Electric Arc Furnace Modeling with Artificial Neural Networks and Arc Length with Variable Voltage Gradient

Abstract

:1. Introduction

2. Background

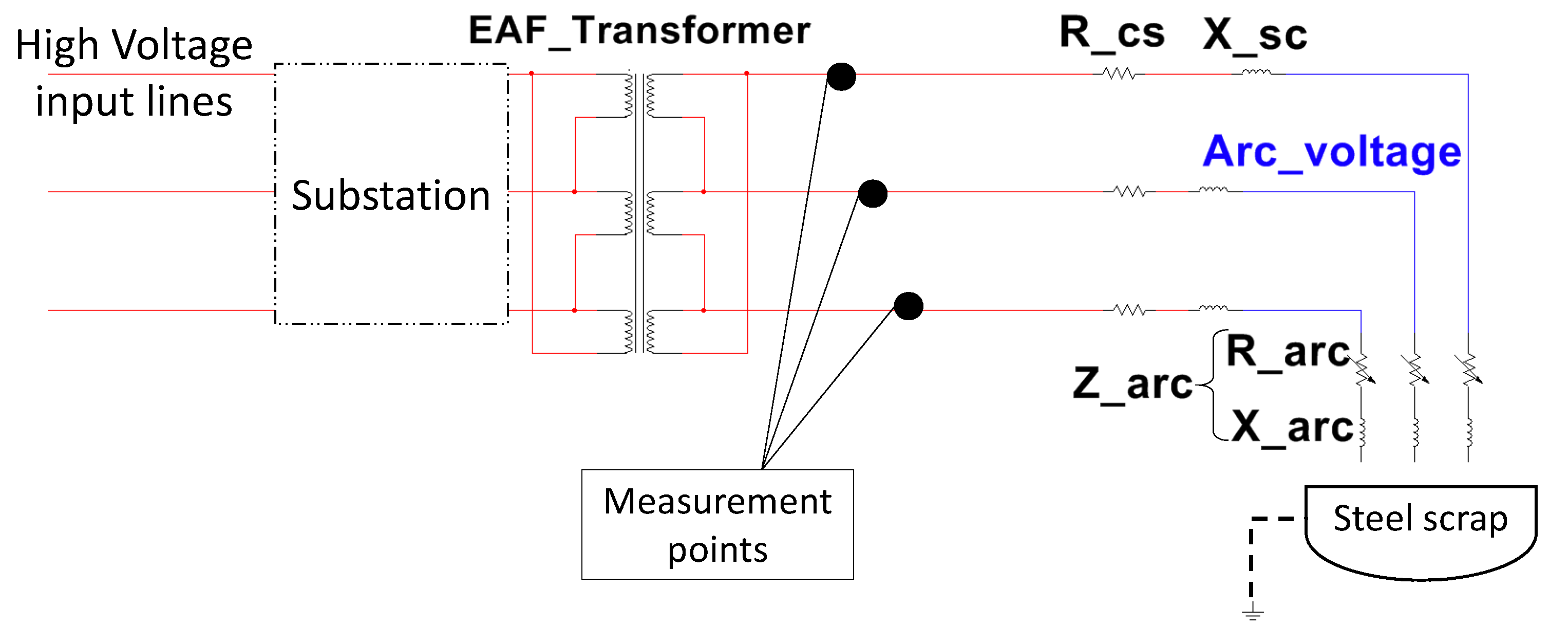

2.1. Electric Arc Furnace (EAF) Model

2.2. Artificial Neural Network

2.3. ANN Training Algorithm

2.4. Theoretical Arc Length Calculation

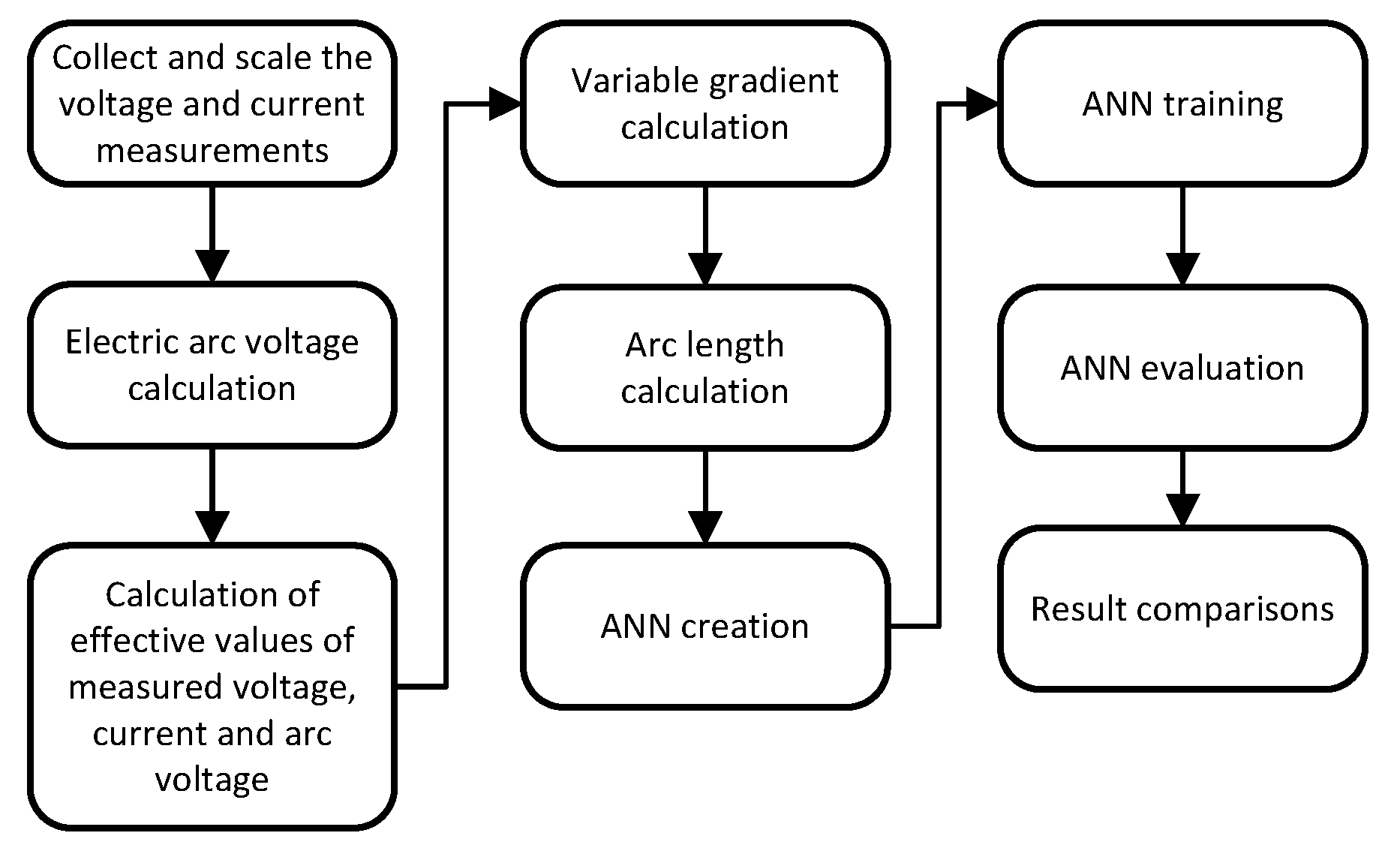

3. Proposed Methodology

3.1. Arc Voltage Calculation

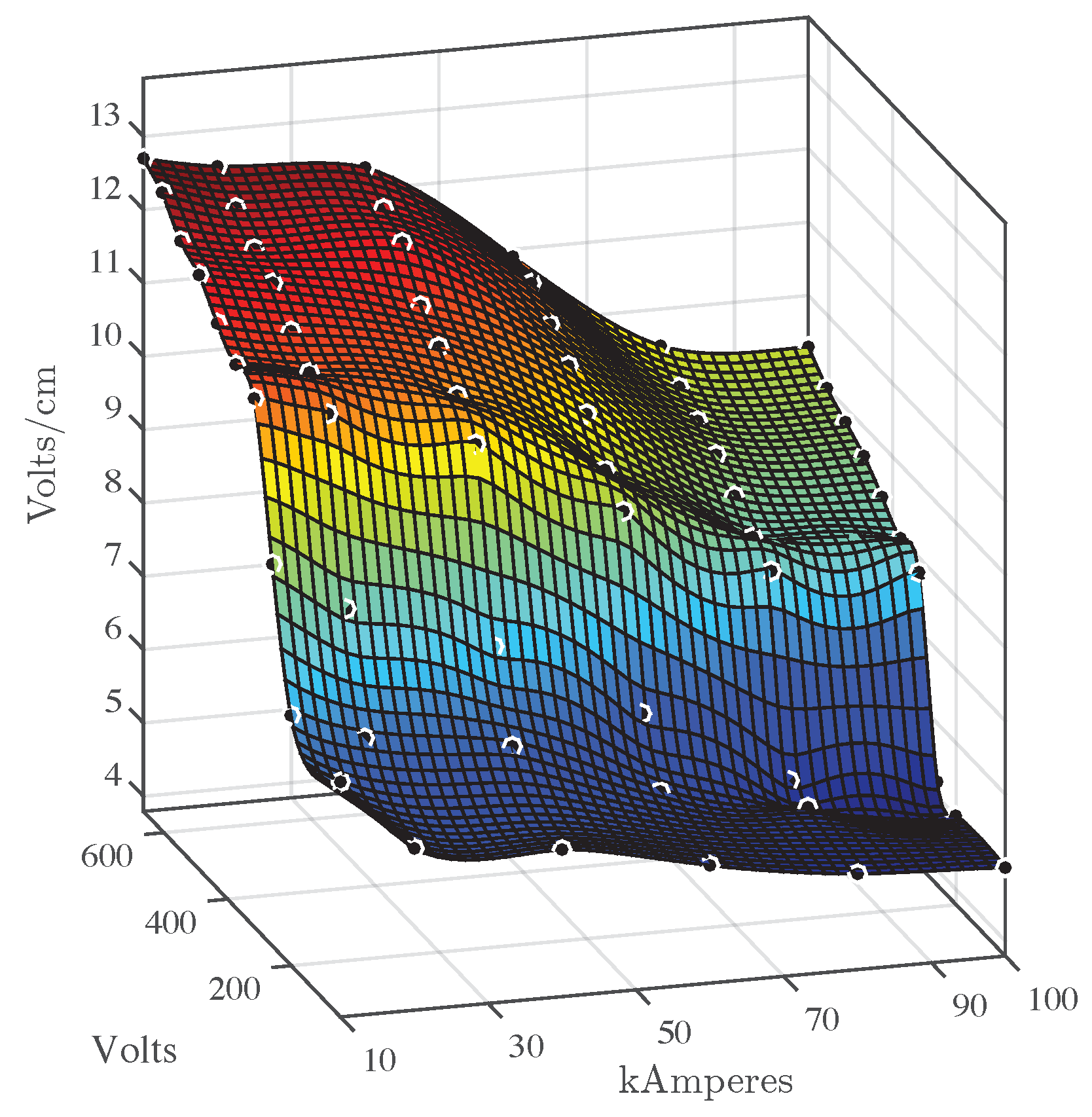

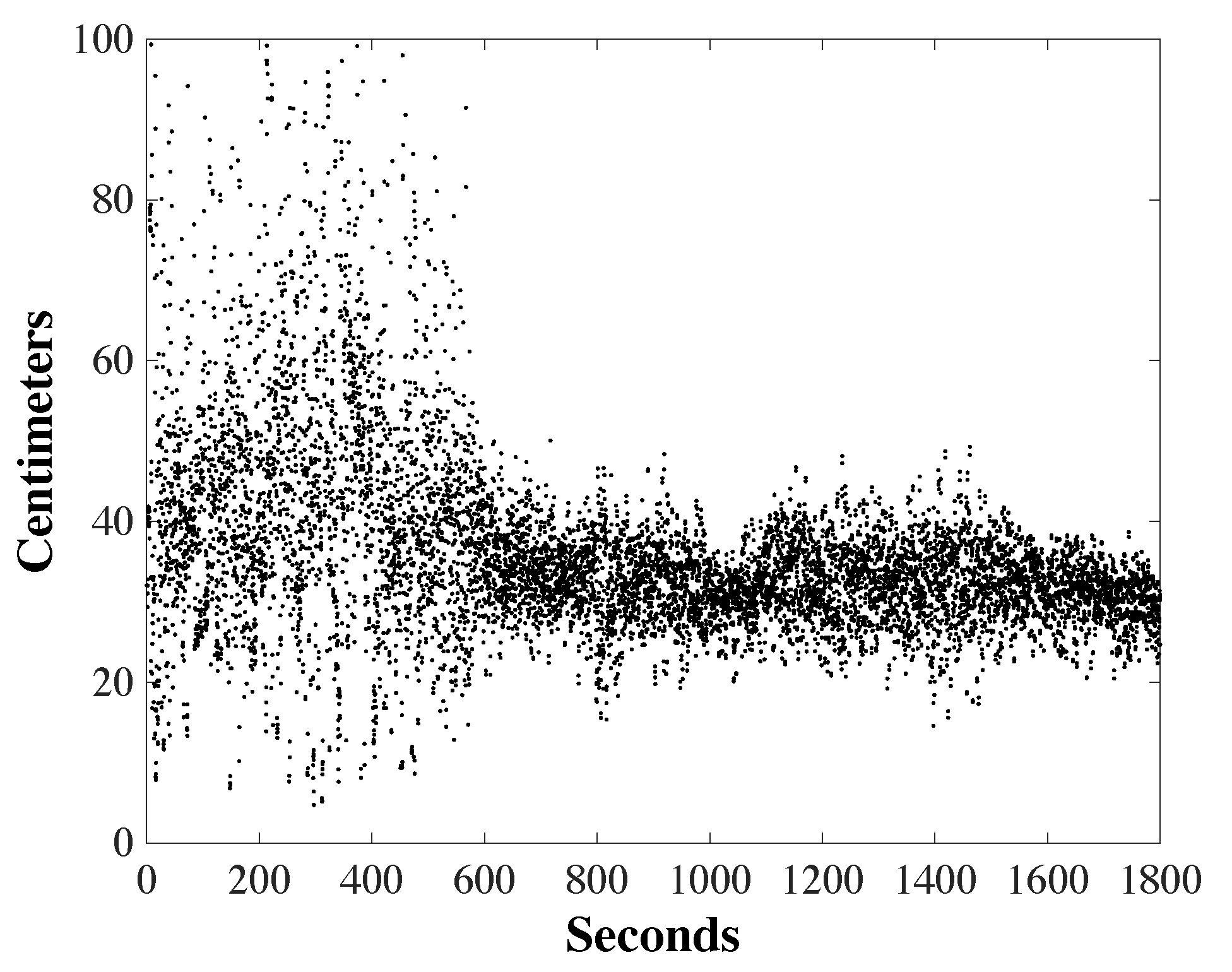

3.2. Arc Length Calculation via Variable Voltage Gradients

3.3. Proposed ANN Architecture

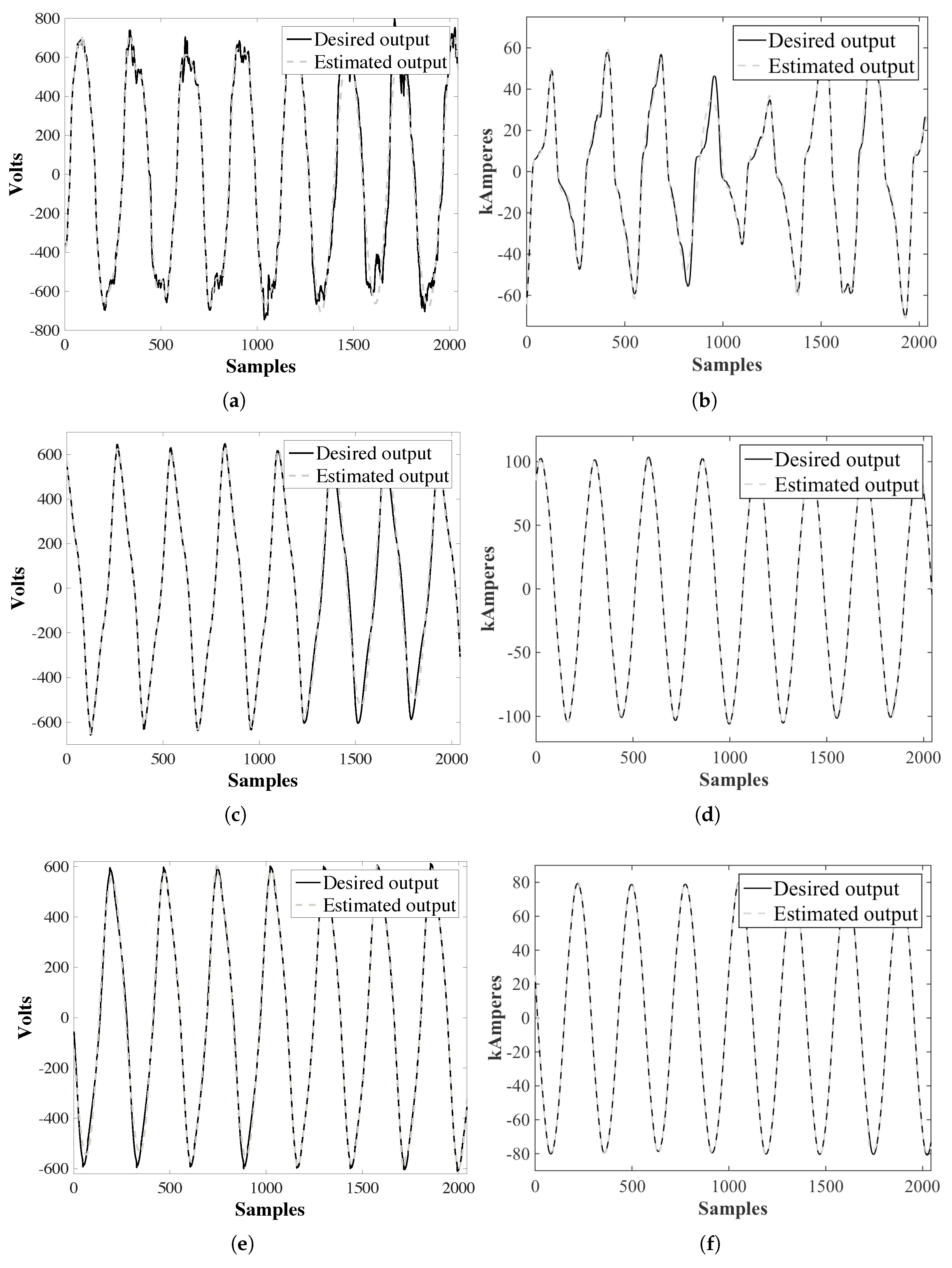

4. ANN Experimental Results

5. Discussion

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Jones, J. Electric Arc Furnace Steelmaking. Available online: http://www.steel.org/making-steel/how-itsmade/processes/processes-info/electric-arc-furnace-steelmaking.aspx (accessed on 7 July 2017).

- Lecompte, S.; Oyewunmi, O.A.; Markides, C.N.; Lazova, M.; Kaya, A.; van den Broek, M.; De Paepe, M. Case study of an organic rankine cycle (ORC) for waste heat recovery from an electric arc furnace (EAF). Energies 2017, 10, 649. [Google Scholar] [CrossRef]

- Peter, M. Wordsteel Association. Available online: http://www.worldsteel.org/media-centre/About-steel.html (accessed on 7 July 2017).

- Trejo, E.; Martell, F.; Micheloud, O.; Teng, L.; Llamas, A.; Montesinos-Castellanos, A. A novel estimation of electrical and cooling losses in electric arc furnaces. Energy 2012, 42, 446–456. [Google Scholar] [CrossRef]

- Kirschen, M.; Badr, K.; Pfeifer, H. Influence of direct reduced iron on the energy balance of the electric arc furnace in steel industry. Energy 2011, 36, 6146–6155. [Google Scholar] [CrossRef]

- Hocine, L.; Yacine, D.; Kamel, B.; Samira, K.M. Improvement of electrical arc furnace operation with an appropriate model. Energy 2009, 34, 1207–1214. [Google Scholar] [CrossRef]

- Hooshmand, R.; Banejad, M.; Esfahani, M.T. A new time domain model for electric arc furnace. J. Electr. Eng. 2008, 59, 195–202. [Google Scholar]

- Burch, R.F. Thoughts on improving the electric arc furnace model. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting—Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–27 July 2008; pp. 1–5. [Google Scholar]

- Bowman, B.; Krüger, K. Arc Furnace Physics; Stahleisen Communications; Verlag Stahleisen: Düsseldorf, Germany, 2009. [Google Scholar]

- López, M.A.; Baena, C.H.; Durango, J.M. Calibración de los Parámetros de un Modelo de Horno de Arco Eléctrico Empleando Simulación y Redes Neuronales; Revista EIA (Escuela de Ingeniería de Antioquia): Antioquia, Columbia, 2014; Volume 11, pp. 39–50. [Google Scholar]

- Wang, F.; Jin, Z.; Zhu, Z. Modeling and prediction of electric arc furnace based on neural network and chaos theory. In Advances in Neural Networks—ISNN 2005, Proceedings of the Second International Symposium on Neural Networks, Chongqing, China, 30 May–1 June 2005; Wang, J., Liao, X.F., Yi, Z., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 819–826. [Google Scholar]

- Wang, F.; Jin, Z.; Zhu, Z.; Wang, X. Modeling the DC electric arc furnace based on chaos theory and neural network. In Proceedings of the IEEE Power Engineering Society General Meeting, San Francisco, CA, USA, 16 June 2005; Volume 3, pp. 2503–2508. [Google Scholar]

- Chang, G.W.; Chen, C.I.; Liu, Y.J. A Neural-network-based method of modeling electric arc furnace load for power engineering study. IEEE Trans. Power Syst. 2010, 25, 138–146. [Google Scholar] [CrossRef]

- Gajic, D.; Savic-Gajic, I.; Savic, I.; Georgieva, O.; Gennaro, S.D. Modelling of electrical energy consumption in an electric arc furnace using artificial neural networks. Energy 2016, 108, 132–139. [Google Scholar] [CrossRef]

- Baumert, J.-C.; Engel, R.; Weiler, C. Dynamic modelling of the electric arc furnace process using artificial neural networks. Rev. Metall. Paris Int. J. Metall. 2002, 99, 839–849. [Google Scholar] [CrossRef]

- Rana, M.; Koprinska, I. Neural network ensemble based approach for 2D-interval prediction of solar photovoltaic power. Energies 2016, 9, 829. [Google Scholar] [CrossRef]

- Beale, M.; Hagan, M.; Demuth, H. Neural Network Toolbox: User’s Guide; Matlab, Inc.: Asheboro, NC, USA, 2017. [Google Scholar]

- Miller, T.J.E. Reactive Power Control in Electric Systems, 1st ed.; Wiley-Interscience: Hoboken, NJ, USA, 1982; p. 381. [Google Scholar]

- Muller, J.M. Elementary Functions: Algorithms and Implementation, 2nd ed.; Birkhauser: Basel, Switzerland, 2005. [Google Scholar]

- Trejo-Arellano, J.M.; Vázquez-Castillo, J.; Longoria-Gandara, O.; Gutiérrez, C.A.; Carrasco-Alvarez, R.; Castillo-Atoche, A. A novel function segmentation methodology for implementing affordable channel emulators. In Proceedings of the 2016 IEEE MTT-S Latin America Microwave Conference (LAMC), Puerto Vallarta, Mexico, 12–14 December 2016; pp. 1–4. [Google Scholar]

- Papoulis, A.; Pillai, S.U. Probability, Random Variables and Stochastic Processes, 4th ed.; McGraw-Hill Europe: New York, NY, USA, 2002. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia-Segura, R.; Vázquez Castillo, J.; Martell-Chavez, F.; Longoria-Gandara, O.; Ortegón Aguilar, J. Electric Arc Furnace Modeling with Artificial Neural Networks and Arc Length with Variable Voltage Gradient. Energies 2017, 10, 1424. https://doi.org/10.3390/en10091424

Garcia-Segura R, Vázquez Castillo J, Martell-Chavez F, Longoria-Gandara O, Ortegón Aguilar J. Electric Arc Furnace Modeling with Artificial Neural Networks and Arc Length with Variable Voltage Gradient. Energies. 2017; 10(9):1424. https://doi.org/10.3390/en10091424

Chicago/Turabian StyleGarcia-Segura, Raul, Javier Vázquez Castillo, Fernando Martell-Chavez, Omar Longoria-Gandara, and Jaime Ortegón Aguilar. 2017. "Electric Arc Furnace Modeling with Artificial Neural Networks and Arc Length with Variable Voltage Gradient" Energies 10, no. 9: 1424. https://doi.org/10.3390/en10091424