3.1. Effect of Processing Conditions on the Compositions of Hydrochar

Usually, peat moss contains high moisture, consequently it has a low energy density (14 MJ/kg) that cannot be used as a fuel or co-combusted in coal-fired power plants. In addition, biomass contains a higher amount of volatile matter, thus, not only does it have poor combustion efficiency and harmful gas emissions, it cannot be combusted with other fuels because of the difference in energy and bulk density [

40]. The moisture, volatile matter (VM) and ash content in the collected peat moss were 47.3%, 66.0%, and 6.6%, respectively. On the other hand, miscanthus contained 4.4% moisture, 87.5% VM, and 0.8% ash [

36] and the energy density was 18.6 MJ/kg. The components of it in feedstock also varied depending on the types of feedstock (

Table 1). However, VM, ash and fixed carbon (FC) in treated peat moss varied from 52–60%, 6–7% and 33–40%, respectively (

Table 1), depending on the treatment conditions. In the case of treated miscanthus, VM, ash, and FC were 74.5%, 0.9%, and 24.6%, respectively. The proximate analysis of untreated and treated biomass shows that VM reduced in the treated biomass, while FC increased and no significant change was observed in ash content. In contrast, a reduction of ash content in the hydrochar was reported where the hydrochar was produced from miscanthus/corn stalk/sawdust [

7,

36], which might be because of the differences in treatment temperature and type of biomass, which need be confirmed by further study.

Physicochemical properties of treated biomass confirmed that HTC improves the quality of the biomass, which can be used as fuel or maybe co-combusted in the existing coal-fired power plants. The ultimate analysis revealed that carbon content is higher in treated biomass; however, nitrogen and sulfur content was reduced with HTC (

Table 2), thus improves the quality of biomass. It seems that the treatment time has a mild impact on the fuel quality. Pretreated biomass has higher energy density and combustion characteristics compared with untreated biomass [

36,

41]. HTC improves the quality of peat moss (i.e., carbonized peat moss can be used in the existing coal-fired power plants) because fuel properties of hydrochar produced from peat moss are found to be similar to those of lignite (

Table 2). This study also reveals that peat moss can be carbonized with energy crops (miscanthus) or with other biomass to produce fuel grade hydrochar even blended with 75% miscanthus.

3.4. Hardness and Durability of Pellets

The HTC process alters the physicochemical properties of biomass, thus it eases the grinding process compared with untreated biomass. In addition, the densification process improves mass and energy density of feedstock [

48], easing the handling and transportation of feedstock such as pellets.

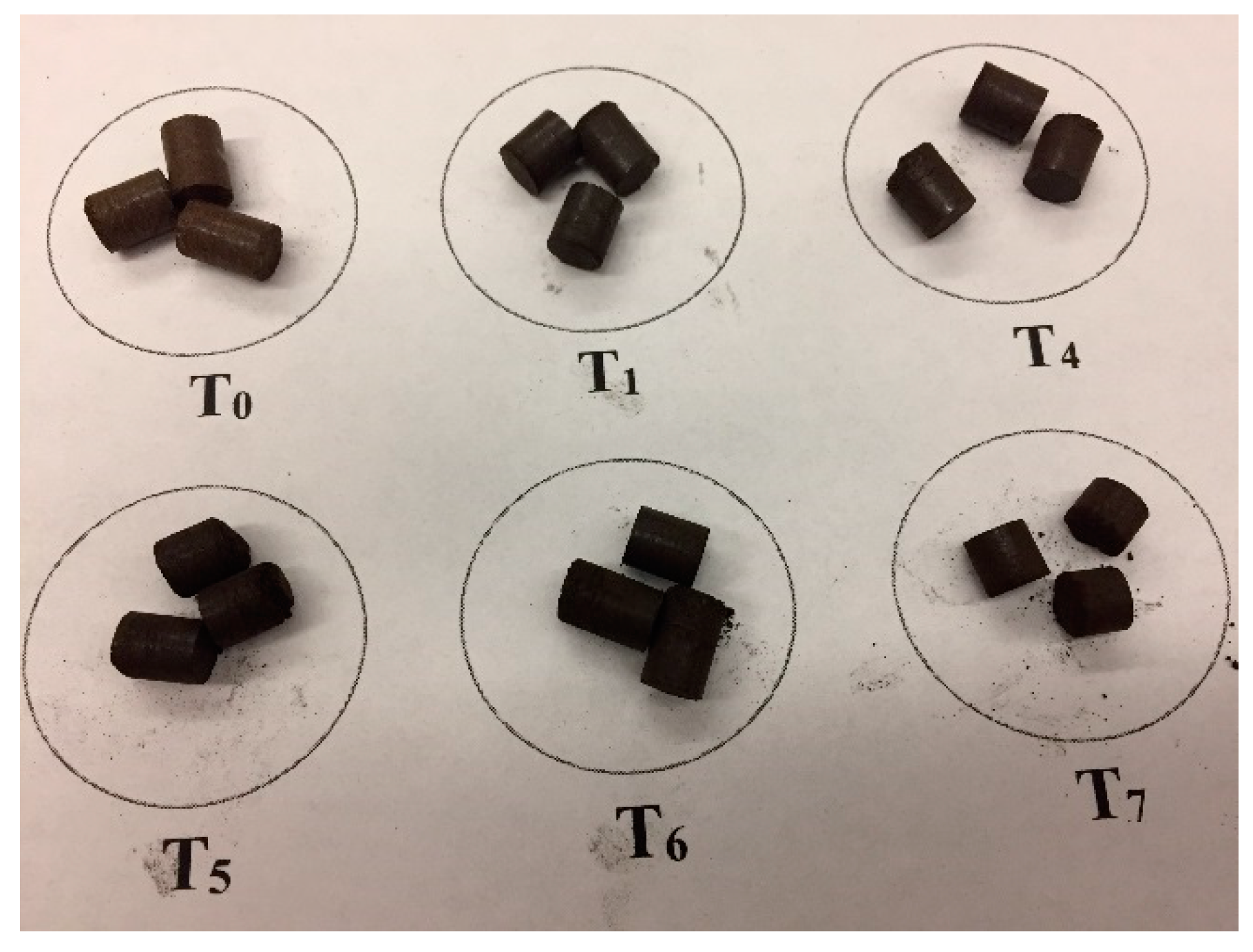

Figure 2 represents the pellets produced from treated and untreated samples. The hardness of pellets decreased because of the HTC treatment and depends on the treatment time. It seems that the longer the treatment time the lower the hardness of pellets, and pellets produced from the untreated sample had greater hardness compared with the treated sample (

Table 4). This table also shows that the collapsing time and extension reduced in the case of pellets produced from treated biomass compared with untreated one. The decomposition of hemicellulose and lignin reduces the binders and solid bonds between the carbonized particles, and thus there are more pore spaces that promote relative movements of particles, which result in lower strength [

46]. The EMC of the sample might play an important role in the hardness of the pellets [

49,

50] as it works as a lubricant and binder during the pelletization process [

51]. It has also been reported that the strength is dependent on the moisture content, species of biomass, and the pelletizing pressure [

37]. The hardness of pellets produced from untreated peat moss was observed to be greater than that of the carbonized samples either only from treated peat moss or from the blend of peat moss and miscanthus.

The optimum moisture content of co-pelletization is reported to be 10–15% [

51]. Untreated samples have higher EMC thus may have influenced the hardness of pellets except the pellets produced from carbonized miscanthus, which is consistent with other studies [

36]. In addition, the co-carbonization and subsequent pelletization might affect the hardness of the pellets [

46]; however, the hardness tends to be influenced by the ratio of the samples that were co-pelletized. The pellets from co-pelletized samples had a lower hardness [

51] compared with peat moss only. The pellets produced from the co-carbonized samples have greater hardness compared with pellets that are produced from miscanthus only, but not the pellets from the peat moss. The decomposition of hemicellulose and depolymerization of cellulose along with the softening of lignin [

52] caused by the HTC process improves the friability [

36,

47]. The strength of the pellets also decreased with the severity of carbonization (200–350 °C) [

53]; beyond this temperature, the strength increased [

54,

55]. In contrast, the durability of engineered pellets noted to be increased with the increasing fraction of hydrocarbon [

56].

Carbonized biomass contains a lower amount of chemically bonded water and compounds that have a low melting point that acted as a binding agent during pelletization at around 100 °C, thus it affects the strength of pellets from carbonized samples [

57]. The lignin in the biomass soften when heated and enhance the binding characteristics of materials during pelletization [

58]; however, natural lignin does not have an effect if the HTC temperature is controlled to less than 260 °C [

59]. It is also noted that the natural binders create solid bridges between particles during the pelletization, thus increasing the hardness [

60] and the durability of the pellets. The durability of pellets produced from untreated samples was greater than the pellets from carbonized samples [

56], consequently, pellets from untreated peat moss have higher durability (

Table 4). In addition, the durability of pellets seems to be dependent on the treatment times and the ratio of peat moss and miscanthus. The durability of pellets decreased with the increase of miscanthus in the feedstock.

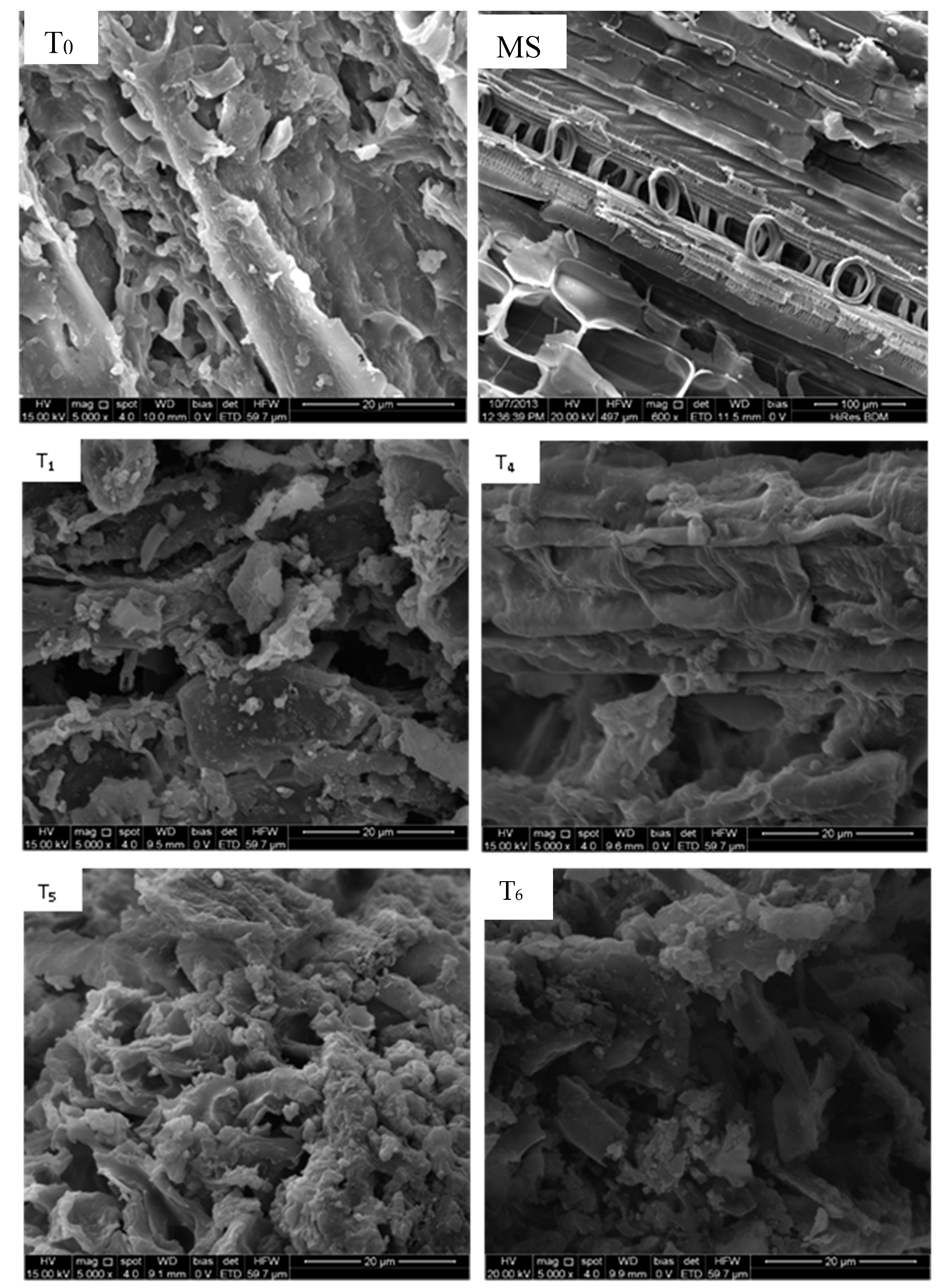

The SEM images confirmed that the HTC process has a significant impact on the structure of biomass. HTC reduces the hemicellulose and cellulose contents in hydrocahr compared with the untreated biomass [

31]. The reduction of hemicellulose and cellulose results in the porous structure of hydrochar. The untreated biomass has a well-defined structure (

Figure 3:

0, MS) which has been changed to be a porous structured biomass; i.e., hydrochar (

Figure 3: T

1, T

4–T

6). It is worthy to mention that a porous structure was observed in hydrochar even with 75% miscanthus was blended in the feedstock (the blends contain 25%, 50%, and 75% miscanthus in T

4, T

5, T

6, respectively). Consequently, the porous structure of hydrochar samples can improve the contaminant adsorption capacity, thus it can be a potential source for wastewater treatment [

61,

62] and broaden the scope of hydrochar for commercial application.

3.5. Effect of HTC on the Combustion Indices of Hydrochar

Most of the lignocellulosic biomass is rich in inorganic components (Ca: calcium, Mg: magnesium, P: phosphorous, K: potassium, Na: sodium, S: sulfur, and Fe: iron), especially agricultural biomass (

Table 5). Usually, these elements are left, and from their oxides that occur during combustion they are responsible for fouling, slagging and agglomeration, and are also corrosive [

63]. It seems that the HTC process enables the production of a hydrochar that has a porous structure [

64], which might have prompted the leaching of some of the alkali and alkaline metals [

31,

63], and thus produced a lesser amount of oxides (

Table 5). The concentration of chemicals (oxides) decreased if treated in HTC processes; however, the oxides concentration depended on the ratio of peat moss and miscanthus. The higher the ratio of miscanthus and peat moss, the greater the oxides may be because of the presence of a higher amount of alkali and alkaline metals in untreated miscanthus compared with peat moss. Consequently, HTC can be a promising option to improve the combustion properties of biomass which can replace coal in the energy industry.

The AI, base to the acid ratio (R

b/a) and BAI of hydrochar varied from 0.00001–0.00017, 0.42282–2.61941, and 0.49275–3.84167, respectively, depending on the ratio of peat moss and miscanthus. The least indices were observed in cases of biochar that was produced only from peat moss. Vamvuka & Zografos [

33] noted that a fuel may or may not cause slagging or fouling if its AI varies from 0.17–0.34 kg/GJ; however, beyond this range, fouling or agglomeration occurred [

65]. On the other hand, bed agglomeration takes place if BAI is lower than 0.15 [

34]. This study confirmed that the fuel properties of both biomass (peat moss and miscanthus) can be improved by the HTC process and reduce the fouling, agglomeration, and slagging in the combustion process to produce heat and power from hydrochar. However, the hydrochar produced from only peat moss seems to have better combustion indices compared to either hydrochar from miscanthus or from the blend of peat moss and miscanthus (

Table 6). The AI, Rb/a and BAI of raw miscanthus were 0.145–0.359, 0.466–0.701 and 0.012–0.02, respectively, depending on fertilizer application (0–80 kg/ha) and harvesting season (Fall/Spring), which may or may not be suitable [

32]. Therefore, the HTC process can be used to improve the fuel quality of high moisture biomass and replace coal or co-combusted with coal in existing coal-fired power plants without interrupting the investment and employment in heat and power industry.