A Pressure-Coordinated Control for Vehicle Electro-Hydraulic Braking Systems

Abstract

:1. Introduction

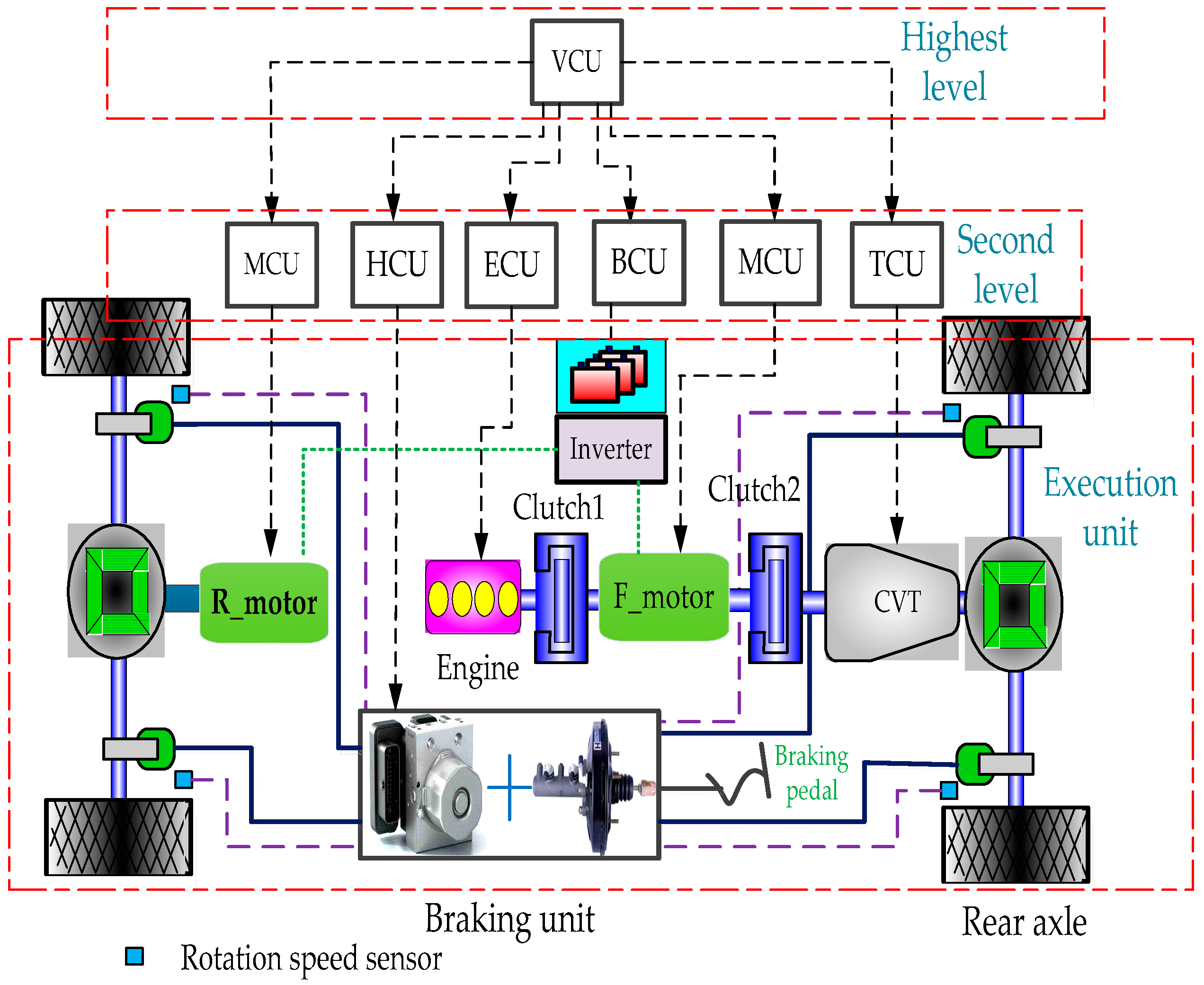

2. Electro-Hydraulic Braking System Structure and Braking Force Control Strategy

2.1. Structure and Function Design of the Braking System

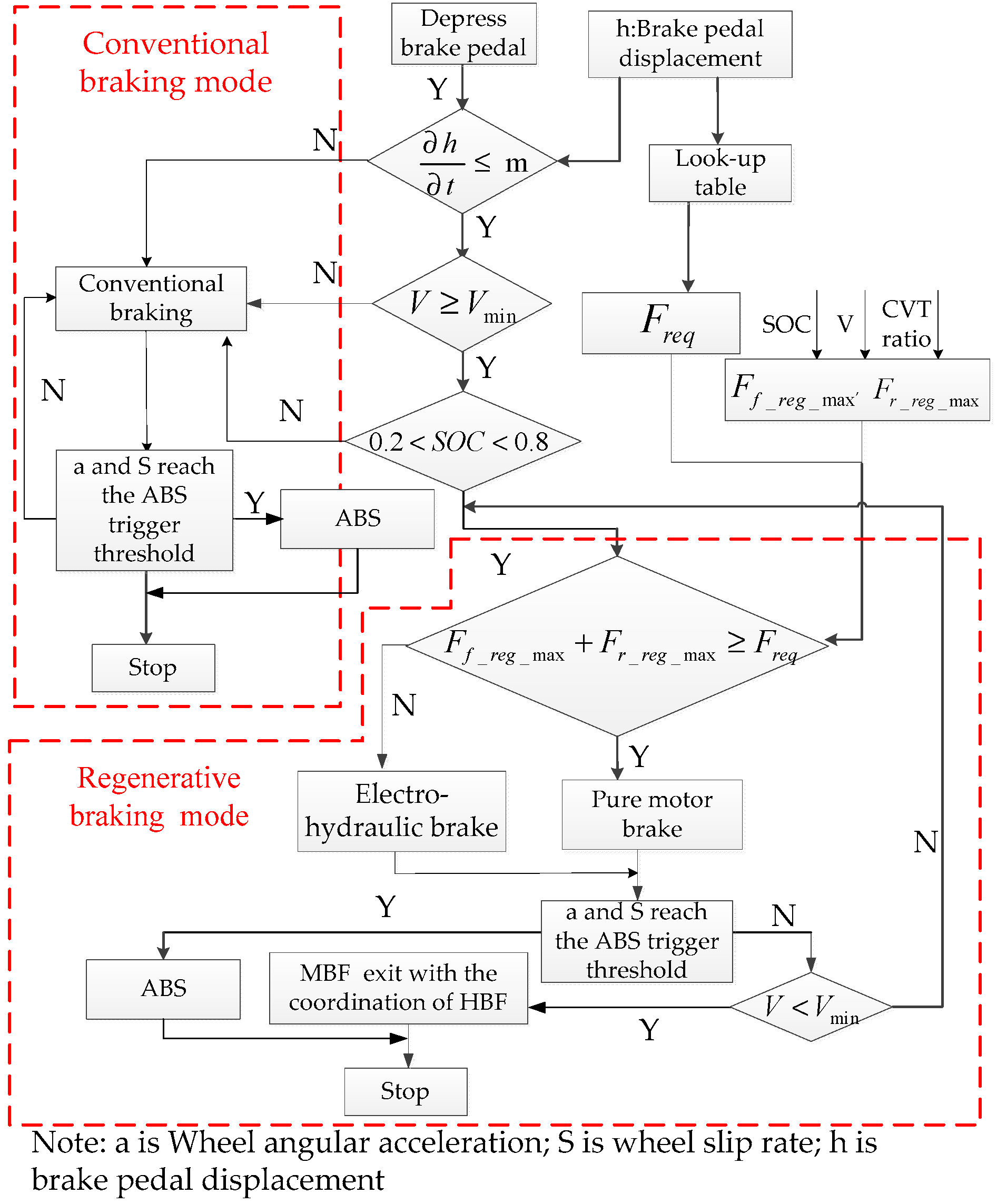

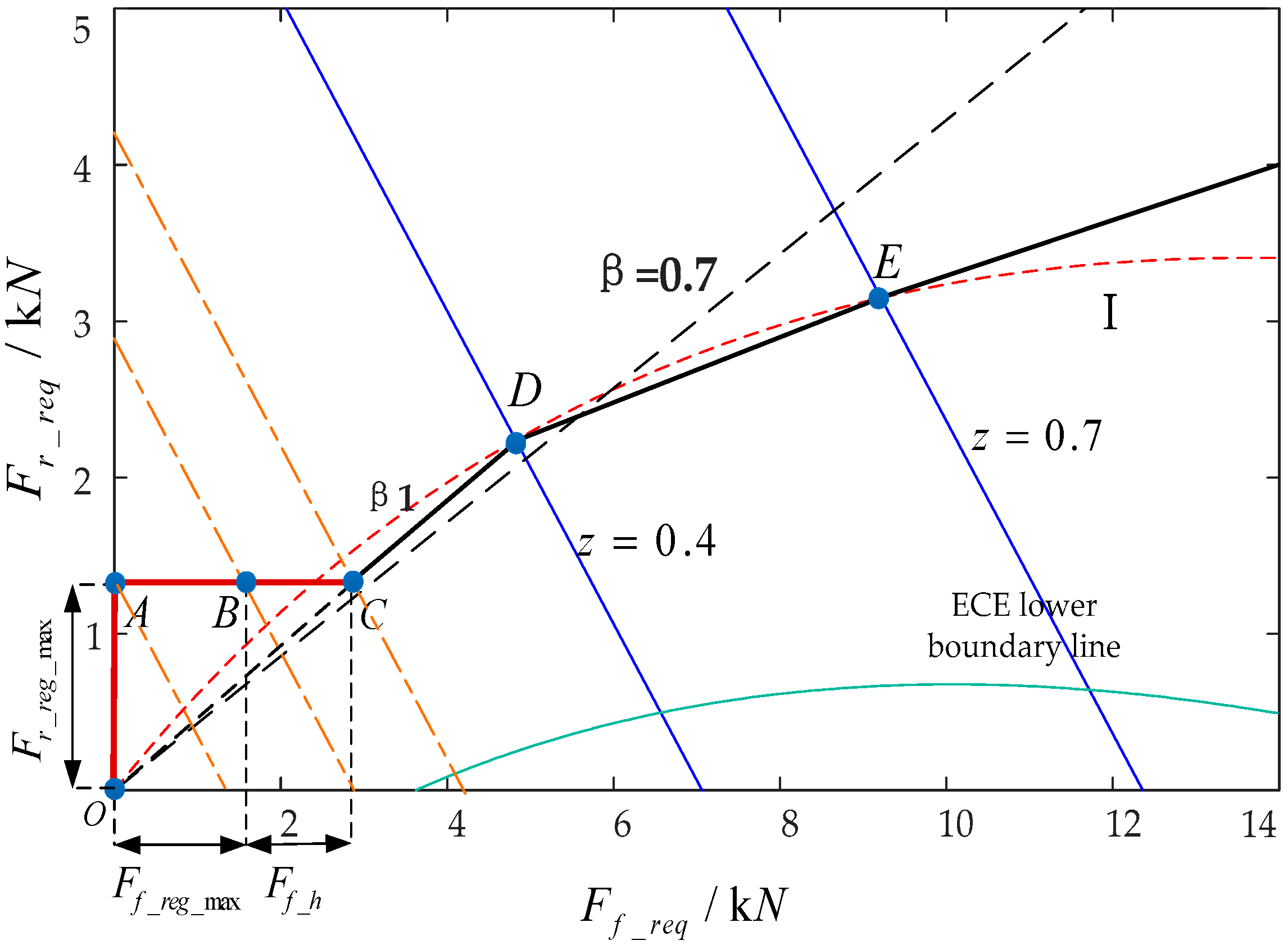

2.2. Braking Force Control Strategy of Pressure Coordinated Control System

2.3. Electro-Hydraulic Braking Pressure Coordinated Control Strategy

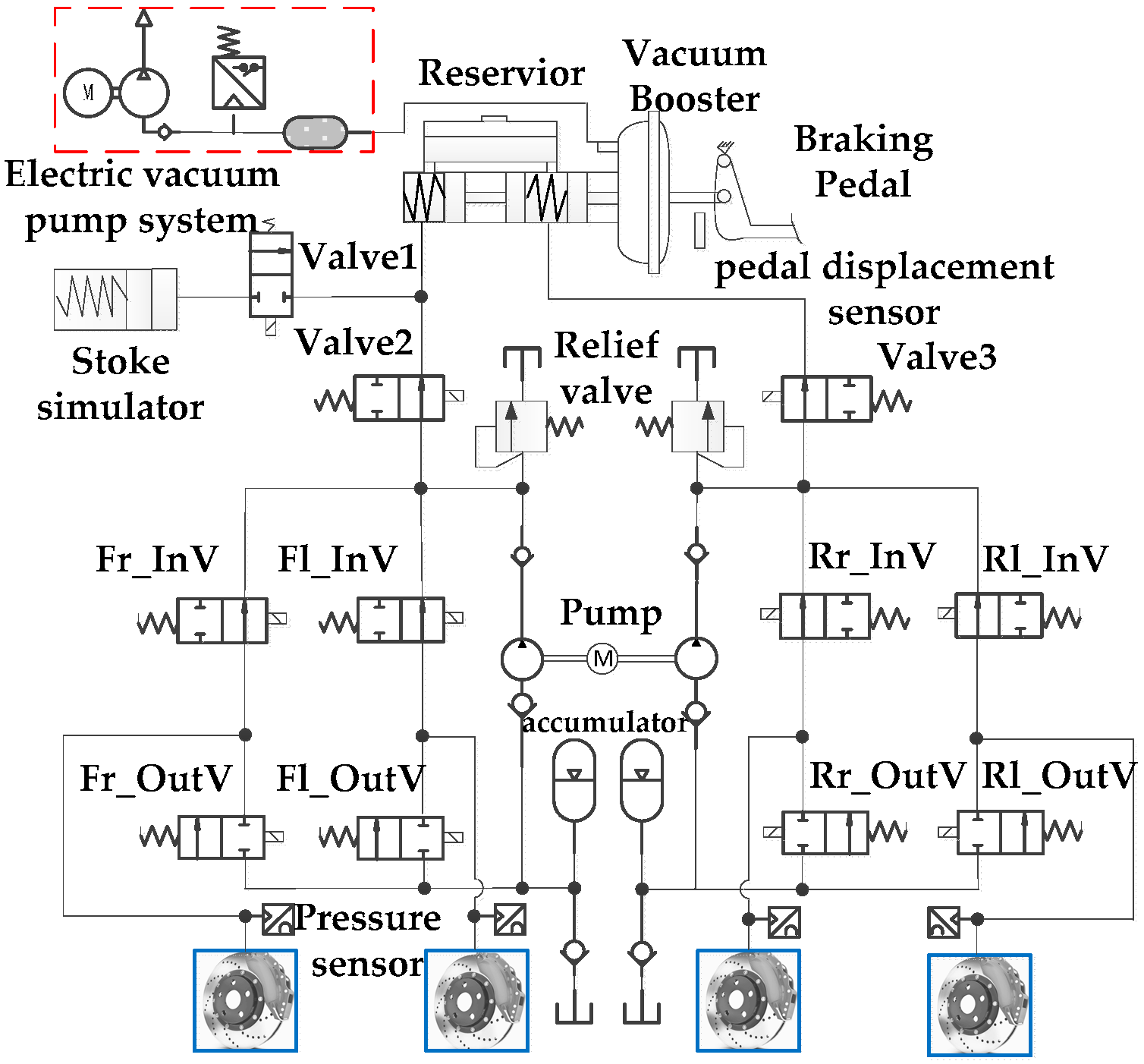

3. Hydraulic Braking System Design and Pressure Control

3.1. Structure Design of Braking System

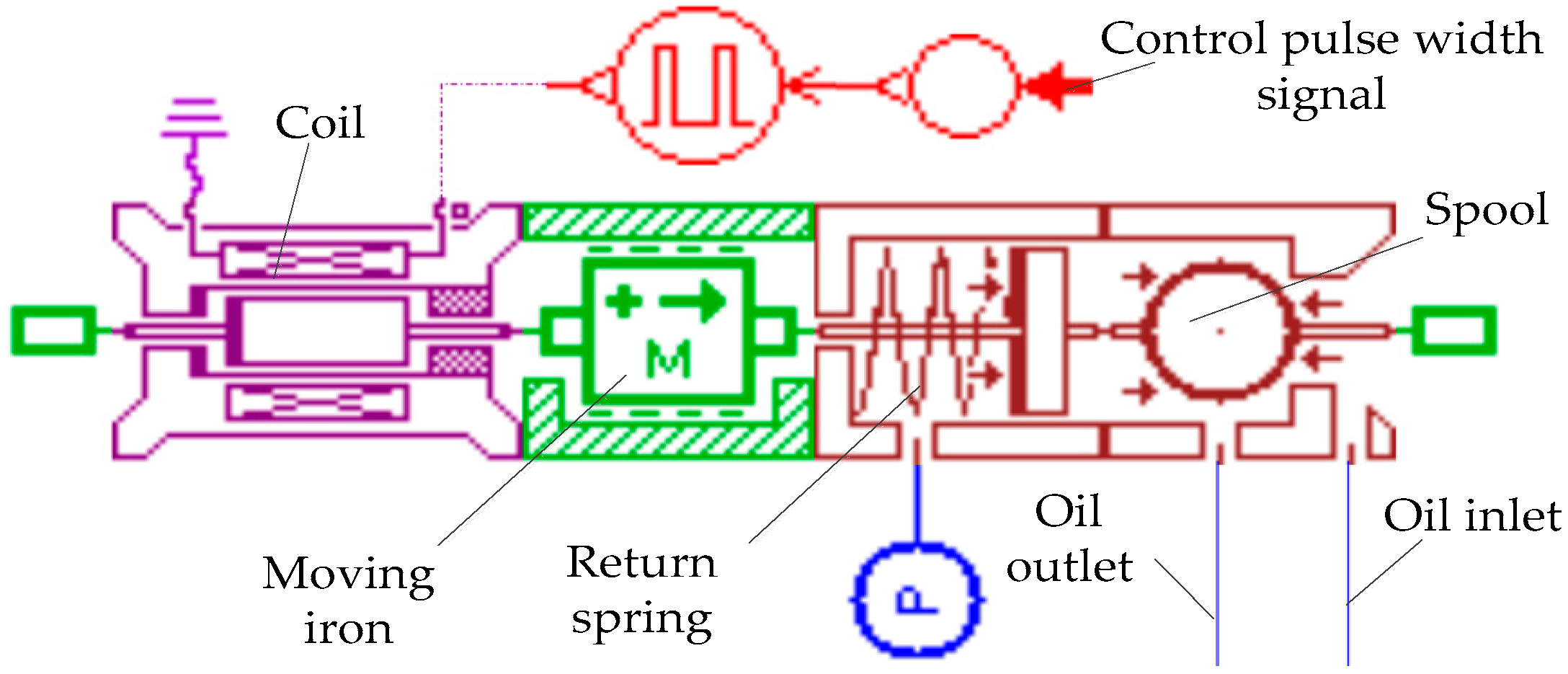

3.2. Mathematical Model of High-Speed Switch Valve

3.3. Brake System Model

3.3.1. Establish the Vacuum Booster Mathematical Model

3.3.2. Establish the Dynamic Model of the Brake Master Cylinder

3.3.3. The Brake Fluid Dynamics Model

3.3.4. The Reflux Pump Model

3.3.5. Hydraulic Pipeline Model

3.3.6. Dynamic Model of Brake Wheel Cylinder Piston

3.4. Model of PID Controller

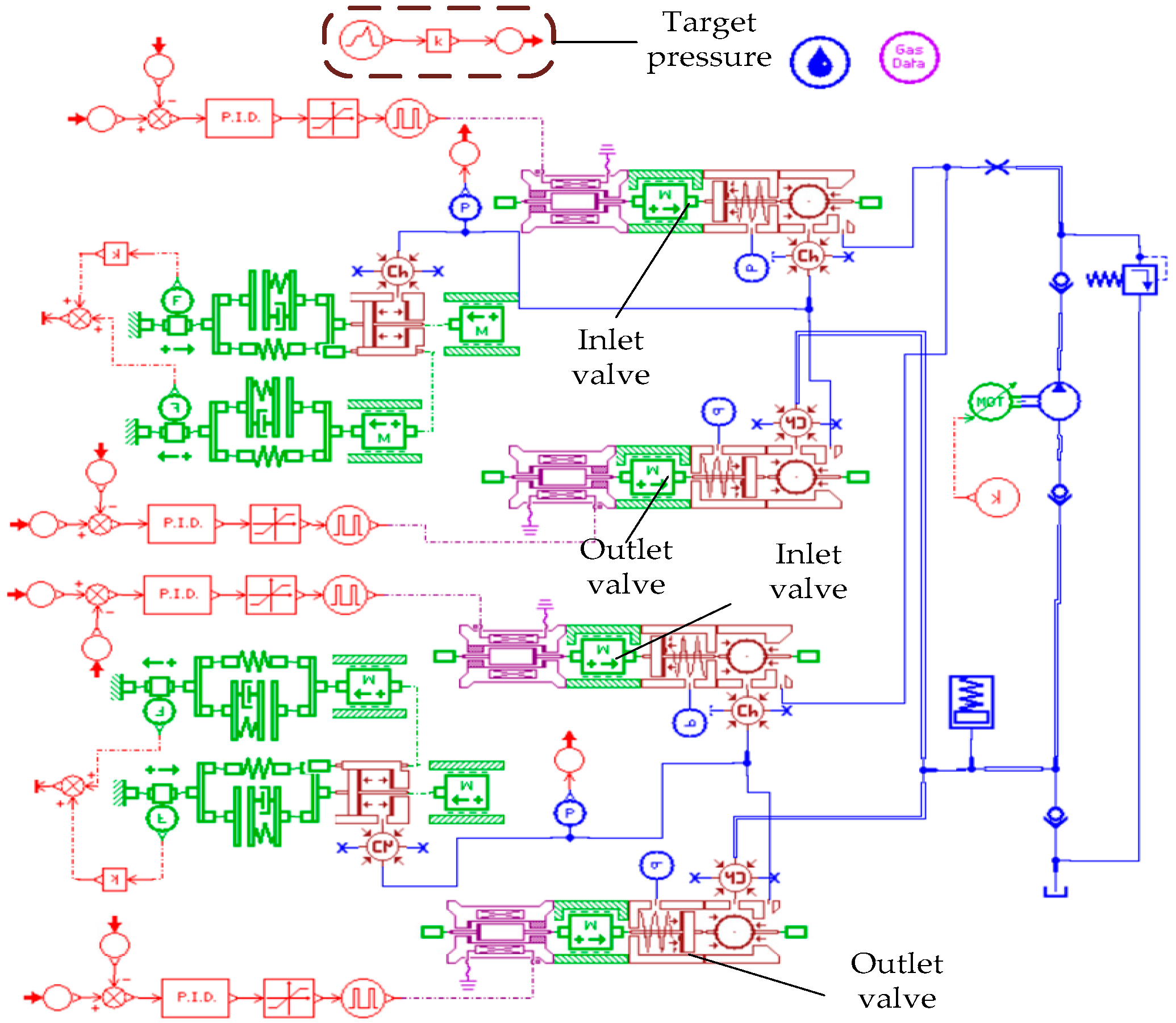

3.5. Simulation Model of the Braking System

3.6. Simulation and Analysis of Dynamic Characteristics of Braking System

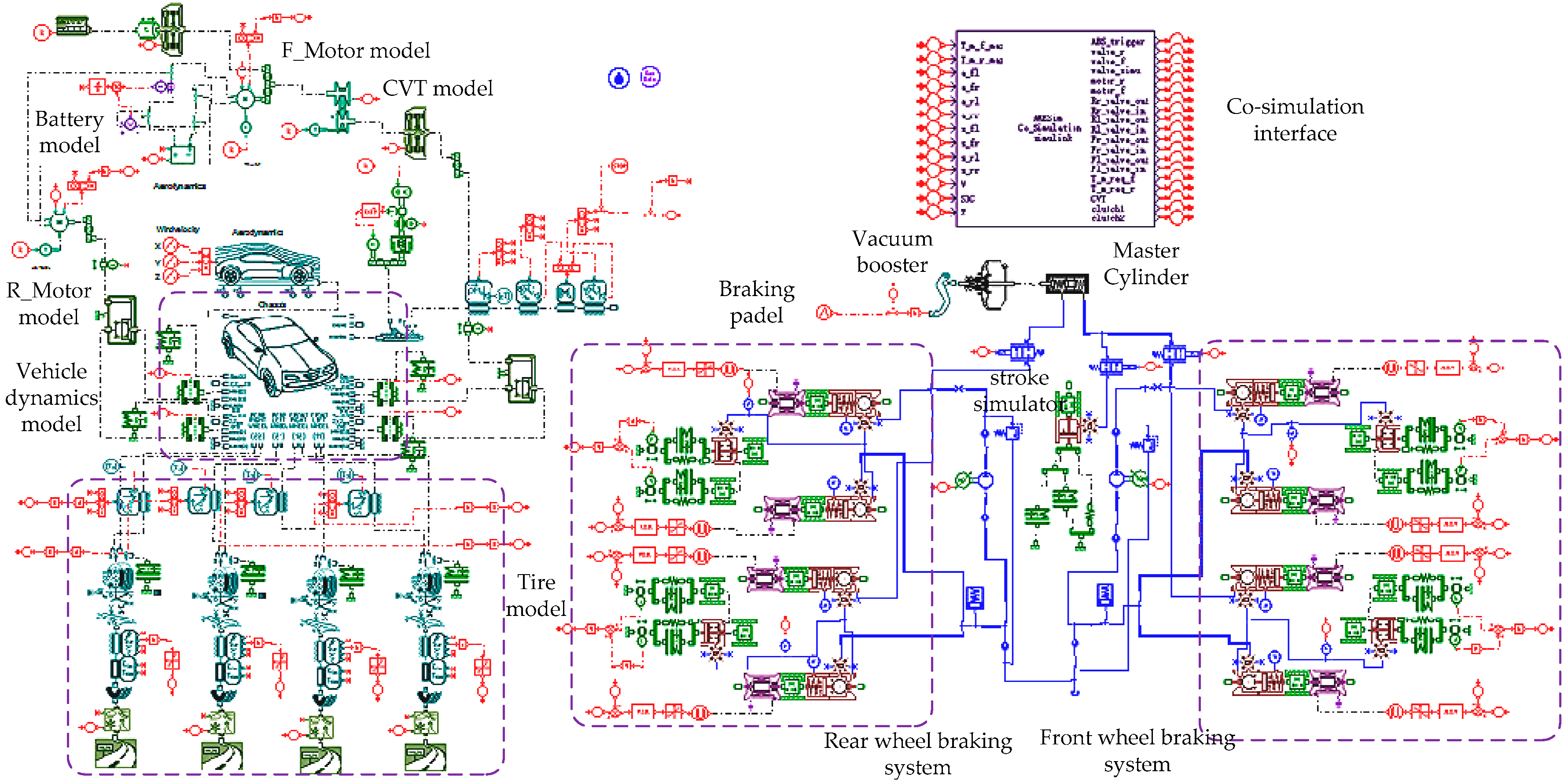

4. Establishment of Simulation Model of Pressure Coordinated Control System Based on the Vehicle

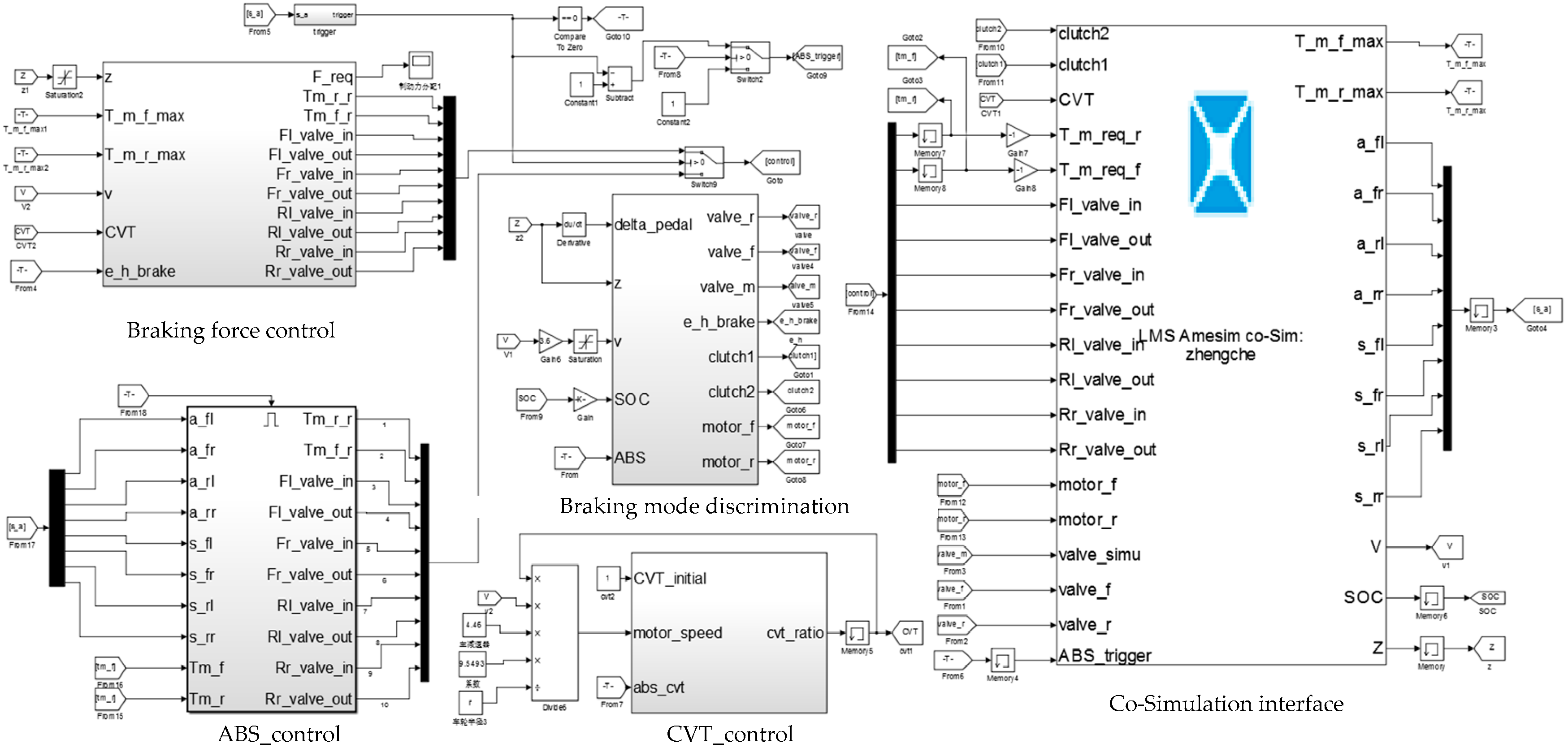

4.1. Model of Control System

4.2. Establishment of Co-Simulation Model

5. Simulation and Analysis of Dynamic Characteristics of Braking System Based on the Vehicle

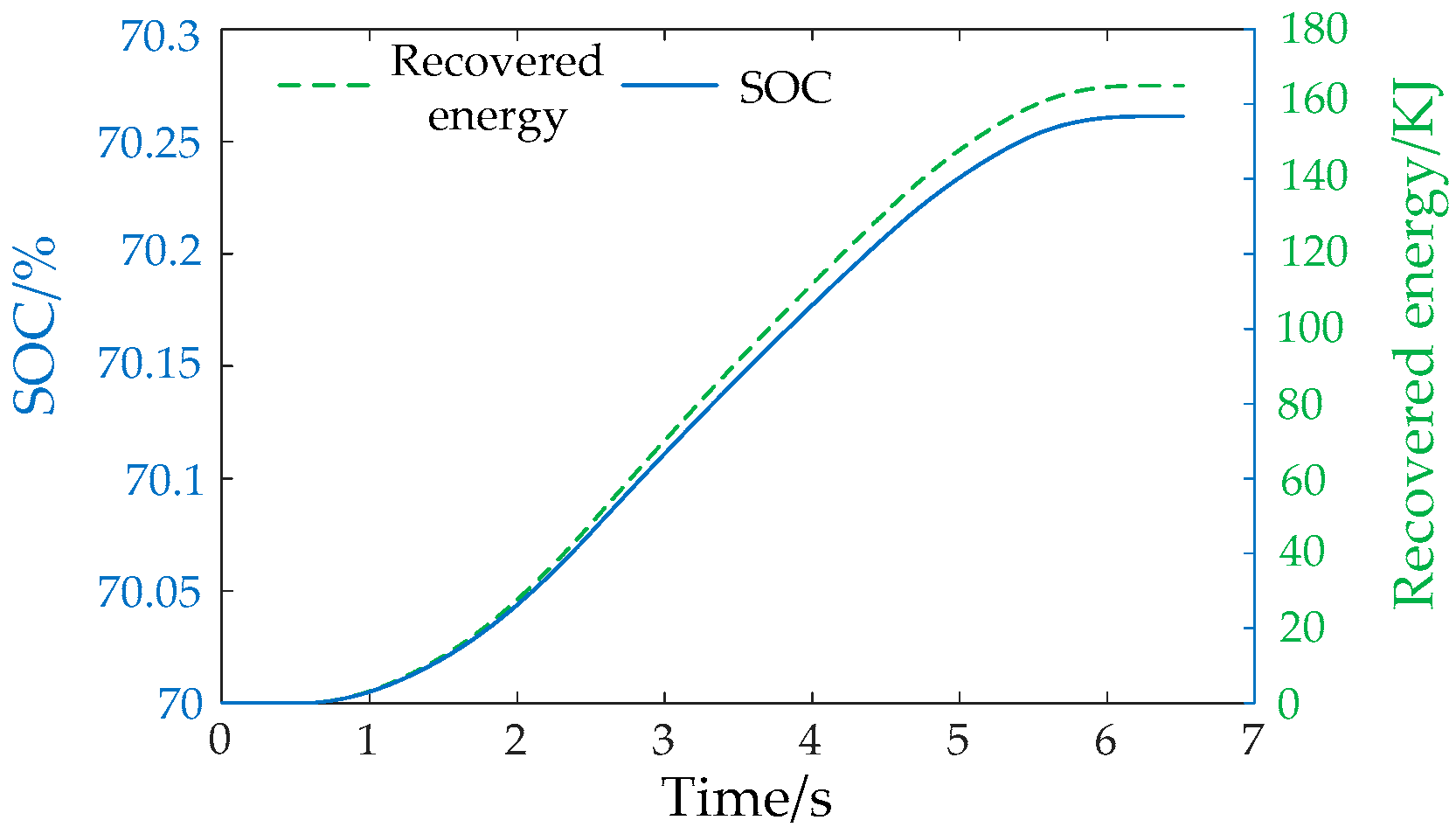

5.1. Simulation and Analysis under Variable Braking Strength

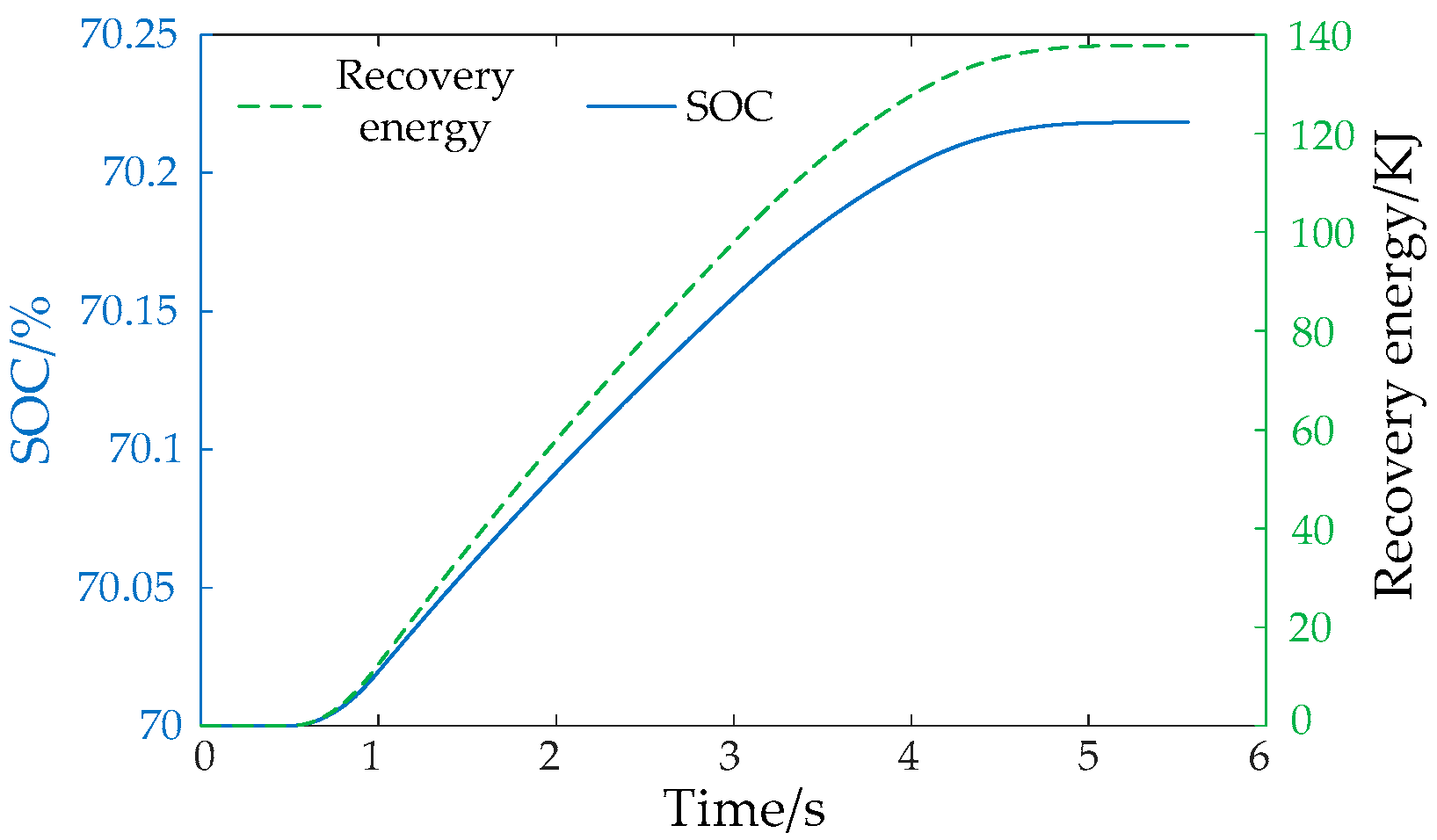

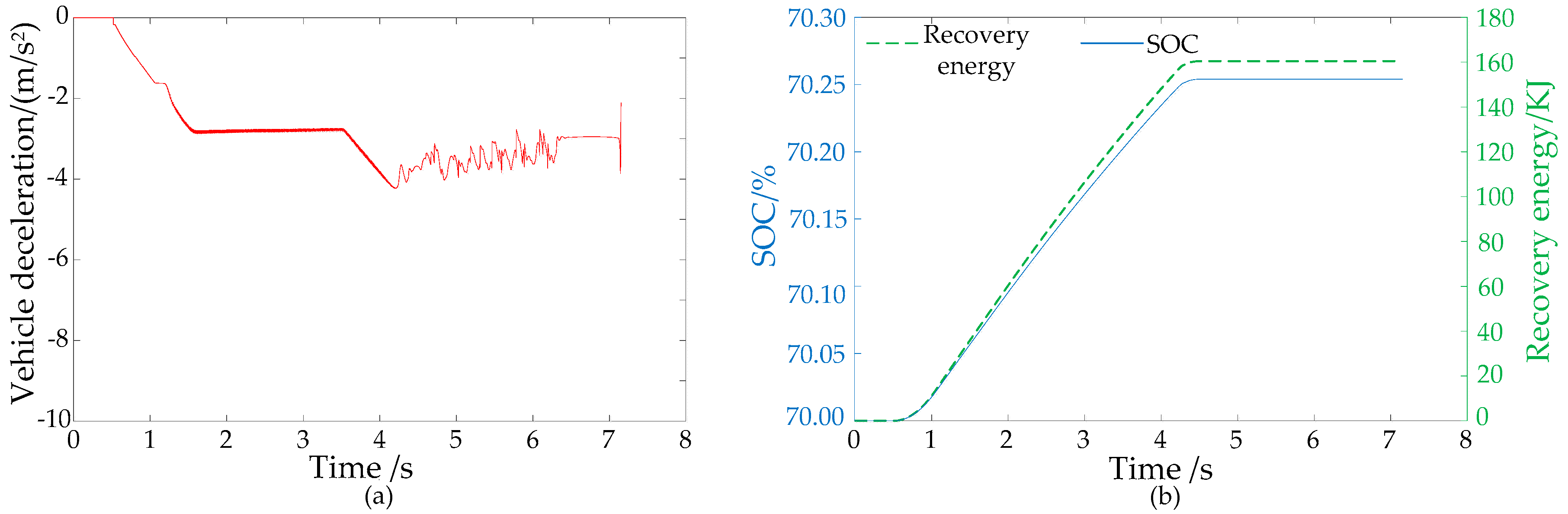

5.2. Simulation and Analysis under Constant Braking Strength

5.3. Simulation and Analysis under Conventional Braking

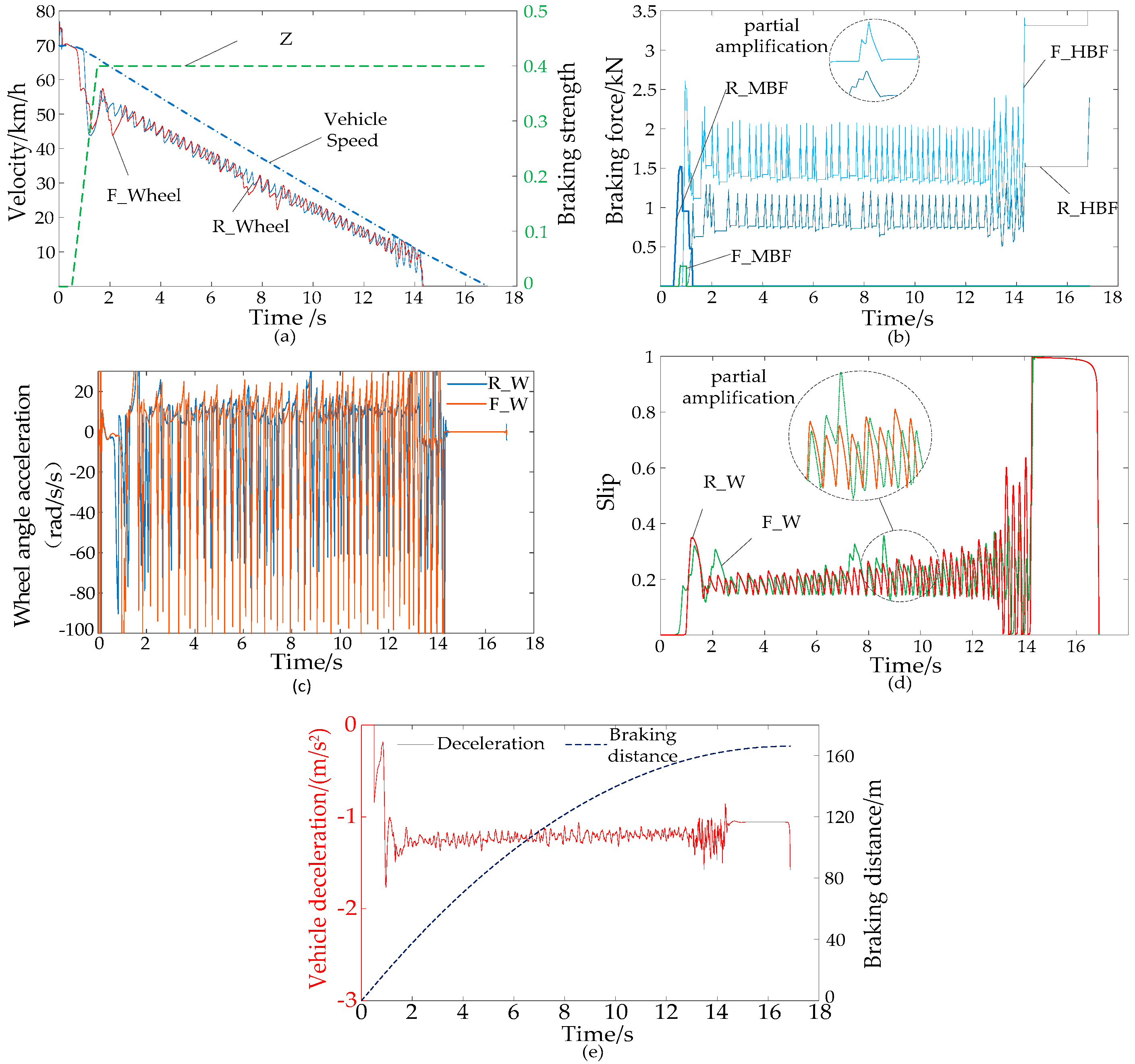

5.4. Simulation and Analysis of ABS

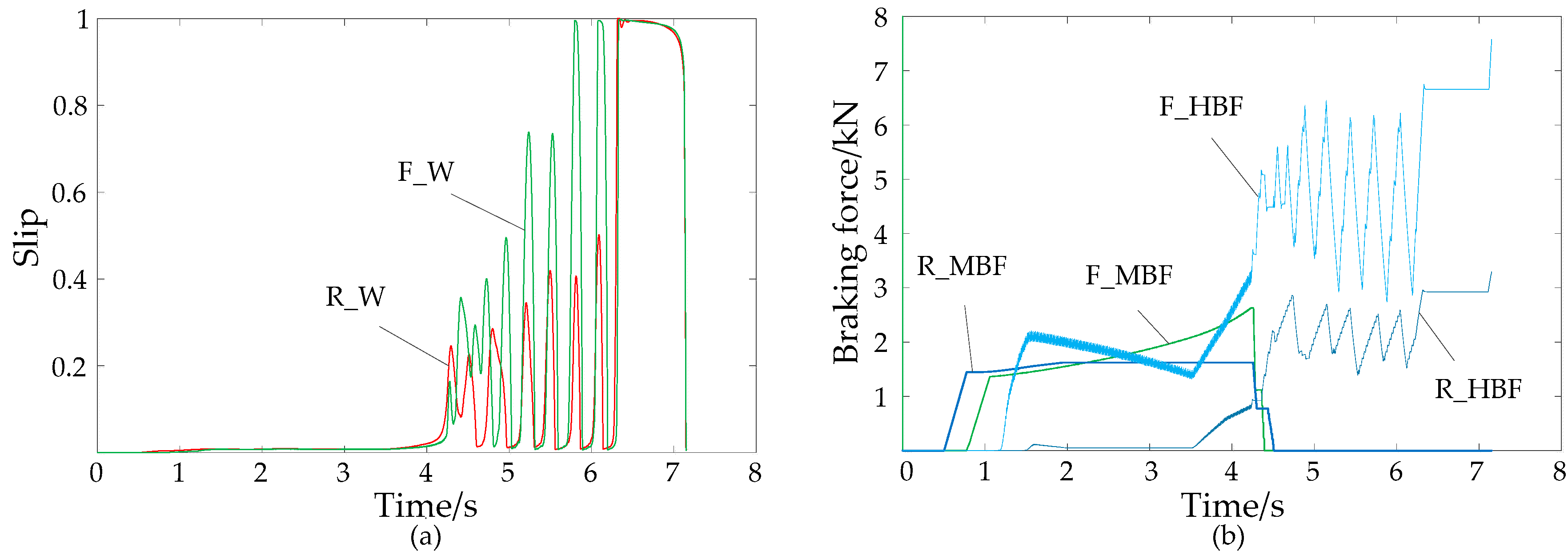

5.5. Analysis and Simulation of Integrated Braking for the System

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Khastgir, S.; Warule, P. Regenerative Braking Strategy for an Unaltered Mechanical Braking System of a Conventional Vehicle Converted into a Hybrid Vehicle. Available online: https://www.sae.org/publications/technical-papers/content/2013-26-0155/ (accessed on 16 August 2018).

- Lian, Y.F.; Tian, Y.T.; Hu, L.L.; Yin, C. A new braking force distribution strategy for electric vehicle based on regenerative braking strength continuity. J. Cent. South Univ. 2013, 20, 3481–3489. [Google Scholar] [CrossRef]

- Liang, Y.; Liang, C.; Zhou, F.; Liu, M.; Zhang, Y.; Wei, W. Simulation and analysis of potential of energy-saving from braking energy recovery of electric vehicle. J. Jilin Univ. 2013, 43, 6–11. [Google Scholar]

- Liu, Y.; Sun, Z.; Wang, M. Decoupled Electro-Hydraulic Brake System for New Energy Vehicles. Available online: http://dl5.tongji.edu.cn/handle/310200/12185 (accessed on 16 August 2018).

- Fujimoto, H.; Harada, S. Model-based range extension control system for electric vehicles with front and rear driving–braking force distributions. IEEE Trans. Ind. Electron. 2015, 62. [Google Scholar] [CrossRef]

- Hernández, M.I.G.; Pérez, B.A.; Sánchez, J.S.M.; Álvarez, E.C. Optimized regenerative friction braking distribution in an electric vehicle with four in-wheel motors. Adv. Microsyst. Automot. Appl. 2013, 2013. [Google Scholar] [CrossRef]

- Itani, K.; Bernardinis, A.D.; Khatir, Z.; Khatir, A. Comparison between two braking control methods integrating energy recovery for a two-wheel front driven electric vehicle. Energy Convers. Manag. 2016, 122, 330–343. [Google Scholar] [CrossRef]

- Nakamura, E.; Soga, M.; Sakai, A.; Otomo, A.; Kobayashi, T. Development of Electronically Controlled Braking System for Hybrid Vehicle. Available online: https://www.sae.org/publications/technical-papers/content/2002-01-0300/ (accessed on 16 August 2018).

- Ko, J.W.; Ko, S.Y.; Kim, I.S.; Hyun, D.Y.; Kim, H.S. Co-operative control for regenerative braking and friction braking to increase energy recovery without wheel lock. Int. J. Auto. Technol. 2014, 15, 253–262. [Google Scholar] [CrossRef]

- Peeie, M.H.B.; Ogino, H.; Oshinoya, Y. Skid control of a small electric vehicle with two in-wheel motors: Simulation model of ABS and regenerative brake control. Int. J. Crashworth. 2016, 21, 396–406. [Google Scholar] [CrossRef]

- Li, L.; Li, X.; Wang, X.; Liu, Y.; Song, J.; Ran, X. Transient switching control strategy from regenerative braking to anti-lock braking with a semi-brake-by-wire system. Veh. Syst. Dyn. 2016, 54, 231–257. [Google Scholar] [CrossRef]

- Cheon, J.S. Brake By Wire System Configuration and Functions using Front EWB (Electric Wedge Brake) and Rear EMB (Electro-Mechanical Brake) Actuators. Available online: https://www.sae.org/publications/technical-papers/content/2010-01-1708/ (accessed on 16 August 2018).

- Ko, J.; Ko, S.; Son, H.; Yoo, B.; Cheon, J.; Kim, H. Development of Brake System and Regenerative Braking Cooperative Control Algorithm for Automatic-Transmission-Based Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2015, 64, 431–440. [Google Scholar] [CrossRef]

- Wang, M.; Sun, Z.; Zhuo, G.; Cheng, P. Maximum Braking Energy Recovery of Electric Vehicles and Its Influencing Factors. Available online: http://en.cnki.com.cn/Article_en/CJFDTOTAL-TJDZ201204016.htm (accessed on 16 August 2018).

- Tao, R.; Zhang, H.; Fu, D.; Xia, Q. Simulation of ABS hydraulic system and optimization of solenoid valve. Trans. CSAE 2010, 26, 135–139, (In Chinese with English Abstract). [Google Scholar]

- Du, Y.C.; Qin, C.A.; You, S.Y.; Xia, H.C. Efficient coordinated control of regenerative braking with pneumatic anti-lock braking for hybrid electric vehicle. Sci. China Technol. Sc. 2017, 60, 399–411. [Google Scholar] [CrossRef]

| Parameter (Units) | Value |

|---|---|

| Vehicle mass (kg) | 1800 |

| Rolling radius (m) | 0.36 |

| Front motor rated/peak power (kW) | 14/28 |

| Rear motor rated/peak power (kW) | 13.5/27 |

| Battery capacity (Ah) | 38.43 |

| Parameter (Units) | Value |

|---|---|

| Front/rear braking cylinder diameter (mm) | 38.34/60.12 |

| Front/rear braking disc radius (mm) | 120/128 |

| Master cylinder diameter (mm) | 22.2 |

| Regulating valve pressure (MPa) | 11 |

| Modulation frequency of high-speed switch valve (Hz) | 90 |

| Pump displacement (mL/r) | 1 |

| Pump-motor rotating speed (r/min) | 2500 |

| Parameter | Value |

|---|---|

| Return spring stiffness | 1.6 N/mm |

| Moving iron mass | 15 g |

| Coil turns | 380 |

| Coil resistance | 5 Ω |

| Initial air gap | 0.3 mm |

| Spool displacement | 0.22 mm |

| Voltage | 12 V |

| Spring preload force | 7 N |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Li, G.; Zhang, Q. A Pressure-Coordinated Control for Vehicle Electro-Hydraulic Braking Systems. Energies 2018, 11, 2336. https://doi.org/10.3390/en11092336

Yang Y, Li G, Zhang Q. A Pressure-Coordinated Control for Vehicle Electro-Hydraulic Braking Systems. Energies. 2018; 11(9):2336. https://doi.org/10.3390/en11092336

Chicago/Turabian StyleYang, Yang, Guangzheng Li, and Quanrang Zhang. 2018. "A Pressure-Coordinated Control for Vehicle Electro-Hydraulic Braking Systems" Energies 11, no. 9: 2336. https://doi.org/10.3390/en11092336