Analysis of Energy Accumulation and Dissipation of Coal Bursts

Abstract

:1. Introduction

2. Energy Forms and the Energy Conservation Equation

3. Energy Accumulation

3.1. Mining Depth

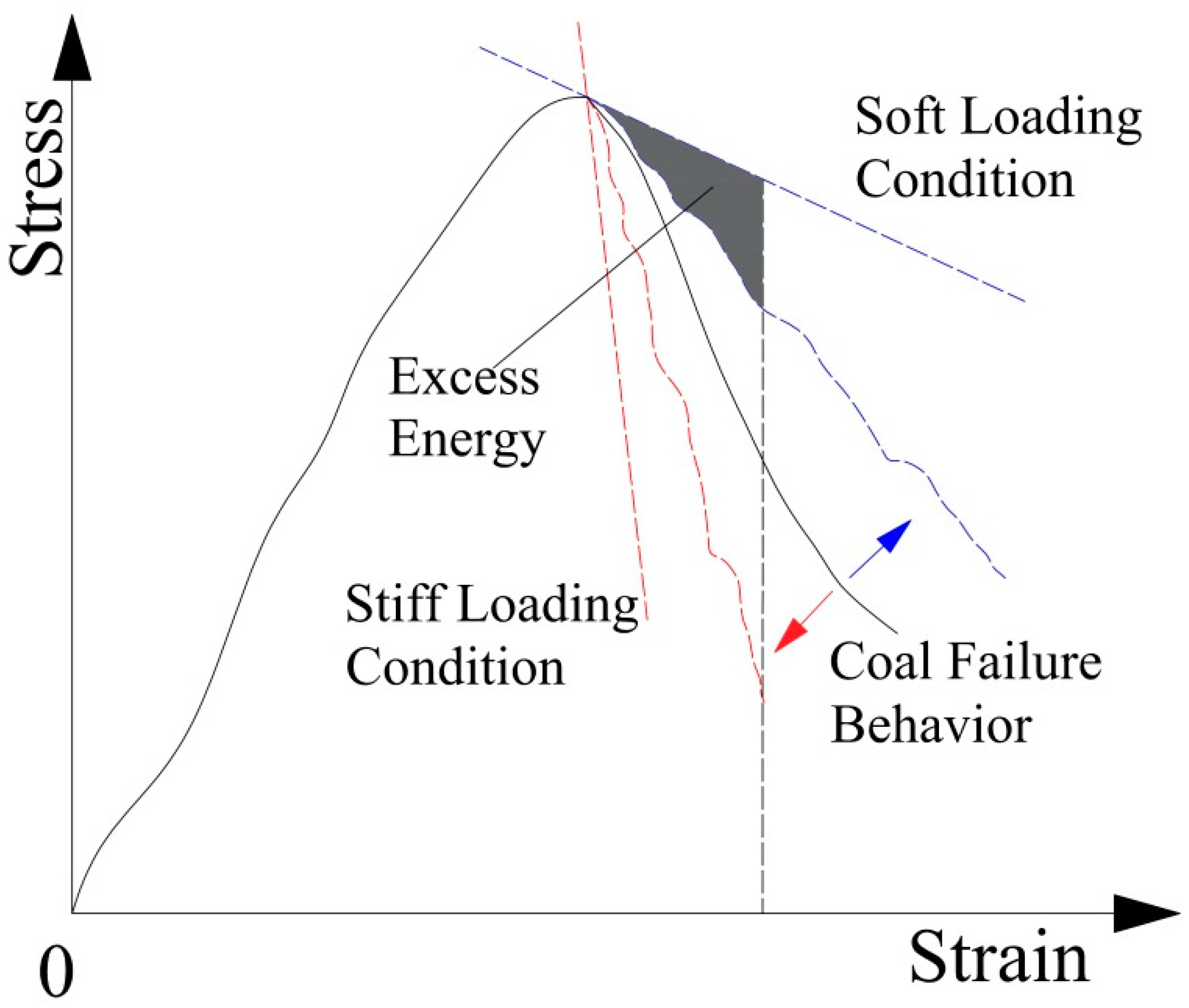

3.2. Stiffness

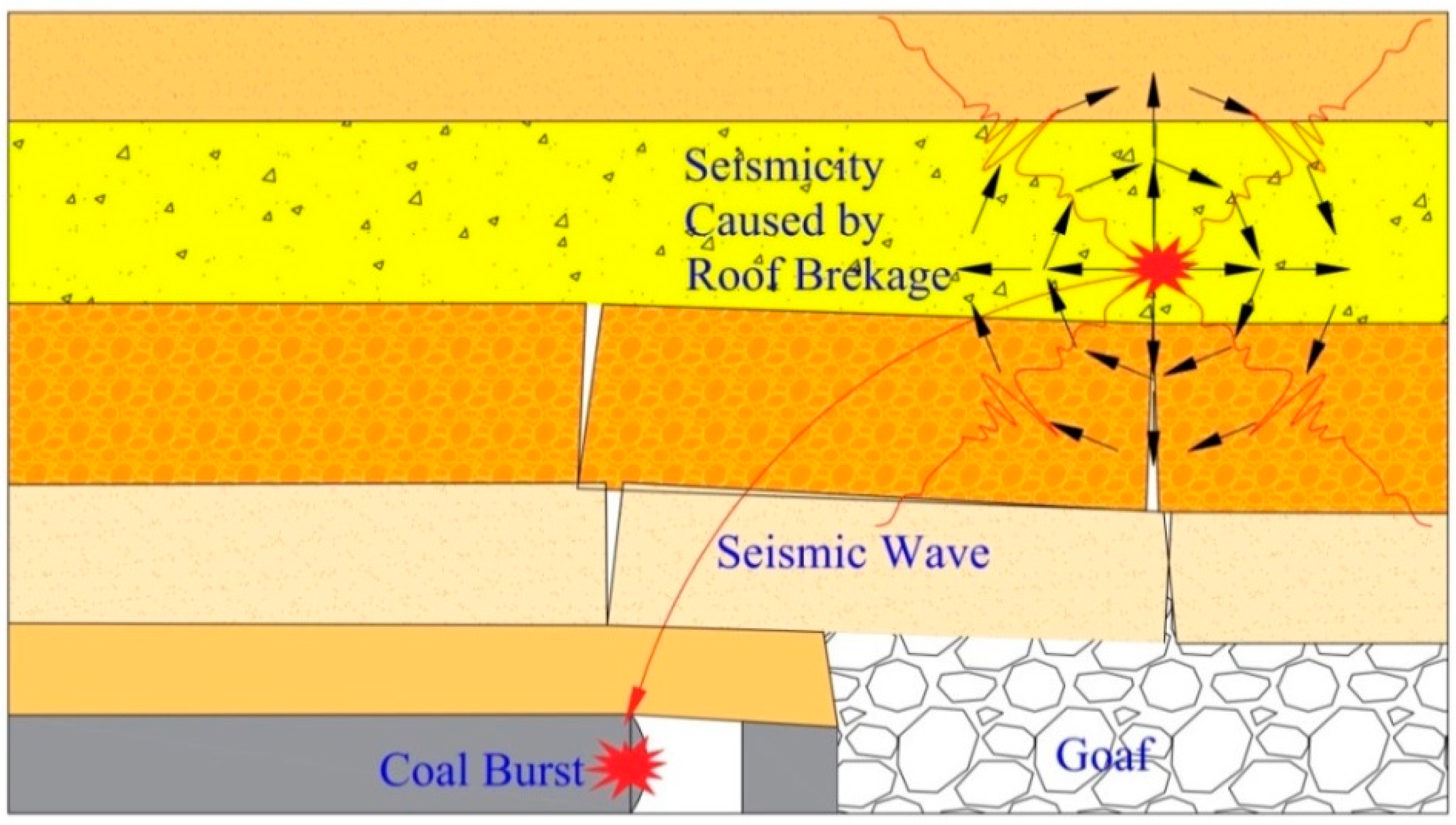

3.3. Seismicity

3.4. Elasticity

4. Energy Dissipation

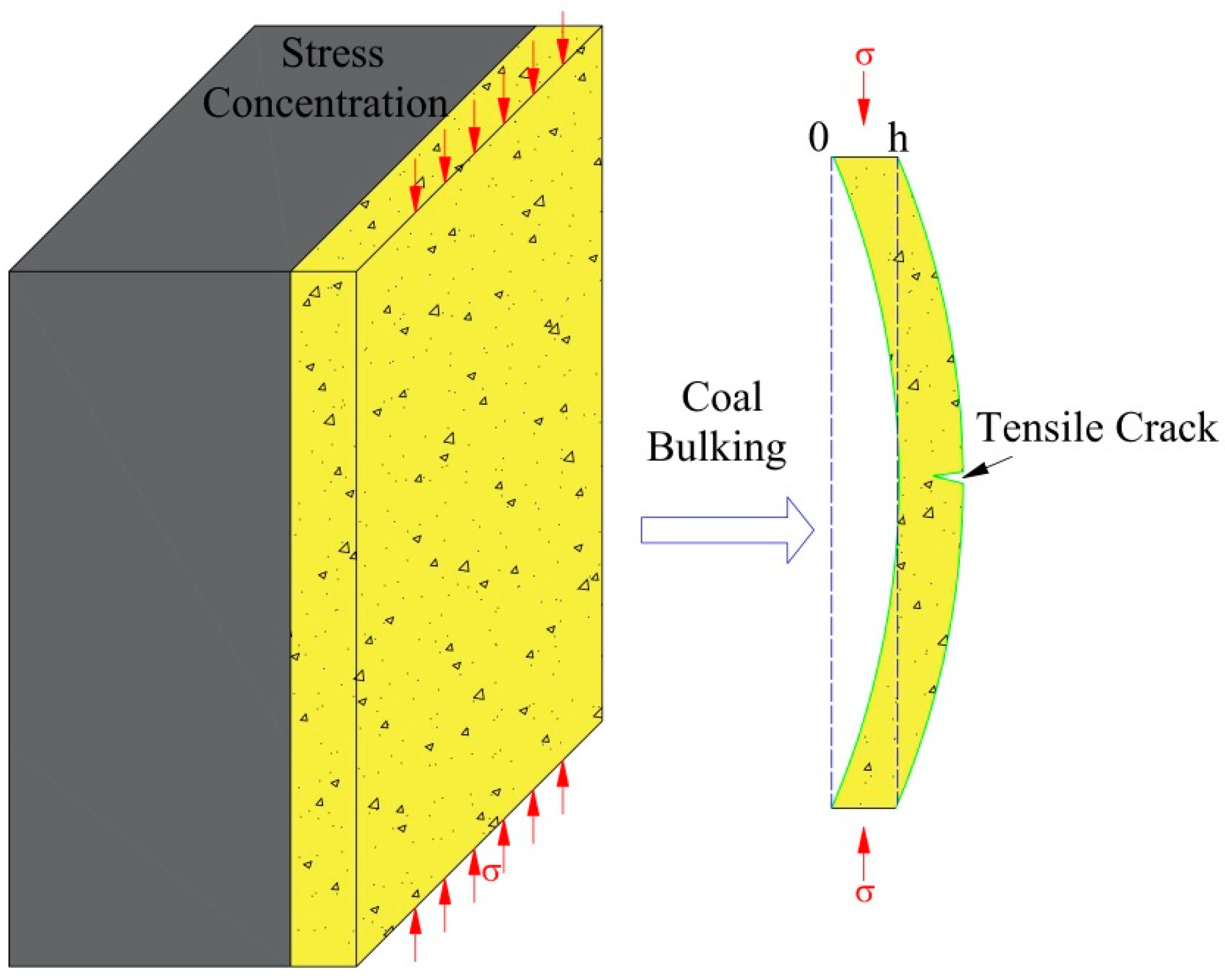

4.1. Bulking

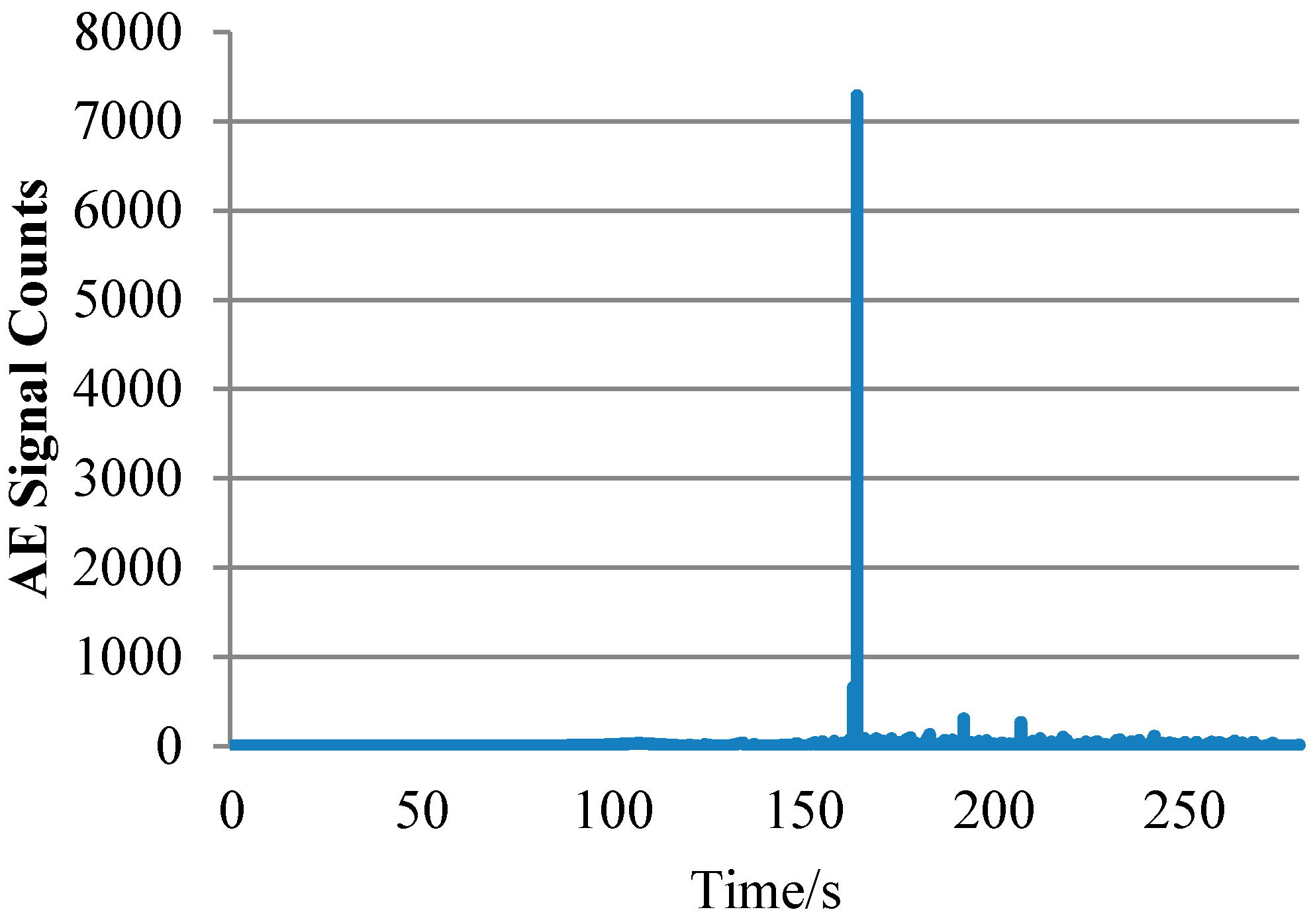

4.2. Acoustic Events

5. Conclusions

- Generally, destruction and safety hazards are caused by ejection energy, as a result of the transformation of elastic energy. The accumulation of elastic energy in coal is dominated by geological conditions, such as mining depth, surrounding rock stiffness, seismicity events, and its mechanical properties. Mining depth and seismicity events are sources of energy caused by static loads and dynamic loads, respectively. The influence of these factors on the accumulation of elastic energy was established through energy analysis.

- According to the analysis of stiffness, energy flows from the surrounding rock (high stiffness) to the coal (low stiffness). Hence, for coalmines with stiff roofs and floors, the elastic energy tends to concentrate in the coal seam.

- The elasticity of coal is determined by its capacity and ability to store elastic energy. It is recommended from our laboratory tests that the ability of coal seams to store elastic energy should be evaluated using the coal-burst propensity index prior to commencing the extraction of long-wall faces or roadways. Australian coalmines can determine their potential risk of coal bursts according to the results of the coal-burst propensity evaluation and other geological conditions.

- Some audible or visible phenomena, such as bulking and acoustic events, may appear prior to the occurrence of coal bursts. These phenomena indicate a concentration of high energy in the body of the coal, suggesting the possibility of coal bursts in the near future.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mark, C. Coal bursts that occur during development: A rock mechanics enigma. Int. J. Min. Sci. Technol. 2018, 28, 35–42. [Google Scholar] [CrossRef]

- Whyatt, J.; Blake, W.; Williams, T.; White, B. 60 Years of Rockbursting in the Coeur D’alene District of Northern Idaho, USA: Lessons Learned and Remaining Issues; Centers for Disease Control and Prevention: Atlanta, GA, USA, 1900. [Google Scholar]

- Bruce, H.; Jim, G. A Review of the Geomechanics Aspects of a Double Fatality Coal Burst at Austar Colliery in Nsw, Australia in April 2014. Int. J. Min. Sci. Technol. 2017, 27, 3–7. [Google Scholar]

- Department of Industry NSW Government. IIR16-05 Austar Coal Burst; Department of Industry NSW Government: Sydney, Australia, 2016.

- Coal Burst Leads to Austar Suspension. Available online: https://www.resourcesandenergy.nsw.gov.au/about-us/news/2018/coal-burst-leads-to-austar-suspension (accessed on 25 June 2018).

- Appin Mine Issued Ban Due to Coal Burst. Available online: https://www.resourcesandenergy.nsw.gov.au/about-us/news/2018/appin-mine-issued-ban-due-to-coal-burst (accessed on 25 June 2018).

- Whyatt, J. Dynamic failure in deep coal: Recent trends and a path forward. In Proceedings of the 27th International Conference on Ground Control in Mining, Morgantown, WV, USA, 29–31 July 2008. [Google Scholar]

- Bieniawski, Z.T. Mechanism of Brittle Fracture of Rock Part II. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1967, 4, 407–423. [Google Scholar] [CrossRef]

- Zhang, C.; Ismet, C.; Faham, T.; Bruce, H. Assessment of Energy Release Mechanisms Contributing to Coal Burst. Int. J. Min. Sci. Technol. 2017, 27, 43–47. [Google Scholar] [CrossRef]

- Kidybiński, A. Bursting Liability Indices of Coal. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1981, 18, 295–304. [Google Scholar] [CrossRef]

- Huang, B.X.; Li, P.F.; Ma, J.; Chen, S.L. Experimental investigation on the basic law of hydraulic fracturing after water pressure control blasting. Rock Mech. Rock Eng. 2014, 47, 1321–1334. [Google Scholar] [CrossRef]

- He, H.; Dou, L.M.; Fan, J.; Du, T.T.; Sun, X.L. Deep-hole directional fracturing of thick hard roof for rockburst prevention. Tunn. Undergr. Space Technol. 2012, 32, 34–43. [Google Scholar] [CrossRef]

- Frid, V. Electromagnetic radiation method water-infusion control in rockburst-prone strata. J. Appl. Geophys. 2000, 43, 5–13. [Google Scholar] [CrossRef]

- Liu, X.F.; Xu, G.; Zhang, C.; Kong, B.; Qian, J.F.; Zhu, D.; Wei, M.Y. Time Effect of Water Injection on the Mechanical Properties of Coal and Its Application in Rockburst Prevention in Mining. Energies 2017, 10, 1783. [Google Scholar] [CrossRef]

- Bieniawski, Z.T.; Denkhaus, H.G.; Vogler, U.W. Failure of Fractured Rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1969, 6, 323–341. [Google Scholar] [CrossRef]

- Song, D.Z.; Wang, E.Y.; Liu, J. Relationship between EMR and Dissipated Energy of Coal Rock Mass during Cyclic Loading Process. Saf. Sci. 2012, 50, 751–760. [Google Scholar] [CrossRef]

- Yamada, I.; Masuda, K.; Mizutani, H. Electromagnetic and Acoustic Emission Associated with Rock Fracture. Phys. Earth Planet. Inter. 1989, 57, 157–168. [Google Scholar] [CrossRef]

- Li, X.L.; Wang, E.Y.; Li, Z.H.; Liu, Z.T.; Song, D.Z.; Qiu, L.M. Rock Burst Monitoring by Integrated Microseismic and Electromagnetic Radiation Methods. Rock Mech. Rock Eng. 2016, 49, 4393–4406. [Google Scholar] [CrossRef]

- Li, Z.L.; He, X.Q.; Dou, L.M.; Wang, G.F. Rockburst occurrences and microseismicity in a longwall panel experiencing frequent rockbursts. Geosci. J. 2018, 22, 623–639. [Google Scholar] [CrossRef]

- Trifu, C.I.; Shumila, V. Microseismic Monitoring of A Controlled Collapse in Field II at Ocnele Mari, Romania. Pure Appl. Geophys. 2010, 167, 27–42. [Google Scholar] [CrossRef]

- Zhang, C.G.; Ismet, C.; Bruce, H.; Ward, C.R. Assessing Coal Burst Phenomena in Mining and Insights into Directions for Future Research. Int. J. Coal Geol. 2017, 179, 28–44. [Google Scholar] [CrossRef]

- Singh, S.P. Burst Energy Release Index. Rock Mech. Rock Eng. 1988, 21, 149–155. [Google Scholar] [CrossRef]

- Guo, W.Y.; Tan, Y.L.; Yang, Z.L.; Zhao, T.B.; Hu, S.C. Effect of Saturation Time on the Coal Burst Liability Indexes and Its Application for Rock Burst Mitigation. Geotech. Geol. Eng. 2017, 36, 589–597. [Google Scholar] [CrossRef]

- Sirait, B.; Wattimena, R.K.; Widodo, N.P. Rockburst Prediction of a Cut and Fill Mine by using Energy Balance and Induced Stress. Procedia Earth Planet. Sci. 2013, 6, 426–434. [Google Scholar] [CrossRef]

- Cai, W.; Dou, L.M.; Si, G.Y.; Cao, A.Y.; He, J.; Liu, S. A principal component analysis/fuzzy comprehensive evaluation model for coal burst liability assessment. Int. J. Rock Mech. Min. Sci. 2016, 81, 62–69. [Google Scholar] [CrossRef]

- NSW Mine Safety Investigation Unit (MSIU). Investigation Report: Report into The Deaths of James Mitchell and Phillip Grant at The Austar Coal Mine; NSW Departmen of Industry (Resources & Energy): Paxton, Australia, 2015. [Google Scholar]

- Su, G.S.; Jiang, J.Q.; Feng, X.T.; Mo, C.; Jiang, Q. Experimental Study of Ejection Process in Rockburst. Chin. J. Rock Mech. Eng. 2016, 35, 1990–1999. [Google Scholar]

- Landis, E.N.; Lucie, B. Experiments to Relate Acoustic Emission Energy to Fracture Energy of Concrete. J. Eng. Mech. 2002, 128, 698–702. [Google Scholar] [CrossRef]

- Shadrin, A.; Klishin, V. Acoustic emission of rock mass under the constant-rate fluid injection. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; p. 012057. [Google Scholar]

- Sikorski, W. Acoustic Emission; InTech Open: London, UK, 2012; p. 409. [Google Scholar]

- Ranjith, P.G.; Jasinge, D.; Choi, S.K.; Mehic, M.; Shannon, B. The Effect of CO2 Saturation on Mechanical Properties of Australian Black Coal Using Acoustic Emission. Fuel 2010, 89, 2110–2117. [Google Scholar] [CrossRef]

- Lockner, D.A.; Byerlee, J.D.; Kuksenko, V.; Ponomarev, A.; Sidorin, A. Quasi-static fault growth and shear fracture energy in granite. Nature 1991, 350, 39–42. [Google Scholar] [CrossRef]

- Kurita, K.; Fujii, N. Stress memory of crystalline rocks in acoustic emission. Geophys. Res. Lett. 1979, 6, 9–12. [Google Scholar] [CrossRef]

- Shkuratnik, V.L.; Filimonov, Y.L.; Kuchurin, S.V. Experimental investigations into acoustic emission in coal samples under uniaxial loading. J. Min. Sci. 2004, 40, 458–464. [Google Scholar] [CrossRef]

- Shkuratnik, V.L.; Filimonov, Y.L.; Kuchurin, S.V. Regularities of acoustic emission in coal samples under triaxial compression. J. Min. Sci. 2005, 41, 44–52. [Google Scholar] [CrossRef]

- Xie, H.P.; Ju, Y.; Li, L.Y. Criteria for Strength and Structural Failure of Rocks Based on Energy Dissipation and Energy Release Principles. Chin. J. Rock Mech. Eng. 2005, 24, 3003–3010. [Google Scholar]

- Amitrano, D.; Arattano, M.; Chiarle, M.; Mortara, G.; Occhiena, C.; Pirulli, M.; Scavia, C. Microseismic activity analysis for the study of the rupture mechanisms in unstable rock masses. Nat. Hazards Earth Syst. Sci. 2010, 10, 831–841. [Google Scholar] [CrossRef] [Green Version]

- Verdon, J.P.; Kendall, J.M.; White, D.J.; Angus, D.A. Linking Microseismic Event Observations with Geomechanical Models to Minimise The Risks of Storing CO2 in Geological Formations. Earth Planet. Sci. Lett. 2011, 305, 143–152. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Jiang, Y.D.; Han, Z.R. Experimental Study on Acoustic and Thermal Infrared Characteristics of Bump-prone Coal. Chin. J. Rock Mech. Eng. 2007, 26, 965–971. [Google Scholar]

- Skrzypkowski, K. Laboratory testing of a long expansion rock bolt support for energy-absorbing applications. In E3S Web of Conferences; EDP Sciences: Szklarska Poreba, Poland, 2018; p. 00004. [Google Scholar]

- Iannacchione, A.T.; Tadolini, S.C. Occurrence, Predication, and Control of Coal Burst Events in The U.S. Int. J. Min. Sci. Technol. 2016, 26, 39–46. [Google Scholar] [CrossRef]

- Vardar, O.; Tahmasebinia, F.; Zhang, C.; Canbulat, I.; Saydam, S. A Review of Uncontrolled Pillar Failures. Procedia Eng. 2017, 191, 631–637. [Google Scholar] [CrossRef]

- Dou, L.M.; Zhao, C.G.; Yang, S.G.; Wu, X.R. Prevention and Control of Rock Burst in Coal Mine; China University of Mining and Technology Press: Xuzhou, China, 2006. [Google Scholar]

- Huang, B.X.; Liu, J.W. The Effect of Loading Rate on the Behavior of Samples Composed of Coal and Rock. Int. J. Rock Mech. Min. Sci. 2013, 61, 23–30. [Google Scholar] [CrossRef]

- Li, H.T.; Zhou, H.W.; Jiang, Y.D.; Wang, H.W. An Evaluation Method for the Bursting Characteristics of Coal Under the Effect of Loading Rate. Rock Mech. Rock Eng. 2016, 49, 3281–3291. [Google Scholar]

- Okubo, S.; Fukui, K.; Qingxin, Q. Uniaxial compression and tension tests of anthracite and loading rate dependence of peak strength. Int. J. Coal Geol. 2006, 68, 196–204. [Google Scholar] [CrossRef]

- Li, Z.; Dou, L.; Wang, G.; Cai, W.; He, J.; Ding, Y. Risk Evaluation of Rock Burst through Theory of Static and Dynamic Stresses Superposition. J. Cent. South Univ. 2015, 22, 676–683. [Google Scholar] [CrossRef]

- Ahn, K.S.; Zhang, C.G.; Canbulat, I. Study of seismic activities associated with Australian underground coal mining. In Proceedings of the Coal Operators’ Conference, Wollongong, Australia, 8–10 February 2017; pp. 275–282. [Google Scholar]

- Dou, L.M.; He, J.; Cao, A.Y.; Gong, S.Y.; Cai, W. Rock Burst Prevention Methods Based on Theory of Dynamic and Static Combined Load Induced in Coal Mine. J. China Coal Soc. 2015, 40, 1469–1476. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Ren, T.; Remennikov, A.; He, X.; Tan, L. Analysis of Energy Accumulation and Dissipation of Coal Bursts. Energies 2018, 11, 1816. https://doi.org/10.3390/en11071816

Yang X, Ren T, Remennikov A, He X, Tan L. Analysis of Energy Accumulation and Dissipation of Coal Bursts. Energies. 2018; 11(7):1816. https://doi.org/10.3390/en11071816

Chicago/Turabian StyleYang, Xiaohan, Ting Ren, Alex Remennikov, Xueqiu He, and Lihai Tan. 2018. "Analysis of Energy Accumulation and Dissipation of Coal Bursts" Energies 11, no. 7: 1816. https://doi.org/10.3390/en11071816