1. Introduction

The overall efficiency of the internal combustion engine is one of its most important operational parameters. It directly influences fuel consumption, which is an extremely important factor both for drivers and car manufacturers who have to meet the strict EU regulations [

1].

The overall engine efficiency is defined as the quotient of the mechanical power on the flywheel to the power of the fuel injected into the cylinders. It takes into account all losses related to both thermodynamic processes, internal friction mainly among moving parts in the crank and piston system, as well as losses in the alternator drive, the coolant pump, and other accessories.

Currently, the efficiency of internal combustion engines is up to 40% for spark ignition (SI) naturally aspirated engines [

2] and up to 36% for SI turbocharged engines [

3]. Over the last 20 years, efficiency has grown by about 10%, due to numerous factors. The main ones are as follows: The use of fuel injection systems, modern lubricants, coatings on pistons and cylinders [

4], optimization of the valve timing [

5], the use of the Atkinson cycle [

2], improved fuels, increased compression ratio and many others.

A well-known method for presenting the efficiency of engines is with the specific fuel consumption, which has been used for many years [

6]. It represents isolines of specific fuel consumption as a function of engine rotational speed and torque. It illustrates the efficiency of the engine in the whole working range and makes it possible to compare different constructions. An important limitation of this characteristic is the possibility of applying it only to steady states of engine operation, where the rotational speed and torque are constant and the throttle position is fixed. Therefore, its use in simulations of vehicle fuel consumption is dedicated to significant errors, because vehicle engines work dominantly in dynamic working states [

7], where energy accumulation in rotating masses, mixture enrichment at throttle opening, and fuel cut off during deceleration significantly influence engine efficiency. Despite this big disadvantage, this characteristic is often used in simulations of vehicle fuel consumption in different driving cycles. However, it can only be used with sufficient accuracy in comparative simulations, e.g., concerning gear ratio selection [

8], allowing differences between different constructions to be shown, rather than nominal values of fuel consumption to be calculated.

A technical problem, where many factors that influence other factors can often be solved with the ANN method, which is capable of approximating non-linear relationships based on a data set from performed measurements. The applications of the ANN method for solving engine performance problems are numerous. The authors of Reference [

9] have developed dynamic models of the engine, where speed, throttle angle, and angular acceleration are considered as ANN inputs and engine torque and fuel consumption are the outputs. In References [

7,

10], the author undertook another attempt. The inertia-related engine features are included in the ANN model enabling fuel flow calculation in dynamic states. In contrast with Reference [

9], this model includes not only engine speed, torque, and angular acceleration, but also torque increase over time, which is an important factor including air-fuel mixture enrichment. This method is very precise, but no 2D or 3D characteristic was presented, thus a simple and quick assessment of the engine dynamic parameters is impossible in this case. Computational simulations must be performed to obtain engine efficiency for each particular engine working state. In Reference [

11], the ANN method was used to predict the exhaust emissions and performance (e.g., brake specific fuel consumption) of a compression ignition engine based on engine load, engine speed, and the percentage of biodiesel fuel derived from waste cooking oil in diesel fuel. Although this article provides relationships between engine speed, load, and performance, it refers only to static working states. Very similar problems and approaches are presented in References [

12,

13], however, in these cases the fuel blends are as follows: Diethyl ether diesel fuel mixtures and Jatropha biodiesel, respectively. Artificial intelligence can also be used in more sophisticated problems concerning the efficiency of a combustion engine working in a hybrid drivetrain [

14]. The literature shows that, apart from the ANN method, other approaches are also possible when solving the problems of engine efficiency (specific fuel consumption). In Reference [

15], the authors’ approach was to analytically calculate energy expenditure and fuel consumption, taking into account the instantaneous specific fuel consumption, approximated by two generalized single dimension polynomial functions. The authors of Reference [

16] developed a dynamic model based on the static characteristic complemented by a factor including vehicle speed and acceleration. This model provides a closer characteristic to real engine behaviour, however, such an attempt also includes vehicle features such as gear ratios. The authors of Reference [

17] used the mean value model representing the engine. A non-linear model includes air flow and engine inertia, however fuel-air mixture composition is assumed constant and values of some efficiencies are assumed, not measured. The authors of Reference [

18] invented the new transient fuel consumption model whose basic structure is steady-state estimation plus transient correction, including engine speed and torque change resulting from the instantaneous speed and acceleration of the vehicle in specific driving cycles.

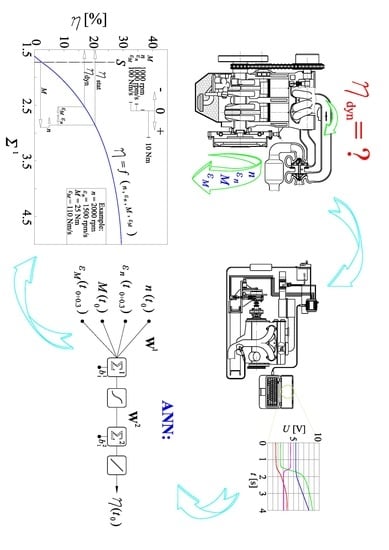

The need to reduce research costs and shorten the time of prototype preparation leads to the use of computer simulations to the widest possible extent. This, in turn, involves the need to develop more and more accurate mathematical models that reflect the physical construction as closely as possible. The above examples present different approaches to the problem of combustion engine efficiency and the use of different calculation methods. Unfortunately, the development of a graphic representation of combustion engine efficiency in dynamic states is complex, because it requires a multidimensional relationship to be developed. Taking the above into consideration, the author used the ANN to develop a novel method that allows graphical representations to be created with the highest possible match with measurement data from dynamic engine working states.

The rest of the manuscript is organized as follows.

Section 2 describes the basics of engine efficiency, including the well-known specific fuel consumption characteristic as well as the problem of engine inertia influencing efficiency in dynamic working states.

Section 3 provides information concerning engine tests and the measurement system in static and dynamic states. All the aspects of the ANN (creating mathematical dependency between engine speed, torque, and its efficiency) concerning its architecture, data scaling, and training method, are precisely described.

Section 4 presents a novel approach to the problem of drawing engine efficiency in dynamic working states and, finally, shows two dimensional characteristics, allowing engine efficiency to be quickly and precisely calculated.

Section 5 presents the simulation results, which prove the correctness of the adopted approach.

2. Problem Formulation

Engine efficiency can be measured for every point in the whole field of work, however, only the maximum values of individual engines are usually given. The efficiency of the engine in the entire work area shows the specific fuel consumption, where, in the coordinate system, torque

M vs. the rotational speed

n, the contours of specific fuel consumption are presented. Such a characteristic is presented in

Figure 1.

The graph in

Figure 1 is created based on a method presented in Reference [

8], where the algorithm of drawing such a characteristic, based on only 4 operating points, is described in detail. This characteristic can be directly converted to a characteristic of engine efficiency:

where

N is the engine power in kW,

G is fuel mass flow in g/s, and

Wd is the heat value of the fuel in MJ/kg.

As mentioned in the Introduction, these characteristics are based on measurements in static states. In dynamic states, the efficiency of the engine can vary significantly. This results from the following factors: Enrichment of the mixture during load increase (in relation to static states), delay of the system response to the control signal, and accumulation of combustion energy in moving parts of the engine (

Figure 2). Although this energy can be partially recovered during deceleration with engine braking, it is usually lost in the form of pumping losses when the throttle is closed and the engine speed is reduced.

It is therefore important to determine the characteristics that, as well as the engine speed

n and torque

M, also take into account the angular acceleration and the increase in the torque over time, which significantly affect efficiency, as shown in

Figure 3.

Such an attempt is strongly desired, because car engines work for a predominant percentage of time in dynamic working conditions, which results from the specificity of road traffic, especially in the area of large urban agglomerations, the impact of road resistance, wind resistance, or the driver’s own operation of the vehicle. It turns out that, in such working conditions, the efficiency of the engine is even smaller. In the WLTP homologation test (Worldwide harmonized light duty vehicle test procedure), the phases in which the engine operates with a constant load are only under 17% of the entire test time. This clearly shows that the use of fuel consumption characteristics in dynamic work states is insufficiently accurate.

4. Development of the Graphic Engine Efficiency Characteristic

The ANN presented in

Section 3 can be used in computer simulations, because it ensures high accuracy. However, it does not allow a simple 2D or 3D characteristic to be obtained. Thus, a modified ANN, with a new architecture, will be used in this chapter to develop such a characteristic. First of all, an ANN with only one hidden neuron will be used. Secondly, it will differ from the previous one, because, in this case, engine efficiency is directly the ANN output. The logsig shape of the transfer function

f1 will be the base for the characteristic. All of the 4 variables must be presented simultaneously, because they influence each other. The architecture used is presented in

Figure 10.

The fact that the output is engine efficiency means that the 2nd and 4th inputs must be scaled inversely proportionally (different than in the first ANN with 5 hidden neurons (

Figure 6)), because both high angular acceleration and increased torque reduce engine efficiency. The input values remain the same:

They are scaled to the range (−1; 1), thus creating the vector

X1:

Data scaling is the following:

The ANN output

Y0 is the engine efficiency

η [%]:

It was also scaled to the range (−1; 1), according to the following formula:

The training process took 18 epochs this time, which resulted in the mean squared error of 0.00854. Its graph during the learning process is presented in

Figure 11.

The matrices

W1,

b1,

W2,

b2 are now the following:

After ANN training, engine torque is re-scaled from the (−1; 1) range to the basic range (0–33%) based on the following relationship:

Then, it must be verified if only one hidden neuron is capable of approximating the whole data set, because it is essential to create a characteristic with reasonable accuracy. Based on the two neural networks above, static characteristics are created. The result obtained with the use of the ANN with one hidden neuron differs no more than 5% for 95% of the engine working field from the ANN with 5 neurons. Thus, the accuracy is reasonable and the ANN with 1 neuron can be used further for 2D characteristic development.

To obtain a simple and direct relationship between the engine parameters and its efficiency scaling coefficients (Equation (21)), its input weights are multiplied and simplified, according to the following equations:

The final coefficients are the following: A1 = −0.0000200, A2 = −0.0001159, A3 = 0.0467000, A4 = −0.0015000, S = 1.7265.

Taking into account (Equation (2)), this results in the final dependency, which can be directly moved further on the graph:

Finally, the logsig function is converted by the output layer weight W

2, and then by rescaling the output data. This is presented in

Figure 12.

To create a graphic representation, the coefficients are scaled to specific lengths in a graph. This allows a simple and quick assessment of engine efficiency. The final characteristic is presented in

Figure 13.

This characteristic allows a simple assessment of engine efficiency in the whole working range. The length of the measurement sections clearly shows the influence of individual components on the overall efficiency of the engine and, in particular, how it decreases where angular acceleration or torque increase occur. The main advantage of the characteristic is that it is a continuous and differentiable function, which allows the efficiency to be calculated at any working point.

5. Simulation Results and Comparison of Dynamic and Static Characteristic

The ANN network with 5 hidden neurons can be used, as mentioned, in simulations of vehicle fuel consumption in WLTP homologation tests, for example. Based on vehicle speed and vehicle parameters (wheel radius, gearbox ratios, and vehicle weight), one can calculate engine speed and torque, and the ANN will calculate engine efficiency at every moment. A sample course of engine parameters is presented in

Figure 14, which allows the newly developed characteristic

ηdyn to be compared with the static characteristic

ηstat.

It can be clearly seen that the engine efficiency drops by 10% during sudden throttle opening (2). In phase (3) when the torque is constant, the increase in engine speed decreases the efficiency by up to 15%. An unusual situation occurs in phase (4–5). Sudden throttle closing results in air-fuel mixture depletion, however, the engine generates torque (due to the speed decrease). This leads to the situation that the engine efficiency reaches up to 42%, whereas its maximum efficiency in steady states is 33%. Phase (7) represents slow engine load and speed increase. In this situation, the difference between characteristics is only 4%. Phases (1,4,6,8) represent static states, so ηdyn = ηstat. This proves that static characteristics (specific fuel consumption characteristic) can only be used in quasi-static conditions. Taking into consideration the accuracy requirements of modern simulation programs, as well as the wide range of engine operation, this is not enough. Only the newly developed characteristic can calculate engine efficiency in any working state with high accuracy.