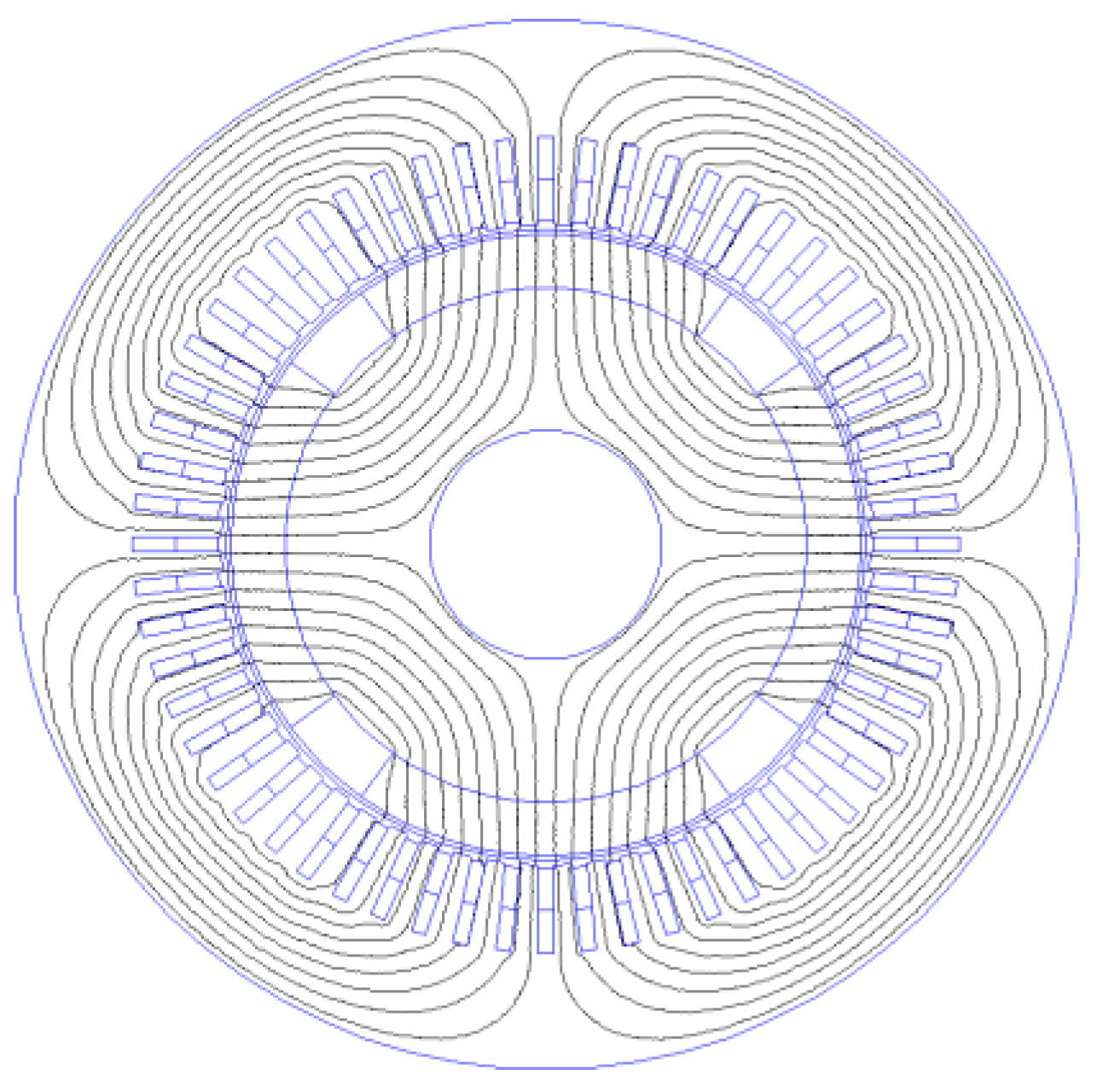

The IM has been simulated by the finite element method. The losses and efficiency have been evaluated through a complete equivalent circuit. The results obtained in this analysis have been compared with the data provided by the manufacturer which confirm the validity of the proposed method. In addition, the method used for the calculation of mechanical and iron losses can be applied subsequently to the proposed PMSM analysis.

3.2. Calculation of Mechanical and Iron Losses

Mechanical losses can be divided into bearing and ventilation losses, which are directly proportional to the speed of the machine. Accurate determination of such losses is a complex task, but certain empirical expressions can provide satisfactory approximations. These expressions include coefficients that vary with machine type, size, ventilation system, etc.

Based on the expressions in [

11], the bearing losses (P

c) can be calculated from:

where N is the speed (rpm), d

c is the axis diameter (cm), n

c is the number of bearings, and k

c is the coefficient depending on motor type (between 0.02 and 0.2).

Ventilation losses (P

vent) are calculated by the following expression:

with:

where p

air is the dissipation loss (W), v

x is the fan tangential speed (m/s), D

v is the fan outer diameter (m), k

vent is the coefficient depending on motor type and ventilation system (between 15,000 and 150,000), and exp is the coefficient depending on motor type and ventilation system (between 2 and 3).

Due to the computational complexity, dissipation losses can be calculated from the output power and estimated efficiency of the motor during operation.

Mechanical losses obtained from manufacturer tests were compared with the results of Equations (1)–(3) as shown in

Figure 5, where an excellent fit was verified between the analytical results and the experimental tests by manufacturer.

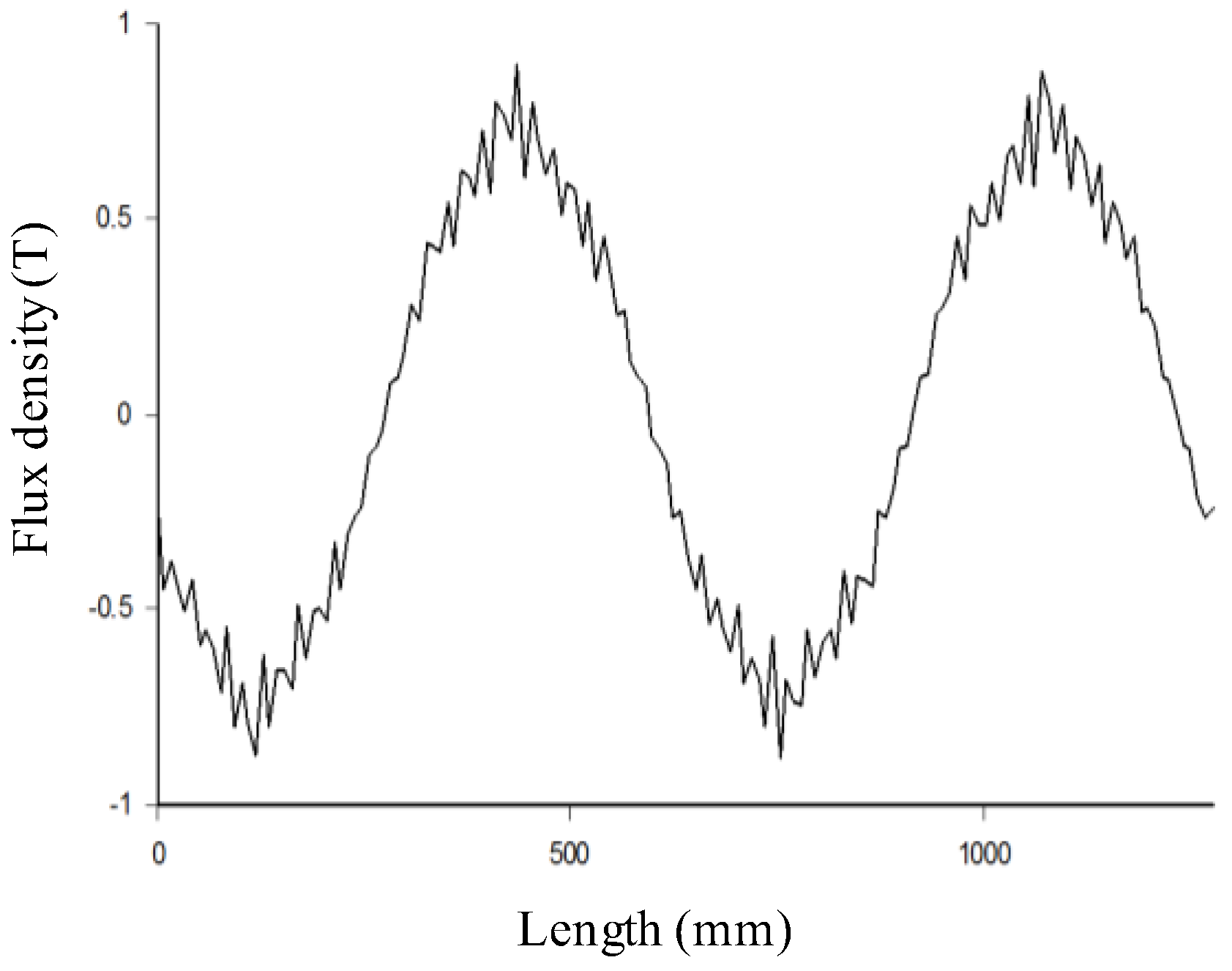

Iron losses can be approximately calculated by Steinmetz equations [

12]. These equations can be used in the presence of sinusoidal or low harmonic waveforms. Since the measurements of the manufacturer laboratory tests were made under sinusoidal excitation, Steinmetz equations’ parameters were fitted to obtain the analytical results of losses, which were then compared with experimental measurements.

Hysteresis losses (P

his) were calculated by Steinmetz equation:

where k

h is the loss constant of the material (between 2 and 5), a is the frequency exponent (between 1 and 1.2), and n is the induction exponent (between 1.8 and 2).

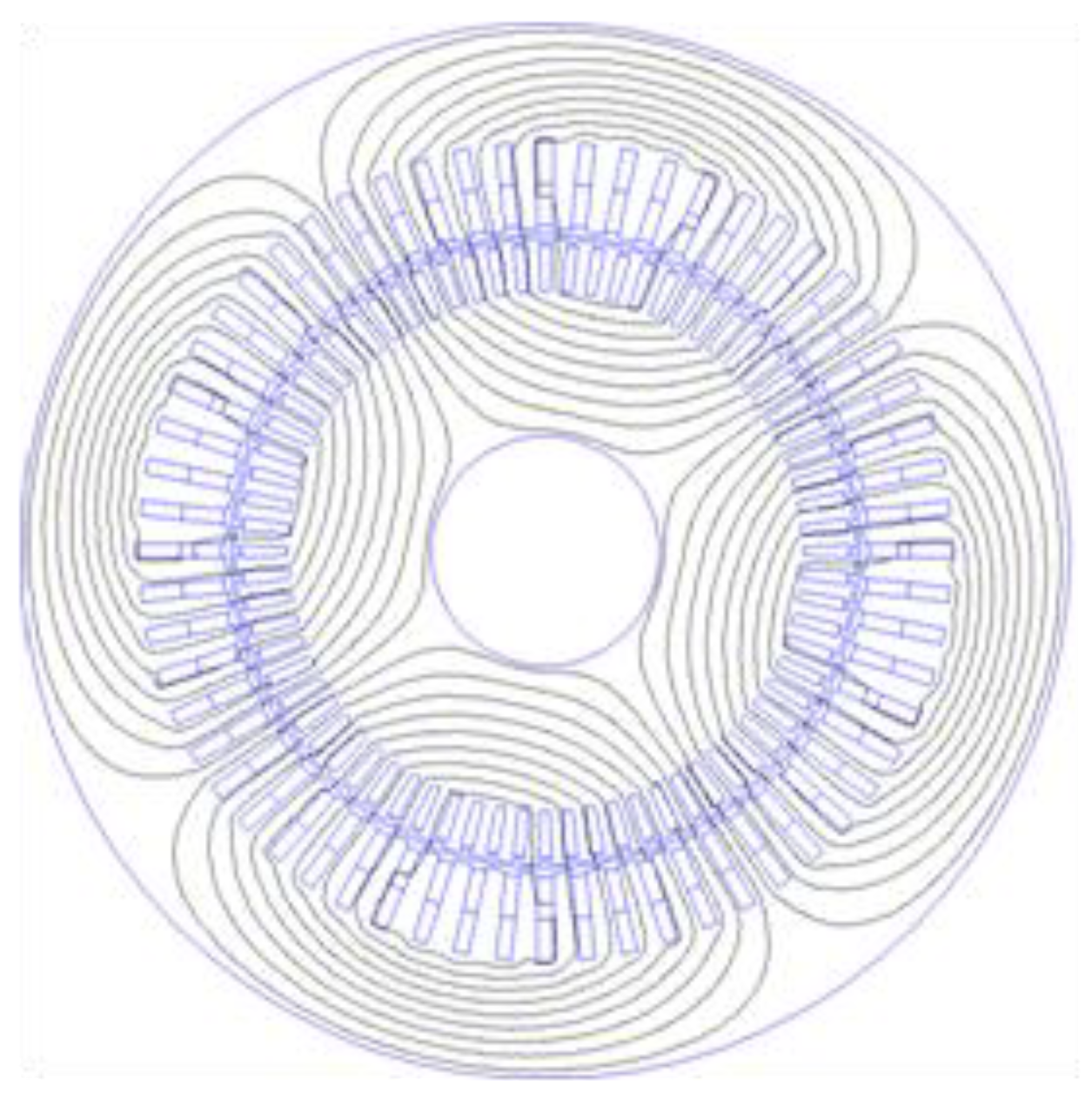

Equation (4) was separately applied to different regions of the motor, i.e., stator yoke, rotor yoke, stator teeth and rotor teeth. In these regions the induction was estimated by finite element simulation. Total losses were obtained by multiplying the specific losses (W/kg) by the weight of iron in each region.

Eddy current losses (P

fou) were calculated by the following Steinmetz equation:

where k

f is the loss constant of the material (between 10 and 100), e is the sheet thickness (m), and x, y, z are the exponents eddy current losses (between 2 and 2.2).

The material of the electrical steel used in manufacturing of the induction motor is the M-19 (nomenclature standard AISI), which corresponds to M290-50A (nomenclature EN10106). This material has also been selected in the finite element simulations carried out. The manufacturer of the electrical steel has given us the specific losses in W/kg [

13] for different flux densities (from 0.1 T to 1.5 T) and for different frequencies (from 50 Hz to 1000 Hz). The adjustment of the different coefficients corresponding to the Steinmetz equations was made by comparing the results of the established model with the specific losses data of the electrical steel provided by the manufacturer. The different coefficients selected from this adjustment and applied in Equations (4) and (5) are: k

h = 4.8, a = 1.2, n = 2 for hysteresis losses in Equation (4), and k

f = 60, e = 0.0005 m, x = 2.05, y = 2, z = 2.05 for eddy current losses in Equation (5).

The procedure for calculation of hysteresis losses in the four tested regions was also followed to quantify the total iron losses as the sum of hysteresis losses and eddy current losses.

Figure 6 compares the results of the manufacturer tests with the results obtained from applying analytical methods using the Equations (4) and (5), for a 50 Hz frequency as a function of the estimated air gap flux density. There were differences between the analytical calculations and the experimental measurements, especially with high flux density values. However, they were not significant, so we could consider the analytical procedure satisfactory.

All experimental measure tests carried out by the motor manufacturer and by the motor user have been made in accordance with international standards IEC 60034-2-1 [

14] and IEC 60349-2 [

15], so that losses are separated as per the standards’ indications into copper losses, iron losses, mechanical losses and stray load losses.

To obtain the mechanical losses and the iron losses, shown in

Figure 5 and

Figure 6 respectively, the sinusoidal voltage and no-load operation have been applied. The measuring equipment used consists of a 3-phase electronic wattmeter (which allows the measurement of voltage, current, power and power factor), an analogical torque-meter on the axis, and a digital transducer for measuring speed. The motor was in service for 30 min before taking the measurements, to achieve the proper behavior of the bearings to correctly determine the mechanical losses.

To obtain the output power and performance, two identical motors have been mechanically coupled (back-to-back method). The same measuring equipment indicated above were used. The measurement of the torque and the speed, together with the measurements of the electronic wattmeter, allowed the determination of the output power and the efficiency of the motor. A temperature of 150 °C was considered as the reference temperature to calculate the stator copper losses.

3.3. Analysis of the Equivalent Circuit

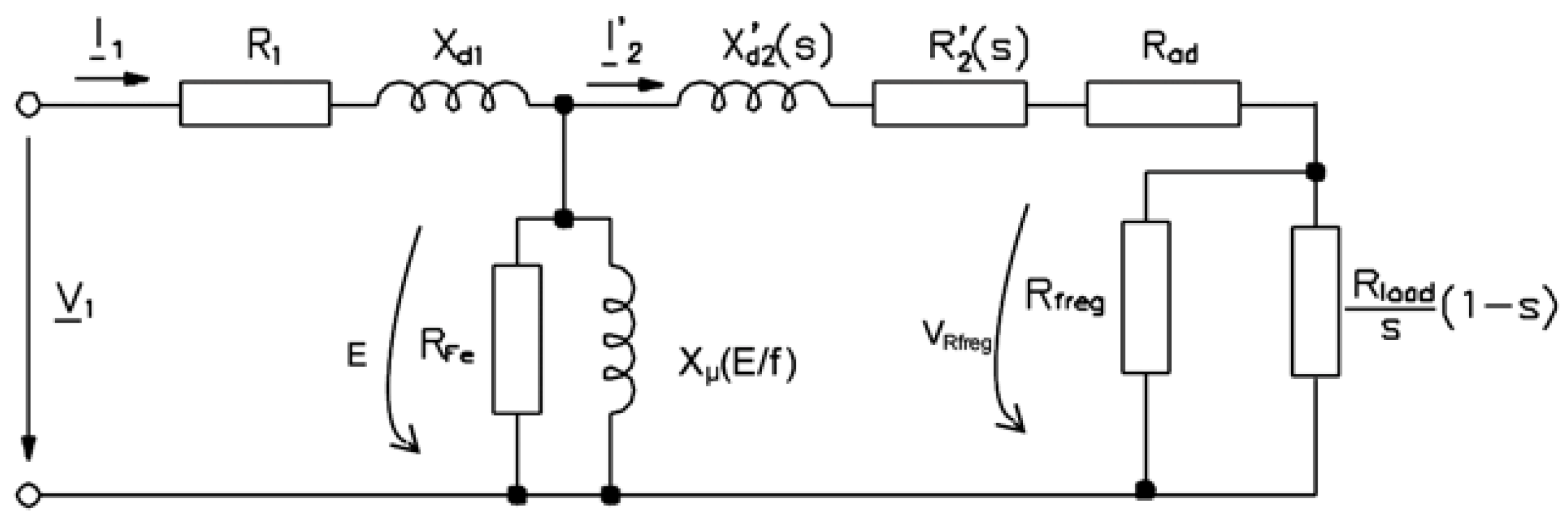

Since losses have a strong influence on motor efficiency, the circuit in [

16] was considered as the equivalent circuit shown in

Figure 7. The considered equivalent circuit parameters are: R

1, stator resistance; R’

2, rotor resistance referred to the stator; X

d1, leakage reactance of the stator; X’

d2, rotor leakage reactance referred to the stator; X

μ, magnetizing reactance; R

Fe , iron loss resistance; s, slip; R

freg, mechanical loss resistance; R

ad, stray load loss resistance; R

load, load resistance.

The main parameters of the equivalent circuit are included in

Table 3. Mechanical loss resistance (R

freg), iron loss resistance (R

Fe), stray load loss resistance (R

ad) and load resistance (R

load) were calculated as specified in [

17], where this equivalent circuit was satisfactorily used in a railway traction motor. The evolution of mechanical losses in

Figure 5 and iron losses in

Figure 6 was used to fit resistances R

freg and R

Fe, respectively. Additionally, the saturation effect was considered on the magnetizing inductance value (

Figure 8) and the variation of rotor parameters with slip (s), as proposed in [

18].

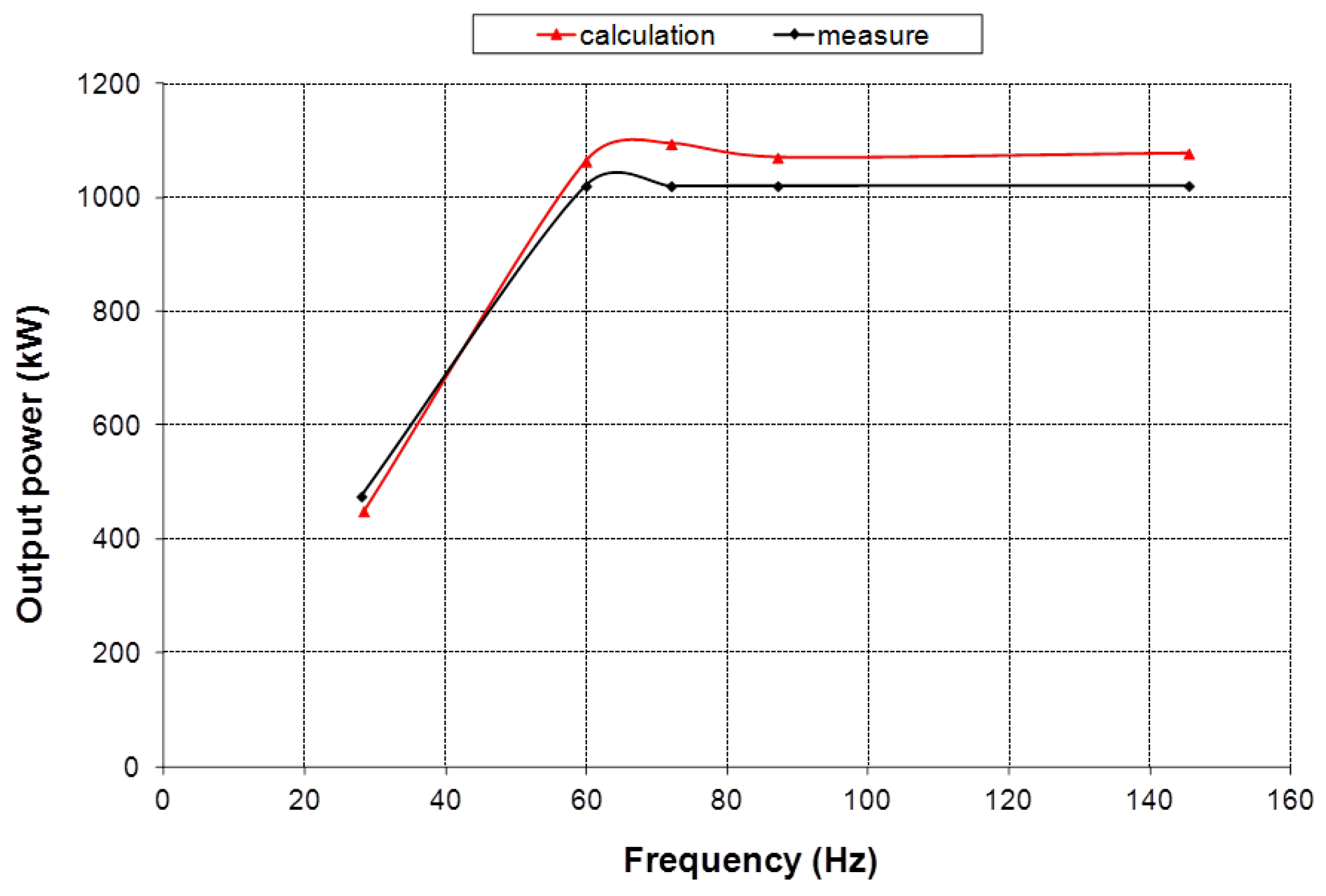

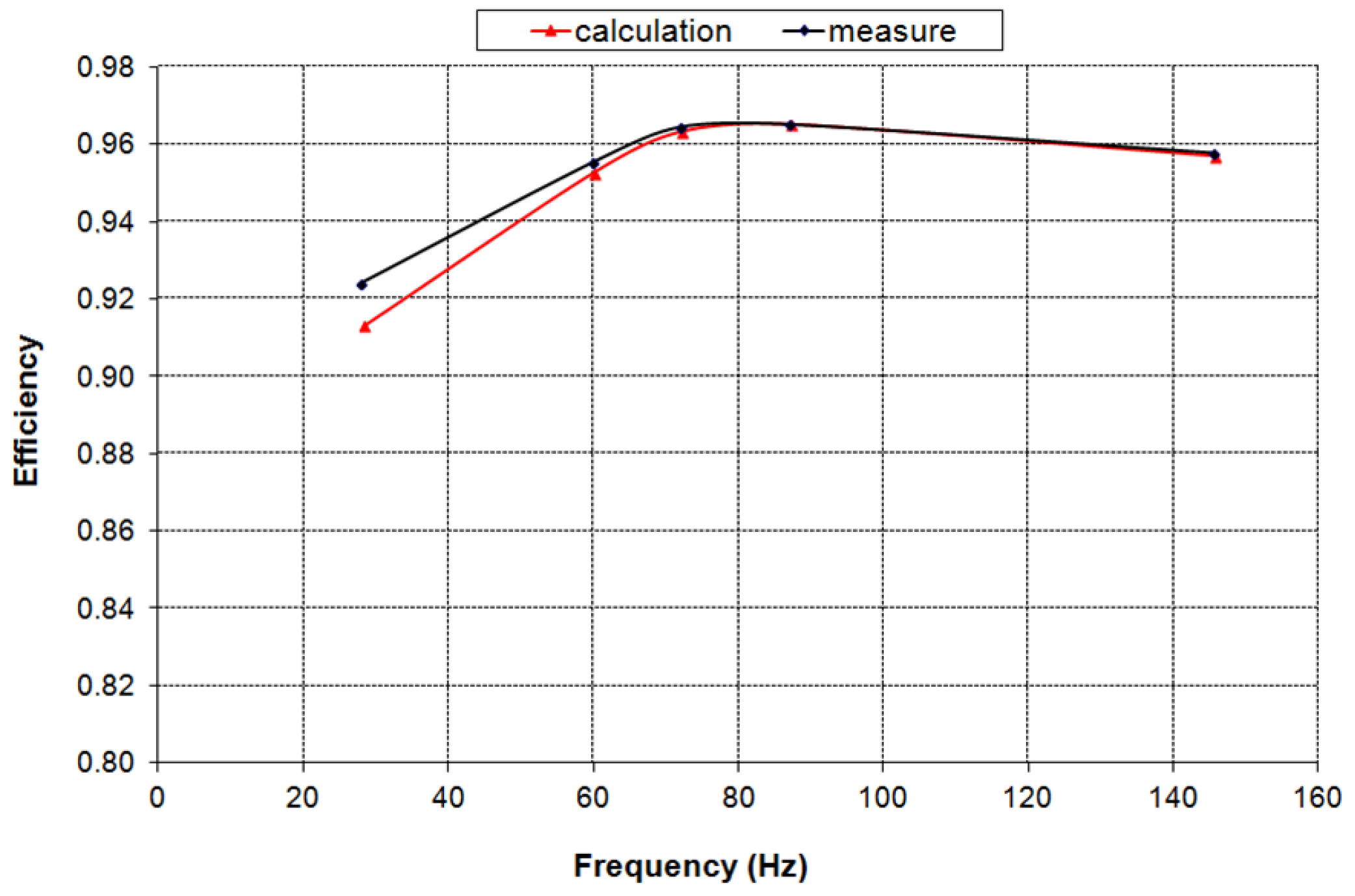

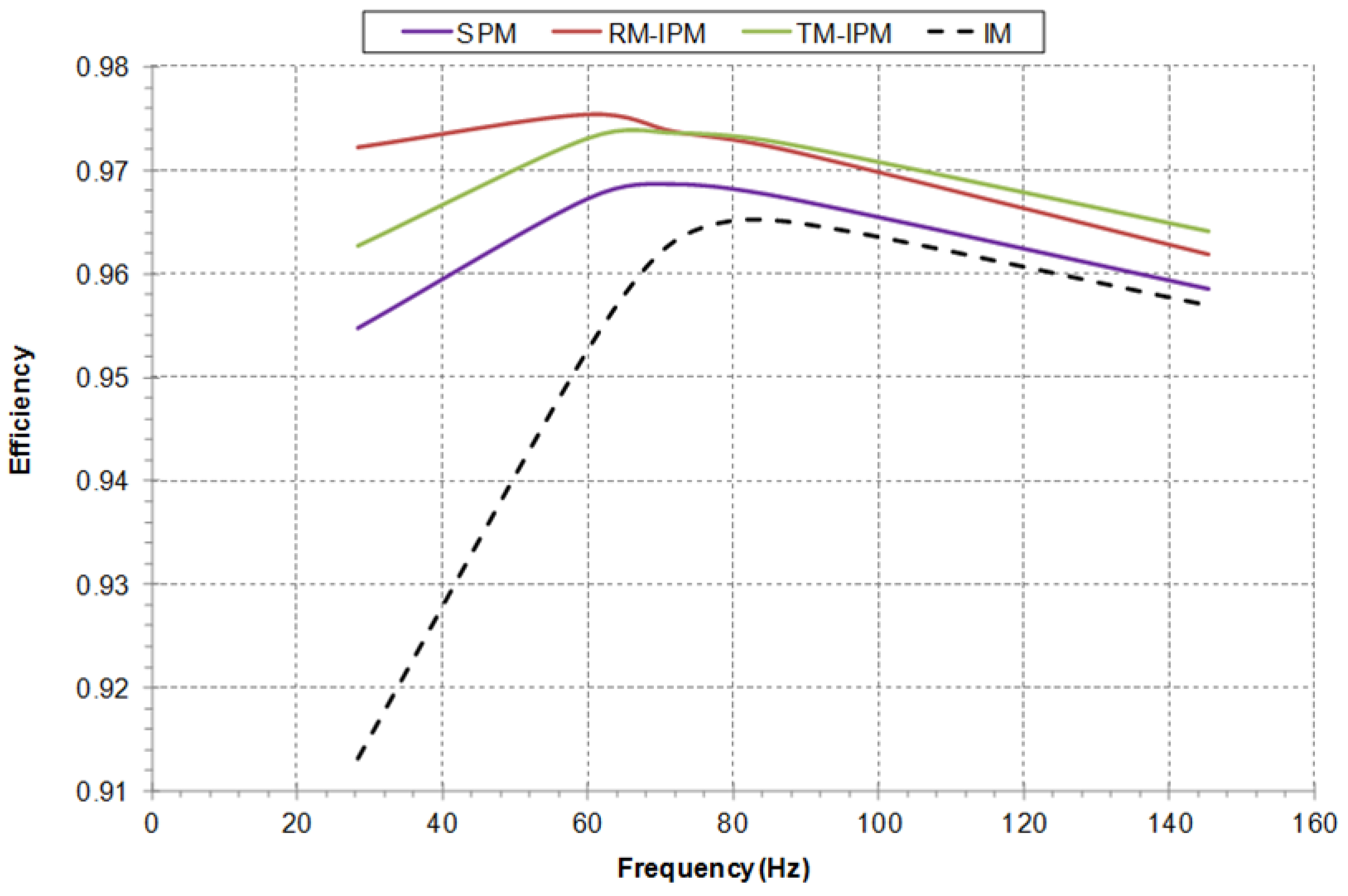

The analytical results of output power and efficiency of the equivalent circuit at different frequencies and those obtained in the tests were compared in

Figure 9 and

Figure 10, respectively. Good results can be observed in the calculation of the efficiency, with only small differences in the operation at low frequencies are appreciated.