New Method for Calculating the Heating of the Conductor

Abstract

:1. Introduction

2. Selection of Cross Section of the Conductors Considering on Heating

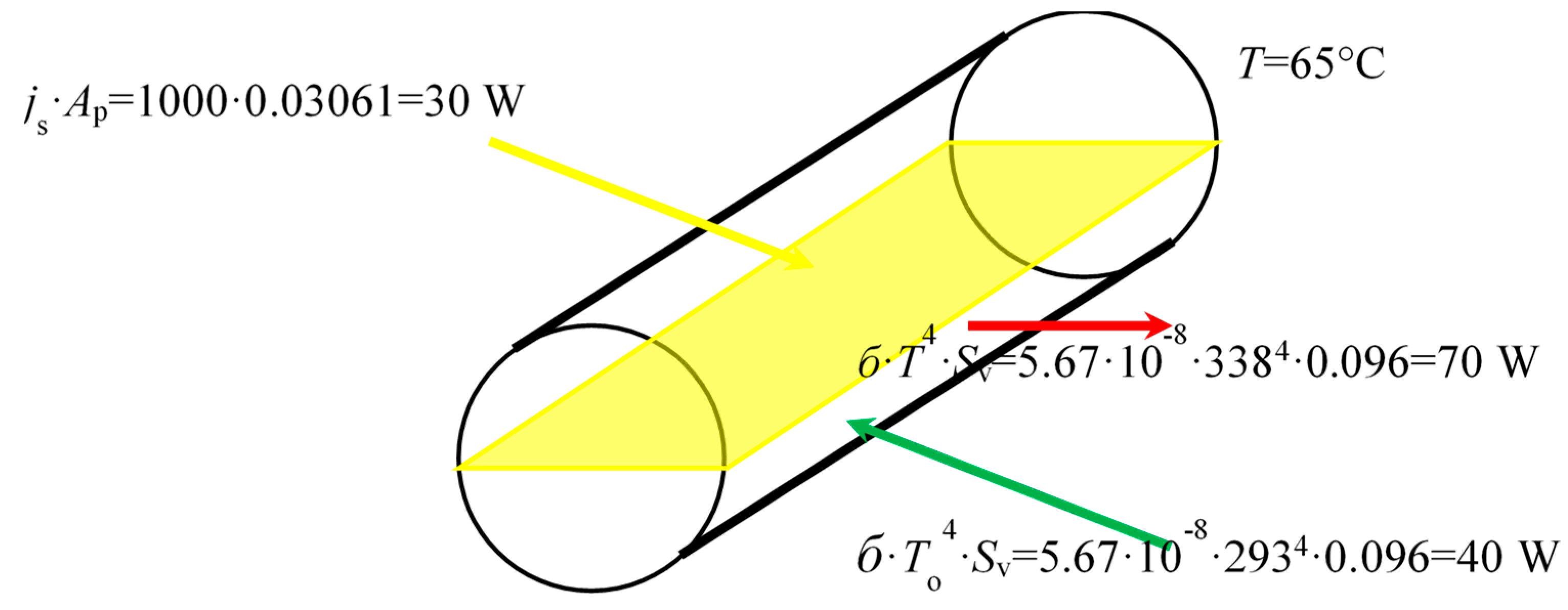

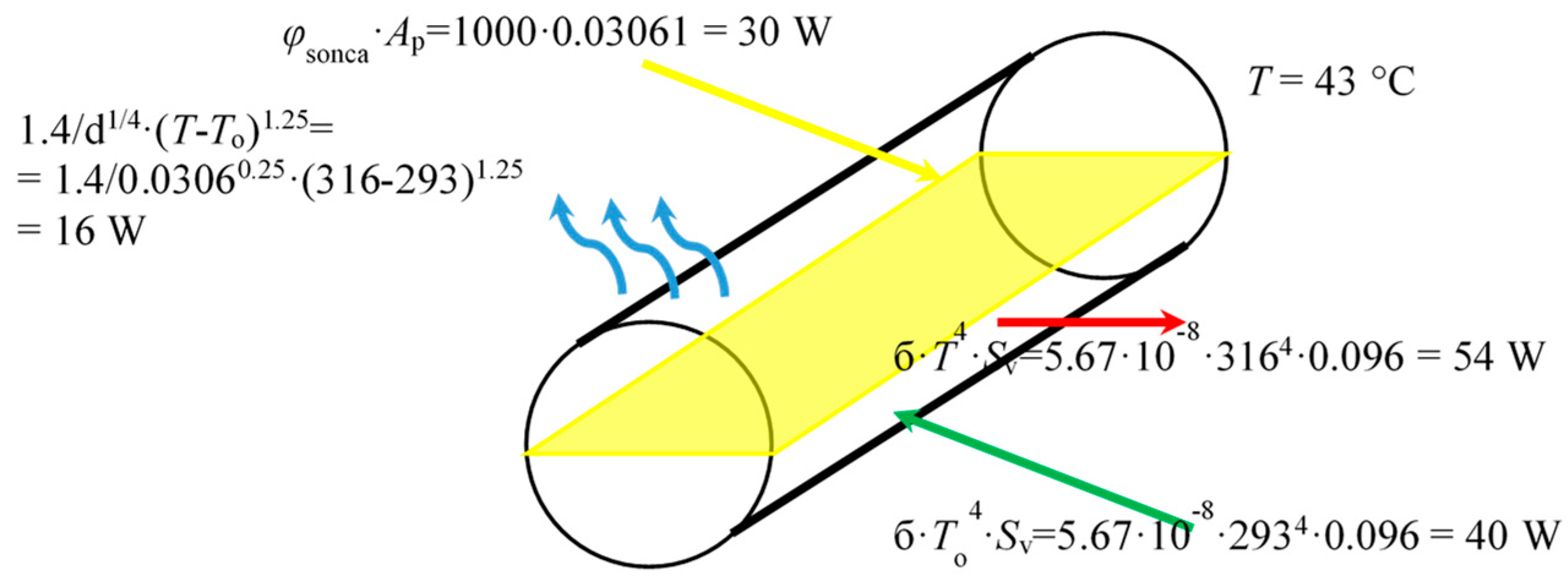

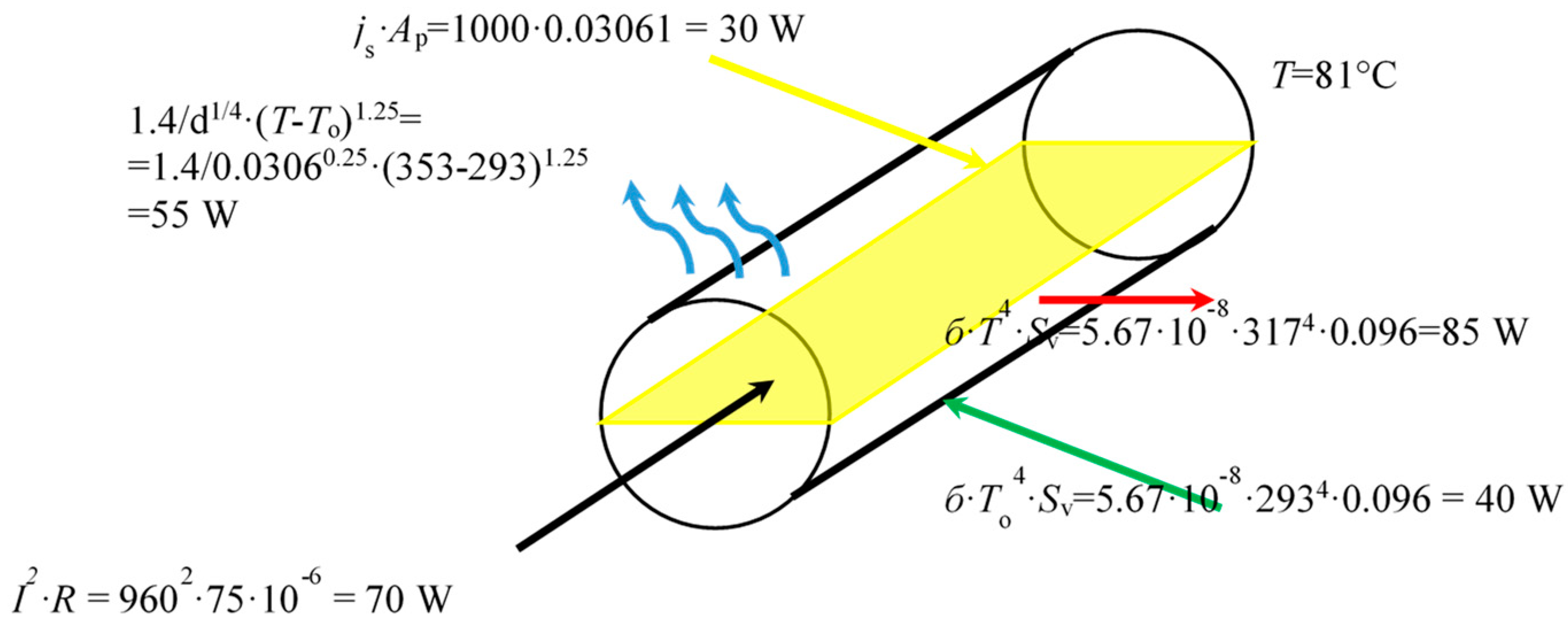

3. Stabile Operation

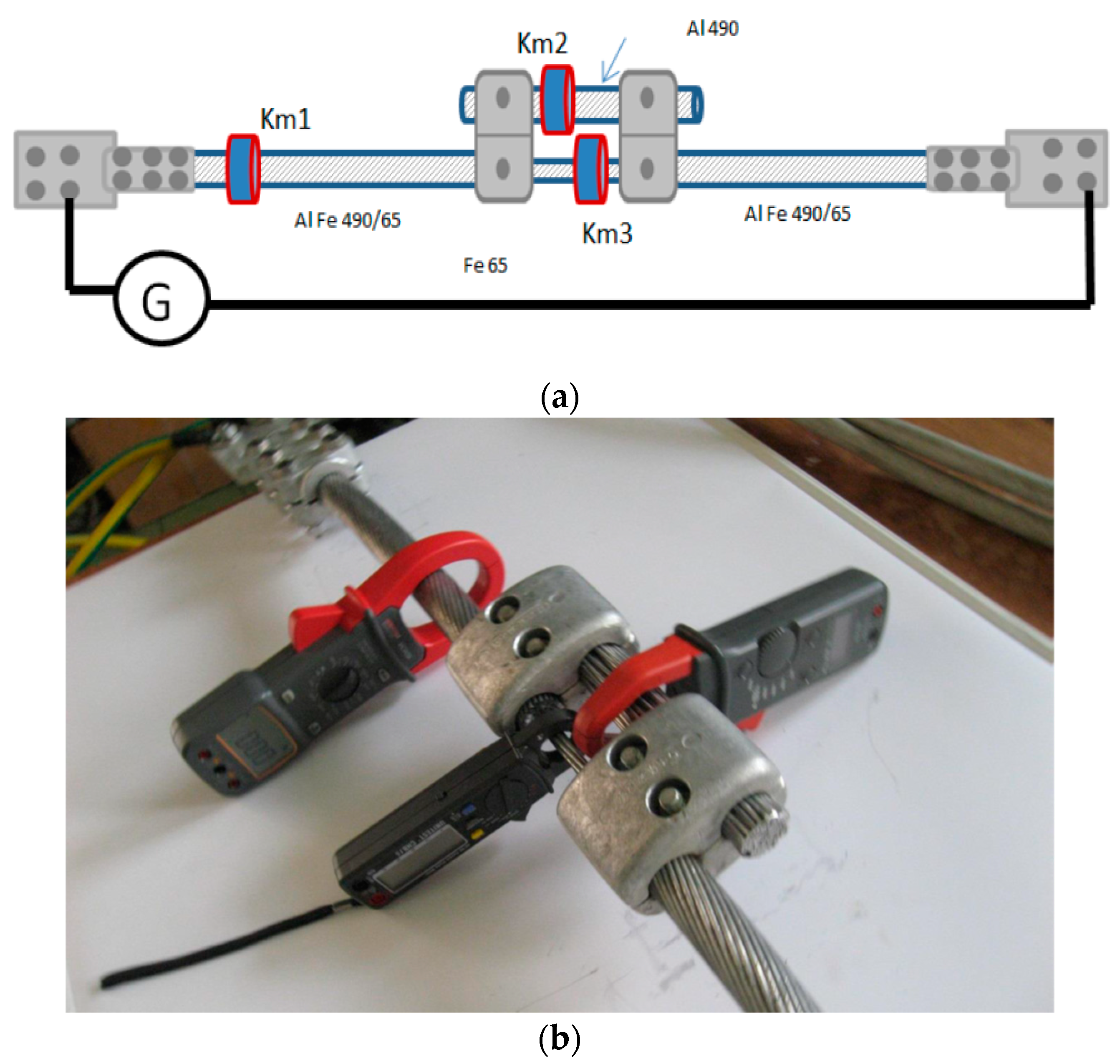

3.1. Power of Radiation

3.2. Convection

3.3. Electric Heating

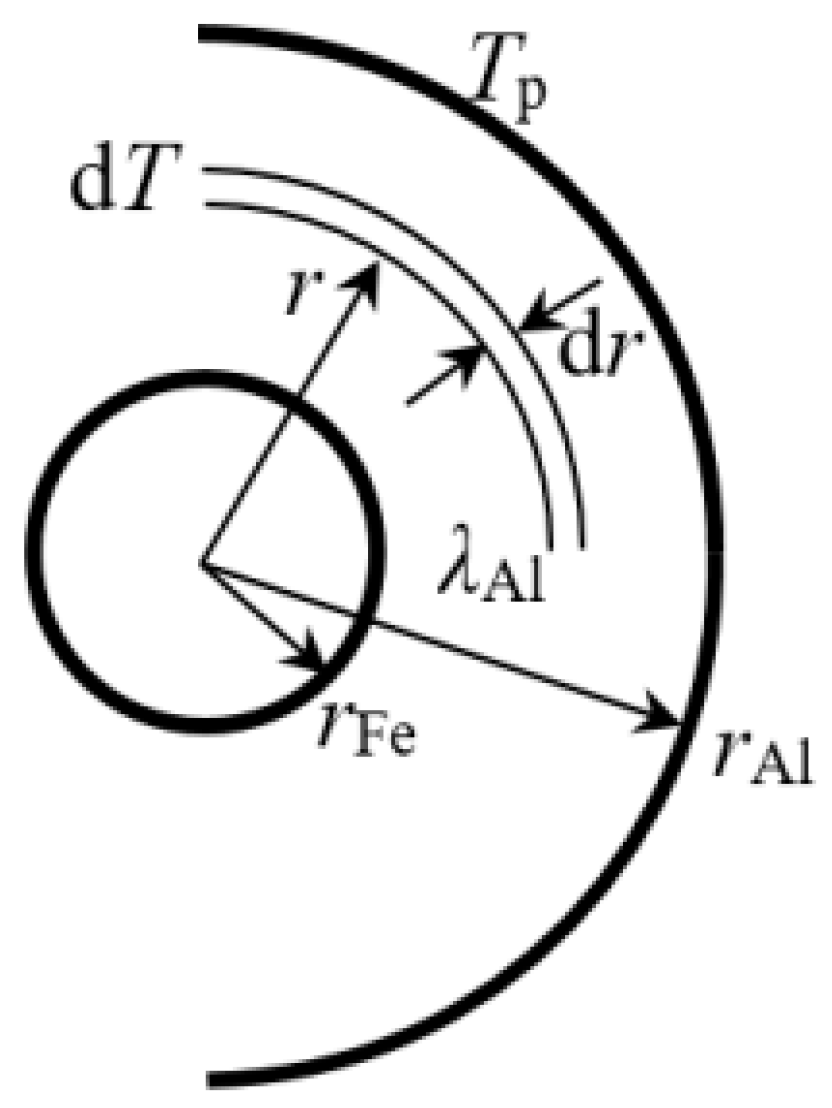

4. Heating a Conductor by Layers

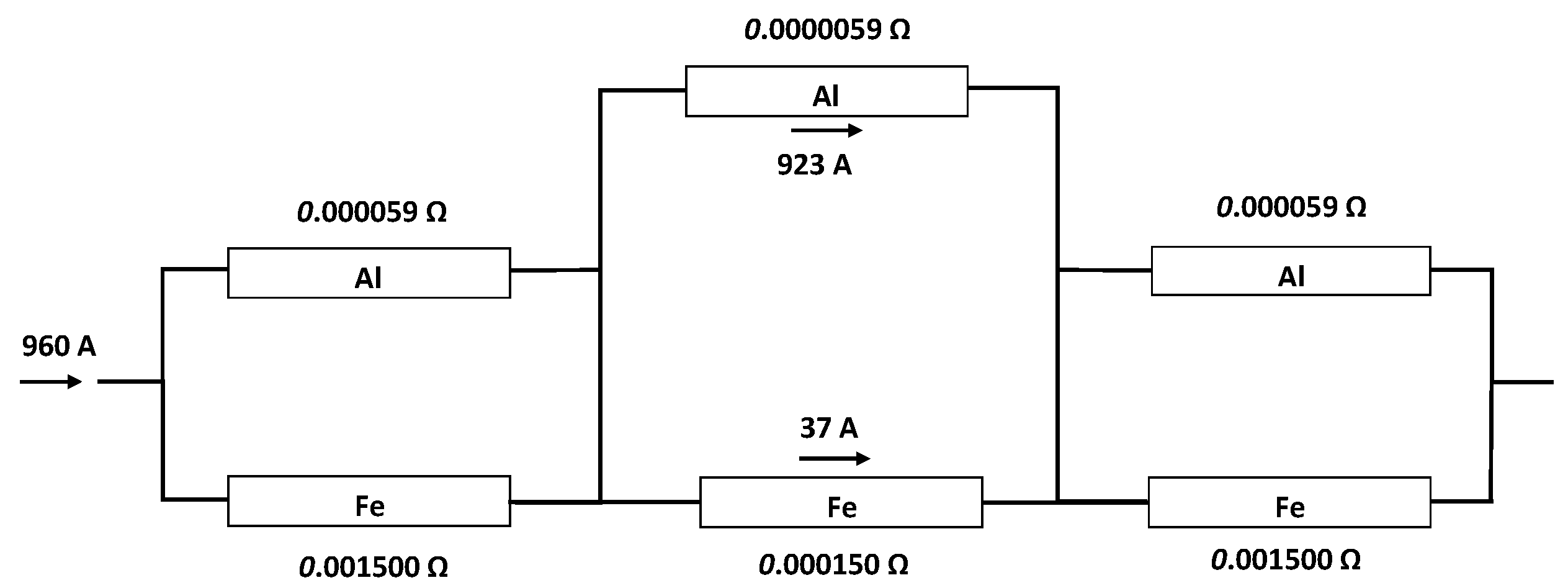

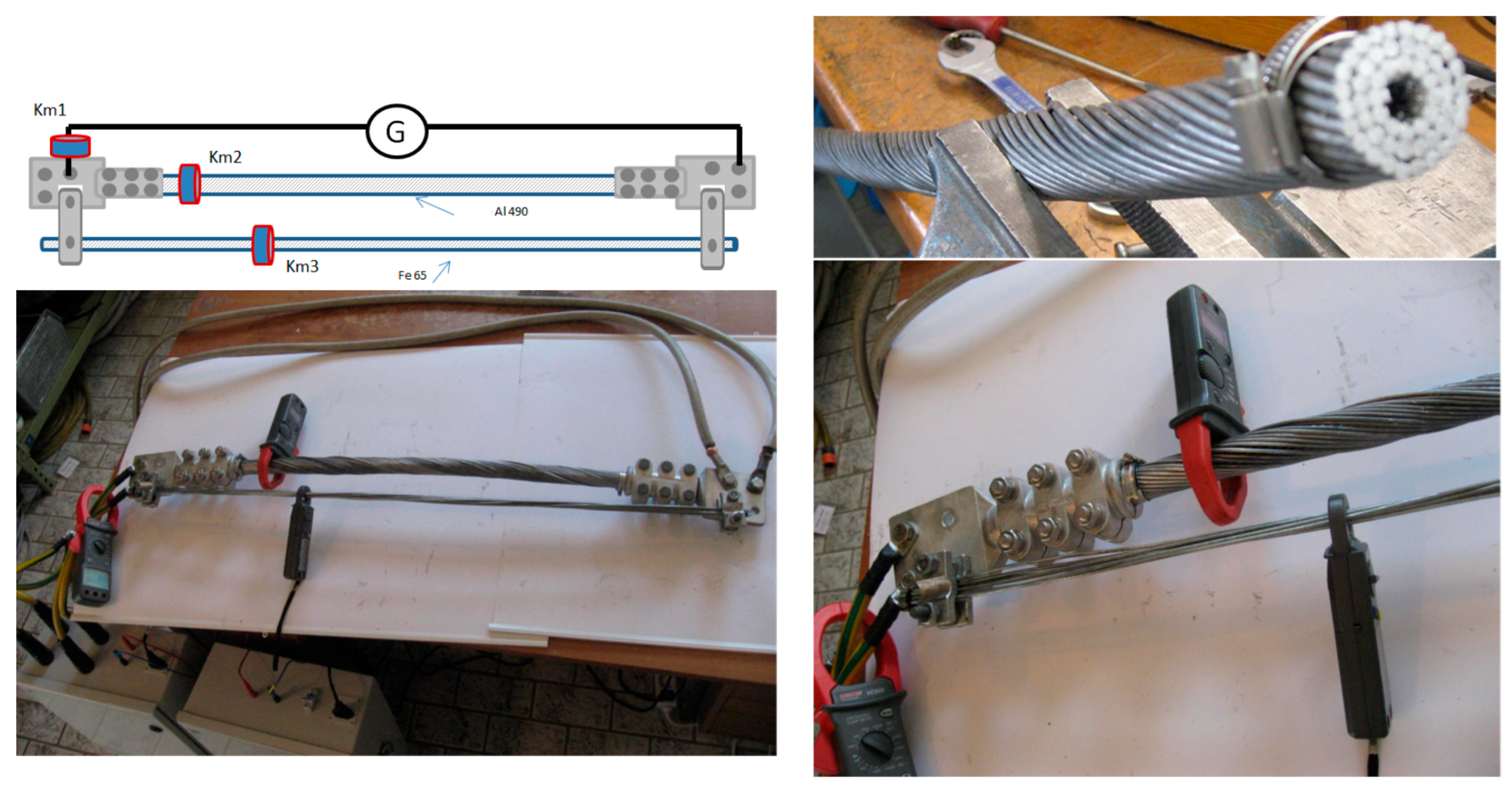

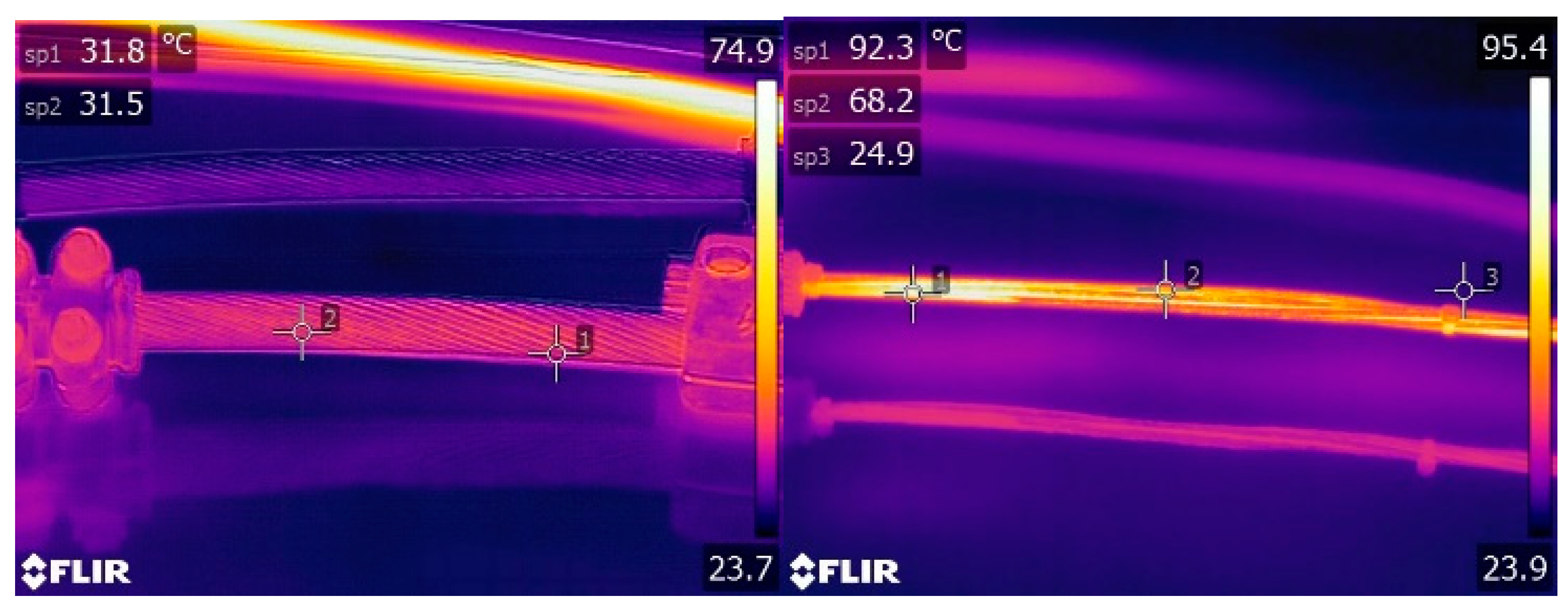

5. Measurement of Current by Layers

6. Heating of Conductor by Layers with Compliance of Air between Spaces

7. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Liu, G.; Zhou, F.; Ye, X.; Hu, Q. Error analysis on calculating conductor temperature based on outer shealth temperature of cable. In Proceedings of the IEEE Power & Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013. [Google Scholar]

- Rules on Technical Norms for the Construction of Overhead Power Lines with Nominal Voltage from 1 kV to 400 kV. Ur.l.RS, 2014, 52. Available online: https://www.uradni-list.si/glasilo-uradni-list-rs/vsebina/2014-01-2280/pravilnik-o-tehnicnih-pogojih-za-graditev-nadzemnih-elektroenergetskih-visokonapetostnih-vodov-izmenicne-napetosti-1-kv-do-400-kv (accessed on 11 May 2019).

- IEEE Standard for Calculating the Current-Temperature Relationship of Bare Overhead Conductors; IEEE: Piscataway, NJ, USA, 2012.

- Albizu, I.; Mazon, A.J.; Fernandez, E.; Bedialauneta, M. Tension—temperature behaviour of an overhead conductor in operation. In Proceedings of the IET Conference on Reliability of Transmission and Distribution Networks, London, UK, 22–24 November 2011. [Google Scholar]

- Dai, Y.; Kong, J.; Dou, H.; Cheng, Y.; Liamh, Y.; Song, A.; Xiao, K. An Improved Temperature Model for Thermal Rating Calculation of Transmission Line. In Proceedings of the IEEE International Conference on Power System Technology, Auckland, New Zealand, 30 October–2 November 2012. [Google Scholar]

- Jenkins, A.; Mekhanoshin, B.; Shkaptsov, V. Conductor Temperature Monitoring as a Tool to Increase Capacity of Transmission Network Infrastructure Elements. In Proceedings of the IEEE PES T&D, New Orleans, LA, USA, 19–22 April 2010. [Google Scholar]

- Lei, C.; Liu, G.; Liu, Y. An Accuracy Assessment Method of Calculating Cable Conductor Temperature through Surface Temperature and Actual Loading Current. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010. [Google Scholar]

- Albizu, I.; Fernandez, E.; Mazon, A.J.; Bengoechea, J. Influence of the conductor temperature error on the overhead line ampacity monitoring systems. IET Gener. Transm. Distrib. 2011, 5, 440–447. [Google Scholar] [CrossRef] [Green Version]

- Antoulinakis, F.; Chernin, D.; Zhang, P.; Lau, Y.Y. Effects of temperature dependence of electrical and thermal conductivities on the Joule heating of a one dimensional conductor. In Proceedings of the IEEE International Conference on Plasma Science (ICOPS), Denver, CO, USA, 19–23 June 2016. [Google Scholar]

- Rahman, S.A.; Kopsidas, K. Modelling of convective cooling on conductor thermal rating methods. In Proceedings of the IEEE Manchester PowerTech, Manchester, UK, 18–22 June 2017. [Google Scholar]

- Auton, J.R.; Grant, C.R.; Houghton, R.L.; Thompson, H.P. A finite element method for the prediction of Joule heating of conductors in electromagnetic launchers. IEEE Trans. Magn. 1989, 25, 63–67. [Google Scholar] [CrossRef]

- Žunec, M.; Tičar, I.; Jakl, F. Determination of Current and temperature Distribution in Overhead Conductors by Using Electromagnetic-Field Analysis tools. IEEE Trans. Power Deliv. 2006, 21, 1524–1529. [Google Scholar] [CrossRef]

- Rahim, A.A.; Abidin, I.Z. Verification of Conductor Temperature and Time to Thermal-Overload Calculations by Experiments. In Proceedings of the 2009 3rd International Conference on Energy and Environment (ICEE), Malacca, Malaysia, 7–8 December 2009; pp. 324–329. [Google Scholar]

- Reddy, S.; Chatterjee, D. Computation of Current and temperature Distribution for High Temperature Low Sag Conductors. In Proceedings of the 2014 6th IEEE Power India International Conference (PIICON), Delhi, India, 5–7 December 2014; pp. 1–6. [Google Scholar]

- Šiler, M.; Heckenbergerova, J.; Musilek, P.; Rodway, J. Sensitivity Analysis of Conductor Current—Temperature Calculations. In Proceedings of the 2013 26th IEEE Canadian Conference on Electrical and Computer Engineering (CCECE), Regina, SK, Canada, 5–8 May 2013. [Google Scholar]

- Sidea, D.; Baran, I.; Leonida, T. Weather—based assessment of the overhead line conductors thermal state. In Proceedings of the IEEE Eindhoven PowerTech, Eindhoven, The Netherlands, 29 June–2 July 2015; pp. 1–6. [Google Scholar]

- IEEE. IEEE Standard for Calculating the Current-Temperature of Bare Overhead Conductors; IEEE: Piscataway, NJ, USA, 2013; pp. 738–2012. [Google Scholar]

- Youssef, M. A New Method for Temperature measurement of Overhead Conductors. In Proceedings of the IEEE Technology Conference, Budapest, Hungary, 21–23 May 2001. [Google Scholar]

- Morgan, V.T. Effects of alternating and direct current, power frequency, temperature, and tension on the electrical parameters of ACSR conductors. IEEE Trans. Power Deliv. 2003, 18, 859–866. [Google Scholar] [CrossRef]

- Morgan, V.T.; Jakl, F.; Jakl, A. Discussion of “Effect of elevated temperatures on mechanical properties under steady-state and short-circuit conditions of overhead conductors”. IEEE Trans. Power. Deliv. 2000, 15, 1345–1347. [Google Scholar] [CrossRef]

- Santos, J.R.; Exposito, A.G.; Sanchez, F.P. Assessment of conductor thermal models for grid studies. IET Gener. Transm. Distrib. 2007, 1, 155–161. [Google Scholar] [CrossRef]

- Morgan, V.T. Thermal Behaviour of Electrical Conductors, Steady, Dynamic and Fault Current Rating, Taunton; Research Study Press: Somerset, UK, 1991. [Google Scholar]

- Rohsenow, W. Handbook of Heat Transfer Fundamentals; Mc Graw-Hill Co: New York, NY, USA, 1985. [Google Scholar]

- Thomas, L. Heat Transfer; Prentice Hall: Upper Saddle River, NJ, USA, 1992. [Google Scholar]

- Voršič, J.; Bratina, J. Electrotermia, UM FERI; Publishing printing University of Maribor: Maribor, Slovenia, 2000. [Google Scholar]

- Girshin, S.S.; Kuznetsov, E.A.; Petrova, E.V. Application of Least square method for heat balance equation solving of overhead line conductors in case of natural convection. In Proceedings of the International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Chelyabinsk, Russia, 19–20 May 2016. [Google Scholar]

- Kraut, B. Kraut’s Mechanical Manual; Buča d.o.o.: Ljubljana, Slovenia, 2017. [Google Scholar]

- Kuščer, I.; Kodre, A. Mathematics in Physics and Technology, Society of Mathematicians, Physicists and Astronomers of Slovenia; Betascript Publishing: Ljubljana, Slovenia, 1994. [Google Scholar]

- Liu, G.; Li, Y.; Qi, K.; Yu, J.; Cai, Y. Sag Calculation Difference Caused By Temperature Difference Between The Steel Core And Outer Surface Of Overhead Transmission Lines. In Proceedings of the 2016 Australasian Universities Power Engineering Conference (AUPEC), Brisbane, QLD, Australia, 25–28 September 2016; pp. 1–5. [Google Scholar]

- Morgan, V.T. Effect of surface-temperature rise on external thermal resistance of single-core and multi-core bundled cables in still air. IEE Proc. Gener. Transm. Distrib. 1994, 141, 215–218. [Google Scholar] [CrossRef]

- Voršič, Ž.; Kumperščak, V.; Pihler, J. Heating of conductors in fixed-state. In Proceedings of the Komunalna Energetika, Maribor, Slovenia, 2015; Available online: http://ke.powerlab.um.si (accessed on 5 May 2019).

| Radius | r [m] | ϑ [°C] |

|---|---|---|

| rAl3 | 0.0153 | 50.80 |

| rAl2 | 0.0119 | 50.8088 |

| rAl1 | 0.0085 | 50.8148 |

| rFe2 | 0.0051 | 50.8177 |

| rFe1 | 0.0017 | 50.8212 |

| center | 0.0000 | 50.8223 |

| Current through the Clamp Meter Km1 [A] | Current through the Clamp Meter Km2 (Aluminum—Surface) | Current through the Clamp Meter Km3 (Steel—Core) | ||

|---|---|---|---|---|

| [A] | [ / ] | [A] | [ / ] | |

| 57 | 46 | 0.81 | 12 | 0.21 |

| 100 | 84 | 0.84 | 22 | 0.22 |

| 206 | 166 | 0.81 | 43 | 0.21 |

| 408 | 323 | 0.79 | 82 | 0.20 |

| 605 | 492 | 0.81 | 122 | 0.20 |

| 810 | 650 | 0.80 | 159 | 0.20 |

| 1004 | 811 | 0.81 | 198 | 0.20 |

| 1209 | 971 | 0.80 | 250 | 0.21 |

| 1406 | 1165 | 0.83 | 310 | 0.22 |

| Current through the Clamp Meter Km1 [A] | Clamp Meter Km2 (Aluminum—Surface) | Clamp Meter Km3 (Steel—Core ro) | ||||

|---|---|---|---|---|---|---|

| I [A] | T [°C] | I [A] | T [°C] | |||

| Measured * | Calculated | Measured * | Calculated | |||

| 57 | 56 | 25.7 | 25.9 | 2 | 25.3 | 25.9 |

| 104 | 99 | 26.3 | 4 | - | 26.3 | |

| 205 | 199 | 27.4 | 27.92 | 7 | - | 27.9 |

| 414 | 397 | 34.2 | 15 | - | 34.2 | |

| 611 | 593 | 41.7 | 43.6 | 22 | 47.9 | 43.6 |

| 814 | 792 | 56.4 | 29 | - | 56.4 | |

| 1005 | 986 | 71.4 | 37 | - | 71.4 | |

| 1210 | 1176 | 90.5 | 44 | - | 90.5 | |

| 1416 | 1370 | 92.3 | 112.8 | 50 | >160 | 112.9 |

| Radius | r [m] | θ [°C] |

|---|---|---|

| rAl3 | 0.015 | 50.8 |

| rzrak4 | 0.012 | 50.807 |

| rAl2 | 0.011 | 52.319 |

| rzrak3 | 0.009 | 52.323 |

| rAl1 | 0.008 | 53.250 |

| rzrak2 | 0.006 | 53.253 |

| rFe2 | 0.005 | 53.479 |

| rzrak1 | 0.002 | 53.482 |

| rFe1 | 0.002 | 53.521 |

| center | 0.000 | 53.522 |

| Current through the Clamp Meter Km1 | Clamp Meter Km2 (Aluminum—Surface) | Clamp Meter Km3 (Steel—Core ro) | ||||||

|---|---|---|---|---|---|---|---|---|

| Current | Temperature [°C] | Current | Temperature [°C] | |||||

| [A] | [A] | [ / ] | Measured | Calculated | [A] | [ / ] | Measured | Calculated |

| 57 | 56 | 98.25 | 25.7 | 25.9 | 2 | 3.51 | 25.3 | 26.1 |

| 104 | 99 | 95.19 | - | 26.3 | 4 | 3.85 | - | 26.1 |

| 205 | 199 | 97.07 | 27.4 | 27.9 | 7 | 3.41 | - | 27.9 |

| 414 | 397 | 95.89 | - | 34.3 | 15 | 3.62 | - | 37.1 |

| 611 | 593 | 97.05 | 41.7 | 43.9 | 22 | 3.60 | 47.9 | 50.9 |

| 814 | 792 | 97.30 | - | 57.3 | 29 | 3.56 | - | 73.9 |

| 1005 | 986 | 98.11 | - | 73.2 | 37 | 3.68 | - | 103.3 |

| 1210 | 1176 | 97.19 | - | 94.3 | 44 | 3.64 | - | 144.4 |

| 1416 | 1370 | 96.75 | 92.3 | 119.6 | 50 | 3.53 | >160 | 197.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voršič, Ž.; Maruša, R.; Pihler, J. New Method for Calculating the Heating of the Conductor. Energies 2019, 12, 2769. https://doi.org/10.3390/en12142769

Voršič Ž, Maruša R, Pihler J. New Method for Calculating the Heating of the Conductor. Energies. 2019; 12(14):2769. https://doi.org/10.3390/en12142769

Chicago/Turabian StyleVoršič, Žiga, Robert Maruša, and Jože Pihler. 2019. "New Method for Calculating the Heating of the Conductor" Energies 12, no. 14: 2769. https://doi.org/10.3390/en12142769