A Combined Experimental and Computational Fluid Dynamics Investigation of Particulate Matter Emissions from a Wall-Guided Gasoline Direct Injection Engine

Abstract

:1. Introduction

1.1. Particulate Matter Formation Process

- Oxidation and/or pyrolysis of fuel under fuel-rich conditions and temperature between 1000 and 2800 K;

- Production of precursor molecules from hydrocarbons species, leading to the formation of polycyclic aromatic hydrocarbons (PAH) gas species molecules;

- Polymerization of hydrocarbon rings;

- Particle inception or nucleation, as a result of the interaction between polymerized structures;

- Particles growth due to interactions between PAH species and particle surface;

- Coagulation of particles due to collision;

- Oxidation of particles in the presence of oxygen species (O2, OH, CO2, H2O) in high temperature environment (during and post combustion).

1.2. Influence of Engine Control Parameters

1.3. Influence of Combustion Parameters

1.4. Computational Fluid Dynamics Analysis of Mixture Preparation

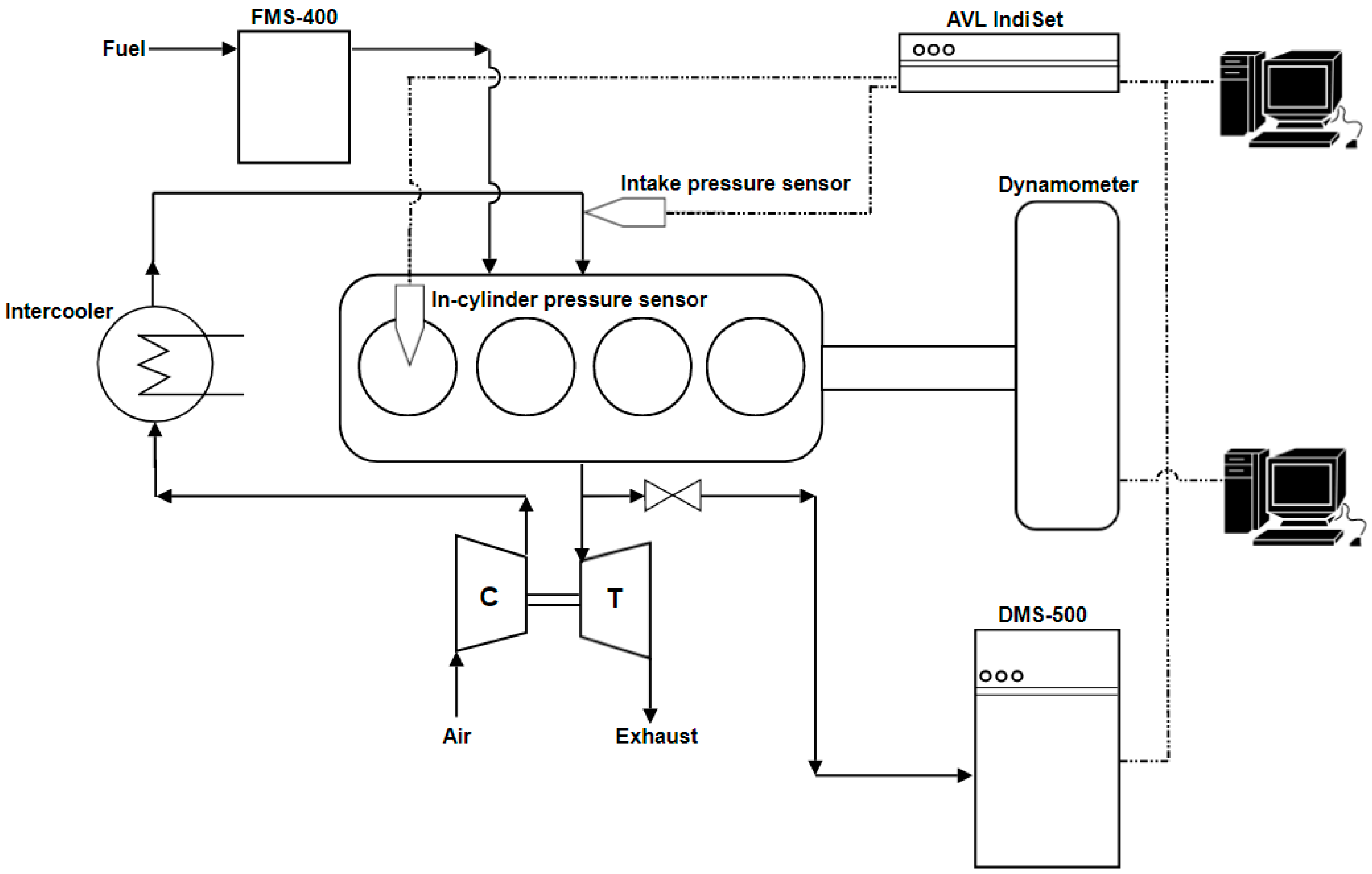

2. Experimental Setup and Methodology

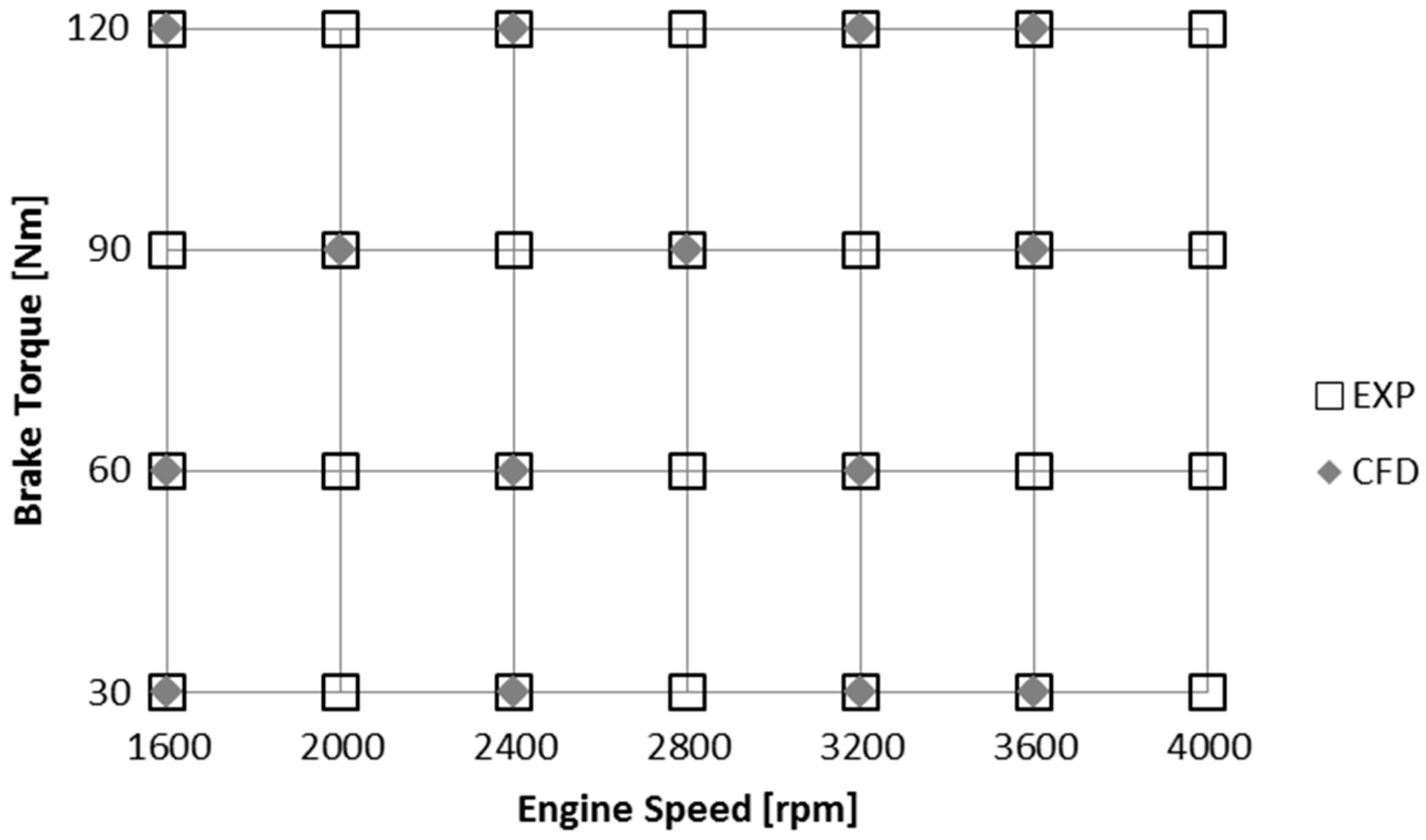

Computational Fluid Dynamics Modelling

3. Results and Discussion

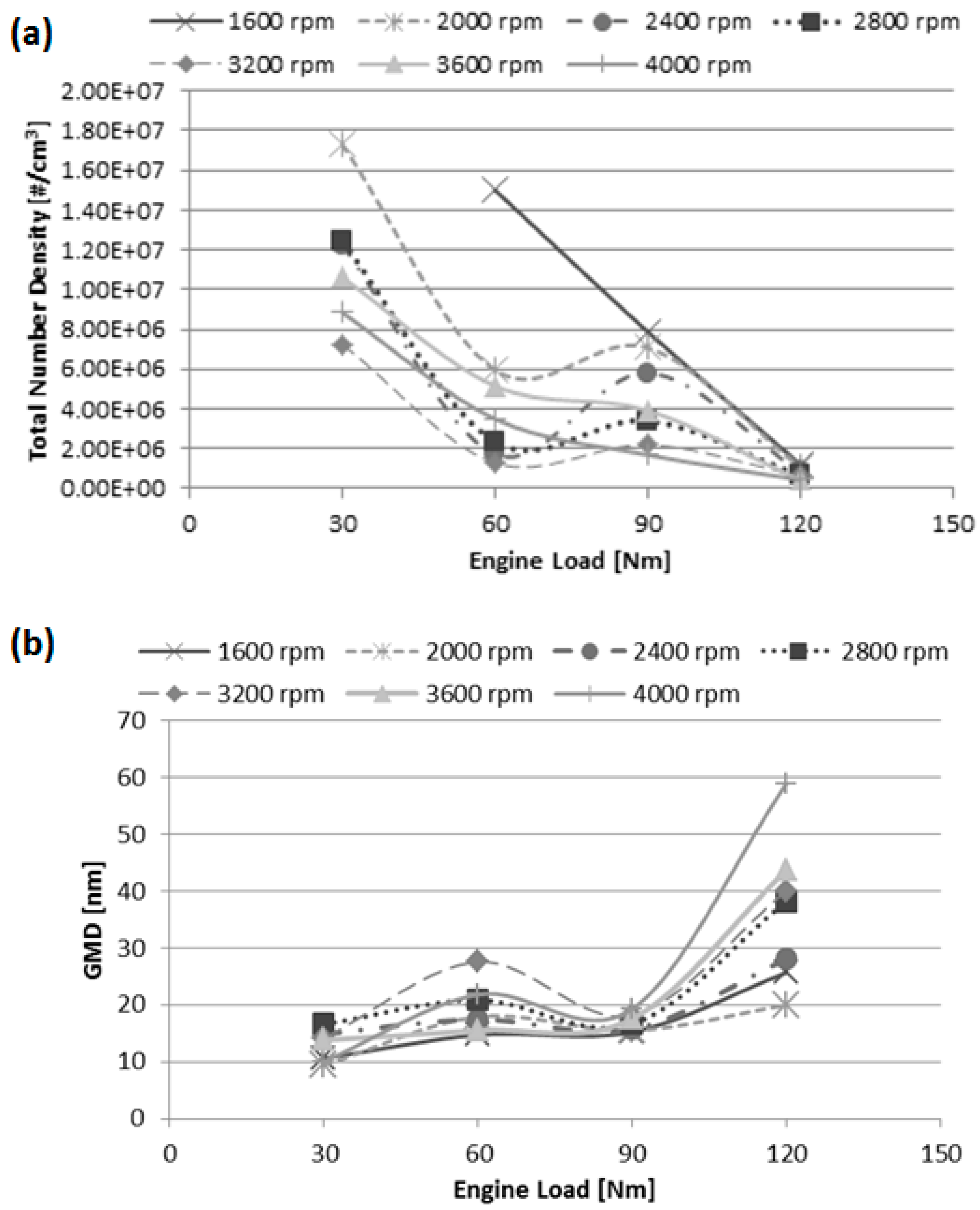

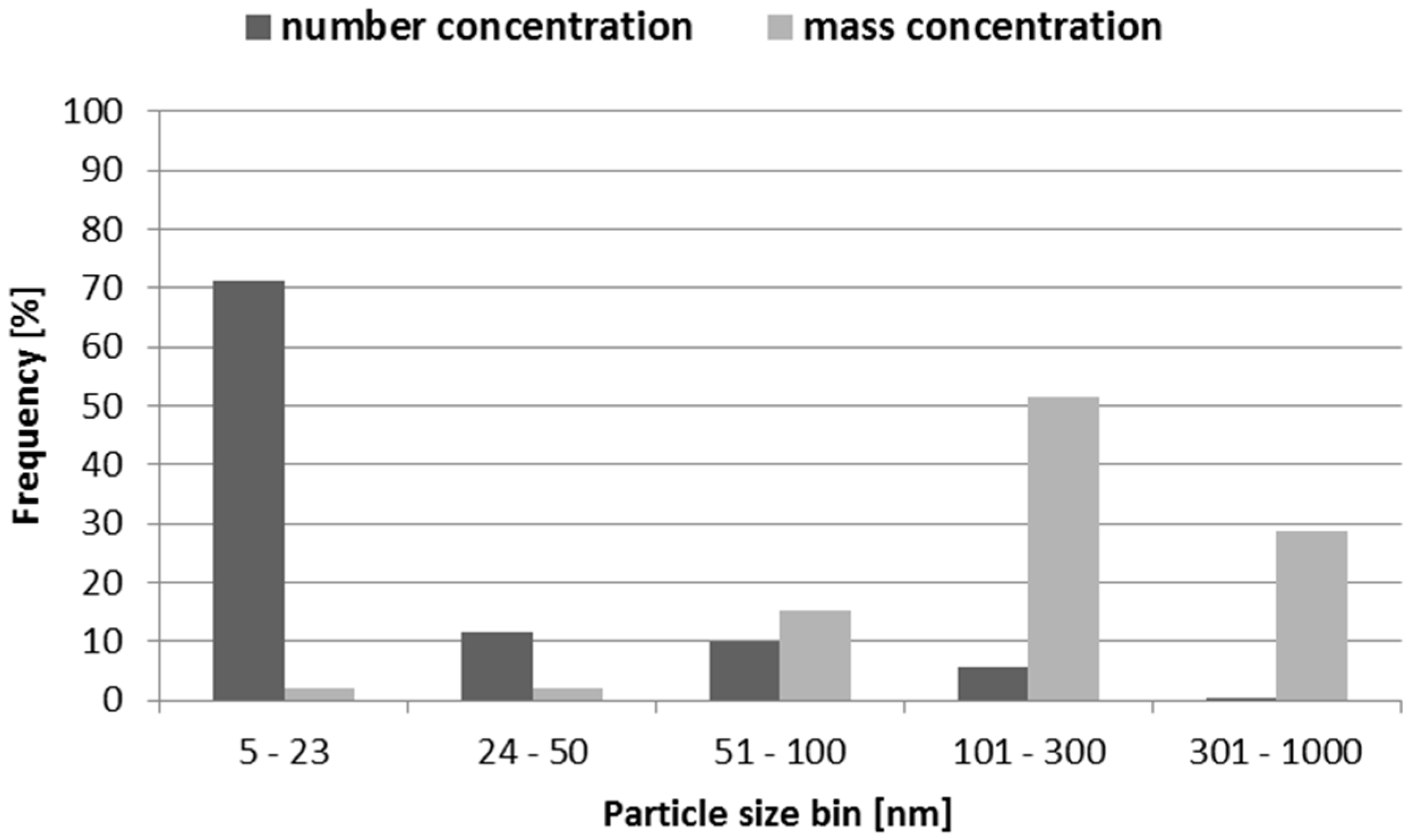

3.1. Particulate Matter Characterisation

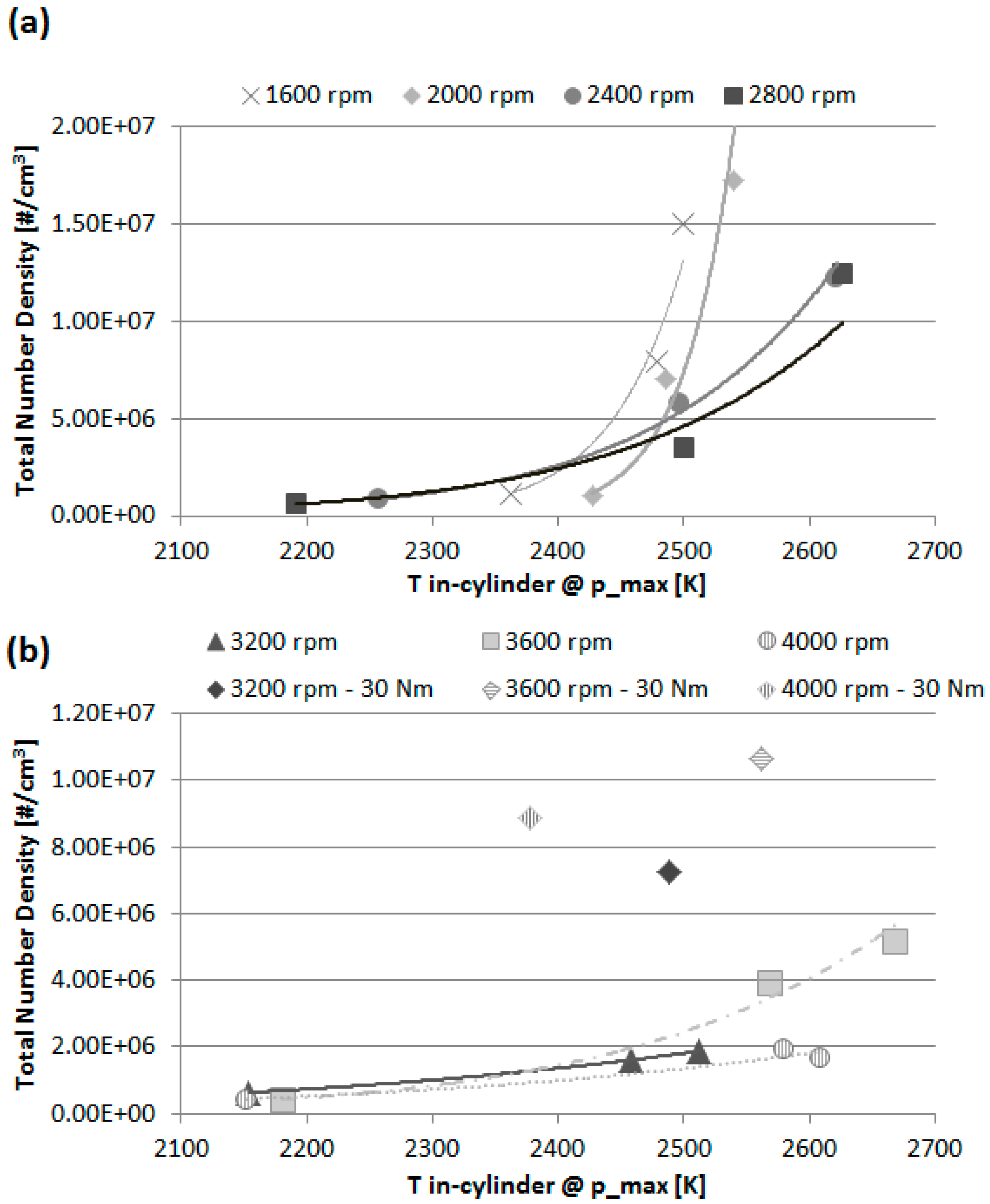

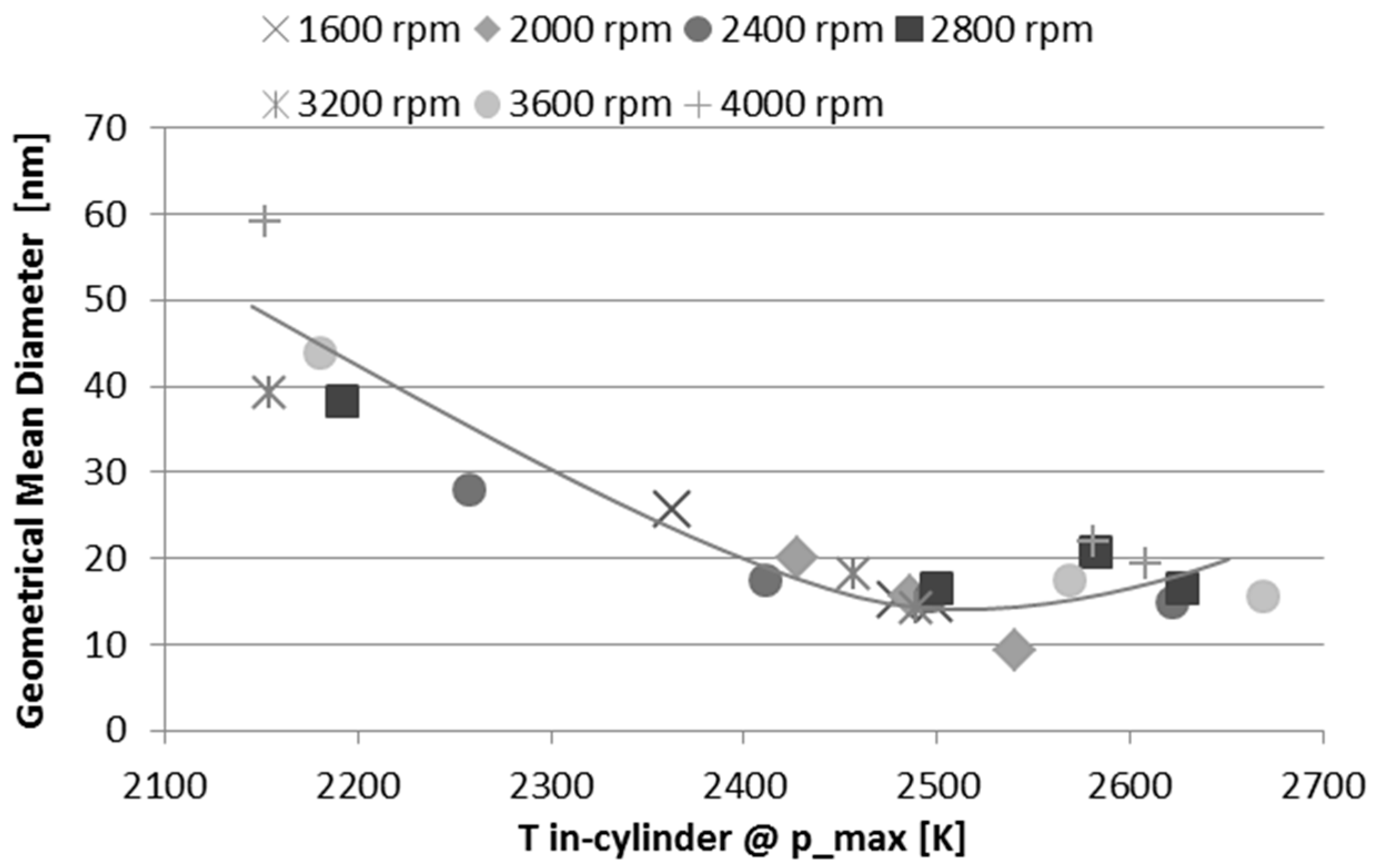

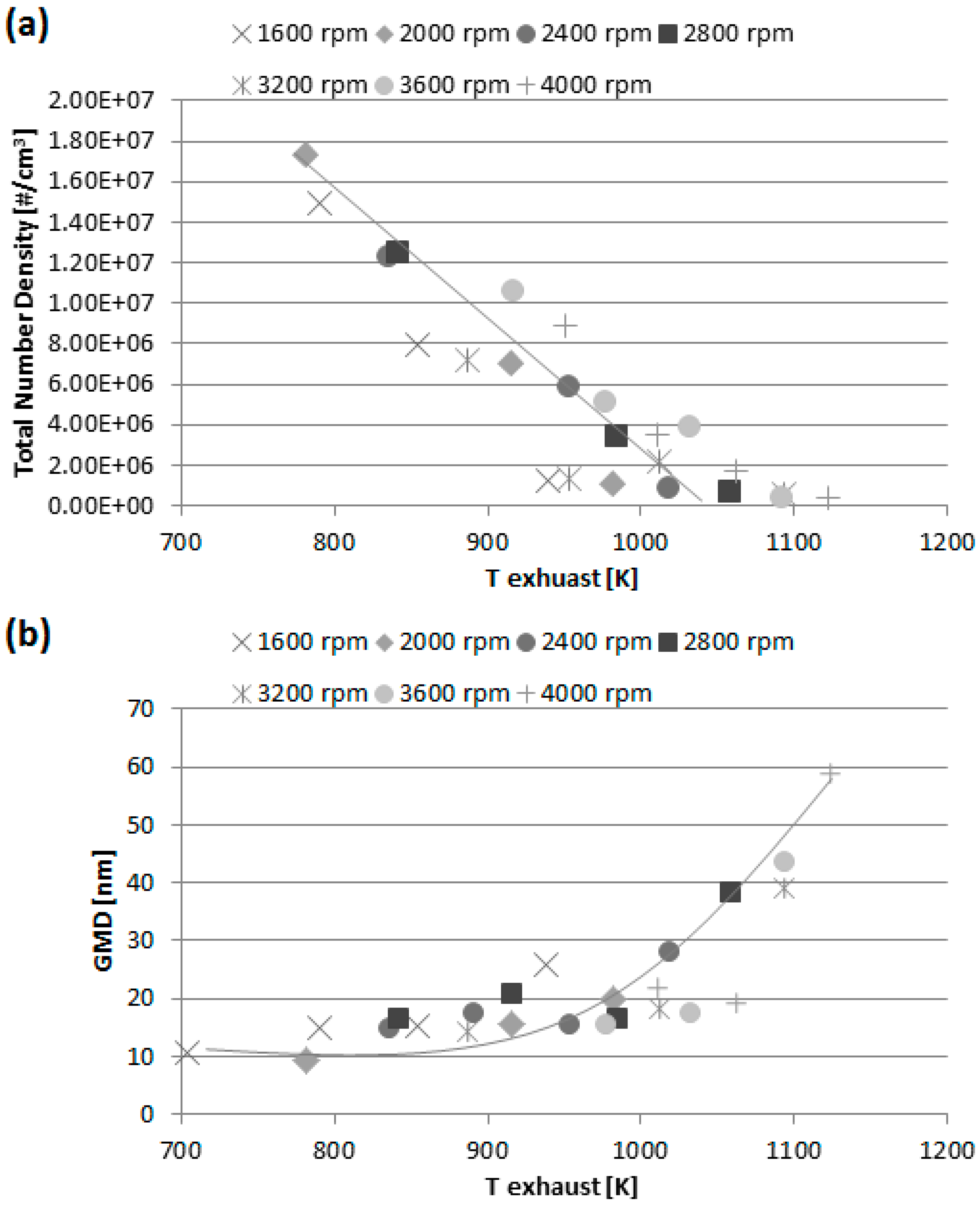

3.2. Apparent Correlation with Gas Temperature

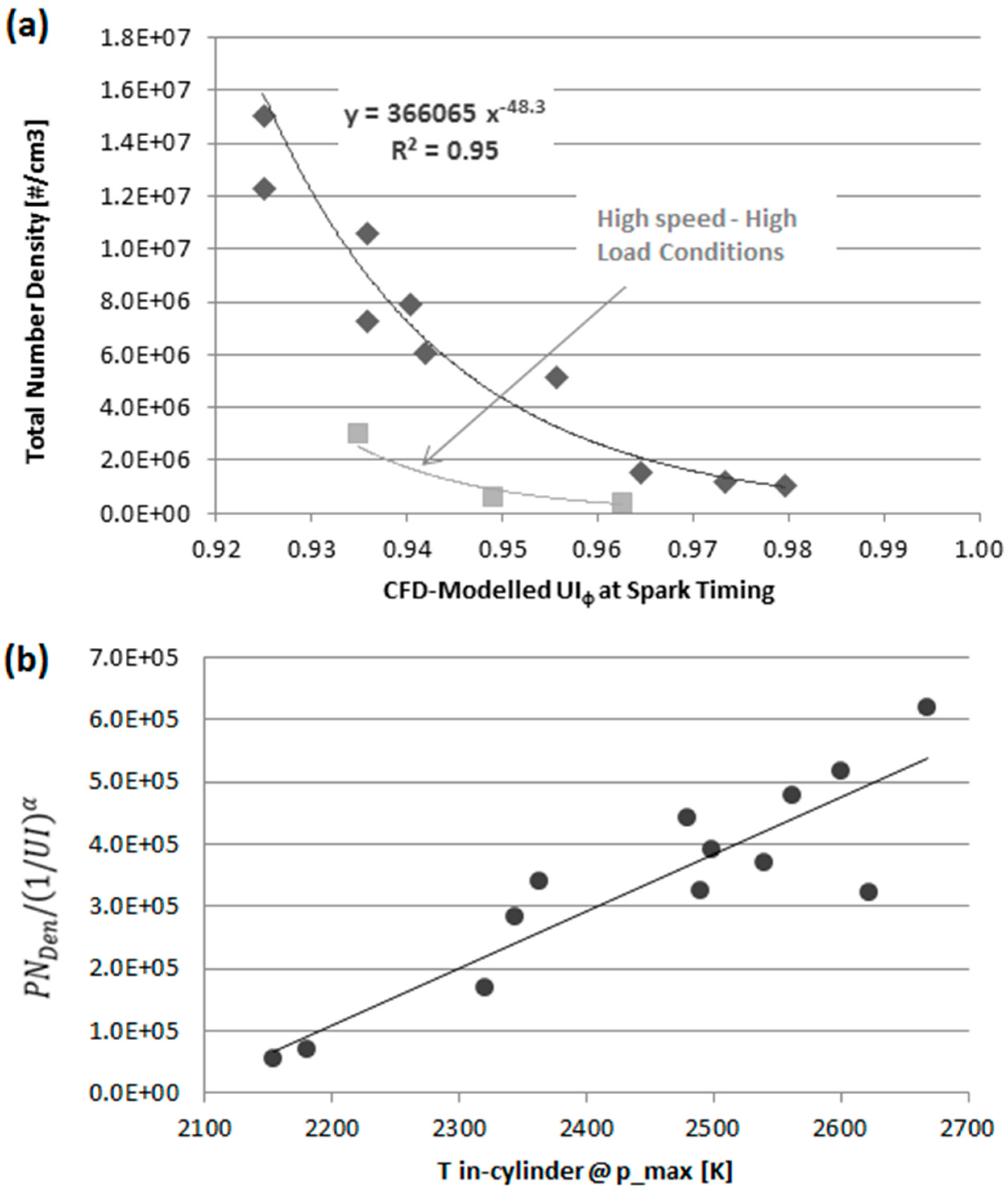

3.3. Correlation between Charge Homogeneity and Particle Number Density

4. Conclusions

- The analysis of size-resolved particle number density distributions reveals a mostly bi-modal functional form, featuring much greater levels in nucleation mode (<50 nm). In the lowest sooting conditions (engine load of 120 Nm and speed of 3600 rpm and above), the distributions present mono-modal form with peak located at the high end of nucleation mode interval.

- Increases in engine speed and load lead to lower particle number densities and larger size. The effect of engine load is more pronounced and results from greater injection pressure which improves charge homogeneity through better fuel atomisation.

- The total PNDen varies between 1.7 × 107 and 4.0 × 105 particles/cm3, showing larger dependence on engine speed at low load and lower dependence at higher load. The results suggest that both improved mixture preparation and lower peak combustion temperature contribute to the reduction in particle number concentration as engine speed and load increase.

- The GMD varies between 10 and 60 nm. Conversely to PNDen, GMD shows low dependence on engine speed at low load and greater dependence at higher load. Stronger particle coagulation and lower oxidation may contribute to greater particle size as engine speed and load increase.

- 72% of particles are emitted on average in the 5–23 nm size range, while over 80% falls in the nucleation mode range. Only 10% of particles are emitted in accumulation mode (51–100 nm). The very high frequencies in the sub-23 nm range expose potential limitations of the incoming EU6c/d emission regulations, which do not consider particles below this threshold.

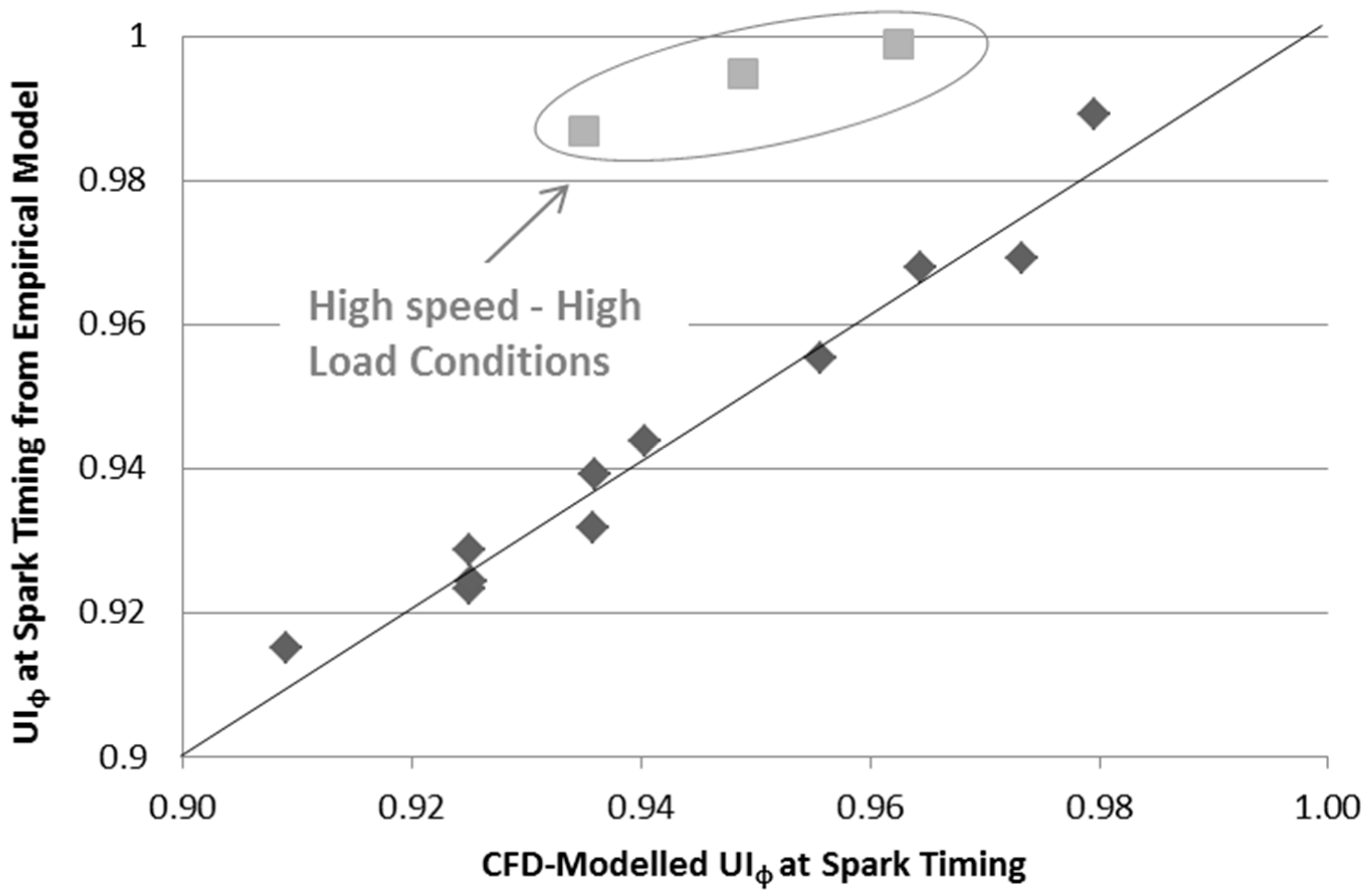

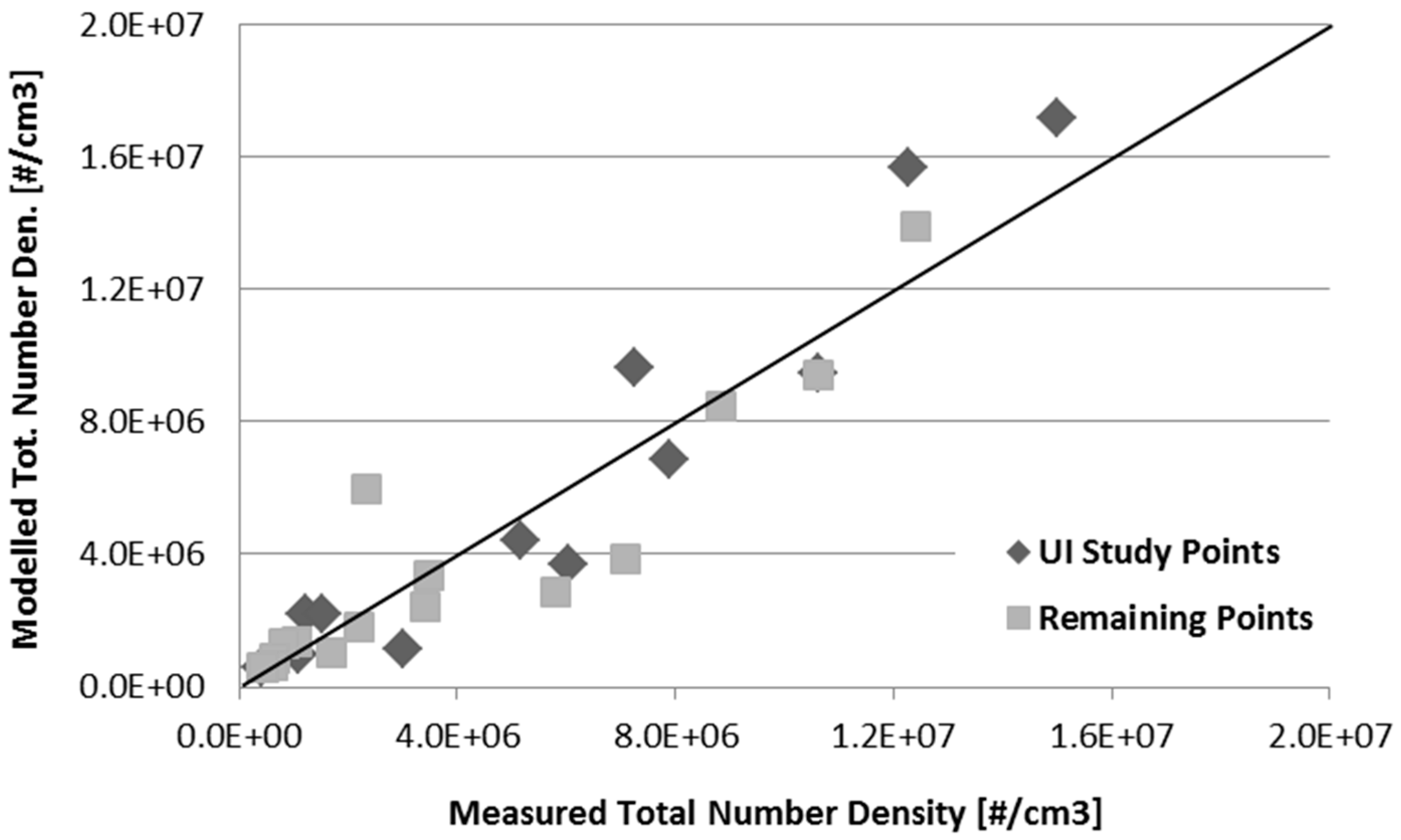

- The volume-based uniformity index of equivalence ratio (UIφ) was calculated through a limited number of CFD simulations of the test-engine, and used as an indication of the effectiveness of the mixture preparation process. A strong power-law type correlation exists between PNDen and UIφ calculated at spark timing. Relatively small increases in charge homogeneity of the order of 6% are associated to large reductions of total particle number density of approximately one order of magnitude.

- A strong correlation can also be identified between PNDen and modelled ideal-gas temperature at the location of peak combustion pressure. Reducing temperature between 2650 K and 2150 K would lead, dependent on engine running conditions, to a three to five-fold increase in average size, as well as to 90% reduction in total number density.

- A simple two-equation functional model was developed which returns satisfactory qualitative predictions of total PNDen as a function of basic engine control variables. The initial model is unsophisticated and requires engine-specific calibration and further improvement; nevertheless, the approach identifies a potential effective route to perform real-time control of soot number output in modern GDI engines. Future work by the Authors will focus on improving this model and explore further potential correlations existing between engine varibales and average particle size.

Author Contributions

Conflicts of Interest

Nomenclature

| AFR | Air Fuel Ratio |

| ATDC | After Top Dead Centre |

| BDC | Bottom Dead Centre |

| BMEP | Brake Mean Effective Pressure |

| BTDC | Before Top Death Centre |

| CA | Crank Angle |

| CF | Conformity Factors |

| CFD | Computational Fluid Dynamics |

| DMS | Differential Mobility Spectrometer |

| ECU | Engine Control Unit |

| EGR | Exhaust Gas Recirculation |

| EOI | End of Injection |

| EU | European Union |

| FMS | Fuel Measurement System |

| GDI | Gasoline Direct Injection |

| GMD | Geometrical Mean Diameter |

| GPF | Gasoline Particulate Filters |

| IMEP | Indicated Mean Effective Pressure |

| IVO | Intake Valve Opening |

| PAH | Polycyclic Aromatic Hydrocarbons |

| PEMS | Portable Emission Measuring System |

| PM | Particulate Matter |

| PMP | Particle Measurement Programme |

| PNDen | Particle Number Density |

| RDE | Real Driving Emission |

| RMSE | Root Mean Square Error |

| RON | Research Octane Number |

| SMD | Sauter Mean Diameter |

| SOI | Start of Injection |

| ST | Spark Timing |

| TDC | Top Dead Centre |

| uHC | Unburned Hydrocarbons |

| UIϕ | Uniformity Index of Equivalence Ratio |

| VVT | Variable Valve Timing |

| WLTC | Worldwide Harmonized Light Duty Vehicles Test Cycle |

References

- Han, D.; Han, S.-K.; Han, B.-H.; Kim, W.-T. Development of 2.0 L Turbocharged DISI Engine for Downsizing Application; SAE Technical Paper 2007-01-0259; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Bonatesta, F.; Altamore, G.; Kalsi, J.; Cary, M. Fuel economy analysis of part-load variable camshaft timing strategies in two modern small-capacity spark ignition engines. Appl. Energy 2016, 164, 475–491. [Google Scholar] [CrossRef]

- Kleeberg, H.; Tomazic, D.; Lang, O.; Habermann, K. Future Potential and Development Methods for High Output Turbocharged Direct Injected Gasoline Engines; SAE Technical Paper 2006-01-0046; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Anderson, J.O.; Thundiyil, J.G.; Stolbach, A. Clearing the air: A review of the effects of particulate matter air pollution on human health. J. Med. Toxicol. 2012, 8, 166–175. [Google Scholar] [CrossRef] [PubMed]

- Raaschou-Nielsen, O.; Andersen, Z.J.; Beelen, R.; Samoli, E.; Stafoggia, M.; Weinmayr, G.; Hoffmann, B.; Fischer, P.; Nieuwenhuijsen, M.J.; Brunekreef, B. Air pollution and lung cancer incidence in 17 European cohorts: Prospective analyses from the European Study of Cohorts for Air Pollution Effects (ESCAPE). Lancet Oncol. 2013, 14, 813–822. [Google Scholar] [CrossRef]

- World Health Organization. The World Health Report 2002: Reducing Risks, Promoting Healthy Life; World Health Organization: Geneva, Switzerland, 2002. [Google Scholar]

- Demuynck, J.; Favre, C.; Bosteels, D.; Hamje, H.; Andersson, J. Real-World Emissions Measurements of a Gasoline Direct Injection Vehicle without and with a Gasoline Particulate Filter; SAE Technical Paper 2017-01-0985; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Wolff, H.; Perry, L. Policy Monitor: Trends in Clean Air Legislation in Europe: Particulate Matter and Low Emission Zones. Rev. Environ. Econ. Policy 2010, 4, 293–308. [Google Scholar] [CrossRef]

- Piock, W.; Hoffmann, G.; Berndorfer, A.; Salemi, P.; Fusshoeller, B. Strategies towards meeting future particulate matter emission requirements in homogeneous gasoline direct injection engines. SAE Int. J. Engines 2011, 4, 1455–1468. [Google Scholar] [CrossRef]

- Velji, A.; Yeom, K.; Wagner, U.; Spicher, U.; Roßbach, M.; Suntz, R.; Bockhorn, H. Investigations of the Formation and Oxidation of Soot inside a Direct Injection Spark Ignition Engine Using Advanced Laser-Techniques; SAE Technical Paper 2010-01-0352; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Jiao, Q.; Reitz, R.D. The effect of operating parameters on soot emissions in GDI engines. SAE Int. J. Engines 2015, 8, 1322–1333. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Manfredi, U.; Martini, G. Engine exhaust solid sub-23 nm particles: I. Literature survey. SAE Int. J. Fuels Lubr. 2014, 7, 950–964. [Google Scholar] [CrossRef]

- Bonatesta, F.; Chiappetta, E.; La Rocca, A. Part-load particulate matter from a GDI engine and the connection with combustion characteristics. Appl. Energy 2014, 124, 366–376. [Google Scholar] [CrossRef]

- Price, P.; Stone, R.; Collier, T.; Davies, M. Particulate Matter and Hydrocarbon Emissions Measurements: Comparing First and Second Generation DISI with PFI in Single Cylinder Optical Engines; SAE Technical Paper 2006-01-1263; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Kittelson, D.B.; Arnold, M.; Watts, W. Review of Diesel Particulate Matter Sampling Methods: Final Report; University of Minnesota: Minneapolis, MN, USA, 1999. [Google Scholar]

- La Rocca, A.; Bonatesta, F.; Fay, M.; Campanella, F. Characterisation of soot in oil from a gasoline direct injection engine using Transmission Electron Microscopy. Tribol. Int. 2015, 86, 77–84. [Google Scholar] [CrossRef]

- Johansson, A.N.; Hemdal, S.; Dahlander, P. Experimental Investigation of Soot in a Spray-Guided Single Cylinder GDI Engine Operating in a Stratified Mode; SAE Technical Paper 2013-24-0052; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Andersson, J.; Collier, A.; Wedekind, B. Particle and Sulphur Species as Key Issue in Gasoline Direct Injection Diesel Exhaust; JSAE Technical Paper; Society of Automotive Engineers: Tokyo, Japan, 1999. [Google Scholar]

- Wang, X.; Huang, Z.; Zhang, W.; Kuti, O.A.; Nishida, K. Effects of ultra-high injection pressure and micro-hole nozzle on flame structure and soot formation of impinging diesel spray. Appl. Energy 2011, 88, 1620–1628. [Google Scholar] [CrossRef]

- Peckham, M.S.; Finch, A.; Campbell, B.; Price, P.; Davies, M.T. Study of Particle Number Emissions from a Turbocharged Gasoline Direct Injection (GDI) Engine Including Data from a Fast-Response Particle Size Spectrometer; SAE Technical Paper 2011-01-1224; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Sabathil, D.; Koenigstein, A.; Schaffner, P.; Fritzsche, J.; Doehler, A. The Influence of DISI Engine Operating Parameters on Particle Number Emissions; SAE Technical Paper 2011-01-0143; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Maricq, M.M.; Podsiadlik, D.H.; Brehob, D.D.; Haghgooie, M. Particulate Emissions from a Direct-Injection Spark-Ignition (DISI) Engine; SAE Technical Paper 1999-01-1530; SAE International: Warrendale, PA, USA, 1999. [Google Scholar]

- Pei, Y.-Q.; Qin, J.; Pan, S.-Z. Experimental study on the particulate matter emission characteristics for a direct-injection gasoline engine. Proc. Inst. Mech. Eng. Part D J. Autom. Eng. 2014, 228, 604–616. [Google Scholar] [CrossRef]

- Farron, C.; Matthias, N.; Foster, D.E.; Andrie, M.; Krieger, R.; Najt, P.; Narayanaswamy, K.; Solomon, A.; Zelenyuk, A. Particulate Characteristics for Varying Engine Operation in a Gasoline Spark Ignited, Direct Injection Engine; SAE Technical Paper 2011-01-1220; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Giovannoni, N.; Breda, S.; Paltrinieri, S.; D’Adamo, A.; Fontanesi, S.; Pulvirenti, F. CFD Analysis of the Effects of Fuel Composition and Injection Strategy on Mixture Preparation and Fuel Deposit Formation in a GDI Engine; SAE Technical Paper 2015-24-2408; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Choi, K.; Kim, J.; Myung, C.-L.; Lee, M.; Kwon, S.; Lee, Y.; Park, S. Effect of the mixture preparation on the nanoparticle characteristics of gasoline direct-injection vehicles. Proc. Inst. Mech. Eng. Part D J. Autom. Eng. 2012, 226, 1514–1524. [Google Scholar] [CrossRef]

- Barone, T.L.; Storey, J.M.; Youngquist, A.D.; Szybist, J.P. An analysis of direct-injection spark-ignition (DISI) soot morphology. Atmos. Environ. 2012, 49, 268–274. [Google Scholar] [CrossRef]

- Kayes, D.; Hochgreb, S. Mechanisms of particulate matter formation in spark-ignition engines. 1. Effect of engine operating conditions. Environ. Sci. Technol. 1999, 33, 3957–3967. [Google Scholar] [CrossRef]

- Huang, Y.; Hong, G.; Huang, R. Numerical investigation to the dual-fuel spray combustion process in an ethanol direct injection plus gasoline port injection (EDI + GPI) engine. Energy Convers. Manag. 2015, 92, 275–286. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Z.; Gong, W.; Liang, Z. Quantifying the effects of fuel compositions on GDI-derived particle emissions using the optimal mixture design of experiments. Fuel 2015, 154, 252–260. [Google Scholar] [CrossRef]

- Wang, C.; Xu, H.; Herreros, J.M.; Wang, J.; Cracknell, R. Impact of fuel and injection system on particle emissions from a GDI engine. Appl. Energy 2014, 132, 178–191. [Google Scholar] [CrossRef]

- Di Iorio, S.; Lazzaro, M.; Sementa, P.; Vaglieco, B.M.; Catapano, F. Particle Size Distributions from a DI High Performance SI Engine Fuelled with Gasoline-Ethanol Blended Fuels; SAE Technical Paper 2011-24-0211; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Daniel, R.; Tian, G.; Xu, H.; Wyszynski, M.L.; Wu, X.; Huang, Z. Effect of spark timing and load on a DISI engine fuelled with 2,5-dimethylfuran. Fuel 2011, 90, 449–458. [Google Scholar] [CrossRef]

- Catapano, F.; Di Iorio, S.; Lazzaro, M.; Sementa, P.; Vaglieco, B.M. Characterization of Ethanol Blends Combustion Processes and Soot Formation in a GDI Optical Engine; SAE Technical Paper 2013-01-1316; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Bermúdez, V.; Luján, J.M.; Climent, H.; Campos, D. Assessment of pollutants emission and aftertreatment efficiency in a GTDi engine including cooled LP-EGR system under different steady-state operating conditions. Appl. Energy 2015, 158, 459–473. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, Y.; Jun, S.; Lee, K.H.; Rew, S.; Lee, D.; Park, S. Strategies for Particle Emissions Reduction from GDI Engines; SAE Technical Paper 2013-01-1556; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Hemdal, S.; Andersson, M.; Dahlander, P.; Ochoterena, R.; Denbratt, I. In-cylinder soot imaging and emissions of stratified combustion in a spark-ignited spray-guided direct-injection gasoline engine. Int. J. Engine Res. 2011, 12, 549–563. [Google Scholar] [CrossRef]

- Kim, J.; Kim, N.; Min, K. Numerical Investigation of Soot Emission in Direct-Injection Spark-Ignition Engines Using a Detailed Soot Model Framework; SAE Technical Paper 2016-01-0580; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Bonatesta, F.; Hopkins, E.; Francavilla, C.; Bell, D.; La Rocca, A. Combustion and Particulate Matter Formation in Modern GDI Engines: A Modelling Study Using CFD. In Proceedings of the FISITA 2016 World Automotive Congress, Busan, Korea, 26–30 September 2016; pp. 1–13. [Google Scholar]

- Jiao, Q.; Reitz, R.D. Modeling of Equivalence Ratio Effects on Particulate Formation in a Spark-Ignition Engine under Premixed Conditions; SAE Technical Paper 2014-01-1607; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Lucchini, T.; D’Errico, G.; Onorati, A.; Bonandrini, G.; Venturoli, L.; Di Gioia, R. Development and application of a computational fluid dynamics methodology to predict fuel-air mixing and sources of soot formation in gasoline direct injection engines. Int. J. Engine Res. 2014, 15, 581–596. [Google Scholar] [CrossRef]

- Mason, B.; Bradley, W.; Pezouvanis, A.; Ebrahimi, K. Repeatable steady-state measurement of particulate number emissions in engine experiments. Int. J. Engine Res. 2016, 17, 1108–1117. [Google Scholar] [CrossRef]

- Malaguti, S.; Fontanesi, S.; Cantore, G. Numerical characterization of a new high-pressure multi-hole GDI injector. In Proceedings of the ILASS-Europe 2010, 23rd Annual Conference on Liquid Atomization and Spray Systems, Brno, Czech Republic, 6–9 September 2010. [Google Scholar]

- Wang, Y. Validation of an Existing Mechanism for N-Heptane, Iso-Octane and Toluene Reference Fuels; Brandenburgische Technische Universitat: Cottbus, Germany, 2015. [Google Scholar]

- Star-CD. Star-CD Methodology Manual, version 4.22; CD-Adapco Siemens PLM: Detroit, MI, USA, 2014. [Google Scholar]

- Malaguti, S.; Bagli, G.; Montanaro, A.; Piccinini, S.; Allocca, L. Experimental and Numerical Characterization of Gasoline-Ethanol Blends from a GDI Multi-Hole injector by Means of Multi-Component Approach; SAE Technical Paper 2013-24-0002; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Rosa, N.G.; Villedieu, P.; Dewitte, J.; Lavergne, G. A new droplet-wall interaction model. In Proceedings of the 10th International Conference on Liquid Atomization and Spray Systems, Tokyo, Japan, 27 August–1 September 2006; pp. 29–32. [Google Scholar]

- Semiao, V.; Andrade, P.; da GraCa Carvalho, M. Spray characterization: Numerical prediction of Sauter mean diameter and droplet size distribution. Fuel 1996, 75, 1707–1714. [Google Scholar] [CrossRef]

- Huang, C.; Lipatnikov, A. Modelling of Gasoline and Ethanol Hollow-Cone sprays Using OpenFOAM; SAE Technical Paper 2011-01-1896; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Montanaro, A.; Allocca, L.; Ettorre, D.; Lucchini, T.; Brusiani, F.; Cazzoli, G. Experimental characterization of high-pressure impinging sprays for CFD modeling of GDI engines. SAE Int. J. Engines 2011, 4, 747–763. [Google Scholar] [CrossRef]

- Yi, Y.; DeMinco, C.M. Numerical Investigation of Mixture Preparation in a GDI Engine; SAE Technical Paper 2006-01-3375; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Whelan, I.C. A Study of Particulate Matter Emissions from Gasoline Direct Injection Engines; University College Dublin: Dublin, Ireland, 2013. [Google Scholar]

- Bonatesta, F.; La Rocca, S.; Hopkins, E.; Bell, D. Application of Computational Fluid Dynamics to Explore the Sources of Soot Formation in a Gasoline Direct Injection Engine; SAE Technical Paper 2014-01-2569; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Mätzing, H.; Baumann, W.; Bockhorn, H.; Paur, H.-R.; Seifert, H. Detection of electrically charged soot particles in laminar premixed flames. Combust. Flame 2012, 159, 1082–1089. [Google Scholar] [CrossRef]

- Wong, D.; Whitesides, R.; Schuetz, C.; Frenklach, M.; Bockhorn, H.; D’Anna, A.; Sarofim, A.; Wang, H. Combustion Generated Fine Carbonaceous Particles; KIT Scientific Publishing: Karlsruhe, Germany, 2007; pp. 275–285. [Google Scholar]

- Xu, Z.; Li, X.; Guan, C.; Huang, Z. Effects of injection timing on exhaust particle size and nanostructure on a diesel engine at different loads. J. Aerosol Sci. 2014, 76, 28–38. [Google Scholar] [CrossRef]

| Characteristic | Units | Value/Description |

|---|---|---|

| Bore | mm | 77 |

| Stroke | mm | 85.8 |

| Compression ratio | - | 10.5:1 |

| Connecting Rod Length | mm | 138.4 |

| Combustion chamber | - | 4-Valve, central spark plug, pent-roof design |

| Engine type | - | In-line 4-cylinder |

| Cycle | - | 4-Stroke spark ignition |

| Fuel injector system | - | Direct injection common rail |

| Fuel injectors | - | Side-mounted, wall-guided spray |

| Maximum injection pressure | bar | 120 |

| Characteristic/Component | Units | Min | Max |

|---|---|---|---|

| RON | - | 95 | - |

| MON | - | 85 | - |

| Aromatics | vol % | 29 | 35 |

| Olefins | vol % | 3 | 13 |

| Saturates | vol % | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sciortino, D.D.; Bonatesta, F.; Hopkins, E.; Yang, C.; Morrey, D. A Combined Experimental and Computational Fluid Dynamics Investigation of Particulate Matter Emissions from a Wall-Guided Gasoline Direct Injection Engine. Energies 2017, 10, 1408. https://doi.org/10.3390/en10091408

Sciortino DD, Bonatesta F, Hopkins E, Yang C, Morrey D. A Combined Experimental and Computational Fluid Dynamics Investigation of Particulate Matter Emissions from a Wall-Guided Gasoline Direct Injection Engine. Energies. 2017; 10(9):1408. https://doi.org/10.3390/en10091408

Chicago/Turabian StyleSciortino, Davide D., Fabrizio Bonatesta, Edward Hopkins, Changho Yang, and Denise Morrey. 2017. "A Combined Experimental and Computational Fluid Dynamics Investigation of Particulate Matter Emissions from a Wall-Guided Gasoline Direct Injection Engine" Energies 10, no. 9: 1408. https://doi.org/10.3390/en10091408