A Co-Opetition Straw Supply Strategy Integrating Rural Official Organizations and Farmers’ Behavior in China

Abstract

:1. Introduction

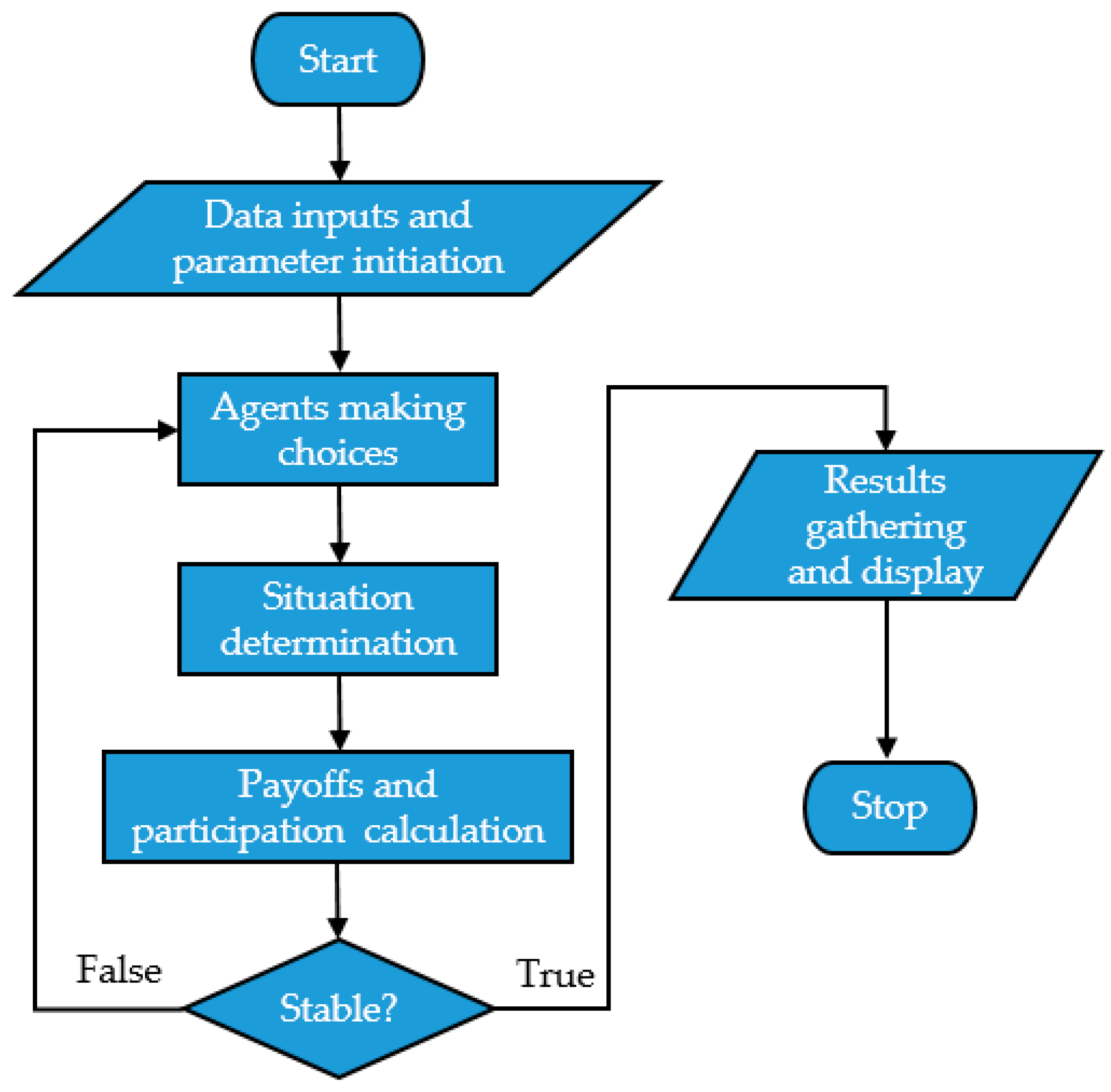

2. Modeling

2.1. Modeling Framework

2.2. Agents

2.2.1. Farmer Agents

2.2.2. VC Agents

2.2.3. Broker Agents

2.2.4. Plant Agent

2.3. Simulation Environment

3. Simulation

3.1. Data

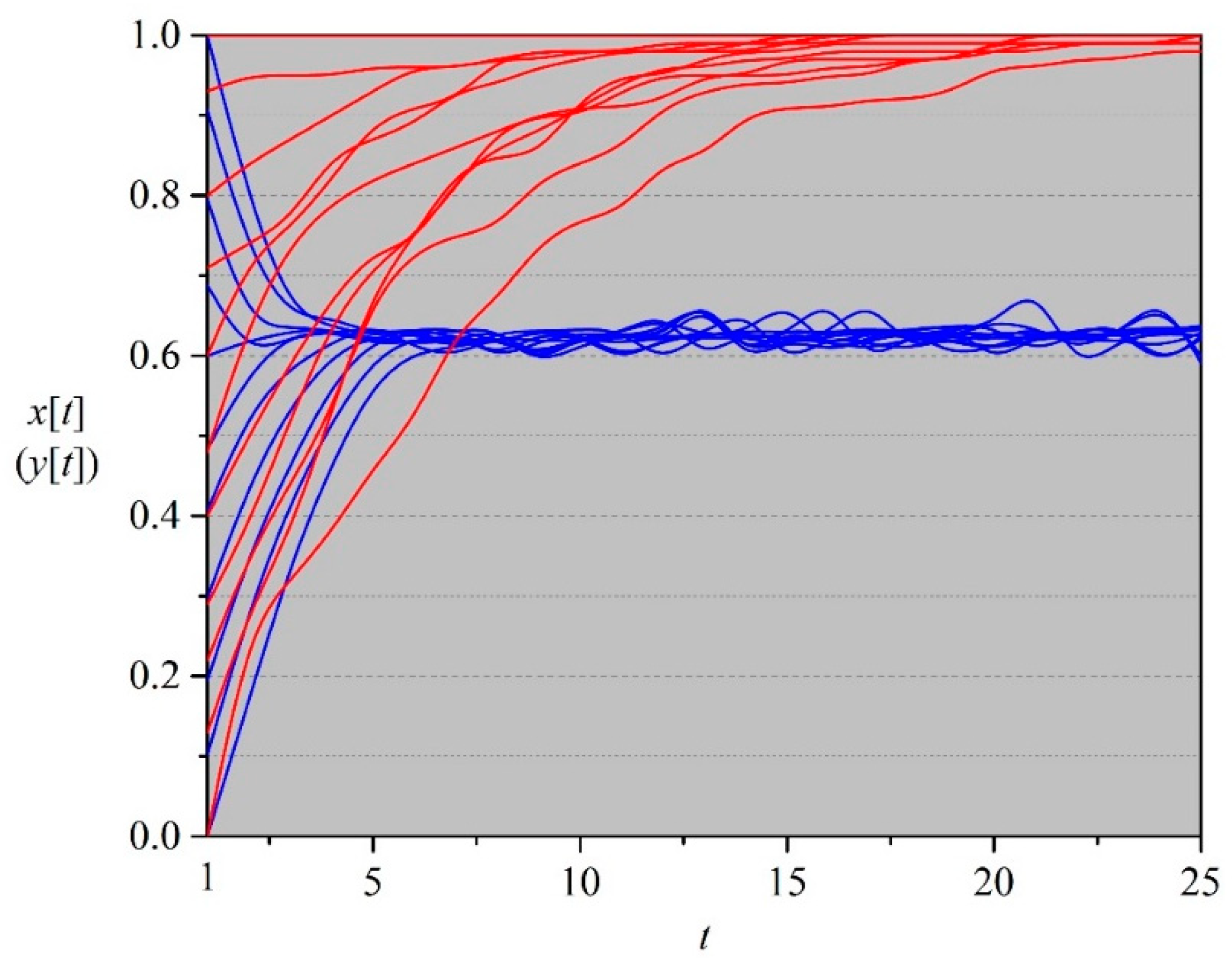

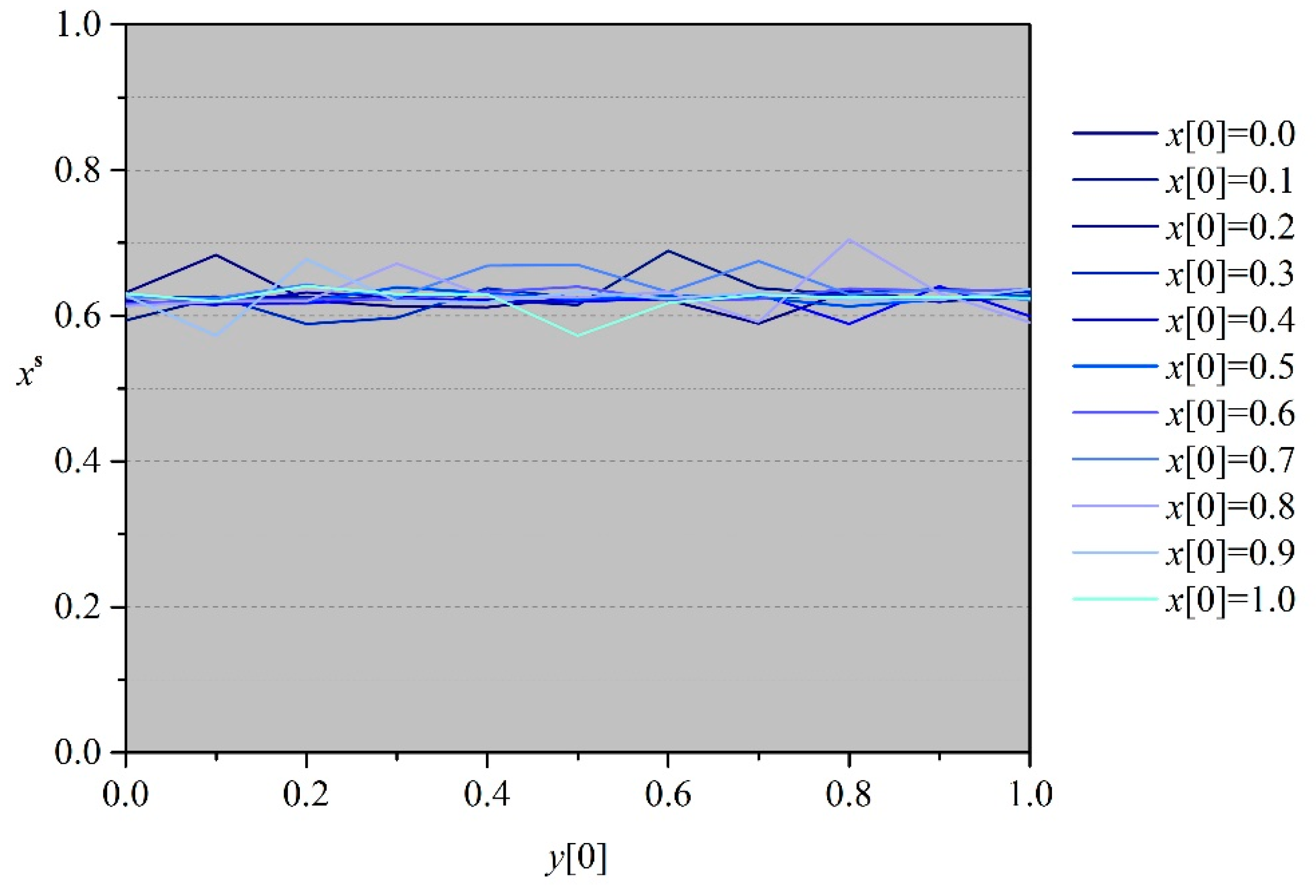

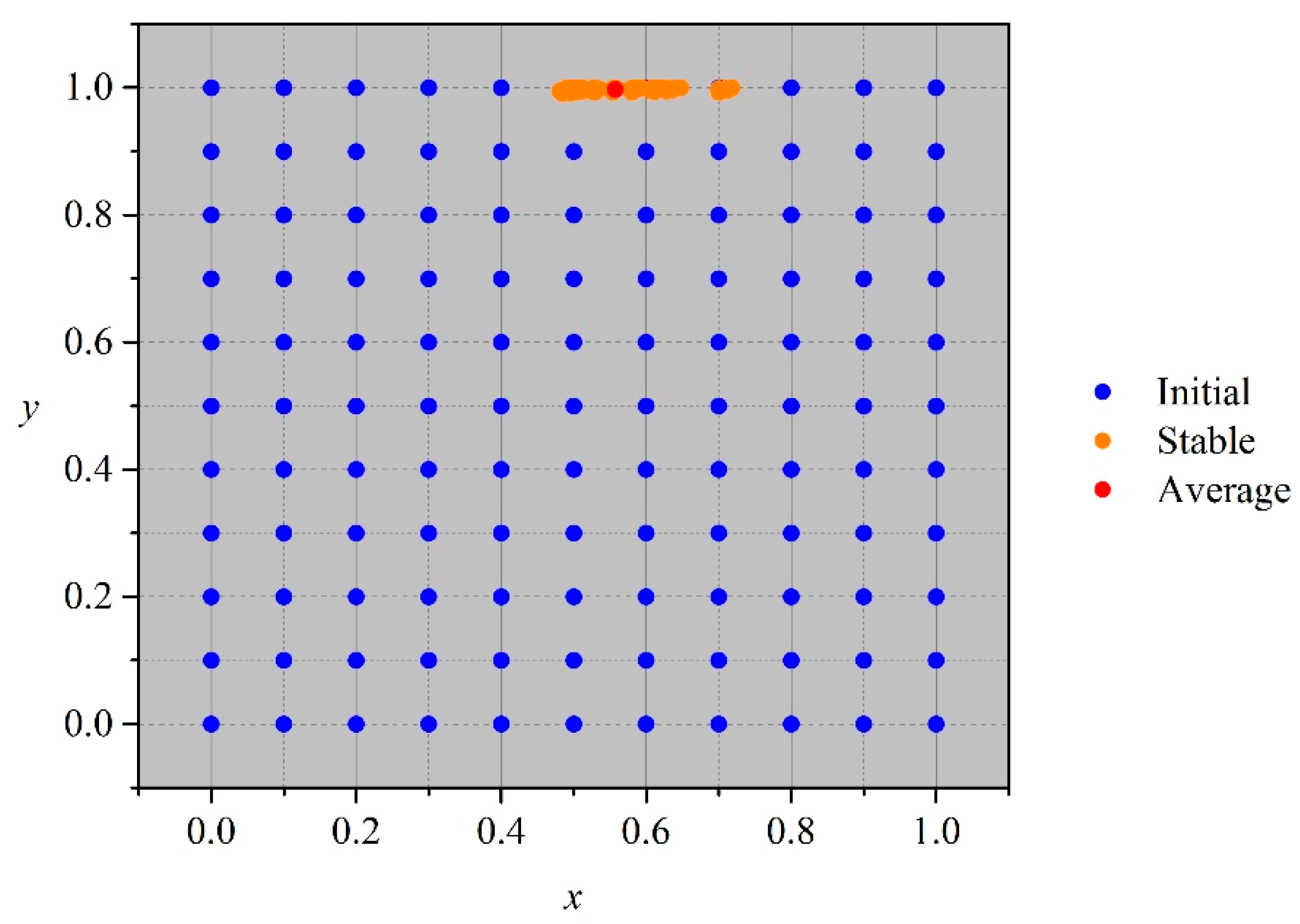

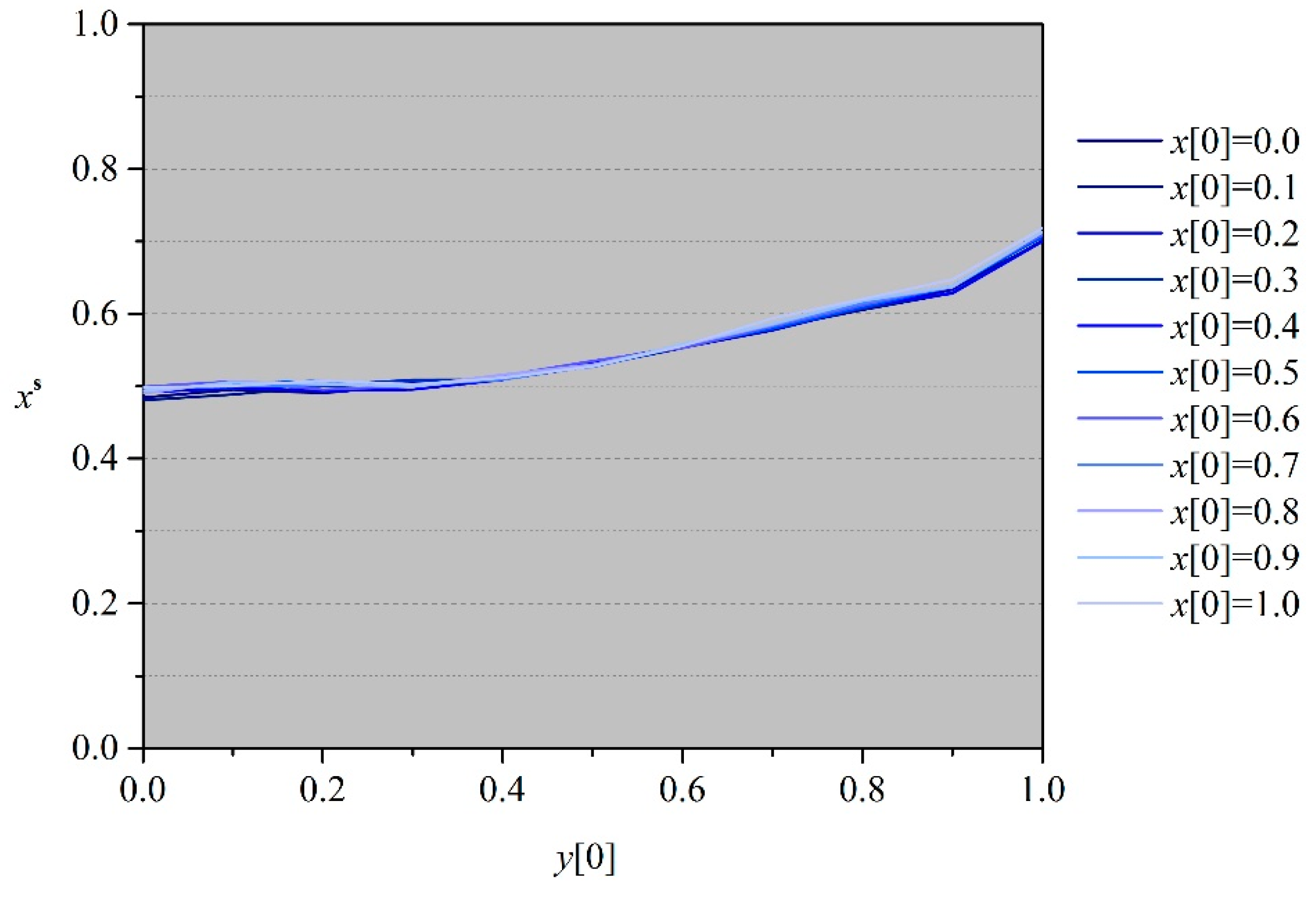

3.2. Results

3.3. Discussion

4. Conclusions and Policy Implications

- (1)

- The smooth operation of the straw supply chain within this strategy is closely related to farmers’ participation, which is positively affected by the cooperative enthusiasm of rural official organizations. Supporting policy is suggested to assist the VCs in the investment of straw collection machines and the reduction of transportation fees to improve their willingness of establishing the cooperative straw supply system;

- (2)

- The co-opetition strategy is suggested to be implemented combined with a benefit sharing policy, which is a supporting measure for the strategy to use part of the profit to improve villagers’ welfare. Currently, the economic development levels in some of China’s rural areas are so backward that the local villagers have strong expectations regarding improvements of local infrastructure. Considering the limited income from selling the straw produced by a single household of farmers and their intense immaterial demand of welfare improvement, collecting straw resources and sharing the benefits from selling it in bulk are helpful to increase villagers’ willingness to participate in the straw supply system; and

- (3)

- Free-ride behaviors will damage the effect of the co-opetition strategy. Rural official organizations are suggested to share benefits through welfare improving actions that are more specific to the farmers who supply straw (e.g., maintaining irrigation facilities, and providing pension insurance and medical care) to prevent the free-ride phenomenon.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Variable | Definition |

|---|---|

| Farmer’s profit per unit of straw (CNY/t) | |

| Straw supplied by the broker player (t) | |

| Straw supplied by the cooperative formed by farmers and the VC (t) | |

| Total straw purchased by the plant agent (t) | |

| Wood biomass purchased by the plant agent (t) | |

| Straw selling price charged by the farmer player (CNY/t) | |

| Straw factory-gate price (CNY/t) | |

| Wood biomass price (CNY/t); | |

| Straw collection cost coefficient | |

| Transportation cost per km∙t, CNY/(km∙t) | |

| Transportation distance, km | |

| Coefficient of plant’s revenue per unit of fired biomass (CNY/t); | |

| Price of biomass-based electricity (CNY/kWh) | |

| Unit operation cost for the plant (CNY/kWh) | |

| Conversion ratio of biomass to electricity (kWh/t) | |

| Fixed cost of the plant (CNY) | |

| Id number of farmer agents | |

| Id number of VC agents | |

| Numbers of farmers and VCs, respectively | |

| Straw yield, t/km2 | |

| Farmer i’s strategy choice in round t (= 0 or 1) | |

| Farmer i’s utility in round t | |

| VC j’s strategy choice in Round t (= 0 or 1) | |

| VC j’s profit in round t | |

| Benefit sharing ratio of VCs; 0 < λ < 1 | |

| Percentage of farmers choosing the VC method within VC j’s area | |

| Weight of monetary benefit for farmers | |

| Annual biomass demand of the plant agent (t) |

| Parameter | Distribution |

|---|---|

| Constant: 240, 0.002 a | |

| Constant: 0.75 b | |

| Constant: 0.15 a | |

| Constant: 20 a | |

| Constant: 700 a | |

| Normal: Mean = 250, Standard Deviation = 20 a | |

| Constant: 300 a | |

| Triangular: Min = 2.5, Likeliest = 2.75, Max = 3 a | |

| Constant: 44.85 c | |

| Uniform: Min = 0, Max = 60 a |

References

- China’s National Development and Reform Commission. Enhanced Actions on Climate Change: China’s Intended Nationally Determined Contributions. 2015. Available online: http://www.gov.cn/xinwen/2015-06/30/content_2887330.htm (accessed on 2 July 2016).

- Thakur, A.; Canter, C.E.; Kumar, A. Life-cycle energy and emission analysis of power generation from forest biomass. Appl. Energy 2014, 128, 246–253. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, L.; Chang, Y.; Pang, M. Biomass direct-fired power generation system in China: An integrated energy, GHG emissions, and economic evaluation for Salix. Energy Policy 2015, 84, 155–165. [Google Scholar] [CrossRef]

- China’s National Energy Administration. The 13th Five-Year Plan of Biomass Energy Development. 2016. Available online: http://zfxxgk.nea.gov.cn/auto87/201612/t20161205_2328.htm?keywords= (accessed on 9 December 2016).

- Wang, L.; Watanabe, T. A Stackelberg game theoretic analysis of incentive effects under perceived risk for China’s straw-based power plant supply chain. Energies 2016, 9, 455. [Google Scholar] [CrossRef]

- Ren, D.; Zhao, Y.; Xie, X.; Zhang, Q. Report on the Development of China’s Renewable Energy Industry (2015); China National Renewable Energy Centre: Beijing, China, 2015. [Google Scholar]

- Zhang, Q.; Zhou, D.; Fang, X. Analysis on the policies of biomass power generation in China. Renew. Sustain. Energy Rev. 2014, 32, 926–935. [Google Scholar] [CrossRef]

- Tan, Q.; Yang, H.; Zhang, X.; Deng, Y.; Wei, Y. Measurement Model and Empirical Analysis of Fuel Collection Cost for Biomass Power Generation. Forum Sci. Technol. China 2014, 21, 117–123. [Google Scholar]

- Liu, L.; Ye, J.; Zhao, Y.; Zhao, E. The plight of the biomass power generation industry in China—A supply chain risk perspective. Renew. Sustain. Energy Rev. 2015, 49, 680–692. [Google Scholar] [CrossRef]

- Ren, L.; Cafferty, K.; Roni, M.; Jacobson, J.; Xie, G.; Ovard, L.; Wright, C. Analyzing and Comparing Biomass Feedstock Supply Systems in China: Corn Stover and Sweet Sorghum Case Studies. Energies 2015, 8, 5577–5597. [Google Scholar] [CrossRef] [Green Version]

- Wang, X. Research on Farmers’ Behavior during the Development and Utilization of Biomass-Energy in China; Chinese Academy of Agricultural Sciences: Beijing, China, 2009. [Google Scholar]

- Qu, W.; Tu, Q.; Bluemling, B. Which factors are effective for farmers’ biogas use?—Evidence from a large-scale survey in China. Energy Policy 2013, 63, 26–33. [Google Scholar] [CrossRef]

- Wang, Y. The Studies of Biomass Power Generation Supply Chain Cooperation Patterns in the Game Situation; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2011. [Google Scholar]

- Zhang, X.; Luo, K.; Tan, Q. A feedstock supply model integrating the official organization for China’s biomass generation plants. Energy Policy 2016, 97, 276–290. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, K.; Tan, Q. A Game Theory Analysis of China’s Agri-biomass-based Power Generation Supply Chain: A Co-opetition Strategy. Energy Procedia 2017, 105, 168–173. [Google Scholar] [CrossRef]

- Fundenberg, D.; Tirole, J. Game Theory; MIT Press: Cambridge, MA, USA, 1991. [Google Scholar]

- Weibull, J.W. Evolutionary Game Theory; The MIT Press: Cambridge, MA, USA, 1995. [Google Scholar]

- Cao, H.; Zhang, S.Y. Analysis of the main interests of agricultural insurance main body based on the perspective of evolutionary game. Agric. Agric. Sci. Proc. 2010, 1, 354–363. [Google Scholar] [CrossRef]

- Wang, Y.; Meng, W. Evolutionary game analysis on co-competition mechanism of supply chain. J. Ind. Eng./Eng. Manag. 2004, 18, 96–98. [Google Scholar]

- Chaib-Draa, B.; Muller, J. Multiagent Based Supply Chain Management; Springer: Berlin, Germany, 2006. [Google Scholar]

- Ge, H.; Gray, R.; Nolan, J. Agricultural supply chain optimization and complexity: A comparison of analytic vs simulated solutions and policies. Int. J. Prod. Econ. 2015, 159, 208–220. [Google Scholar] [CrossRef]

- Moncada, J.A.; Lukszo, Z.; Junginger, M.; Faaij, A.; Weijnen, M. A conceptual framework for the analysis of the effect of institutions on biofuel supply chains. Appl. Energy 2017, 185, 895–915. [Google Scholar] [CrossRef]

- Shastri, Y.; Rodrguez, L.; Hansen, A.; Ting, K.C. Agent-based analysis of biomass feedstock production dynamics. Bioenergy Res. 2011, 4, 258–275. [Google Scholar] [CrossRef]

- Xiong, W.; Wei, P. Evolutionary analysis on co-comeptition relationship among enterprises of supply chain net based on multi-agent. J. Syst. Sci. Math. Sci. 2015, 37, 779–787. [Google Scholar]

- Sun, J.; Chen, J.; Xi, Y.; Hou, J. Mapping the cost risk of agricultural residue supply for energy application in rural China. J. Clean. Prod. 2011, 19, 121–128. [Google Scholar] [CrossRef]

- Luo, K.; Zhang, X.; Tan, Q. Novel role of rural official organization in the biomass-based power supply chain in China: A combined game theory and agent-based simulation approach. Sustainability 2016, 8, 814. [Google Scholar] [CrossRef]

- Jiang, N.; Sun, J. The strategy of co-opetition research for the straw supply market in the technology of straw and coal hybrid co-firing. J. Xi’an Jiaotong Univ. (Soc. Sci.) 2015, 35, 47–52. [Google Scholar]

| Parameter | Distribution |

|---|---|

| Constant: 50 a | |

| Constant: 100 a | |

| Constant: 0.2 b | |

| Scenario without uncertainty | |

| Constant: 250 | |

| Constant: 2.75 | |

| Constant: 30 | |

| Scenario with uncertainty | |

| Normal: Mean =250, Standard Deviation = 20 | |

| Triangular: Min = 2.5, Likeliest = 2.75, Max = 3 | |

| Uniform: Min = 0, Max = 60 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, K.; Zhang, X.; Tan, Q. A Co-Opetition Straw Supply Strategy Integrating Rural Official Organizations and Farmers’ Behavior in China. Energies 2018, 11, 2802. https://doi.org/10.3390/en11102802

Luo K, Zhang X, Tan Q. A Co-Opetition Straw Supply Strategy Integrating Rural Official Organizations and Farmers’ Behavior in China. Energies. 2018; 11(10):2802. https://doi.org/10.3390/en11102802

Chicago/Turabian StyleLuo, Kaiyan, Xingping Zhang, and Qinliang Tan. 2018. "A Co-Opetition Straw Supply Strategy Integrating Rural Official Organizations and Farmers’ Behavior in China" Energies 11, no. 10: 2802. https://doi.org/10.3390/en11102802