Energy Analysis of Cascade Heating with High Back-Pressure Large-Scale Steam Turbine

Abstract

:1. Introduction

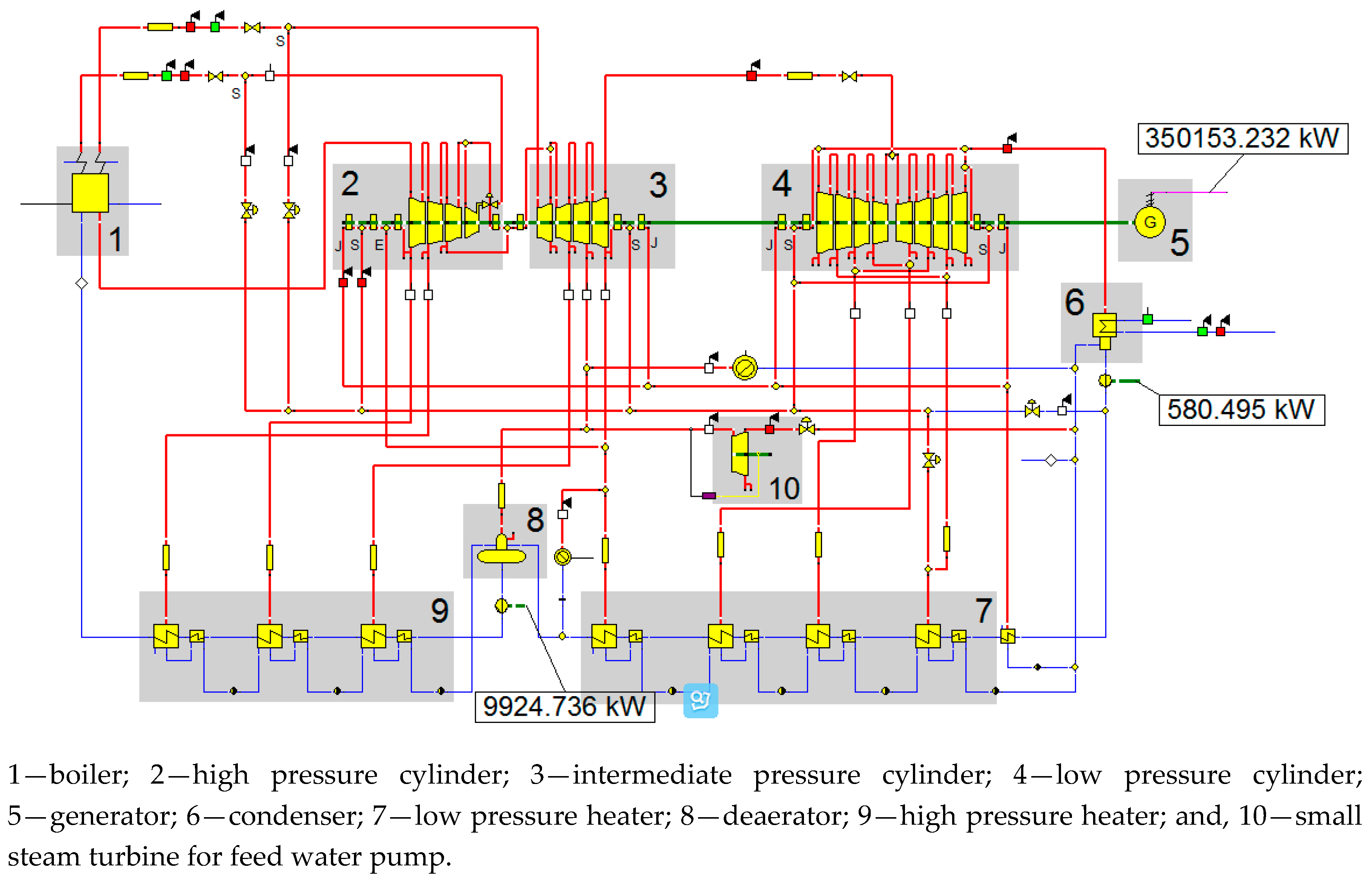

2. Research Object and Analytical Model

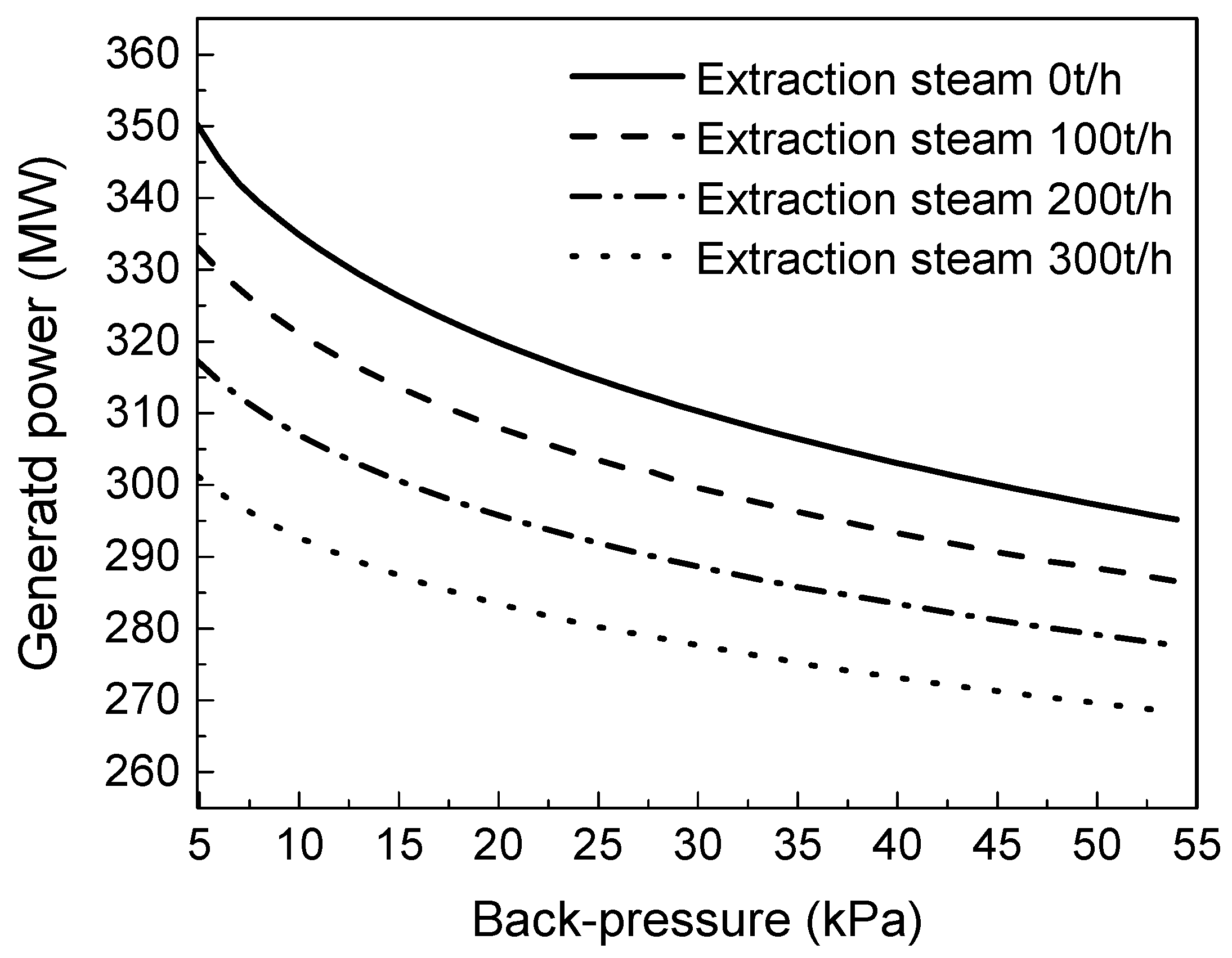

2.1. Model for Analyzing off-Design Operating Conditions

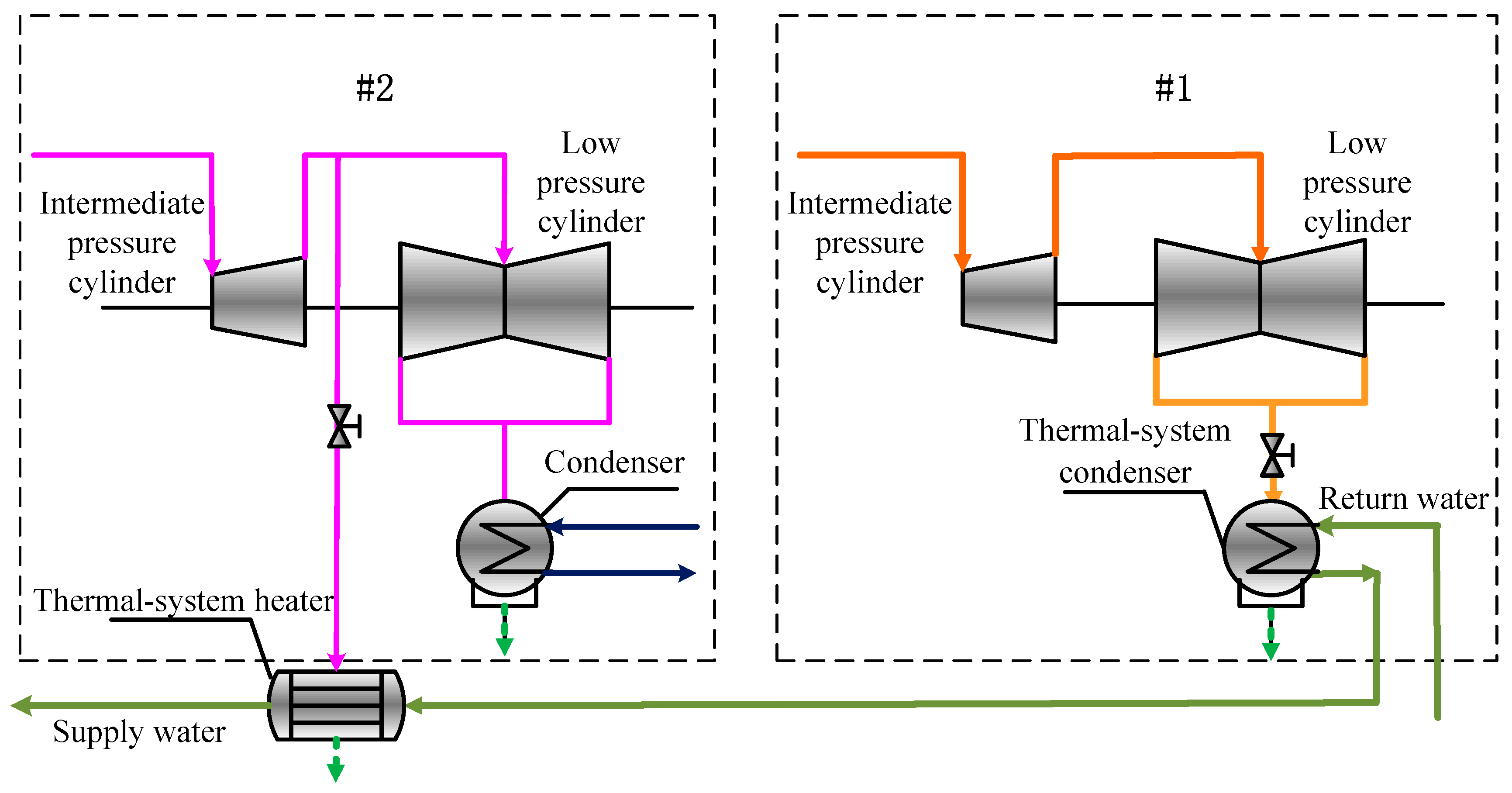

2.2. Heat Load Distribution of the High Back-Pressure Cascade Heating System

2.3. Heating Efficiency and Coal Consumption of the High Back-Pressure Cascade Heating Unit

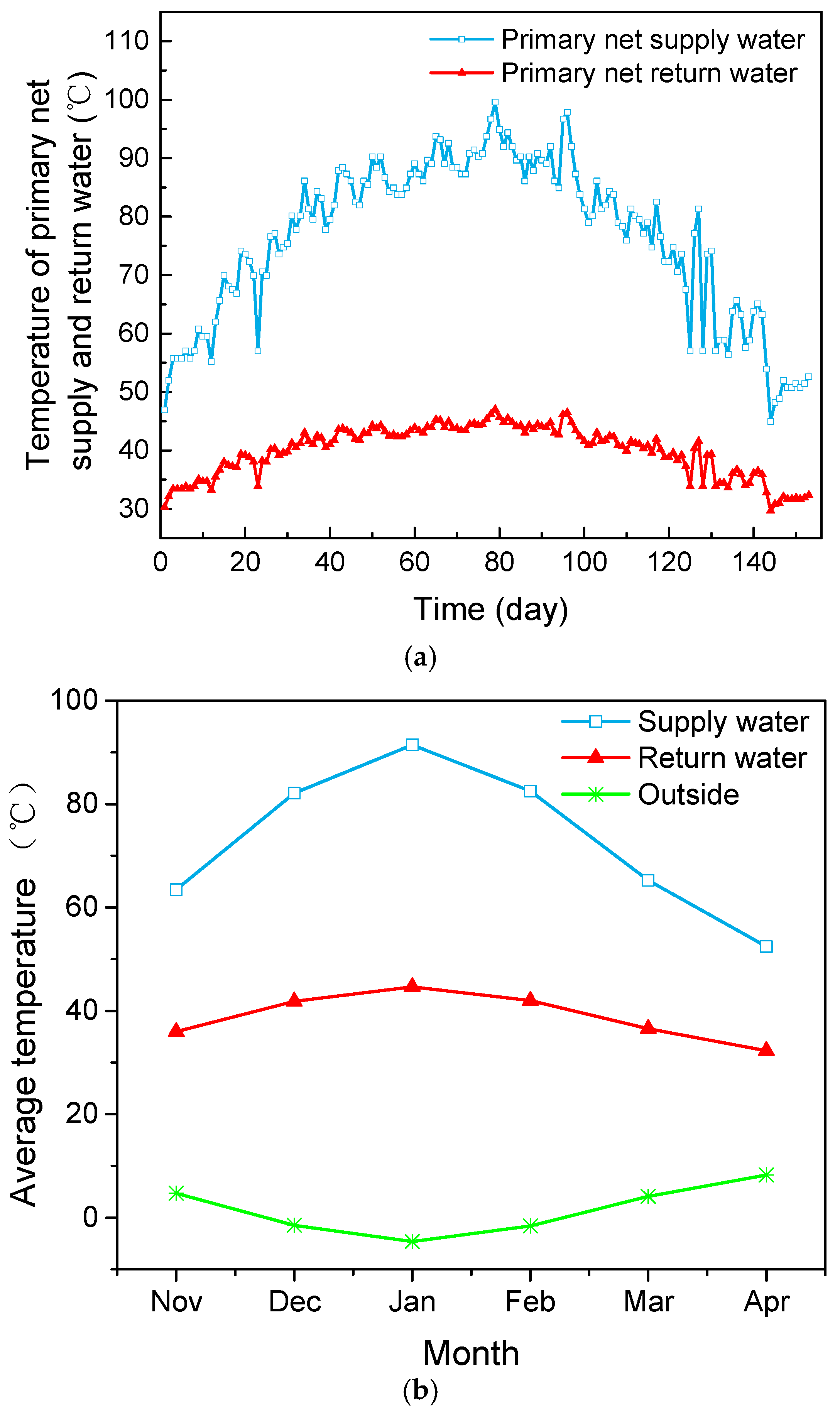

3. Determination of the Boundary Conditions for High Back-Pressure Cascade Heating

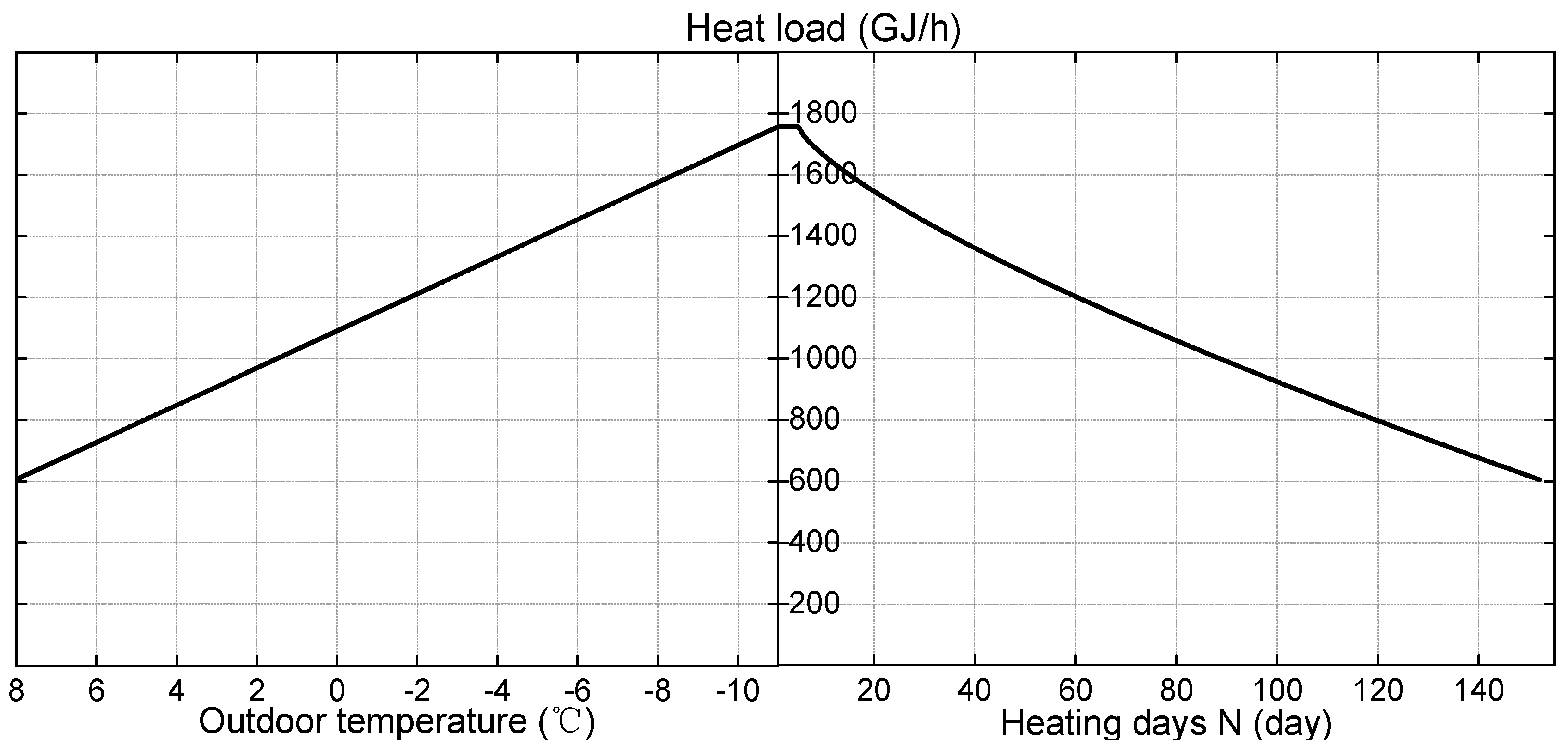

3.1. Heating Load Delay Map during Heating Period

3.2. Determination of the Heating Network’s Return Water Temperature

4. Results and Analysis

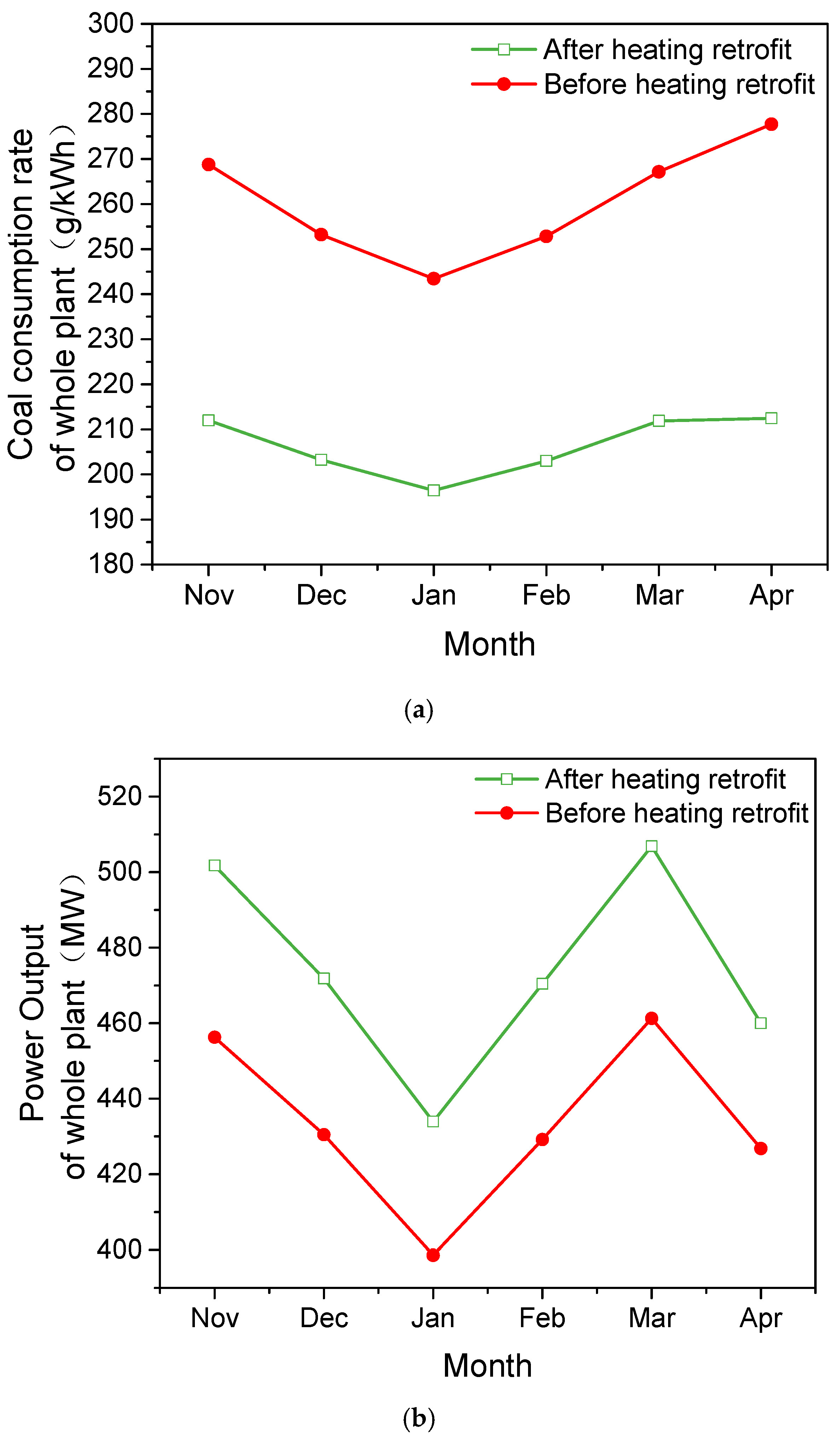

4.1. The Heating Load Distributions of the Two CHP Units after the Retrofit

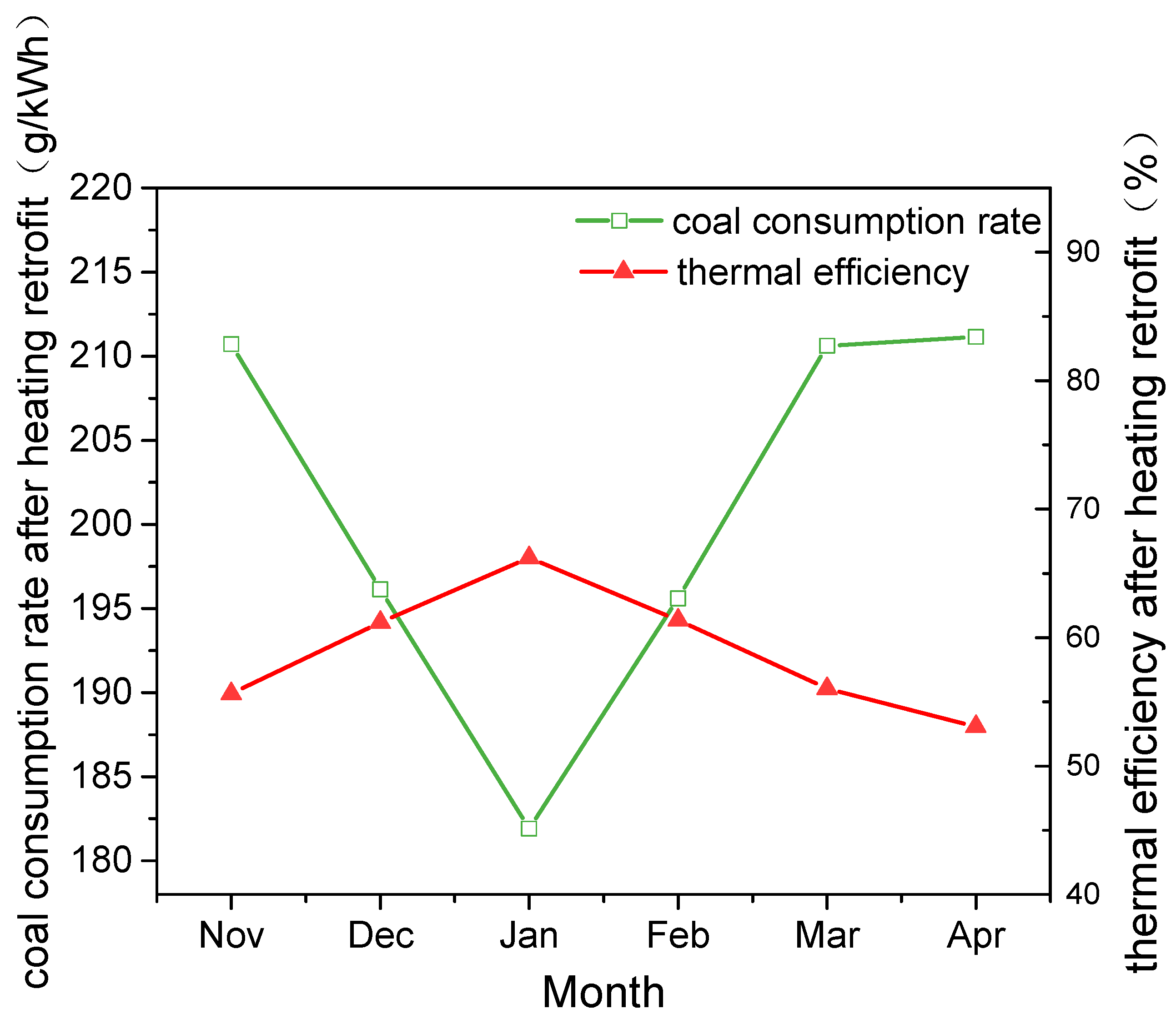

4.2. Comparison of the Heating Efficiencies before and after the Retrofit

4.3. Heating Efficiency at the Maximum Heating Capacity

5. Conclusions

- (1)

- The present high back-pressure cascade heating system recovered the waste heat of low grade steam, the heating efficiency improved significantly. Under the design heating load, the average standard coal consumption rate for the heating season was 205.46 g/kWh. About 37.5 kt coal can be saved for a single heating season, which reduces CO2 emission by approximately 98.2 kt.

- (2)

- The maximum heating capacity of the retrofitted CHP unit was determined. Under the maximum heating conditions, the standard coal consumption rate for the heating season was 199.07 g/kWh, and the thermal power generation efficiency was 61.79%.

- (3)

- The performance of the high back-pressure cascade heating system is greatly influenced by the heating load. Higher heating load leads to more significant energy saving and emission reduction. In practical applications of high back-pressure cascade heating technology, high heating load is proposed to achieve the expected benefits.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | speed of sound (m/s) |

| C | specific heat (kJ/(kg·°C)) |

| F | area (m2) |

| G | mass flow (kg/s) |

| h | specific enthalpy (kJ/kg) |

| k | adiabatic index |

| p | pressure (MPa) |

| Q | heat (MW) |

| t | time (s) |

| T | temperature (K, °C) |

| V | volume (m3) |

| v | specific volume (m3/kg) |

| W | power output (kW) |

| x | ammonia concentration (kg/kg) |

| Greek Symbols: | |

| π | pressure ratio |

| η | efficiency |

| Subscripts: | |

| 0 | initial |

| a | axial |

| b | boiler |

| c | condense |

| e | extraction/electricity |

| fw | feedwater |

| is | isentropy process |

| p | piping or pipe |

| r | return water |

| rh | reheat |

| s | supply water |

| t | thermal |

| tp | thermal power |

| w | water |

References

- Ghorbani, N. Combined heat and power economic dispatch using exchange market algorith. Int. J. Electr. Power Energy Syst. 2016, 82, 58–66. [Google Scholar] [CrossRef]

- Athawale, R.; Felder, F.A.; Goldman, L.A. Do Combined Heat and Power plants perform Case study of publicly funded projects in New York. Energy Policy 2016, 97, 618–627. [Google Scholar] [CrossRef]

- Wells, P.; Nithyanandam, K.; Wirz, R. Cost Optimal Strategies of High Temperature Thermal Energy Storage Systems in Combined Heat and Power Applications. In Proceedings of the ASME 2016 10th International Conference on Energy Sustainability collocated with the ASME 2016 Power Conference and the ASME 2016 14th International Conference on Fuel Cell Science, Engineering and Technology, Charlotte, NC, USA, 26–30 June 2016; p. V001T03A006. [Google Scholar]

- Long, W.C.; Luck, R.; Mago, P.J. Uncertainty based operating strategy selection in combined heat and power systems. Appl. Therm. Eng. 2016, 98, 1013–1024. [Google Scholar] [CrossRef]

- Smith, A.D.; Mago, P.J. Effects of load-following operational methods on combined heat and power system efficiency. Appl. Energy 2014, 115, 337–351. [Google Scholar] [CrossRef]

- Van der Veen, R.A.C.; Kasmire, J. Combined heat and power in Dutch greenhouses: A case study of technology diffusion. Energy Policy 2015, 87, 8–16. [Google Scholar] [CrossRef]

- Li, H.; Svendsen, S. Energy and exergy analysis of low temperature district heating network. Energy 2012, 45, 237–246. [Google Scholar] [CrossRef]

- Lund, H.; Moller, B.; Mathiesen, B.V. The role of district heating in future renewable energy systems. Energy 2010, 35, 1381–1390. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Svendsen, S. Energy, economy and exergy evaluations of the solutions for supplying domestic hot water from low-temperature district heating in Denmark. Energy Convers. Manag. 2016, 122, 142–152. [Google Scholar] [CrossRef]

- Byuna, S.; Parka, H.; Yia, S.; Songa, C.; Choib, Y.; Leeb, S.; Shinc, J. Study on the optimal heat supply control algorithm for district heating distribution network in response to outdoor air temperature. Energy 2015, 86, 247–256. [Google Scholar] [CrossRef]

- Ji, Y.; Xu, P.; Duan, P.; Lu, X. Estimating hourly cooling load in commercial buildings using a thermal network model and electricity submetering data. Appl. Energy 2016, 169, 309–323. [Google Scholar] [CrossRef]

- Fu, L.; Li, Y.; Zhang, S.; Jiang, Y. A district heating system based on absorption heat exchange with CHP systems. Front. Energy Power Eng. China 2010, 4, 77–83. [Google Scholar] [CrossRef]

- Guo, J.; Yang, H. A fault detection method for heat loss in a tyre vulcanization workshop using a dynamic energy consumption model and predictive baselines. Appl. Therm. Eng. 2015, 90, 711–721. [Google Scholar] [CrossRef]

- Galindo, J.; Climent, H.; Dolz, V.; Royo-Pascual, L. Multi-objective optimization of a bottoming Organic Rankine Cycle (ORC) of gasoline engine using swash-plate expander. Energy Convers. Manag. 2016, 126, 1054–1065. [Google Scholar] [CrossRef]

- Sun, F.; Fu, L.; Zhang, S. New waste heat district heating system with combined heat and power based on absorption heat exchange cycle in China. Appl. Therm. Eng. 2012, 37, 136–144. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, H.; Li, Z. Thermodynamic performance study on solar-assisted absorption heat pump cogeneration system in the coal-fired power plant. Energy 2016, 116, 942–955. [Google Scholar] [CrossRef]

- Federico, S.; Luca, A. Exploitation of humid air latent heat by means of solar assisted heat pumps operating below the dew point. Appl. Therm. Eng. 2016, 100, 820–828. [Google Scholar]

- Sobamowo, M.G. Thermal analysis of longitudinal fin with temperature-dependent properties and internal heat generation using Galerkin’s method of weighted residual. Appl. Therm. Eng. 2016, 99, 1316–1330. [Google Scholar] [CrossRef]

- Sun, W.; Yu, X.; Wang, Y. Exergy efficiency analysis of ORC (Organic Rankine Cycle) and ORC-based combined cycles driven by low-temperature waste heat. Energy Convers. Manag. 2017, 135, 63–73. [Google Scholar] [CrossRef]

- Wang, H.; Yin, W.; Abdollahi, E.; Lahdelma, R.; Jiao, W. Modelling and optimization of CHP based district heating system with renewable energy production and energy storage. Appl. Energy 2015, 159, 401–421. [Google Scholar] [CrossRef]

- Li, P.; Nord, N.; Ertesvåg, I.S.; Ge, Z.; Yang, Z.; Yang, Y. Integrated multiscale simulation of combined heat and power based district heating system. Energy Convers. Manag. 2015, 106, 337–354. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Dong, C.; Morosuk, T.; Tsatsaronis, G. Multi-objective optimization of coal-fired power plants using differential evolution. Appl. Energy 2014, 115, 254–264. [Google Scholar] [CrossRef]

- Xu, D.; Deng, D.; Wang, S.; Chen, W. Application of characteristic flow area of steam turbines and improvement on flugel formula. J. Chin. Soc. Power Eng. 2010, 30, 473–477. (In Chinese) [Google Scholar]

- Al-Shammari, E.T.; Keivani, A.; Shamshirband, S.; Mostafaeipourd, A.; Yee, P.L.; Petkoviće, D.; Chf, S. Prediction of heat load in district heating systems by Support Vector Machine with Firefly searching algorithm. Energy 2016, 95, 266–273. [Google Scholar] [CrossRef]

- Cao, J.; Liu, J.; Man, X. A united WRF/TRNSYS method for estimating the heating/cooling load for the thousand-meter scale megatall buildings. Appl. Therm. Eng. 2017, 114, 196–210. [Google Scholar] [CrossRef]

- Pirouti, M.; Bagdanavicius, A.; Ekanayake, J. Energy consumption and economic analyses of a district heating network. Energy 2013, 57, 149–159. [Google Scholar] [CrossRef]

| Condition | Heat Balance Diagram Value/MW | Calculated Value/MW | Calculation Error/% |

|---|---|---|---|

| THA | 350.153 | 350.153 | 0 |

| 75% THA | 262.552 | 260.630 | 0.73 |

| 50% THA | 175.223 | 174.626 | 0.34 |

| 40% THA | 140.020 | 141.083 | 0.76 |

| Time | Outdoor Temperature/°C | Relative Calorie Ratio | Heating Load/MW | Exhaust Steam Heating/MW | Extraction Steam Heating/MW | Water Temperature after Exhaust Heating/°C | Percentage of Exhaust Steam Heating/% |

|---|---|---|---|---|---|---|---|

| Nov. | 4.72 | 0.46 | 223.37 | 223.37 | 0 | 63.45 | 100.0 |

| Dec. | −1.46 | 0.67 | 327.47 | 228.88 | 98.60 | 69.99 | 69.89 |

| Jan. | −4.62 | 0.78 | 380.55 | 206.15 | 174.40 | 70.00 | 54.17 |

| Feb. | −1.60 | 0.68 | 329.82 | 227.85 | 101.97 | 70.26 | 69.08 |

| Mar. | 4.13 | 0.48 | 233.31 | 233.31 | 0 | 65.26 | 100.0 |

| Apr. | 8.26 | 0.34 | 163.87 | 163.87 | 0 | 52.45 | 100.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, Z.; Zhang, F.; Sun, S.; He, J.; Du, X. Energy Analysis of Cascade Heating with High Back-Pressure Large-Scale Steam Turbine. Energies 2018, 11, 119. https://doi.org/10.3390/en11010119

Ge Z, Zhang F, Sun S, He J, Du X. Energy Analysis of Cascade Heating with High Back-Pressure Large-Scale Steam Turbine. Energies. 2018; 11(1):119. https://doi.org/10.3390/en11010119

Chicago/Turabian StyleGe, Zhihua, Fuxiang Zhang, Shimeng Sun, Jie He, and Xiaoze Du. 2018. "Energy Analysis of Cascade Heating with High Back-Pressure Large-Scale Steam Turbine" Energies 11, no. 1: 119. https://doi.org/10.3390/en11010119