4.1. Taguchi Parameter Design Method

In general, to improve the performance of electrical machines, many optimization methods can be employed, such as the intelligent optimization algorithms, multilevel, multiobjective and multidisciplinary optimization methods [

25,

26,

27,

28,

29,

30,

31,

32,

33]. For the optimization of the investigated FSPMM under manufacturing variations, this is a kind of robust design optimization problem. To solve this problem, Taguchi parameter design, worst case design and design for six-sigma (DFSS) are three normally used methods [

26,

32,

33,

34,

35,

36,

37,

38]. Among them, Taguchi parameter design method requires the least simulation cost.

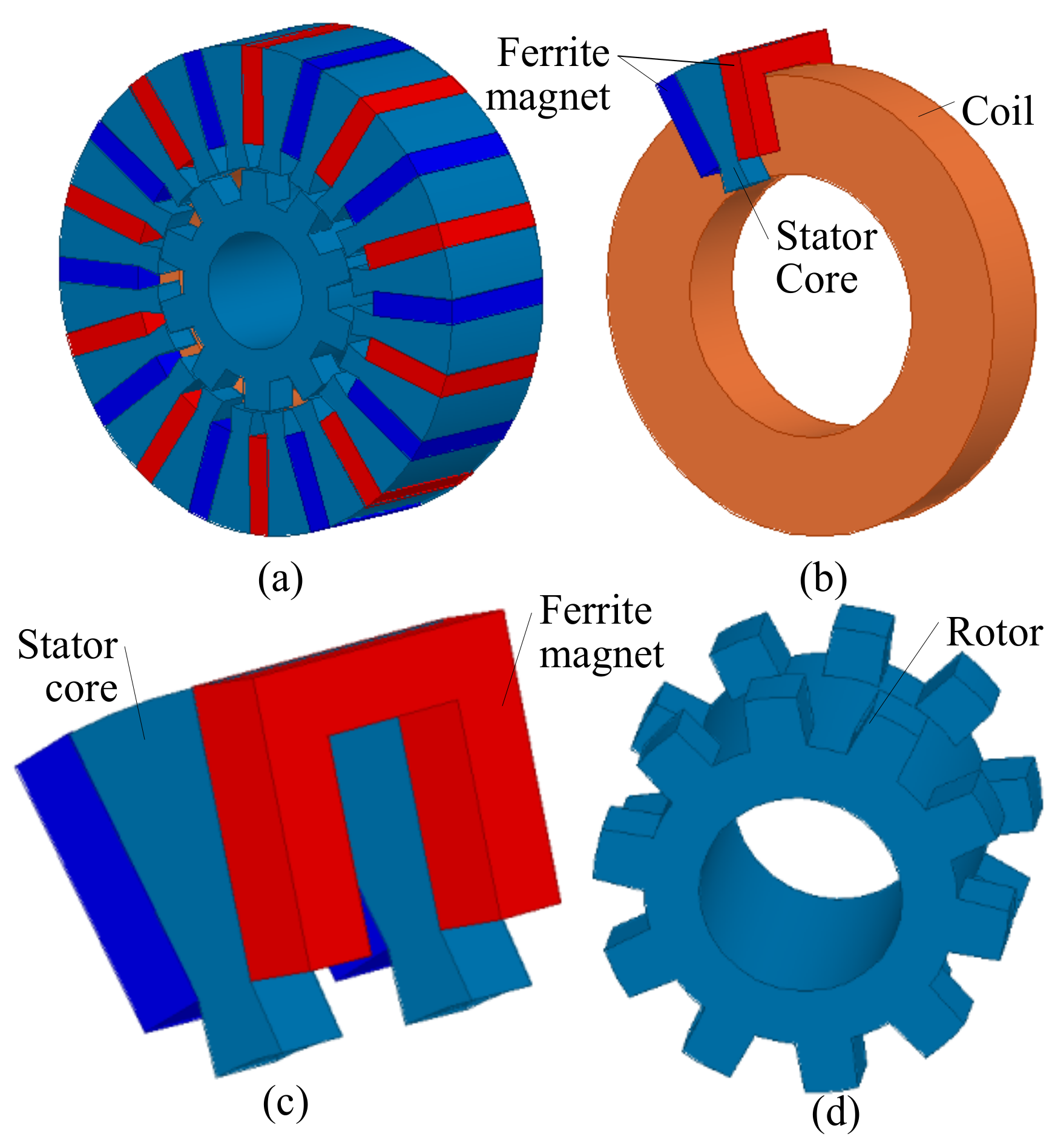

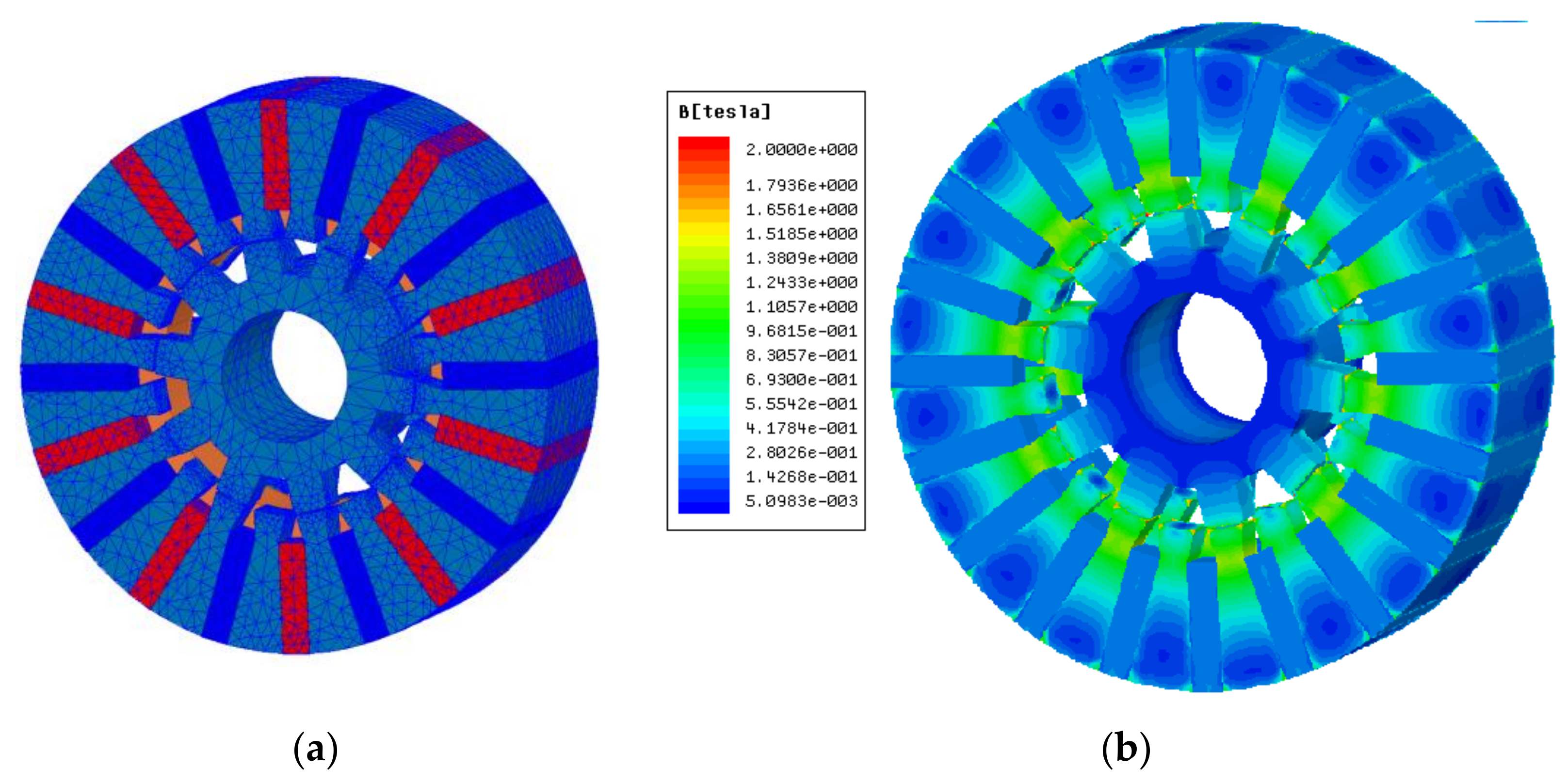

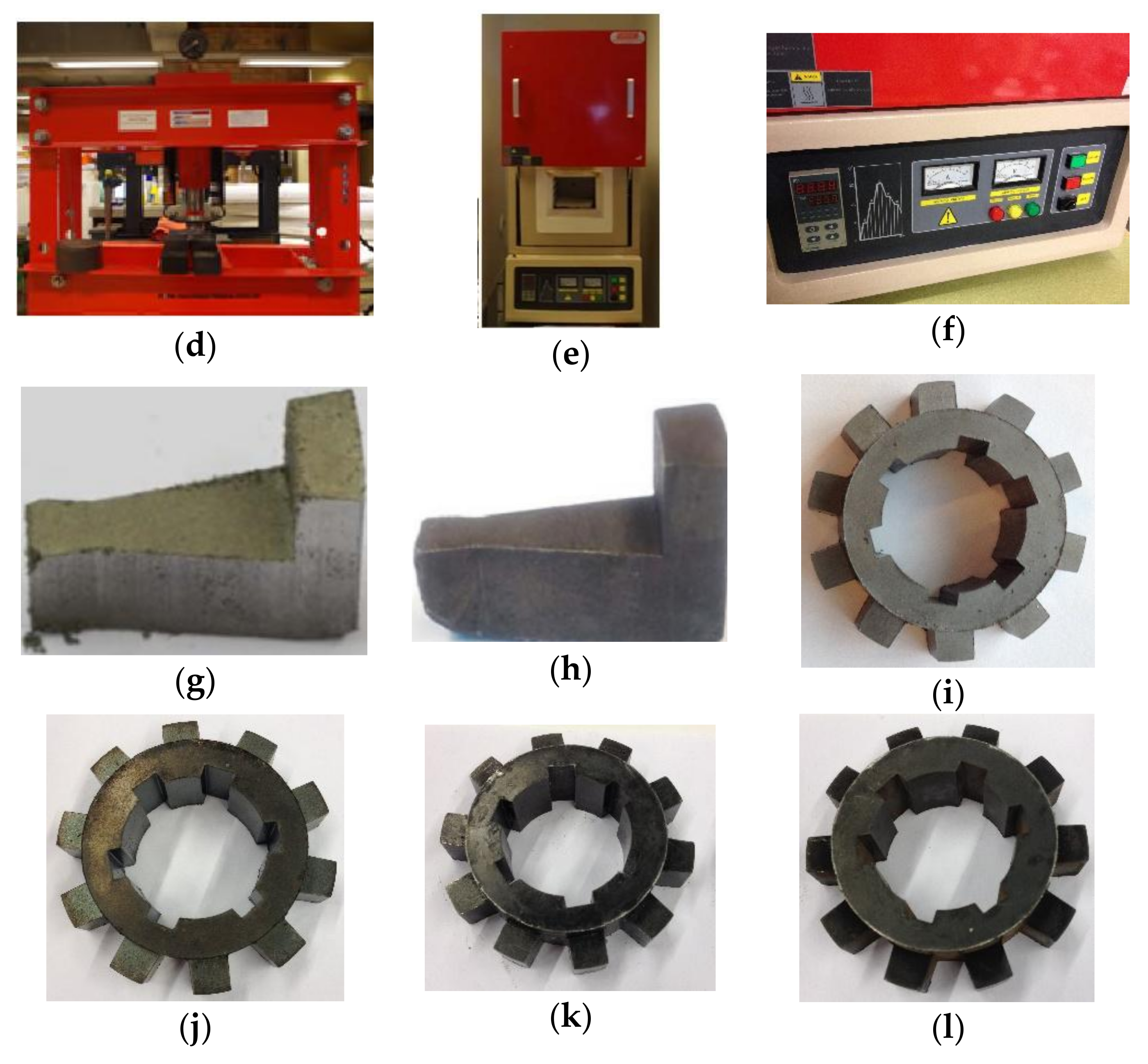

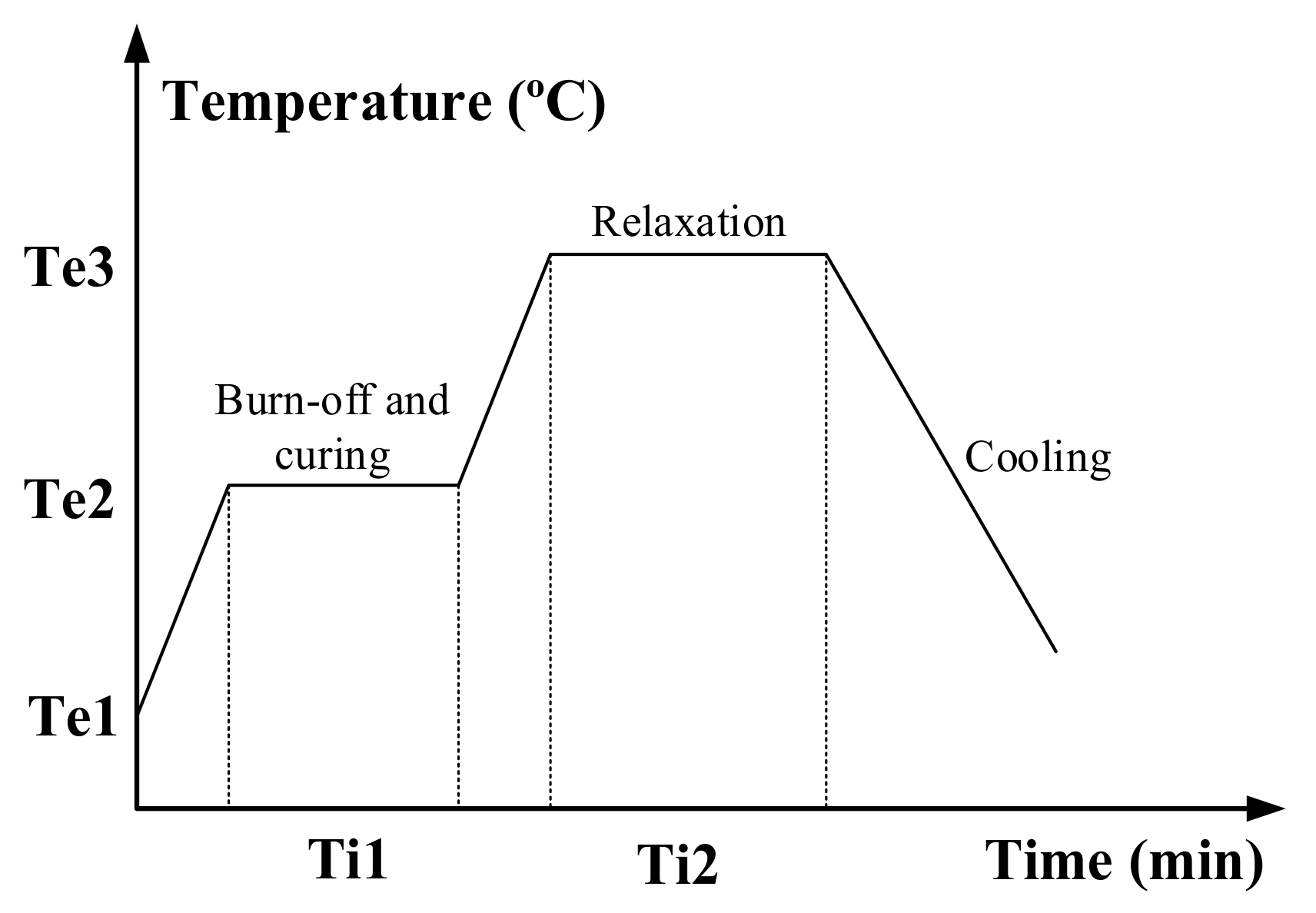

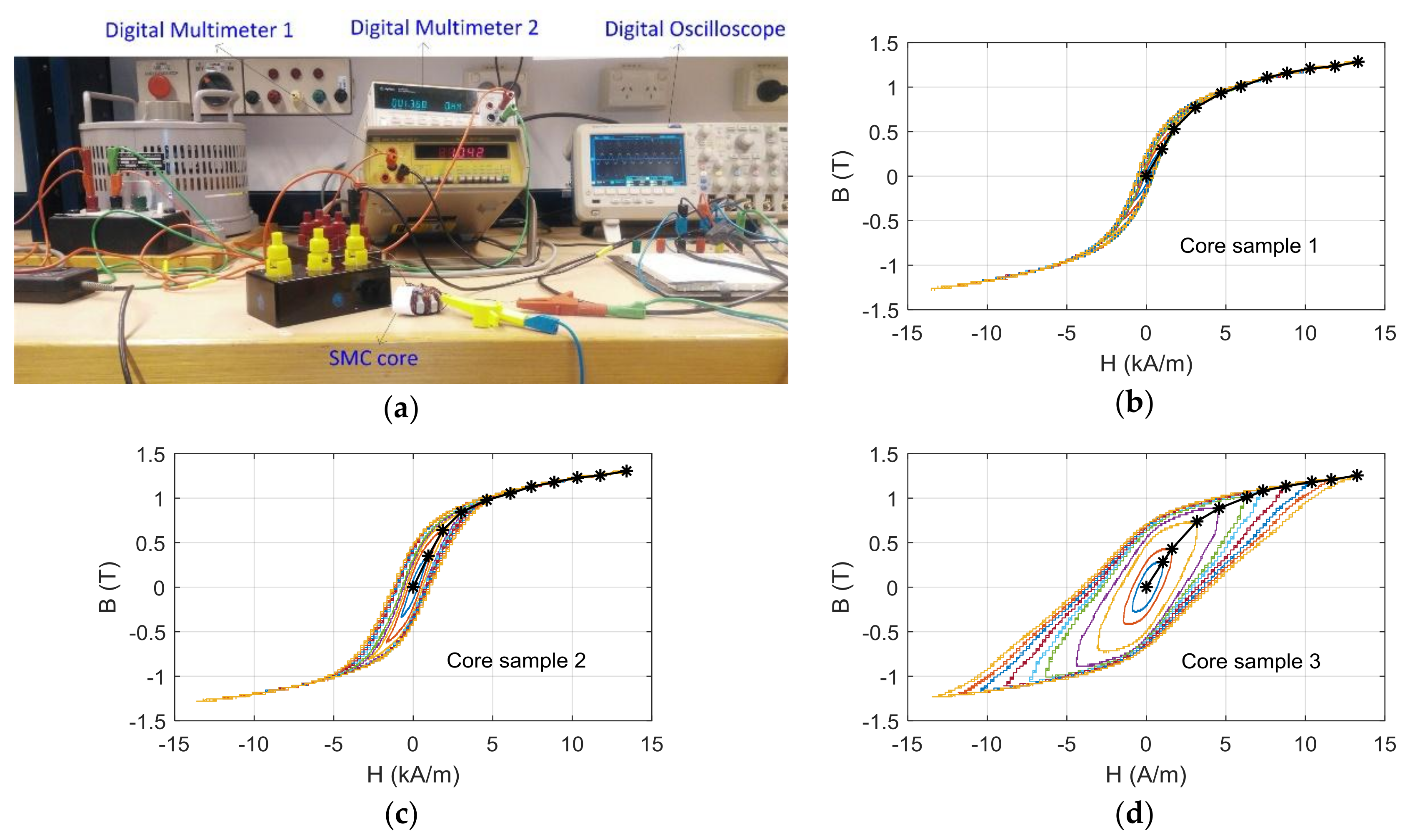

For the investigated FSPMM, 3D finite element model (FEM) as shown in

Figure 2a is required as this is a 3D flux machine. The simulation time of one design with Maxwell is around 25 min on a PC with 3.2 GHz CPU and 8 GB RAM. This is a huge computation cost if several thousand FEM samples are required. Therefore, to decrease the computation cost, the Taguchi parameter design method will be employed to optimize the investigated FSPMM in this work. In the implementation, two types of factors, control and noise factors, are required to define for this motor. The control factors are the design parameters that will be optimized, whereas the noise factors are parameters that characterize the manufacturing tolerances. An orthogonal array consisting of an inner array and an outer array will be generated to conduct the simulations. Based on that, the signal/noise (S/N) ratio, as an index of motor quality, is used to determine the best combination of the control factor values that make the motor robust to those manufacturing tolerances [

34,

35,

36,

37,

38].

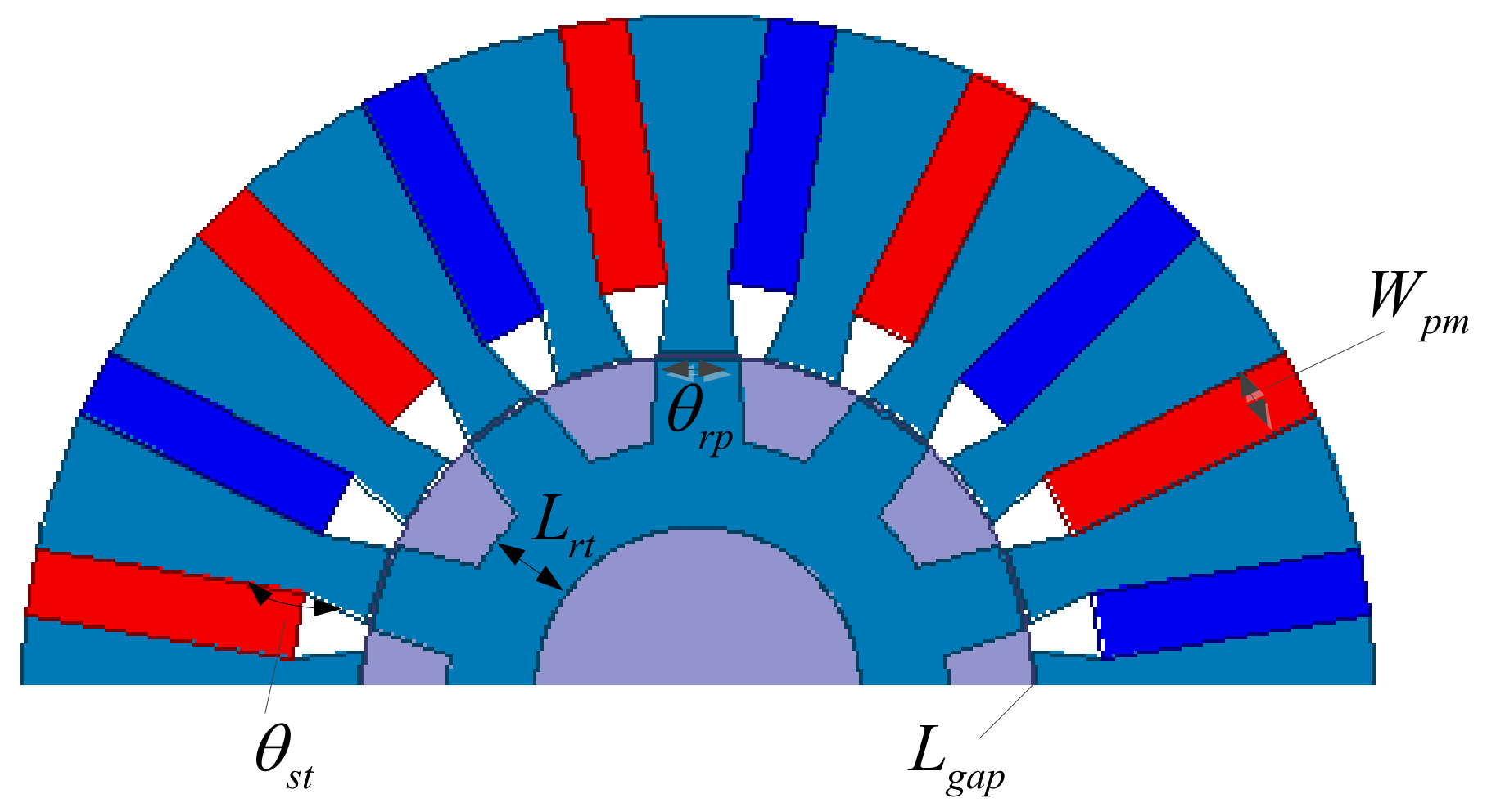

For this motor, five parameters (

θst,

Lgap,

Lrt,

Wpm, and

θrp) as shown in

Figure 8 are crucial to its performance, where

Wpm is the width of the ferrite magnet in the direction of magnetization,

Lgap is the length of the air gap, and the others are three parameters for SMC cores.

Table 5 lists the initial design ranges of them. These parameters are considered as the control factors for the Taguchi parameter design of this motor.

Table 6 tabulates the levels for these five control factors. As shown, each factor has four levels.

Table 7 lists three noise factors and their levels. These factors are related to the manufacturing tolerances of the ferrite magnets, SMC cores and the air gap. They account for the main performance variations for this FSPMM, and they are hard to control in the manufacturing. As listed in the table, each noise factor has two levels. For example, the two levels for the core density (

ρ) are −0.15 and 0.15 g/cm

3, meaning that the practical core densities in the manufacturing are 6.77 and 7.07 g/cm

3, respectively. They are calculated by 6.92 − 0.15 and 6.92 + 0.15, respectively, where 6.92 is the core density of the initial design.

Based on these control and noise factors,

Table 8 lists an orthogonal array for the robust design and analysis of this motor. As shown, there are 16 rows, meaning that 16 combinations of the control factors are required to form the inner array. For the noise factors, four combinations are needed to form the outer array, and they are listed as 111, 122, 212 and 221 in the table. 1 or 2 means the level of the control factor. For example, 122 represents the combination of levels 1, 2, and 2 for these three noise factors, respectively. Therefore, 64 (16 × 4) combinations (FEM samples) will be required for the simulation in Maxwell.

Table 8 lists the average torques and core losses of these 64 samples.

For the performance optimization of this motor, there are two objectives, maximizing the average torque (

Tave) and minimizing the core loss (

Pcore). Based on them, an objective function is defined as follows to determine the best combination of control factor values:

where

i (1, 2, …, 16) and

j (1, 2, 3, 4) are the numbers of experiments for the inner and outer arrays, respectively.

Table 9 lists the S/N ratios for all 16 rows of the control factors. The calculation method can be briefly summarized as follows:

First, use (3) to compute the objective of all 64 samples listed in

Table 8.

Second, calculate the S/N ratio for each row in the table. According to the Taguchi parameter design method (with a target as the smaller the better), the calculation equation is:

Third, compute the average S/N ratio for each level of all control factors. For example, for the third level of the second control factor

Lgap, it average S/N ratio can be calculated by:

the numbers 3, 7, 11 and 15 can be found from the orthogonal array.

To identify the best combination of the control factor values,

Figure 9 illustrates the average S/N ratios for all five factors. The best level of each factor can be obtained by selecting a level with the highest S/N ratio. As shown, levels 4, 1, 4, 3, and 1 should be chosen for these five control factors, respectively. Their corresponding values can be found from

Table 6.

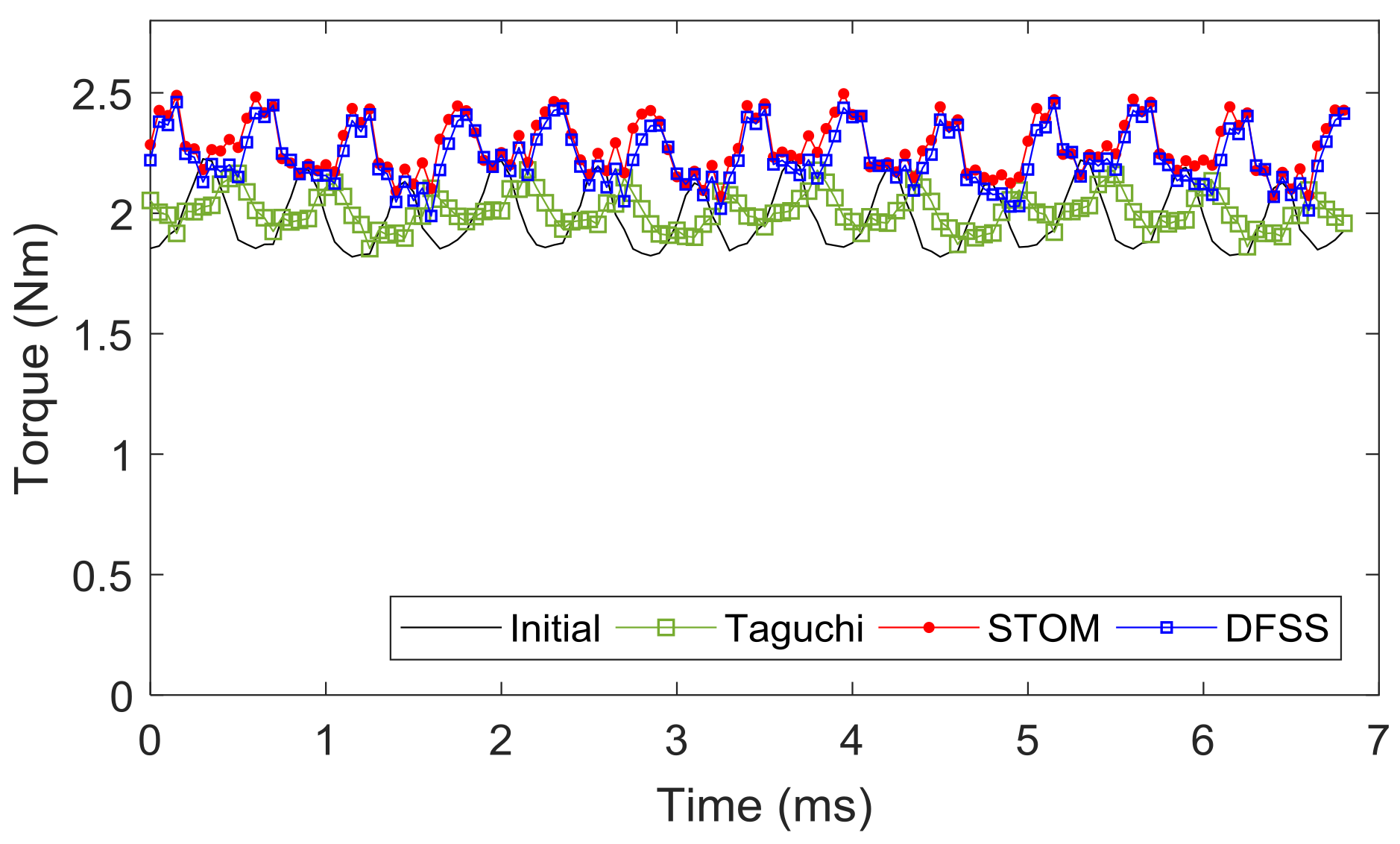

4.2. Sequential Taguchi Optimization Method

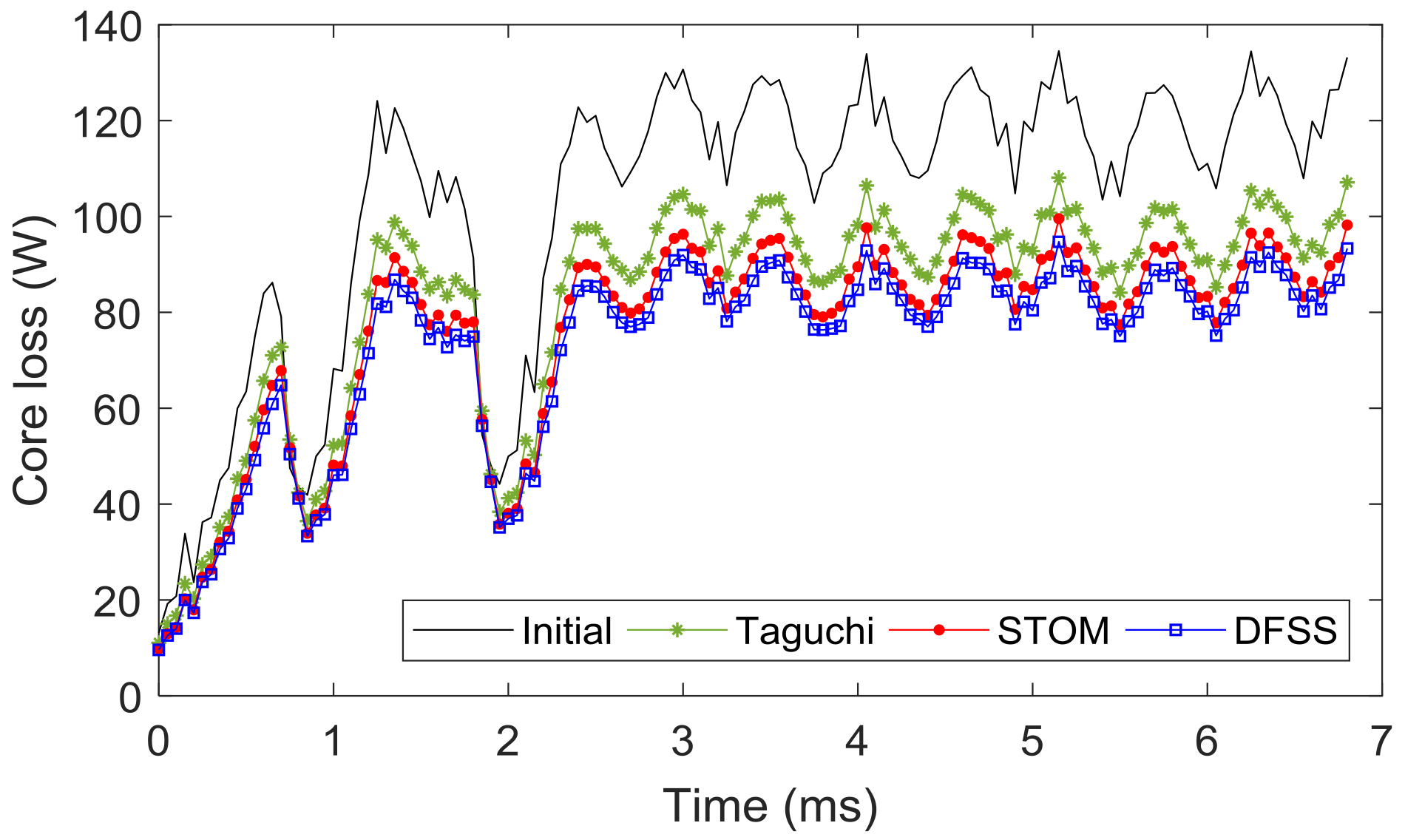

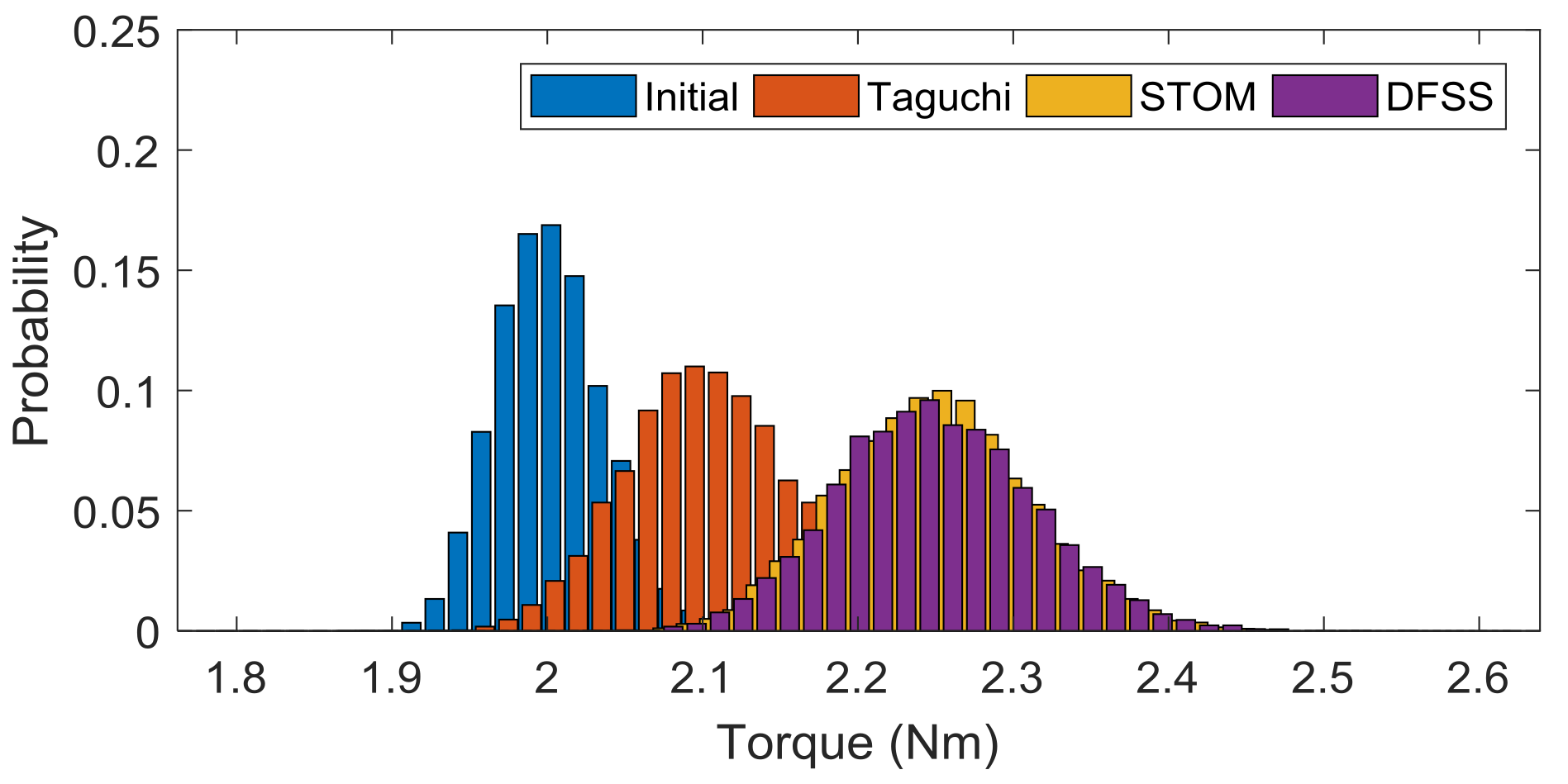

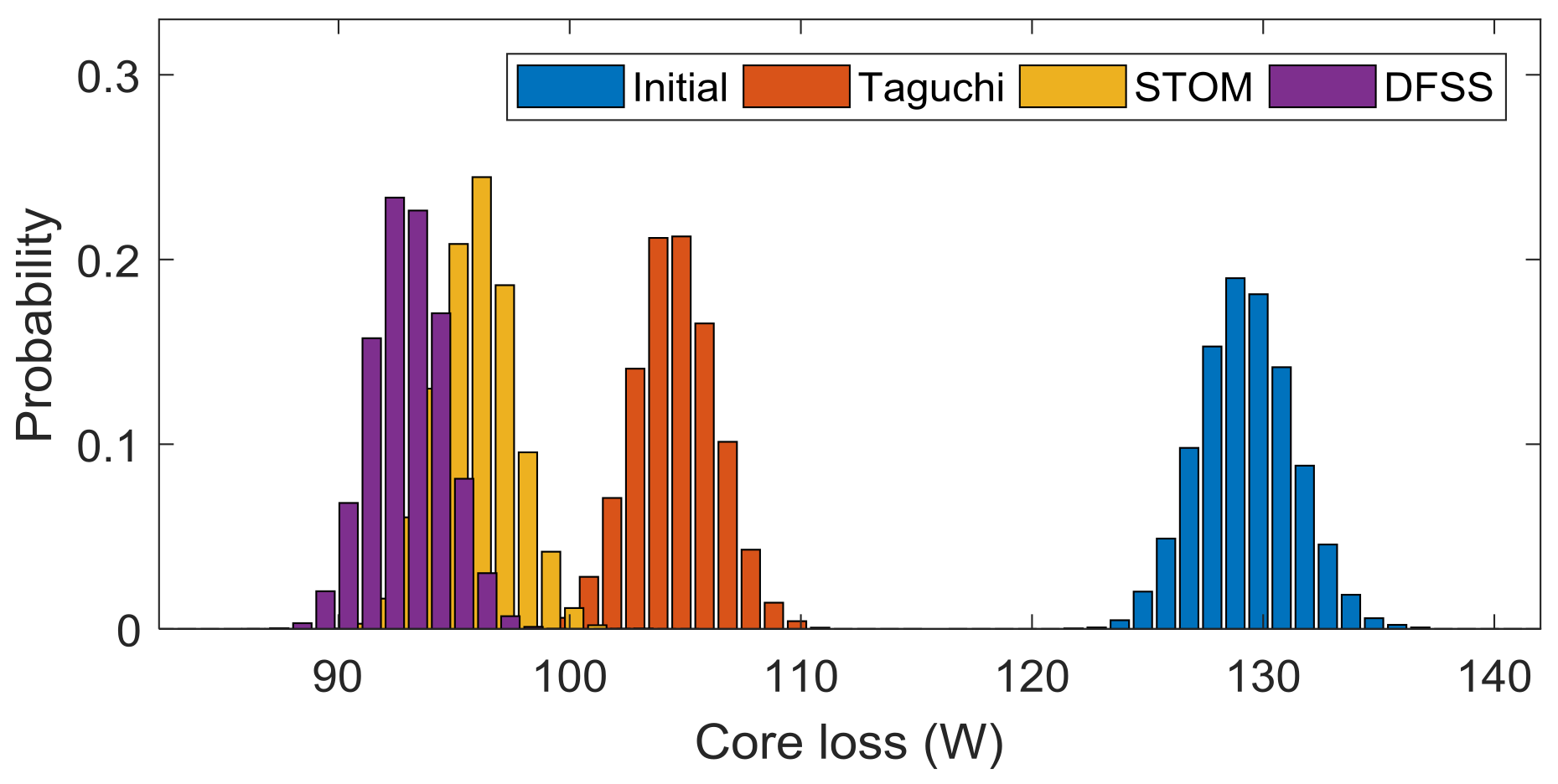

For the optimal design obtained from Taguchi parameter design, the motor average torque is torque 2.01 Nm and core loss is 104.07 W. They are better than those of the initial design (2.00 Nm and 129.24 W). However, the improvements are not significant. The main reason is that only 64 samples and 4 levels have been considered for the control factors in the optimization process. There are big step sizes for different levels. To overcome this disadvantage and further improve the motor performance, a sequential Taguchi optimization method (STOM) is proposed as follows.

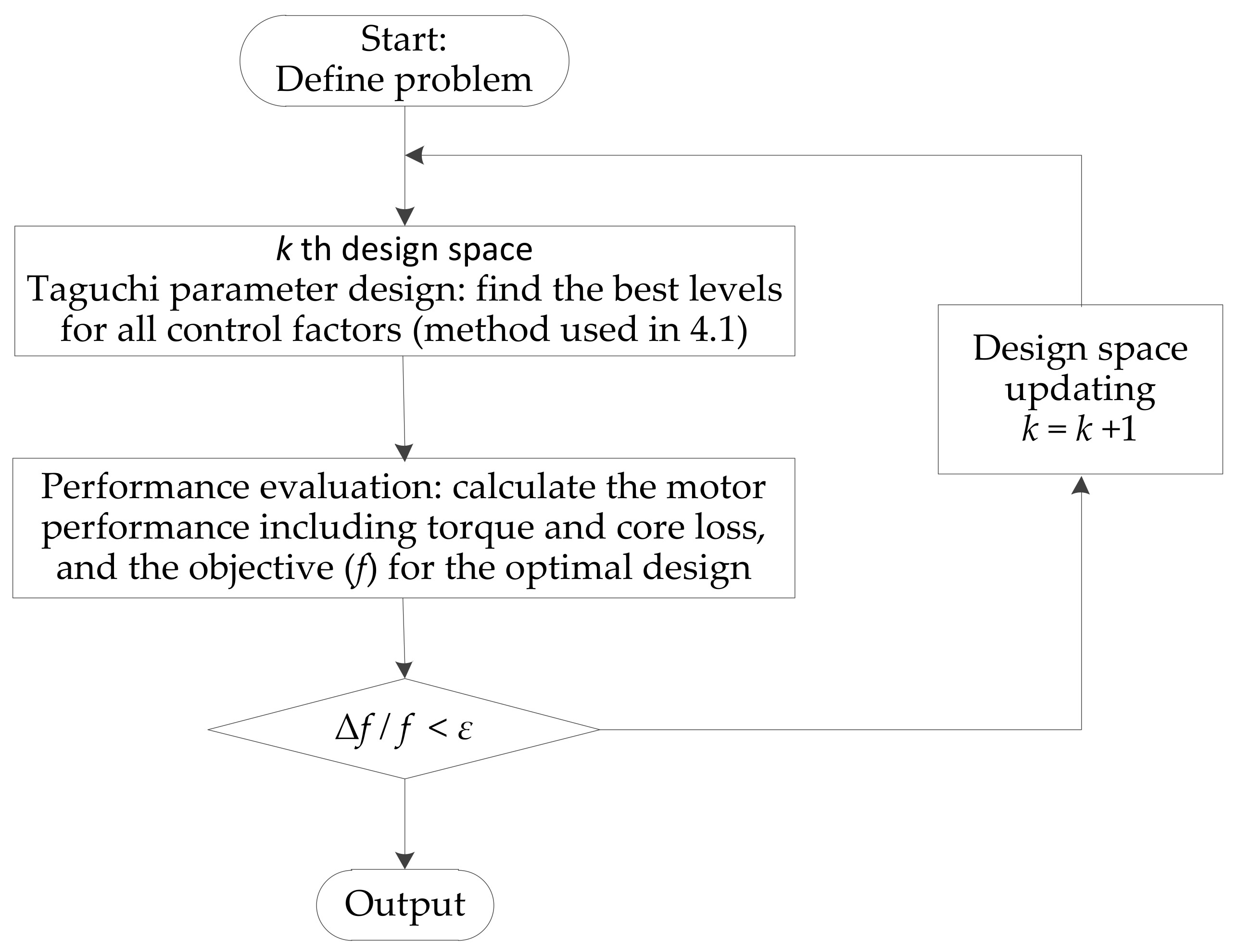

Figure 10 illustrates the flowchart of the proposed STOM. There are five main steps:

Step 1: Problem definition. This step defines the design objectives, control and noise factors of the motor.

Step 2: Taguchi parameter design. This step conducts the analysis of the Taguchi parameter design discussed in

Section 4.1. First, define an orthogonal array for the control and noise factors. Second, simulate the motor performance. Third, calculate the S/N ratios of each factor at different levels and determine the best level combination.

Step 3: Motor performance evaluation. This step evaluates the motor performance of the obtained optimal design, including average torque and core loss, and calculates the objective.

Step 4: Determination of the convergence. Compare the objectives obtained from this step and the last step. If the relative error is less than ε (a positive value like 1%), terminate the optimization process and output the optimal design. Otherwise, go to next step.

Step 5: Updating the design space. For most engineering optimization problems, the optimal point should be located in a small subspace compared with the initial big design space. Therefore, if that subspace can be found, the optimum should be better than the initial one. Following this idea, the design space will be reduced in this step by using a sequential optimization strategy [

39,

40]. In the implementation, the step size of each control factor will be halved in this step. For example, for the fourth control factor (

Wpm), the best level is 3 given by the Taguchi design, meaning that its value is 6 mm. As the initial step size is 0.5 mm, the next one is 0.25 mm. Thus, the next four levels of this control factor will be 5.625, 5.875, 6.125 and 6.375, respectively. As shown, 6 is the mean of the second and third levels (mean of 5.875 and 6.125). If the best level is the lower or upper limit of the design space, the next design levels will start from or end with that level. For example, for the second control factor (

Lgap), the best level is 1 given by the Taguchi design. Its value is 0.45 mm, which is the lower limit of its design space. Therefore, the next four levels will start from it and the step size for any two levels is 0.025 mm, and they are 0.45, 0.475, 0.5 and 0.525, respectively. Based on these updated design levels, the Taguchi parameter design should be conducted again until the convergence criterion is met.

Figure 11 shows the objectives obtained from the proposed STOM with

ε = 1%. As shown, four Taguchi parameter design processes (

k = 1, 2, 3, 4) are required for the proposed optimization method. The objectives for these design processes are 1.800, 1.657, 1.631, and 1.627 respectively. Meanwhile, a total of 256 samples are required for the performance simulation as 64 FEM samples are needed for each design process. Therefore, this method is efficient. The detailed optimal control factors and motor performance will be given in the next section.