Wire Structure Heat Exchangers—New Designs for Efficient Heat Transfer

Abstract

:1. Introduction

2. Results

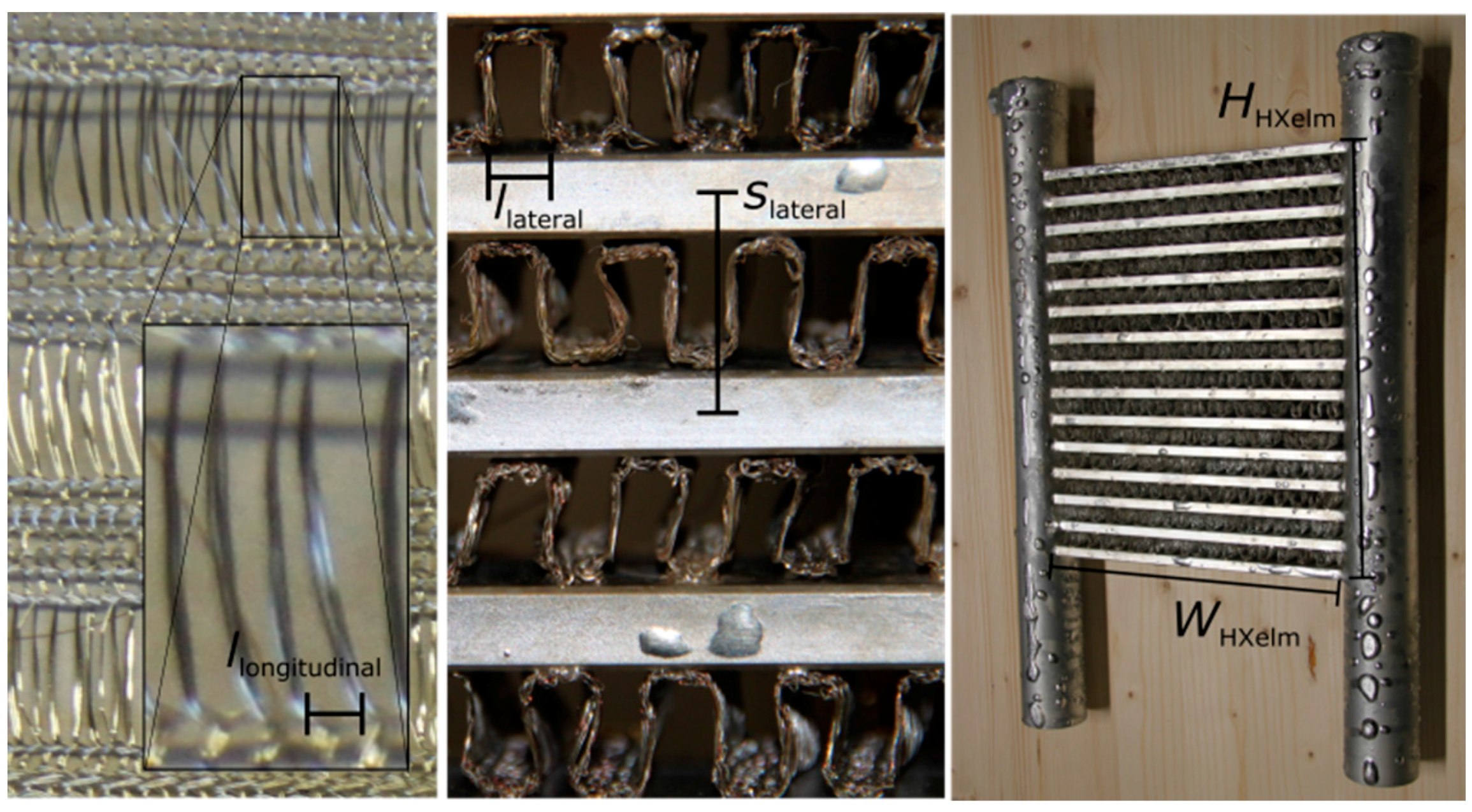

2.1. Manufacture of Samples

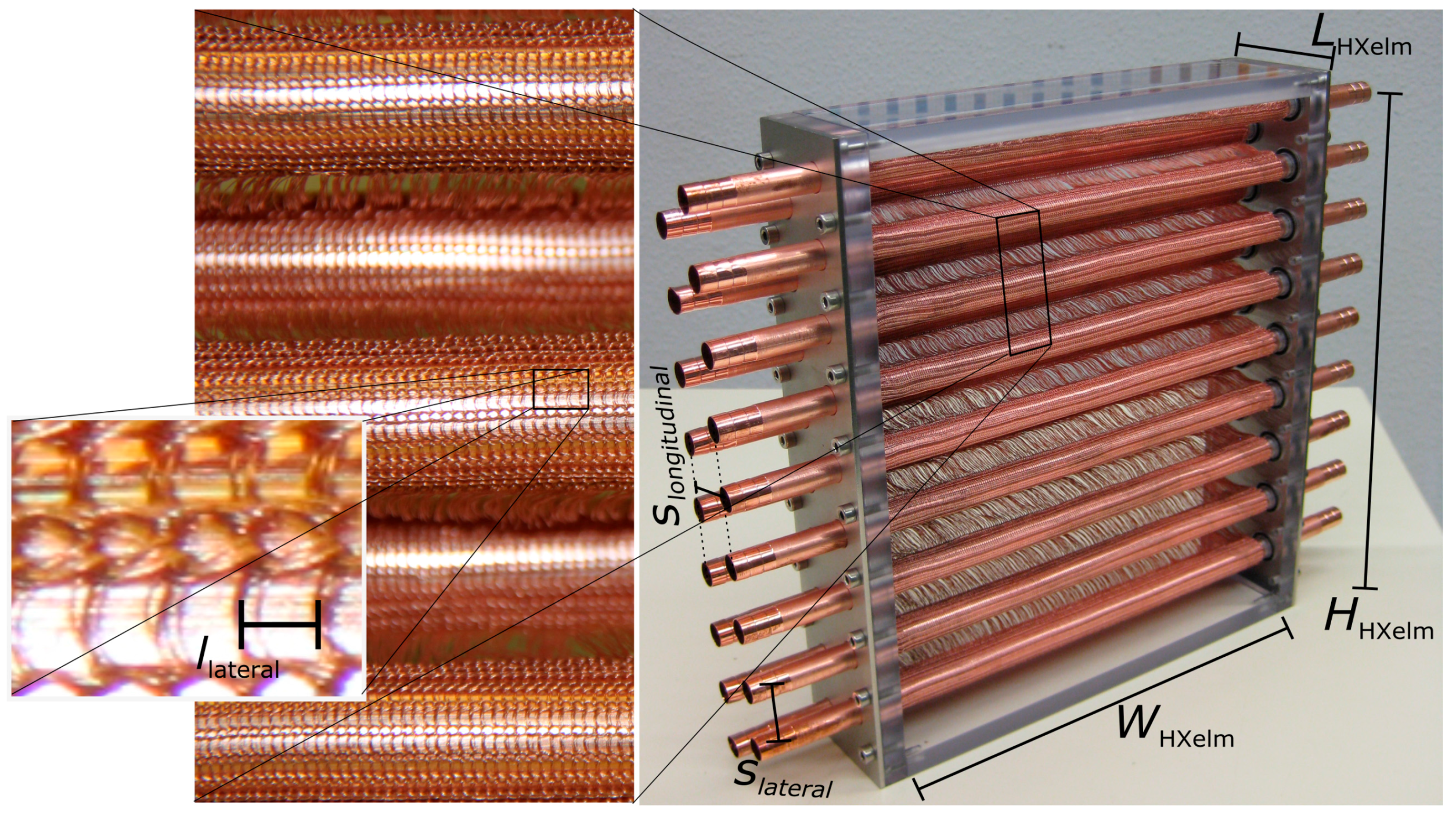

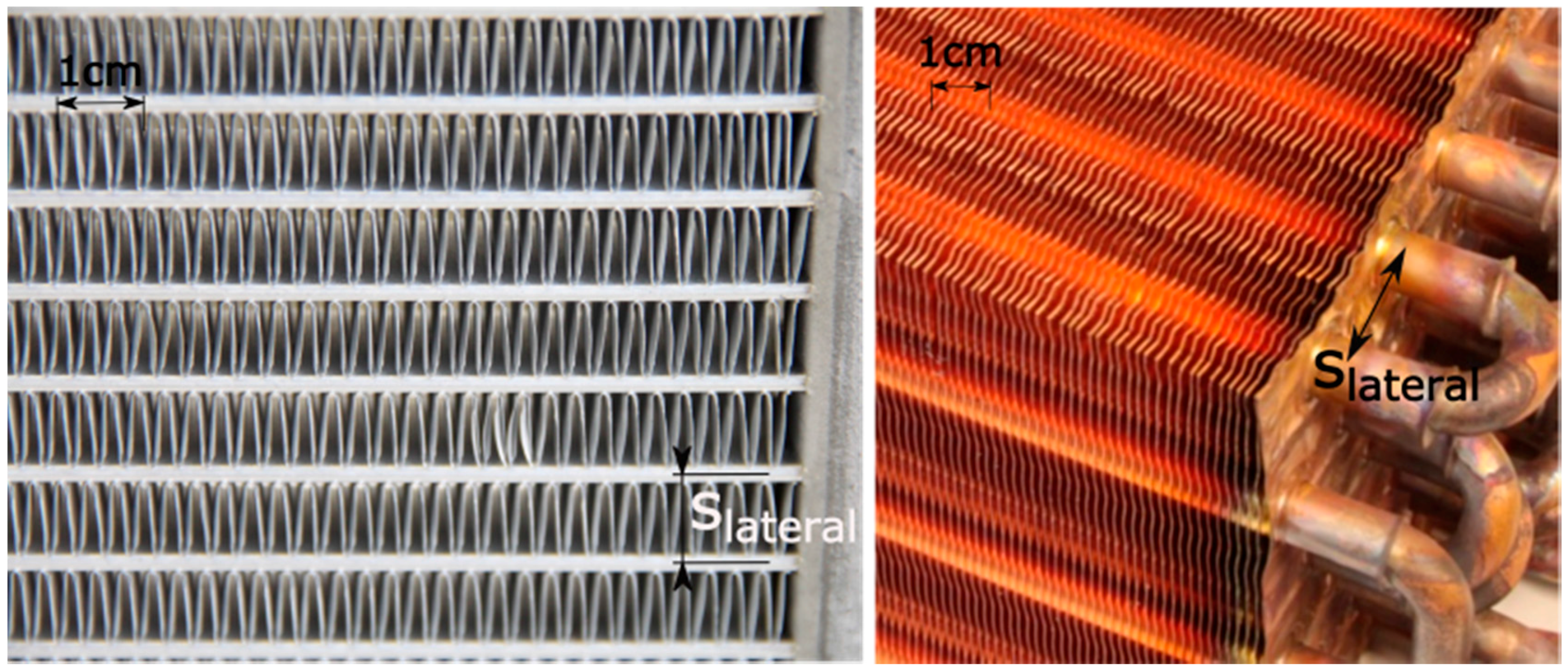

2.1.1. The Round Tube Wire Heat Exchanger

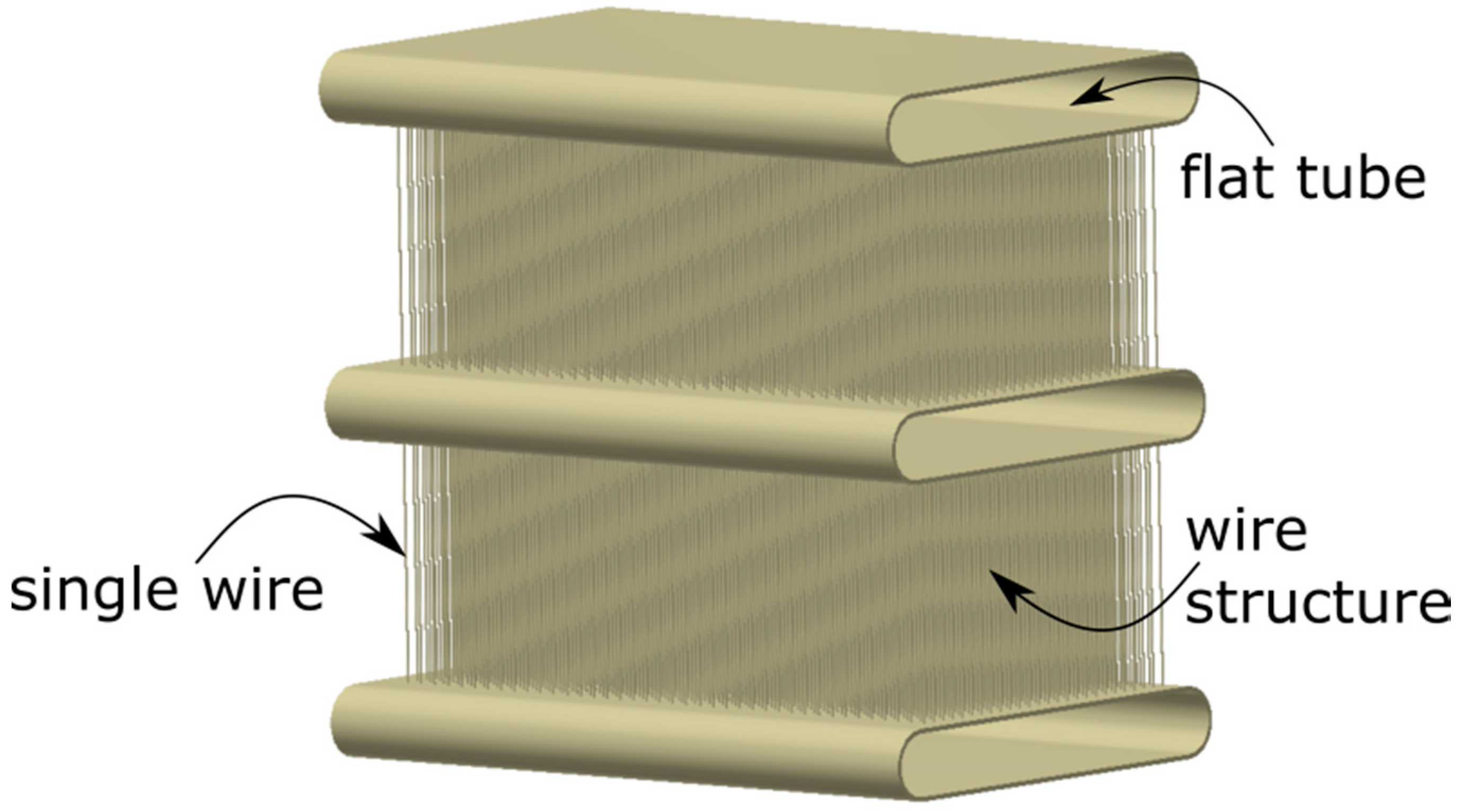

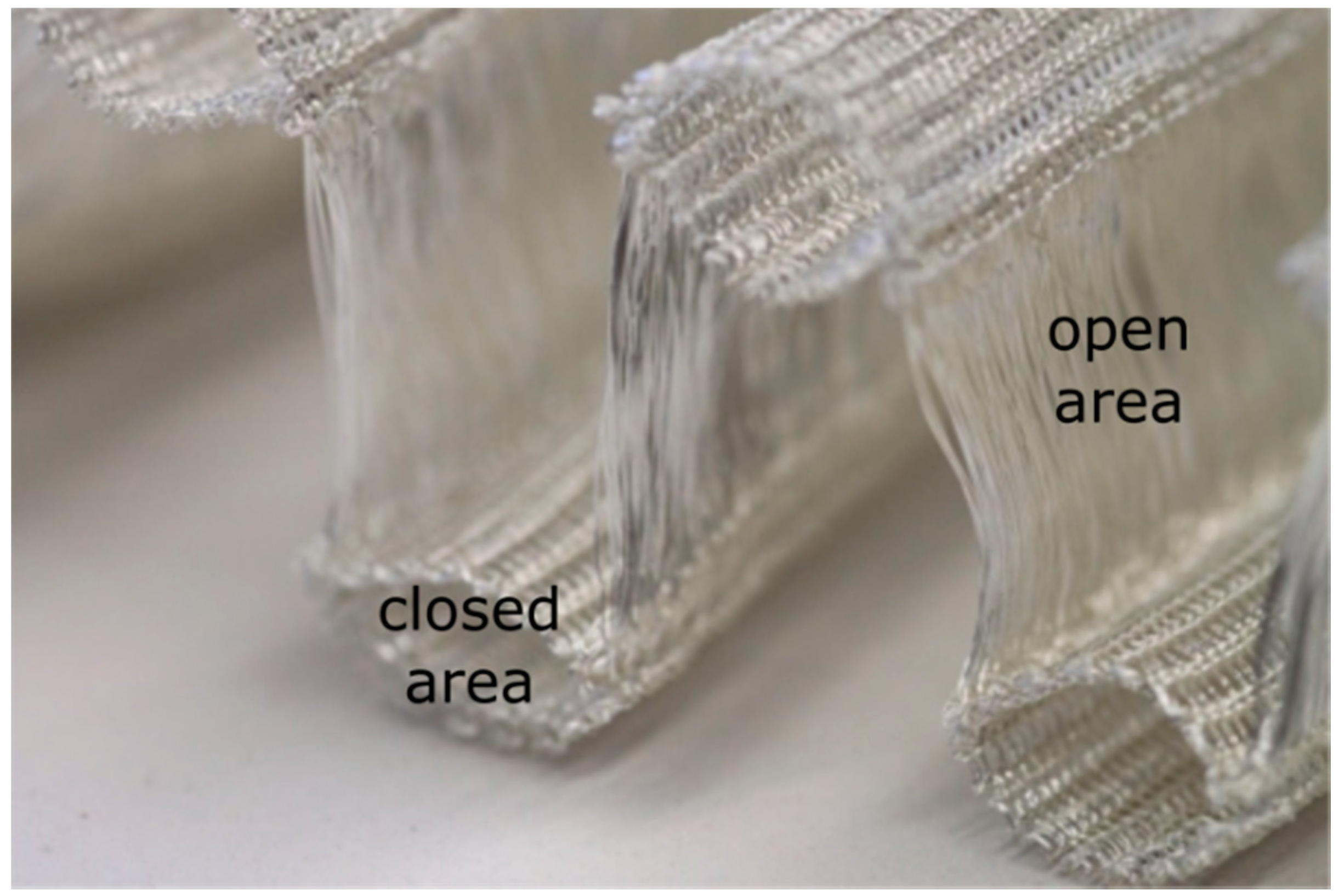

2.1.2. The Flat Tube Wire Heat Exchanger

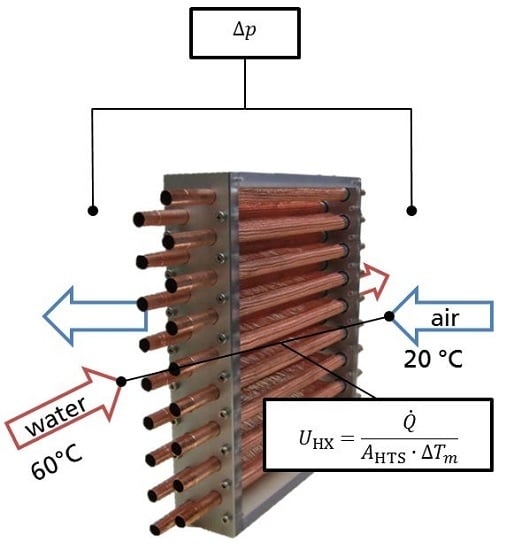

2.2. Methods of Determining the Performance

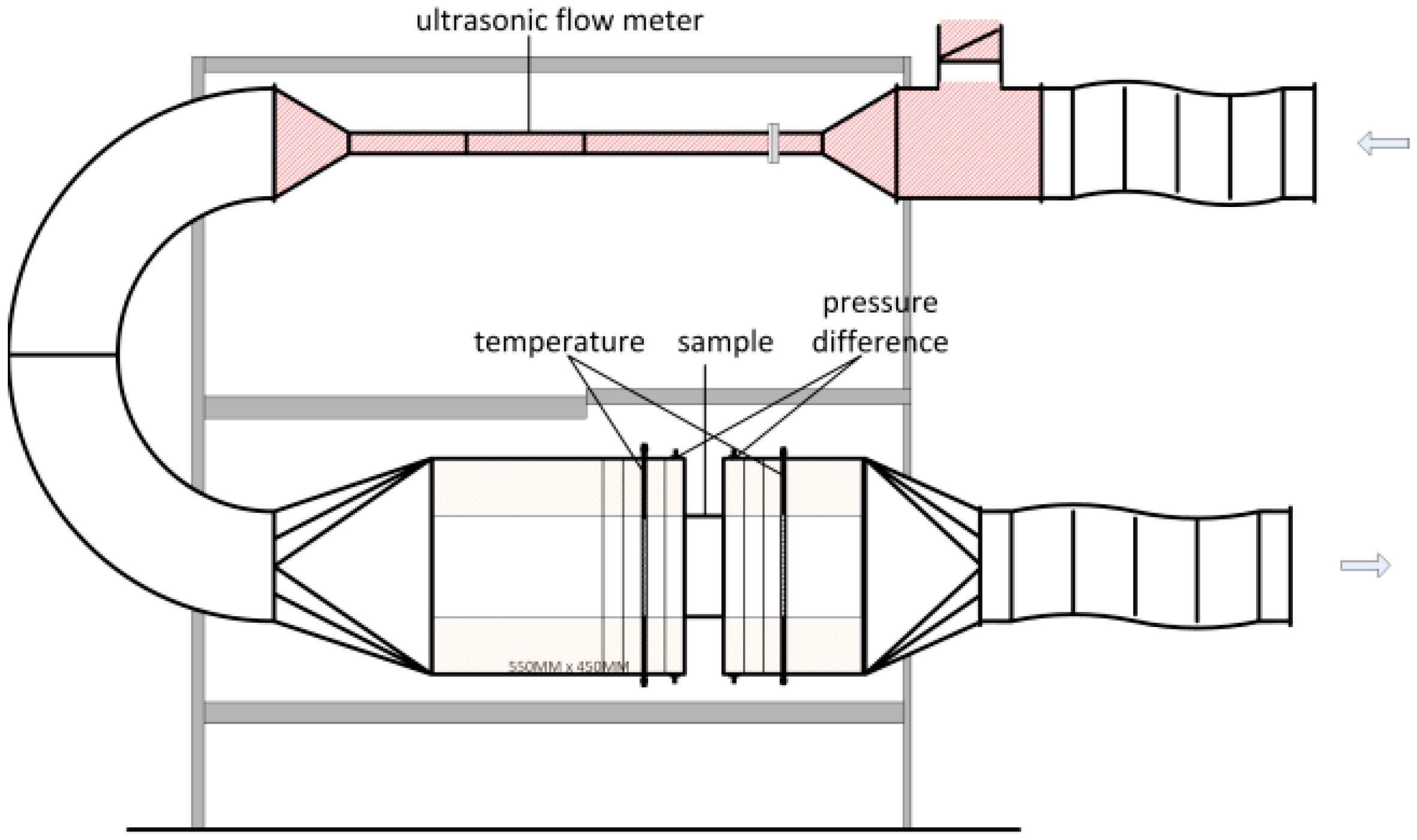

2.2.1. Experimental Setup

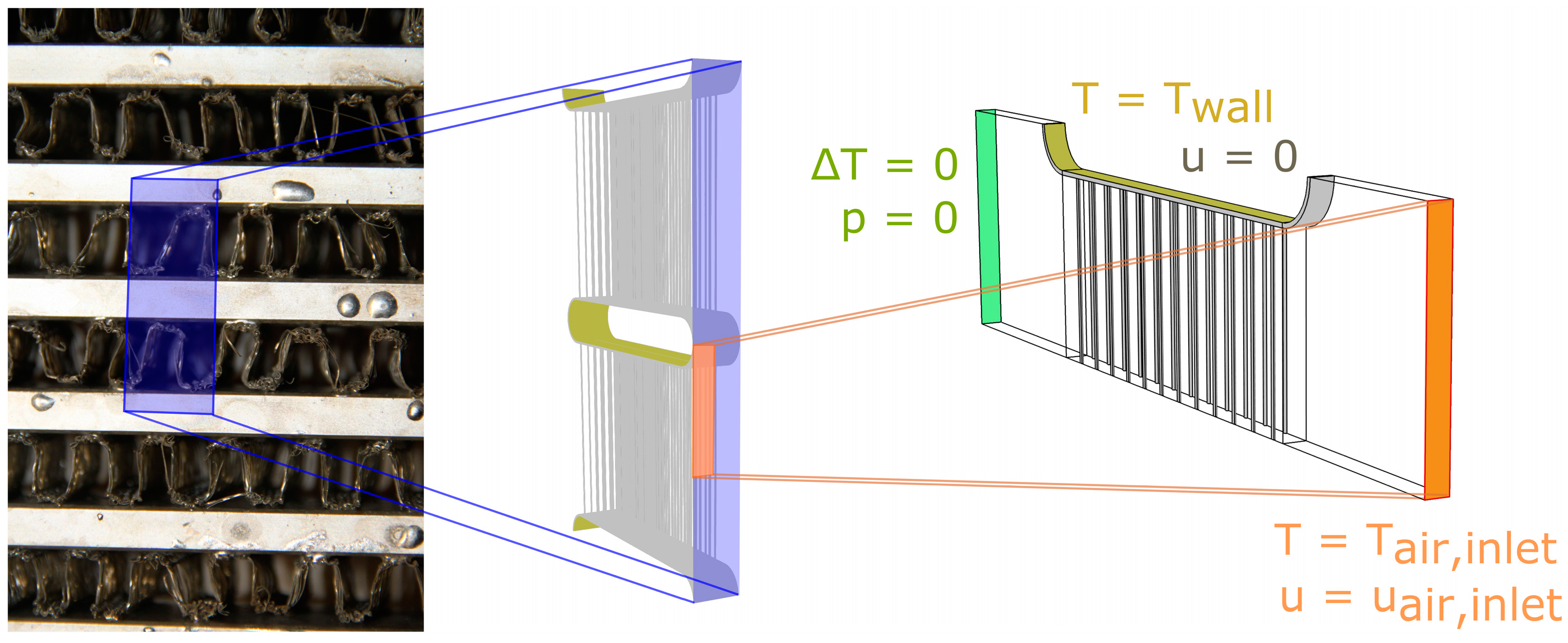

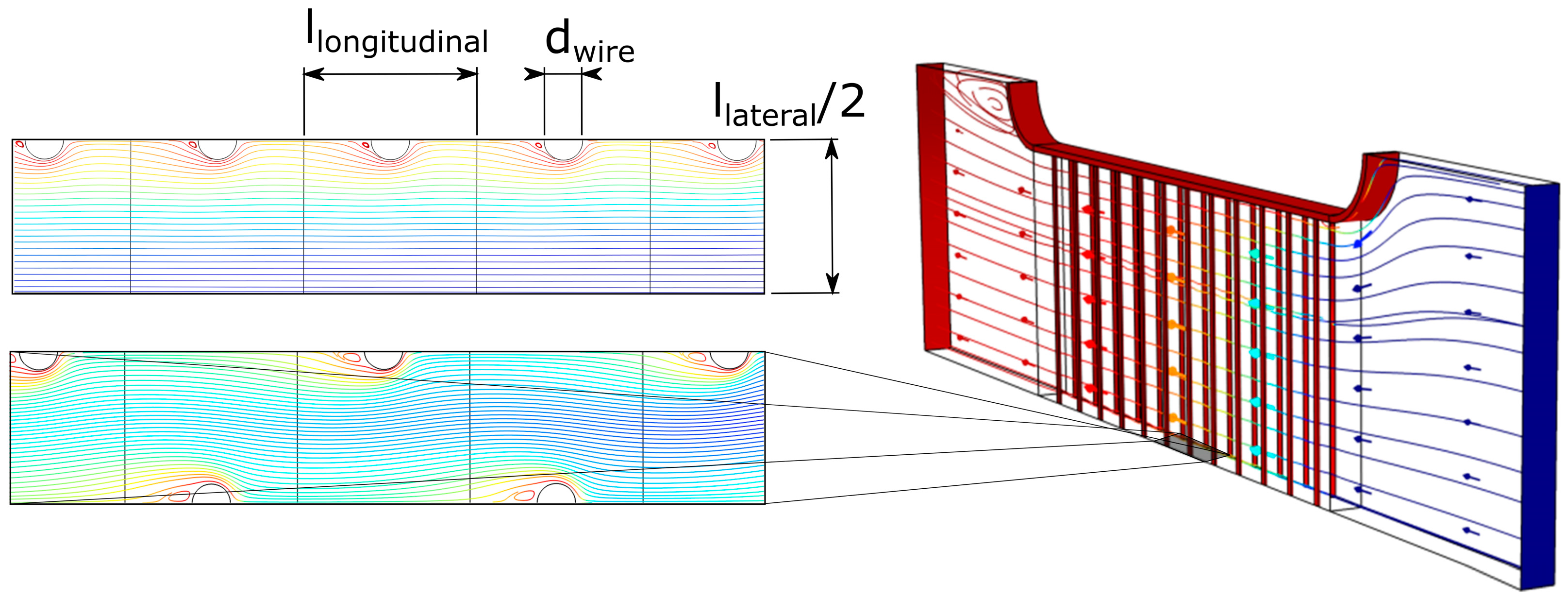

2.2.2. CFD Simulation

2.2.3. Performance Evaluation Criteria

- the dissipated power on the air side , which is proportional to the power of the fans in W;

- the mass of the material used for the wire or fin structure (excluding tubes, solder material, and header) in kg;

- the volume available for heat transfer enhancement in m3 (including tube volume, excluding header).

2.2.4. Reference Heat Exchangers and Potential Analysis

2.3. Evaluation

3. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| area (m2) | |

| specific heat (J/kg·K) | |

| diameter, thickness or characteristic length (m) | |

| friction factor | |

| height (m) | |

| convection heat transfer coefficient (W/m2K) | |

| thermal conductivity (W/m K) | |

| length (m) | |

| wire pitch (m) | |

| mass (kg) | |

| mass flow rate (kg/s) | |

| number of wires | |

| Nusselt number | |

| pressure (Pa) | |

| heat transfer rate (W) | |

| Reynolds number | |

| tube pitch (m) | |

| temperature (K) | |

| temperature difference (K) | |

| overall heat transfer coefficient (W/m2K) | |

| volume (m3) | |

| volume flow rate (m3/s) | |

| width (m) | |

| Greek Symbols | |

| β | heat transfer surface area density (m2/m3) |

| extended surface efficiency | |

| Subscripts | |

| air | air side |

| diss | dissipated |

| eff | effective |

| HTS | heat transfer surface |

| HX | heat exchanger |

| HXelm | heat exchanger element (without header) |

| inlet | fluid inlet section |

| lateral | perpendicular to the air flow direction |

| lm | log-mean |

| longitudinal | in air flow direction |

| m | mean |

| outlet | fluid outlet section |

| st | domain between tubes for heat transfer enhancement structure |

| wall | section between water side and air side |

| water | water side |

| wpb | wires per bundle |

| Abbreviations | |

| RT | round tube |

| FT | flat tube |

| WHX | wire heat exchanger |

Appendix A. Specification of the Heat Exchanger Geometry

| Specification | Unit | FT Ref1 | FT Ref2 | RT Ref | FT WHX Sim1/2/3 |

|---|---|---|---|---|---|

| number of tubes | – | 21 | 2 × 11 | 18 | 11 |

| tube outer dimensions × tube wall thickness | mm | (1.8 × 16.4) × 0.25 | (2.1 × 12) × 0.25 | Ø10 × 0.5 | (2.1 × 25) × 0.2 |

| length of tubes, | mm | 265 | 250 | 231 | 250 |

| distance between centers of tubes perpendicular to flow direction, | mm | 9.9 | 10.2 | 26.0 | 10.23 |

| thickness of fins, or wire diameter, | mm | 0.08 | 0.04 | 0.15 | 0.1 |

| material | – | Al | Cu | Al | Cu |

| fin pitch, | mm | 1 | 1 | 2.4 | 0.9/0.8/0.7 |

| distance between center of wires in flow direction, | mm | – | – | – | 0.45 |

| outer dimension of heat exchanger (without header), × × | mm3 | 195 × 265 × 16.4 | 120 × 250 × 32.5 | 195 × 231 × 43.0 | 120 × 250 × 25 |

| outer dimension of heat exchanger (including header) | mm3 | 218 × 305 × 21.0 | 121 × 300 × 49.5 | – | – |

| mass of heat exchanger (fins only; excluding header; including header) | kg | 0.18; 0.35; 0.49 | 0.28; 0.4; 1.12 | 0.19; –; – | – |

| heat transfer surface area density, | 1/m | 1820 | 1780 | 800 | 810/880/980 |

| Heat Exchanger Type | Geometrical Determination of |

|---|---|

| flat tube with fins | |

| flat tube with wires | |

| round tube with fins | |

| round tube with wires |

References

- Schnabel, L.; Roell, F.; Hattler, K.; Studnitzky, T.; Laurenz, E.; Kaina, S. Energieeffiziente Wärmeübertragung durch 3D-Metallgewebestrukturen (EffiMet): Gemeinsamer Abschlussbericht; 10.2314/GBV:835139093; Techn. Informationsbibl. und Univ.-Bibl: London, UK, 2015. [Google Scholar]

- Boomsma, K.; Poulikakos, D.; Zwick, F. Metal foams as compact high performance heat exchangers. Mech. Mater. 2003, 35, 1161–1176. [Google Scholar] [CrossRef]

- Hutter, C.; Büchi, D.; Zuber, V.; Rudolf von Rohr, P. Heat transfer in metal foams and designed porous media. Chem. Eng. Sci. 2011, 66, 3806–3814. [Google Scholar] [CrossRef]

- Girlich, D. Grundsatzuntersuchungen zum Einsatz Offenporiger Metallschäume in der Luft-, Kälte- und Wärmetechnik Abschlussbericht; Laufzeit: 01.11.2002 bis 31.10.2004: Abschlussbericht; M-Pore GmbH: Dresden, Germany, 2005. [Google Scholar]

- Kotcioglu, I.; Omeroglu, G.; Caliskan, S. Thermal performance and pressure drop of different pin-fin geometries. Hittite J. Sci. Eng. 2014, 1. [Google Scholar] [CrossRef]

- Sahiti, N.; Lemouedda, A.; Stojkovic, D.; Durst, F.; Franz, E. Performance comparison of pin fin in-duct flow arrays with various pin cross-sections. Appl. Therm. Eng. 2006, 26, 1176–1192. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, G.; Luo, X.; Li, H.; Ma, J. An experimental investigation on fluid flow and heat transfer characteristics of sintered woven wire mesh structures. Appl. Therm. Eng. 2015, 80, 118–126. [Google Scholar] [CrossRef]

- Xu, J.; Tian, J.; Lu, T.J.; Hodson, H.P. On the thermal performance of wire-screen meshes as heat exchanger material. Int. J. Heat Mass Transf. 2007, 50, 1141–1154. [Google Scholar] [CrossRef]

- Prasad, S.B.; Saini, J.S.; Singh, K.M. Investigation of heat transfer and friction characteristics of packed bed solar air heater using wire mesh as packing material. Sol. Energy 2009, 83, 773–783. [Google Scholar] [CrossRef]

- Li, C.; Wirtz, R.A. Development of a High Performance Heat Sink Based on Screen-Fin Technology; University of Nevada: Remo, NV, USA, 2003. [Google Scholar]

- Van Andel, E. Heat Exchanger and Method for Manufacturing Same. U.S. Patent EP0714500 B1, 19 August 1994. [Google Scholar]

- Bonestroo, J.P. Calculation Model of Fine-Wire Heat Exchanger. Master’s Thesis, Twente University, Enschede, The Netherlands, 2012. [Google Scholar]

- Sahiti, N. Thermal and Fluid Dynamic Performance of Pin Fin Heat Transfer Surfaces. Ph.D Thesis, Universität Erlangen-Nürnberg, Erlangen, Germany, 2006. [Google Scholar]

- Kumra, A.; Rawal, N.; Samui, P. Prediction of Heat Transfer Rate of a Wire-on-Tube Type Heat Exchanger: An Artificial Intelligence Approach. Procedia Eng. 2013, 64, 74–83. [Google Scholar] [CrossRef]

- Lee, T.-H.; Yun, J.-Y.; Lee, J.-S.; Park, J.-J.; Lee, K.-S. Determination of airside heat transfer coefficient on wire-on-tube type heat exchanger. Int. J. Heat Mass Transf. 2001, 44, 1767–1776. [Google Scholar] [CrossRef]

- Van Andel, E.; van Andel, E. Heat Exchanger and Applications Thereof. U.S. Patent 7963067 B2, 3 April 2006. [Google Scholar]

- Balzer, R. Wärmetauschvorrichtung für Einen Wärmeaustausch Zwischen Medien und Webstruktur. German Patent DE102006022629 A1, 12 May 2006. [Google Scholar]

- Shah, R.K.; Sekulić, D.P. Fundamentals of Heat Exchanger Design; Wiley: Hoboken, NJ, USA, 2003. [Google Scholar]

- Fugmann, H.; Tahir, A.J.; Schnabel, L. Woven Wire Gas-To-Liquid Heat Exchanger. In World Congress on Mechanical, Chemical and Material Engineering; Avestia Publishing, International ASET Inc.: Ottawa, ON, Canada, 2015. [Google Scholar]

- Celik, I.B.; Ghia, U.; Roache, P.J.; Freitas, C.J.; Coleman, H.; Raad, P.E. Procedure for Estimation and Reporting of Uncertainty Due to Discretization in CFD Applications. J. Fluids Eng. 2008, 130, 78001. [Google Scholar]

- Verein Deutscher Ingenieure. Wärmeatlas, 9th ed.; Springer: Berlin, Heidelberg, 2002. [Google Scholar]

- Hesselgreaves, J.E. Compact Heat Exchangers: Selection, Design, and Operation; Pergamon: Amsterdam, The Netherlands; New York, NY, USA, 2001. [Google Scholar]

- Jiang, H.; Aute, V.; Radermacher, R. CoilDesigner: A general-purpose simulation and design tool for air-to-refrigerant heat exchangers. Int. J. Refrig. 2006, 29, 601–610. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung e.V. Guide to the Expression of Uncertainty in Measurement (Deutsche Übersetzung); DIN: Berlin, Germany, 1999. [Google Scholar]

- Dong, J.; Chen, J.; Chen, Z.; Zhou, Y. Air-side thermal hydraulic performance of offset strip fin aluminum heat exchangers. Appl. Therm. Eng. 2007, 27, 306–313. [Google Scholar] [CrossRef]

| Specification | Unit | RT WHX | FT WHX |

|---|---|---|---|

| number of tubes | – | 18 | 15 |

| tubes outer dimensions × wall thickness | mm | Ø10 × 0.5 | 30 × 6.5 × 1.5 |

| tube pitch perpendicular to flow direction, | mm | 26.0 | 16.4 |

| tube pitch in flow direction, | mm | 22 | n.a. |

| tube length with contact to air side, | mm | 195 | 195 |

| wire diameter, | mm | 0.1 | 0.1 |

| material / thermal conductivity | W/mK | Cu-HCP/385 | Cu-HCP/385 |

| wire pitch perpendicular to flow direction (bundles of 4 wires), | mm | 0.77 | 5.4 |

| wire pitch in flow direction (bundles of 4 wires), | mm | n.a. | 1 |

| heat exchanger outer dimension (without headers), × × | mm3 | 195 × 231 × 32 | 195 × 231 × 30 |

| header outer dimensions × wall thickness | mm × mm | Ø40 × 1 | Ø43 × 1.7 |

| wire structure mass, | kg | 0.19 | 0.18 |

| heat transfer surface area density, | m2/m3 | 180 | 160 |

| Efficiency | Unit | Definition |

|---|---|---|

| energetic efficiency | 1/K | |

| mass efficiency | W/(K·kg) | |

| volume efficiency | W/(K·m3) |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fugmann, H.; Laurenz, E.; Schnabel, L. Wire Structure Heat Exchangers—New Designs for Efficient Heat Transfer. Energies 2017, 10, 1341. https://doi.org/10.3390/en10091341

Fugmann H, Laurenz E, Schnabel L. Wire Structure Heat Exchangers—New Designs for Efficient Heat Transfer. Energies. 2017; 10(9):1341. https://doi.org/10.3390/en10091341

Chicago/Turabian StyleFugmann, Hannes, Eric Laurenz, and Lena Schnabel. 2017. "Wire Structure Heat Exchangers—New Designs for Efficient Heat Transfer" Energies 10, no. 9: 1341. https://doi.org/10.3390/en10091341