Investigation of Hydraulic-Mechanical Properties of Paste Backfill Containing Coal Gangue-Fly Ash and Its Application in an Underground Coal Mine

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characterization of Components

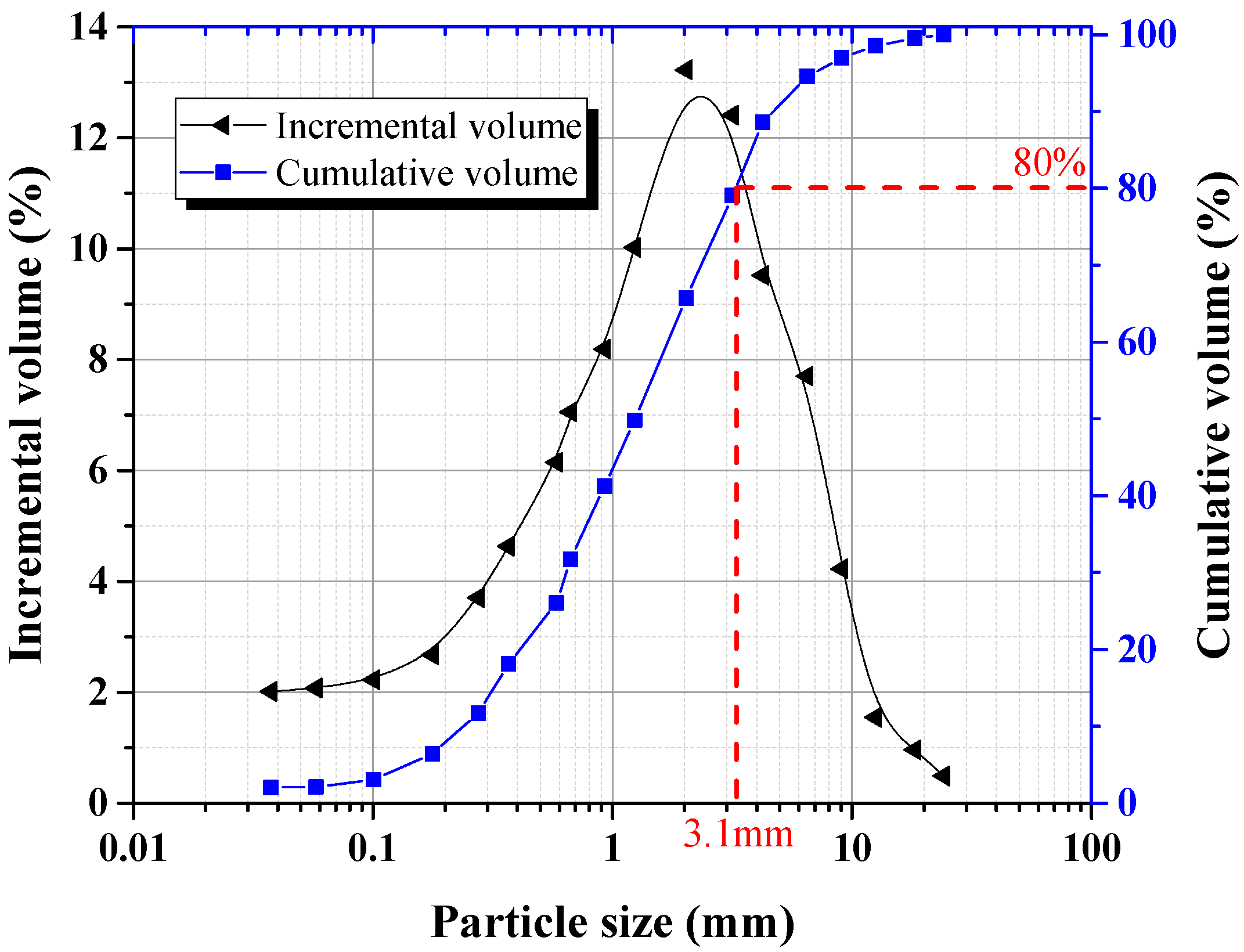

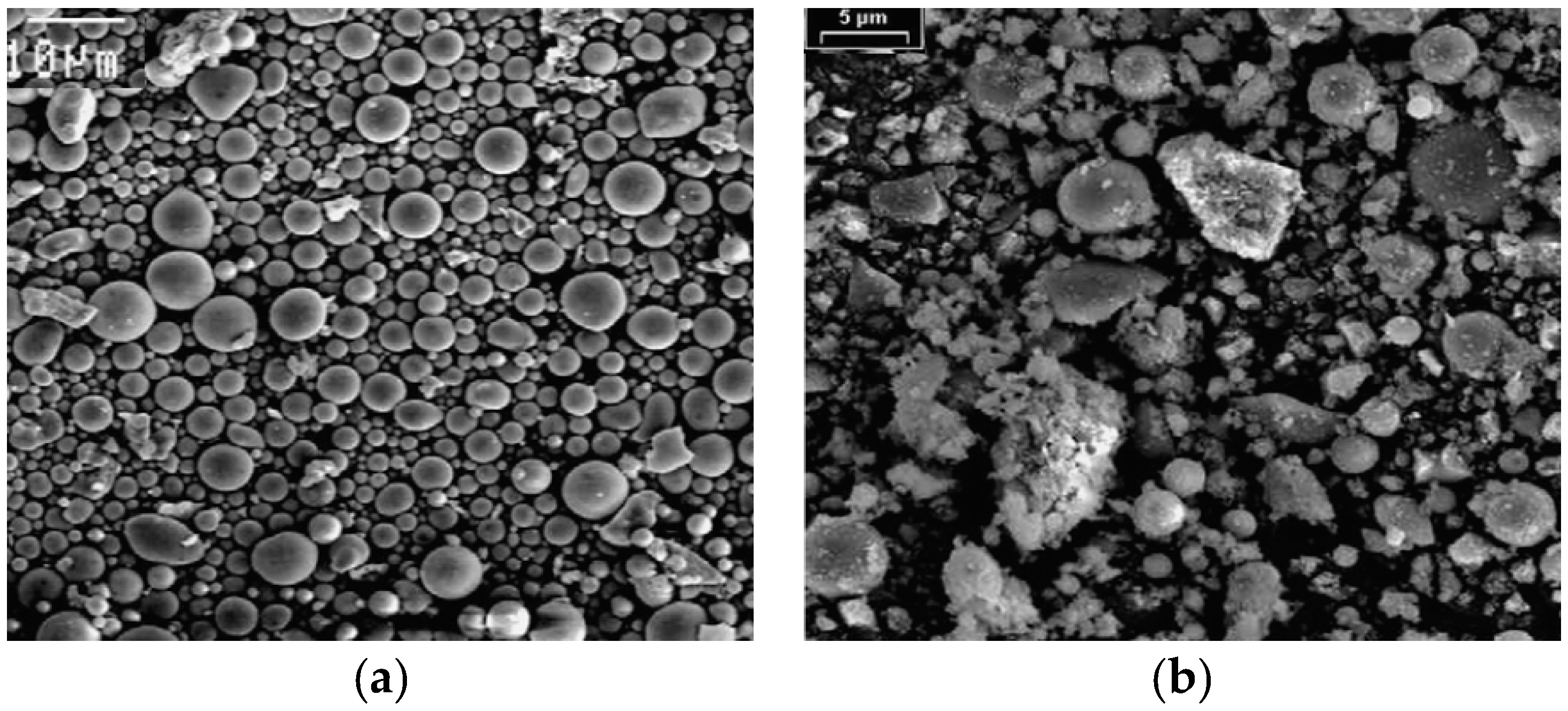

2.1.1. Coal Gangue

2.1.2. Hydraulic Binder

2.1.3. CPB Preparation

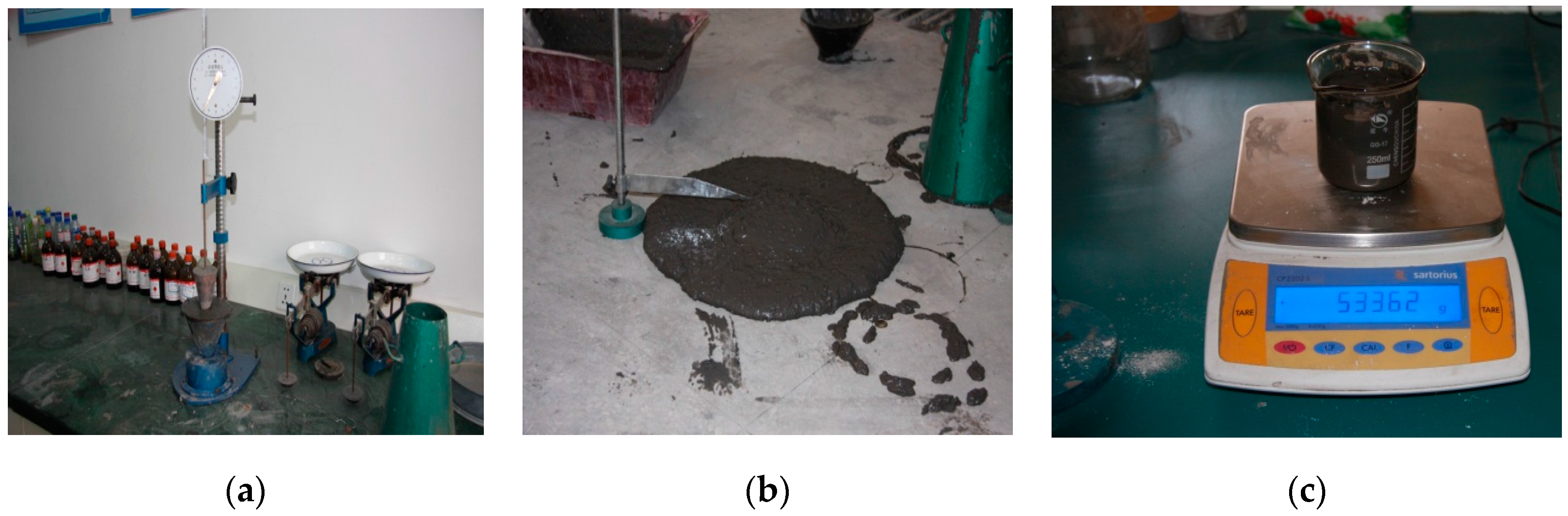

2.2. Geotechnical Characterization Testing

2.2.1. Slump, Bleeding and Segregation Test

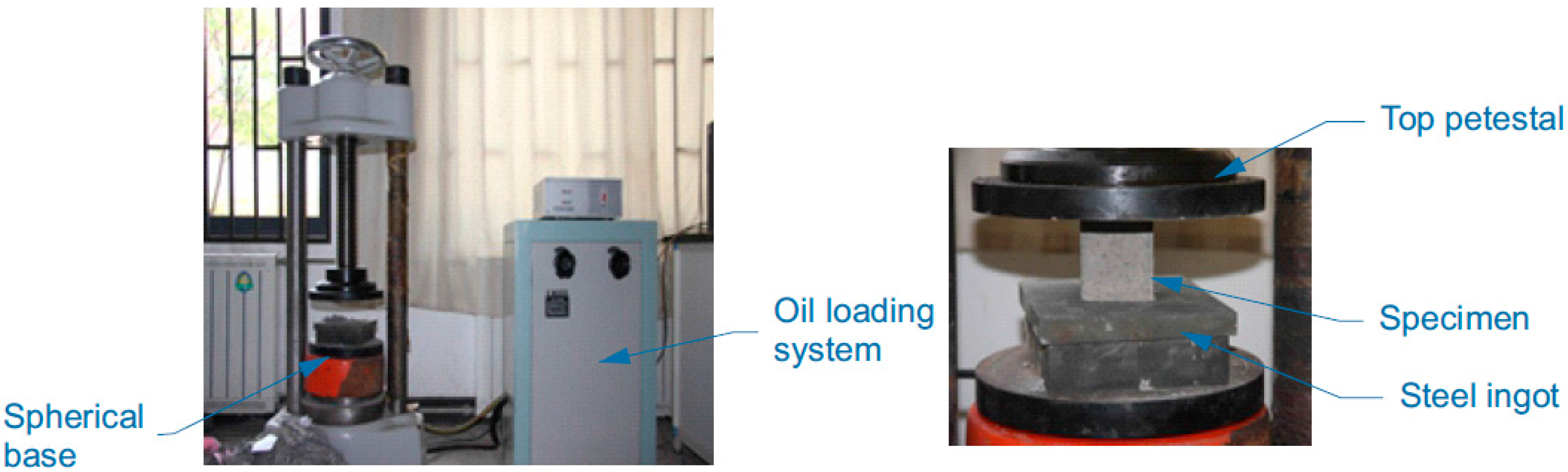

2.2.2. UCS Testing

2.3. Results and Discussions

2.3.1. Effect of Fly Ash and Coal Gangue on Hydraulic-Geotechnical Properties of Different CPB Samples

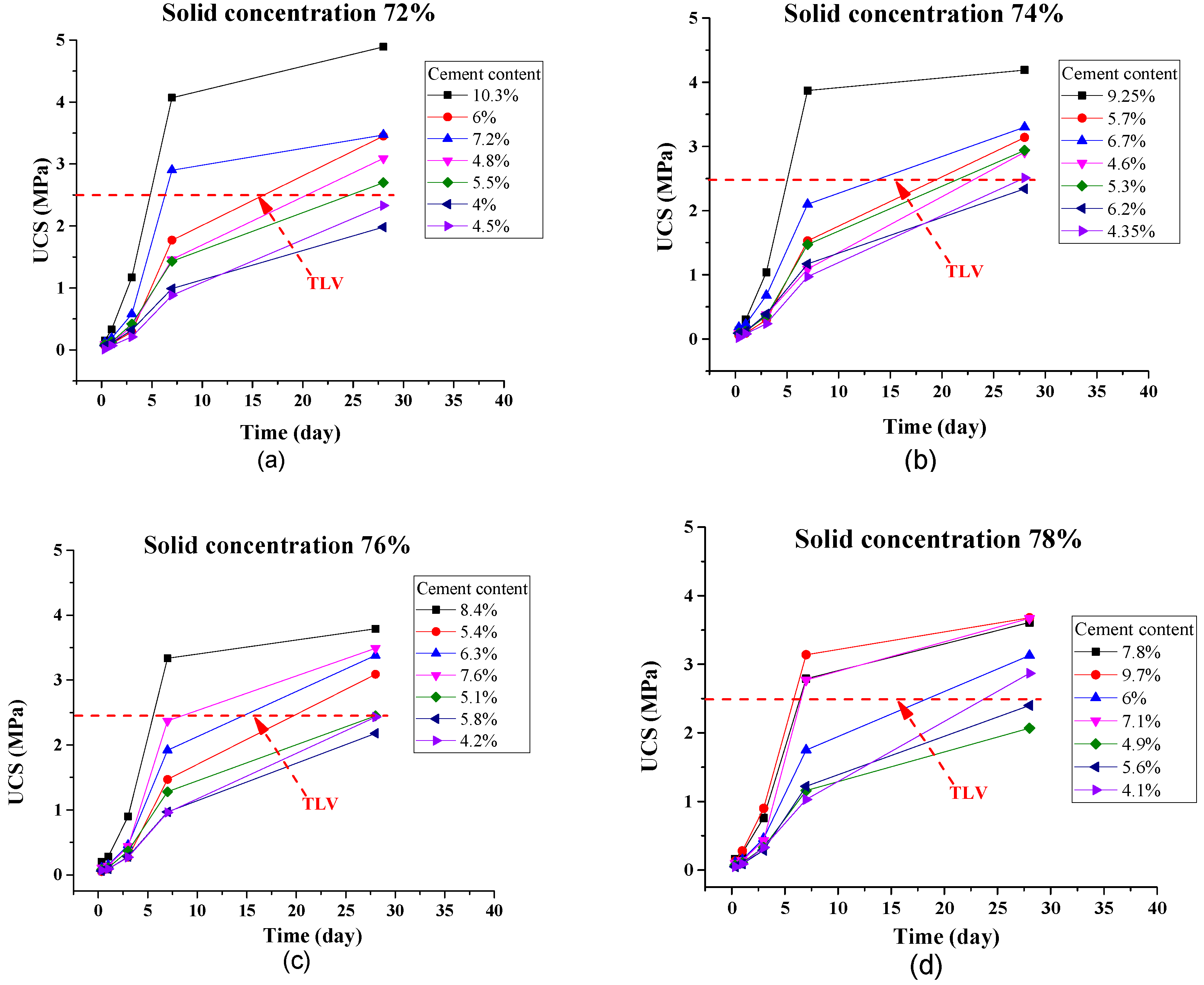

2.3.2. The UCS Results

3. Field Application

3.1. Geological Conditions

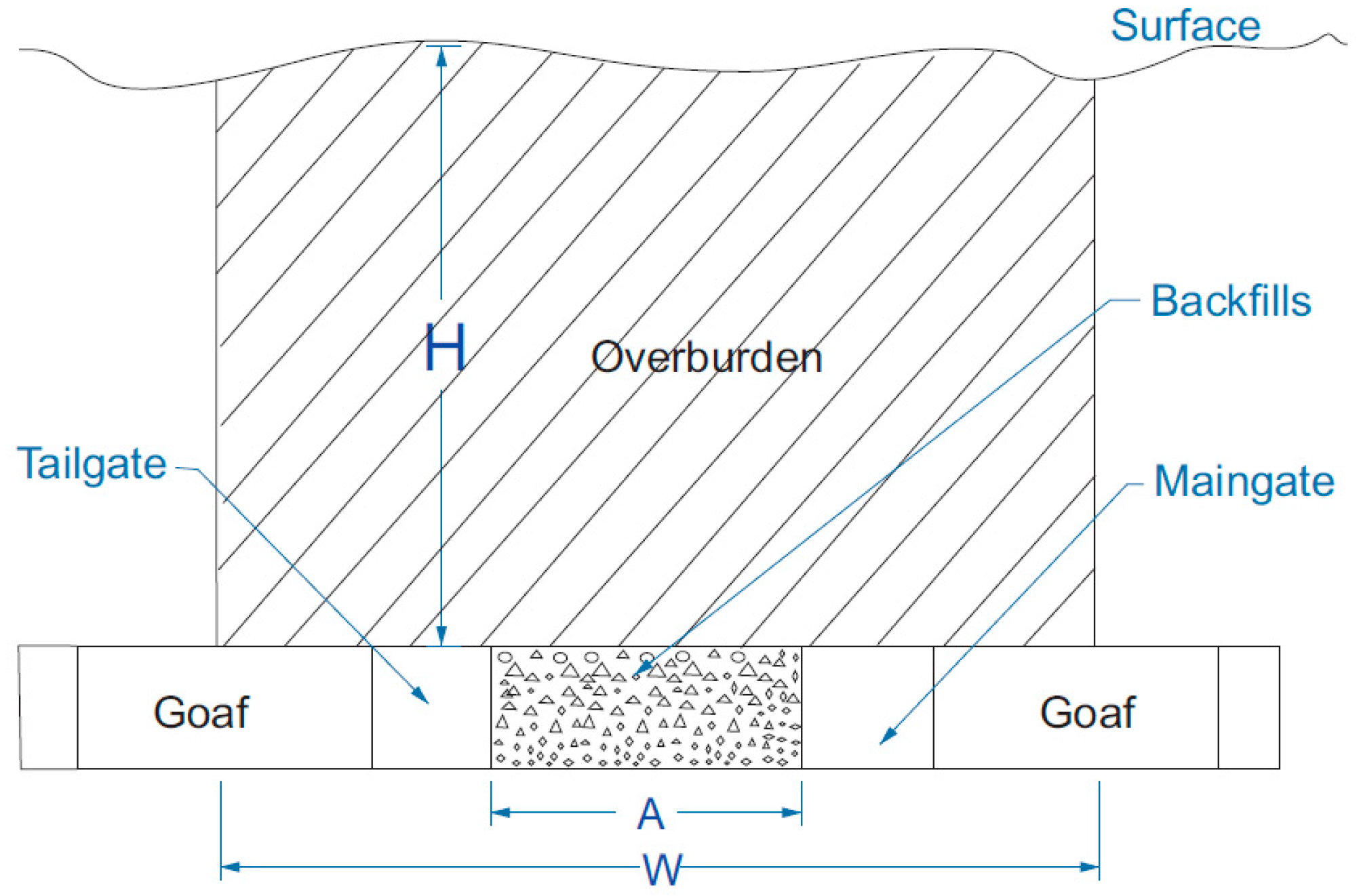

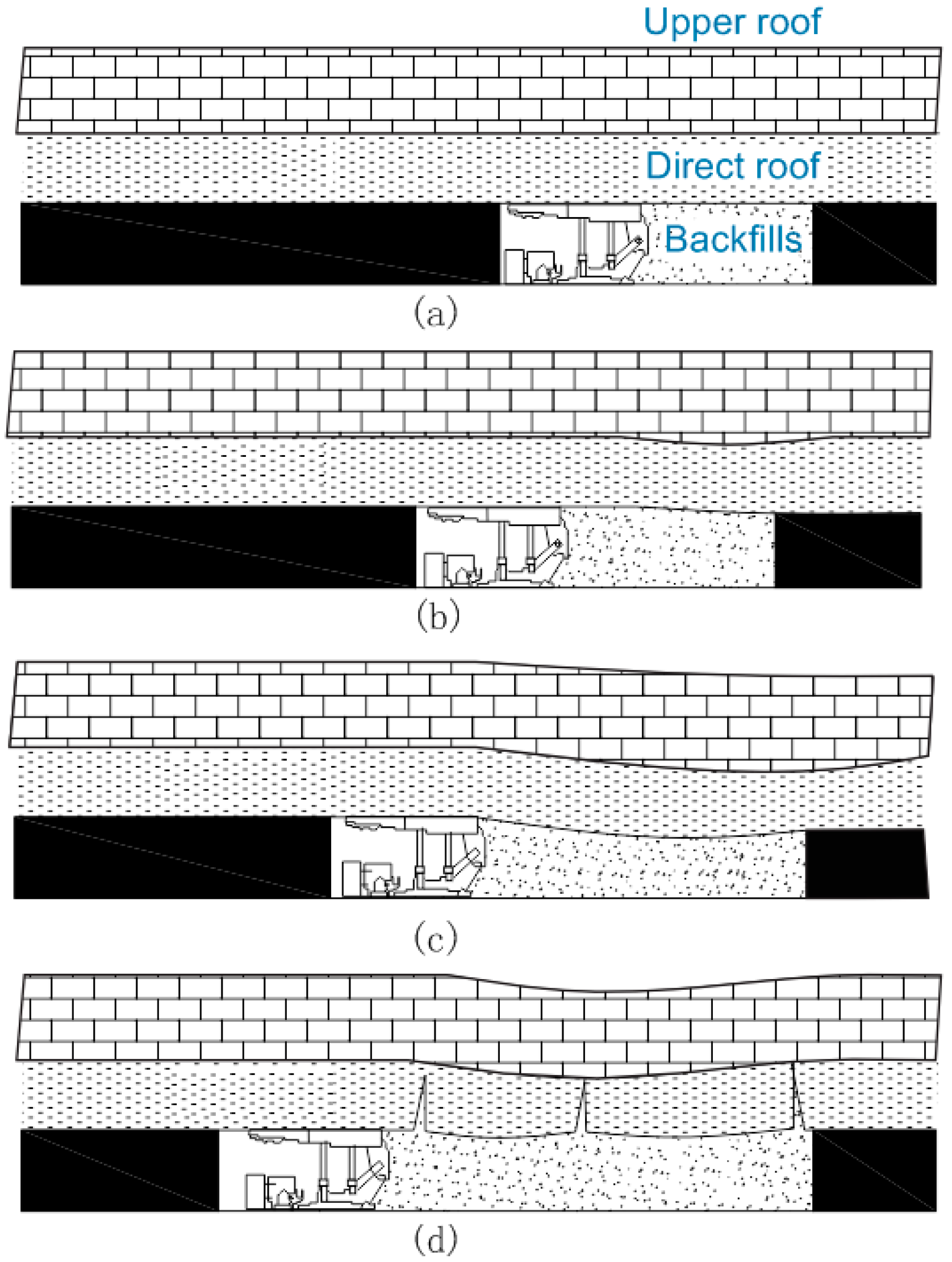

3.2. Mining and Backfilling Process

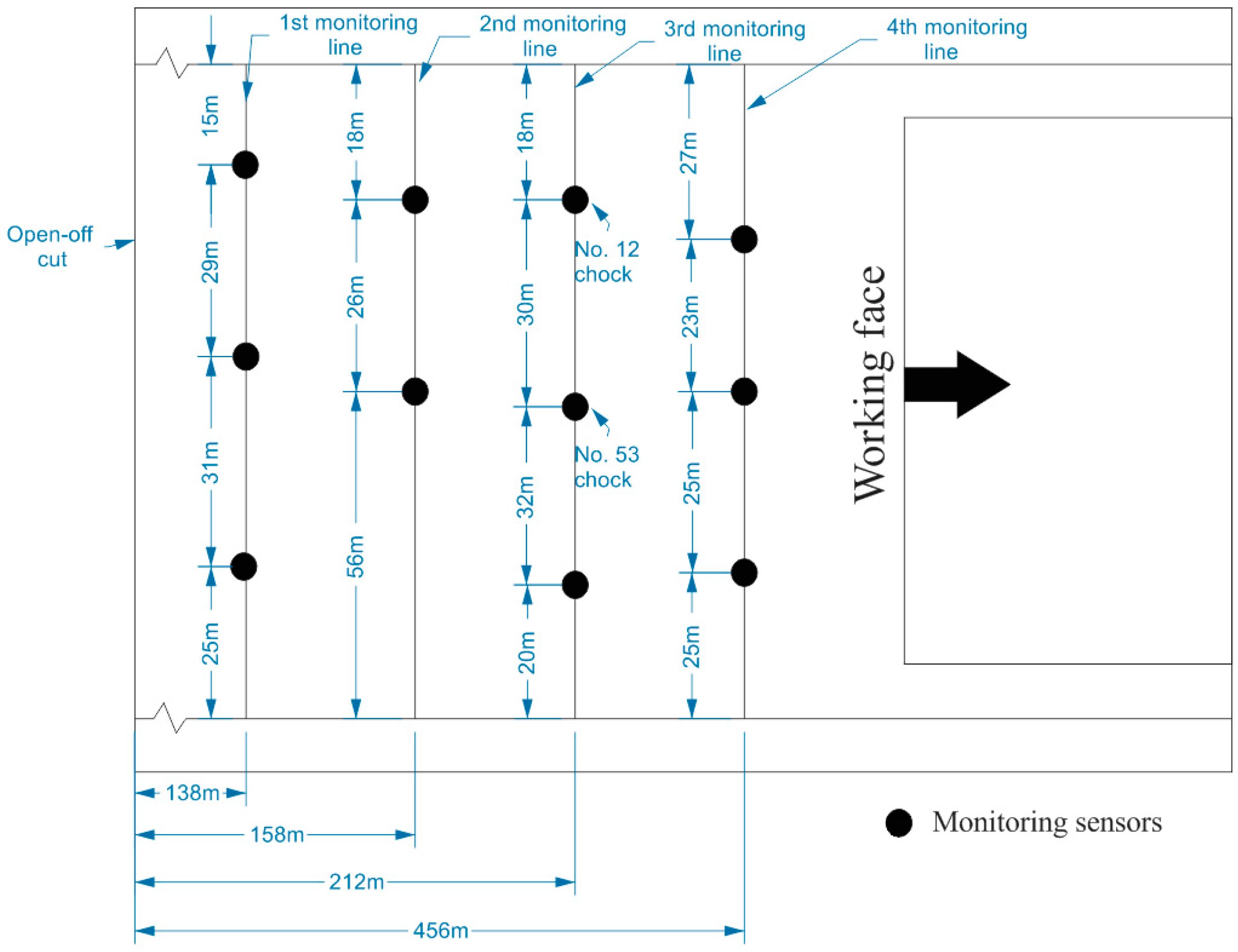

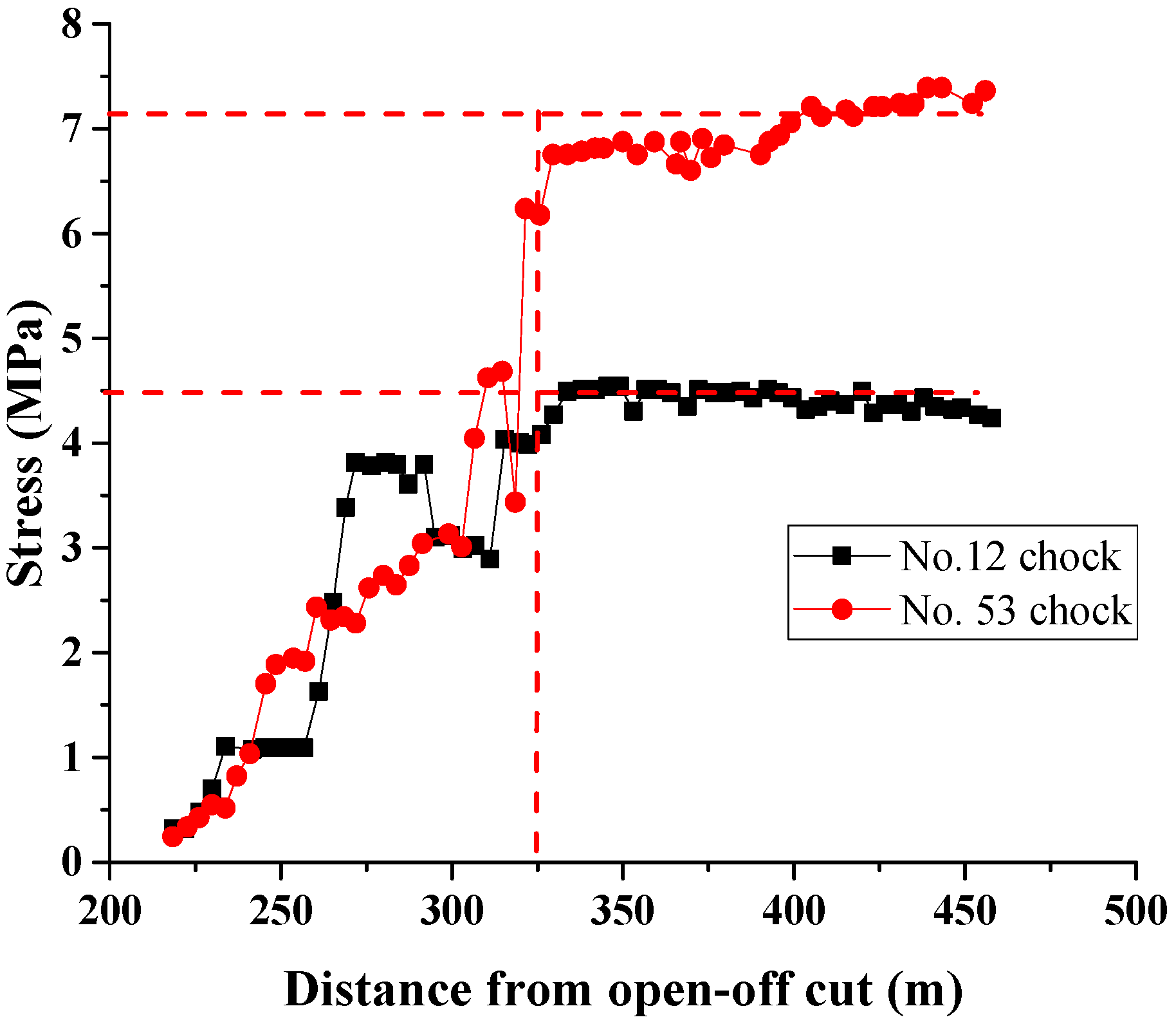

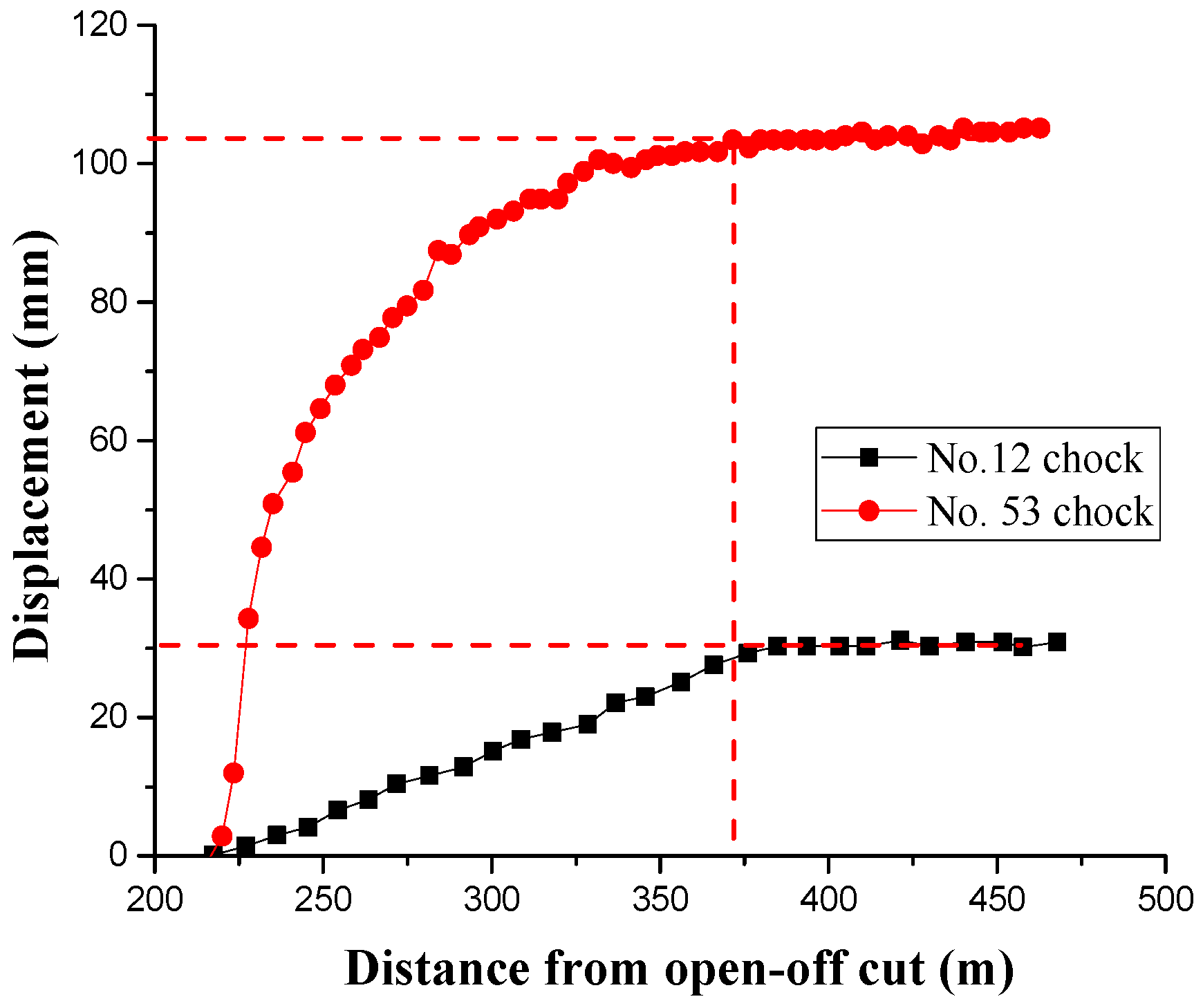

3.3. Displacement and Stress Monitoring

3.4. Monitoring Results and Discussion

4. Conclusions

- (1)

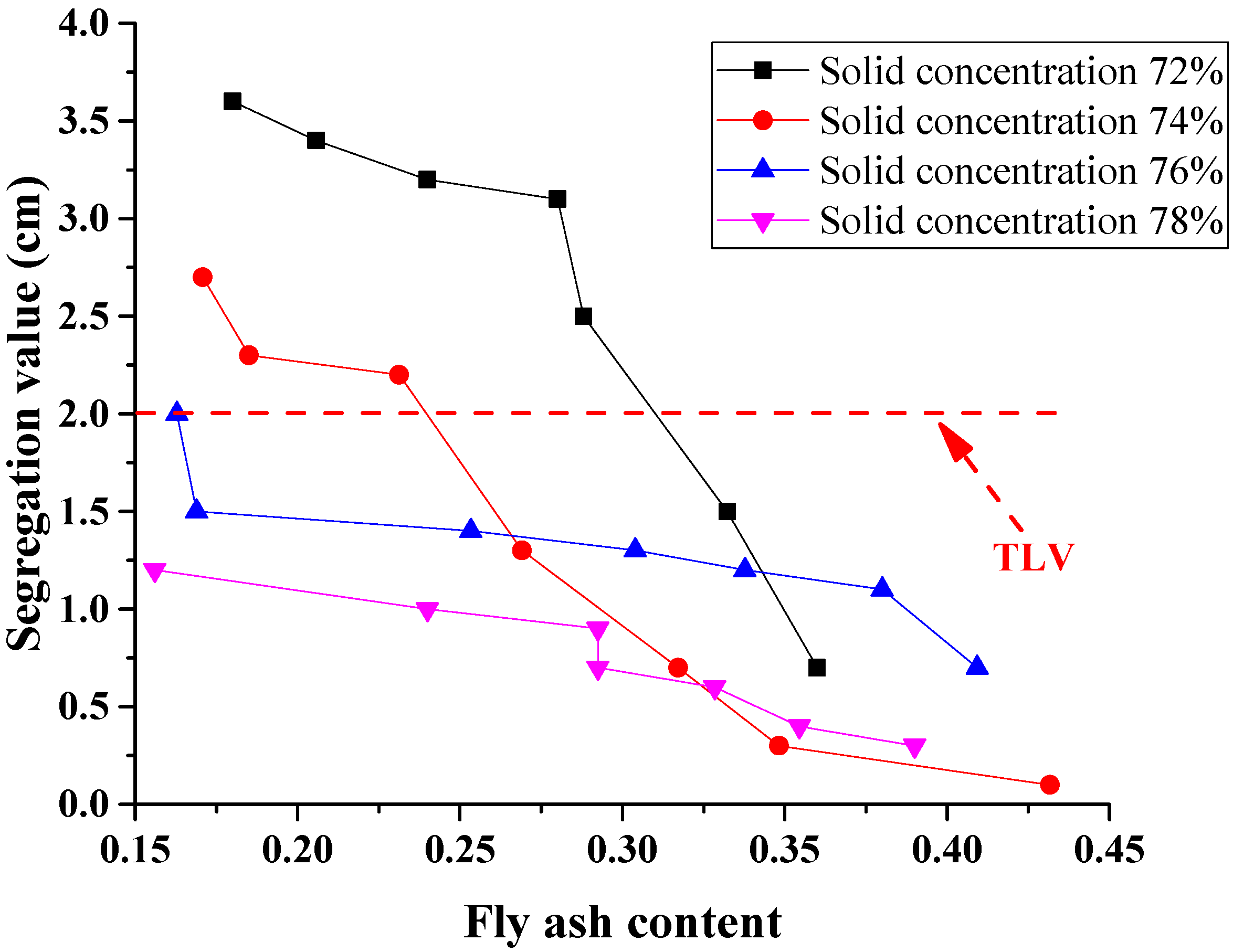

- Fly ash had a significant impact on the slump and segregation properties of CPB. As the fly ash content increased, the slump of the mixture increased and segregation decreased. Coal gangue content also affected the water bleeding ratio, which was due to the large size particle percentage. The higher content of coal gangue could produce a higher water bleeding ratio slurry. Solid concentration (water content) was a key parameter that affected both the hydraulic and mechanical properties of the CPB samples.

- (2)

- Cement content was the primary factor that affected the strength of CPB samples from an early strength (eight hours curing time) and late strength aspect (28 days curing time). Based on the field conditions, the required early strength was 0.13 MPa and the late strength was 2.47 MPa.

- (3)

- Based on the experiment results, the p10 sample was optimized with the ratio of cement:fly ash:coal gangue (1:4:6) and solid concentration was 74%. This recipe was used in the field trial.

- (4)

- The longwall cut and fill mining method was used in the field trial. The displacement and stress of the CPB was monitored. The maximum stress in the third monitoring line was 4.5 MPa (No. 12 chock) and 7 MPa (No. 53 chock), and the maximum displacement was 100 mm and 30 mm, respectively. These monitoring results suggest that backfills can effectively control the roof deformation.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Brackebusch, F.W. Basics of paste backfill systems. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 3, 122A. [Google Scholar]

- Deng, X.; Zhang, J.; Kang, T.; Han, X. Strata behavior in extra-thick coal seam mining with upward slicing backfilling technology. Int. J. Min. Sci. Technol. 2016, 26, 587–592. [Google Scholar] [CrossRef]

- Wu, D.; Sun, G.; Liu, Y. Modeling the thermo-hydro-chemical behavior of cemented coal gangue-fly ash backfill. Constr. Build. Mater. 2016, 111, 522–528. [Google Scholar] [CrossRef]

- Yilmaz, E. Advances in reducing large volumes of environmentally harmful mine waste rocks and tailings. Gospod. Surow. Miner. 2011, 27, 89–112. [Google Scholar]

- Yilmaz, E.; Belem, T.; Benzaazoua, M. Effects of curing and stress conditions on hydromechanical, geotechnical and geochemical properties of cemented paste backfill. Eng. Geol. 2014, 168, 23–37. [Google Scholar] [CrossRef]

- Wu, D.; Hou, Y.; Deng, T.; Chen, Y.; Zhao, X. Thermal, hydraulic and mechanical performances of cemented coal gangue-fly ash backfill. Int. J. Miner. Process. 2017, 162, 12–18. [Google Scholar] [CrossRef]

- Deng, D.; Liu, L.; Yao, Z.; Song, K.-I.; Lao, D. A practice of ultra-fine tailings disposal as filling material in a gold mine. J. Environ. Manag. 2017, 196, 100–109. [Google Scholar] [CrossRef] [PubMed]

- Amaratunga, L.M.; Yaschyshyn, D.N. Development of a high modulus paste fill using fine gold mill tailings. Geotech. Geol. Eng. 1997, 15, 205–219. [Google Scholar] [CrossRef]

- Bernier, R.; Li, M.G.; Moerman, A. Effects of tailings and binder geochemistry on the physical strength of paste backfill. Proc. Sudburry 1999, 99, 1113–1122. [Google Scholar]

- Belem, T.; Benzaazoua, M.; Bussière, B. Mechanical behaviour of cemented paste backfill. In Proceedings of the 53rd Candadian Geotechnical Conference, Montreal, QC, Canada, 15–18 October 2000; pp. 373–380. [Google Scholar]

- Yılmaz, T.; Ercikdi, B. Predicting the uniaxial compressive strength of cemented paste backfill from ultrasonic pulse velocity test. Nondestruct. Test. Eval. 2016, 31, 247–266. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Benzaazoua, M.; Kesimal, A.; Ercikdi, B.; Cihangir, F. Use of high-density paste bacfill for safe disposal of copper/zinc mine tailings. Gospod. Surow. Miner. 2011, 27, 81–94. [Google Scholar]

- Cihangir, F.; Ercikdi, B.; Kesimal, A.; Deveci, H.; Erdemir, F. Paste backfill of high-sulphide mill tailings using alkali-activated blast furnace slag: Effect of activator nature, concentration and slag properties. Miner. Eng. 2015, 83, 117–127. [Google Scholar] [CrossRef]

- Ercikdi, B.; Külekci, G.; Yılmaz, T. Utilization of granulated marble wastes and waste bricks as mineral admixture in cemented paste backfill of sulphide-rich tailings. Constr. Build. Mater. 2015, 93, 573–583. [Google Scholar] [CrossRef]

- Rong, H.; Zhou, M.; Hou, H. Pore Structure Evolution and Its Effect on Strength Development of Sulfate-Containing Cemented Paste Backfill. Minerals. 2017, 7, 8. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Bussière, B.; Demers, I.; Aubertin, M.; Fried, É.; Blier, A. Integrated mine tailings management by combining environmental desulphurization and cemented paste backfill: Application to mine Doyon, Quebec, Canada. Miner. Eng. 2008, 21, 330–340. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Zheng, J.; Zhu, Y.; Zhao, Z. Utilization of limestone powder and water-reducing admixture in cemented paste backfill of coarse copper mine tailings. Constr. Build. Mater. 2016, 124, 31–36. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Belem, T.; Bussiere, B. Chemical factors that influence the performance of mine sulphidic paste backfill. Cem. Concr. Res. 2002, 32, 1133–1144. [Google Scholar] [CrossRef]

- Kesimal, A.; Ercikdi, B.; Yilmaz, E. The effect of desliming by sedimentation on paste backfill performance. Miner. Eng. 2003, 16, 1009–1011. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M. Modeling the effect of sulphate on strength development of paste backfill and binder mixture optimization. Cem. Concr. Res. 2005, 35, 301–314. [Google Scholar] [CrossRef]

- Ercikdi, B.; Cihangir, F.; Kesimal, A.; Deveci, H.; Alp, İ. Utilization of industrial waste products as pozzolanic material in cemented paste backfill of high sulphide mill tailings. J. Hazard. Mater. 2009, 168, 848–856. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Li, L.; Yao, M.; Landry, D.; Malek, F.; Yang, X.; Guo, L. An investigation of the uniaxial compressive strength of a cemented hydraulic backfill made of alluvial sand. Minerals 2017, 7, 4. [Google Scholar] [CrossRef]

- Feldman, R.F.; Carette, G.G.; Malhotra, V.M. Studies on mechanics of development of physical and mechanical properties of high-volume fly ash-cement pastes. Cem. Concr. Compos. 1990, 12, 245–251. [Google Scholar] [CrossRef]

- Zhou, N.; Zhang, J.; Yan, H.; Li, M. Deformation Behavior of Hard Roofs in Solid Backfill Coal Mining Using Physical Models. Energies 2017, 10, 557. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and application of underground mine paste backfill technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Ouellet, J.; Servant, S.; Newman, P.; Verburg, R. Cementitious backfill with high sulfur content Physical, chemical, and mineralogical characterization. Cem. Concr. Res. 1999, 29, 719–725. [Google Scholar] [CrossRef]

- Koohestani, B.; Koubaa, A.; Belem, T.; Bussière, B.; Bouzahzah, H. Experimental investigation of mechanical and microstructural properties of cemented paste backfill containing maple-wood filler. Constr. Build. Mater. 2016, 121, 222–228. [Google Scholar] [CrossRef]

- Qiu, J.; Yang, L.; Sun, X.; Xing, J.; Li, S. Strength Characteristics and Failure Mechanism of Cemented Super-Fine Unclassified Tailings Backfill. Minerals 2017, 7, 58. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem. Concr. Res. 2004, 34, 1817–1822. [Google Scholar] [CrossRef]

- Ouellet, S.; Bussière, B.; Aubertin, M.; Benzaazoua, M. Microstructural evolution of cemented paste backfill: Mercury intrusion porosimetry test results. Cem. Concr. Res. 2007, 37, 1654–1665. [Google Scholar] [CrossRef]

- Huang, Y.; Li, J.; Song, T.; Kong, G.; Li, M. Analysis on filling ratio and shield supporting pressure for overburden movement control in coal mining with compacted backfilling. Energies 2016, 10, 31. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Strength evolution and deformation behaviour of cemented paste backfill at early ages: Effect of curing stress, filling strategy and drainage. Int. J. Min. Sci. Technol. 2016, 26, 809–817. [Google Scholar] [CrossRef]

- Fall, M.; Samb, S.S. Effect of high temperature on strength and microstructural properties of cemented paste backfill. Fire Saf. J. 2009, 44, 642–651. [Google Scholar] [CrossRef]

- Nasir, O.; Fall, M. Coupling binder hydration, temperature and compressive strength development of underground cemented paste backfill at early ages. Tunn. Undergr. Space Technol. 2010, 25, 9–20. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Bussière, B.; Benzaazoua, M. Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills. Cem. Concr. Compos. 2011, 33, 702–715. [Google Scholar] [CrossRef]

- Ge, Z.; Gao, Z.; Sun, R.; Zheng, L. Mix design of concrete with recycled clay-brick-powder using the orthogonal design method. Constr. Build. Mater. 2012, 31, 289–293. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Tyan, Y.-Y.; Chang, T.-P.; Chang, C.-Y. An assessment of optimal mixture for concrete made with recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 1373–1380. [Google Scholar] [CrossRef]

- Zurovac, J.; Brown, R. Orthogonal Design: A Powerful Method for Comparative Effectiveness Research with Multiple Interventions; Center on Health Care Effectiveness (CHCE); Mathematica Policy Research: Princeton, NJ, USA, 2012. [Google Scholar]

- Yilmaz, E.; Belem, T.; Benzaazoua, M. Specimen size effect on strength behavior of cemented paste backfills subjected to different placement conditions. Eng. Geol. 2015, 185, 52–62. [Google Scholar] [CrossRef]

- Zhang, Q.-L.; Xie, S.-Q.; Zheng, J.-J.; Wang, X.-M. Sedimentation law research and transportation feasibility study of backfilling slurry. J. Chongqing Univ. 2011, 1, 019. [Google Scholar]

- Wang, X.-M.; Zhao, B.; Zhang, C.-S.; Zhang, Q.-L. Paste-like self-flowing transportation backfilling technology based on coal gangue. Min. Sci. Technol. (China) 2009, 19, 137–143. [Google Scholar] [CrossRef]

- Zhang, Q.-L.; Wang, X.-M. Performance of cemented coal gangue backfill. J. Cent. South Univ. Technol. 2007, 14, 216–219. [Google Scholar] [CrossRef]

- Josserand, L.; de Larrard, F. A method for concrete bleeding measurement. Mater. Struct. 2004, 37, 666. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Wang, X.; Xiao, C.; Hu, Q. A hydraulic gradient model of paste-like crude tailings backfill slurry transported by a pipeline system. Environ. Earth Sci. 2016, 75, 1099. [Google Scholar] [CrossRef]

- Baogui, Y.; Yuantao, L.; Yukai, W. Admixture Ratio of High Concentration Cementation Backfilling Materials in Coal Mine. Electron. J. Geotech. Eng. 2015, 20, 10091–10101. [Google Scholar]

- Wu, D.; Yang, B.; Liu, Y. Transportability and pressure drop of fresh cemented coal gangue-fly ash backfill (CGFB) slurry in pipe loop. Powder Technol. 2015, 284, 218–224. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. The effect of specimen size on compressive strength of coal. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1968, 5, 325–335. [Google Scholar] [CrossRef]

- Bieniawski, Z.T.; Van Heerden, W.L. The significance of in situ tests on large rock specimens. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1975, 12, 101–113. [Google Scholar] [CrossRef]

- Zhao, T.; Zhang, Y.; Zhang, Z.; Li, Z.; Ma, S. Deformation Monitoring of Waste-Rock-Backfilled Mining Gob for Ground Control. Sensors 2017, 17, 1044. [Google Scholar] [CrossRef] [PubMed]

| Composition | Loss | SiO2 | Fe2O3 | Al2O3 | CaO | MgO | TiO2 | Na2O | K2O |

|---|---|---|---|---|---|---|---|---|---|

| Percentage (%) | 17.8 | 51.92 | 3.87 | 19.03 | 1.0 | 1.18 | 0.75 | 0.54 | 1.47 |

| No. | Ratio of Fly Ash/Cement | Ratio of Coal Gangue/Cement | Solid Concentration (%) | Cement Percentage in CPB (%) | Fly Ash Percentage in CPB (%) | Coal Gangue Percentage (%) |

|---|---|---|---|---|---|---|

| p01 | 2 | 4 | 72 | 10.3 | 20.6 | 41.1 |

| p05 | 3 | 8 | 72 | 6 | 18 | 48 |

| p09 | 4 | 5 | 72 | 7.2 | 28.8 | 36 |

| p13 | 5 | 9 | 72 | 4.8 | 24 | 43.2 |

| p17 | 6 | 6 | 72 | 5.5 | 33.2 | 33.2 |

| p21 | 7 | 10 | 72 | 4 | 28 | 40 |

| p25 | 8 | 7 | 72 | 4.5 | 36 | 31.5 |

| p02 | 2 | 5 | 74 | 9.25 | 18.5 | 46.25 |

| p06 | 3 | 9 | 74 | 5.7 | 17.1 | 51.2 |

| p10 | 4 | 6 | 74 | 6.7 | 26.9 | 40.4 |

| p14 | 5 | 10 | 74 | 4.6 | 23.1 | 46.2 |

| p18 | 6 | 7 | 74 | 5.3 | 31.7 | 37 |

| p22 | 7 | 4 | 74 | 6.2 | 43.2 | 24.7 |

| p26 | 8 | 8 | 74 | 4.3 | 34.8 | 34.8 |

| p03 | 2 | 6 | 76 | 8.4 | 16.9 | 50.6 |

| p07 | 3 | 10 | 76 | 5.4 | 16.3 | 54.3 |

| p11 | 4 | 7 | 76 | 6.3 | 25.3 | 44.3 |

| p15 | 5 | 4 | 76 | 7.6 | 38 | 30.4 |

| p19 | 6 | 8 | 76 | 5.1 | 30.4 | 40.5 |

| p23 | 7 | 5 | 76 | 5.8 | 40.9 | 29.2 |

| p27 | 8 | 9 | 76 | 4.2 | 33. 8 | 38 |

| p04 | 2 | 7 | 78 | 7.8 | 15.6 | 54.6 |

| p08 | 3 | 4 | 78 | 9.7 | 29.3 | 39 |

| p12 | 4 | 8 | 78 | 6 | 24 | 48 |

| p16 | 5 | 5 | 78 | 7.1 | 35.5 | 35.4 |

| p20 | 6 | 9 | 78 | 4.8 | 29.3 | 43.8 |

| p24 | 7 | 6 | 78 | 5.6 | 39 | 33.4 |

| p28 | 8 | 10 | 78 | 4.1 | 32.8 | 41.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Lin, J.; Liu, J.; Li, F.; Pang, Z. Investigation of Hydraulic-Mechanical Properties of Paste Backfill Containing Coal Gangue-Fly Ash and Its Application in an Underground Coal Mine. Energies 2017, 10, 1309. https://doi.org/10.3390/en10091309

Zhang X, Lin J, Liu J, Li F, Pang Z. Investigation of Hydraulic-Mechanical Properties of Paste Backfill Containing Coal Gangue-Fly Ash and Its Application in an Underground Coal Mine. Energies. 2017; 10(9):1309. https://doi.org/10.3390/en10091309

Chicago/Turabian StyleZhang, Xinguo, Jia Lin, Jinxiao Liu, Fei Li, and Zhenzhong Pang. 2017. "Investigation of Hydraulic-Mechanical Properties of Paste Backfill Containing Coal Gangue-Fly Ash and Its Application in an Underground Coal Mine" Energies 10, no. 9: 1309. https://doi.org/10.3390/en10091309