Novel Approach for Lithium-Ion Battery On-Line Remaining Useful Life Prediction Based on Permutation Entropy

Abstract

:1. Introduction

2. Related Theory

2.1. Permutation Entropy (PE)

2.2. Variational Mode Decomposition (VMD)

- (a)

- In order to build a variational model, we use the Hilbert transform to get the processing signal of BLIMFs . Next, the spectrum of each BLIMF is moved to the baseband by multiplying the exponential term with the processing signal. Then we use the square L2-norm of the gradient of the signal to calculate the bandwidth of each BLIMF. The constrained variational problem can be shown as follow:where is the original signal, is the Dirac function, is the corresponding center frequency, is the kth BLIMF, is the pre-determined number of decomposed modes, and .

- (b)

- The above constraint variational problem can be unconstrained by inputting the Lagrangian multiplier and quadratic penalty term . The augmented Lagrangian formula can be described as follows:

2.3. ARIMA Model

2.4. GM(1,1) Model

3. On-Line RUL Prediction Approach Based on PE

3.1. Experimental Data

- Charge: 1.5 A constant current until the battery voltage reached 4.2 V and then continued in a constant voltage until the charge current dropped to 20 mA.

- Discharge: 2 A constant current until the battery fell to the predefined cutoff voltage.

- Impedance measurement: an electrochemical impedance spectroscopy (EIS) frequency tested from 0.1 Hz to 5 kHz.

3.2. On-Line HI Extraction

- Step 1:

- Collect discharge voltage degradation data from NASA’s lithium-ion batteries. Count the history cycles of discharge process as N;

- Step 2:

- Count the length of discharge voltage sequence of ith cycle as , for example, is the length of discharge voltage sequence of 150th cycle, which has been shown in Figure 2;

- Step 3:

- Count the sequence length of ith cycle at discharge stage as , for example, has also been shown in Figure 2;

- Step 4:

- Calculate the sequence length of ith cycle at self-recharge stage as , ;

- Step 5:

- Repeat Step 2–Step 4 until ;

- Step 6:

- Count the effective length at self-recharge stage as , ;

- Step 7:

- Rebuild a new sequence with first data of original sequence of ith cycle;

- Step 8:

- Set entropy parameter: and . Make a phase space reconstruction for the new sequence;

- Step 9:

- Calculate the probability by data order. Then, obtain the PE value of ith cycle as ;

- Step 10:

- Repeat Step 7–Step 9 until ;

- Step 11:

- Obtain the HI sequence based on PE, named as .

3.3. Hybrid Model for Battery RUL

- Step 1:

- Obtain the HI sequence based on PE;

- Step 2:

- Perform EMD denoising based on the HI sequence and obtain the denoised data;

- Step 3:

- Build the ARIMA model and predict the HI;

- Step 4:

- Obtain the residual sequence between the original HI sequence and the HI prediction of ARIMA model;

- Step 5:

- Build the GM(1,1) and predict the residual data;

- Step 6:

- Add the ARIMA model prediction and the GM(1,1) model prediction;

- Step 7:

- Establish the relationship between HI and capacity. Calculate the failure threshold of HI according to the failure threshold of capacity;

- Step 8:

- RUL value is defined by the length between the starting point and the point of which the estimated HI meets the failure threshold.

4. Result and Discussion

4.1. Verification of HI Extraction

4.2. RUL Prediction Results and Analysis

4.2.1. Evaluation Criteria

- AE

- RMSEwhere is the actual RUL and is the predicted RUL. is the actual HI and is the predicted HI, respectively. N is the sampling size. is the prediction starting cycle.

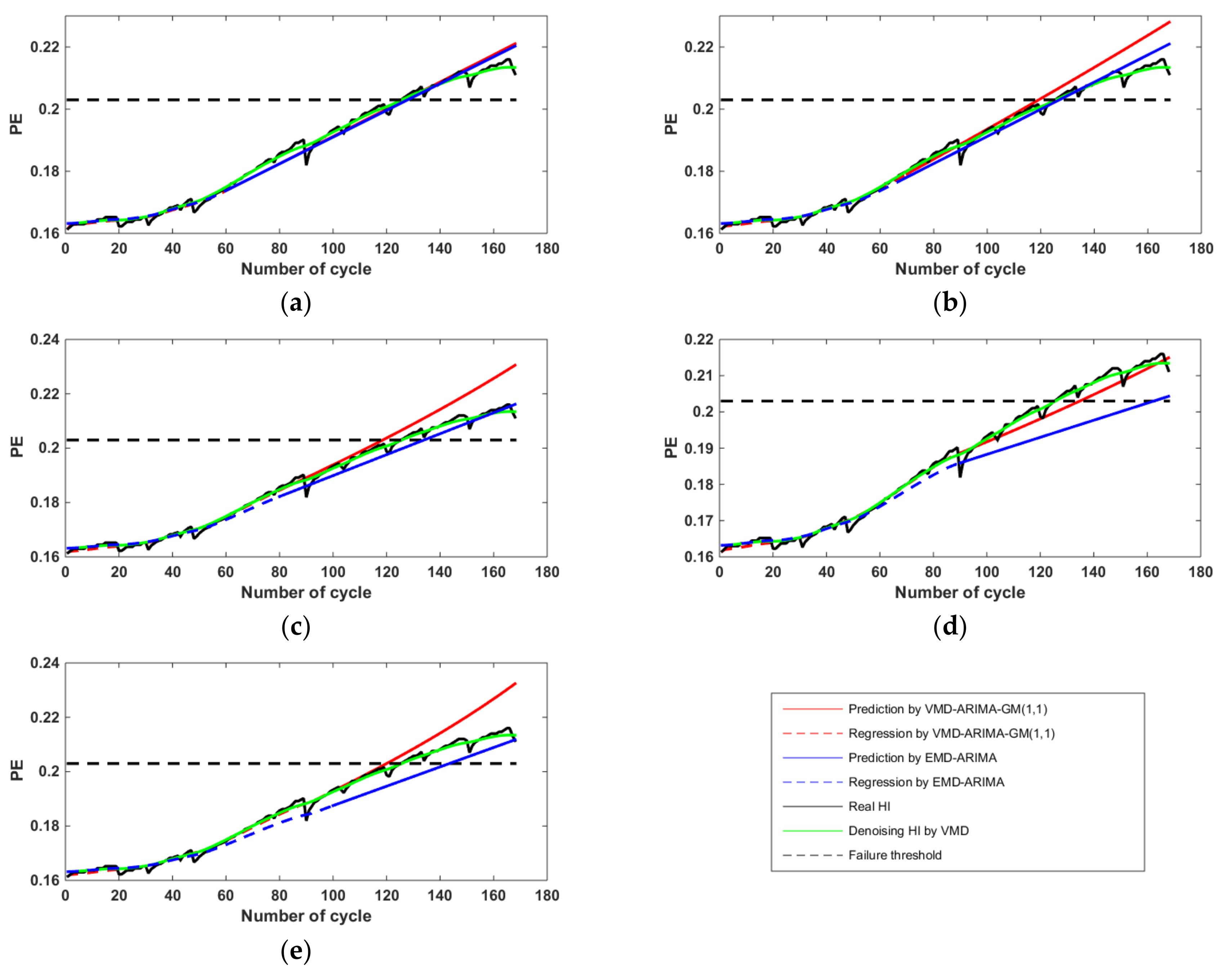

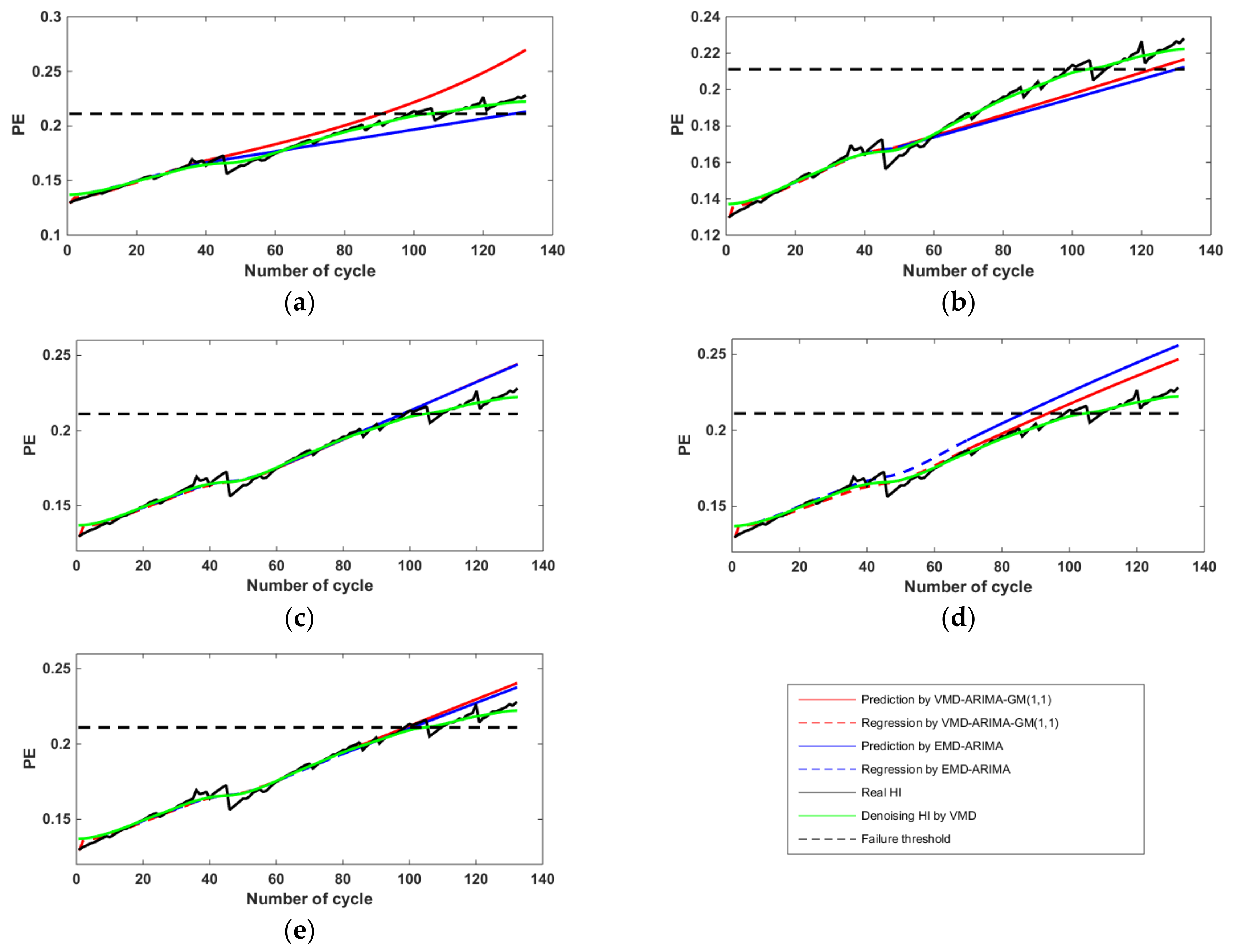

4.2.2. Prediction Results and Analysis

5. Conclusions

- By Pearson and Spearman correlation analyses, we can find the correlation absolute value between PE and capacity is close to 1, indicating that PE has a high linear relationship with capacity. PE features can express the battery degradation process well.

- The Pearson correlation absolute value of PE, MVF, and DVD_ETI is 0.9977, 0.9897, and 0.9920, respectively. The Spearman correlation absolute value of PE, MVF and DVD_ETI is 0.9994, 0.9868, and 0.9890, respectively. Both results show that PE has better presentation ability than MVF and DVD_ETI.

- The AEs with VMD–ARIMA–GM(1,1) range from 7.7 to 29 cycles, while the range of EMD–ARIMA is 14.8–41cycles. The RMSE values range from 0.0026 to 0.1065, while the range of EMD–ARIMA is 0.0025–0.1392. The error analysis illustrates VMD–ARIMA–GM(1,1) usually has an advantage over EMD–ARIMA in accuracy.

- Different training sequence leads to different time of building ARIMA model, so the execution time statistics can only be a range. The execution time of VMD–ARIMA–GM(1,1) is 2.9617–6.0966 s, while the range of EMD–ARIMA is 3.0554–6.1818 s. Compared with EMD–ARIMA, the proposed approach has a slight advantage in execution time.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

Main Symbols

| m | Embedding dimension |

| Delay time | |

| f (t) | Original signal of VMD |

| δ (t) | Dirac function |

| Corresponding center frequency | |

| The kth BLIMF | |

| Quadratic penalty term | |

| Number of modes | |

| Estimated value | |

| Normal white noise process with zero mean | |

| Previous observed value | |

| Previous noise value |

Abbreviations

| RUL | Remaining useful life |

| HI | Health indicator |

| PE | Permutation entropy |

| SE | Sample entropy |

| SVM | Support vector machine |

| RVM | Relevance vector machine |

| ANN | Artificial Neural Network |

| DE | Differential evolution |

| VMD | Variational mode decomposition |

| EMD | Empirical mode decomposition |

| AR | Auto-regressive |

| MA | Moving average |

| ARMA | Auto-regressive and moving average |

| ARIMA | Auto-regressive integrated moving average |

| GM(1,1) | Grey model of one variable and one dimension |

| TIEDVD | Time interval of equal discharging voltage difference |

| DVDETI | Discharging voltage difference of equal time interval |

| MVF | Mean voltage falloff |

| BLIMF | Band-limited intrinsic mode function |

| AGO | Accumulated generating operation |

| AE | Absolute error |

| RMSE | Root mean squared error |

References

- Genc, R.; Alas, M.O.; Harputlu, E.; Repp, S.; Kremer, N.; Castellano, M.; Colak, S.G.; Ocakoglu, K.; Erdem, E. High-capacitance hybrid supercapacitor based on multi-colored fluorescent carbon-dots. Sci. Rep. 2017, 7, 11222. [Google Scholar] [CrossRef] [PubMed]

- Zou, C.; Manzie, C.; Nešić, D.; Kallapur, A.G. Multi-time-scale observer design for state-of-charge and state-of-health of a lithium-ion battery. J. Power Sources 2016, 335, 121–130. [Google Scholar] [CrossRef]

- Prasad, G.K.; Rahn, C.D. Model based identification of aging parameters in lithium ion batteries. J. Power Sources 2013, 232, 79–85. [Google Scholar] [CrossRef]

- Orchard, M.E.; Hevia-Koch, P.; Zhang, B.; Tang, L. Risk measures for particle-filtering-based state-of-charge prognosis in lithium-ion batteries. IEEE Trans. Ind. Electron. 2013, 60, 5260–5269. [Google Scholar] [CrossRef]

- Hu, C.; Youn, B.D.; Wang, P. Ensemble of data-driven prognostic algorithms for robust prediction of remaining useful life. Reliabil. Eng. Syst. Saf. 2012, 103, 120–135. [Google Scholar] [CrossRef]

- Patil, M.A.; Tagade, P.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Doo, S. A novel multistage support vector machine based approach for li-ion battery remaining useful life estimation. Appl. Energy 2015, 159, 285–297. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, C.; Chen, Z. An online method for lithium-ion battery remaining useful life estimation using importance sampling and neural networks. Appl. Energy 2016, 173, 134–140. [Google Scholar] [CrossRef]

- Zhang, C.; He, Y.; Yuan, L.; Xiang, S.; Wang, J. Prognostics of lithium-ion batteries based on wavelet denoising and de-rvm. Comput. Intell. Neurosci. 2015, 2015, 14. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; He, Y.; Yuan, L.; Xiang, S. Capacity prognostics of lithium-ion batteries using emd denoising and multiple kernel rvm. IEEE Access 2017, 5, 12061–12070. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, M. Lithium-ion batteries remaining useful life prediction based on a mixture of empirical mode decomposition and arima model. Microelectron. Reliabil. 2016, 65, 265–273. [Google Scholar] [CrossRef]

- Liu, D.; Wang, H.; Peng, Y.; Xie, W.; Liao, H. Satellite lithium-ion battery remaining cycle life prediction with novel indirect health indicator extraction. Energies 2013, 6, 3654–3668. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, J.; Liao, H.; Peng, Y.; Peng, X. A health indicator extraction and optimization framework for lithium-ion battery degradation modeling and prognostics. IEEE Trans. Syst. Man Cybern. Syst. 2015, 45, 915–928. [Google Scholar]

- Zhang, Y.; Guo, B. Online capacity estimation of lithium-ion batteries based on novel feature extraction and adaptive multi-kernel relevance vector machine. Energies 2015, 8, 12439–12457. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, M.; Chen, Y.; Tao, Y. A novel health indicator for on-line lithium-ion batteries remaining useful life prediction. J. Power Sources 2016, 321, 1–10. [Google Scholar] [CrossRef]

- Widodo, A.; Shim, M.C.; Caesarendra, W.; Yang, B.S. Intelligent prognostics for battery health monitoring based on sample entropy. Expert Syst. Appl. Int. J. 2011, 38, 11763–11769. [Google Scholar] [CrossRef]

- Tang, G.; Wang, X.; He, Y.; Liu, S. Rolling bearing fault diagnosis based on variational mode decomposition and permutation entropy. In Proceedings of the IEEE International Conference on Ubiquitous Robots and Ambient Intelligence, Xi’an, China, 19–22 August 2016; pp. 626–631. [Google Scholar]

- Li, Y.; Li, Y.; Chen, X.; Yu, J. Denoising and feature extraction algorithms using npe combined with vmd and their applications in ship-radiated noise. Symmetry 2017, 9, 256. [Google Scholar] [CrossRef]

- Bandt, C.; Pompe, B. Permutation entropy: A natural complexity measure for time series. Phys. Rev. Lett. 2002, 88, 174102. [Google Scholar] [CrossRef] [PubMed]

- Dragomiretskiy, K.; Zosso, D. Variational mode decomposition. IEEE Trans. Signal Process. 2014, 62, 531–544. [Google Scholar] [CrossRef]

- Box, G.E.P.; Jenkins, G.M. Time series analysis: Forecasting and control. J. Time 2010, 31, 303. [Google Scholar]

- Calheiros, R.N.; Masoumi, E.; Ranjan, R.; Buyya, R. Workload prediction using arima model and its impact on cloud applications’ qos. IEEE Trans. Cloud Comput. 2015, 3, 449–458. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, Y. Applications of grey relative relational grade to optimization of grey model gm(1,1). J. Grey Syst. 2007, 19, 321–332. [Google Scholar]

- Saha, B.; Kai, G.; Poll, S.; Christophersen, J. Prognostics methods for battery health monitoring using a bayesian framework. IEEE Trans. Instrum. Measur. 2009, 58, 291–296. [Google Scholar] [CrossRef]

| Battery Number | No. 5 | No. 6 | No. 7 | No. 18 |

|---|---|---|---|---|

| Pearson correlation | −0.9977 | −0.9931 | −0.9979 | −0.9909 |

| Spearman correlation | −0.9994 | −0.9999 | -0.9995 | −0.9919 |

| HI | PE | MVF | DVD_ETI |

|---|---|---|---|

| Pearson correlation | −0.9977 | −0.9897 | −0.9920 |

| Spearman correlation | −0.9994 | −0.9868 | −0.9890 |

| Approach | HI | Battery No. | Starting Point | Actual RUL | Predicted RUL | AE | RMSE | TIME(s) |

|---|---|---|---|---|---|---|---|---|

| VMD–ARIMA–GM(1,1) | PE | #05 | 60 | 65 | 67 | 2 | 0.0026 | 5.7240 |

| 70 | 55 | 49 | 6 | 0.0054 | 3.1329 | |||

| 80 | 45 | 38 | 7 | 0.0067 | 3.0489 | |||

| 90 | 35 | 45 | 10 | 0.0028 | 3.1980 | |||

| 100 | 25 | 20 | 5 | 0.0079 | 3.9542 | |||

| #18 | 40 | 59 | 51 | 8 | 0.0182 | 4.6548 | ||

| 50 | 49 | 73 | 24 | 0.0092 | 5.0305 | |||

| 60 | 39 | 38 | 1 | 0.0087 | 6.0966 | |||

| 70 | 29 | 24 | 5 | 0.0120 | 5.2689 | |||

| 80 | 19 | 19 | 0 | 0.0083 | 4.2462 | |||

| Capacity | #05 | 60 | 65 | 59 | 6 | 0.0599 | 3.6518 | |

| 70 | 55 | 50 | 5 | 0.0552 | 5.5227 | |||

| 80 | 45 | 44 | 4 | 0.0326 | 3.5595 | |||

| 90 | 35 | 54 | 19 | 0.0509 | 4.9536 | |||

| 100 | 25 | 27 | 2 | 0.0245 | 2.9617 | |||

| #18 | 40 | 59 | 88 | 29 | 0.0559 | 4.3129 | ||

| 50 | 49 | 63 | 14 | 0.0435 | 5.5490 | |||

| 60 | 39 | 31 | 8 | 0.1065 | 3.5446 | |||

| 70 | 29 | 22 | 7 | 0.0917 | 4.1230 | |||

| 80 | 19 | 14 | 5 | 0.0764 | 3.8354 | |||

| EMD–ARIMA | PE | #05 | 60 | 65 | 68 | 3 | 0.0025 | 5.6949 |

| 70 | 55 | 57 | 2 | 0.0027 | 3.0554 | |||

| 80 | 45 | 54 | 9 | 0.0031 | 3.1098 | |||

| 90 | 35 | 72 | 37 | 0.0089 | 3.2036 | |||

| 100 | 25 | 43 | 18 | 0.0060 | 3.8054 | |||

| #18 | 40 | 59 | 89 | 30 | 0.0100 | 4.7045 | ||

| 50 | 49 | 80 | 31 | 0.0115 | 5.0143 | |||

| 60 | 39 | 38 | 1 | 0.0086 | 6.1818 | |||

| 70 | 29 | 16 | 13 | 0.0192 | 5.2857 | |||

| 80 | 19 | 21 | 2 | 0.0067 | 4.2334 | |||

| Capacity | #05 | 60 | 65 | 59 | 6 | 0.0593 | 3.7034 | |

| 70 | 55 | 54 | 1 | 0.0452 | 5.5080 | |||

| 80 | 45 | 53 | 8 | 0.0356 | 3.5589 | |||

| 90 | 35 | 72 | 37 | 0.0894 | 4.8837 | |||

| 100 | 25 | 39 | 14 | 0.0470 | 3.0115 | |||

| #18 | 40 | 59 | 100 | 41 | 0.0734 | 4.3695 | ||

| 50 | 49 | 73 | 24 | 0.0604 | 5.0888 | |||

| 60 | 39 | 26 | 13 | 0.1392 | 3.5195 | |||

| 70 | 29 | 25 | 4 | 0.0775 | 3.9590 | |||

| 80 | 19 | 20 | 1 | 0.0551 | 3.9384 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Xu, L.; Zhou, Y. Novel Approach for Lithium-Ion Battery On-Line Remaining Useful Life Prediction Based on Permutation Entropy. Energies 2018, 11, 820. https://doi.org/10.3390/en11040820

Chen L, Xu L, Zhou Y. Novel Approach for Lithium-Ion Battery On-Line Remaining Useful Life Prediction Based on Permutation Entropy. Energies. 2018; 11(4):820. https://doi.org/10.3390/en11040820

Chicago/Turabian StyleChen, Luping, Liangjun Xu, and Yilin Zhou. 2018. "Novel Approach for Lithium-Ion Battery On-Line Remaining Useful Life Prediction Based on Permutation Entropy" Energies 11, no. 4: 820. https://doi.org/10.3390/en11040820

APA StyleChen, L., Xu, L., & Zhou, Y. (2018). Novel Approach for Lithium-Ion Battery On-Line Remaining Useful Life Prediction Based on Permutation Entropy. Energies, 11(4), 820. https://doi.org/10.3390/en11040820