. Eng. 2018, 142, 89–99. [Google Scholar] [CrossRef]

- Lu, S. Study of Solar Water Heating System Integrated with High-rise Building for the Large Scale Application; Tianjin University: Tianjin, China, 2008. [Google Scholar]

- Zhong, J.; Zhang, L. A Study on Application of Solar Water Heating System in High-rise Apartments. Hous. Sci. 2009, 6–11. [Google Scholar] [CrossRef]

- Peng, C.; Hao, B. From Solar Energy to Solar Can, Efficiency and Design of Solar Water Heating System, 1st ed.; China Building Industry Press: Beijing, China, 2018. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Code for Design of Building Water Supply and Drainage (GB50015–2003), 2nd ed.; China Planning Press: Beijing, China, 2009.

- QU, Y. Research on Application of Solar Hot Water System Technology for Residential Buildings in Shanghai. Archit. Technol. 2012, 43, 1–4. [Google Scholar]

- Kalogirou, S.A.; Kalogirou, S.A. Performance of Solar Collectors. Sol. Energy Eng. 2014, 221–256. [Google Scholar] [CrossRef]

- Buker, M.S.; Riffat, S.B. Building integrated solar thermal collectors—A review. Renew. Sustain. Energy Rev. 2015, 51. [Google Scholar] [CrossRef]

- Horta, P.; Brunner, C.; Kramer, K.; Frank, E. IEA/SHC T49 Activities on Process Heat Collectors: Available Technologies, Technical-Economic Comparison Tools, Operation and Standardization Recommendations. Energy Procedia 2016, 91, 630–637. [Google Scholar] [CrossRef]

- Visa, I.; Duta, A. Innovative Solutions for Solar Thermal Systems Implemented in Buildings. Energy Procedia 2016, 85, 594–602. [Google Scholar] [CrossRef]

- Visa, I.; Comsit, M.; Duta, A. Urban acceptance of facade integrated novel solar thermal collectors. Energy Procedia 2014, 48, 1429–1435. [Google Scholar] [CrossRef]

- Jie, S.; Dexuan, S.; Huaning, C.; Wei, S. Reseach on intergreted design solar energy with high-rise apartement in Shanghai. Archit. J. 2009, 10, 11–15. (In Chinese) [Google Scholar]

- Liu, J. Comparative study on performance of different auxiliary heating modes for separated solar water heating system. Water Supply Sewerage 2017, 43, 6. [Google Scholar] [CrossRef]

- Wan, S. Discussion on the Selection of Solar Hot Water System Types in High-rise Residential Buildings. Water Wastewater Eng. 2009, 65–69. [Google Scholar] [CrossRef]

- Yan, F.; Ma, G.; Xia, L. Study on Integration of Veranda Fence Solar Heat Collector with Building. Archit. Technol. 2017, 48, 3. [Google Scholar]

- China National Standardization Administration. Assessment Code for Performance of Solar Water Heating Systems (GB/T 20095–2006); China Standard Press: Beijing, China, 2006. [Google Scholar]

- Huide, F.; Xuxin, Z.; Lei, M.; Tao, Z.; Qixing, W.; Hongyuan, S. A comparative study on three types of solar utilization technologies for buildings: Photovoltaic, solar thermal and hybrid photovoltaic/thermal systems. Energy Convers. Manag. 2017, 140, 1–13. [Google Scholar] [CrossRef]

- Kosori, V.; Lau, S.; Tablada, A.; Lau, S.S. General model of Photovoltaic (PV) integration into existing public high-rise residential buildings in Singapore—Challenges and benefits. Renew. Sustain. Energy Rev. 2018, 91, 70–89. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, H.; Liu, L.; Wennersten, R.; Sun, Q. High-rise building peak load shaving using rooftop attached PV. Energy Procedia 2018, 152, 484–489. [Google Scholar] [CrossRef]

- Harmim, A.; Boukar, M.; Amar, M.; Haida, A. Simulation and experimentation of an integrated collector storage solar water heater designed for integration into building facade. Energy 2019, 166, 59–71. [Google Scholar] [CrossRef]

| Measured Variables | Equipment | Accuracy |

|---|---|---|

| Ambient air temperature | Thermometer | ±0.1 K |

| Wind speed | Anemometer | ±0.1m/s |

| Solar radiation | Pyranometer | ±10% |

| Water temperature | 4-wire PT100 | ±0.5K |

| Collector fluid temperature | 4-wire PT100 | ±0.5K |

| The total water flow rate in the water heating system | Flowmeter | ±1% |

| The collector fluid flow rate in the solar collector | Flowmeter | ±1% |

| System Type | Individual Household System | Central System | Hybrid System |

|---|---|---|---|

| System schematic |  |  |  |

| System description | The collectors are installed on the balcony, or walls individually. The heat obtained by the solar collector is stored in individual water tanks by heat exchangers inside in households. | Solar collectors are centrally installed on the roof, the heat obtained by the solar collector is stored in a central water tank which supplies hot water to households (A). Alternatively, absent a central water tank, heat obtained by the solar collector is stored in individual water tanks by heat exchangers inside in households (B). | Some collectors are installed centrally on the roof and partially on balconies or walls between windows. This is a hybrid of an individual household system and a central system. |

| Collector area | 1.5–3.0 m2/household | 0.67–3.9 m2/household | 1.4–2.8 m2/household |

| Advantages | Property rights are clear, the system is simple, the performance is stable, and the control is flexible. | The collectors are installed on the roof, which does not affect the appearance of the building. The system has a high collection efficiency. | Maximizes solar energy collection. |

| Disadvantages | The collectors of the households in bottom floors are easily shaded by other buildings, which reduces the thermal performance. The use point is far from the balcony, a high heat loss from long pipelines will increase the energy consumption of the auxiliary heat source [51]. It has a significant influence on the appearance of the building, and the heat collection is greatly affected by the duration of exposure to sunshine. The sunshine exposure of households below the 4th floor is affected by shading, which decreases system efficiency. | The property rights are not clear, while the use factor is low and the actual efficiency is low. Users need to share the costs for assisted heating and water charges, so the system needs to be measured and charged to households. A building with fewer active households will pay a higher price. The system requires an increased power capacity due to the use of electric-assisted heating with extreme heating power, which will increase the initial investment. The heat loss of the pipeline will increase the cost of hot water due to the protracted operation of the auxiliary heating system. The installation area of the collectors is limited by the roof area and is often less than the demand, which results in a low solar fraction [40]. | Long pipes, considerable heat loss. For households under 10th floor, cold water in the pipe needs to be drained before using hot water. |

| Cases |  |  |  |

| FPC | HPETC | CPC | UPETC | AGETC | |

|---|---|---|---|---|---|

| Pictures of collectors |  |  |  |  |  |

| Coefficient of performance | , = 2.41, = 0.015 | = 1, = 0.618 = 1.38, = 0.018 | = 1, = 0.632 = 0.338, = 0.011 | = 1, = 0.632 = 0.638, = 0.016 | = 1, = 0.636 a1 = 0.654, = 0.013 |

| Aperture area | 2.88 m2 | 2.1 m2 | 2.1 m2 | 2.1 m2 | 2.1 m2 |

| Temperature | 60–80 °C | 60–120 °C | 60–120 °C | 60–120 °C | 60–100 °C |

| Weight* | 17.5 kg/m2 | 23.1 kg/m2 | 18.5 kg/m2 | 22.0 kg/m2 | 50 kg/m2 |

| Incremental cost** | 40 CNY/m2 | 55 CNY/m2 | 65 CNY/m2 | 57 CNY/m2 | 32 CNY/m2 |

| Durability | Strong weather durability with a thicker tempered glass cover. | More susceptible to breaking with thinner glass. | The sealed silicone ring is easy to age, causing the entire tube to lose vacuum. | Same as HPETC and CPC | Fragile and prone to more maintenance. |

| Installation | More walls, fewer roofs | More roofs, fewer walls | Walls and roofs | Walls and roofs | More roofs, fewer walls |

| Advantages | Easy to install, safer | Higher efficiency | Higher efficiency | Higher efficiency | Cheap |

| Disadvantages | Weak wind resistance | Difficulty for integration | Difficulty for integration | Difficulty for integration | Fragile |

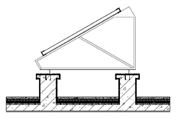

| Types | Type 1: Flat Roof | Type 2: Slope Roof | Type 3: Floating Board |

|---|---|---|---|

| Sketches |  |  |  |

| Installation mode | Mounted on a bracket | Embedded roof | Mounted on a bracket |

| Angle | Local latitude | Same as the slope of the roof | Local latitude |

| Cases |  |  |  |

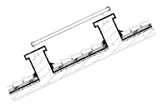

| Types | Type 1: Attached | Type 2: Embedded | Type 3: Bracket | Type 4: Pallet |

|---|---|---|---|---|

| Sketches |  |  |  |  |

| Installation mode | Attached to the wall | Embedded in the wall | Attached to the wall by a stainless-steel bracket | Supported by a pallet |

| Angle | 0° | 0° | 15° | 15° |

| Cases for FPCs |  |  |  |  |

| Cases for ETCs |  |  |  |  |

| Types | Type 1: Attached | Type 2: Bracket | Type 3: Pallet |

|---|---|---|---|

| Sketches |  |  |  |

| Installation mode | Integrated with balcony railings | Attached to balcony railings by a stainless-steel bracket | Attached and supported by a pallet |

| Angle | 0° | 15° | 15° |

| Cases |  |  |  |

| Heat Sources | Electric Heating Element | GWH or Gas Boiler | ASHP |

|---|---|---|---|

| Efficiency | 70% | 90%–107% | COP*, 2.5–3 |

| Cost/Household | 50–100 CNY | 2500–6000 CNY | 6000 CNY |

| Advantages | Space saving, a low initial investment | Instant heat when using, Low operating cost | Low operating cost |

| Disadvantages | High operating cost | The high initial investment, Needs installation space | The high initial investment, Requires a large installation space, noisy |

| Types | Unit | SWH System | EWH | GWH | ASHP Water Heater |

|---|---|---|---|---|---|

| Power | kW | 27a | 2 | 27 | 0.8 |

| Efficiency | % | 60%b | 70% | 89% | COP, 3.4 |

| Life span | years | 15 | 8 | 6 | 15 |

| Initial investment | CNY | 7500 + 2500 | 1500 | 2500 | 6000 |

| Subsidies | CNY | 5400c | 0 | 0 | 0 |

| Energy price | CNY/m3, CNY/ kWh | 0 / 3.3 | 0.6 | 3.3 | 0.6 |

| Operation cost | CNY/a | 363 | 2190 | 960 | 451 |

| Maintenance cost | CNY/a | 300 | 100 | 200 | 200 |

| LCoH | CNY/kWh | 0.38 | 0.97 | 0.62 | 0.41 |

| Test Items | Total Solar Radiation on the Day | |||

|---|---|---|---|---|

| R < 8 | 8 ≤ R < 13 | 13 ≤ R < 18 | R ≥ 18 | |

| Days () | 98 | 101 | 77 | 89 |

| SF of the day () | 15.5% | 48.4% | 72.4% | 100% |

| The annual = 57.2% | ||||

| Location | Shanghai |

|---|---|

| Weather data | Meteonorm weather data |

| Water tank volume | 150 L |

| The output power of the gas boiler | 24 kW |

| Supply temperature | 45 °C |

| Collector area | 3 m2 |

| Collector orientation | South |

| Collector tilt | 15° |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Fan, J.; Furbo, S.; Li, L. Solar Water Heating Systems Applied to High-Rise Buildings—Lessons from Experiences in China. Energies 2019, 12, 3078. https://doi.org/10.3390/en12163078

Huang J, Fan J, Furbo S, Li L. Solar Water Heating Systems Applied to High-Rise Buildings—Lessons from Experiences in China. Energies. 2019; 12(16):3078. https://doi.org/10.3390/en12163078

Chicago/Turabian StyleHuang, Junpeng, Jianhua Fan, Simon Furbo, and Liqun Li. 2019. "Solar Water Heating Systems Applied to High-Rise Buildings—Lessons from Experiences in China" Energies 12, no. 16: 3078. https://doi.org/10.3390/en12163078