1. Introduction

In electric vehicles, one of the typical battery rating voltages is 144 V. In order to meet the voltage requirements, 600 V-IGBTs (Insulated Gate Bipolar Transistor) is usually adopted, which increases the cost of the inverter [

1]. As a result, an inverter consisting of low-rating-voltage MOSFETs is proposed in the paper to decrease the cost, meet the voltage requirements, carry out the power conversion, and drive the motor.

Multilevel inverters have gained much attention and are very popular nowadays. People can realize high-voltage power conversions with low-voltage power electric devices [

2,

3], while the inverter in [

2] drops to two-level output at high-frequency, and in [

3], full-bridge in series with level doubling network is used to achieve multilevel output and several isolated sources are needed. The CHB inverters are used widely in the market because of their high modularity, low derivative voltages, low total harmonic distortion (THD), high DC-AC gain, and et al [

4,

5,

6], also corresponding control algorithm is adopted, such as passivity-based control (PBC) [

4], model predictive control (MPC) [

5], and simplified small-signal model [

6]. A large range of voltage and power capacity can be achieved based on CHB inverters. However, some drawbacks still exist in CHB inverters, such as the line-frequency transformers and a lack of bidirectional power flow ability [

7,

8]. Also, a large number of isolated DC supplies are need in the CHB inverter; hence, the outputs of the H-bridges can be connected in series to raise the voltage [

9].

Some solutions to overcome the disadvantages of CHB have been proposed, such as the use of high-frequency transformers [

10,

11,

12], floating capacitors as supplies [

13,

14], pulse width modulation (PWM) rectifiers [

15,

16], hybrid DC sources [

17,

18], and double level circuit [

19]. A modified high- frequency phase disposition pulse width modulation (PDPWM) technique is proposed in [

10], the total harmonic distortion (THD) performance is improved. A 15-level high-frequency ac-link single-stage asymmetrical topology in [

11] and high-frequency-link DC transformer in [

12] are adopted to reduce the system size. Floating capacitors instead of isolated sources in [

13,

14] are used to reduce the device count. PWM technique is utilized in [

15,

16] to improve the performance of voltage balancing of the DC links at low-frequency. Hybrid multi-cell converter (HMC) are used to generate a positive variable dc-link voltage in [

17,

18], and the output waveforms are improve in a large range. Combination of a double level circuit in [

19], the output voltage level is increased nearly twice, while the device count is increased either. These solutions focus on the partial drawbacks and they cannot meet the requirements of the motor drives in electric vehicles, in which there is only one DC power source and the voltage is comparatively low to drive conventional motors directly. Output transformers are introduced in some occasions to raise the voltage [

20], but they can only be used when the frequency is constant, such as in SVCs (Static Var Compensator), SVGs (Static Var Generator), and APFs (Active Power Filter). The line-frequency transformers are not eliminated.

This paper proposes a solution to eliminate the line-frequency transformers in CHB inverters and to inherit the advantages, such as high modularity and low THD. The characteristics of the proposed topology are as follows: (1) Only one DC power is needed; (2) The line-frequency transformer is replaced with a high-frequency transformer; (3) bidirectional power flow is available; (4) high modularity and easy to expand; and, (5) HFL and high power density. The output voltage can be raised with more H-bridges.

A main H-bridge and a multi-winding high-frequency transformer are introduced in the topology to generate the isolated DC supplies for all of the H-bridges. The DC bus voltages in every H-bridge can be controlled by regulating the high-frequency voltages on the windings of the high-frequency transformer [

21]. A three-phase inverter is powered in parallel by the input DC source [

22], while several non-isolated or isolated power supplies are needed. A number of H-bridges, which have the same parameters, are connected in series to form a string that can generate multilevel voltages. All of the three-phase H-bridge strings are connected to the three-phase inverter in Y-type [

23]. PWM strategy can be used to generate the gate signals and to achieve multilevel output waveforms in a large range [

24].

This paper is organized as follows: The structure of the inverter is discussed in

Section 2. The control of the power flow in the high-frequency transformer is studied and the PWM strategy is established to minimize the THD in

Section 3.

Section 4 shows the experimental results. The comparison with relevant works is given in

Section 5, and the conclusion is given in

Section 6.

3. High-Frequency Link

3.1. Concept of the High-Frequency Link

The HFL is a bridge among the H-bridges. The energy flows from the battery to the H-bridges when the motor is accelerating. The HFL can transfer the energy from the H-bridges to the battery when the motor is braking. The operation of the circuit is quite simple because all of the DC bus voltages are equal to VDC. All of the MOSFETs have the same rating parameters. It is easy to maintain the converter because of the high modularity.

Each H-bridge can generate a square waveform of voltage, and the phase of the square waveform is controlled to regulate the power flow. Literature [

26] introduced a high-frequency link based on soft magnetic cores. the power is up to 400 kW. In the electric vehicles, the total power can be 10 kW typically. In that case, the power flows through the high-frequency link can be shown in

Table 3.

The high-frequency technology means small size, weight, and cost.

Figure 8 shows the flux linkage and voltage in the transformer. Since the voltages are square waves, different design should be implemented. The flux linkage is a triangular function because the voltage on the winding is square wave, as shown in

Figure 8. The slope of the triangular wave is proportional to the amplitude of the voltage. The flux linkage and voltage can be written as:

where

k = 1, 2, 3, …

where

N is the number of turns,

A is the core area,

Bmax is the flux density, and

f is the frequency of the square waveform. In the proposed high-frequency transformer,

f is equal to 20 kHz and

Bmax is constant for the magnetic cores. Thus,

N and

A can become very small.

The four windings (primary wind W1 and secondary winds W2~W4, the turns ratio is 1:1:1:1) of the transformer in the proposed topology can be described, as in

Table 3.

If the core area of the HF transformer is 324 mm

2 (18 mm × 18 mm) and the flux density is 0.2 T, the number of turns can be calculated as:

Hence, all of the windings have at least 19 turns. In that case, the maximal voltage can be as high as 144 V. For W1, the maximal current is 45 A. As a result, a 10 mm2 copper wire is enough. For W2~W4, 5 mm2, copper wires are required. Hence the total area of the wires can be 5 × 19 × 3 + 10 × 19 = 475 mm2.

3.2. Control of DC Bus Voltages

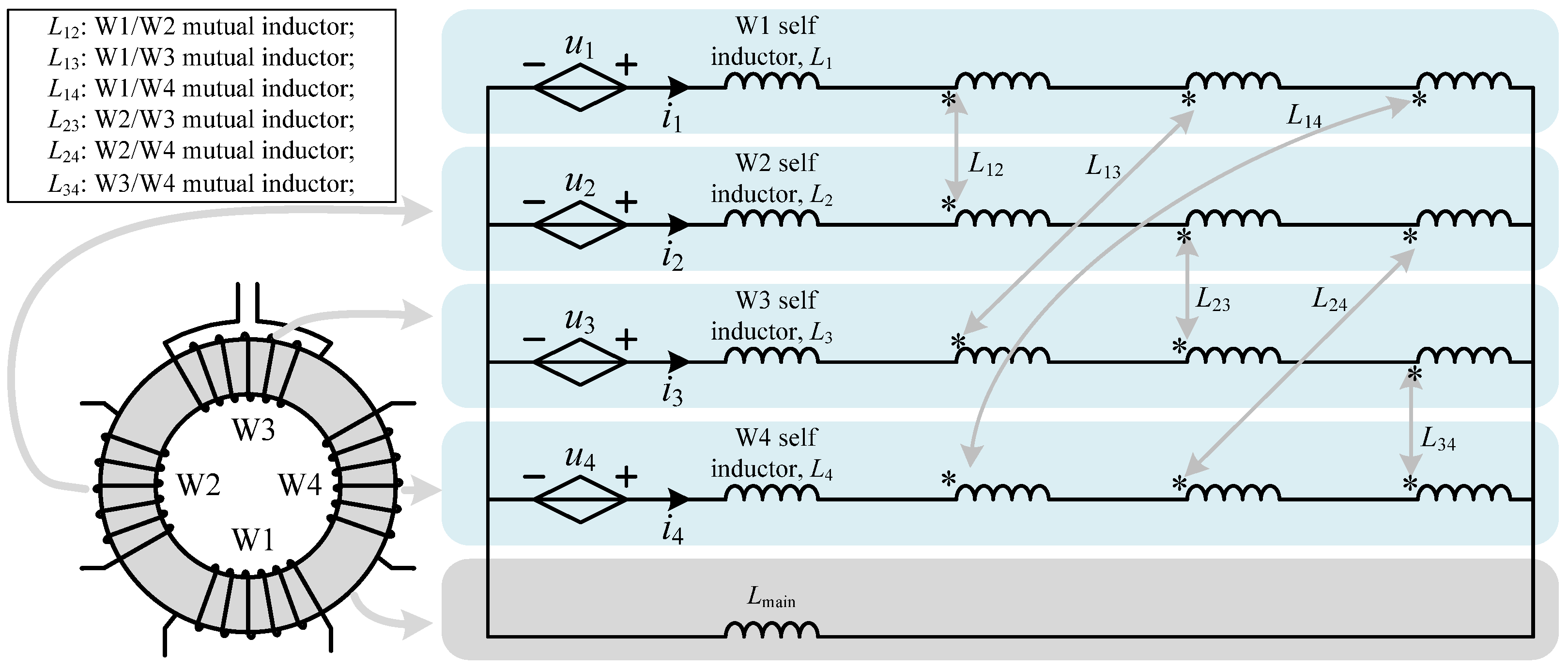

The power flows among W1~W4 separately in the system and the equivalent circuit can be drawn, as in

Figure 9. The four voltages sources can be replaced with four HF sinusoidal voltages to simplify the analysis.

The mutual inductors are also omitted as it is much smaller than the self-inductor on each winding. The currents flowing out of

u1~

u4 are

i1~

i4.

N is the number of turns of each winding.

im is the equivalent magnetizing current of the core. Thus,

Since all of the windings have the same number of turns,

L1 =

L2 =

L3 =

L4 =

L.

Lm can be removed because

im ≈ 0. The equivalent circuit can be shown in

Figure 10, where

U1~

U4 are the voltage phasors of

u1~

u4 and

I1~

I4 are the current phasors of

i1~

i4. The angles of

U1~

U4 are denoted by

β1~

β4.

The current phasor

Ik (

k = 1, 2, 3, 4) can be calculated as

The amplitude of phasor

Uk (

k = 1, 2, 3, 4) is denoted by

Ubase. Hence, the active power released by phasor

Uk (

k = 1, 2, 3, 4) can be

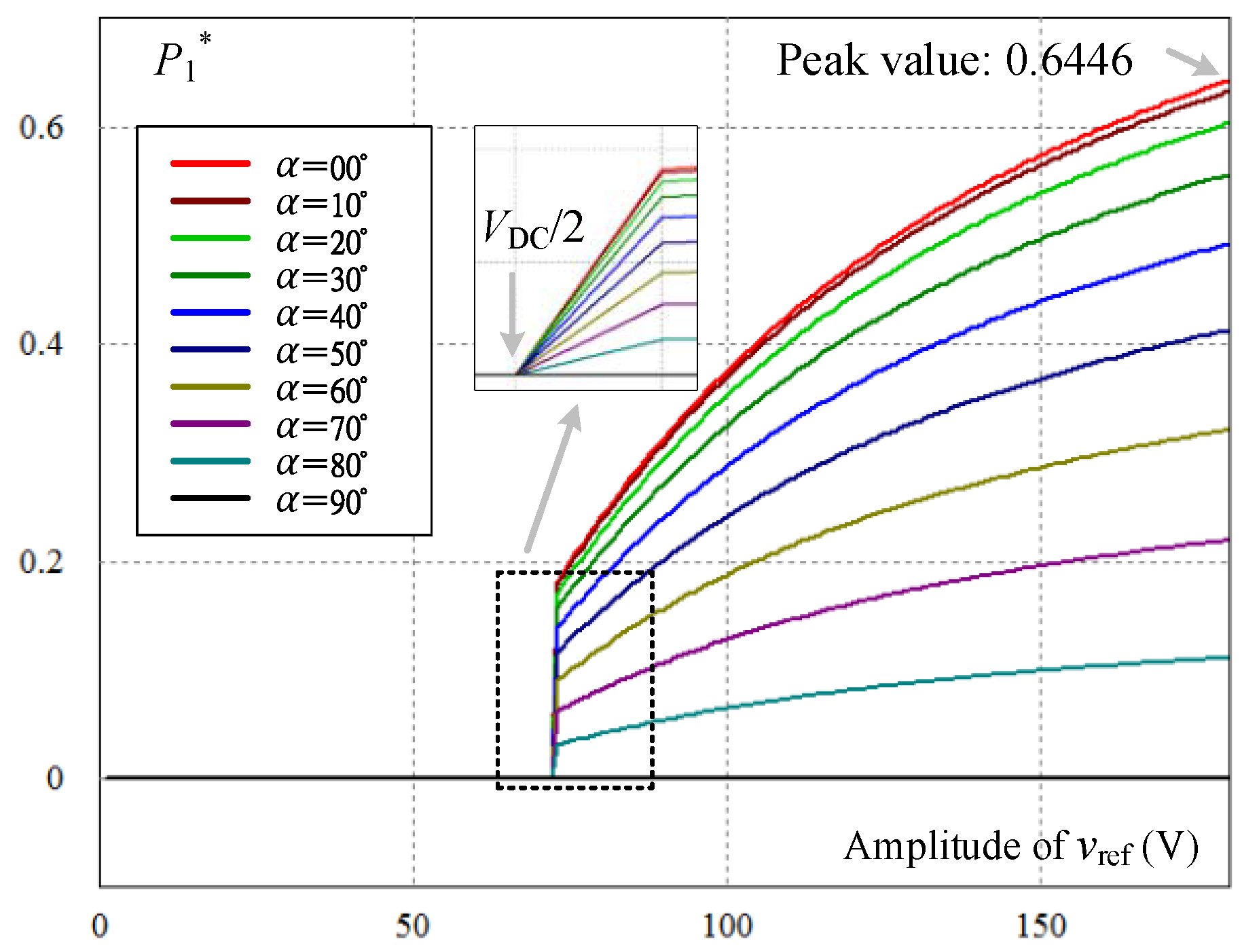

and

Hence, a larger angle

βk will enlarge the active power

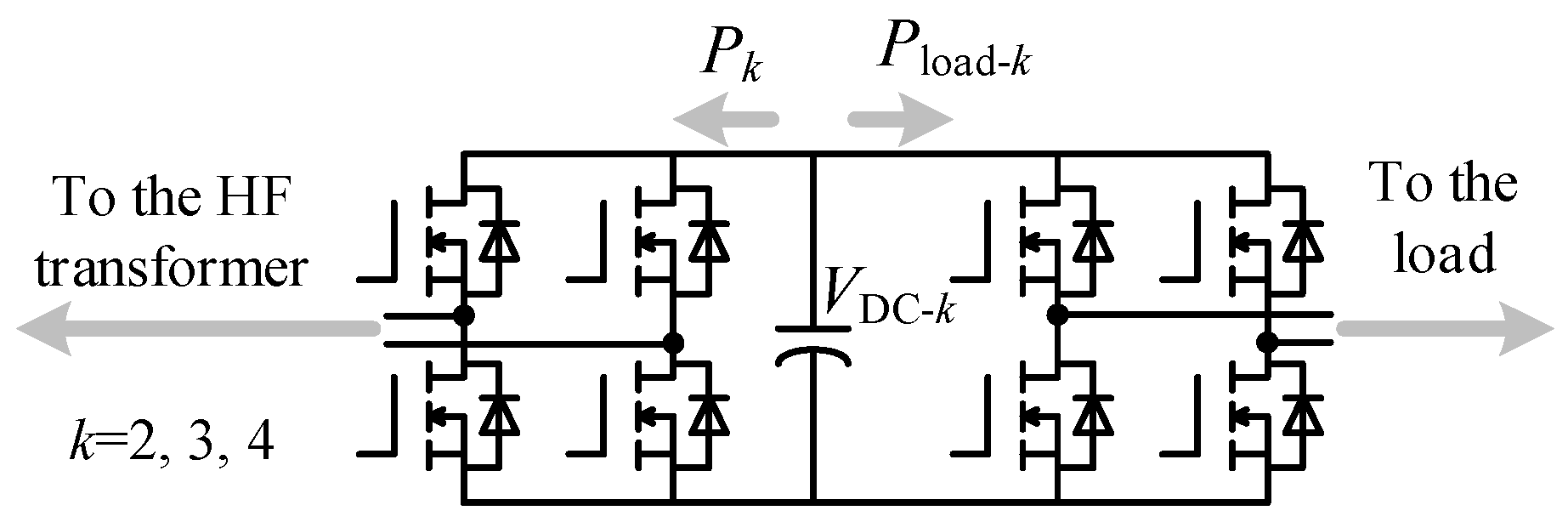

Pk released by the voltage source. The DC bus voltage

VDC–k can be controlled by maintaining

Pk, since the DC bus capacitor voltage is considered to be the integration of the active power released by the DC capacitor, as shown in

Figure 11 and described in Equation (20), where

C is the equivalent capacitance of the DC capacitors.

β1 is set to zero since there are only three independent variables in Equation (17) (

P1 +

P2 +

P3 +

P4 = 0, so only three formulas about the active power and angle can be obtained).

β2~

β4 are generated by the voltage close-loop, as shown in

Figure 12, to control

VDC–2~

VDC–4, respectively. The control algorithm shown in

Figure 12 works as follows (

k = 2, 3, 4):

if VDC–k is lower than 144 V, βk goes lower, Pk goes lower, and VDC–k goes higher;

if VDC–k is higher than 144 V, βk goes higher, Pk goes higher, and VDC–k goes lower; and,

if VDC–k is equal to 144 V, βk keeps constant, Pk is constant, and VDC–k is constant.

The polarity of the phase-shift angle βk determines the direction of the power flow. Fluctuation occurs when the motor is braking, and in this situation, the motor will charge the H-bridges and cause DC voltage raise on each power cell in each phase. Due to the algorithm above, βk goes higher, Pk goes higher, and the energy is transferred to the input battery through the HFL, and VDC–k goes lower to the set value.

3.3. Magnetic Biasing Suppression

The magnetic biasing will occur if the positive-voltage time span is not equal to the negative-voltage time span for u1~u4. Some factors, such as the dead band, the vibration of the clock, the performance of the driving circuits, and the system delay will deteriorate the symmetry of the square waveforms. Hence, a magnetic biasing suppression method is necessary to keep the system stable.

Take W1

, for example, the terminal voltage

u1 is divided into two parts:

(the DC component) and

(the AC component). Hence, the flux linkage in the core

ψcore is

Because of the first expression in the Equation (21), the amplitude of ψcore will go higher and higher and make magnetic biasing happen. Even more, the magnetic core will be saturated and the system will fail.

Based on the Gauss Formula, the equivalent magnetizing current

im will generate

ψcore, and the formula is

where

l is the equivalent length in the magnetic core,

μr is the relative permeability, and

S is the area of the magnetic core.

A low-pass filter can be introduced to observe the DC component, which is exactly an indicator of the magnetic biasing phenomenon, in

im. The magnetic biasing suppression algorithm is shown in

Figure 13. Typically, the algorithm is made up of two parts, which are the magnetic-biasing observer and voltage-biasing generator. It should be noticed that the magnetic biasing might be generated by all of the windings, but only W1 is used to carry out the suppression method. In this way, the control system is simplified and the reliability can be improved.

Figure 14a shows the experimental result when there is no magnetic biasing suppression method. The period of the

u1 is 25 us. In every period, the voltage is positive for the first 13 us, which will result in magnetic biasing. The parameters of the experimental system are shown in

Table 4.

The magnetizing current is also shown in

Figure 14a. It coincides with the analysis in Equation (22). A comparative experimental result is shown in

Figure 14b.

4. Experiments

4.1. Experimental prototype introduction

An experimental prototype is built to test the proposed converter. The HFL works with a square waveform of voltage. The frequency is 20 kHz and the amplitude of the voltage is 30 V (equal to the battery voltage). The photo of the prototype is shown in

Figure 15.

Figure 15 shows the connection of the proposed inverter (HF transformer: high-frequency transformer, HFL: high frequency link, PRI: primary side, PHA: phase A, PHB: phase B, PHC: phase C, INV: inverter side), the DC bus is obtain by the battery, the HFL and INV and CHBare configured through the basic H-bridge cell. The load is an asynchronous motor. Through the voltage sensor, the DC bus voltage of three phases is sampled to the control unit, with PI (Proportion Integration) controller the phase shift angle is calculated and the power transferred to each phase is obtained, as a result, the DC bus voltage is constant. Through current sensor, the current of PHA and PHB is sampled to the control unit. Through DQ (Direct-Quadrature) transform, the motor is controlled in current close loop.

The parameters of the asynchronous motor is shown in

Table 5.

The cost list of the key components is shown in

Table 6.

Utilizing multilevel technique, low-voltage MOSFETs are adopted instead of 600 V-IGBTs on the high voltage condition. In the proposed topology, thirty-four MOSFETs, one transformer, and four capacitors are applied, and the main cost is $55.44. While for topology based on 600 V-IGBTs, only the cost of the three-phase bridge is over $77. Thus, the cost of the proposed topology sharply decreased.

4.2. Start-Up Mode and Steady State

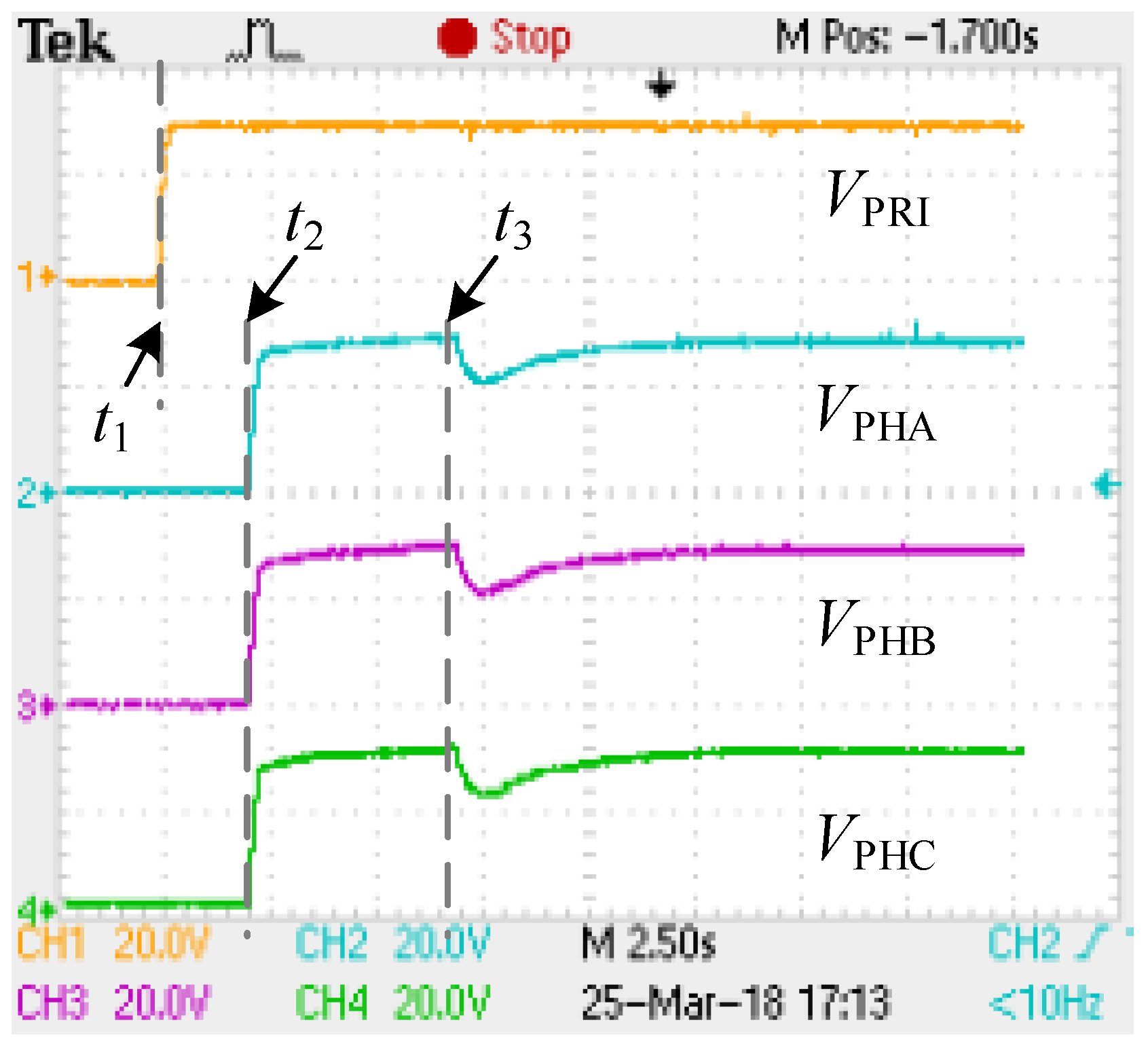

Figure 16 shows the voltages on each phase during the HFL start-up period and the inverter start-up period.

At time t1, the primary side of the HFL starts working, while at time t2, the secondary side of the HFL starts working, and the PI controller is working. At time t3, the inverter starts working, the DC bus voltage experienced a decrease due to the load, after few seconds the DC bus voltage is regulated back to 30 V.

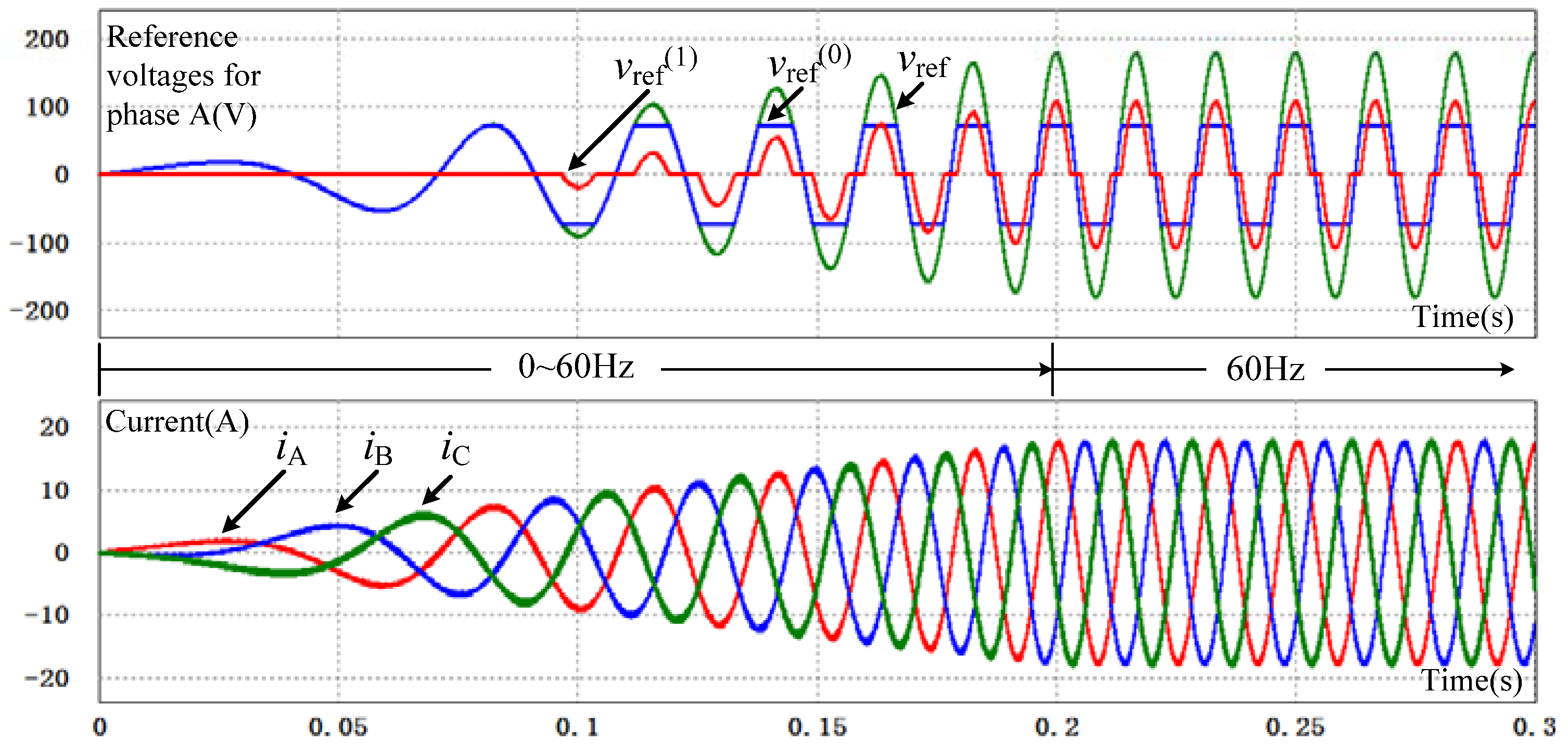

Figure 17 shows the three phase current with the V/f starting method. In this method, the amplitude of the current divided by its frequency is constant. In other words, the current increased with the frequency. This method guaranteed the increase of the rotation rate within a reasonable speed.

Figure 18 shows the output voltage and output current of three phases on steady state (60 Hz). Each phase of the inverter achieves multilevel working. The four voltage levels are −

VDC, 0,

VDC, 2

VDC (with respect to the GND, the ground of the DC bus, rather than the center tap of the DC bus,

VDC = 30 V).

4.3. Acceleration and braking mode

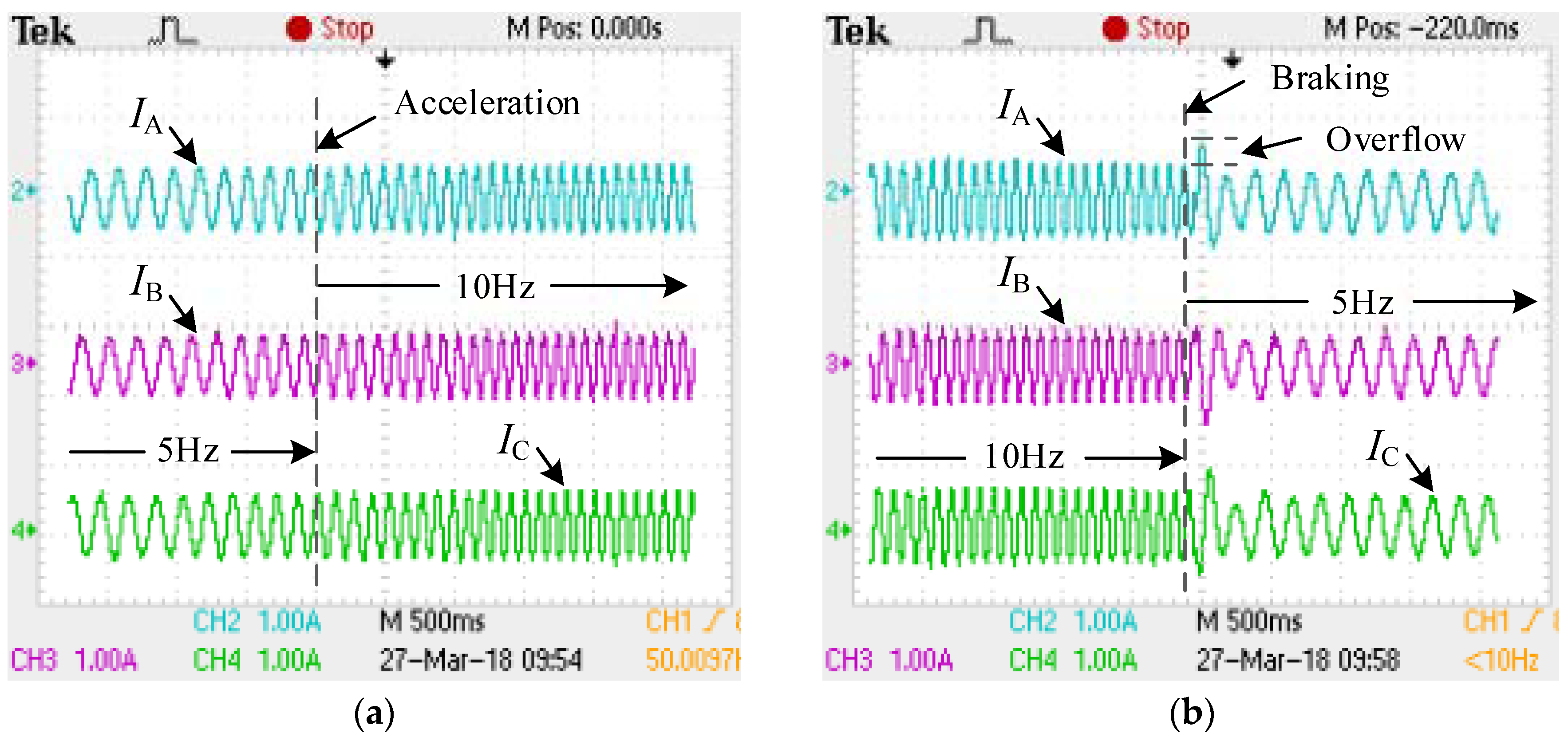

For better presentation of the waveforms sampled by the oscilloscope, the acceleration mode, and the braking mode are tested between 5 Hz and 10 Hz.

Figure 19a shows the output current of three phase on acceleration mode. With current close loop based on DQ transform, the amplitude of the current remains constant, only the frequency changes from 5 Hz to 10 Hz.

Figure 19b shows the output current of three phase on braking mode. With current close loop based on DQ transform, the amplitude of the current remains constant, only the frequency changes from 10 Hz to 5 Hz. The instantaneous instruction of braking is a sudden change of frequency, however, the rotation rate of motor cannot be changed immediately, excessive speed causes transient current overflow on each phase. Extra power is transferred to the battery through the three phase inverter topology.

An interface software is compiled to communicate with the control unit (consists of a DSP: Digital Signal Processing and a CPLD: Complex Programmable Logic Device), instructions are sent to the control unit, while sample data and logic values are sent back to PC side.

Figure 20 shows the whole process of the control presented by this software.

First, in the V/f start-up process, the HFL start working in state 1 and state 2, after state 2 PI controller is working to balance the DC bus voltage at 30 V, and the inverter start working in state 3. While the motor works on low speed condition, an acceleration instruction is made, and the motor begins to speed up with V/f method, the rotation increases with the increase of the amplitude of reference voltage, while the output current remains constant. While the motor works on the high speed condition, a braking instruction is made, a sudden decrease is obtained through braking method, and a current overflow occurs in that time.

4.4. Harmonic Analysis

HFL is used to create several isolated DC sources for the system, and on steady state, the DC voltage on each phase is balanced and identical. Thus, the HFL will not introduce harmonics in the output of the inverter. The harmonics are mainly caused by the cascaded low-frequency H-bridges, where the switching frequency is 5 kHz.

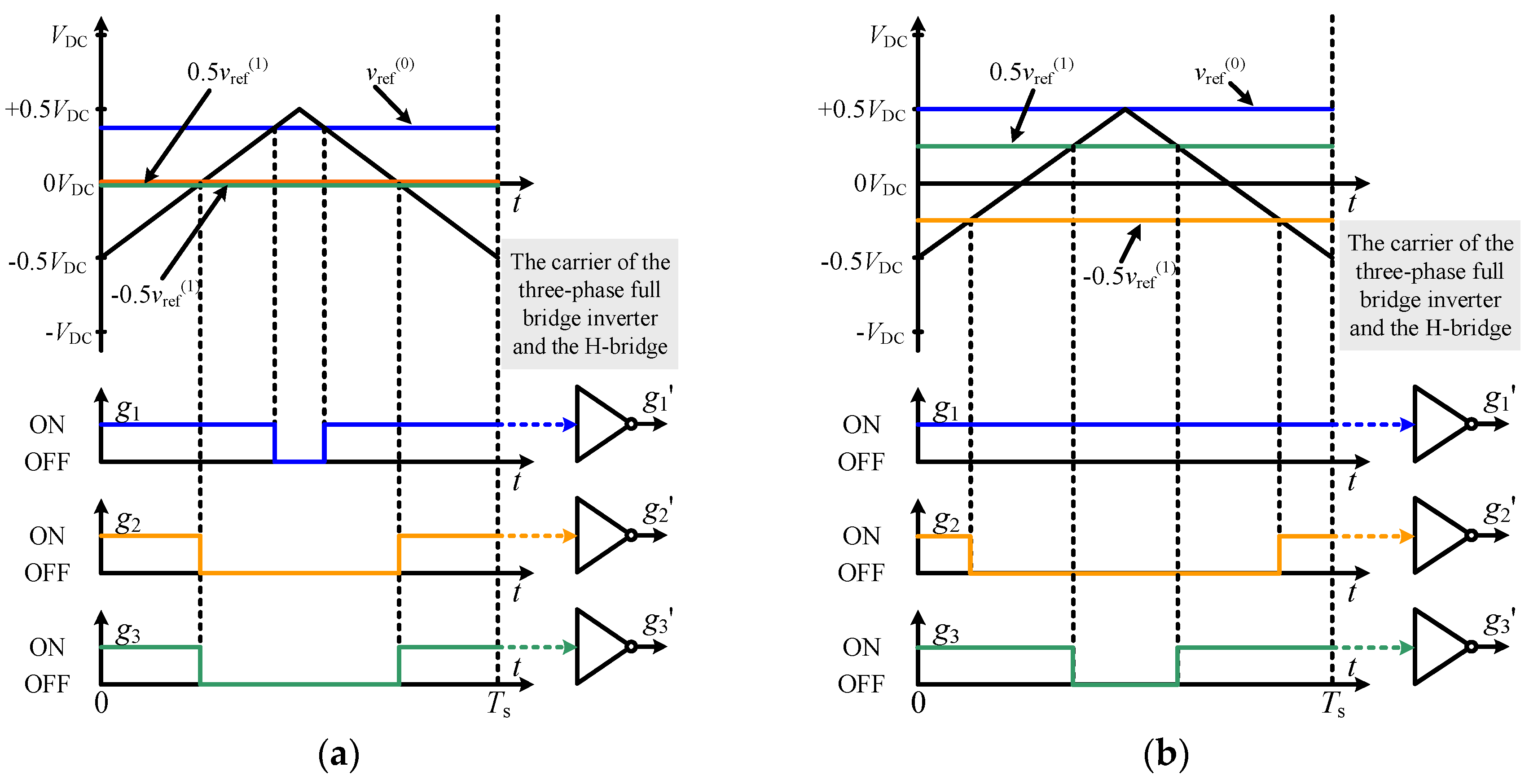

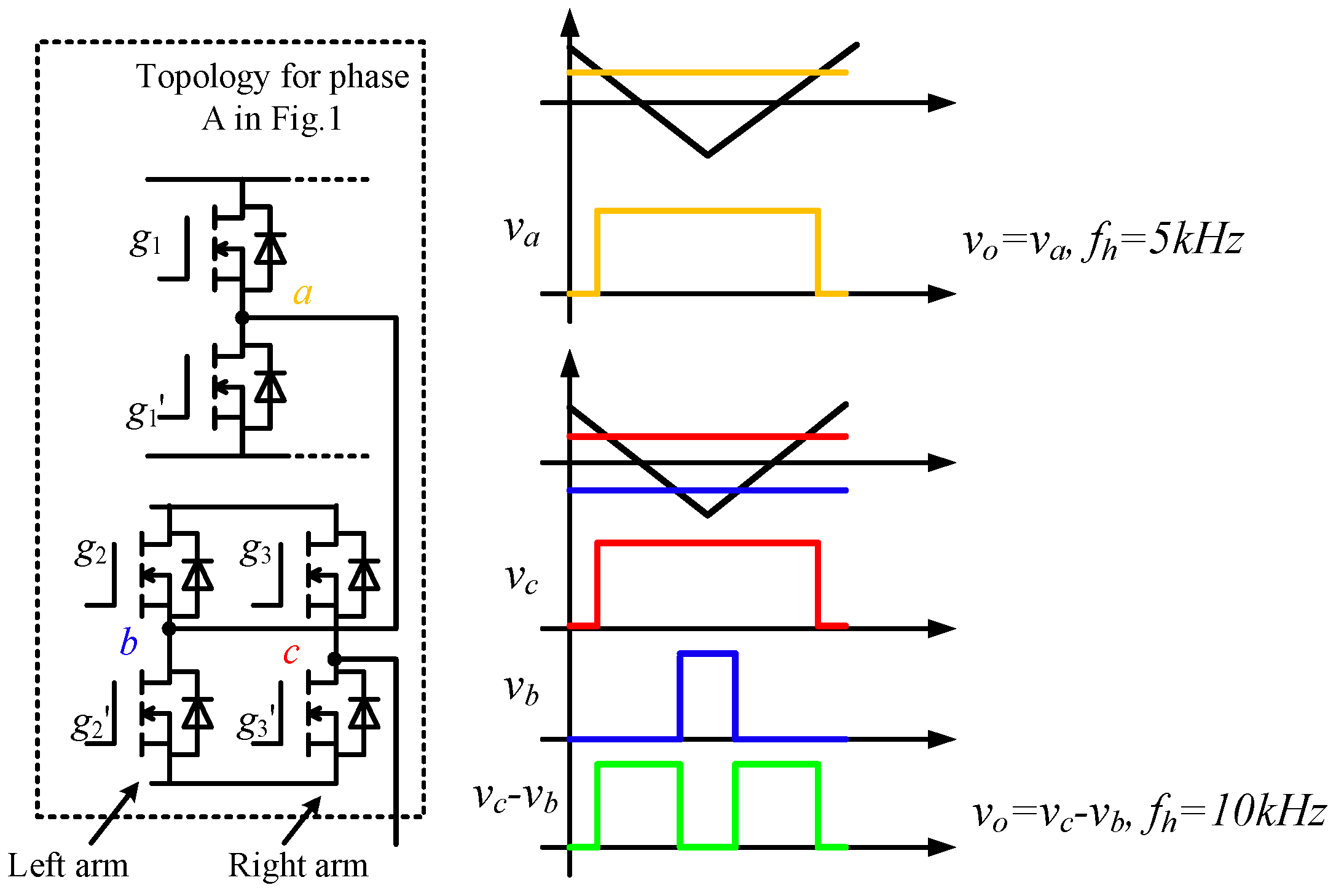

As shown in

Figure 21, the half-bridge of the three-phase inverter introduces harmonics at 5 kHz and its multiples, which is the switching frequency. As for the CHB, the phase difference between the switching signals on the left arm and the right arm is half period (the switching frequency of each arm is 5 kHz). While the output voltage is the difference between the potential on the middle point, as a result, the harmonic frequency of the H-bridge is doubled. Thus, the main harmonics of phase A are at 5 kHz and 10 kHz. A mathematic analysis on harmonics of the H-bridge is given, as following.

Supposing that the pulse width of the left arm and right arm of the H-bridge is

xL and

xR, the range of which is [0, 2

]. Using triangular carrier for modulation, then

vb can be expressed, as below

where

is the angular frequency of the carrier,

k is an integer. In [

],

vb can be expressed as following

where

vb can be simplified as

vc is calculated in the same way

Then, the output of the H-bridge is obtained

The forward component denotes the effect of the reference waveform, and the backward component denotes the harmonics. As the phase difference between the two arms is half period, which means that the reference waveform is symmetrical through

t-axis, as shown in

Figure 21, thus

. As

From (28) and (29), if n = 1, 2, 3, …, 2k + 1, vH is zero.

Thus, the lowest order harmonic of the CHB is at 10 kHz.

Figure 22 shows the experimental result of Fast Fourier Transformation (FFT) spectrum through oscilloscope, which is coincident with the analysis above.

4.5. Efficiency Analysis

Measurement of the efficiency is based on 60 Hz working state. The number of levels and efficiency changes with the amplitude of the reference output voltage.

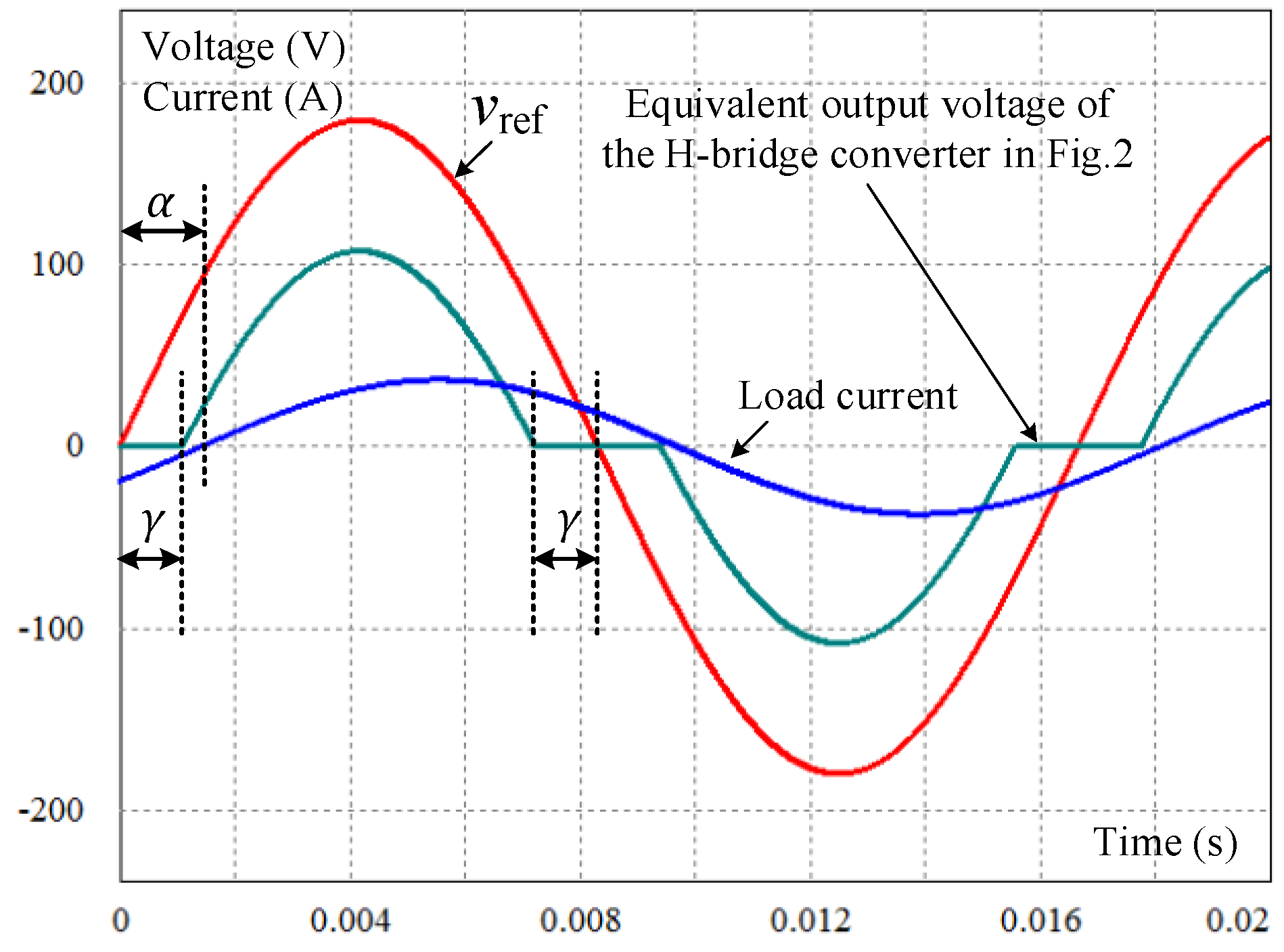

As shown in

Figure 23, the output voltage is based on two levels when the amplitude of the reference voltage is smaller than 0.5

VDC (only three phase inverter works in this mode), and it is based on four levels when the amplitude of the reference voltage is larger than 0.5

VDC, and smaller than the limit of 1.5

VDC (CHB works in this mode). The THD decreases with the increase of the levels, as a result the efficiency increases. With four levels, the efficiency is nearly above 90%, while larger reference voltage also benefits on each voltage level. There is a significant improvement of efficiency with four levels, and with more CHB, the efficiency can be improved further more.

5. Comparison with Relevant Works

CHB topology is widely used for implementing large-scale converters in power electronic applications due to its improved output waveforms. However, some challenges still exist. One is the isolation of the cascaded cells. Leakage currents can cause safety issues and additional losses, thus a large number of well isolated DC sources are needed in implementation. Another challenge is the voltage imbalance. One common method is to inject a zero-sequence voltage the exchange any excess energy between phase legs. However the voltage rating is increased. A new connection on converter topology is proposed in [

27], by extending the function of dc-dc converters for photovoltaic (PV) applications. To solve the voltage imbalance, DC cells on different phases are connected in specific order. However, the imbalance of cells in the same phase is not solved. Though high efficiency is achieved through transformer-less connection, large number of isolated DC sources (PV arrays) are needed to guarantee the isolation. It is not feasible in vehicles where normally only one DC source (DC 144V) is available. On the contrary, a transformer with one magnetic core and multi windings is adopted to create several DC voltages with only one input source. Though magnetic loss is introduced, the power density is improved. As power conversion is allowed between all of the CHBs through the same transformer, it allows for balancing the voltage of cells both on same phase and different phases. Besides, isolation between cells is achieved as the power conversion is through coupling coil.

Three-phase switched reluctance (SR) motor drives with integrated charging functions are proposed in [

28,

29]. Less active switches are adopted in [

28], and a three-phase rectifier is used to connect with the internal combustion engine (ICE) generator and the grid. Though it allows for bidirectional power conversion between the motor and the battery, the power from the ICE or the grid is unidirectional. While braking, the motor will charges the battery to regenerate the energy. As this energy cannot be transferred to the grid or the ICE due to the diode-rectifier, the voltage of the battery goes up which is bad for its life. An integrated multilevel converter of switched reluctance motors (SRMs) that were fed by a modular front-end circuit for plug-in hybrid electric vehicle (PHEV) applications. Due to the single-stage structure, the voltage stress of the active switches is high, thus high-voltage IGBTs are applied, which then increases the cost. When comparing with these motor drives above, the proposed converter combines dual-active bridge (DAB) and CHB configuration to realize higher multilevel output, and the DC voltage on each power cell is lowered. Thus, low-voltage MOSFETs are adopted to decrease the cost. To overcome the difficulties of isolation sources and voltage imbalance and to improve the power density, HFL is adopted for power conversion. Besides, hybrid frequency is adopted to reduce the volume of the transformer and decrease the switching losses. Comparison details are shown in

Table 7.

6. Conclusions

A cascaded multilevel inverter using only one DC source has been implemented and tested. To improve the output voltage with low-rating-voltage MOSFETs, the multilevel theory, HFL, and CHB are combined. The HFL is made up of a multi-winding transformer and several H-bridges, where each phase is connected in the DAB configuration. It works in high-frequency mode, so as to reduce the cost and the size, also improve the power density. The corresponding control algorithm is proposed on the CHB inverter to output the multilevel voltage on each phase. Four-level output waveform is realized, and it can increase with the number of the CHB. Phase-shift control logic is adopted in the DAB configuration of the HFL side to balance the voltage of each power cell. Hybrid frequencies are utilized in the HFL side and CHB motor drive for multiple purpose. High-frequency in the HFL is to reduce the size and improve the power density, while low-frequency in the CHB motor drive is to reduce the switching loss. A magnetic biasing suppression method is proposed in order to eliminate the magnetic saturation. The theoretical analysis shows that about 64% of the power is delivered by the HFL. The proposed solution is capable to drive the 220 V or higher devices with only one 144 V DC power. An experimental prototype is established to verify the topology, and it will be installed on an electric vehicle to drive the squirrel-cage induction motor. Bidirectional power flow ability is tested, and extra energy can be regenerated and transferred to the input source. The less order output harmonics from the switching frequency on the low-frequency CHB are analyzed. The efficiency of the converter is higher than 90%, which increases with the levels of output. All of the H-bridges have the same parameters thus they are easy to be replaced and maintained. More ever, by simply increasing the number of H-bridges, the topology can also be used in other higher voltage applications to reduce the cost, where usually IGBTs are widely used before.