1. Introduction

With the exhaustion of resources and deterioration of the global environment, it is an exceptionally urgent task to exploit all kinds of new energy, one of which is wind energy [

1,

2,

3]. Nowadays, the doubly fed machine has become the most widely used in wind farms because it uses a fractionally rated inverter to achieve variable-speed operation. However, the slip ring and brush gear present in the doubly fed machine result in significant maintenance costs, particularly for wind farms in remote areas. The brushless doubly fed machine (BDFM) retains the advantage of a low-cost inverter, but does not need a brush gear and slip ring, achieving low maintenance costs and a high reliability. The BDFM has the attractive feature of becoming the next generation of wind generators, so research on the BDFM has great practical significance [

4,

5,

6]. However, the BDFM is a system with multi variable, strong coupling and complex nonlinearity, which raises difficulties for BDFM’s high performance controlling. The BDFM’s control strategies proposed mainly include vector control and direct torque control (DTC).

Zhou D et al. proposed vector control of the double synchronous frame BDFM model, where the BDFM was divided into the control winding subsystem and the power winding subsystem [

7,

8]. To insure the variables of the control winding subsystem and power winding the subsystem in their own respective coordinate systems are direct current (DC) values under the static state, the power winding subsystem adopted stator flux orientation and the control winding subsystem adopted rotor flux orientation. The control system which depends on the motor parameters is complicated. Poza et al. developed vector control of the unified coordinate system BDFM model [

9,

10]. At present, the control system based on the unified coordinate system model is usually used to control the reactive power and active power in a grid-connected wind power system by stator flux orientation [

11,

12]. However, these control strategies also need motor parameters. In order to achieve the decoupling control of BDFM, Xia C et al. derived the synchronous coordinate system state-space model of current source power supply. Based on this model, the decoupling control scheme of BDFM was obtained by applying the input-output feedback linearization method, while the BDFM parameters are required in the control strategy [

13].

After the development of the vector control, direct torque control (DTC) is another high-performance alternating current (AC) motor control method. Direct torque control (DTC) has the advantages of a simple structure and less dependence on motor parameters [

14,

15]. Thus, the DTC technique has been widely applied to the AC machine speed-governing system [

16,

17]. However, it also has some drawbacks. Due to hysteresis control, actual flux and torque ripples are inevitable [

18,

19,

20]. Under unbalanced voltages, in a permanent magnet synchronous motor drive, motor torque equations were developed and the oscillation components created, and an improved DTC was presented to remove speed and torque oscillator factors [

21]. The conventional DTC was applied to the BDFM variable speed system. Researches show that the inverter switching voltage vectors cannot always meet the control demands of the CM stator flux and the torque [

22]. The BDFM’s conventional DTC has the losing control problem. For the purpose of reducing the flux and the torque ripples of BDFM’s DTC, several solutions with modified DTC were presented, such as predictive DTC and the fuzzy logic DTC, etc.; however, the effects of these improved schemes are not evident [

23,

24]. Zhang A et al. proposed an indirect torque control strategy for the BDFM, where the change of CM stator flux angle is used to calculate the change of the next sampling period CM stator flux. The control system requires not only the motor parameters and did not solve the losing control problem of BDFM’s conventional DTC [

25].

The rest of the content of this paper is arranged as follows: In

Section 2, the derived procedure of the BDFM model is introduced in the control motor (CM) static coordinate system. In

Section 3, the losing control problem of the conventional DTC is analyzed in detail. Additionally, by the deduced flux-angle-difference derivative equation, the scheme of flux-angle-difference feedback control (FADFC) is presented. In

Section 4, by the simulation experiments, comparison between the DTC and the proposed FADFC strategy illustrates that the steady-state performance can be obviously improved by utilizing the proposed strategy. Finally,

Section 5 is the conclusion.

2. Brushless Doubly Fed Machine (BDFM) Model

BDFM is composed of two stator windings and one special rotor winding, where the two stator windings have different pole pairs. The stator winding of one of the motors, known as the power motor (PM), is connected to the grid directly. The stator winding of another motor, named the control motor (CM), is supplied through an inverter. The rotor winding adopts a special design in which it is coupled to two stator windings. Because of the special design of the BDFM’s rotor winding, the stator and rotor windings of the power motor and control motor will generate two steady magnetic fields when the rotor winding flows a steady sinusoidal. The rotating electrical angular velocities of two magnetic fields are equal, but the rotating directions are opposite, relative to the rotor. So, the PM and CM complex variables are two groups of rotating vectors, under the static state, in the rotor coordinate system, and their velocities are same, but their directions are opposite. For a wound rotor BDFM, if we keep the PM complex variables unchanged and take the negative conjugates of the CM complex variables, the rotor coordinate system model of BDFM is obtained as follows [

9]:

and

where

,

,

, and

are the stator resistance, stator inductance, mutual inductance, and rotor inductance of PM, respectively;

,

,

and

are the stator resistance, stator inductance, mutual inductance, and rotor inductance of CM, respectively;

and

are the rotor total resistance and rotor total inductance, respectively;

represents the imaginary unit;

is the rotor machinery angular speed;

and

are PM and CM pole pairs, respectively;

,

, and

are the stator flux, stator current, and stator voltage of PM, respectively;

,

, and

are the stator flux, stator current, and stator voltage of CM after a negative conjugate operation, respectively;

and

are the rotor flux and rotor current, respectively, where

is also the current flowing into the PM rotor; and

is the sum of the PM rotor flux vector and CM rotor flux vector (after a negative conjugate operation). In this paper, all the variables of the fluxes, currents, and voltages are expressed in plural form. The plural form variable is a vector on the flat surface, so in the following it is also known as “vector”.

After negative conjugation, the PM complex variables and the CM complex variables rotate at the same velocity and in the same direction relative to the rotor under the static state. This will make future analysis more convenient.

The electromagnetic torque can be expressed as:

And the motion equation of BDFM is:

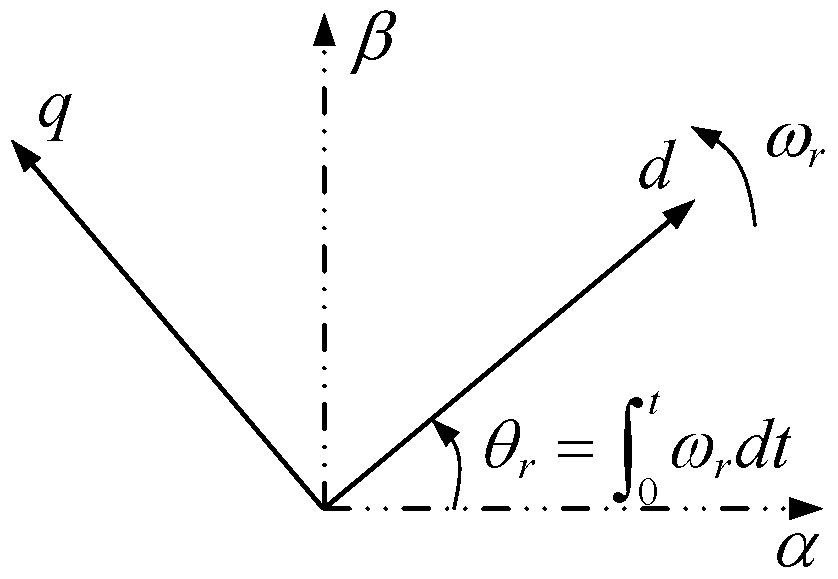

In the DTC system, the static coordinate system model is commonly used. Therefore, all the variables of BDFM must be transformed from the rotor coordinate system to the CM static coordinate system. The relationships between the rotor coordinate system (

coordinate system) and the CM static coordinate system (

coordinate system) are shown in

Figure 1.

All the variables of the BDFM model Equations (1)–(3) rotate clockwise by

, and the model of BDFM is obtained in the CM static coordinate system as follows:

and

The electromagnetic torque is again expressed as:

and the motion equation is the same as Equation (4).

By Equation (6), the electromagnetic torque can be re-expressed as a function of PM stator flux, CM stator flux, and rotor flux [

22]:

For BDFM, the slip frequency in general is larger, so the rotor reactance is much larger than the rotor resistance, and from the third line of Equation (1), the rotor flux is small and is negligible (Because the pole pairs of PM and CM are different, the PM rotor flux and CM rotor flux are not offset in space, but in the two rotor windings, the inductive back electromotive forces are almost offset) [

21]. Therefore, the electromagnetic torque of the BDFM can be simplified as:

where

is the PM stator flux amplitude,

is the CM stator flux amplitude, and

δ is the angle difference between the PM stator flux and CM stator flux, known as the flux-angle-difference.

3. Losing Control Problem of Conventional Direct Torque Control for BDFM and Its Improved Strategy

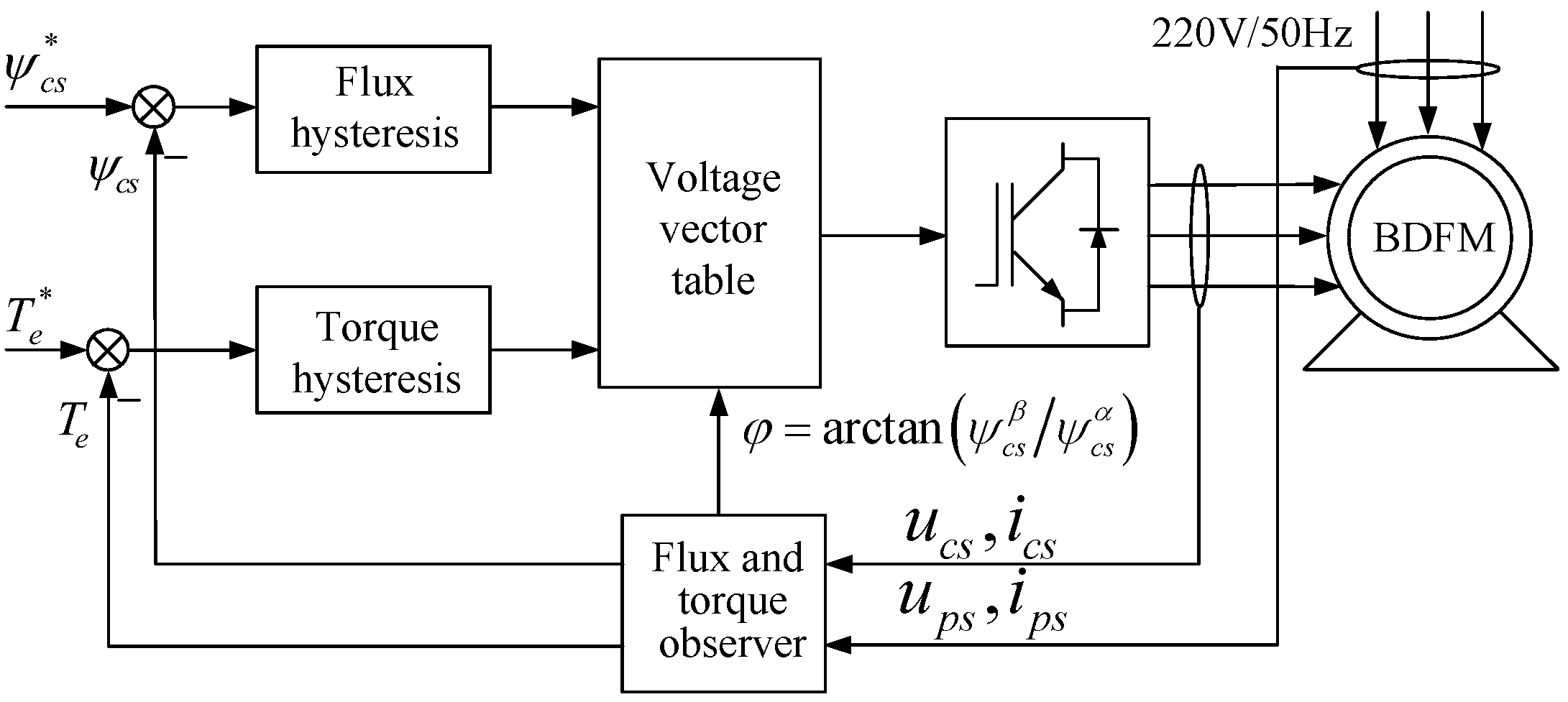

The operation principle of the BDFM’s DTC is based on the output of hysteresis comparators of the torque and CM stator flux amplitude to directly select voltage vectors of the voltage source converter, to keep the torque error and CM stator flux amplitude error within the scope of the hysteresis ring width. In the following, when the CM stator flux is in different sectors, the effects of different voltage vectors on the torque and CM stator flux amplitude are analyzed.

The torque derivative equation about time is firstly deduced as [

22]:

where

. Here, it is assumed that the motor is a large power motor, and the PM is powered by the mains power of 220 V/50 Hz. The voltage drop in stator resistance of PM is neglected, and the PM stator flux lags behind the stator voltage by 90° (

). So, the PM stator flux amplitude

is a constant, and the PM stator flux amplitude derivative

, and Equation (10) becomes:

In the torque derivative expression (11), both derivatives of CM stator flux amplitude and flux-angle-difference are contained, so it is essential to express them as a function of voltage vectors. When the motor is in a steady-state operation, the two-phase static reference frame is divided into six sectors, as shown in

Figure 2, where

is the CM stator flux angle,

is the PM stator flux angle,

is the electrical angular velocity of the PM supply, and

is the angle between the voltage vector and the stator flux vector of CM. For a given voltage vector

, it can be decomposed into the horizontal component and vertical component of CM stator voltage in CM stator flux,

and

, where

is the CM stator voltage vector amplitude.

Similarly to the PM, the voltage drops in stator resistance of CM are neglected. There is

, so we have

. Further, the derivative of CM stator flux can be expressed as:

From the above equation, we have

Obviously, the CM stator flux amplitude and speed (or phase angle) are controlled by the horizontal component and vertical component of CM stator voltage in CM stator flux, respectively. Therefore, the derivatives of CM stator flux amplitude and CM stator flux angle

are obtained as:

So, the derivative equation of the flux-angle-difference is obtained as:

Here, the CM stator is supplied through a three-phase bridge converter, and the converter output voltage vectors are as follows:

where

is the DC bus voltage of the converter, and

corresponds to the six fundamental nonzero voltage vectors of the converter. Substituting Equation (17) into Equations (14) and (16), the derivative equations of CM stator flux amplitude and flux-angle-difference about time can be easily obtained as a function of the voltage vector as:

where

is the electrical angular velocity of the CM stator. Then, substituting Equations (18) and (19) into Equation (11), the final torque derivative equation around the static working point is obtained:

where

are constant, and they are the derivative values of the flux-angle-difference and torque when the converter output voltage is the two zero voltage vectors.

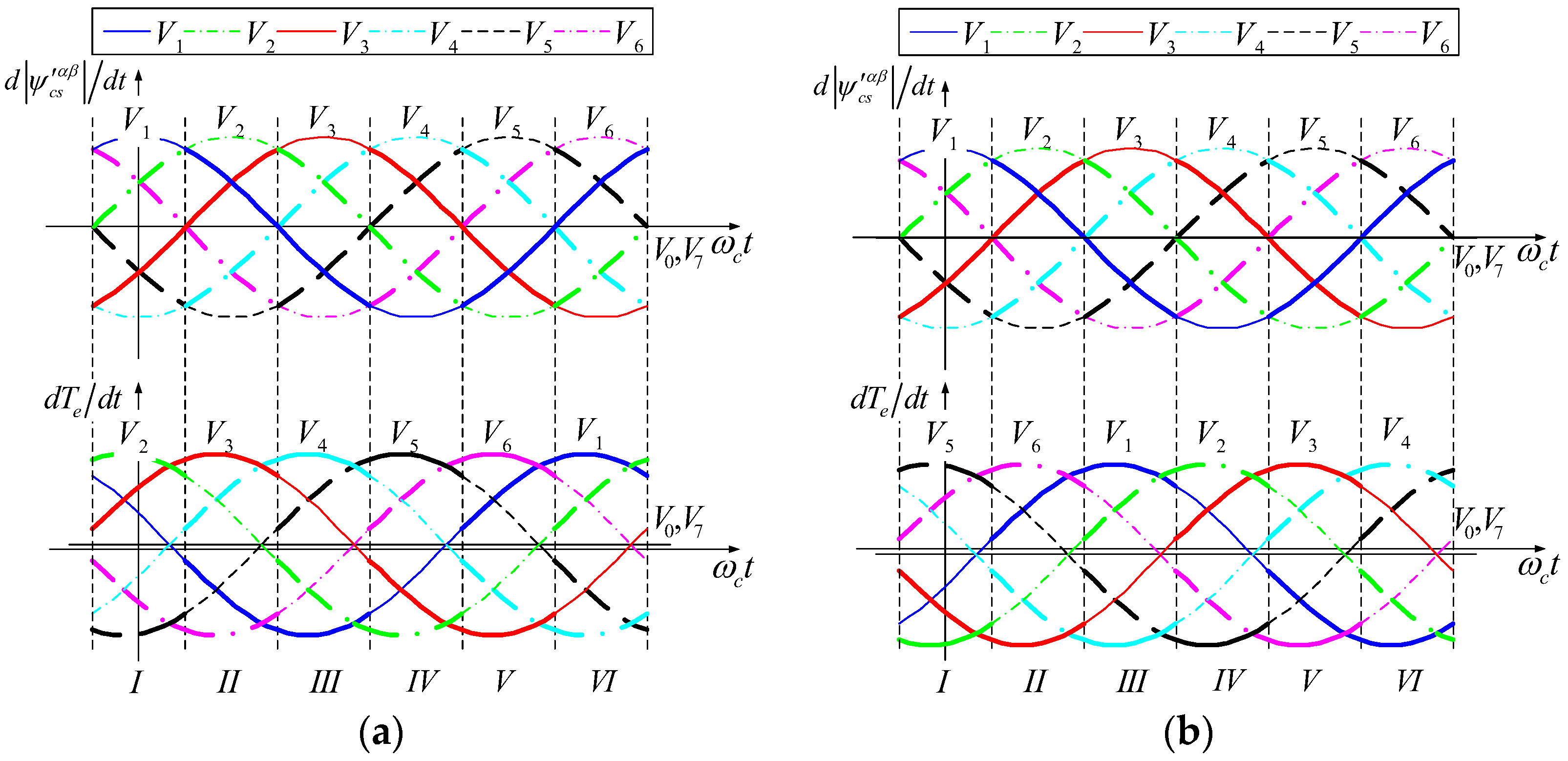

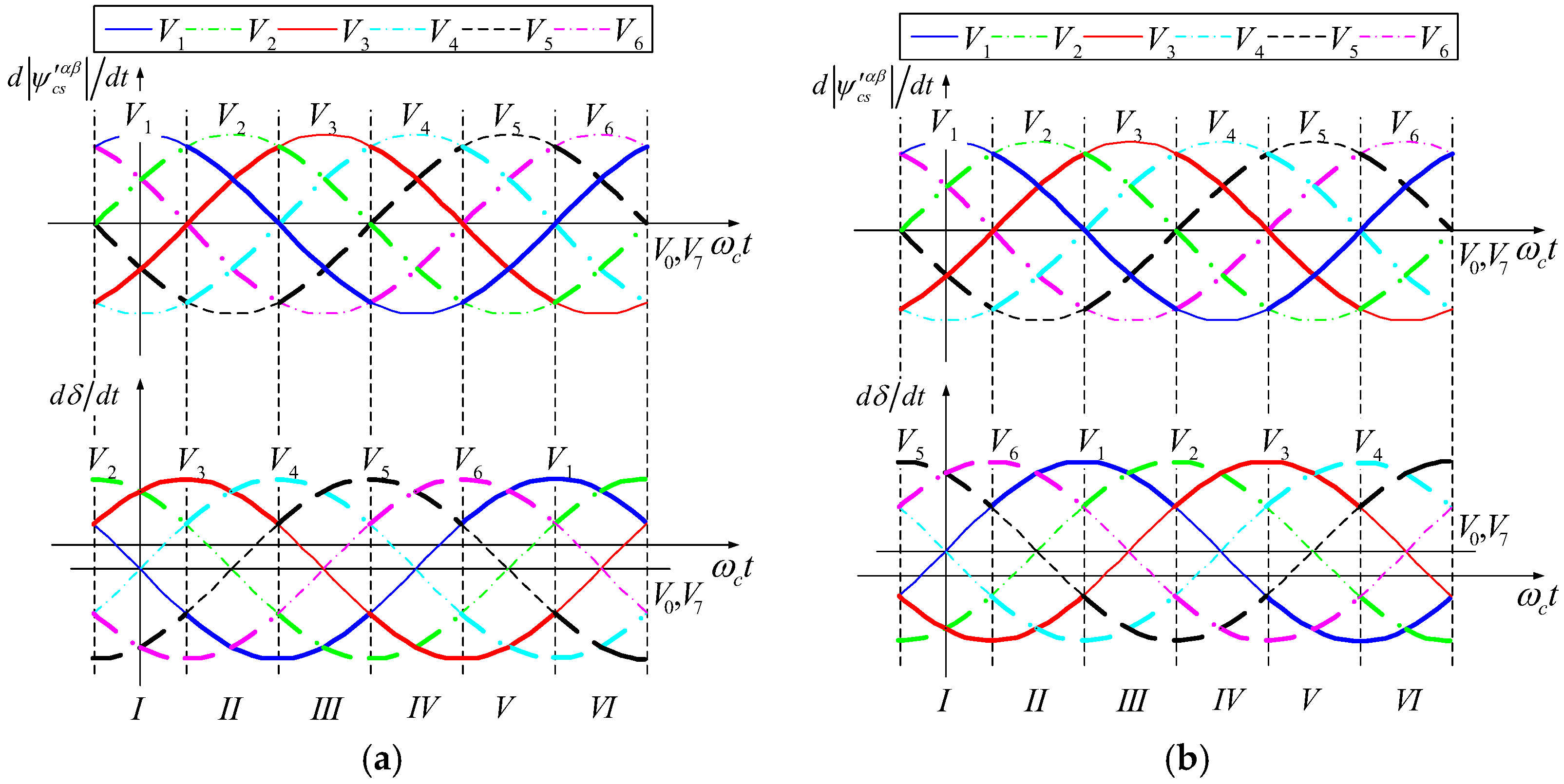

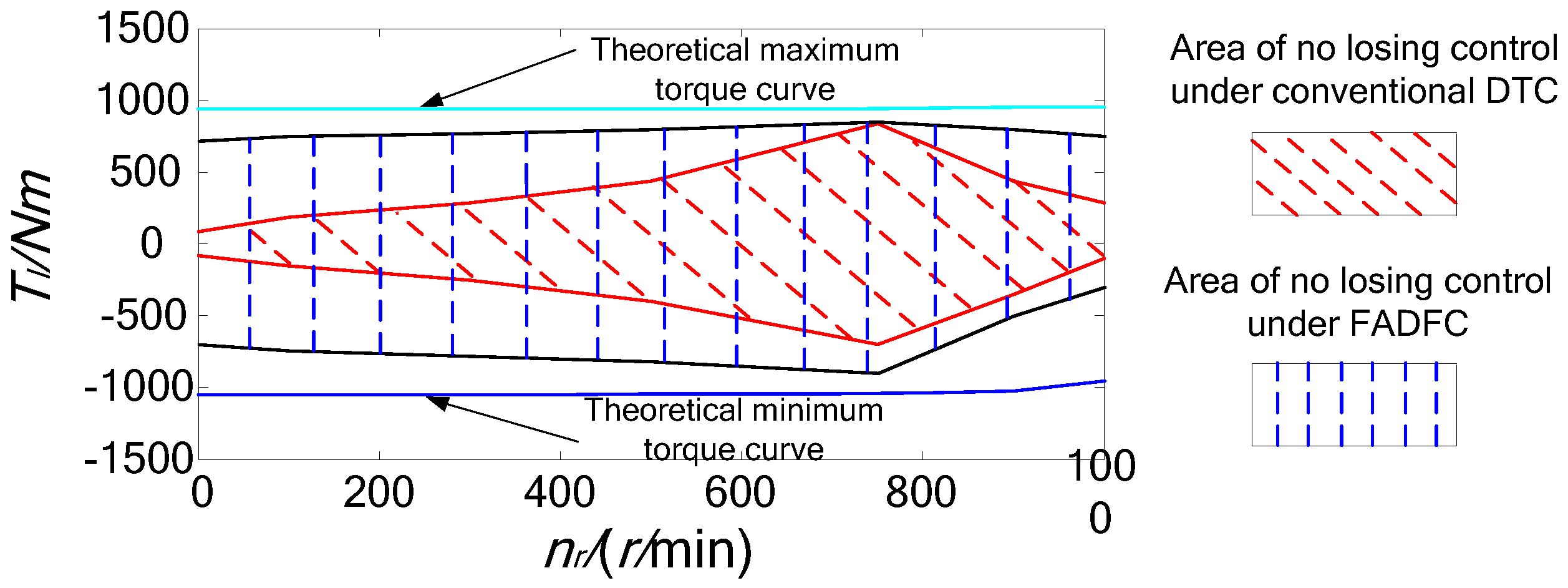

The losing control problem of the BDFM’s conventional DTC (the selected voltage vectors cannot meet the control demands of flux and torque simultaneously in some time intervals, the torque ripple goes outside the hysteresis band) is analyzed specifically by Equations (18) and (20) in the following.

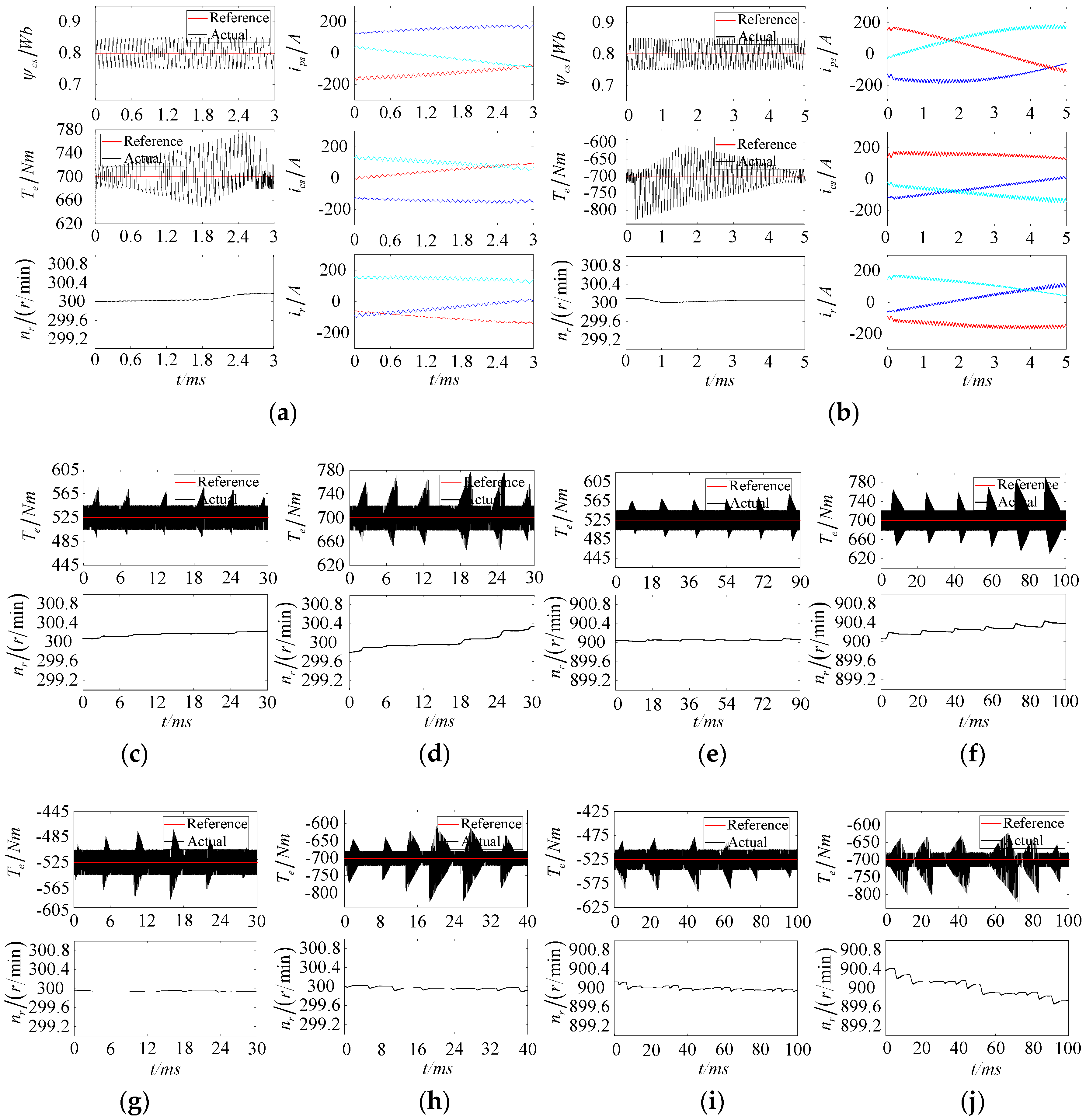

A rated power 30 kW BDFM prototype is utilized as an example whose parameters are listed in

Appendix A, where the rated torque is 350 Nm, the rated flux is 0.8 Wb, and the PM stator is supplied by the constant voltage and constant frequency, 220 V/50 Hz. The derivative curves of the CM stator flux amplitude and the torque are obtained by Equations (18) and (20), as shown in

Figure 3a,b. Where the CM stator flux amplitude is 0.8 Wb, the motor speed is 300 r/min (subsynchronous), and the output torques are rated torques, 350 Nm (motoring mode) and −350 Nm (generating mode). According to the derivative curves, the voltage vectors are selected. When the BDFM operates in the motoring mode, take the first sector as an example, where the voltage vectors

V5,

V3,

V6, and

V2 are selected to meet the four kinds of control requirements of the CM stator flux and the torque: decreasing in flux and torque, decreasing in flux and increasing in torque, increasing in flux and decreasing in torque, and increasing in flux and torque, respectively. Similarly, the other sectors and the generating mode voltage vector can also be selected. The voltage vector switch tables can be obtained under the motoring mode and the generating mode, as shown in

Table 1 and

Table 2, called the conventional DTC. The control system of conventional DTC is shown in

Figure 4.

With the increase in torque, under the different operation modes, the phase angles of the flux derivative curves remain unchanged, the DC component B increases, and the torque derivative curves shift right or left relative to the flux derivative curves, as shown in

Figure 5a,b. Where the CM stator flux amplitude is 0.8 Wb, the motor speed is 300 r/min (subsynchronous), and the output torque is two times the rated torque, 700 Nm (motoring mode) and −700 Nm (generating mode). The voltage vectors of the demands of four kinds of flux and torque cannot be found in the six basic voltage vectors. The choice of voltage vector can only enable the percentage of time of losing control to be as small as possible. The obtained voltage vector switch tables are same as the

Table 1 and

Table 2. The losing control of torque will appear at heavy load. The losing control regions are the circular regions in

Figure 5a,b.

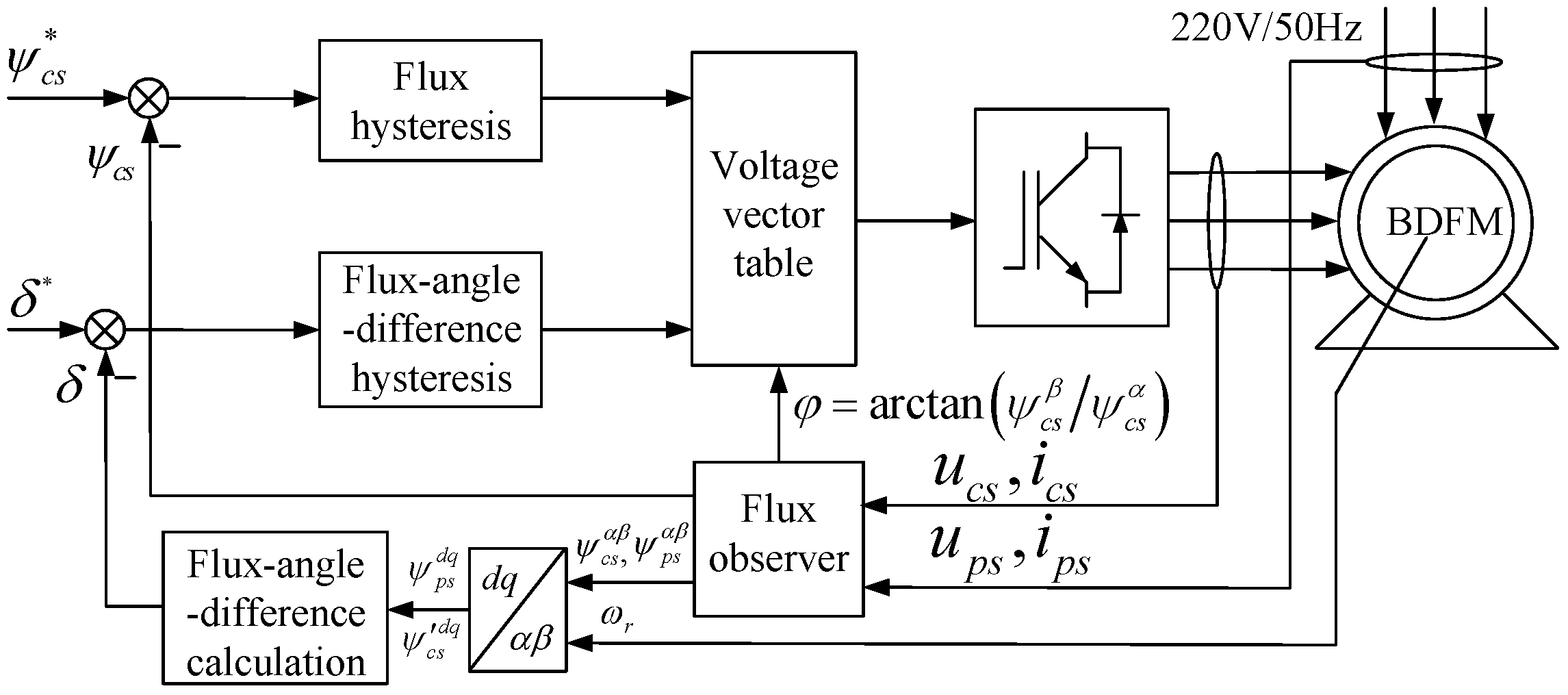

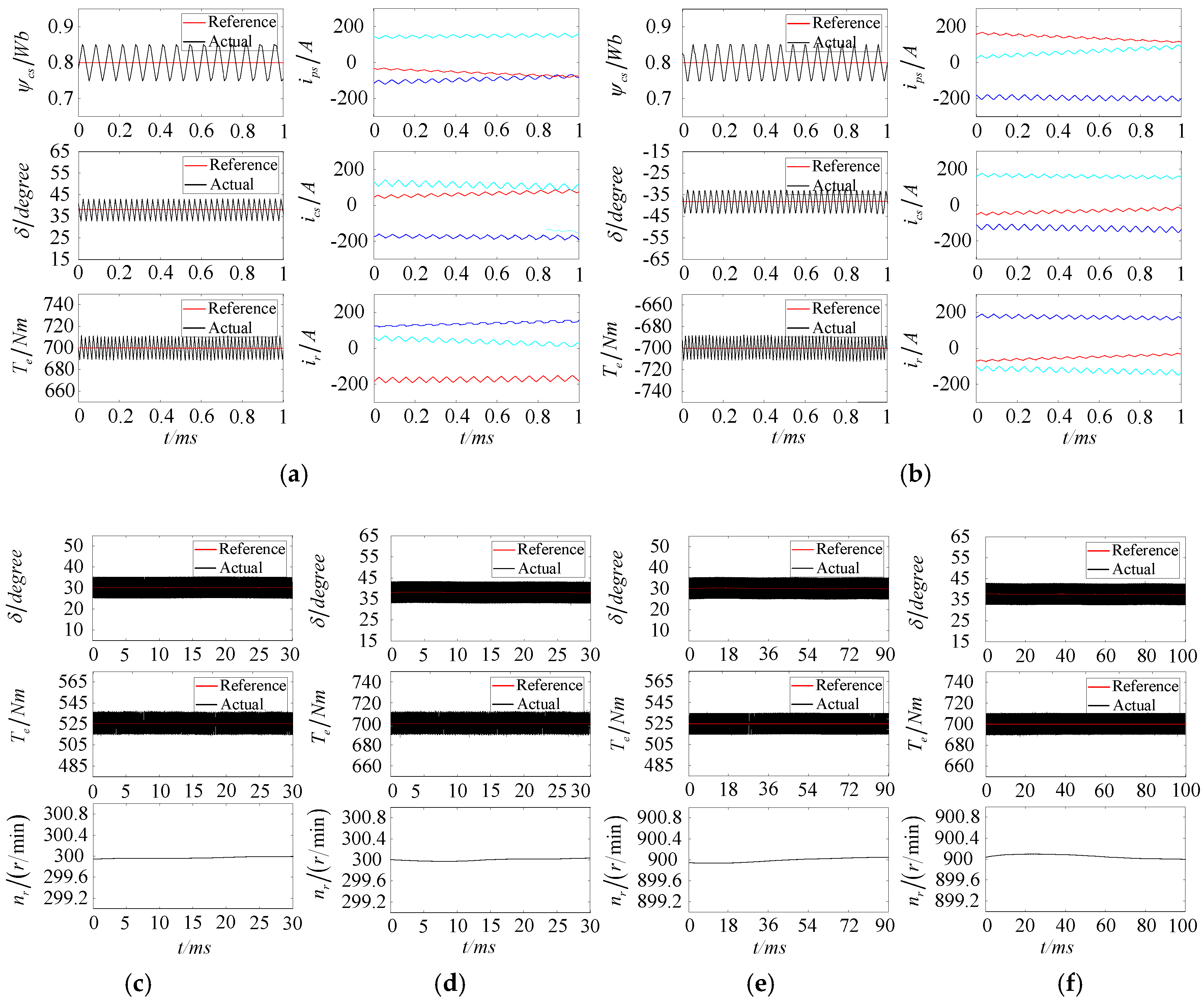

On the other hand, when the stator fluxes of BDFM remain constant, the torque can be adjusted by the flux-angle-difference. From the CM stator flux amplitude derivative Equation (18) and the flux-angle-difference derivative Equation (19), it can be seen that the DC component A is only related to the speed, but not related to the load conditions. With the increase in torque, the phase angles of the flux derivative and the flux-angle-difference derivative also remain unchanged, and they are independent of the load conditions. To solve the problem of losing control, an improved method for indirectly controlling torque is proposed by controlling the angle difference between PM stator flux and CM stator flux. In the following, the validity of the improved method will be explained by utilizing the CM stator flux amplitude and the flux-angle-difference derivative curves.

According to Equations (18) and (19), CM stator flux amplitude and flux-angle-difference derivative curves are shown in

Figure 6a,b. Where CM stator flux amplitude is 0.8 Wb, the motor speed is 300 r/min (subsynchronous), and the output torques are 350 Nm (motoring mode) and −350 Nm (generating mode). Similarly, according to the derivative curves, the voltage vectors are selected to satisfy the four kinds of control requirements of the flux and the flux-angle-difference: decreasing in flux and flux-angle-difference, decreasing in flux and increasing in flux-angle-difference, increasing in flux and decreasing in flux-angle-difference, and increasing in flux and flux-angle-difference, respectively. The voltage vector switch tables can be obtained under the motoring mode and the generating mode, as shown in

Table 3 and

Table 4. Except for the fact that the torque hysteresis comparator is replaced with the flux-angle-difference hysteresis comparator, the selected voltage vectors are the same as in

Table 1 and

Table 2, called the flux-angle-difference feedback control (FADFC). The control system of the FADFC is shown in

Figure 7.

With the increase in torque, because the phase angles of the flux derivative and the flux-angle-difference derivative remain unchanged, the flux-angle-difference derivative curves will not move right or left, as shown in

Figure 8a,b. With the change in speed, the DC component A will change, and the flux-angle-difference derivative curves will move down or up. From the flux-angle-difference derivative Equation (19), the amplitude of the flux-angle-difference derivative is proportional to the DC bus voltage. Therefore, before entering the field-weakening area, the selected voltage vectors can always satisfy the control requirements of the flux and the flux-angle-difference in accordance with

Table 3 and

Table 4.

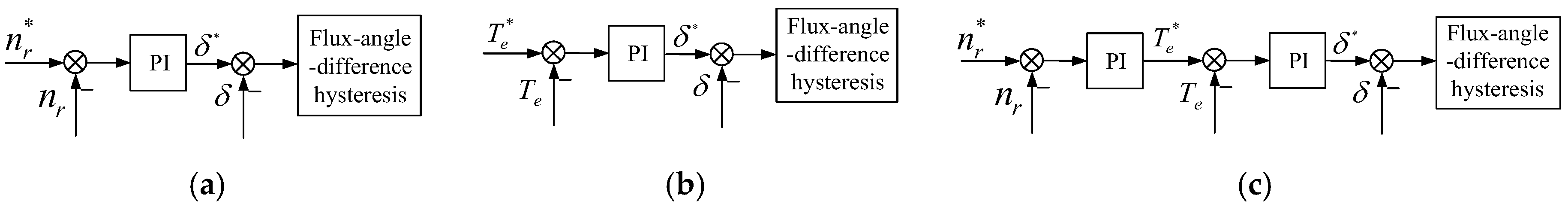

Based on the FADFC system of

Figure 7, according to the different control requirements, there are three kinds of control system design: the speed outer loop and the flux-angle-difference inner loop, the torque outer loop and the flux-angle-difference inner loop, and the three loops (the speed, the torque, and the flux-angle-difference), respectively, as shown in

Figure 9.

5. Conclusions

The stator flux amplitude and speed (or phase angle) are controlled by the horizontal component and vertical component of the CM stator voltage in CM stator flux, respectively. Under the condition of constant stator flux amplitude, the torque of BDFM is proportional to the sine of the angle difference between PM stator flux and CM stator flux. Attention to these characteristics, using the flux-angle-difference hysteresis comparator instead of the torque hysteresis comparator of the conventional DTC, the design scheme of the flux-angle-difference feedback control (FADFC) is obtained. The proposed FADFC strategy can not only solve the losing control problems of the BDFM’s conventional DTC, but can also keep the advantages of DTC, such as the simple structure, less dependence on motor parameters, and strong robustness.

BDFM is a dual source supply, where the voltage current model can be used to observe the stator fluxes of PM and CM, and the drift rejection problem of pure integral has many solutions unless the BDFM operates near the synchronous speed.

The model of the BDFM is complex, and in practice its parameters are difficult to measure. Compared to the asynchronous motor, the losing control problems of the BDFM’s conventional DTC are more evident.

The models of the wound rotor BDFM and cage rotor BDFM only have a slight difference [

27], so the design scheme of FADFC is also suitable for a cage rotor BDFM.

Therefore, the proposed flux-angle-difference feedback control (FADFC) scheme will have a great practical value.