A Numerical Investigation of Frost Growth on Cold Surfaces Based on the Lattice Boltzmann Method

Abstract

:1. Introduction

2. Numerical Model and Theory

2.1. The Mass of Frost Layer

2.2. The Velocity Field and the Temperature Field in LB Model

- Migration:

- Collision:

2.3. Initial and Boundary Condition

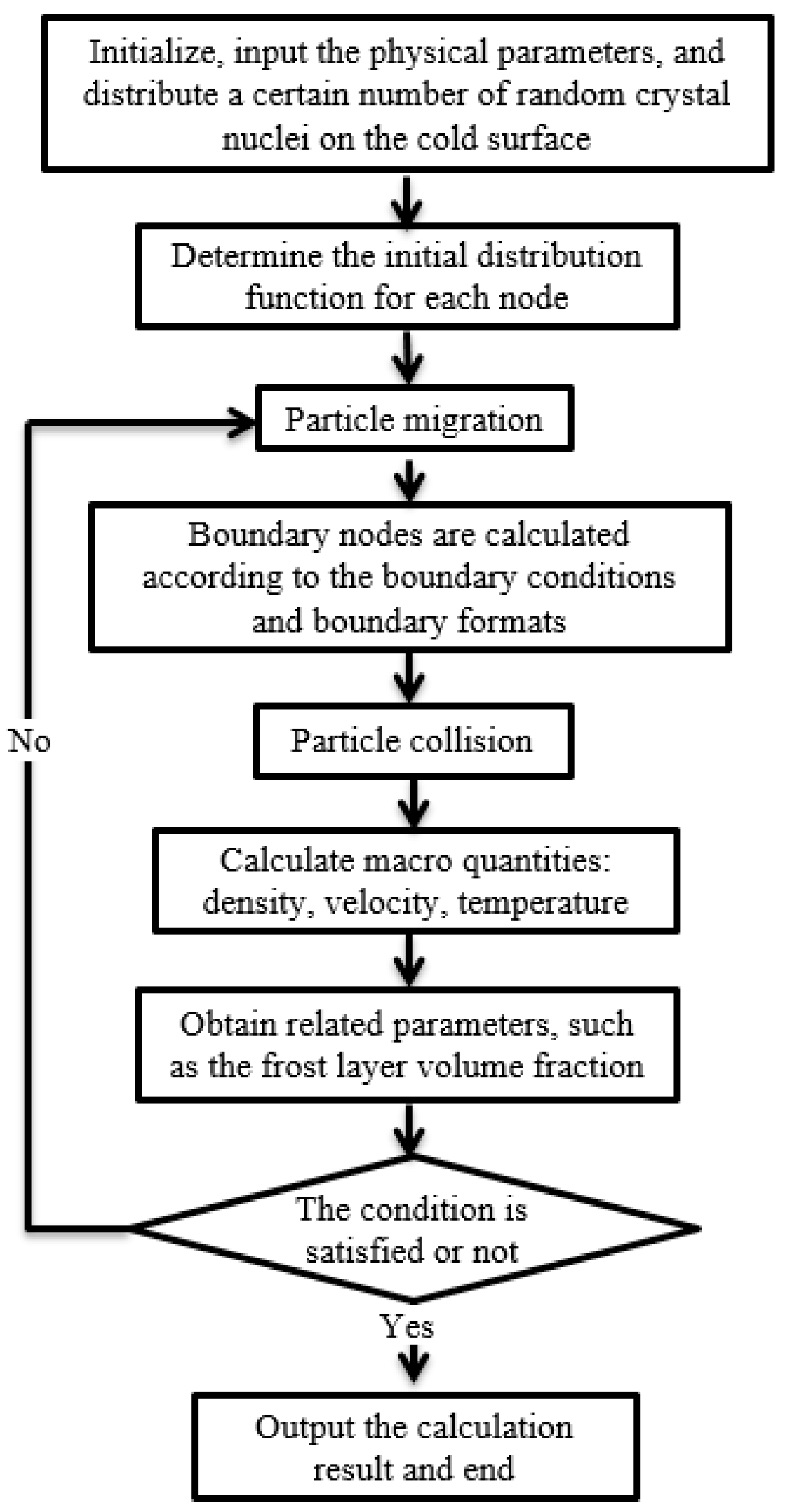

2.4. Procedure of Numerical Model

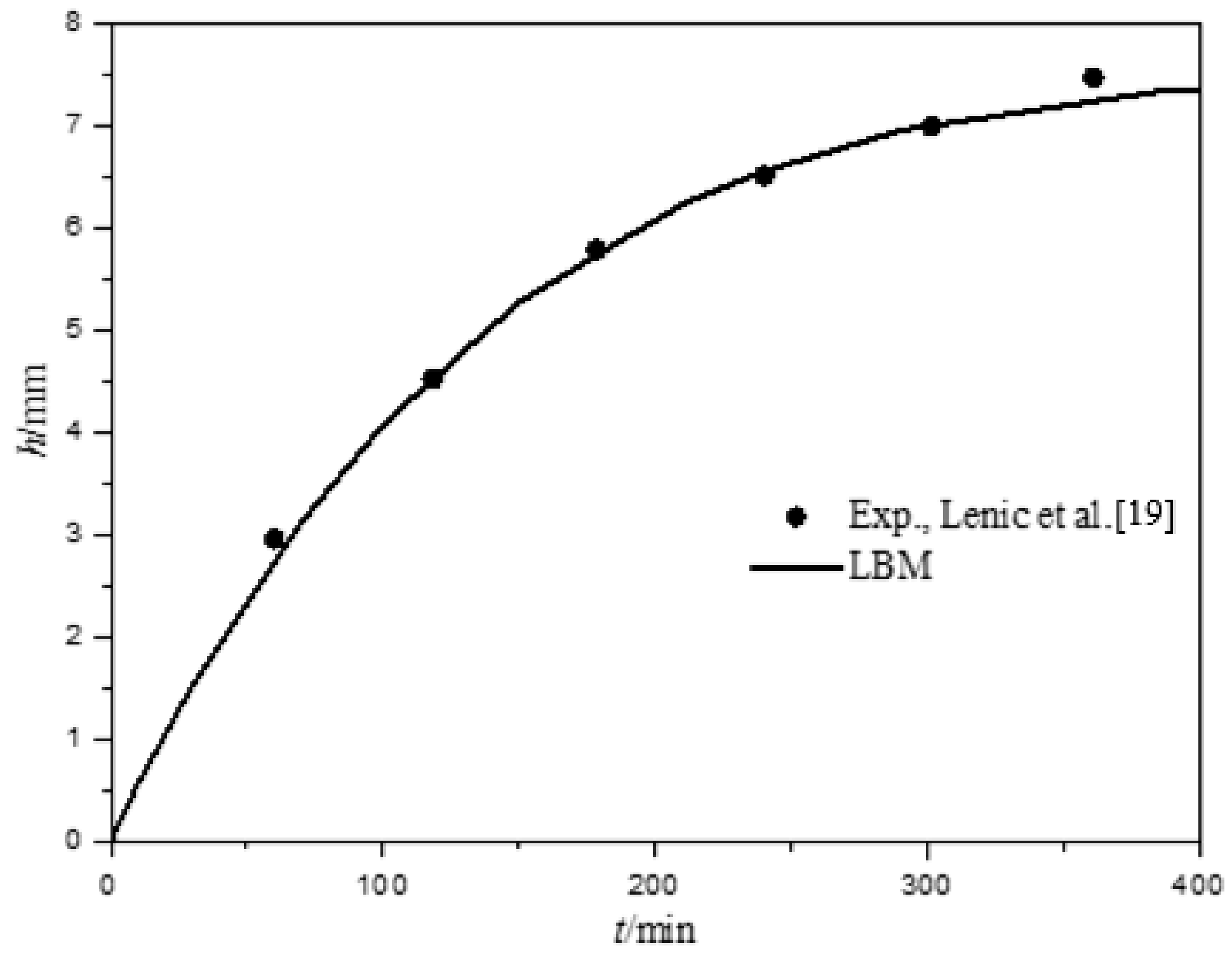

2.5. Validation of LB Model

3. Results and Discussion

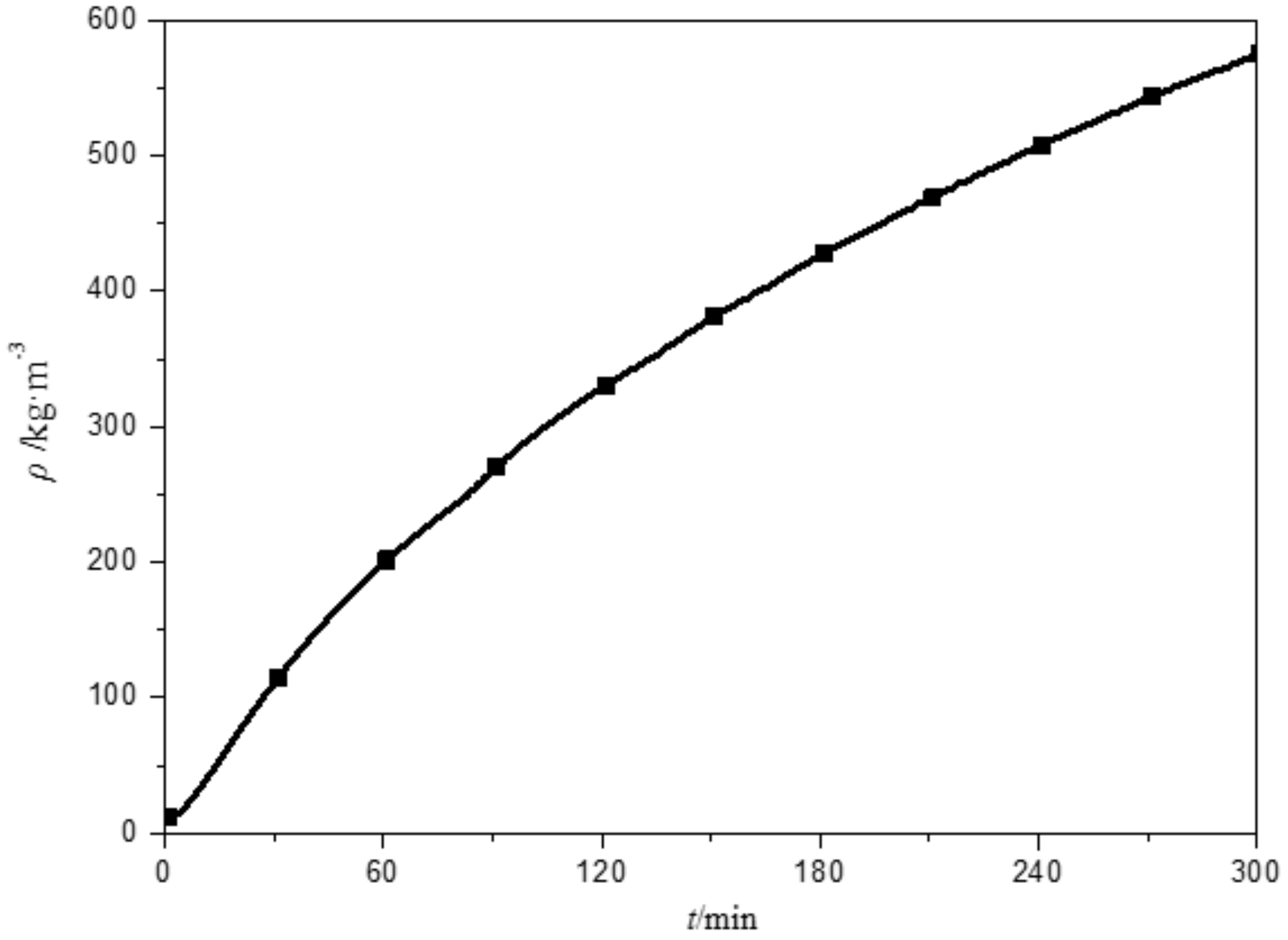

3.1. Frost Density

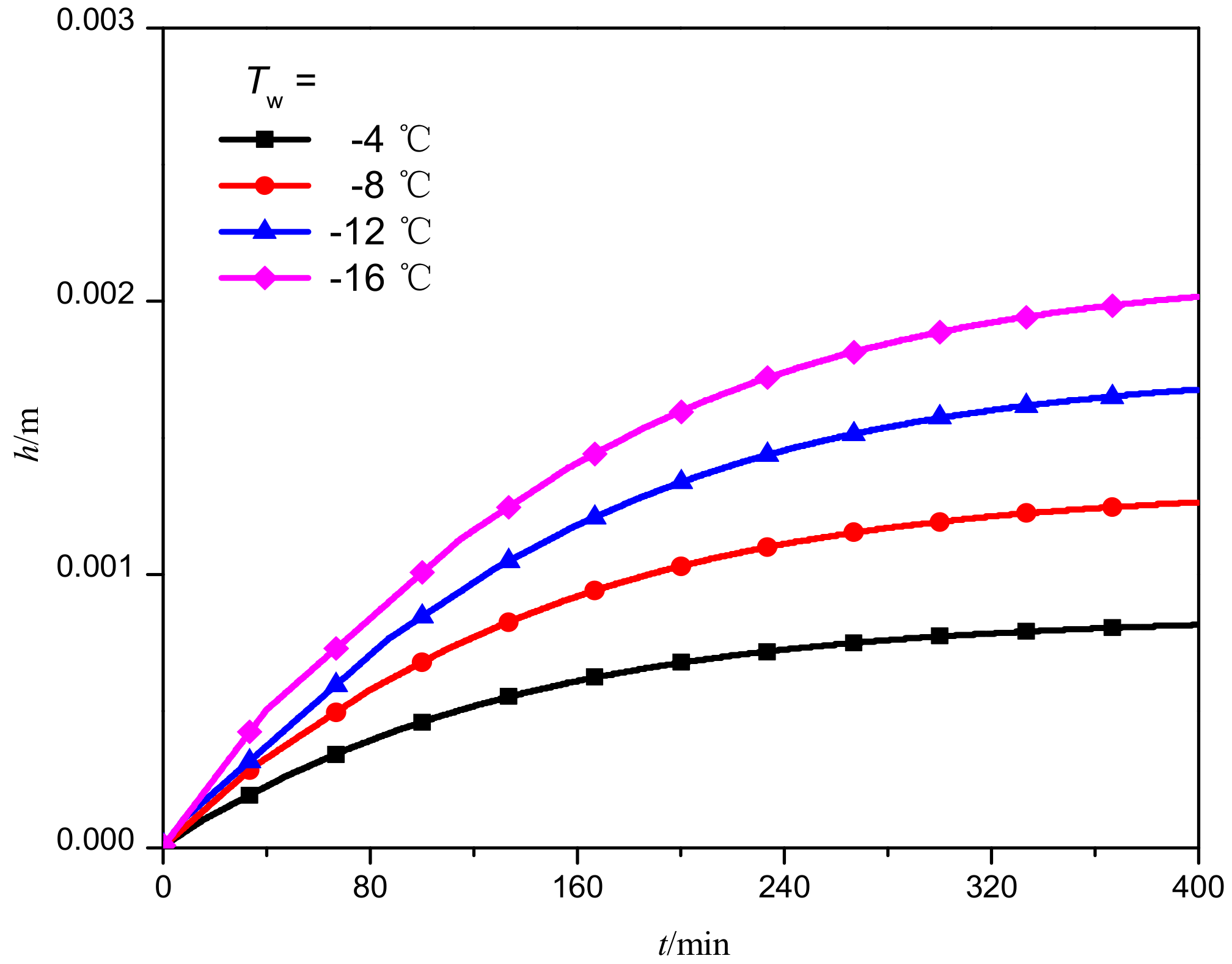

3.2. Frost Thickness

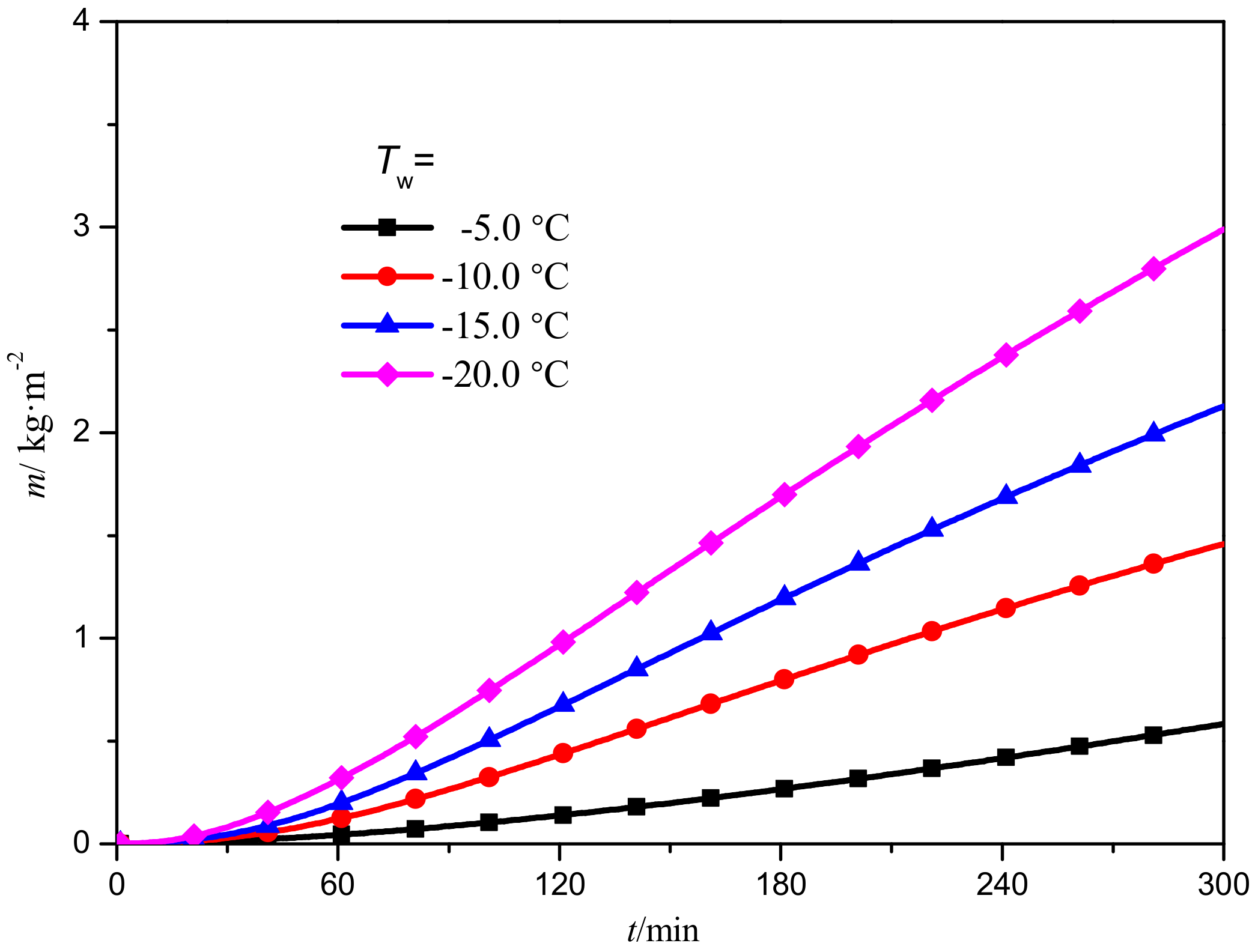

3.3. Frost Deposition

3.4. Frost Crystal Volume Fraction

4. Conclusions

- (1)

- Frost average density shows different increasing rates at different frosting stages. The increase in the frost layer average density in the later frost growth stage is slower due to the rise of frost surface temperature.

- (2)

- Due to the effect of the cold surface temperature on the water vapor concentration gradient, the frost thickness increases dramatically with the decrease in the cold surface temperature.

- (3)

- The frost crystal deposition mass and deposition rate are greatly affected by the cold surface temperature. With the decrease in the cold surface temperature, the frost crystal deposition mass increase rapidly, and the deposition rate first increases rapidly, then gradually slows down, finally remaining unchanged.

- (4)

- The frost crystal volume fraction is greatly affected by the cold surface temperature. When the cold surface temperature decreases, the frost crystal volume fraction is greater. The further away from the cold surface, the smaller the frost crystal volume fraction. As a result, the frost layer porous structure appears more obvious.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| isothermal sound velocity, m/s | |

| parameter of auxiliary velocity | |

| specific heat at the constant pressure | |

| ,, | diffusion resistance factor |

| Diameter of the solid particle | |

| discrete velocity, m/s | |

| velocity distribution function | |

| geometric function | |

| specific enthalpy in the gas-solid phase transition, J/kg | |

| nucleation rate | |

| kinetic constant of nucleation rate, /m2s | |

| Boltzmann constant, J/K | |

| permeability | |

| increase of frost crystal mass, kg | |

| water molecular mass, kg | |

| nucleation correction factor | |

| freezing probability | |

| pressure, Pa | |

| critical radius, m | |

| universal gas constant, J/(mol⋅K) | |

| water vapor super-saturation degree | |

| temperature, K | |

| velocity, m/s | |

| auxiliary velocity | |

| Greek symbols | |

| water vapor saturation ratio | |

| thermal diffusivity | |

| lattice spacing | |

| time step | |

| contact angle, rad | |

| kinematic viscosity, m2/s | |

| density, kg/m3 | |

| interface energy, J/m2 | |

| , | dimensionless relaxation time |

| air relative humidity | |

| weight coefficient | |

| specific heat capacity ratio | |

| non-isothermal correction factor | |

| heat capacity ratio | |

| frost crystal volume fraction | |

| porosity | |

| discretized source term | |

| nucleation parameter | |

| Subscript | |

| air | |

| frost | |

| frost surface | |

| ice | |

| direction | |

| water vapor in saturated state | |

| water vapor in local state | |

| cold flat surface | |

| Superscript | |

| equilibrium state | |

References

- Lee, M.Y.; Kim, Y.; Lee, D.Y. Experimental study on frost height of round plate fin-tube heat exchangers for mobile heat pumps. Energies 2012, 5, 3479–3491. [Google Scholar] [CrossRef]

- Gao, T.; Gong, J. Modeling the airside dynamic behavior of a heat exchanger under frosting conditions. J. Mech. Sci. Technol. 2011, 25, 2719. [Google Scholar] [CrossRef]

- Xu, B.; Han, Q.; Chen, J.; Li, F.; Wang, N.; Li, D.; Pan, X. Experimental investigation of frost and defrost performance of microchannel heat exchangers for heat pump systems. Appl. Energy 2013, 103, 180–188. [Google Scholar] [CrossRef]

- O’Neal, D.L.; Tree, D.R. Measurement of frost growth and density in a parallel plate geometry. Ashrae Trans. 1984, 90, 278–290. [Google Scholar]

- Sami, S.M.; Duong, T. Mass and heat transfer during frost growth. Ashrae Trans. 1989, 95, 158–165. [Google Scholar]

- Lee, K.S.; Jhee, S.; Yang, D.K. Prediction of the frost formation on a cold flat surface. Int. J. Heat Mass Transf. 2003, 46, 3789–3796. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, Y.; Deng, S.; Ma, Z. A study on the performance of the airside heat exchanger under frosting in an air source heat pump water heater/chiller unit. Int. J. Heat Mass Transf. 2004, 47, 3745–3756. [Google Scholar]

- Tao, Y.X.; Besant, R.W.; Rezkallah, K.S. A mathematical model for predicting the densification and growth of frost on a flat plate. Int. J. Heat Mass Transf. 1993, 36, 353–363. [Google Scholar] [CrossRef]

- Hayashi, Y.; Aoki, A.; Adachi, S.; Hori, K. Study of frost properties correlating with frost formation types. J. Heat Transf. 1977, 99, 239. [Google Scholar] [CrossRef]

- Lee, K.S.; Kim, W.S.; Lee, T.H. A one-dimensional model for frost formation on a cold flat surface. Int. J. Heat Mass Transf. 1997, 40, 4359–4365. [Google Scholar] [CrossRef]

- Na, B.; Webb, R.L. New model for frost growth rate. Int. J. Heat Mass Transf. 2004, 47, 925–936. [Google Scholar] [CrossRef]

- Hermes, C.J.L.; Piucco, R.O.; Barbosa, J.R., Jr.; Melo, C. A study of frost growth and densification on flat surfaces. Exp. Therm. Fluid Sci. 2009, 33, 371–379. [Google Scholar] [CrossRef]

- Kandula, M. Frost growth and densification in laminar flow over flat surfaces. Int. J. Heat Mass Transf. 2011, 54, 3719–3731. [Google Scholar] [CrossRef] [Green Version]

- Jones, B.W.; Parker, J.D. Frost formation with varying environmental parameters. Int. J. Heat Mass Transf. 1975, 97, 255–259. [Google Scholar] [CrossRef]

- Cheng, C.H.; Cheng, Y.C. Predictions of frost growth on a cold plate in atmospheric air. Int. Commun. Heat Mass Transf. 2001, 28, 953–962. [Google Scholar] [CrossRef]

- Loyola, F.R.; Nascimento, V.S., Jr.; Hermes, C.J.L. Modeling of frost build-up on parallel-plate channels under supersaturated air-frost interface conditions. Int. J. Heat Mass Transf. 2014, 79, 790–795. [Google Scholar] [CrossRef]

- Lüer, A.; Beer, H. Frost deposition in a parallel plate channel under laminar flow conditions. Int. J. Therm. Sci. 2000, 39, 85–95. [Google Scholar] [CrossRef]

- Armengol, J.M.; Salinas, C.T.; Xaman, J.; Ismail, K.A.R. Modeling of frost formation over parallel cold plates considering a two-dimensional growth rate. Int. J. Therm. Sci. 2016, 104, 245–256. [Google Scholar] [CrossRef]

- Lenic, K.; Trp, A.; Frankovic, B. Transient two-dimensional model of frost formation on a fin-and-tube heat exchanger. Int. J. Heat Mass Transf. 2009, 52, 22–32. [Google Scholar] [CrossRef]

- Cui, J.; Li, W.Z.; Liu, Y.; Jiang, Z.Y. A new time- and space-dependent model for predicting frost formation. Appl. Therm. Eng. 2011, 31, 447–457. [Google Scholar] [CrossRef]

- Kim, D.; Kim, C.; Lee, K.S. Frosting model for predicting macroscopic and local frost behaviors on a cold plate. Int. J. Heat Mass Transf. 2015, 82, 135–142. [Google Scholar] [CrossRef]

- Wu, X.; Ma, Q.; Chu, F.; Hu, S. Phase change mass transfer model for frost growth and densification. Int. J. Heat Mass Transf. 2016, 96, 11–19. [Google Scholar] [CrossRef]

- Negrelli, S.; Cardoso, R.P.; Hermes, C.J.L. A finite-volume diffusion-limited aggregation model for predicting the effective thermal conductivity of frost. Int. J. Heat Mass Transf. 2016, 101, 1263–1272. [Google Scholar] [CrossRef]

- Gao, D.; Chen, Z. Lattice Boltzmann method for heat transfer of melting in porous media with high Darcy number. CIESC J. 2011, 62, 321–328. [Google Scholar]

- Manz, B.; Gladden, L.F.; Warren, P.B. Flow and dispersion in porous media: Lattice-Boltzmann and NMR studies. AICHE J. 2010, 45, 1845–1854. [Google Scholar] [CrossRef]

- Tang, G. Microscale Gas Flow and Heat Transfer Characteristics and Lattice-Boltzmalm Method Analysis. Ph.D. Thesis, Xi’an Jiaotong University, Xi’an, Shanxi, China, 2004. [Google Scholar]

- Li, X.; Cao, J.; Wang, X. Fluid Flow Modeling Using the Lattice Boltzmann Method. Comput. Tech. Geophys. Geochem. Explor. 2002, 3, 220–223. [Google Scholar]

- Xu, Y. A new numerical method for simulating fluid flow through porous media. Acta Phys. Sin. 2003, 52, 626–629. [Google Scholar]

- Wang, H.; Chai, Z.; Guojun, Z. Lattice Boltzmann Simulation of gas transfusion in compact porous media. Chin. J. Comput. Phys. 2009, 26, 389–395. [Google Scholar]

- Sun, J.; Gong, J.; Li, G. A lattice Boltzmann model for solidification of water droplet on cold flat plate. Int. J. Refrig. 2015, 59, 53–64. [Google Scholar] [CrossRef]

- Liu, Y. A Fractal Model and Experimental Study of Frost Deposition on Cold Surface. Ph.D. Thesis, Beijing University of Technology, Beijing, China, 2012. [Google Scholar]

- Gall, R.L.; Grillot, J.M.; Jallut, C. Modelling of frost growth and densification. Int. J. Heat Mass Transf. 1997, 40, 3177–3187. [Google Scholar] [CrossRef]

- Guo, Z.L.; Zheng, C.G. Theory and Applications of Lattice Boltzmann Method; Science Press: Beijing, China, 2009. [Google Scholar]

- He, Y.-L.; Wang, Y.; Li, Q. Lattice Boltzmann Method: Theory and Applications; Science Press: Beijing, China, 2009. [Google Scholar]

- Vafai, K. Convective flow and heat transfer in variable porosity media. J. Fluid Mech. 2006, 147, 233–259. [Google Scholar] [CrossRef]

- Guo, Z.; Zhao, T.S. A Lattice Boltzmann Model for convection heat transfer in porous media. Numer. Heat Transf. Part B Fundam. 2005, 47, 157–177. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, J.; Hou, J.; Sun, J.; Li, G.; Gao, T. A Numerical Investigation of Frost Growth on Cold Surfaces Based on the Lattice Boltzmann Method. Energies 2018, 11, 2077. https://doi.org/10.3390/en11082077

Gong J, Hou J, Sun J, Li G, Gao T. A Numerical Investigation of Frost Growth on Cold Surfaces Based on the Lattice Boltzmann Method. Energies. 2018; 11(8):2077. https://doi.org/10.3390/en11082077

Chicago/Turabian StyleGong, Jianying, Jianqiang Hou, Jinjuan Sun, Guojun Li, and Tieyu Gao. 2018. "A Numerical Investigation of Frost Growth on Cold Surfaces Based on the Lattice Boltzmann Method" Energies 11, no. 8: 2077. https://doi.org/10.3390/en11082077