Towards Improved Energy and Resource Management in Manufacturing

Abstract

:1. Introduction

1.1. Approaches to Resource Accounting for Manufacturing

- Many production processes require inputs from building services, thus resulting in an interdependent relationship between the two. Analyzing one while ignoring the other may therefore lead to misleading results.

- Often, the use of energy, material, and water is interdependent, where the consumption or conservation of one can affect the other. Thus, a holistic approach prevents problem shifting, which may arise from isolated analysis of the factory sub-components.

- A holistic analysis of the factory resource flows allows identifying greater opportunities for resource recovery.

1.2. Energy Management Standards

1.3. Derivation of Research Demand

- When considering manufacturing facilities as holistic systems that are comprised of the manufacturing processes and the factory building, allows for identifying greater opportunities for resource recovery.

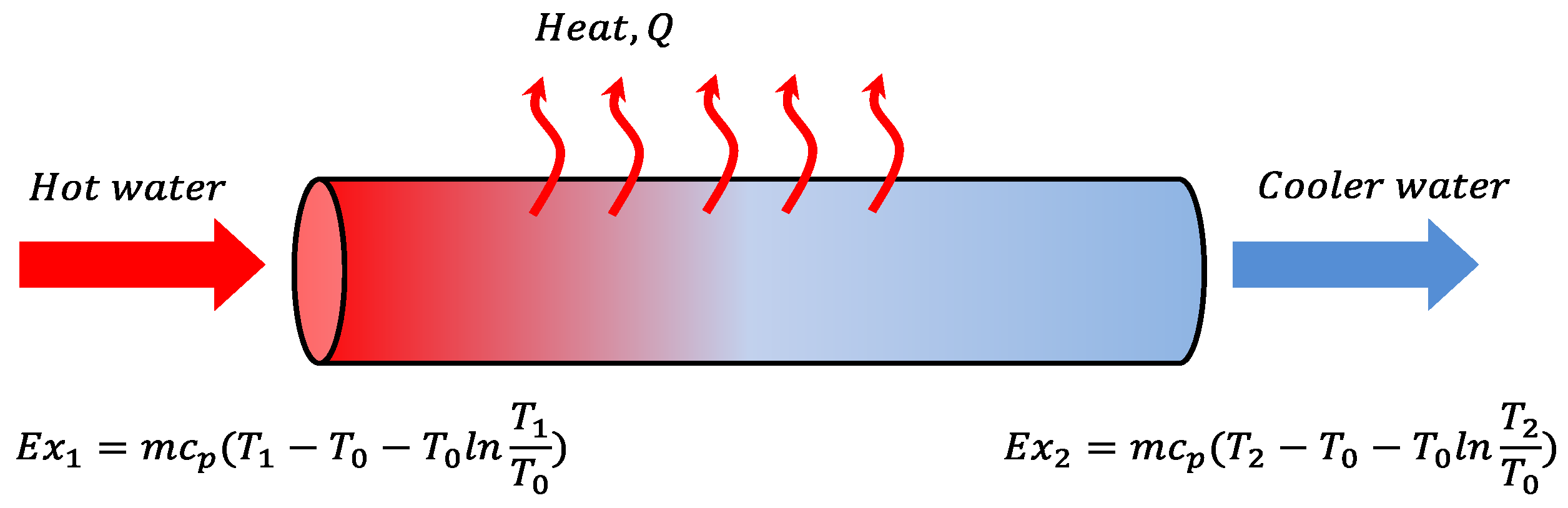

- Modelling resource flows in terms of exergy has the benefits of (i) energy quality is considered in addition to its quantity; (ii) resource flows other than energy can be modelled on a common unit basis, thus allowing for identifying greater resource recovery opportunities.

- The use of exergy analysis for energy and resource management is widespread in academic literature, however its use in the industry is limited. This may be due to lack of acceptance of the exergy concept in the industry and the lack of consistent application in practice.

- Tools and methods pertaining to energy management can benefit from including non-energy based flows in the analyses [28].

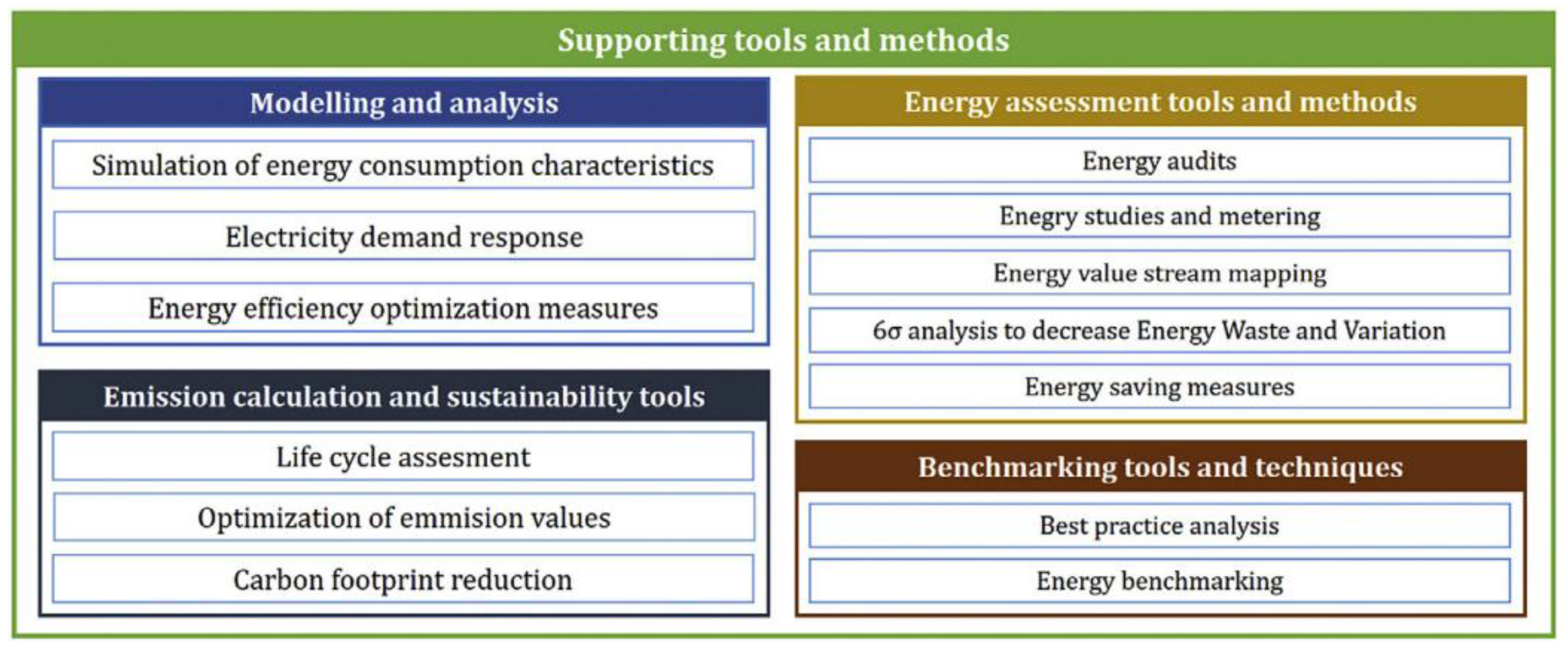

2. Methods

3. Towards Improved Industrial Energy and Resource Management

3.1. Scope and Boundaries

3.1.1. Physical Boundaries

- —

- A physical boundary is drawn in line with a gate-to-gate analysis. For a production facility, the factory building is the physical boundary.

3.1.2. Analysis Scope

- —

- The analysis scope depends on the factory flows modelling method and analysis type.

- —

- The analysis must incorporate a holistic view of the factory, while taking into considering the interaction between the production equipment and factory building.

- —

- This methodology is designed to be applied to a broad range of industries, energy intensive and non-energy intensive alike, as resource flows includes material and water as well.

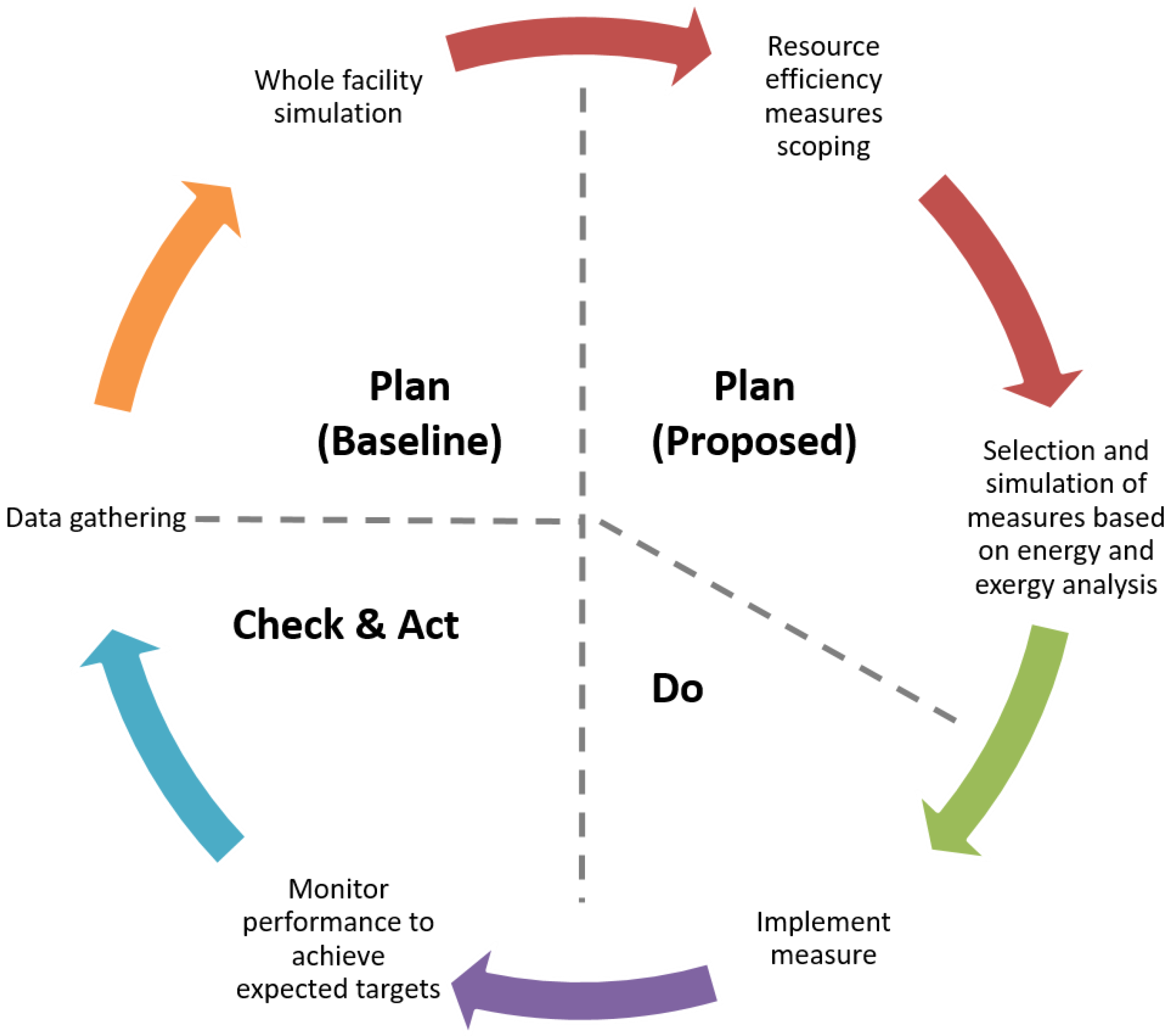

3.2. Planning for Improved Resource Efficiency

Data Collection

- —

- Data about the manufacturing system, factory building, production equipment, and production schedule is acquired.

- Acquisition of data through BMS (Building Management Systems) or SCADA (Supervisory Control and Data Acquisition) system.

- Installation of data collection equipment (sensors).

- Application of rough-cut methodology to fill missing gaps in data.

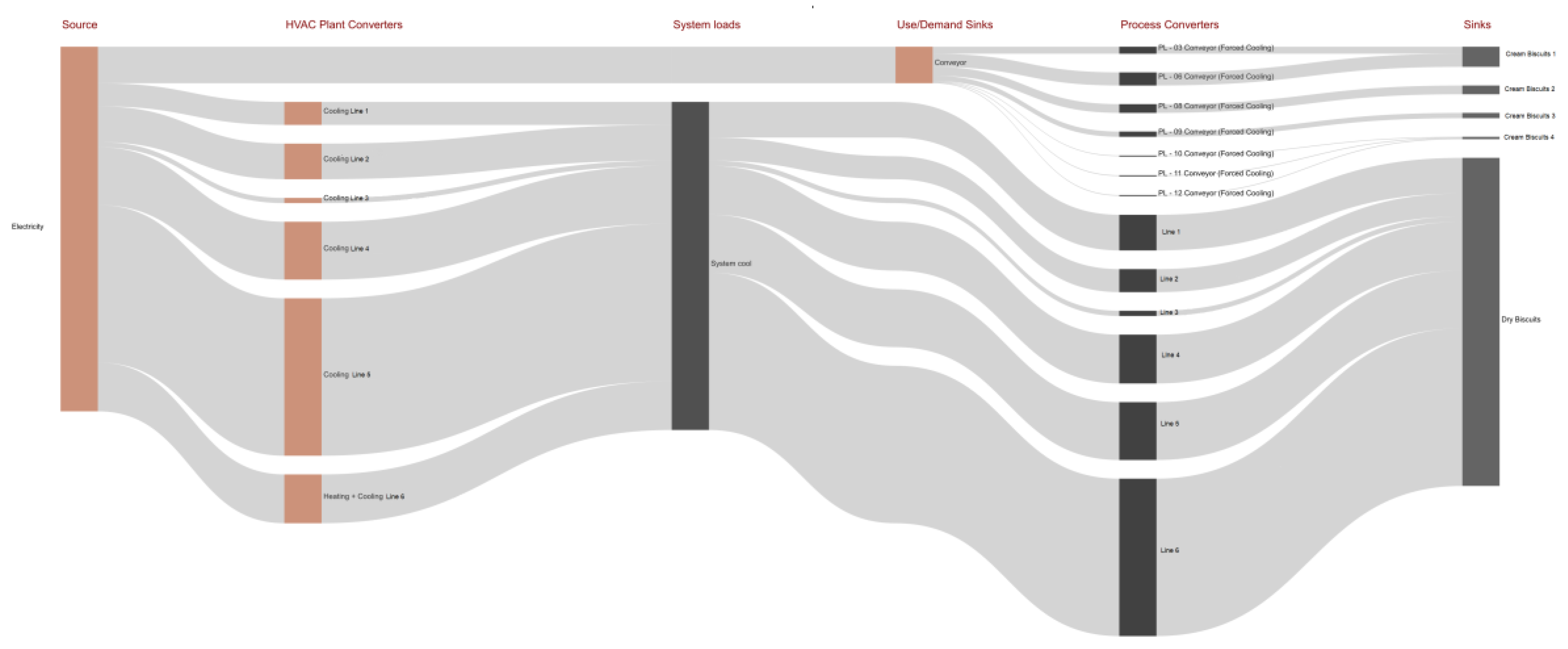

3.3. Baseline

- —

- The baseline resource consumption of the manufacturing system is established by modelling and simulation.

- —

- The resource flows in the facility are mapped and visualized based on either energy or material basis, generating Sankey diagrams.

Identification of Resource Reuse/Recovery Opportunities

- —

- Based on resource flows visualization, opportunities for resource reuse or consumption minimization are identified.

- Stop: Identify opportunities to stop equipment when not in use,

- Eliminate: Eliminate unnecessary usage of resources,

- Repair: If equipment is not operating within its intended parameters, repair it,

- Reduce: Improve efficiency to reduce resource consumption,

- Recover: Recover resources by linking factory components (building and production related), and

- Change: Replace low efficiency components in the factory with high efficiency ones.

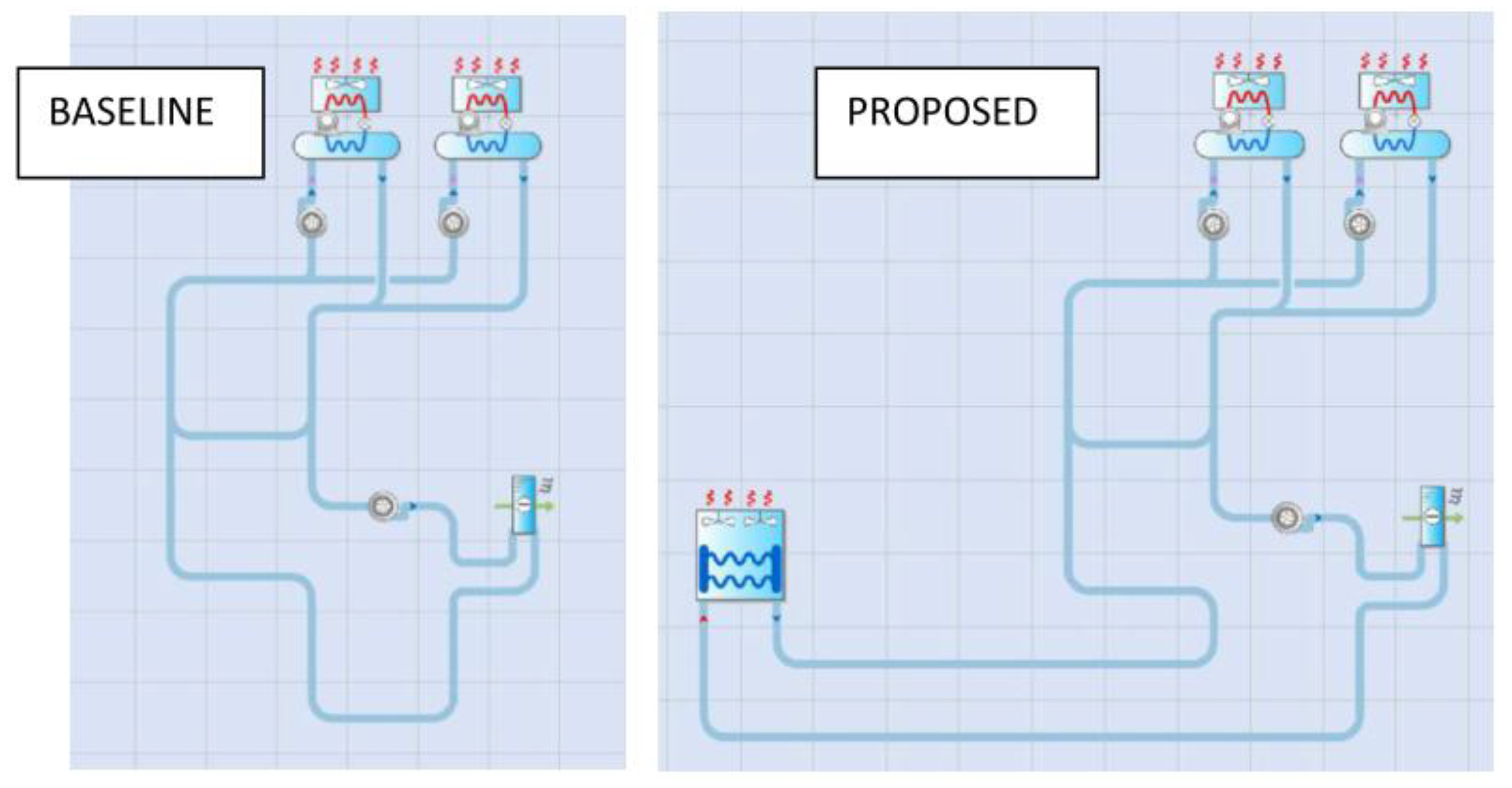

3.4. Modelling, Simulation and Analysis of Measures

- —

- The selected technologies after the screening process are to be simulated to estimate savings in resources.

- —

- A dynamic energy simulation engine is to be used, which allows for modelling the manufacturing facility from a holistic perspective. For a production facility, the factory needs to be modelled as an integrated system of the production processes, the factory building, and building services.

- —

- A suitable method for analyzing the consumption of resources has to be used (such as exergy analysis).

- —

- The predicted performance profile of the selected technologies will serve as ‘target desired performance’ of the measure.

3.5. Implementation and Operation

- —

- Physically implement the selected technologies.

- —

- Provide relevant training to personnel to ensure correct operation and maintenance of implemented measure.

- —

- Install appropriate data collection equipment to ensure comparison against simulated desired performance.

3.6. Monitoring and Correction

- —

- Monitor the performance of the implemented measure, and to identify solutions to possible issues that impede performing to the desired level.

- —

- Take corrective action at the implemented measure.

3.7. Review and Repeat

- —

- Monitor performance to ensure operation is at targeted desired performance.

- —

- Scope for further opportunities for continual improvement.

4. Implementation and Findings: Case Study

4.1. Physical Boundaries

4.2. Analysis Scope

4.3. Planning for Improved Resource Efficiency

4.3.1. Data Collection

4.3.2. Baseline

4.3.3. Identification of Resource Reuse/Recovery Opportunities

4.3.4. Modelling, Simulation and Analysis of Measures

4.4. Implementation and Operation

4.5. Monitoring and Correction

4.6. Review and Repeat

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Administration, E.I. Industrial Sector Energy Consumption—International Energy Outlook; U.S. Energy Information Administration: Washington, DC, USA, 2016.

- European Commission. A Resource-Efficient Europe—Flagship Initiative under the Europe 2020 Strategy; European Commission: Brussels, Belgium, 2011; Volume 21, pp. 1–17. [Google Scholar]

- Kaźmierczyk, P.; Stenbaek Hansen, M.; Günther, J.; McKinnon, D.; Loewe, C.; Lingvall, F.; Kallay, T.K.; Szlezak, J.; Bahn-Walkowiak, B.; Herczeg, M. Resource Efficiency in Europe: Policies and Approaches in 31 EEA Member and Cooperating Countries; European Environment Agency: Copenhagen, Denmark, 2012. [Google Scholar]

- Dawkins, E.; Roelich, K.; Barrett, J.; Baiocchi, G. Securing the Future—The Role of Resource Efficiency; WRAP: Banbury, UK, 2010. [Google Scholar]

- Herrmann, C.; Thiede, S.; Heinemann, T. A Holistic Framework for Increasing Energy and Resource Efficiency in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 3–4. [Google Scholar]

- Wright, A.J.; Oates, M.R.; Greenough, R. Concepts for dynamic modelling of energy-related flows in manufacturing. Appl. Energy 2013, 112, 1342–1348. [Google Scholar] [CrossRef]

- Ball, P.D.; Despeisse, M.; Evans, S.; Greenough, R.M.; Hope, S.B.; Kerrigan, R.; Levers, A.; Lunt, P.; Murray, V.; Oates, M.R.; et al. Factory modelling: Combining energy modelling for buildings and production systems. IFIP Adv. Inf. Commun. Technol. 2013, 397, 158–165. [Google Scholar]

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Ann. Technol. 2012, 61, 587–609. [Google Scholar] [CrossRef]

- Herrmann, C.; Schmidt, C.; Kurle, D.; Blume, S.; Thiede, S. Sustainability in manufacturing and factories of the future. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 283–292. [Google Scholar] [CrossRef]

- Cerdas, F.; Kurle, D.; Andrew, S.; Thiede, S.; Herrmann, C.; Zhiquan, Y.; Jonathan, L.S.C.; Bin, S.; Kara, S. Defining circulation factories—A pathway towards factories of the future. Procedia CIRP 2015, 29, 627–632. [Google Scholar] [CrossRef]

- Kovacic, I.; Orehounig, K.; Mahdavi, A.; Bleicher, F.; Dimitrou, A.-A.; Waltenbereger, L. Energy Efficient Production—Interdisciplinary, Systemic Approach through Integrated Simulation. Stroj. J. Theory Appl. Mech. Eng. 2013, 55, 17–34. [Google Scholar]

- Caggiano, A.; Marzano, A.; Teti, R.; Design, S. Sustainability Enhancement of a Turbine Vane Manufacturing Cell through Digital Simulation Based Design. Energies 2016, 9, 790. [Google Scholar] [CrossRef]

- Garwood, T.L.; Hughes, B.R.; Oates, M.R.; Connor, D.O. A review of energy simulation tools for the manufacturing sector. Renew. Sustain. Energy Rev. 2018, 81, 895–911. [Google Scholar] [CrossRef]

- Sousa, T.; Brockway, P.E.; Cullen, J.M.; Miller, J.; Cabrera, A.; Domingos, T. The Need for Robust, Consistent Methods in Societal Exergy Accounting. Ecol. Econ. 2017, 141, 11–21. [Google Scholar] [CrossRef]

- Hernandez, A.G.; Cullen, J.M. Unlocking Plant-level Resource Efficiency Options: A Unified Exergy Measure. Procedia CIRP 2016, 48, 122–127. [Google Scholar] [CrossRef]

- Mousavi, S.; Kara, S.; Kornfeld, B. A hierarchical framework for concurrent assessment of energy and water efficiency in manufacturing systems. J. Clean. Prod. 2016, 133, 88–98. [Google Scholar] [CrossRef]

- Thiede, S.; Schönemann, M.; Kurle, D.; Herrmann, C. Multi-level simulation in manufacturing companies: The water-energy nexus case. J. Clean. Prod. 2016, 139, 1118–1127. [Google Scholar] [CrossRef]

- Khattak, S.H.; Greenough, R. Resource Accounting in Factories and the Energy-Water Nexus; Springer: New York, NY, USA, 2017. [Google Scholar]

- Khattak, S.H.; Greenough, R. Resource efficient manufacturing: Can reduced energy efficiency lead to improved sustainability? ECEE Ind. Summer Study Proc. 2014, 163–169. Available online: www.eceee.org (accessed on 2 March 2018).

- Khattak, S.H.; Greenough, R.; Korolija, I.; Brown, N. An exergy based approach to resource accounting for factories. J. Clean. Prod. 2016, 121, 99–108. [Google Scholar] [CrossRef]

- Wall, G. Exergy flows in industrial processes. Energy 1988, 13, 197–208. [Google Scholar] [CrossRef]

- Atmaca, A.; Yumrutaş, R. Thermodynamic and exergoeconomic analysis of a cement plant: Part I—Methodology. Energy Convers. Manag. 2014, 79, 790–798. [Google Scholar] [CrossRef]

- McKenna, R. Industrial Energy Efficiency: Interdisciplinary Perspectives on the Thermodynamic, Technical and Economic Constraints; University of Bath: Bath, UK, 2009. [Google Scholar]

- Gaudreau, K.; Fraser, R.A.; Murphy, S. The characteristics of the exergy reference environment and its implications for sustainability-based decision-making. Energies 2012, 5, 2197–2213. [Google Scholar] [CrossRef]

- Rosen, M.A. Does industry embrace exergy? Exergy Int. J. 2002, 2, 221–223. [Google Scholar] [CrossRef]

- Khattak, S.H. An Exergy Based Method for Resource Accounting in Factories. Ph.D. Thesis, De Montfort University, Leicester, UK, January 2016. [Google Scholar]

- Sangi, R.; Müller, D. Implementation of a solution to the problem of reference environment in the exergy evaluation of building energy systems. Energy 2018, 149, 830–836. [Google Scholar] [CrossRef]

- May, G.; Stahl, B.; Taisch, M.; Kiritsis, D. Energy management in manufacturing: From literature review to a conceptual framework. J. Clean. Prod. 2017, 167, 1464–1489. [Google Scholar] [CrossRef]

- Johansson, M.T.; Thollander, P. A review of barriers to and driving forces for improved energy efficiency in Swedish industry—Recommendations for successful in-house energy management. Renew. Sustain. Energy Rev. 2018, 82, 618–628. [Google Scholar] [CrossRef]

- Iker, L.; Ander, I.; Allur, A.; Larrea, E. Contribution to Energy Management of the Main Standards for Environmental Management Systems. Energies 2017, 10, 1758. [Google Scholar] [CrossRef]

- A Management System for Energy. ANSI/MSE 2000:2008. Available online: https://webstore.ansi.org (accessed on 10 March 2018).

- Dzene, I.; Polikarpova, I.; Zogla, L.; Rosa, M. Application of ISO 50001 for implementation of sustainable energy action plans. Energy Procedia 2015, 72, 111–118. [Google Scholar] [CrossRef]

- Standardization, I.O. The ISO Survey of Management System Standard Certifications 2016. Available online: https://www.iso.org/the-iso-survey.html (accessed on 10 March 2018).

- Bonacina, F.; Corsini, A.; De Propris, L.; Marchegiani, A.; Mori, F. Industrial Energy Management Systems in Italy: State of the art and perspective. Energy Procedia 2015, 82, 562–569. [Google Scholar] [CrossRef]

- Gopalakrishnan, B.; Ramamoorthy, K.; Crowe, E.; Chaudhari, S.; Latif, H. A structured approach for facilitating the implementation of ISO 50001 standard in the manufacturing sector. Sustain. Energy Technol. Assess. 2014, 7, 154–165. [Google Scholar] [CrossRef]

- Vermeeren, R.; Mulder, B.; Meta, B.V.; Reijnders, M. Implementation of ISO 50001 in Industry in the Netherlands. ECEE Ind. Summer Study Proc. 2012, 679–688. Available online: www.eceee.org (accessed on 2 March 2018).

- Kanneganti, H.; Gopalakrishnan, B.; Crowe, E.; Al-shebeeb, O.; Yelamanchi, T.; Nimbarte, A.; Currie, K.; Abolhassani, A. Speci fi cation of energy assessment methodologies to satisfy ISO 50001 energy management standard. Sustain. Energy Technol. Assess. 2017, 23, 121–135. [Google Scholar]

- Jovanovi, B.; Filipovi, J. ISO 50001 standard-based energy management maturity model e proposal and validation in industry. J. Clean. Prod. 2016, 112, 2744–2755. [Google Scholar] [CrossRef]

- Karakasli, E.; Oztop, H.; Hepbasli, A. Performance assessment of a polyclinic heating and cooling system in a hospital building. Int. J. Exergy 2016, 21, 70–86. [Google Scholar] [CrossRef]

- Hepbasli, A. Towards Developing An Exergy Management System Standard and Its Application to a University Building. In CLIMA 2016—Proceedings of the 12th REHVA World Congress; Aalborg University, Department of Civil Engineering: Aalborg, Denmark, 2016. [Google Scholar]

- Nguyen, A.; Reiter, S.; Rigo, P. A review on simulation-based optimization methods applied to building performance analysis. Appl. Energy 2014, 113, 1043–1058. [Google Scholar] [CrossRef]

- Wang, J.; Chang, Q.; Xiao, G.; Wang, N.; Li, S. Data driven production modeling and simulation of complex automobile general assembly plant. Comput. Ind. 2011, 62, 765–775. [Google Scholar] [CrossRef]

- Resource and Energy Efficient Manufacturing. Available online: http://www.reemain.eu/ (accessed on 12 March 2018).

- CETIAT Energy Performance Diagnosis: The Key to Improve Your Performance. Available online: http://industrie.cetiat.fr/gb/p-gb/energy-performance-diagnosis-the-key-to-improve-your-performance.html (accessed on 4 April 2018).

- Harish, V.S.; Kumar, A. A review on modeling and simulation of building energy systems. Renew. Sustain. Energy Rev. 2016, 56, 1272–1292. [Google Scholar] [CrossRef]

- Air-conditioning, heating and refrigeration institute. AHRI 550/590 (I-P/2015): Performance Rating of Water-Chilling and Heat Pump Water-Heating Packages Using the Vapour Compression Cycle. Available online: https://ahrinet.org/search-standards (accessed on 15 April 2018).

- Bakshi, B.R.; Gutowski, T.G.; Sekulic, D.P. Thermodynamics and the Destruction of Resources; Thoughts on the Application of Thermodynamics to the Development of Sustainability Science; Cambridge University Press: Cambridge, UK, 2011; pp. 477–488. [Google Scholar]

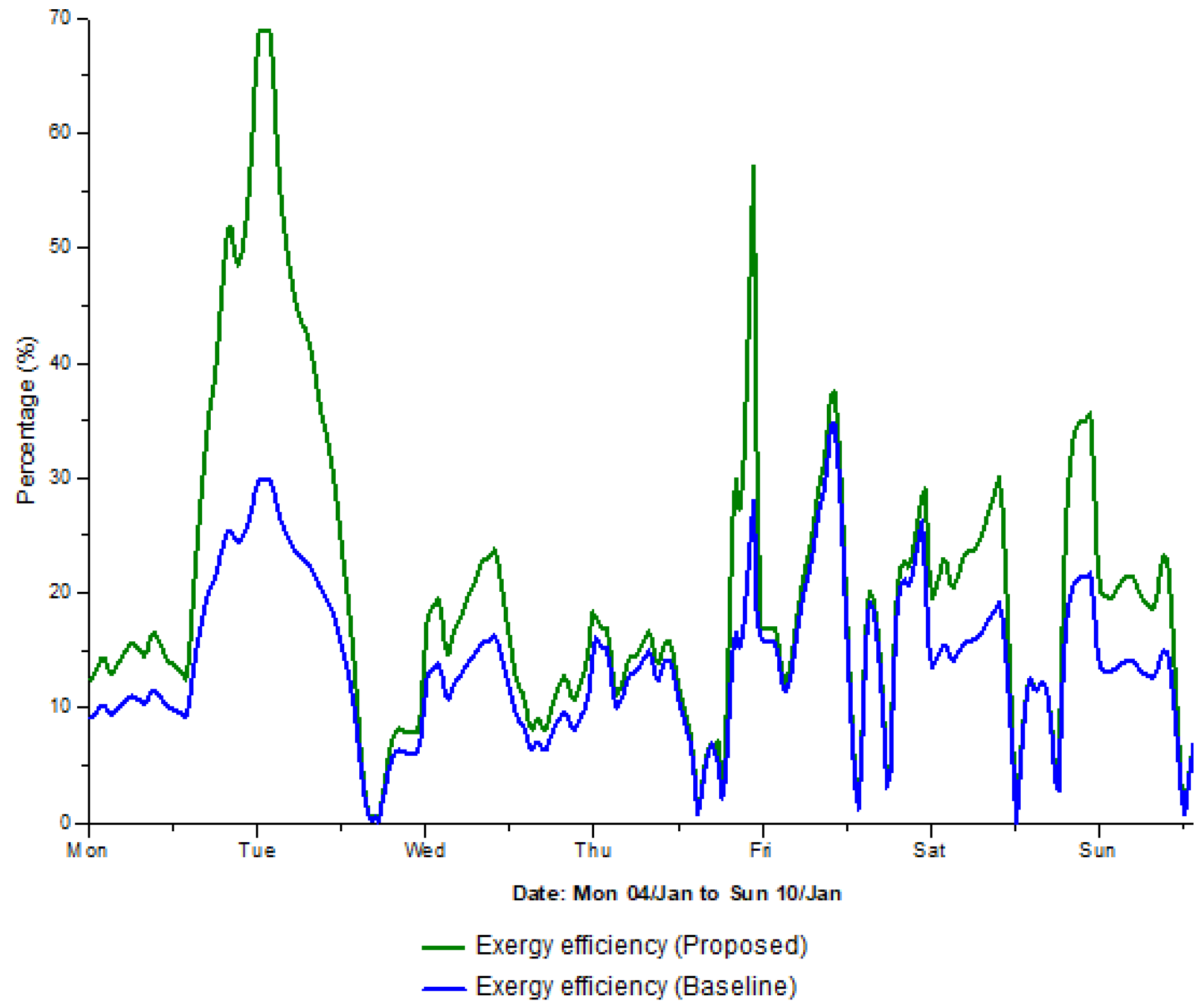

| Scenario | Baseline (%) | Proposed (%) | Improvement over Baseline (%) |

|---|---|---|---|

| Mean Energy Efficiency Ratio | 14.11 | 17.73 | 25.7 |

| Mean Exergy Efficiency | 13.94 | 20.42 | 46.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan Khattak, S.; Oates, M.; Greenough, R. Towards Improved Energy and Resource Management in Manufacturing. Energies 2018, 11, 1006. https://doi.org/10.3390/en11041006

Hassan Khattak S, Oates M, Greenough R. Towards Improved Energy and Resource Management in Manufacturing. Energies. 2018; 11(4):1006. https://doi.org/10.3390/en11041006

Chicago/Turabian StyleHassan Khattak, Sanober, Michael Oates, and Rick Greenough. 2018. "Towards Improved Energy and Resource Management in Manufacturing" Energies 11, no. 4: 1006. https://doi.org/10.3390/en11041006