1. Introduction

The Nissan Altra EV was introduced as the first production lithium-ion battery electric vehicle in 1997 [

1]. The goals for EVs are to operate at a temperature from −30 to +52 °C with a driving range of 300 miles per single charge and a use life of 15 years, according to the U.S. Advanced Battery Consortium (USABC) [

2]. Implementation of rechargeable batteries for electrical vehicles (EVs) has become very popular because they can displace the consumption of fossil fuels and reduce the emissions of greenhouse gas [

3]. Lithium-ion batteries are widely adopted due to their high energy and power density, high efficiency, high open-circuit cell voltage, broad temperature operating, and long lifespan [

4].

In 1980, John Goodenough [

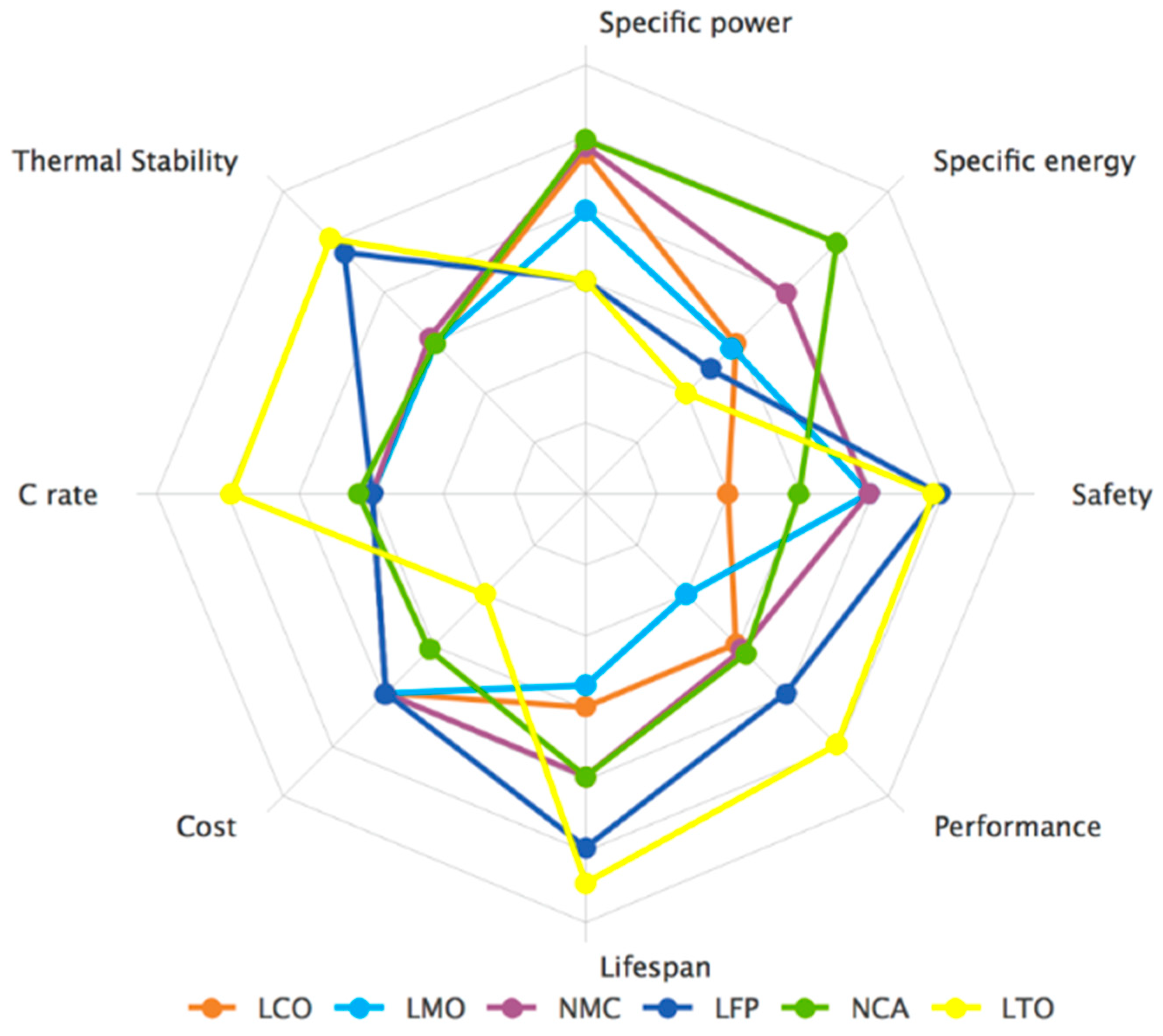

5] created the first lithium-ion batteries, which use lithium cobalt oxide and lithium manganese dioxide as cathodes. Commercial lithium-ion batteries such as lithium cobalt oxide (LCO), lithium iron phosphate (LFP), lithium manganese oxide (LMO), lithium nickel manganese cobalt oxide (NMC), lithium nickel cobalt aluminum oxide (NCA), and lithium titanate oxide (LTO) have been widely accepted by electric vehicles in recent years [

6]. According to USABC, today’s lithium-ion batteries cannot meet the standards of EVs. At present, lots of scholars, scientists, and engineers are focusing on new battery research such as Li-O

2 batteries [

2,

7], lithium–sulfur batteries [

8,

9,

10,

11,

12,

13,

14], lithium metal batteries [

15,

16], all-solid-state lithium batteries [

17], al-ion batteries [

18], fuel cells [

19,

20,

21,

22], supercapacitors [

23,

24], and so on. Electric vehicles require a high power and high capacity for lithium-ion battery systems, thus demanding a battery management system to ensure a reliable and safe operation [

25]. Additionally, a battery model is very important in states estimation of the model-based battery management system in EVs [

26]. Haran [

27] introduced a single particle model in order to develop a lumped structure. A physics-based model can predict microscopic behavior and performance, but requires a large computational power to solve the differential equations [

28]. Equivalent circuit models (ECMs) have also been proposed to control-oriented purposes to estimate the electrical response and the amount of heat generation, which are frequently used to model cells due to their simplicity, the fact that their parameters are easy to obtain, and their real-time adaptability [

28,

29]. Various ECMs are now extensively used in EV studies, such as the Rint [

30], Thevenin [

31], The Partnership for a New Generation of Vehicles, (PNGV) [

31], General nonlinear model (GNL) [

32], and Resistance-Capacitance (RC)model [

31]. In recent years, many new battery models have been put forward or improved, such as the fractional order PNGV model [

33], invariant imbedding method [

34], improved equivalent-circuit model [

35], reduced order equivalent circuit battery models [

36], fractional order impedance model [

37,

38,

39], fuzzy model [

40], kinetic battery model (KIBaM) [

41], electrochemical/electrical-thermal coupled model [

42], battery degradation model [

42], and so on. The limitations of current battery technology include underutilization, capacity fade, thermal runaway, and stress-induced material damage [

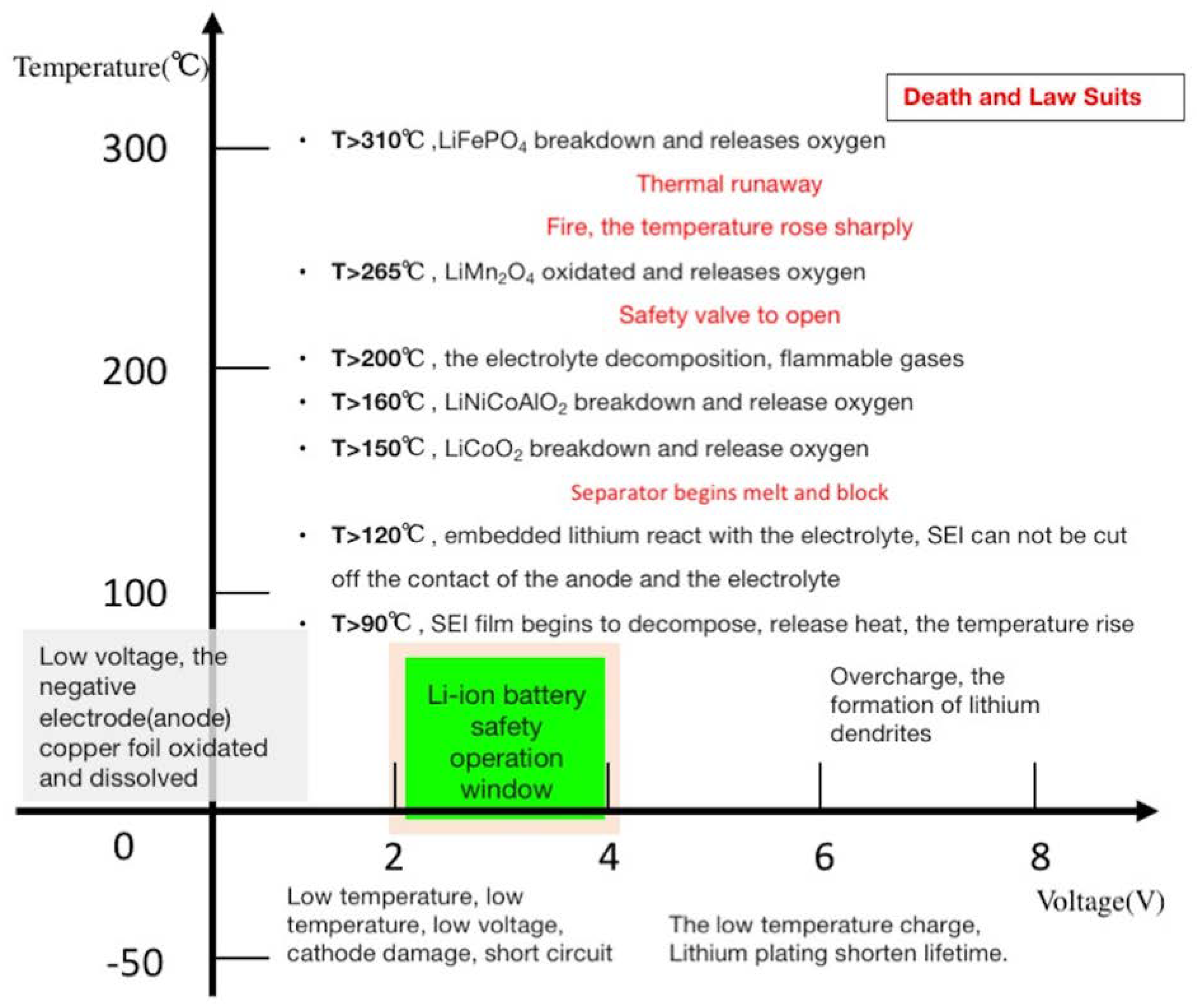

28].

In such a large number of models, the first step is to accurately identify the parameters of the model for battery state estimation. Two methods for battery model identification are electrochemical impedance spectroscopy (EIS) and pulse tests [

43]. Because these methods rely on specific equipment for testing and processing large amounts of data, they are not suitable for online applications of electric vehicles. Therefore, some researchers have proposed recursive least squares (RLS) methods or adaptive filtering (AF) methods for on-line identification of battery model parameters [

44]. Practice has proved that these methods are easier to implement in on-line applications. Besides, these methods can help to compensate for parameter values for battery variations and aging.

The state of the battery cell includes State of Charge (SOC) [

45], State of Health (SOH) [

46], State of Energy (SOE) [

47,

48,

49], and State of Power (SOP) [

35,

50]. In order to estimate these states of batteries, the researchers need to put forward a new mathematical model or an algorithmic model besides the battery model mentioned above. The well-known techniques include the Kalman filter (KF) [

51], extended Kalman filter (EKF) [

52], unscented Kalman filter (UKF) [

45], fading Kalman filter algorithm(FKF) [

53], strong tracking cubature extended Kalman filter (STCEKF) [

54], multirate strong tracking extended Kalman filter (MRSTEKF) [

55], lazy extended Kalman filter (LEKF) [

56], particle filter (PF) [

57], sliding mode observer (SMO) [

58,

59,

60,

61,

62,

63], H-infinity observer [

64,

65,

66,

67], Luenberger observer [

68], etc. The filter algorithms based on the equivalent circuit model with fixed model parameters are often used to estimate the battery state. However, the parameters of the equivalent circuit model are often affected by temperature, C-rate, SOC, and battery aging. Therefore, some joint-estimation methods have been proposed to handle these problems. These methods are usually made up of two parts. The first part is used to identify the parameters of the model with recursive least squares (RLS) on-line. The second part is used to estimate the battery state parameters with filter algorithms. Recently, because of the improvement of embedded hardware performance, some researchers have wanted to estimate battery state only using data, instead of using battery models. The Artificial Intelligence (AI) based learning approach including artificial neural network (ANN) modelling as well as the support vector machine (SVM) was proposed [

69], and could be very accurate depending on the training data.

In order to make a perfect EV, scientists, academics, researchers, and engineers have performed much research to improve the accuracy of lithium-ion battery SOC estimation for EVs. In this paper, the SOC estimation approaches and shortcomings of the EV battery system are reviewed. This paper focuses on battery SOC estimation and its issues and challenges by exploring different existing estimation methodologies. At the beginning of the article, the lithium-ion battery characteristics of the EVs are reviewed. Following this, the common key technologies of battery state estimation are explored in an in-depth analysis. Besides, the various SOC issues and challenges are also discussed. At the end of this article, the development direction of SOC is summarized. This review paper will be very helpful for scientists, academics, researchers, engineers, and automobile engineers and manufacturers for using the appropriate estimation method, which is especially important for the development of implementing a new battery management system or upgrading the battery management system in EVs in the future.

3. State of Charge Estimation Methods

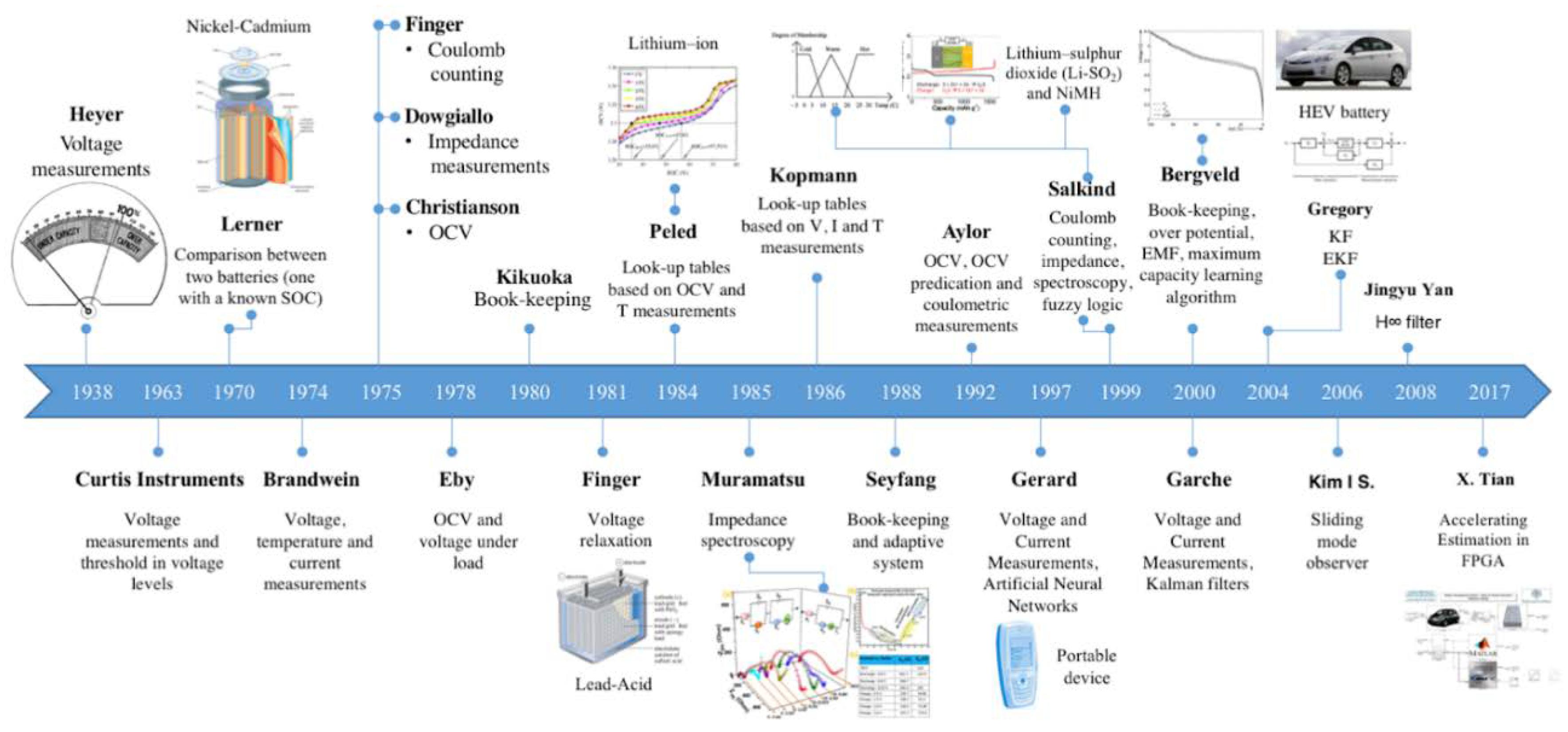

Almost since the emergence of rechargeable batteries have systems that can indicate the available capacity value of the battery inside existed, such as the single-meter device invented by Heyer [

75] in 1938. Curtis Instruments pioneered the development of gauges for monitoring the battery SOC of traction vehicles in 1963. Finger et al. [

76] invented a battery current flowing integrator module in 1975. Peled [

77] proposed a method based on predetermined voltage and temperature measurements relationship tables for the determination of lithium-ion batteries SOC in 1984. Aylor [

78] presented a coulomb counting method for LA batteries. Gerard [

79] developed an artificial neural network method for portable equipment battery state accurate estimation in 1997. Garche et al. [

80] proposed a Kalman filters method to estimation SOC in 2000. KIM [

60] presented the state equation for battery models and the systematic design approach for sliding mode observers in 2006. Tian [

81] recently proposed the implementation of an SOC estimator for lithium-ion batteries in a field programmable gate array (FPGA). The most important points of the battery SOC estimation evolution are shown in

Figure 3.

According to the evolution history of battery SOC, it is known that when the rechargeable battery appears, research on the SOC also appears. Until now, the SOC is still the hot point and key point of research. The existing SOC estimation methodologies can also be categorized into five groups, which are the conventional method, the adaptive filter algorithm, the learning algorithm, the nonlinear observer, and the hybrid algorithm.

3.1. Conventional Method

The conventional method of SOC estimation consists of ampere-hour counting, the open circuit voltage (OCV) method, the impedance and internal resistance method, the electrochemical method, and the model-based method.

(1) Ampere-hour counting method

Ampere-hour counting is easy to implement with low computational complexity to estimate the SOC of a battery [

4]. The Ampere-hour (Ah) counting estimation method is used to integrate the discharging or charging current to calculate the remaining charge in the battery, as follows [

82]:

where

is the battery initial SOC,

is the current at time

,

T is the sampling period,

is the nominal capacity of the battery,

is the coulombic efficiency, and

is the self-discharging rate. For a LiFePo

4 battery,

under room temperature, the self-discharging rate is about 5% per month.

The biggest advantage of the Ah counting method is its low power computation cost, so it is widely used for battery SOC estimation. But the disadvantage of the Ah counting method is that it cannot remain accurate for a long time. The unknown initial SOC, capacity fading, self-discharge rate, and current sensor errors are the error sources for the Ah counting method. In order to improve the accuracy of the Ah method, the initial capacity and SOC value of the battery, and the current sensor drift can be corrected and adjusted regularly [

83].

(2) OCV method

OCV is the method that uses the stable battery electromotive force in the open circuit state and SOC relationship to estimate the SOC value [

83]. Although there is an approximate linear relationship between SOC and OCV, this relationship is not exactly the same for different batteries. It depends on the capacity and electrode material of the battery. For example, a lead-acid battery has a linear SOC and OCV relationship, while a lithium-ion battery does not have this relationship [

4]. LFP batteries have a very flat SOC-OCV relationship and a significant OCV hysteresis phenomenon. Thus, the OCV method is not reliable in LFP batteries [

84]. Although the SOC-OCV relationship of lithium ion batteries is relatively stable, it will change according to the environmental temperature and cycle life of the battery. In addition, in order to have a reliable SOC-OCV relationship, researchers and engineers may need to conduct massive experiments at different temperatures and cycle lives [

83].

Accurate SOC-OCV relationship data is the key issue for OCV method estimation depending on the fitting OCV relaxation model parameters [

85]. However, the OCV voltage cannot be directly measured if there is no sufficient rest time. Direct use of the OCV method is employed to estimate SOC which has a very low power computation and a relatively high accuracy, but this method is limited by the working conditions. Therefore, it is generally used as a calibration auxiliary technology.

(3) Impedance and internal resistance method

The lithium-ion battery impedance and internal resistance can be used to describe the intrinsic electric characteristic under any current excitation, if temperature, SOC, and SOH are fixed. But it is very difficult to measure online electrical impedance spectroscopy (EIS), because sinusoidal alternating current (AC) may be required, the SOC and impedance relationship is not stable, and the cost is expensive [

83]. To obtain the internal resistance, it needs direct current (DC) and the value of the voltage and current at a small time interval. However, internal resistance changes slowly and is hard to observe for SOC estimation. In general, SOC estimation based on the impedance and internal resistance method is not suitable for use in EVs [

83].

(4) Electrochemical method

Estimating the amount of Li or the average Li concentration in the positive or negative electrodes is critical for SOC estimation based on the electrochemical model with partial differential equations. The SOC can be directly calculated from Li amount identification in the negative or positive electrodes of the electrochemical model. Nevertheless, the solution of partial differential equations is always too complex for online applications [

83]. Generally speaking, the electrochemical model can theoretically obtain the most accurate SOC estimation. But, this model is only suitable for off-line design and performance analysis for lithium-ion batteries. Nevertheless, due to the complexity of the electrochemical model and the dozens of parameters of the battery model, this method is too difficult to use for online SOC estimation [

83].

(5) Model-based method

In the conventional method, the above methods are not unsatisfactory for online SOC values. In order to achieve an accurate online SOC value, the battery models need to be developed. The most common usage of battery models includes the electrochemical model and equivalent circuit model (ECMs). ECMs mainly use resistances and RCs to simulate the electrical characteristics for lithium-ion batteries. An ideal ECM should be able to simulate the actual battery voltage under any current excitation. However, some characteristics of the lithium-ion batteries cannot be well represented by circuit elements, such as the hysteresis effect or the Warburg effect. Therefore, pure mathematical models with hysteresis are used to further improve the accuracy of voltage simulation [

83].

Two technical routes are usually used to estimate SOC using ECM. The first method is a simple way to estimate SOC directly through ECM parameter identification. The second method firstly uses a predetermined SOC to realize OCV and then estimates the lithium-ion battery voltage through ECM. Hence, the SOC-OCV relationship is very important not only in OCV method estimation, but also in model-based method estimation [

83].

3.2. Adaptive Filter Algorithm

In order to improve the accuracy and robustness of the battery SOC estimation and reduce the noise influence on the battery model, the adaptive filtering algorithm of modern control theory provides another method for estimating the SOC.

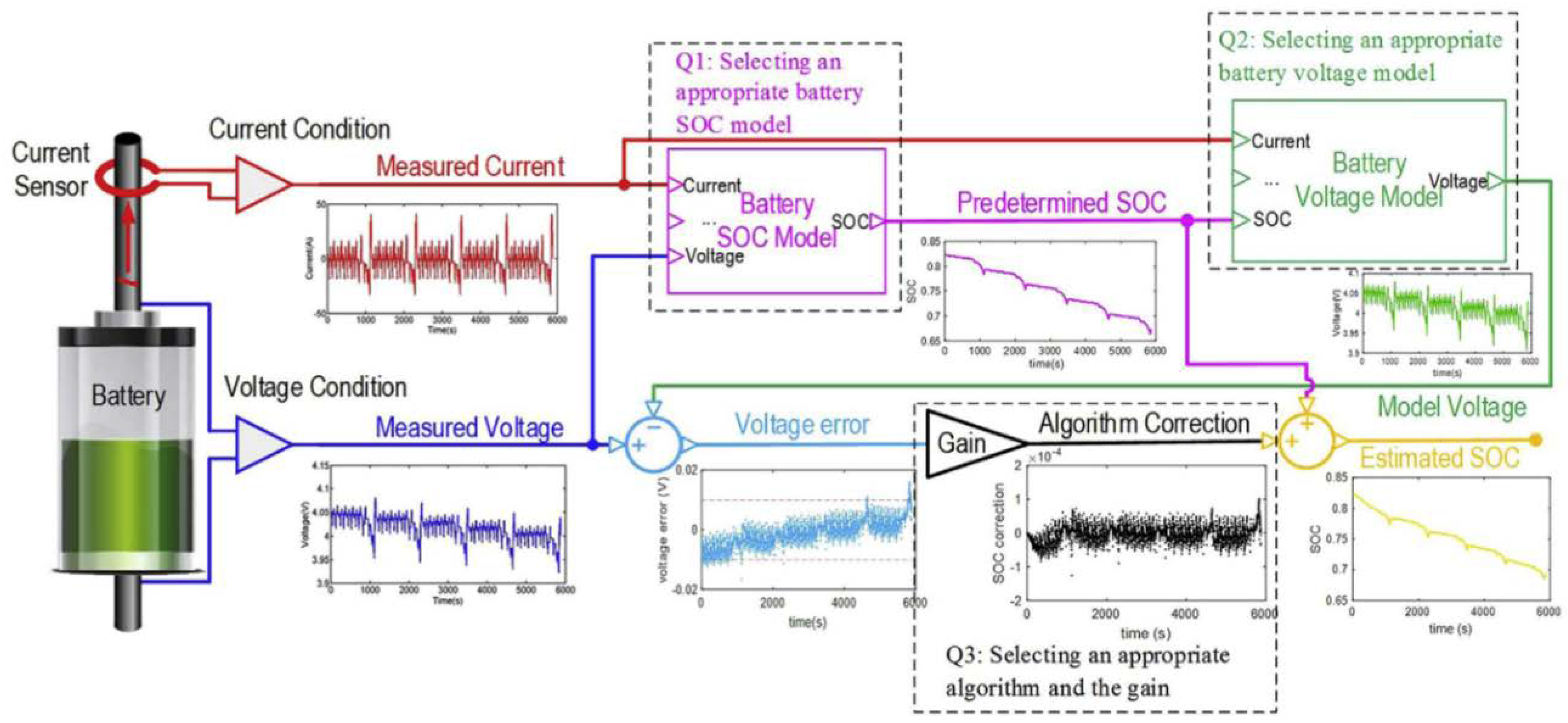

Figure 4 shows the flow chart of the adaptive filter algorithm based on the modern control theory. As suggested in the flow chart, there are three basic functions that need to be discussed. The first is how to use the battery SOC model to estimate a predetermined SOC as an input for the models. The second is which model should calculate the battery voltage at the predetermined SOC as an output for the models. The third is how to calculate the gain to update the SOC by comparing the measured voltage and model voltage.

(1) Kalman filter

The Kalman filter is the optimum state estimator and intelligent tool for a linear system, and is often used to estimate the battery dynamic state, such as that described in [

4,

51]. The most attractive feature of KF is that it has a self-correcting nature when the system is running, which helps to tolerate high variations. The Kalman filter algorithm is shown in

Table 2. The KF linear state-space model includes the process of predicting the current state from the earlier state and a measurement which updates the current state to converge it to the real value.

According to Ting and Yatsui’s [

86,

87] research, researchers should use the KF method and combine the open-circuit voltage and Ah counting to compensate for the non-ideal factors that can prolong the operation of the battery. The advantage of the KF method is that it can accurately estimate the states affected by external disturbances. Nonetheless, KF cannot be directly applied to the state prediction of a nonlinear system and it requires complex calculations [

4,

88].

(2) Extended Kalman filter

If the system is nonlinear, then we can use a linearization process at each time step to approximate the nonlinear system with a linear time varying (LTV) system. Then, the system is applied to the Kalman filter, resulting in an extended Kalman filter (EKF) on the true nonlinear system applied for the SOC estimation [

44,

51,

52,

82,

89,

90,

91,

92,

93,

94,

95].

EKF linearized the battery model using partial derivatives and first order Taylor series expansion. The state-space model is linearized at each time instance, which compares the predicted value with its measured batteries terminal voltage to correct the estimation parameters for SOC. However, if the system is highly non-linear, linearization error may occur due to the lack of accuracy in the first order Taylor series under a highly non-linear condition [

4]. The extended Kalman filter algorithm is shown in

Table 3.

Because of the advantages of EKF, many researchers have applied this method to the study of battery SOC, such as Lee et al. [

96], who proposed dual EKF, and Chen et al. [

97] and Zhu et al. [

98], who improved the nonlinear battery model with EKF to estimate the SOC of a lithium-ion battery. Compared to other extended Kalman filter algorithms, the strong tracking cubature extended Kalman filter (STCEKF) proposed by Gao et al. [

54] gave an accurate SOC prediction and faster computational time. J. Jia et al. [

55] proposed a multirate strong tracking extended Kalman filter (MRSTEKF) by introducing the multirate control strategy and lifting technology into a strong tracking extended Kalman filter (STEKF) to improve the tracking stability and estimation precision of SOC. Result shows that the MRSTEKF is faster than EKF and STEKF by 55.34% and 49.51%, and is more precise by 52.66% and 33.88%, respectively [

55]. The advanced EKF method has a better performance than generality EKF, KF, and the ampere-hour counting method in terms of effectiveness and dynamic adaptability [

96,

97,

98].

(3) Adaptive extended Kalman filter

An adaptive extended Kalman filter (AEKF) is proposed in [

95] using a modified second-order RC network-based battery model and automatic correction of the process noise matrix and measurement noise matrix to obtain a correct and robust lithium-ion battery. A summary of the adaptive extended Kalman filter algorithm is shown in

Table 4.

Xiong et al. [

100] built an online AEKF algorithm with the Thevenin model to estimate SOC. This AEKF algorithm can reduce the SOC estimation error by 2%, validated by an urban dynamometer driving schedule (UDDS). It shows that AEKF is better than EKF in regard to accuracy and reliability.

(4) Fading Kalman filter

The Fading Kalman filter (FKF) is insensitive to noise covariance variations and capable of compensating for any modeling error, because it uses a fading factor that can limit its memory. The Fading Kalman filter algorithm is shown in

Table 5.

KaiChin Lim et al. [

53] proposed an FKF to estimate the OCV and SOC. According to this study, FKF can avoid the possibility of large estimation errors, which may occur when using the traditional Kalman filter because of its capability to compensate for any modeling error through a fading factor. The advantage of the Fading Kalman filter

i that it can provide the feasibility and simplicity required for real-time application with highly precise SOC estimation [

53].

(5) Unscented Kalman filtering

The EKF method is good at the first and second order of a non-linear model, but is bad at a highly non-linear state-space model. The Unscented Kalman filtering (UKF) algorithm is used to handle this problem [

83]. UKF is an updated version of EKF that applies a discrete-time filtering algorithm and unscented transform to solve filtering problems. UKF based on unscented transformation was proposed to avoid the weakness of Taylor series expansion compared to EKF [

45,

92,

101]. The UKF approach for SOC estimation is shown in

Table 6.

(6) Sigma-point Kalman filter

The sigma-point Kalman filter (SPKF) is another method for the estimation of the states in the non-linear system. SPKF depends on numeric approximations instead of EKF analytic approximations [

103,

104]. The algorithm selects sets of sigma points, which is completely similar to the value of mean and covariance of the model being developed. The sigma-point Kalman filter approach for SOC estimation is shown in

Table 7.

He et al. [

105] proposed a joint battery model and SOC estimation method based on the sigma point Kalman filter. These reports show that the proposed combinatorial method only requires a very small computational load and less memory storage to achieve effective results.

The advantages of using SPKF are that it has an identical calculation complexity to EKF without considering Jacobian matrices. In SPKF, derivatives do not need to be calculated, the original functions do not need to be differentiable, and the computational complexity is the same order as EKF, so the gains are made at little or no additional cost and are theoretically more precise than EKF [

103].

(7) Particle Filter (PF)

The Particle filter (PF) algorithm is used to estimate the states, which approximate the probability density function of a non-linear system by using the Monte Carlo simulation technique [

4]. Ruifeng Zhang et al. [

106] proposed a cubature particle filter (CPF) for accurate and reliable SOC estimation. Min Ye [

107] proposed double-scale dual particle filtering (D-PF) and a double-scale dual adaptive particle filter (D-APF) for SOC estimation. However, the particle filter method has a higher computation. The double-scale dual adaptive particle filter approach for SOC estimation is shown in

Table 8.

(8) H∞ filter

The H∞ filter is a simple design model with a strong robustness under certain conditions. However, hysteresis, aging, and temperature effects may deviate the accuracy of the model [

4]. Charkhgard et al. [

108] proposed a universal linear model using an adaptive H∞ filter (AHF) to estimate SOC and compared it with the adaptive extended Kalman filter and square-root unscented Kalman filter. The adaptive H∞ filter for SOC estimation is shown in

Table 9.

Particle filter and observer methods can further improve the quality of the feedback gain, leading to better SOC estimation. However, the particle filter and observer method have a higher computational complexity compared to the Kalman filter method.

In the summary of the SOC estimation method based on modern control theory, using the Ah counting method, ECM, and the EKF algorithm, this estimation method could be quite reliable, with an acceptable computational complexity for online applications. Therefore, it has become a widely studied and implemented battery SOC estimation method.

3.3. Learning Algorithm

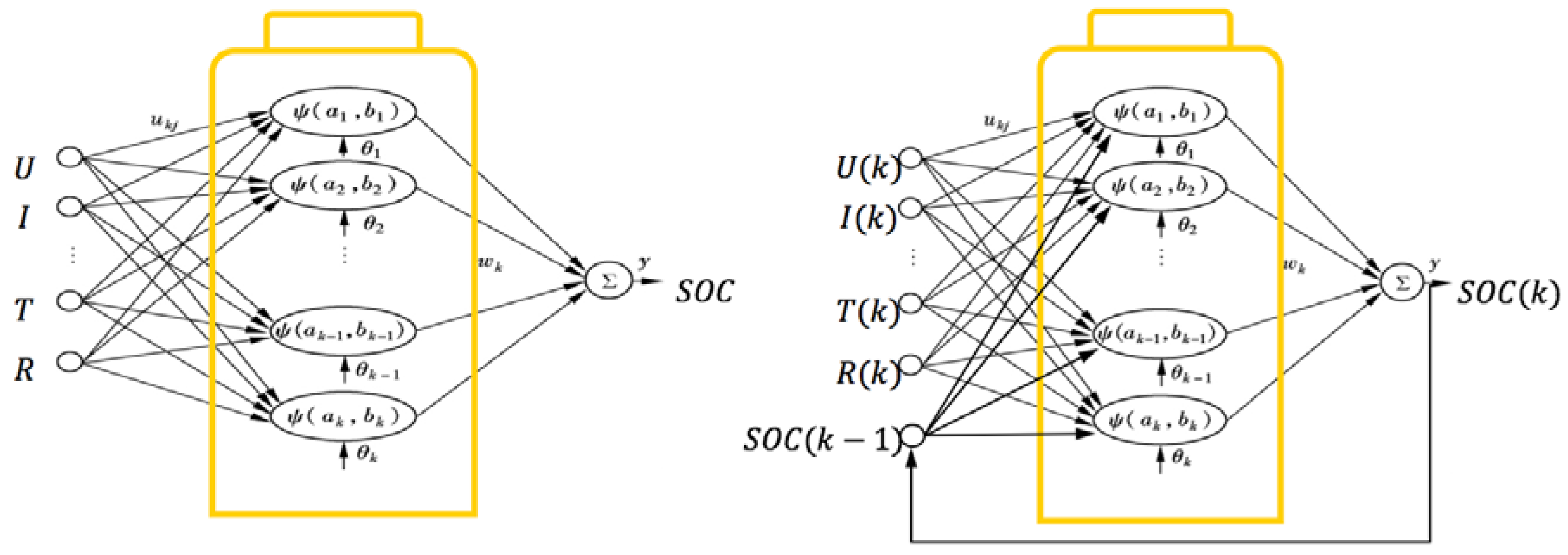

(1) Artificial Neural Network (ANN)

The artificial neural network (ANN) has the self-learning skills and adaptability to demonstrate a complex non-linear model. ANN can use the training data to estimate SOC without knowing information about the internal structure of the battery and initial SOC information. Generally, at least three layers are used for the formation of an ANN algorithm, including an input layer, one or more hidden layers, and an output layer. The structure of ANN for estimating SOC is shown in

Figure 5.

Usually, the ANN method uses the lithium-ion battery terminal voltage, discharge or charge current, and ambient temperature as the input and SOC as the output. Ruifeng and Cui et al. [

109] proposed the Levenberg-Marquardt (L-M) algorithm optimized multi-hidden-layer wavelet neural network (WNN) for SOC estimation. Xuanju Dang et al. [

110] proposed the dual neural network fusion battery model for SOC estimation. Shijie Tong et al. [

111] proposed a new architecture for SOC estimation using a load-classifying neural network and yielded a 3.8% average estimation error. This method has a simpler model training procedure, broader choice of training data, and smaller computational cost. Hicham Chaoui et al. [

112] proposed an SOC and SOH estimation based on the input time-delayed neural network (ITDNN) that accounts for both aging and temperature effects. This technique uses the multi-layer perceptron structure with the back-propagation (BP) learning rule to adjust the intra-neuron connecting weights to yield accurate results.

The advantage of the ANN method is that it can operate in non-linear conditions. Nevertheless, the algorithm needs to store large amounts of training data, which not only requires a super computing power but also large memory storage in the whole system.

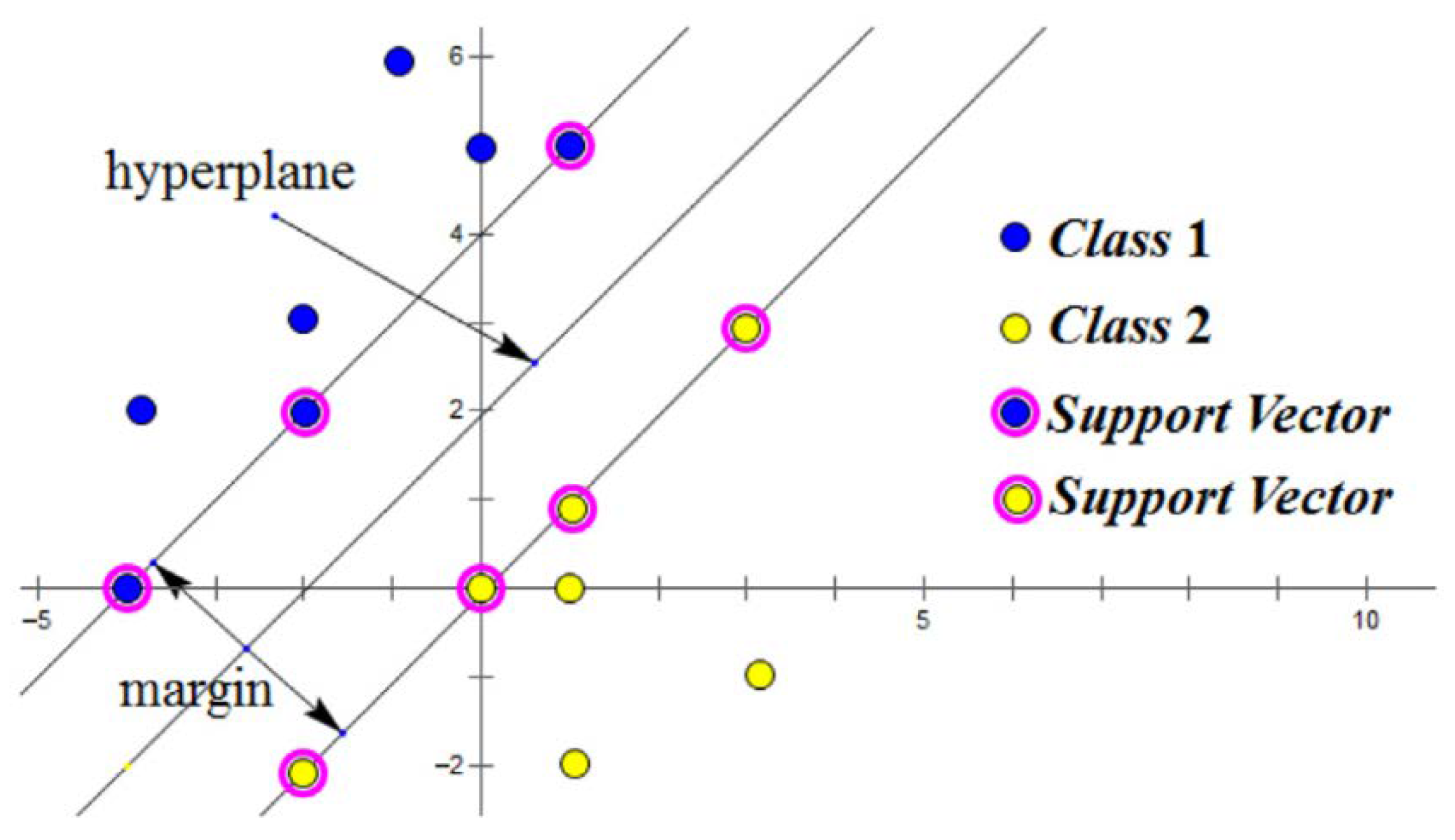

(2) Support Vector Machine (SVM)

SVM is the method that uses the regression algorithm to transform a lower dimension model into a high dimension linear model [

4]. SVM was first designed to solve the nonlinear two-class classification problem [

113]. The key point of SVM is to map the original sample from the low dimensional space to high dimensional space so that a linear hyperplane can be found to separate samples from two classes, as shown in

Figure 6.

Hanmin Sheng et al. [

114] proposed an SOC estimation method based on the fuzzy least square support vector machine. J.N. Hu et al. [

113] proposed an SOC estimation based on an optimized SVM for regression with a double search optimization process.

SVM architecture is simple and elegant, which used in the SOC estimation is time-consuming. Moreover, it can have the ability to tolerate noise and be scalable to integrate knowledge from other indicators such as temperature, power, etc.

(3) Extreme Machine Learning (ELM)

There are different ELM methods such as online-sequential ELM(OS-ELM), parallel chaos search ELM(P-ELM), incremental-ELM(I-ELM), bidirectional-ELM(B-ELM), and the proposed adaptive online-sequential ELM(AOS-ELM) that have been used to estimate the SOC of batteries in recent year [

113]. For example, Cheng Siong Chin et al. [

113] proposed an adaptive online sequential extreme learning machine (AOS-ELM) to estimate the battery SOC at different ambient temperatures. According to the research, the ELM method can reduce the error and produce a faster computational time. An example of ELM architecture is shown in

Figure 7.

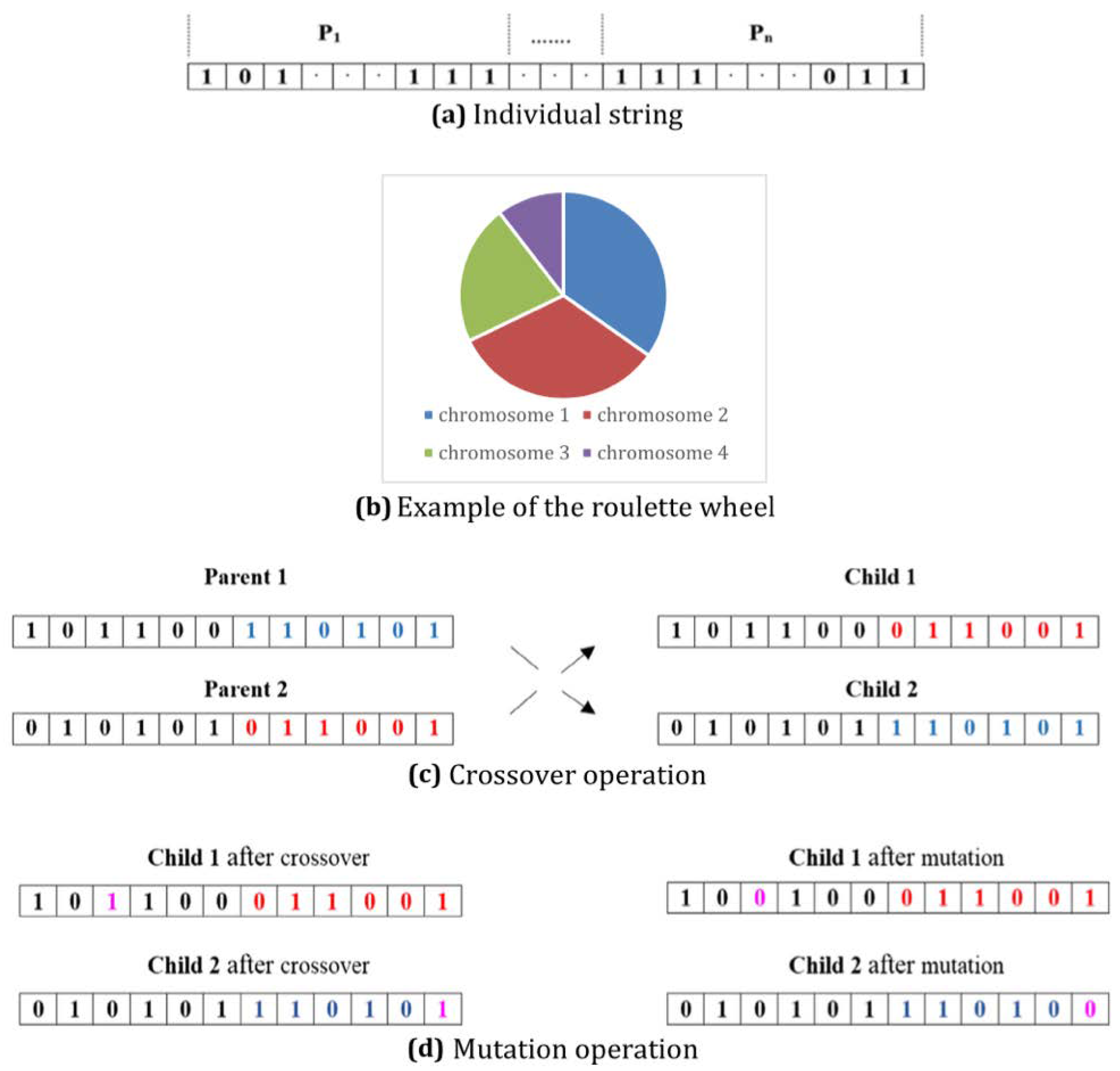

(4) Genetic Algorithm (GA)

GA is an inspiration of the biological genetic process to find approximate optimal solutions. Its basic function is to transform parameters in the most effective way, so as to enhance the efficiency of the system. Basically, GA will randomly generate N chromosomes and imitate the process of biological evolution, including selection, crossover, and mutations based on good individuals surviving and breed good individuals to optimize the variables problem [

115]. An example of the genetic algorithm steps is shown in

Figure 8.

Xu et al. [

116] used GA to optimize lithium-ion battery model parameters. Zheng Chen et al. [

117] proposed GA to estimate the battery model parameters by using battery current and voltage measurements. Besides, the GA-based BP neural network approach proposed by Zuchang Gao [

118] shows that it can display a lower error range and higher value.

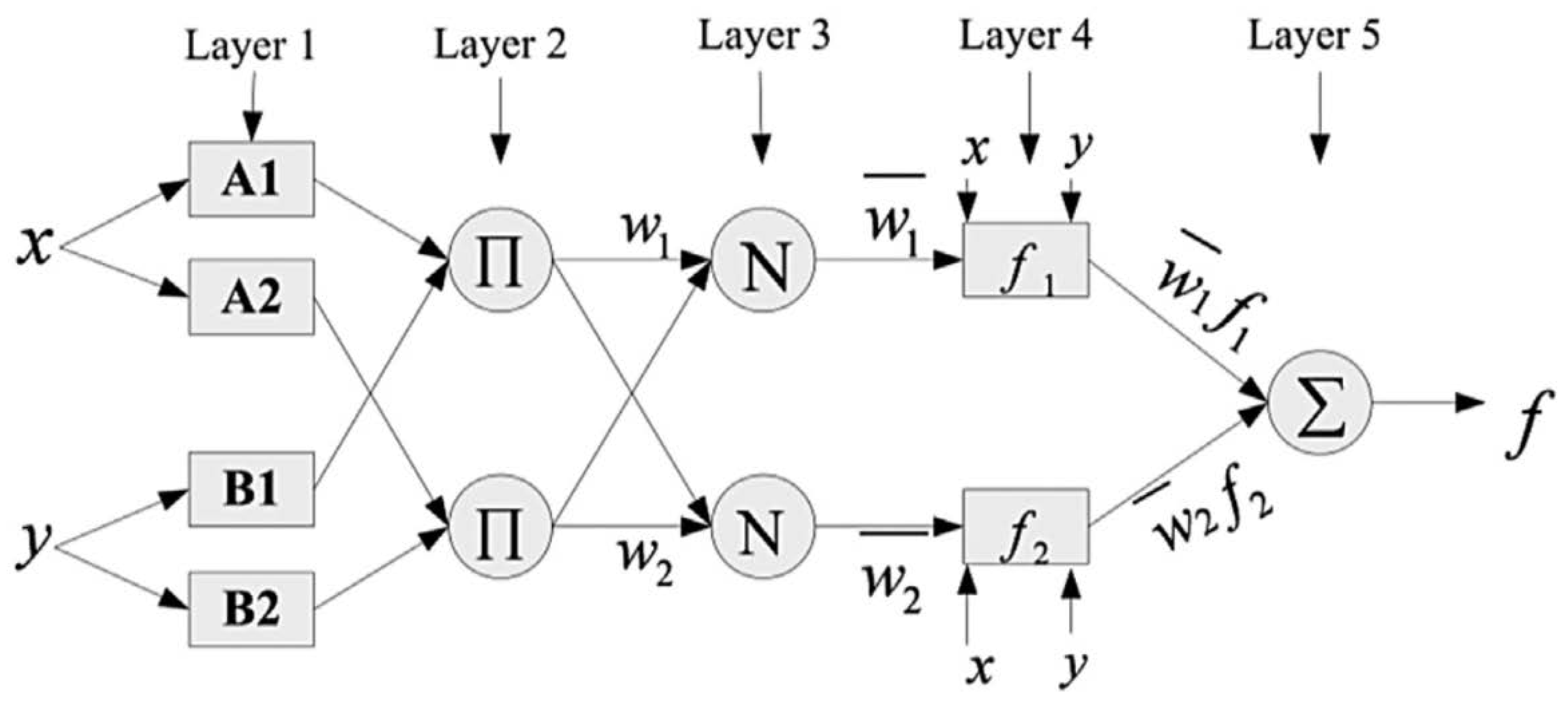

(5) Fuzzy logic (FL)

Fuzzy logic (FL) is another useful algorithm used to present a non-linear complex model with the help of the appropriate training dataset. Adaptive neuro-fuzzy inference system (ANFIS) methods are proposed to estimate lithium-ion batteries SOC, which are studied in [

119,

120,

121,

122]. Haifeng Dai et al. [

123] proposed a novel approach for online pack SOC estimation, which combines a traditional SOC estimator and an ANFIS. This method has excellent adaptation to different current conditions and the variations of the battery’s state, even with an aging process.

Figure 9 graphically illustrates a basic ANFIS structure with five layers.

Though fuzzy logic has a powerful ability to predict non-linear models, it requires complex computations and large storage memory units, as well as an expensive processing unit.

3.4. Non-Linear Observer

Non-linear observers (NLO), sliding mode observer (SMO), and proportional-integral observer (PIO) theories are proposed to estimate the SOC of lithium-ion batteries [

58,

59,

60,

61,

62,

63,

124,

125].

(1) Non-linear Observers (NLO)

Linear and non-linear observers have been used to estimate the system states. Linear observers are commonly used, but will increase the SOC estimation error. Hence, the non-linear observer is used in a linear system with non-linear observation mathematical equations [

124]. Chaoren et al. [

126] proposed the SOC estimation method based on NLO. Ma et al. [

127] proposed a novel state observer based on input-to-state stability (ISS) theory for lithium-ion battery SOC estimation. The results show that the proposed method has a high SOC estimation accuracy with an error of about 2%.

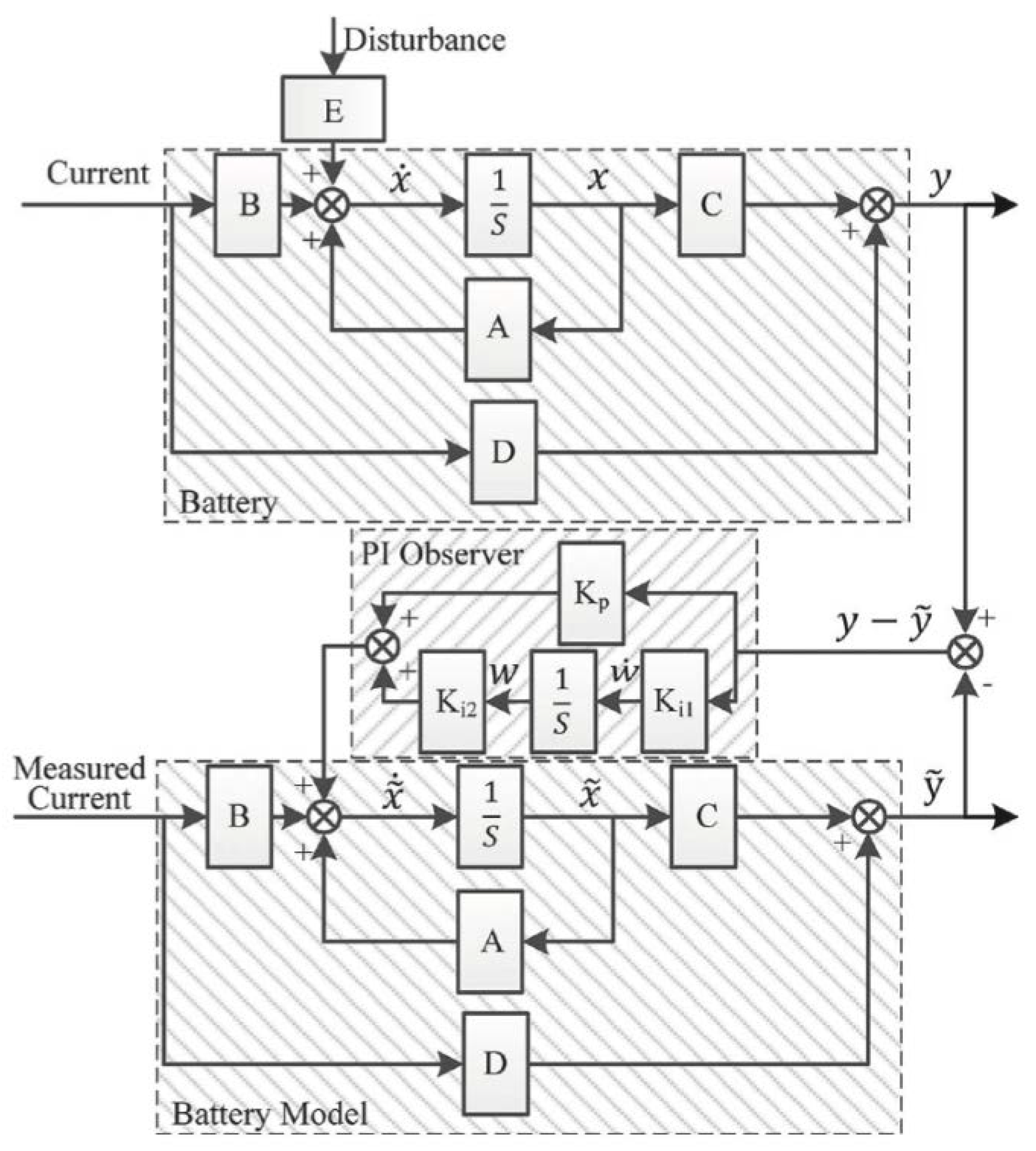

(2) Proportional-integral Observer (PIO)

PIO has been widely applied to the replacement of feedback control system [

125]. The function of a PIO controller is to converge the estimated voltage to the measured voltage in an accurate and fast way. Jun Xu [

128] proposed the PIO to estimate the SOC of lithium-ion batteries in EVs. The results show that the error is limited to 2% compared with both unknown and known SOC cases by the UDDS driving cycle. An example of the PIO algorithm for SOC estimation is shown in

Figure 10.

The PI method has a simple structure and is easy to implement. Hence, this method has a high efficiency and high precision.

(3) Sliding Mode Observer (SMO)

SMO can guarantee the stability and robustness of the system against model uncertainties and environmental disturbances [

58,

59,

60,

61,

62,

63]. The model is established by using the state equation as the output state and a feedback switching gain is designed to control the sliding regime to ensure the robustness of tracking control.

Kim et al. [

129] developed a battery SOC estimation based on the SMO method to compensate for the non-linear dynamic characteristics of the battery for hybrid electric vehicles. The proposed method was able to control the convergence time at a high value of charge or discharge value. UDDS is used to evaluate the performance of the methods and the results show that SOC error is less than 3%. Ruifeng and Wenhui et al. [

130] proposed a novel sliding mode observer for SOC estimation. Federal urban driving schedule (FUDS), the West Virginia suburban driving schedule (WVUSUB), and The New European driving cycle (NEDC) experiments are used to validate the performance of the proposed method. Experimental results show that the SOC estimation error is less than 3%.

Compared with results of the EKF method, the SMO method has a faster convergence rate and higher estimation accuracy than the EKF method, but lower computational costs.

3.5. Others and Hybrid Algorithm Method

The hybrid algorithm method is composed of two more algorithms. It can improve the efficiency and accuracy of the battery model and avoid the shortcomings of a single algorithm. The hybrid algorithm method not only achieves reliable and effective results, but also reduces the cost of the battery management system. However, this method has a very complex mathematical calculation, which requires a large storage memory and computing power unit.

(1) EKF-Ah algorithm

Choosing a suitable algorithm is a very important step in estimating SOC. However, in order to improve the accuracy of SOC estimation, the dependence on hardware and cost implications should also be considered. The EKF-Ah optimal estimation algorithm adopted by Qianqian et al. [

131] is shown in

Table 10, which relies on the current integration method to optimize the estimation with the observation value. Compared with the current integration method, the EKF-Ah algorithm overcomes the interference of the initial value on SOC estimation.

(2) Adaptive Unscented Kalman Filter and Support Vector Machine

Jinhao et al. [

132] proposed a highly accurate algorithm for lithium polymer battery SOC estimation based on adaptive unscented Kalman filters (AUKF) and least square support vector machines (LSSVM). A summary of AUKF-LSSVM for SOC estimation is shown in

Table 11.

This chapter summarizes the estimation of SOC including coulomb counting, the OCV method, Impedance and internal resistance method, Kalman family and filter method, learning algorithm method, non-linear observer method, hybrid algorithm method, and others [

133,

134,

135]. In addition to the above estimation methods, there are still other methods in the study, such as a mixture of the Kalman and H∞ filters method, mixture of SMO and the adaptive Luenberger method, the RBF-PF algorithm, and so on. To verify the advantages and disadvantages of an estimation algorithm, one of the key factors is to test the error of the result. The summary of SOC estimation error is shown in

Table 12. There are many reasons for estimated result error in the actual use, such as work environment, hardware, software code technology, battery dynamic hysteresis characteristics, self-discharge, battery aging process, temperature impact, C rate, and cell imbalance, which may lead to a decline in battery performance, so it is not enough to judge the advantages and disadvantages of the algorithm by error alone.

4. SOC Issues and Challenges

The accuracy of SOC estimation in a battery system is necessary and important. For the battery cell, an accurate SOC can provide precise parameters to make a batter lithium-ion battery cell. For the EV battery systems, an accurate SOC can prevent the battery from over-discharge and charge, thus ensuring battery system safety, making more efficient use of the limited energy, and extending the battery life. Specifically, it can support the precise calculation of the vehicle driving range, provide a better discharging or charging strategy, improve the efficiency of other power sources, and make balance strategies work more effectively. The lithium-ion battery SOC estimation in EVs has become a major challenge due to its complex electrochemical reactions and performance degradation caused by various factors [

4].

In order to improve the accuracy, stability, robustness, economy, and other challenges of the SOC estimation algorithm in electric vehicles, these issues, such as lithium-ion battery hysteresis characteristic, battery model, aging, estimation algorithm, and cell unbalancing, are worth studying in depth and are also solutions to solve SOC estimation problems.

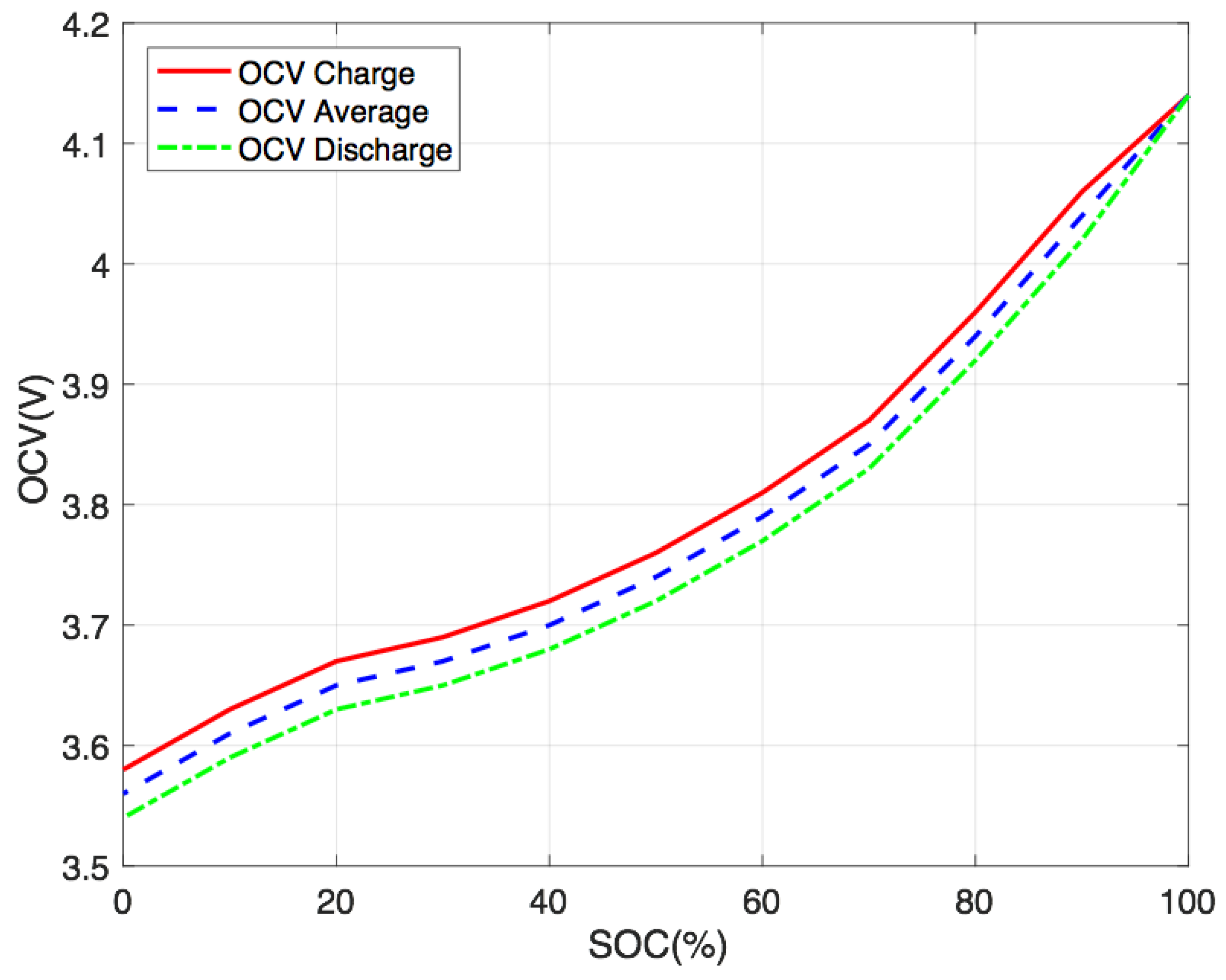

4.1. Lithium-Ion Battery Hysteresis Characteristic

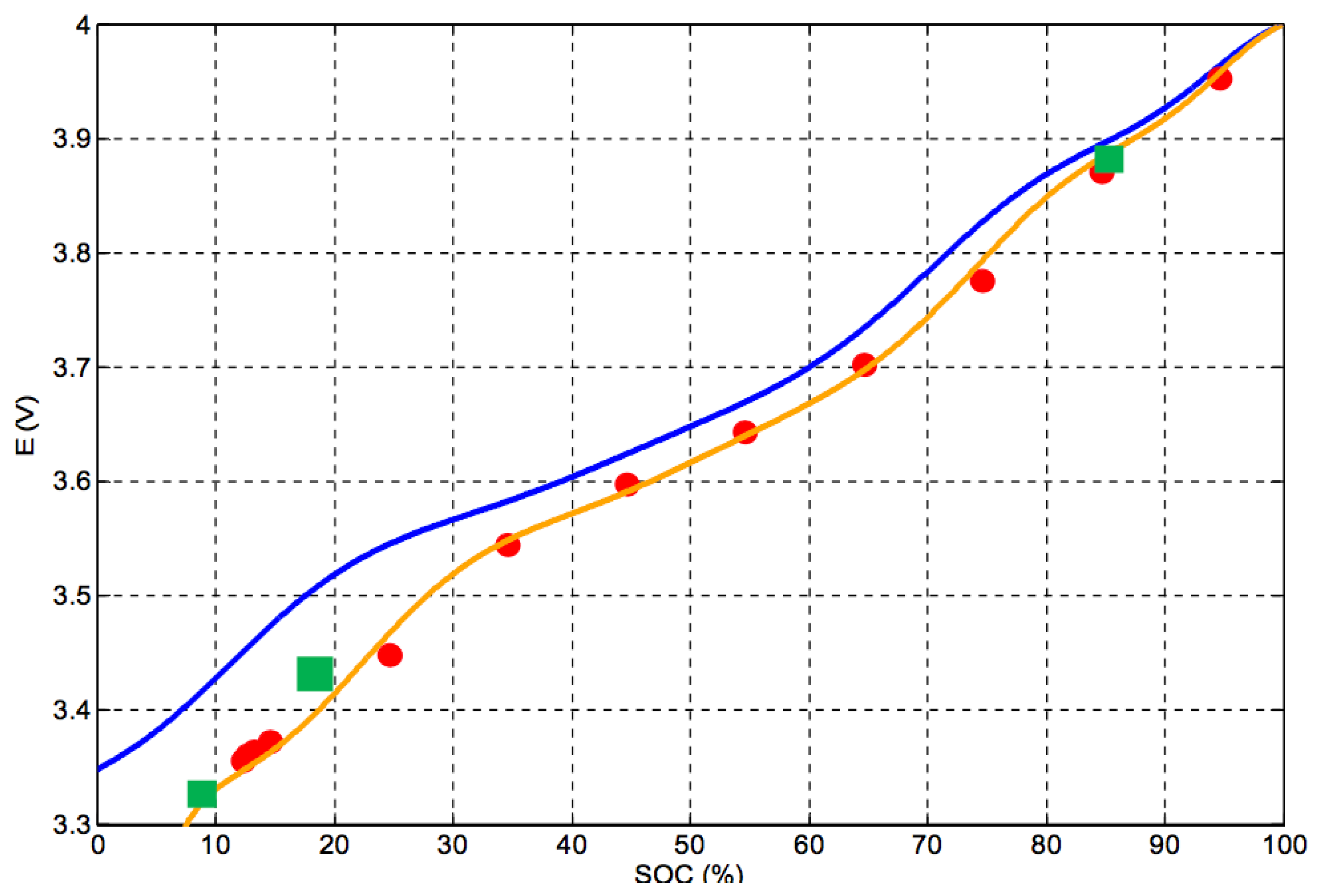

Due to the lithium-ion battery having a polarization phenomenon, this phenomenon will lead to the battery dynamic hysteresis characteristics. Because of battery dynamic hysteresis characteristics, the OCV curve of the charging and discharging process is different, as shown in

Figure 11. The battery OCV of the charging process is higher than discharging.

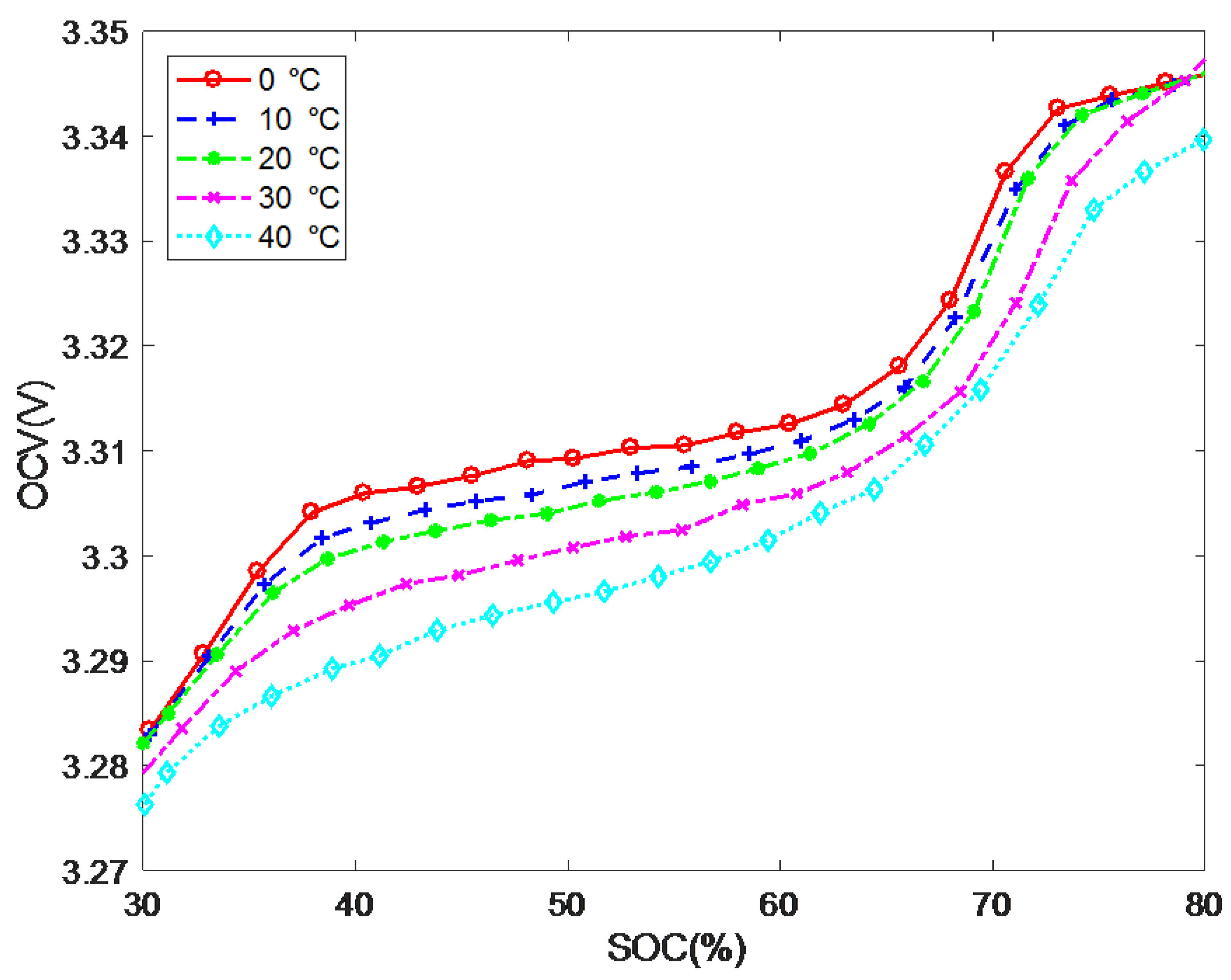

Thus, the SOC-OCV curve is not consistent with the charge and discharge. Even for a battery under the same discharge/charge, the SOC-OCV curve performance is very different under different temperature conditions, as shown in

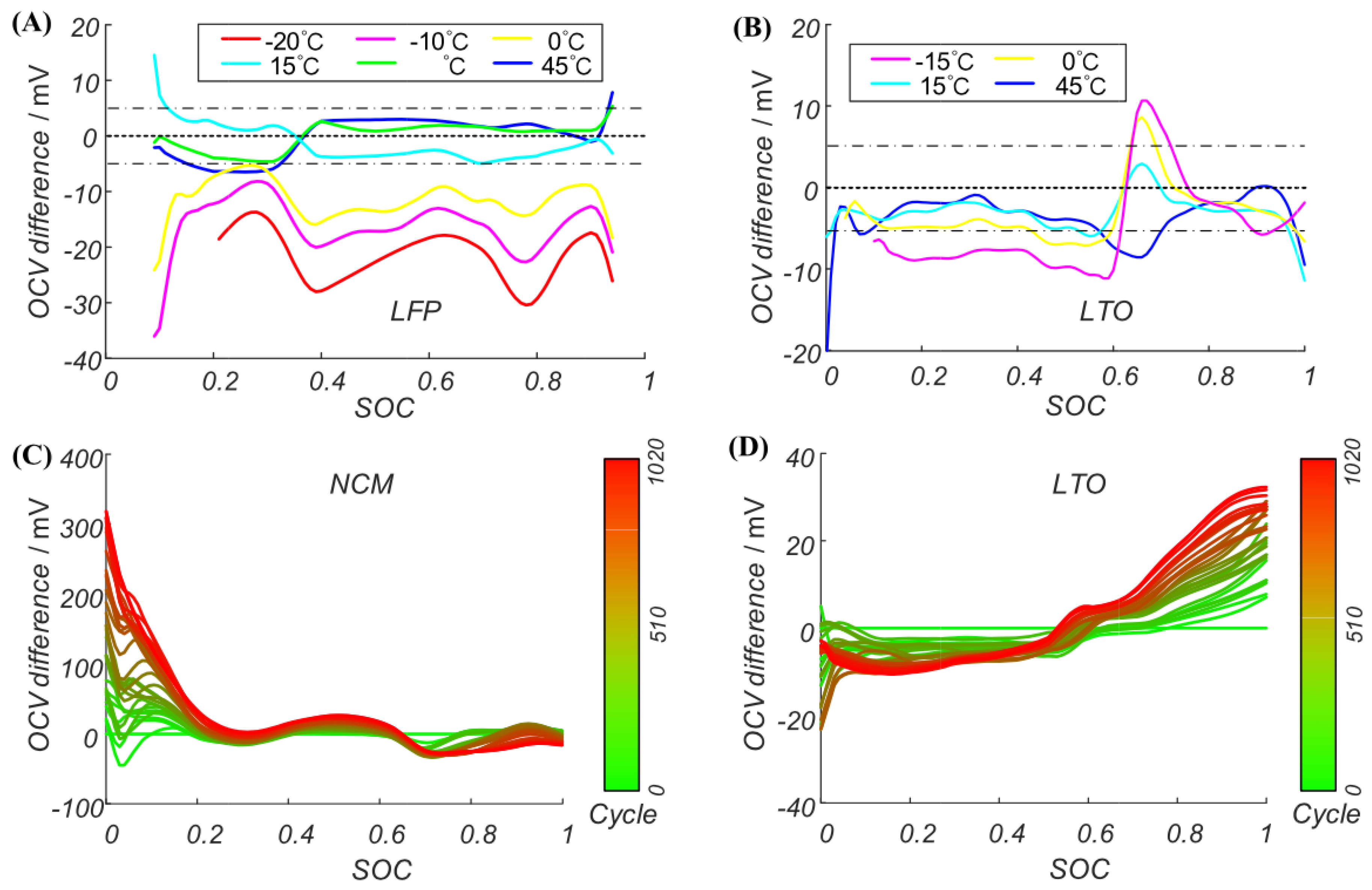

Figure 12. Furthermore, the SOC-OCV curve will be drifting when the battery ages. There are also great differences in SOC-OCV under different material systems. For example, the SOC-OCV platform of LiFePO

4 is very flat, which will bring some error to the accurate estimation of SOC. SOC-OCV characteristics under different temperatures and aging at different SOCs are shown in

Figure 13.

The SOC-OCV curve drifting after two calendar years of ageing is shown in

Figure 14. In order to overcome the challenges of aging, Lavigne et al. [

136] proposed a two stage lithium-ion OCV curve model to estimate battery SOC.

4.2. Lithium-Ion Battery Model

The state parameters of positive and negative electrodes, such as electricity, OCV, impedance, internal resistance, and Li amount, are related to the SOC estimation of lithium-ion batteries. In order to realize the identification of these parameters and estimate the battery state, a battery model is needed. A lithium-ion battery model can be classified as an electrochemical model, physical model, equivalent circuit model (ECMs), thermal model, coupled electro-thermal model, and so on. Among them, ECMs are the most commonly used in lithium-ion batteries SOC estimation for EV applications due to their simple model structure.

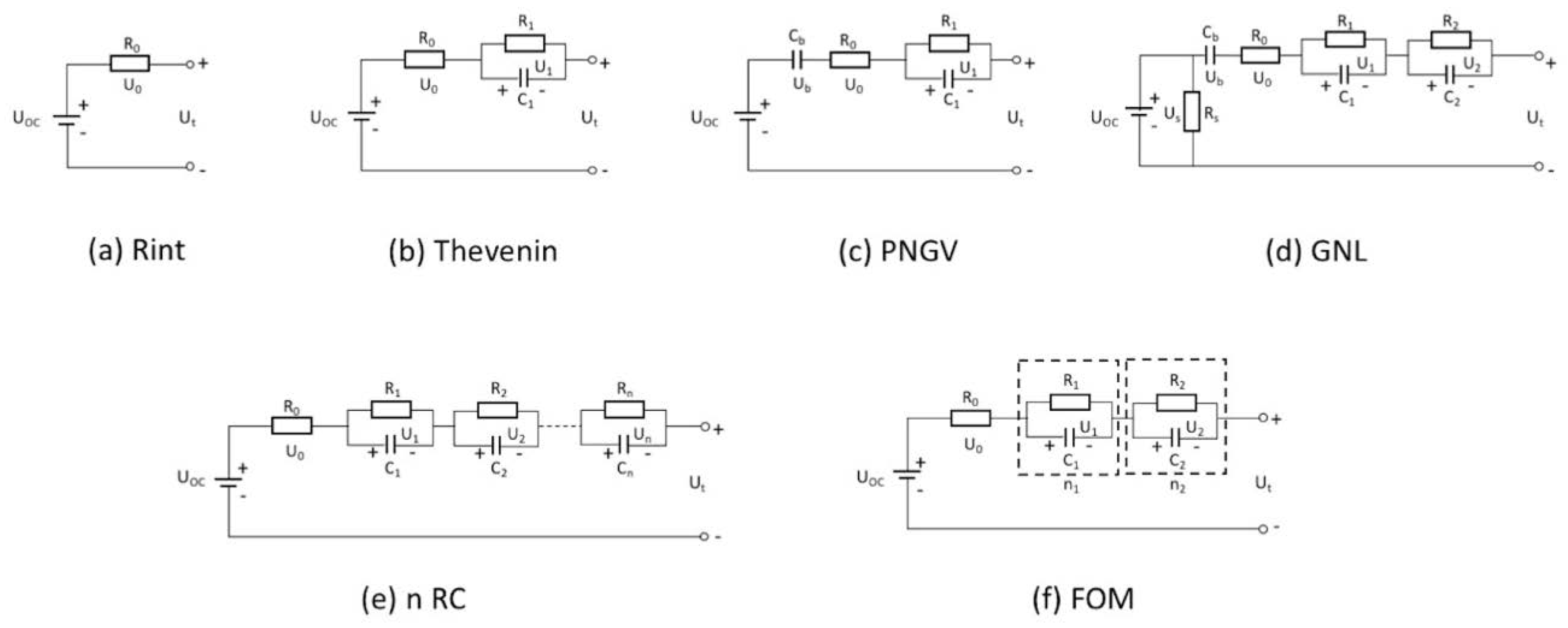

ECMs such as the Rint model, Thevenin model, PNGV model, GNL, n RC model, and FOM (Fractional Order Model), are shown in

Figure 15. The Rint model is very simple to implement in real time. However, the model’s output equation expressed is only a rough estimate actual terminal voltage of the battery, which may lead to large uncertainties in SOC estimates [

30]. The Thevenin model connects a parallel RC network in series based on the Rint model [

31]. The PNGV model can be used to describe the changing of open circuit voltage generated in the time accumulation of load current by adding a capacitor in series based on the Thevein model [

31]. The GNL nonlinear equivalent circuit battery model takes into account the influence of the self-discharge on characteristics of the battery [

137]. The nRC consists of an n parallel RC network in series based on the Thevenin model in order to considering dynamic voltage performances [

138]. In order to conquer the traditional ECMs shortcoming and guarantee the optimal trade-off between model complexity and computation efficiency, the fractional order model impedance model is studied by [

37].

These battery ECM models and equations are summarized in

Table 13.

Different battery anode-cathode material systems have different properties. Therefore, different battery models are needed to simulate different types of batteries. Battery modeling has an important influence on SOC estimation. Establishing a battery model is a challenge, because of the complex electrochemical and dynamic environment. Each model may lack accuracy and adaptability to use in different operating conditions. In addition, the battery hysteresis effect is not considered in many ECMs. So, we need to develop a suitable battery model that can work accurately under different load conditions.

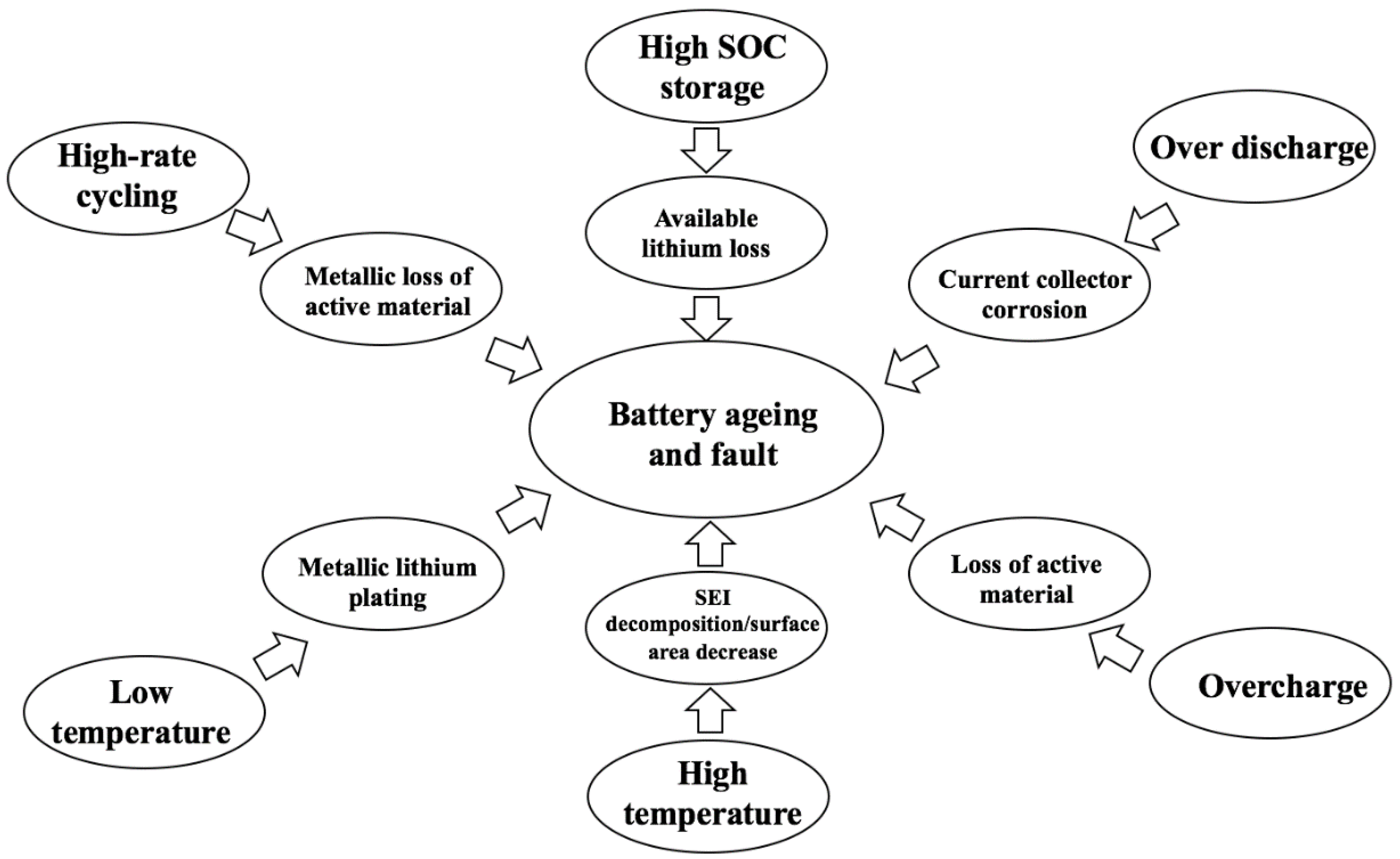

4.3. Lithium-Ion Battery Aging

Due to battery aging, SOC could not be accurately estimated. Degradation of internal resistance and capacitance, and available power fade are the main factors leading to battery aging. Main aging causes for Li-ion batteries are the decomposition of solid electrolyte interphase (SEI), deposition at the anode, metal dissolution from the anode, the loss of active material, and lithium plating [

139]. The analysis of the reasons for battery aging is shown in

Figure 16.

4.4. Estimation Algorithm

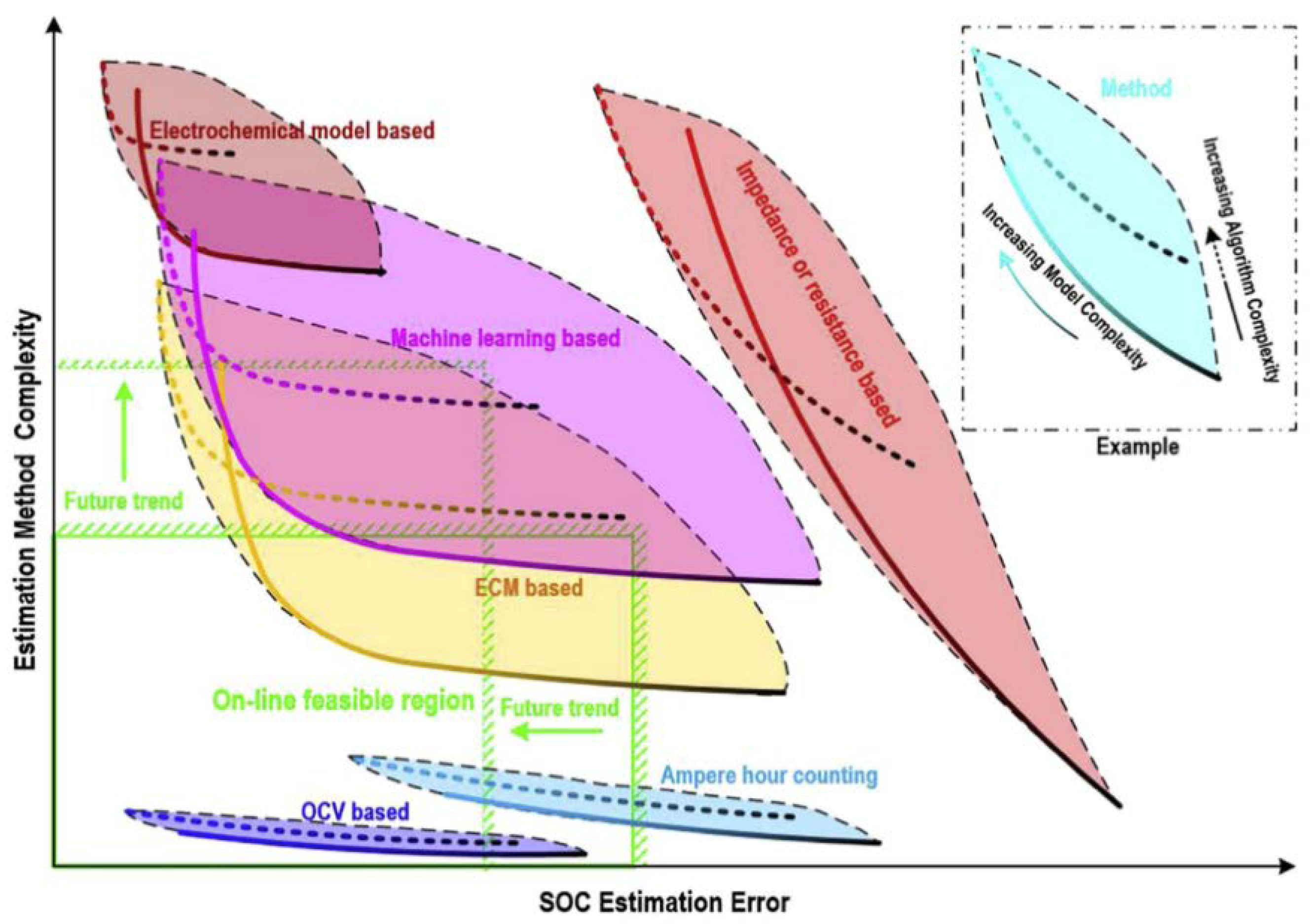

Figure 17 approximately demonstrates the estimation error and computational complexity of the SOC estimation methods, according to the estimation algorithm study. Compared to the six SOC estimation families, the Ah counting estimation method, based on the OCV estimation method and based on the ECM model, and the filter algorithms estimation method are the main three SOC estimation families, which are currently applicable EVs for online applications [

83].

At present, the most potential and most widely used SOC estimation algorithm in the battery management system of electric vehicles is a hybrid algorithm based on the combination of the equivalent circuit model and the Kalman filter algorithm family. The most significant error source of this method is that the voltage and current sensor drifts the battery model shortcoming, for which the influence of the variable effect are not enough, for example, the aging, temperature, and hysteresis effect. Thus, we should focus on these error factors, and solve the sensor drift, aging, temperature, and hysteresis effect problems.

Other measurements, such as the ultrasound velocity [

140], magnetic field intensity [

141], or mechanical stress [

142] can also be used for some special SOC estimation in research. Nevertheless, the feasibility is poor because additional sensors are needed. Besides, the accuracy is also questionable.

4.5. Cell Unbalancing

In the application of electric vehicles, the battery system is made up of numerous single cells in series and parallel. Because of the difference in the complex chemical composition, manufacturing process, environment temperature, and operating conditions of each cell, cell imbalance can be caused by the use process. Using the same estimation algorithm to estimate the SOC value of all battery cell or module will also bring greater error to the overall SOC estimation accuracy of the electric vehicle. The control strategy and the management mode of the battery system are affected. Therefore, in addition to improving the estimation accuracy of the battery cell, it is necessary to effetely monitor the state of each cell and precise control cell balance to improve the overall estimation accuracy of the SOC of the electric vehicle so that electric vehicle battery pack can deliver energy for long periods and safety [

4]. In order to simulate the battery pack model efficiently, Zuchang Gao et al. [

143] proposed prototyping a simulation model to determine the SOC and temperature of the battery working in a real world environment.

5. Conclusions

The paper describes the evolution of battery SOC estimation and various SOC estimation family algorithms were reviewed. The development and deployment of an EVs battery management system with the state estimation of SOC has been a major challenge as a result of the complex electrochemical reactions and performance degradation caused by a variety of factors. Battery dynamic hysteresis characteristics, self-discharge, ambient temperature, battery aging, C rate, and cell unbalancing are the other reasons responsible for the accuracy of SOC estimation. SOC estimation based on ECMs with the KF family method should pay more attention to the sensor drift and battery OCV hysteresis effect instead of using a more complicated algorithm according to this paper study.

Because of the severe demand of electric vehicles, the variety of battery developments will become more and more, and the electrochemical components and performance of all kinds of batteries are different, which will bring a lot of uncertainty and challenges to the general SOC estimation. In order to improve the research and application of electric vehicle battery estimation, two kinds of basic accumulation are essential. On one hand, it is needed to establish a full-type and full-life cycle test database, but this method will occupy a lot of time and cost; on the other hand, it is used to establish a foundation based battery simulation and verification tool, including the simulation software tool from the battery cell simulation, the battery model module simulation, the battery estimation simulation, to the battery heat management simulation, in order to accelerate the battery from the cell prototype design to the pack practical application. Although the battery simulation and verification base tool will include a high cost and long time, it is very meaningful and worthy of our research in the future.