Multi-Step Loading Creep Behavior of Red Sandstone after Thermal Treatments and a Creep Damage Model

Abstract

:1. Introduction

2. Experiments

2.1. Specimen Preparation

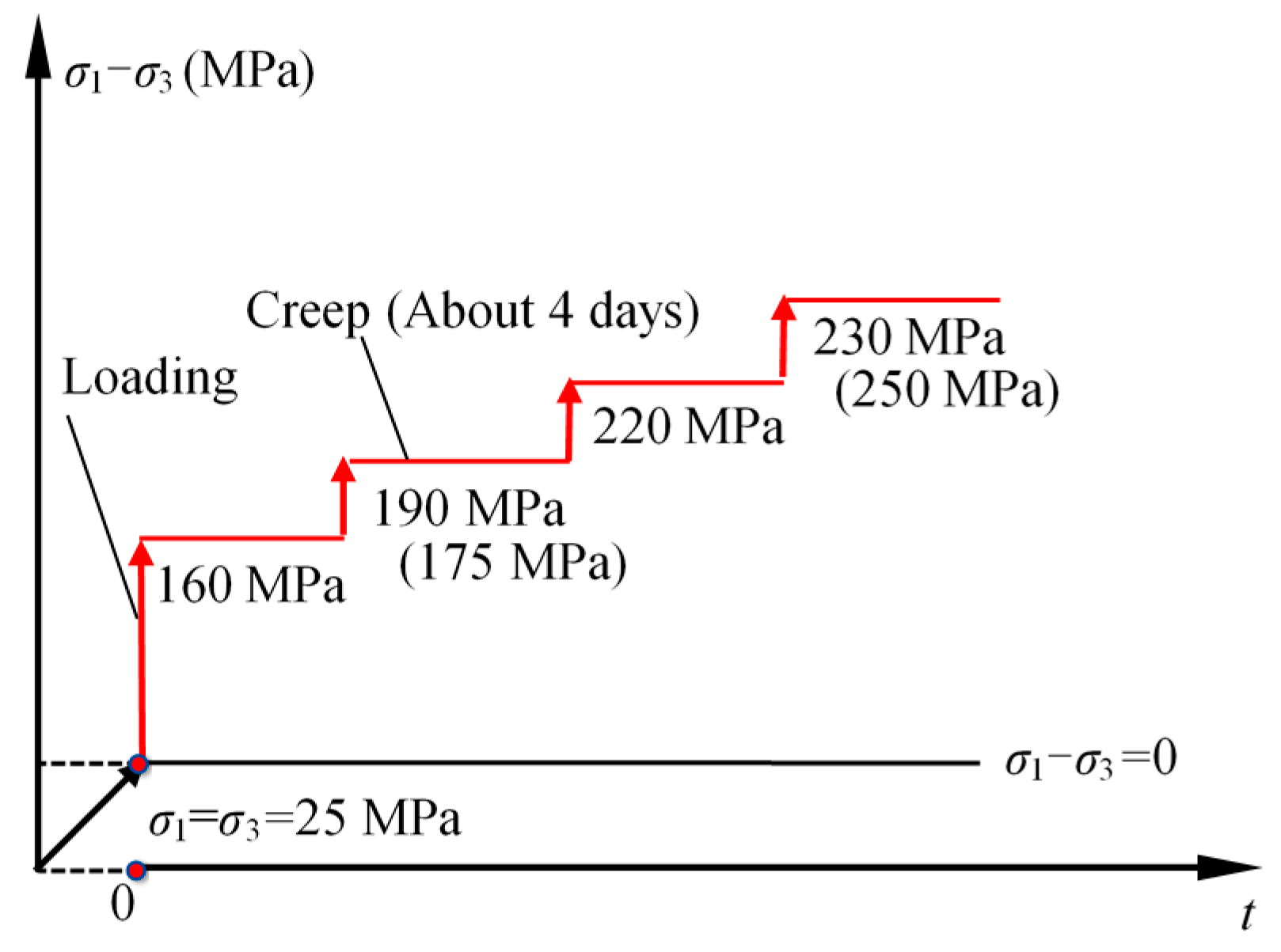

2.2. Testing Apparatus and Method

3. Creep Experimental Results

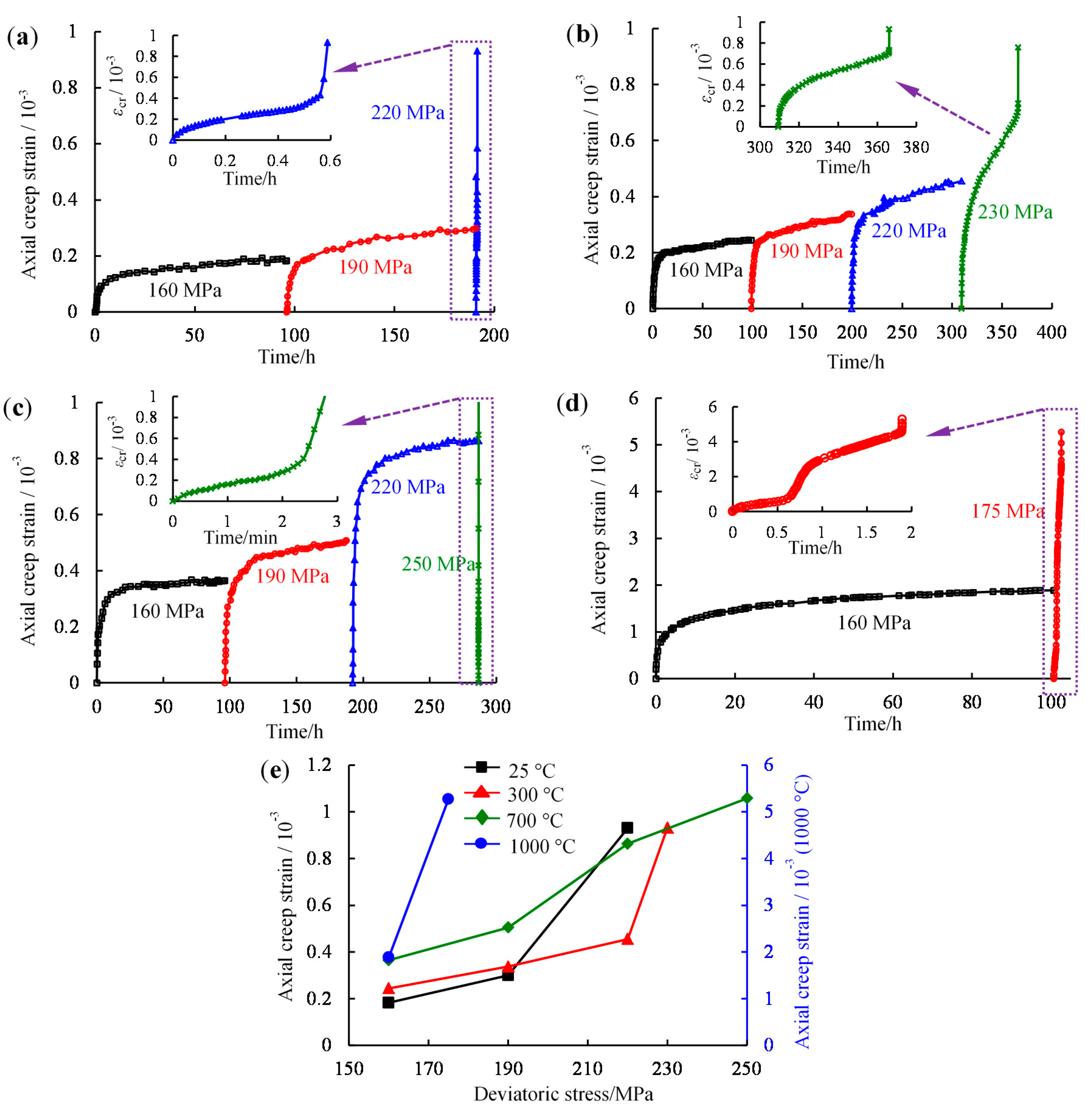

3.1. Axial Strain

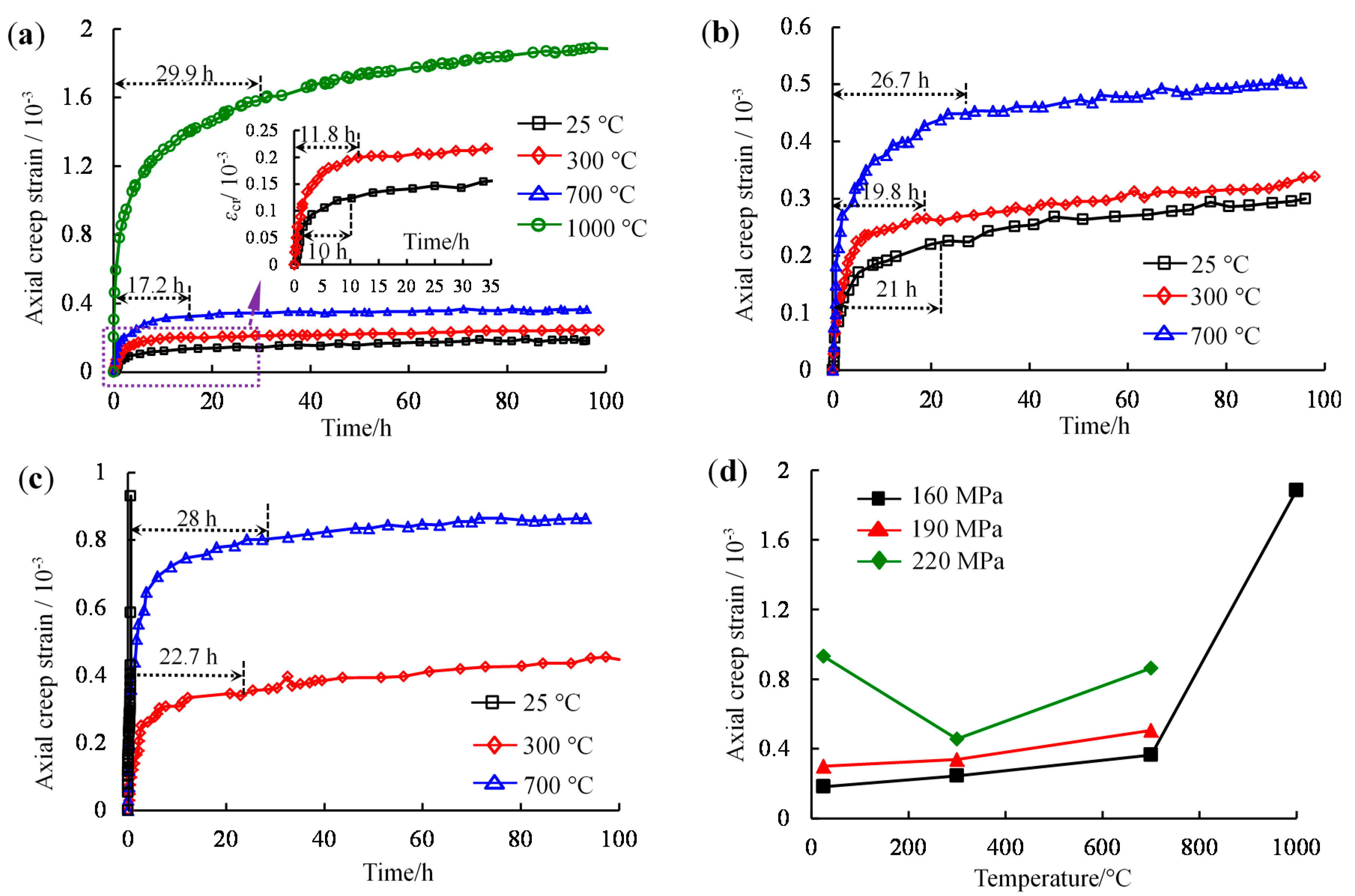

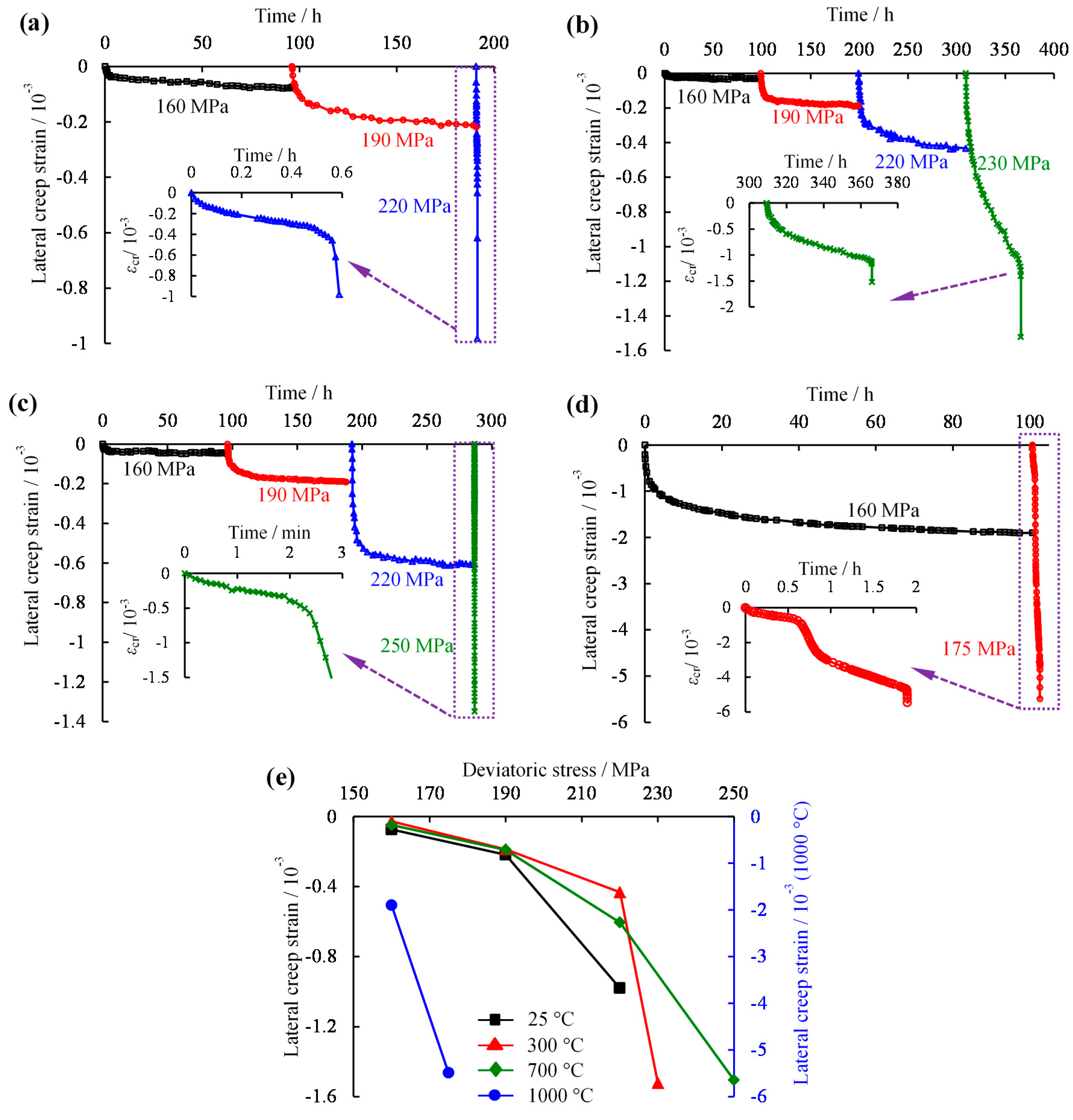

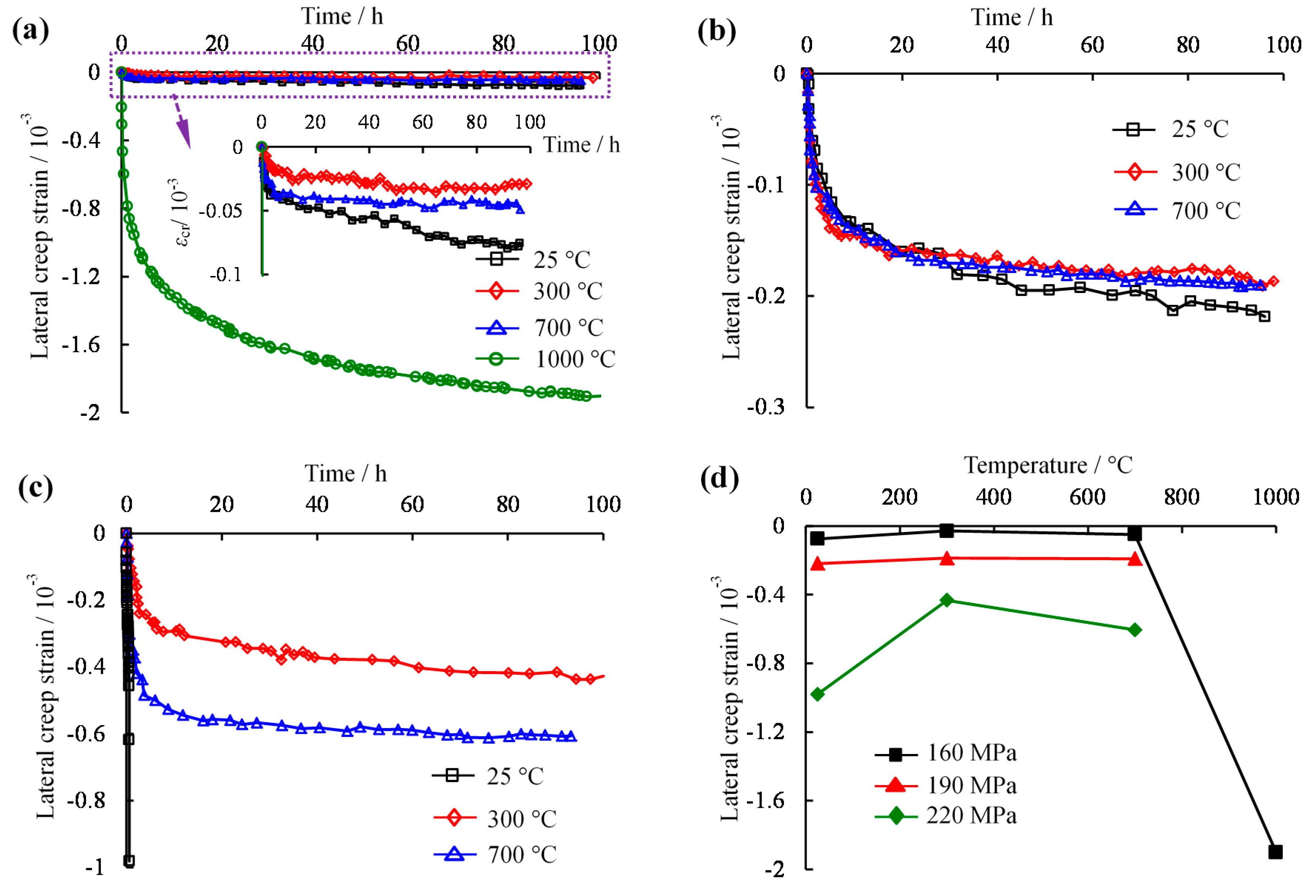

3.2. Lateral Creep Strain

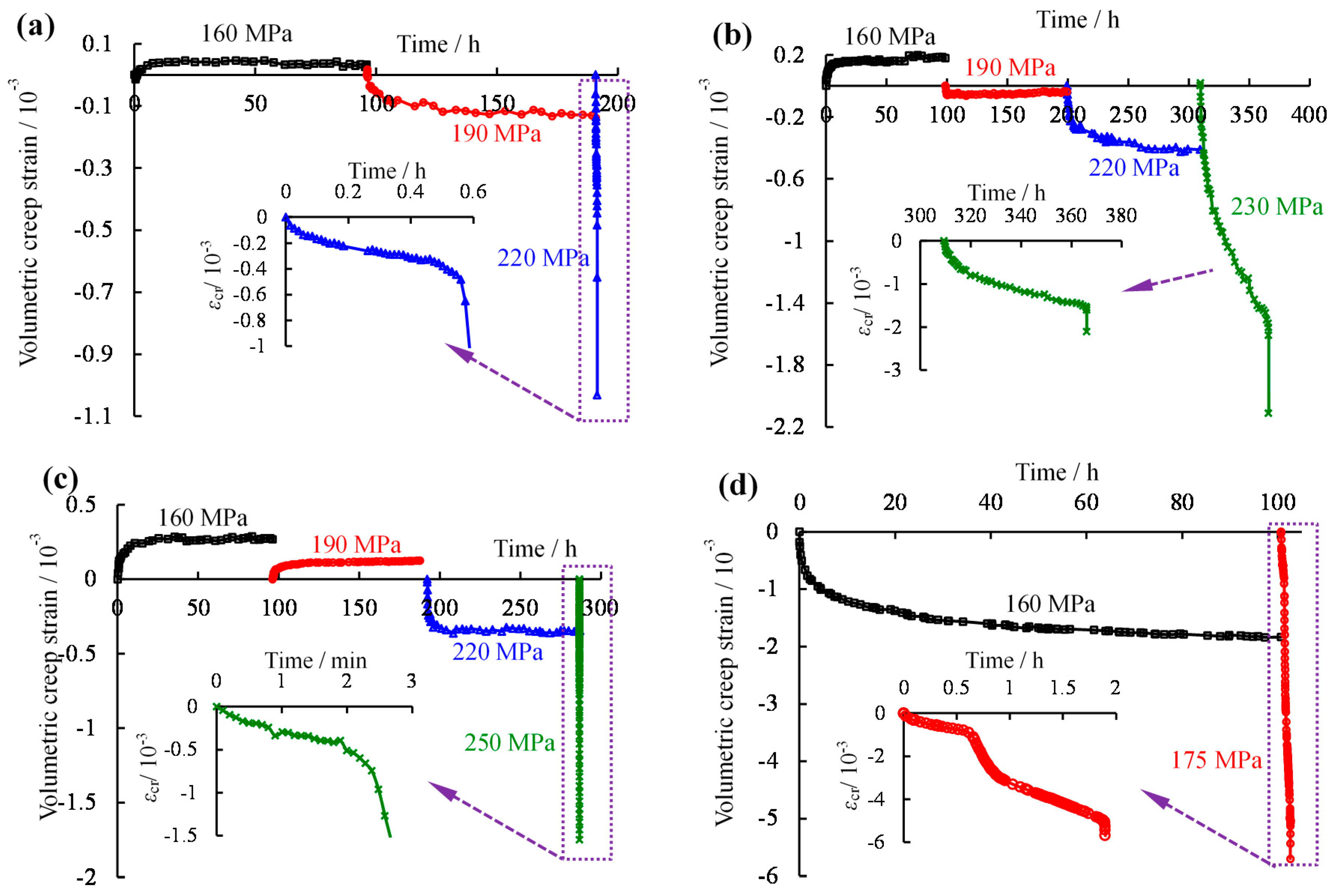

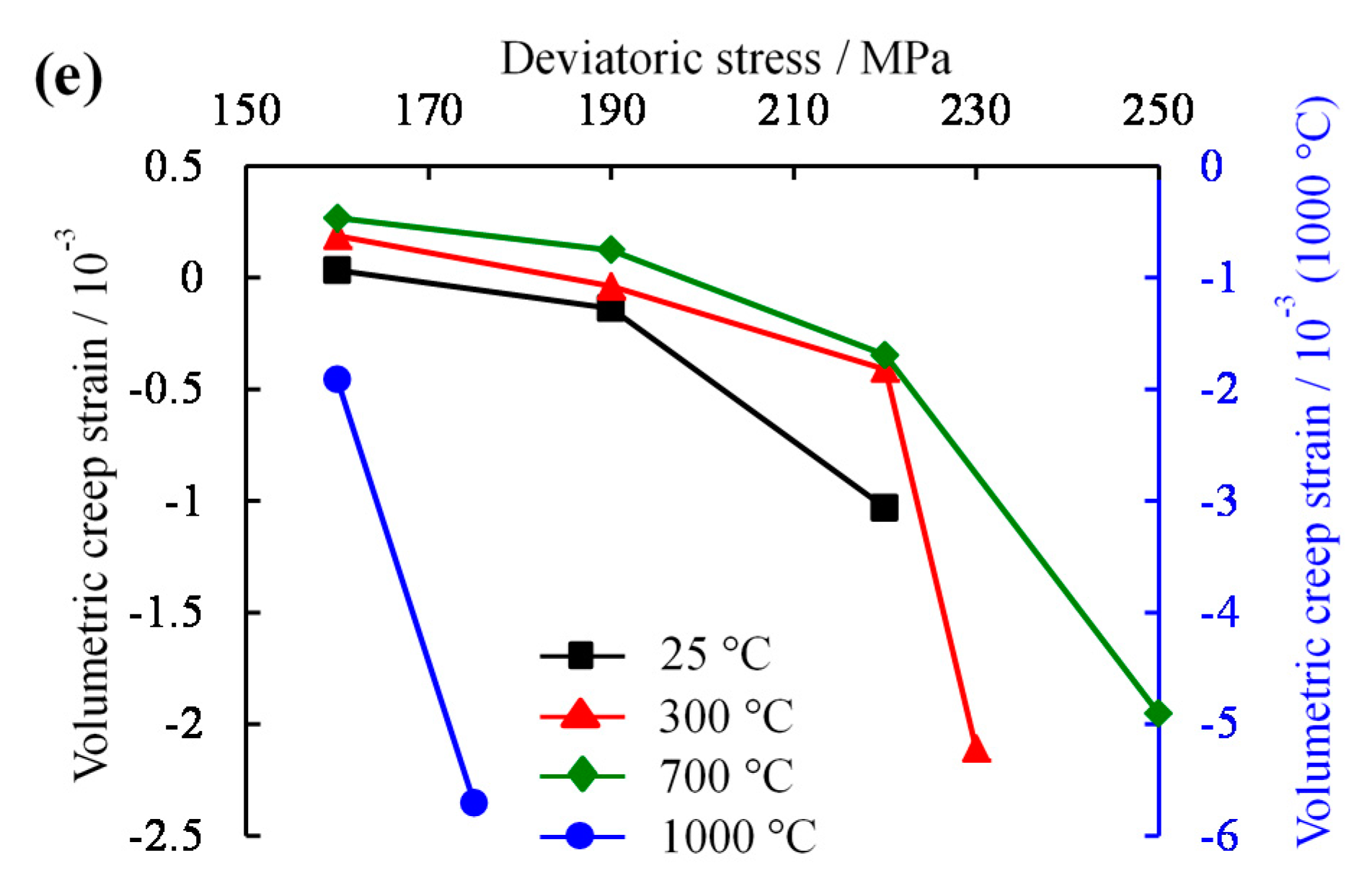

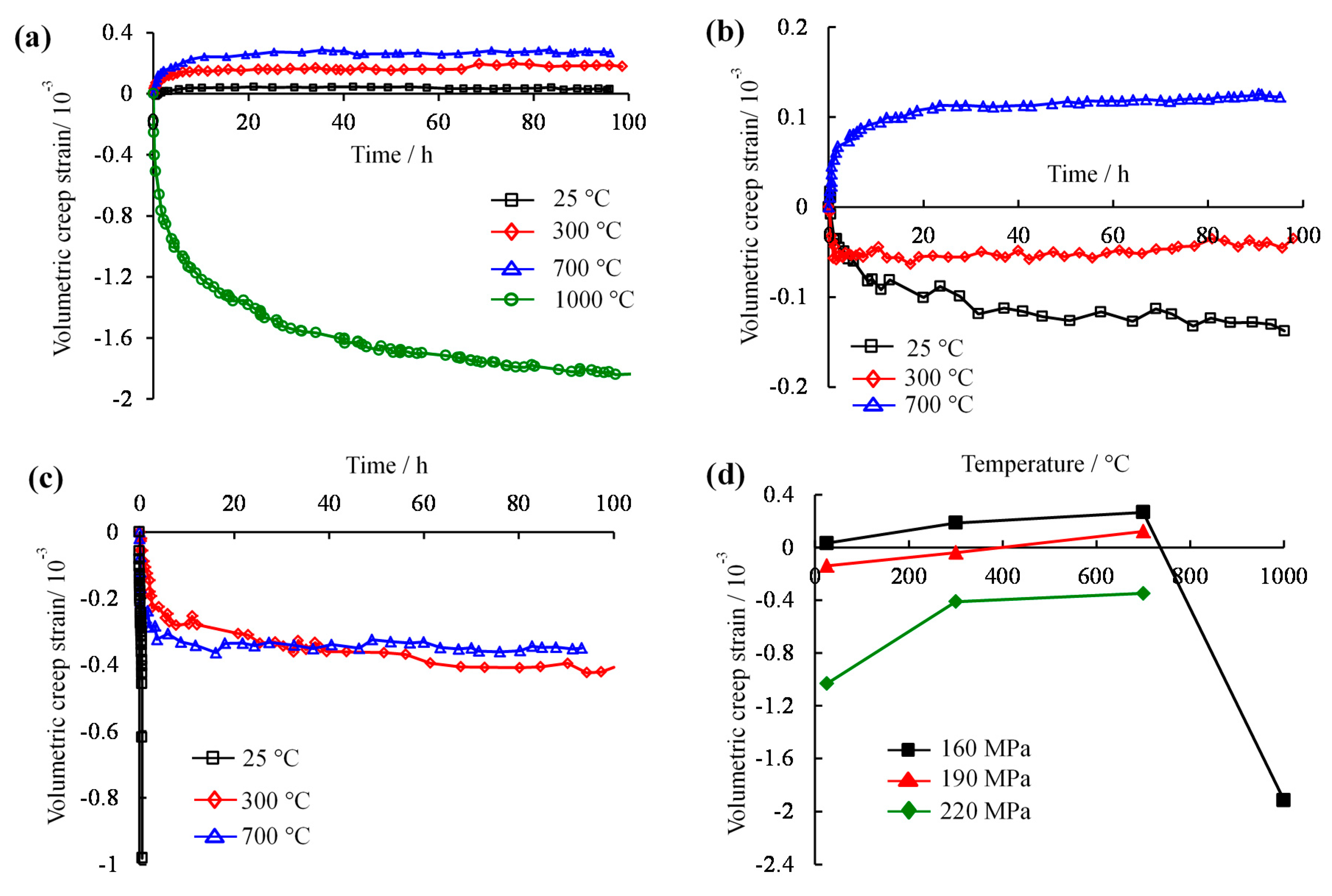

3.3. Volumetric Creep Strain

4. Creep Damage Model

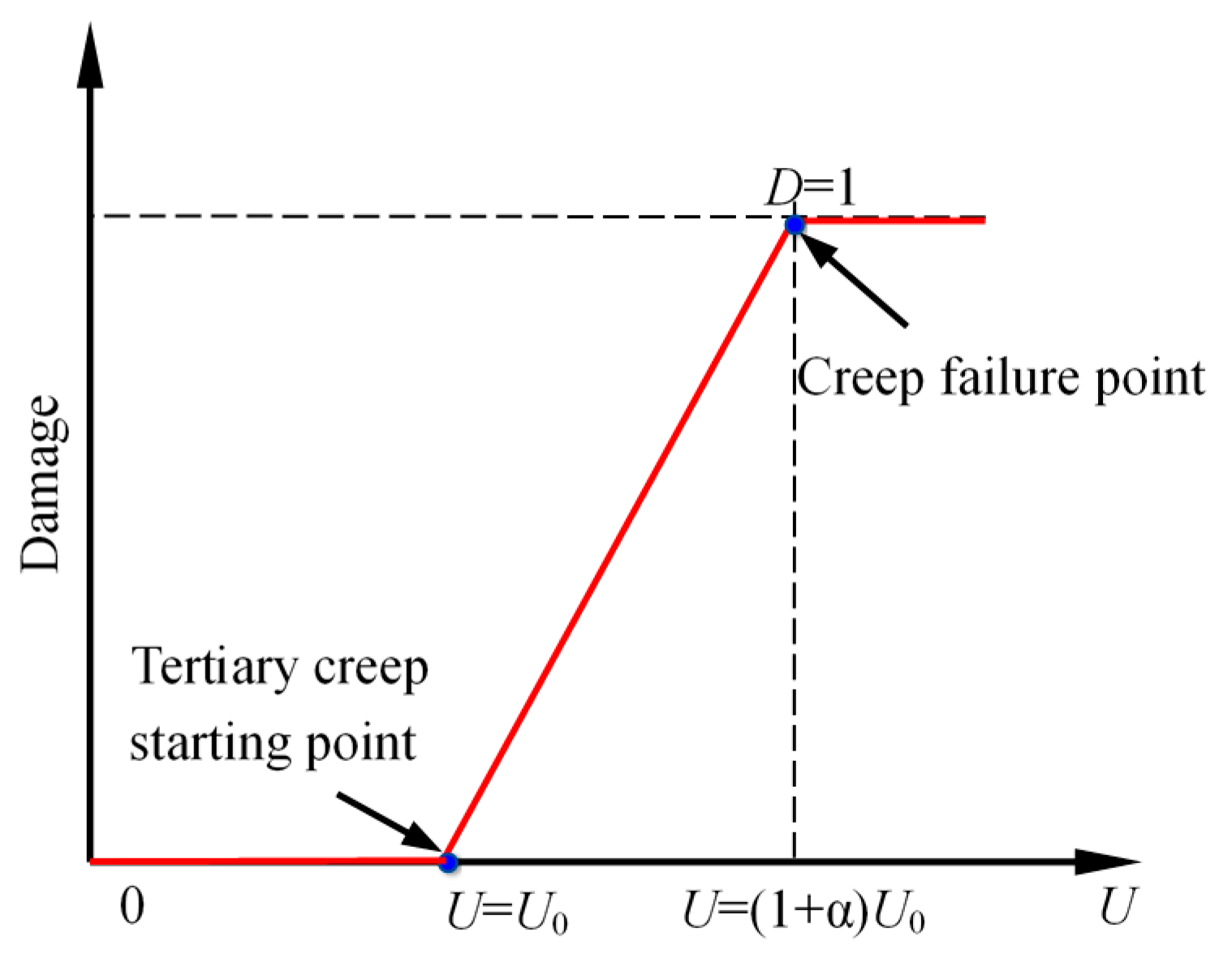

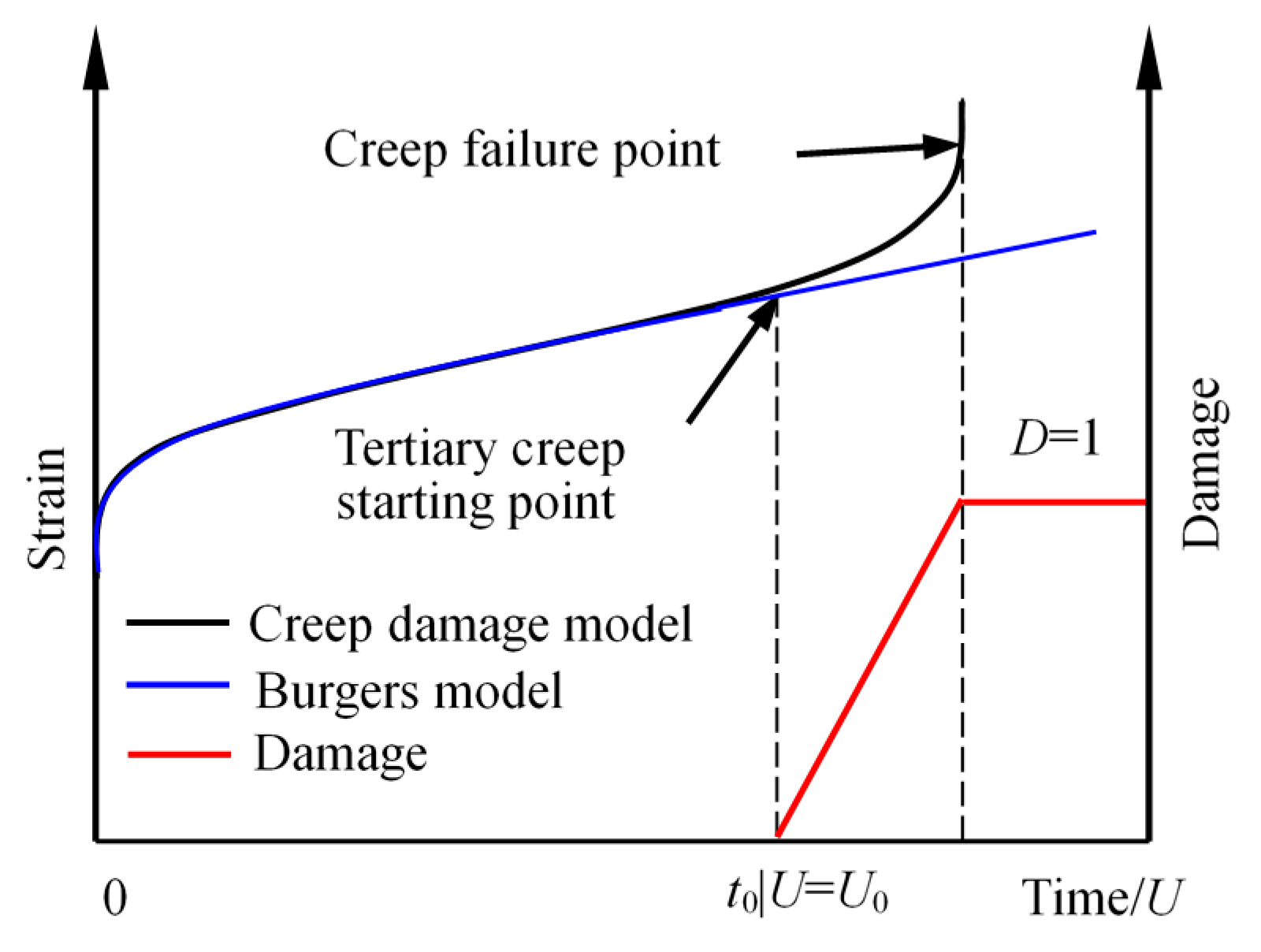

4.1. Construction of Creep Damage Equation

4.2. Sensitivity Analysis of the Damage Parameters

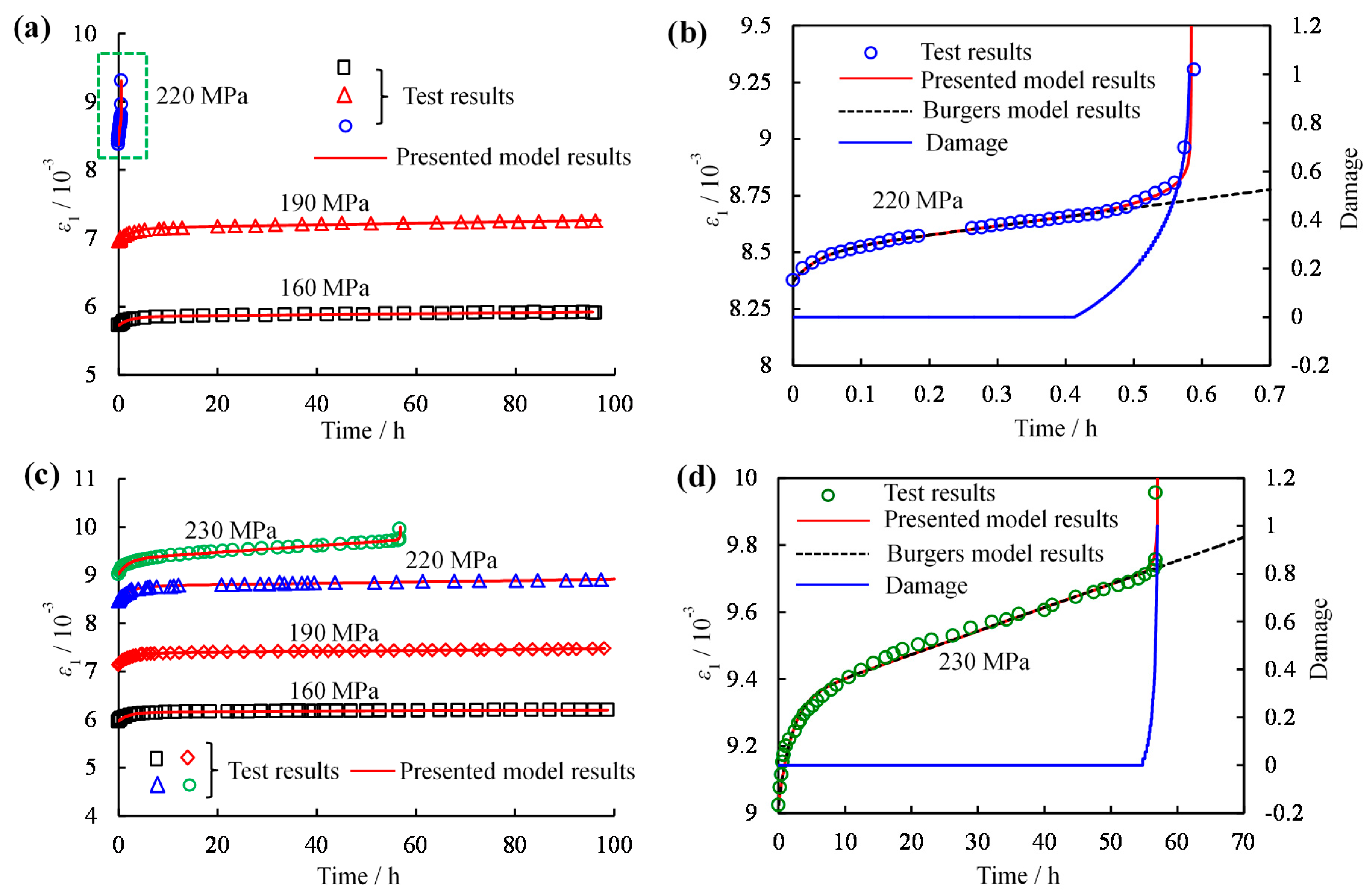

4.3. Model Validation

5. Discussion

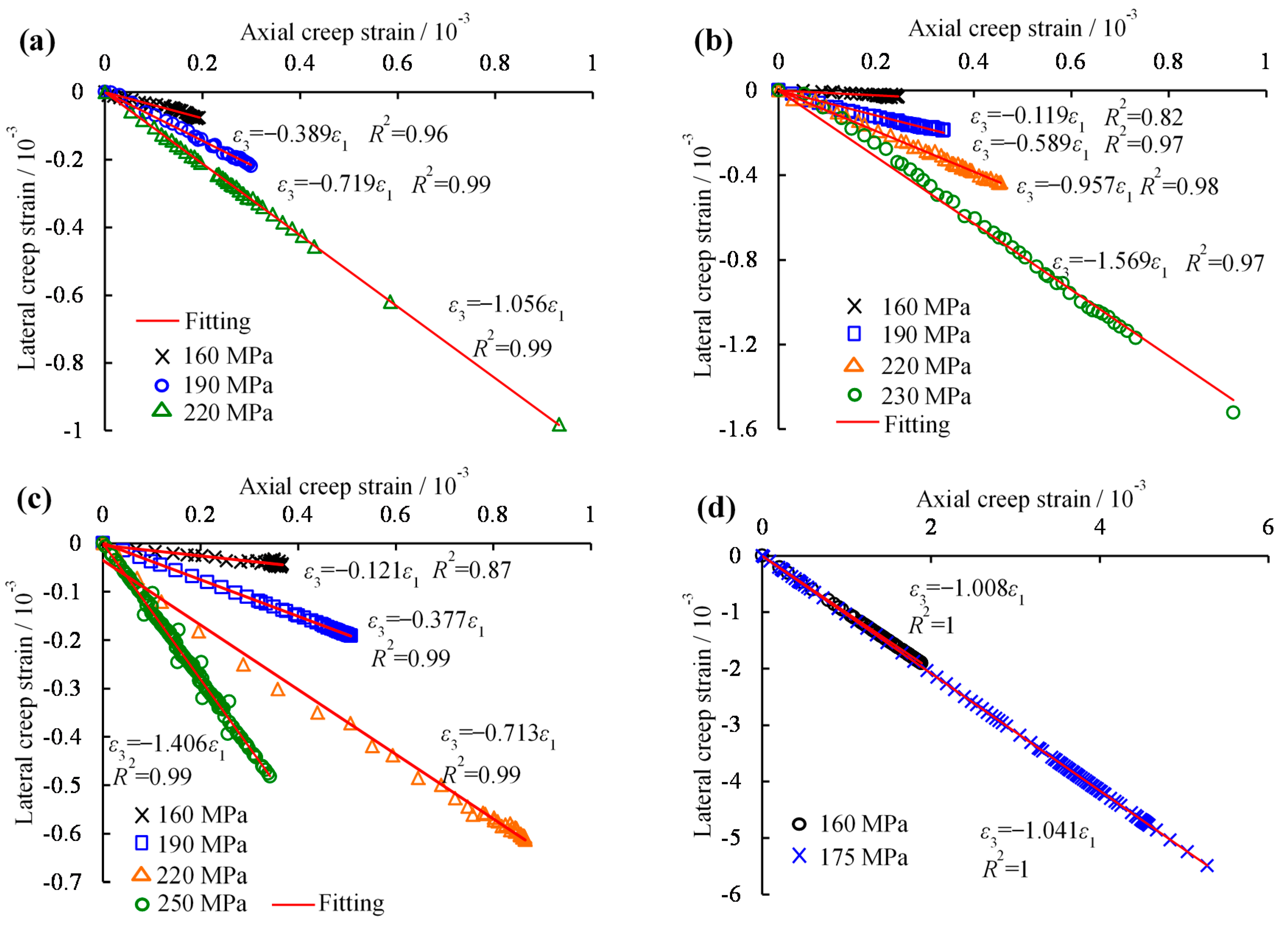

5.1. Relationship between the Axial and Lateral Creep Strain

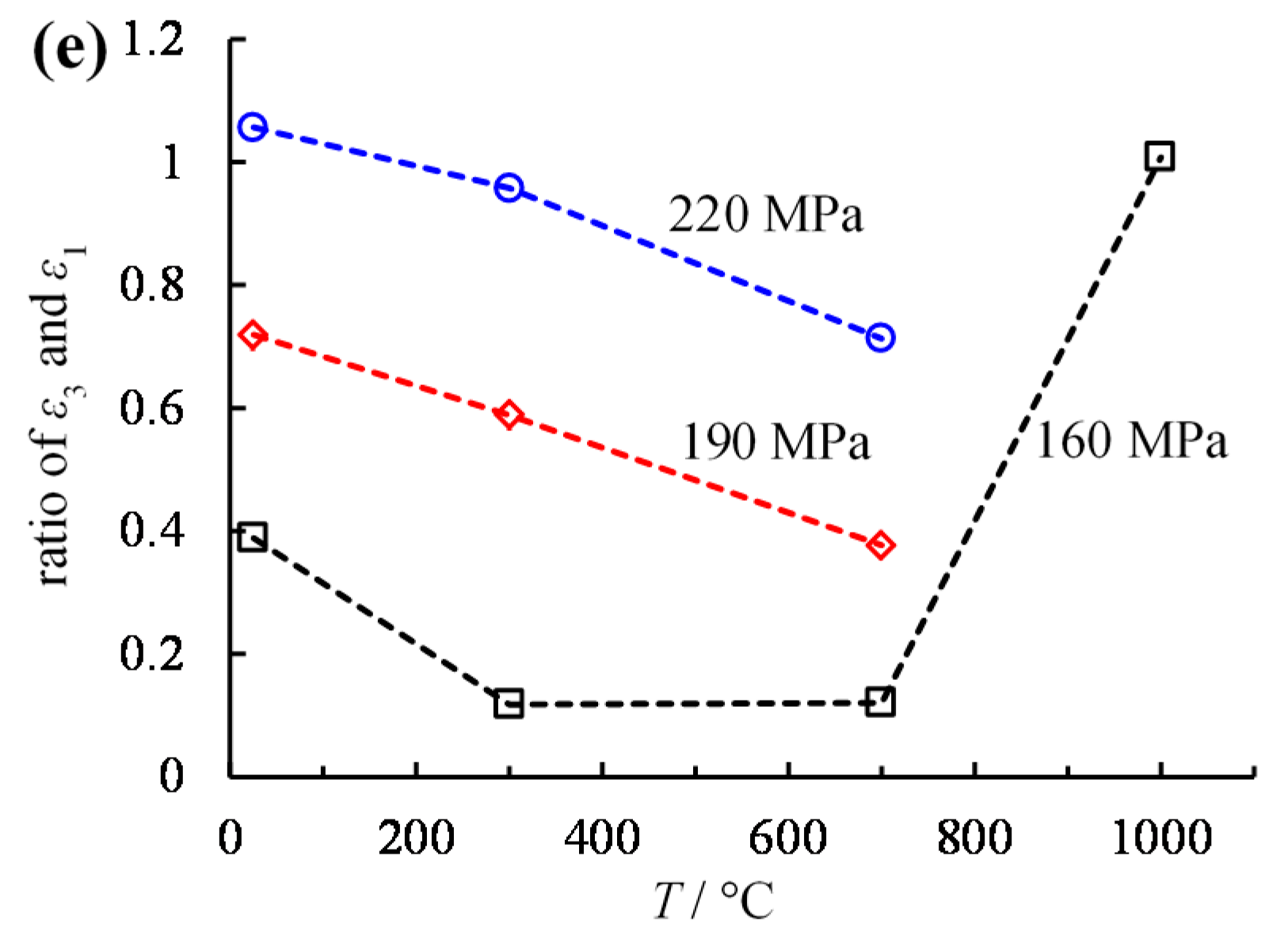

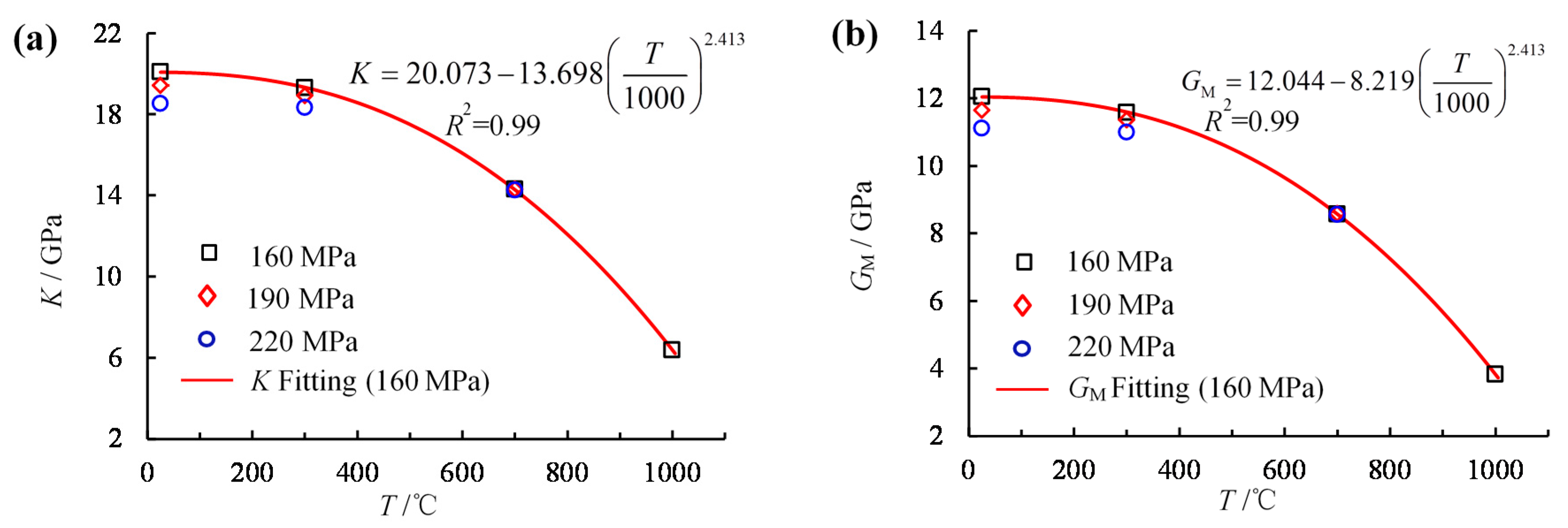

5.2. Thermal Influence on Parameters of Creep Model

5.3. Thermal Influence on Creep Behavior

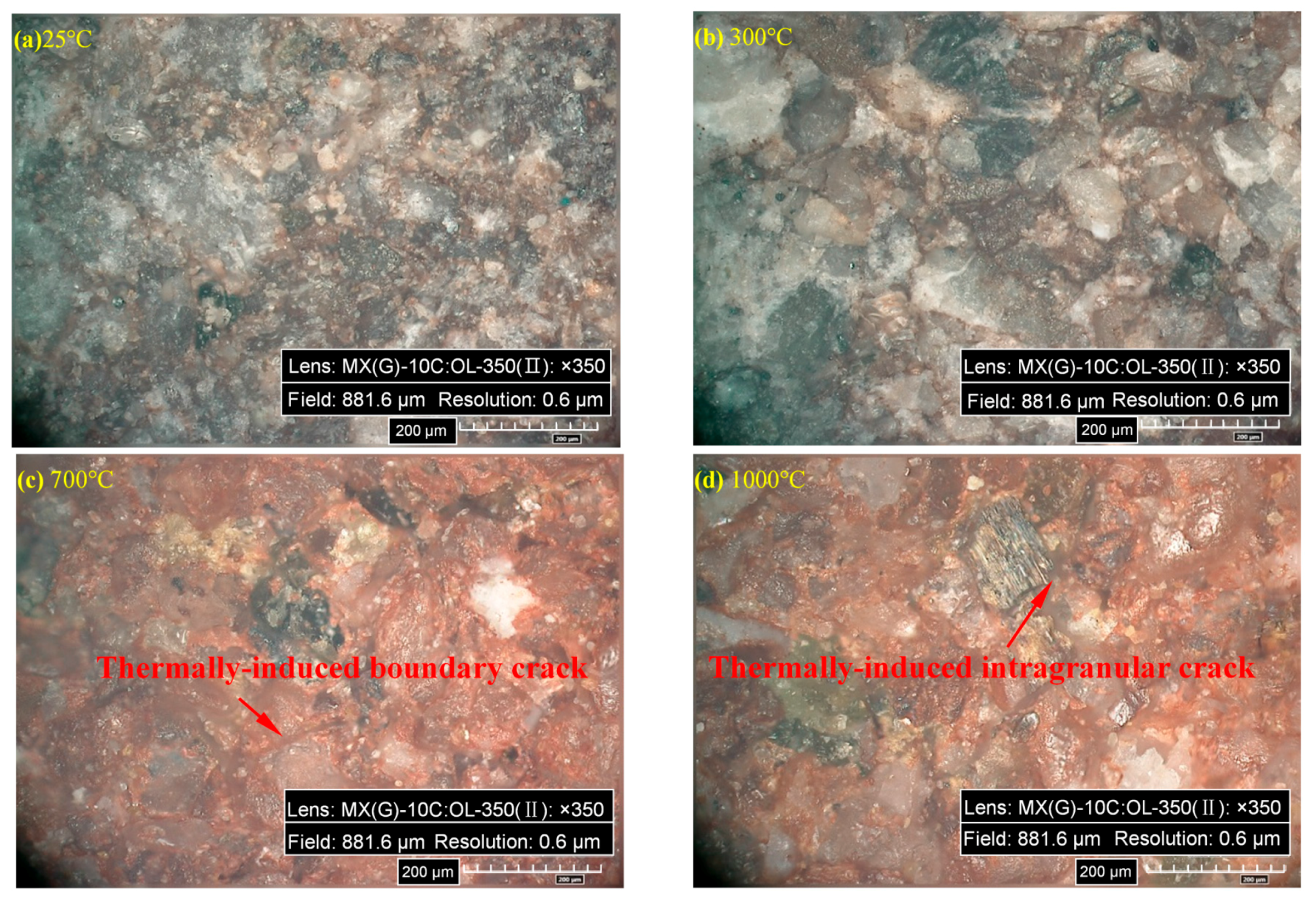

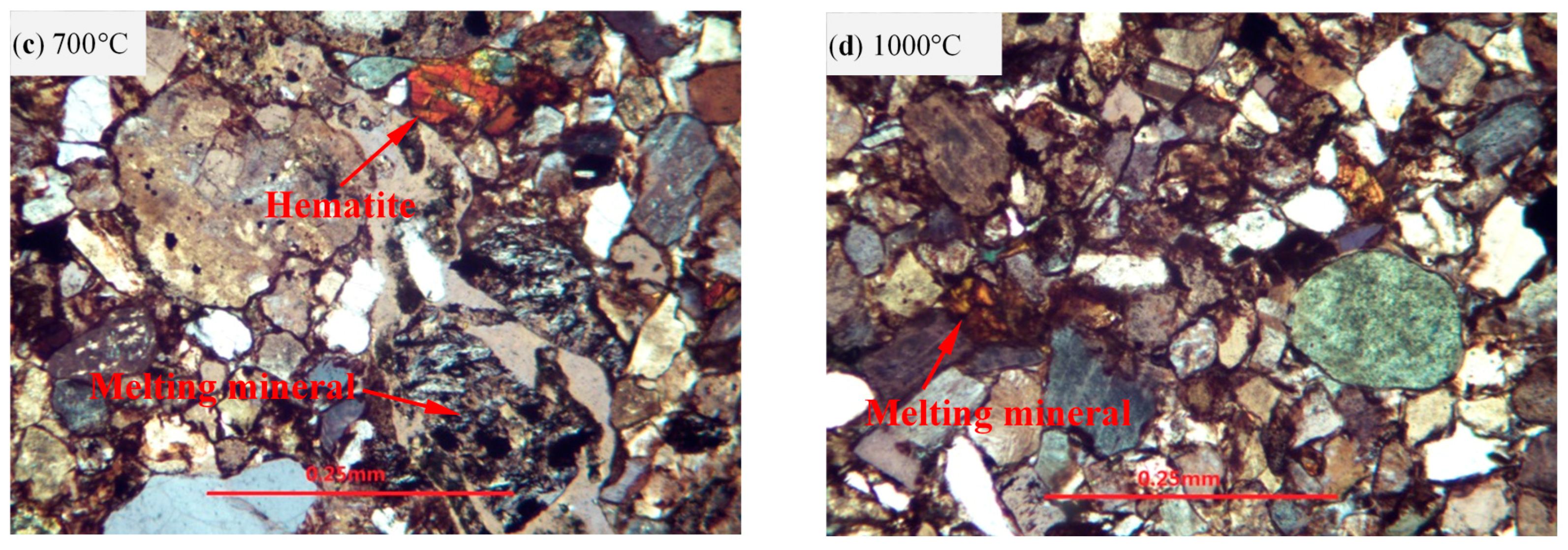

5.4. Thermal Influence on Microstructure/Composition

6. Conclusions

- (1)

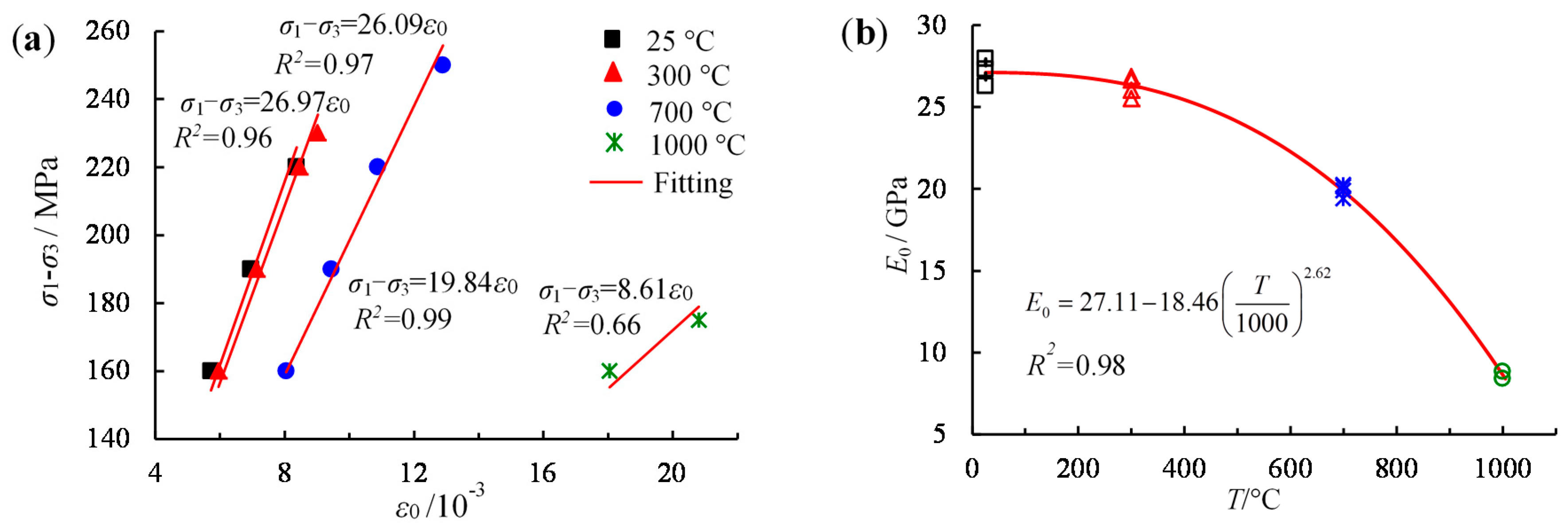

- The axial instantaneous strain increased linearly with increasing partial stress at the same temperatures. As the deviatoric stress increased, both the lateral creep strain and the increment in the axial creep strain with time gradually rose, whereas the volumetric creep strain decreased from positive to negative values, which represented the initial compression, dilation, and finally failure by shear dilatancy of the specimens.

- (2)

- Under the same deviatoric stress and as the temperature was increased, the instantaneous deformation modulus (E0) decreased nonlinearly, the axial creep strain increased gradually, but the lateral creep strain first decreased when the temperature was below 300 °C and then increased when the temperature increased above 300 °C. The bulk expansion became easier as the applied stress approached σp. In addition, as the temperature increased, CSR decreased.

- (3)

- A creep damage model based on strain energy was established, and a secondary development was implemented in FLAC3D; the latter can effectively reproduce the entire creep process. In the model, the two damage parameters mainly affect the onset of tertiary creep and its duration.

- (4)

- The axial creep strain had an apparent linear relationship with the lateral creep strain. In addition, the slopes of fit lines increased gradually with increasing deviatoric stress. Under identical deviatoric stresses, the elastic parameters (K, GM and GK) and the viscosity coefficient (ηK) of the creep model decreased with temperature, whereas the viscosity coefficient (ηM) at first increased as the temperature rose to 300 °C and then decreased as temperature exceeded 300 °C.

- (5)

- Nevertheless, despite the preliminary experimental investigation of the thermal influence on the time-dependent behavior and creep damage model of red sandstone, more refined studies are necessary. In particular, further experimental work is essential to provide sufficient tests data to gain a deeper understanding of the mechanism of thermal effects. Furthermore, the coupled thermal and creep damage model requires study, verification and optimization.

Acknowledgments

Author Contributions

Conflicts of Interest

List of Symbols

| CSR | Critical stress ratio |

| D | Damage variable (0 ≤ D ≤ 1) |

| E0 | Instantaneous deformation modulus |

| GM | Shear modulus of Maxwell body |

| GK | Shear modulus of Kelvin body |

| K | Bulk modulus |

| P | Differencial stress (P = σ1 − σ3) |

| Q | The sum of the least error square |

| R2 | The square of correlation coefficient |

| S | Deviatoric stress |

| Sij | Partial stress tensor |

| Se, Sv, Sve | Partial stress tensors on elastic, viscosity and visco-elastic portions |

| SN | New deviatoric stress for a time step |

| S° | Old deviatoric stress for a time step |

| Ṡ | The derivative of S |

| T | Temperature |

| t | Creep time |

| t0 | Beginning time of accelerating creep |

| Ud | Dissipation energy |

| Dissipation energy corresponding to the initial damage | |

| U | Strain energy |

| U0 | Critical strain energy |

Greek Symbols

| σ1, σ2, σ3 | Principle stresses (σ1 ≥ σ3 = σ2 compression positive) |

| σij | Stress tensor |

| σp | Triaxial peak strength |

| σcd | Triaxial damage stress |

| σr | Triaxial residual strength |

| σc | Creep failure stress |

| σm | Spheric stress |

| εij | Strain tensor |

| εm | Spheric strain |

| ε0 | Instantaneous axial strain |

| εcr | Creep strain |

| eij | Partial strain tensor |

| ee, ev, eve | Partial strain tensors of elastic, viscosity and visco-elastic portions |

| ėK | Partial strain rate of Kelvin body |

| eK | Partial strain of Kelvin body |

| eM | Partial strain of Maxwell body |

| eN | New deviatoric strain for a time step |

| e° | Old deviatoric strain for a time step |

| New deviatoric strain for a time step of Kelvin body | |

| Old deviatoric strain for a time step of Kelvin body | |

| New deviatoric strain for a time step of Maxwell body | |

| Old deviatoric strain for a time step of Maxwell body | |

| Δt | Increment step of creep time |

| ηM | Viscosity coefficient of Maxwell body |

| ηK | Viscosity coefficient of Kelvin body |

| μ | Poisson’s ratio |

| α | Parameter related to the material |

| β | Parameter related to the material |

| Ω0 | Initial creep parameter |

| Ωcd | Creep parameter rafter creep damage |

References

- Yang, S.Q.; Ranjith, P.G.; Jing, H.W.; Tian, W.L.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Yang, S.Q.; Xu, P.; Li, Y.B.; Huang, Y.H. Experimental investigation on triaxial mechanical and permeability behavior of sandstone after exposure to different high temperature treatments. Geothermics 2017, 69, 93–109. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Wan, Z.J.; Kang, J.R. Introduction to Geothermal Extraction of Hot Dry Rock; Sciences Press: Beijing, China, 2004; pp. 9–18. [Google Scholar]

- Yang, S.Q.; Tian, W.L.; Huang, Y.H. Failure mechanical behavior of pre-holed granite specimens after elevated temperature treatment by particle flow code. Geothermics 2018, 72, 124–137. [Google Scholar] [CrossRef]

- Stiegel, G.J.; Ramezan, M. Hydrogen from coal gasification: An economical pathway to a sustainable energy future. Int. J. Coal Geol. 2006, 65, 173–190. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Daniel, R.V.; Chen, B.J.; Perera, M.S.A. Transformation plasticity and the effect of temperature on the mechanical behaviour of Hawkesbury sandstone at atmospheric pressure. Eng. Geol. 2012, 151, 120–127. [Google Scholar]

- Yang, S.Q.; Tian, W.L.; Ranjith, P.G. Experimental investigation on deformation failure characteristics of crystalline marble under triaxial cyclic loading. Rock. Mech. Rock Eng. 2017, 50, 2871–2889. [Google Scholar] [CrossRef]

- Voight, B. Structural stability of andesite volcanoes and lava domes. Philos. Trans. R. Soc. A 2000, 358, 1663–1703. [Google Scholar] [CrossRef]

- Watters, R.J.; Zimbelman, D.R.; Bowman, S.D.; Crowley, J.K. Rock mass strength assessment and significant to edifice stability, Mt Rainer and Mt Hood, Cascade Range volcanoes. Pure Appl. Geophys. 2005, 157, 957–976. [Google Scholar] [CrossRef]

- Heap, M.J.; Baud, P.; Meredith, P.G. The influence of temperature on brittle creep in sandstones. Geophys. Res. Lett. 2009, 36, L19305. [Google Scholar] [CrossRef]

- Heap, M.J.; Baud, P.; Meredith, P.G.; Vinciguerra, S.; Bell, A.F.; Main, I.G. Brittle creep in basalt and its application to time-dependent volcano deformation. Earth Planet Sci. Lett. 2011, 307, 71–82. [Google Scholar] [CrossRef]

- Logan, S.E. Deep self-burial of radioactive wastes by rock-melting capsules. Nucl. Technol. 1974, 21, 111–124. [Google Scholar] [CrossRef]

- Heuze, F.E. On the Geotechnical Modelling of High-Level Nuclear Waste Disposal by Rock Melting; UCRL-53183; Lawrence Livermore Laboratory: Livermore, CA, USA, 1981.

- Gibb, S.E. High-temperature, very deep geological disposal: A safer alternative for high-level radioactive waste? Waste Manag. 1999, 19, 207–211. [Google Scholar] [CrossRef]

- Qin, B.D.; Chen, L.J.; Liu, X. Experimental research on the swelling stresses in limestone at high temperatures. J. China Univ. Min. Technol. 2009, 38, 326–330. [Google Scholar]

- Michalski, S.R. The jharia mine fire control technical assistance project: An analysis. Int. J. Coal Geol. 2004, 59, 83–90. [Google Scholar] [CrossRef]

- Otto, C.; Kempka, T. Thermo-mechanical simulations of rock behavior in underground coal gasification show negligible impact of temperature dependent parameters on permeability changes. Energies 2015, 8, 5800–5827. [Google Scholar] [CrossRef]

- Goetze, C.; Brace, W.F. Laboratory observations of high-temperature rheology of rocks. Tectonophysics 1972, 13, 583–600. [Google Scholar] [CrossRef]

- Weertman, J.; Weertman, J.R. High temperature creep of rock and mantle viscosity. Annu. Rev. Earth Planet Sci. 1975, 3, 293–315. [Google Scholar] [CrossRef]

- Post, R.L. High temperature creep of Mt. Burnet dunite. Tectonophysics 1977, 42, 75–110. [Google Scholar] [CrossRef]

- Zhou, Y.S.; He, C.R.; Huang, X.G.; Song, J.; Sang, Z. Rheological complexity of mafic rocks and effect of mineral component on creep of rocks. Earth Sci. Front. 2009, 16, 76–87. [Google Scholar]

- Chen, L.; Wang, C.P.; Liu, J.F.; Li, Y.; Liu, J.; Wang, J. Effects of temperature and stress on the time-dependent behavior of Beishan granite. Int. J. Rock Mech. Min. Sci. 2017, 93, 16–323. [Google Scholar] [CrossRef]

- Lipponen, A.; Manninen, S.; Niini, H.; Ro, E. Effect of water and geological factors on the long-term stability of fracture zones in the Päijänne Tunnel, Finland: A case study. Int. J. Rock Mech. Min. Sci. 2005, 42, 3–12. [Google Scholar] [CrossRef]

- Cao, P.; Wan, L.H.; Wang, Y.X.; Huang, Y.H.; Zhang, X.Y. Viscoelasto-plastic properties of deep hard rocks under water environment. Trans. Nonferrous Met. Soc. China 2011, 21, 2711–2718. [Google Scholar] [CrossRef]

- Yang, S.Q.; Jing, H.W.; Cheng, L. Influences of pore pressure on short-term and creep mechanical behavior of red sandstone. Eng. Geol. 2014, 179, 10–23. [Google Scholar] [CrossRef]

- Tsai, L.S.; Hsieh, Y.M.; Weng, M.C.; Huang, T.H.; Jeng, F.S. Time-dependent deformation behaviors of weak sandstones. Int. J. Rock Mech. Min. Sci. 2008, 45, 144–154. [Google Scholar] [CrossRef]

- Heap, M.J.; Baud, P.; Meredith, P.G.; Bell, A.F.; Main, I.G. Time-dependent brittle creep in Darley Dale sandstone. J. Geophys. Res. 2009, 114, 4288–4309. [Google Scholar] [CrossRef]

- Yang, D.S.; Chen, L.F.; Yang, S.Q. Experimental investigation of the creep and damage behavior of Linyi red sandstone. Int. J. Rock Mech. Min. Sci. 2014, 72, 164–172. [Google Scholar] [CrossRef]

- Maranini, E.; Brignoli, M. Creep behaviour of a weak rock: Experimental characterization. Int. J. Rock Mech. Min. Sci. 1999, 36, 127–138. [Google Scholar] [CrossRef]

- Brantut, N.; Heap, M.J.; Meredith, P.G.; Baud, P. Time-dependent cracking and brittle creep in crustal rocks: A review. J. Struct. Geol. 2013, 52, 17–43. [Google Scholar] [CrossRef]

- Cristescu, N. Rock Rheology; Kluwer Academic: Dordrecht, The Netherlands, 1989. [Google Scholar]

- Chopra, P.N. High-temperature transient creep in olivine rocks. Tectonophysics 1997, 279, 93–111. [Google Scholar] [CrossRef]

- Ferrero, A.M.; Marini, P. Technical note experimental studies on the mechanical behavior of two thermal cracked marbles. Rock Mech. Rock Eng. 2001, 34, 57–66. [Google Scholar] [CrossRef]

- Du, S.J.; Liu, H.; Zhi, H.T.; Chen, H.H. Testing study on mechanical properties of post-high-temperature granite. Chin. J. Rock Mech. Eng. 2004, 23, 2359–2364. (In Chinese) [Google Scholar]

- Brotóns, V.; Tomás, R.; Ivorra, S.; Alarcón, J.C. Temperature influence on the physical and mechanical properties of a porous rock: San Julian’ calcarenite. Eng. Geol. 2013, 167, 117–127. [Google Scholar] [CrossRef]

- Tian, H.; Kempka, T.; Xu, N.X.; Ziegler, M. Physical properties of sandstones after high temperature. Rock Mech. Rock. Eng. 2012, 45, 1113–1117. [Google Scholar] [CrossRef]

- Tian, H.; Kempka, T.; Yu, S.; Ziegler, M. Mechanical properties of sandstones exposed to high temperature. Rock Mech. Rock. Eng. 2016, 49, 321–327. [Google Scholar] [CrossRef]

- Tian, H.; Ziegler, M.; Kempka, T. Physical and mechanical behavior of claystone exposed to temperature up to 1000 °C. Int. J. Rock Mech. Min. Sci. 2014, 70, 144–153. [Google Scholar] [CrossRef]

- Li, M.; Mao, X.B.; Cao, L.L.; Mao, R.R.; Tao, J. Experimental study of mechanical properties on strain rate effect of sandstones after high temperature. Chin. Rock Soil. Mech. 2014, 23, 3479–3488. [Google Scholar]

- Ye, G.L.; Nishimura, T.; Zhang, F. Experimental study on shear and creep behaviour of green tuff at high temperatures. Int. J. Rock Mech. Min. Sci. 2015, 79, 19–28. [Google Scholar] [CrossRef]

- Sun, Q.; Lü, C.; Cao, L.W.; Li, W.C.; Geng, J.S.; Zhang, W.Q. Thermal properties of sandstone after treatment at high temperature. Int. J. Rock Mech. Min. Sci. 2016, 85, 60–66. [Google Scholar] [CrossRef]

- Carter, N.L.; Horseman, S.T.; Russell, J.E.; Handin, J. Rheology of rock-salt. J. Struct. Geol. 1993, 15, 1257–1271. [Google Scholar] [CrossRef]

- Main, I.G. A damage mechanics model for power-law creep and earthquake aftershock and foreshock sequences. Geophys. J. Int. 2000, 142, 151–161. [Google Scholar] [CrossRef]

- Burgers, J.M. Mechanical Considerations-Model Systems-Phenomenological Theories of Relaxation and of Viscosity; Nordemann Publishing Company: New York, NY, USA, 1935. [Google Scholar]

- Fahimifar, A.; Tehrani, F.M.; Hedayat, A.; Vakilazdeh, A. Analytical solution for the excavation of circular tunnels in a visco-elastic Burger’s material under hydrostatic stress field. Tunn. Undergr. Space Technol. 2010, 25, 297–304. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Wang, Y.X.; Wang, W.J.; Tang, J.Z. Modeling of non-linear rheological behavior of hard rock using triaxial rheological experiment. Int. J. Rock Mech. Min. Sci. 2017, 93, 66–75. [Google Scholar] [CrossRef]

- Valanis, K.C. Theory of viscoplasticity without a yield surface Part.1. Gen. Theory Arch. Mech. 1971, 23, 517. [Google Scholar]

- Yang, C.H.; Wang, W.L.; Fan, J.H. A kind of endochronic constitutive description of mechanical properties of soft rock under static loading. Rock Soil Mech. 1987, 8, 11–17. (In Chinese) [Google Scholar]

- Abu Al-Rub, R.K.; Darabi, M.K. A thermodynamic framework for constitutive modeling of time- and rate-dependent materials. Part I: Theory. Int. J. Plast. 2012, 34, 61–92. [Google Scholar] [CrossRef]

- Xie, H.P.; Peng, R.D.; Ju, Y. Energy dissipation of rock deformation and fracture. Chin. J. Rock Mech. Eng. 2004, 23, 3565–3570. (In Chinese) [Google Scholar]

- Yoshida, H.; Horii, H. A micromechanics-based model for creep behavior of rock. Appl. Mech. Rev. 1992, 45, 294–303. [Google Scholar] [CrossRef]

- Lu, Y.L.; Elswort, D.; Wang, L.G. A dual-scale approach to model time-dependent deformation, creep and fracturing of brittle rocks. Comput. Geotech. 2014, 60, 61–76. [Google Scholar] [CrossRef]

- Shao, J.F.; Chau, K.T.; Feng, X.T. Modeling of anisotropic damage and creep deformation in brittle rocks. Int. J. Rock Mech. Min. Sci. 2006, 43, 582–592. [Google Scholar] [CrossRef]

- Kachanov, L.M. Time of the rupture process under creep conditions. Izv. Akad. Nauk S S R Otd. Tech. Nauk 1958, 8, 26–31. [Google Scholar]

- Lemaitre, J. Evaluation of dissipation and damage in metals under dynamic loading. In Proceedings of the International Congress on Mechanical Behavior of Materials (ICM), Kyoto, Japan, August 1971. [Google Scholar]

- Murakami, S. Notion of Continuum Damage Mechanics and Its Application to Anisotropic Creep Damage Theory. J. Eng. Mater. Technol. 1983, 105, 99–105. [Google Scholar] [CrossRef]

- Kyoya, T. A damage mechanics theory for discontinuous rock mass. In Proceedings of the Fifth International Conference on Numerical Methods in Geomechanics, Nagoya, Japan, 1–5 April 1985; pp. 469–480. [Google Scholar]

- Lockner, D.; Byerlee, J. Acoustic emission and creep in rocks at high confining pressure and differential stress. Bull. Seismol. Soc. Am. 1977, 67, 247–258. [Google Scholar]

- Baud, P.; Meredith, P.G. Damage accumulation during triaxial creep of Darley Dale sandstone from pore volumometry and acoustic emission. Int. J. Rock Mech. Min. Sci. 1997, 34, 24.e1–24.e10. [Google Scholar] [CrossRef]

- Atkinson, B.K. Subcritical crack growth in geological materials. J. Geophys. Res. 1984, 89, 4077–4114. [Google Scholar] [CrossRef]

- Meredith, P.G.; Atkinson, B.K. Stress corrosion and acoustic emission during tensile crack propagation in Whin Sill dolerite and other basic rocks. Geophys. J. Int. 1983, 75, 1–21. [Google Scholar] [CrossRef]

- Yang, S.Q.; Xu, P.; Ranjith, P.G. Damage model of coal under creep and triaxial compression. Int. J. Rock Mech. Min. Sci. 2015, 80, 337–345. [Google Scholar] [CrossRef]

- Xie, H.P.; Li, L.; Peng, R.; Ju, Y. Energy analysis and criteria for structural failure of rocks. J. Rock Mech. Geotech. Eng. 2009, 1, 11–20. [Google Scholar] [CrossRef]

- Lin, Q.X.; Liu, Y.M.; Tham, L.G.; Tang, C.A.; Lee, P.K.K.; Wang, J. Time-dependent strength degradation of granite. Int. J. Rock Mech. Min. Sci. 2009, 46, 1103–1114. [Google Scholar] [CrossRef]

- Yu, T.Q.; Wang, X.W.; Liu, Z.H. Elasticity and Plasticity; China Architecture and Building Press: Beijing, China, 2004. [Google Scholar]

- Sun, J. Rheological Behavior of Geomaterials and Its Engineering Applications; China Architecture and Building Press: Beijing, China, 1999. [Google Scholar]

- Wong, T.F. Effects of temperature and pressure on failure and post-failure behavior of Westerly granite. Mech. Mater. 1982, 1, 3–17. [Google Scholar] [CrossRef]

- Hajpál, M.; Török, Á. Mineralogical and colour changes of quartz sandstones by heat. Environ. Geol. 2004, 46, 311–322. [Google Scholar] [CrossRef]

- Heap, M.J.; Mollo, S.; Vinciguerra, S. Thermal weakening of the carbonate basement under Mt. Etna volcano (Italy): Implications for volcano instability. J. Volcanol. Geotherm. Res. 2013, 250, 42–60. [Google Scholar] [CrossRef]

- Hajpál, M. Changes in Sandstones due to Thermal Effect. Unpublished Ph.D. Thesis, Budapest University of Technology and Economics, Budapest, Hungary, 2002. (In Hungarian with English and German Abstract). [Google Scholar]

| T/°C | σ3/MPa | σS/MPa | σp/MPa | σcd/MPa | ES/GPa | E50/GPa |

|---|---|---|---|---|---|---|

| 25 | 25 | 259.32 | 234.32 | 223.34 | 26.13 | 28.65 |

| 300 | 25 | 269.78 | 244.78 | 228.32 | 28.42 | 28.77 |

| 700 | 25 | 316.29 | 291.29 | 263.53 | 25.49 | 21.23 |

| 1000 | 25 | 232.36 | 207.36 | 132.99 | 10.49 | 7.84 |

| T/°C | P/MPa | P/σp/% | K/GPa | GM/GPa | ηM × 103/GPa·h | GK/GPa | ηK/GPa·h | α | U0/J mm−1 | R2 | Q × 10−3 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 160 | 68 | 20.09 | 12.05 | 76.93 | 407.09 | 956.58 | 0.99 | 1.53 | ||

| 190 | 81 | 19.41 | 11.64 | 53.19 | 325.88 | 826.49 | 0.99 | 3.31 | |||

| 220 | 94 | 18.51 | 11.11 | 0.18 | 590.20 | 21.54 | 0.065 | 9.86 × 105 | 0.98 | 10.32 | |

| 300 | 160 | 65 | 19.30 | 11.58 | 84.83 | 279.28 | 498.57 | 0.99 | 1.03 | ||

| 190 | 78 | 18.92 | 11.35 | 66.63 | 260.97 | 561.20 | 0.99 | 1.37 | |||

| 220 | 90 | 18.33 | 10.99 | 50.37 | 232.90 | 514.73 | 0.99 | 5.82 | |||

| 230 | 94 | 17.92 | 10.75 | 10.96 | 247.73 | 494.99 | 0.03 | 1.024 × 106 | 0.98 | 14.54 | |

| 700 | 160 | 55 | 14.29 | 8.57 | 79.98 | 172.57 | 289.35 | 0.99 | 7.28 | ||

| 190 | 65 | 14.29 | 8.58 | 41.99 | 166.80 | 282.35 | 0.98 | 2.36 | |||

| 220 | 76 | 14.25 | 8.55 | 41.56 | 100.77 | 137.15 | 0.98 | 5.39 | |||

| 1000 | 160 | 77 | 6.37 | 3.82 | 0.79 | 40.18 | 77.37 | 0.98 | 3.67 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.-Q.; Hu, B.; Ranjith, P.G.; Xu, P. Multi-Step Loading Creep Behavior of Red Sandstone after Thermal Treatments and a Creep Damage Model. Energies 2018, 11, 212. https://doi.org/10.3390/en11010212

Yang S-Q, Hu B, Ranjith PG, Xu P. Multi-Step Loading Creep Behavior of Red Sandstone after Thermal Treatments and a Creep Damage Model. Energies. 2018; 11(1):212. https://doi.org/10.3390/en11010212

Chicago/Turabian StyleYang, Sheng-Qi, Bo Hu, Pathegama G. Ranjith, and Peng Xu. 2018. "Multi-Step Loading Creep Behavior of Red Sandstone after Thermal Treatments and a Creep Damage Model" Energies 11, no. 1: 212. https://doi.org/10.3390/en11010212