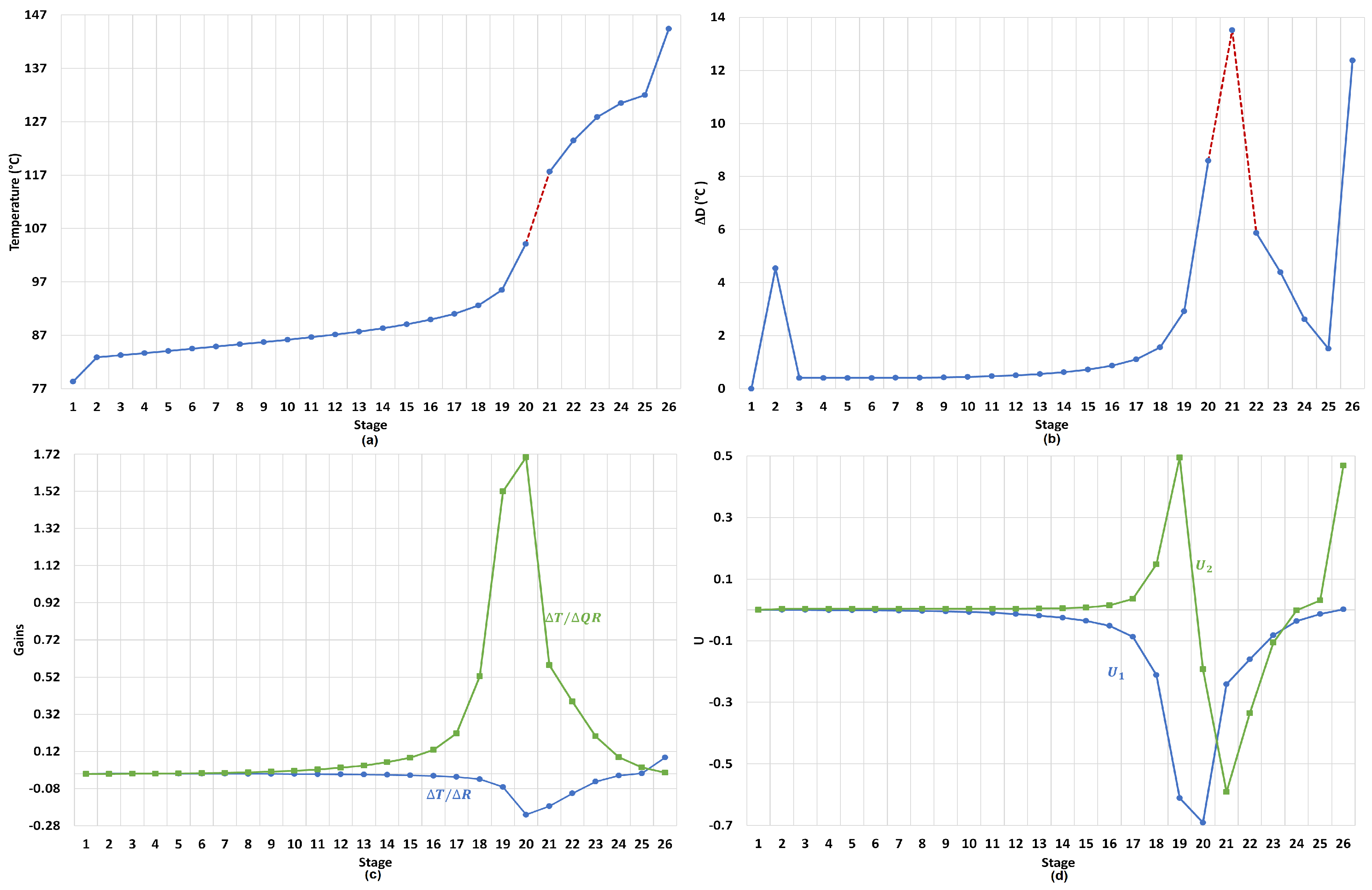

2.1. Simulation Methodology

The simulator of the salt extractive distillation column for dehydrating fuel ethanol was built within the

Aspen Plus®/

Aspen Dynamics® (aspenONE

® v8, Aspen Technology, Inc. Burlington, MA USA) environment. We used the RADFRAC module for simulating the steady-state performance. The module solves the so-called MESH equations for modeling equilibrium stages, which includes Mass Balance Equations (M), Equilibrium Relations (E), Sum or Conservation Equations (S) and Heat or Enthalpy Balance Equations (H). The simulation was performed in terms of the apparent mole fractions defined for the electrolytic system (6) in

Section 2.2.

Aspen Plus has Symmetric and Unsymmetric Electrolyte NRTL Activity Coefficient Models. The ENRTL-RK (electrolyte NRTL - Redlich-Kwong) was used to determine the VLE behavior of the ethanol–water-CaCl system, and it is based on the Unsymmetric Electrolyte NRTL activity coefficient model (GMENRTLQ) with unsymmetric reference states for ions at infinite dilution in aqueous solution, but they differ slightly in the mixing rules used for multiple electrolytes, which is not the case for the considered mixture.

The parameters of the former NRTL model for computing the liquid activity coefficients of the binary ethanol–water system were obtained from the Aspen Plus VLE-IG (VLE ideal gas) database and are reported in

Table 1 in the columns of binary interactions. The adjustable parameters needed to predict the ethanol–water-CaCl

VLE (with the ENRTL-RK model) are the symmetric non-random factor parameters

and the asymmetric binary interaction energy parameters

, which were estimated for different type of interactions to complete the database. The model parameters for molecule–molecule pair interactions (

=

and

≠

) were estimated by using Equation (1) in terms of

,

,

and making the temperature (

T) dependent parameters

,

,

equal to zero, and the resulting values are provided in

Table 1, referred to as molecule–molecule pairs. Furthermore, the molecule–electrolyte pair interactions (

=

and

≠

) were estimated by means of the Data Regression System (DRS) of Aspen Properties and are reported as molecule–electrolyte pairs in

Table 1. Finally, the electrolyte–electrolyte interaction pairs (

=

and

=

;

≠

and

≠

) were considered equal to zero:

The VLE model of the ethanol–water-CaCl

was correlated on salt-free basis mole fractions, defining a pseudo-binary mixture (7) as indicated in

Section 2.2, Later on, the VLE prediction was validated with experimental data; the fitting results and the estimated interaction parameters are presented in

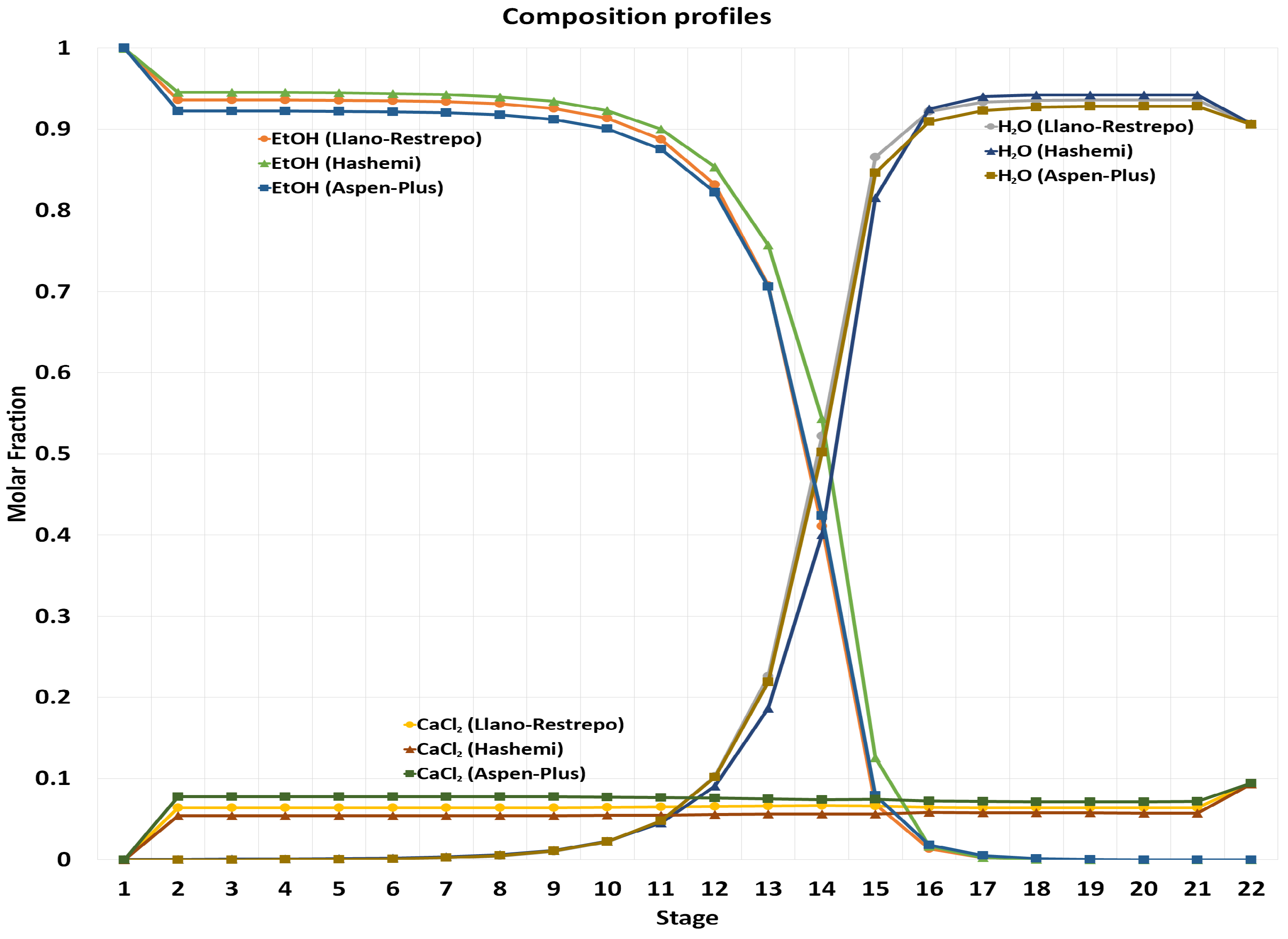

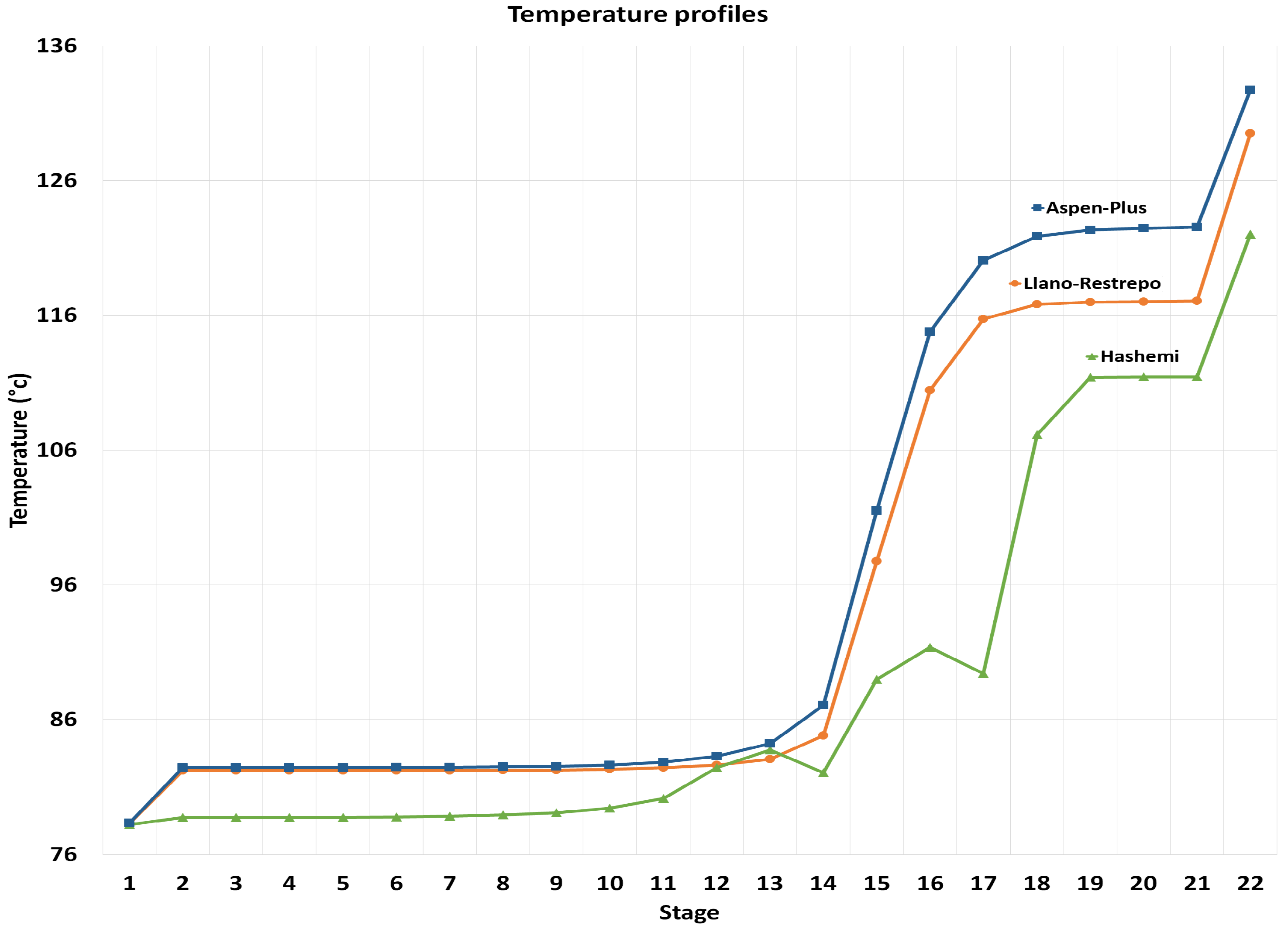

Section 2.2. With the goal to demonstrate the validity of the salt extractive distillation simulator, we considered the process design used by Llano-Restrepo et al. [

26] and Hashemi et al. [

27], and we compared their steady-state modeling solution with the results of our plant simulator built within the Aspen-Plus environment. The temperature and compositions profiles obtained by the Aspen-Plus simulator match the profiles provided by the two reference works (

Figure 1 and

Figure 2).

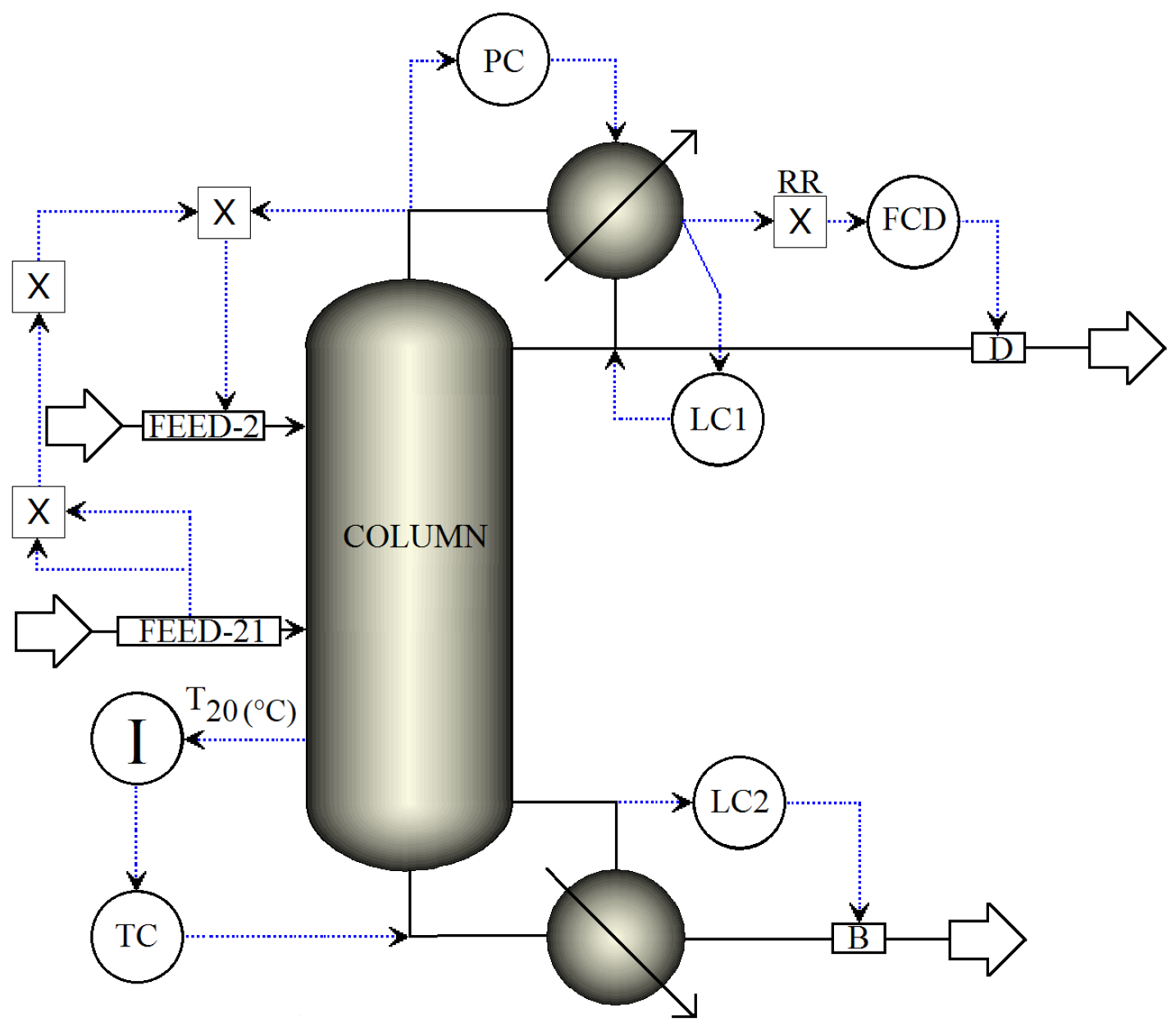

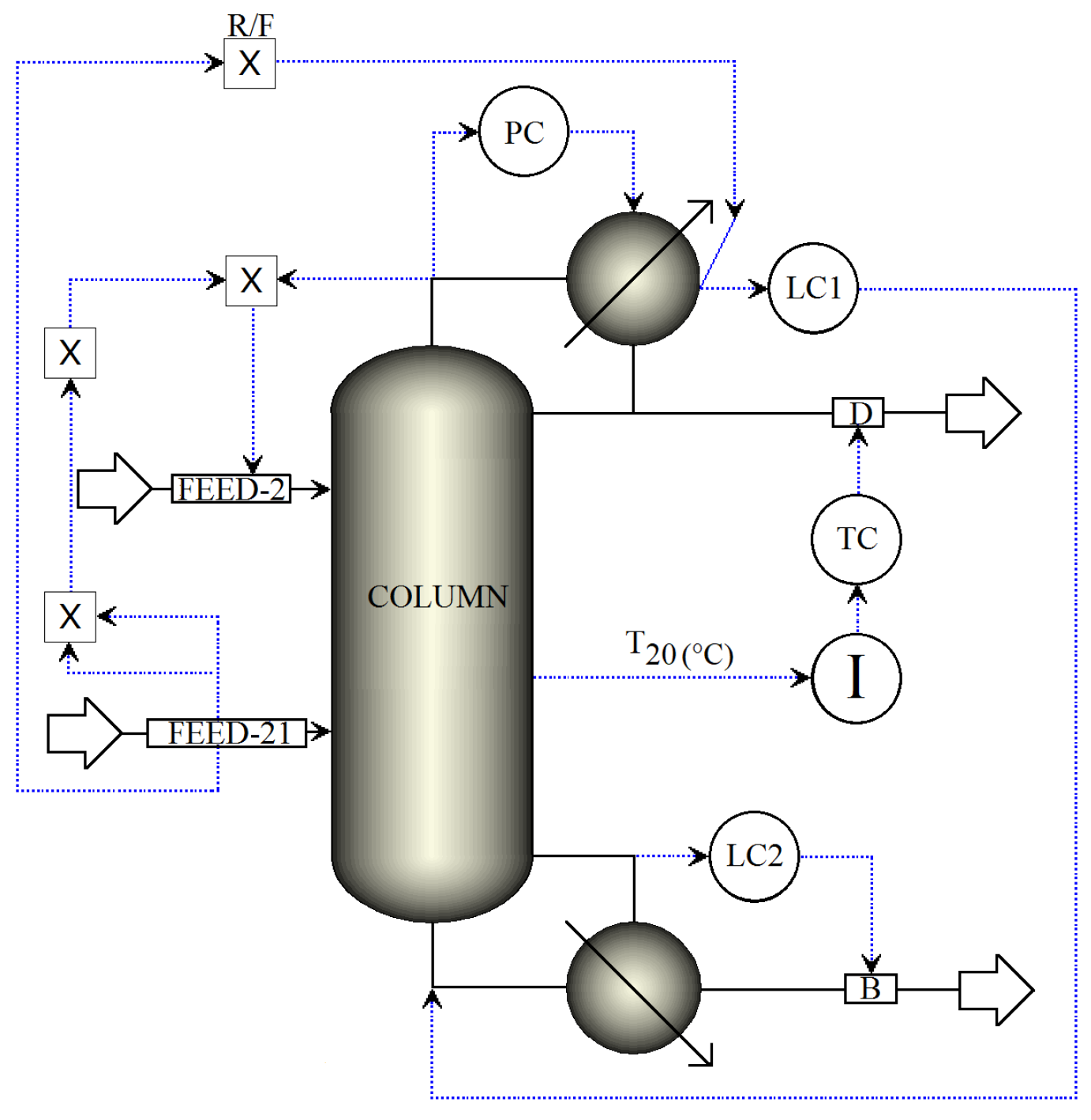

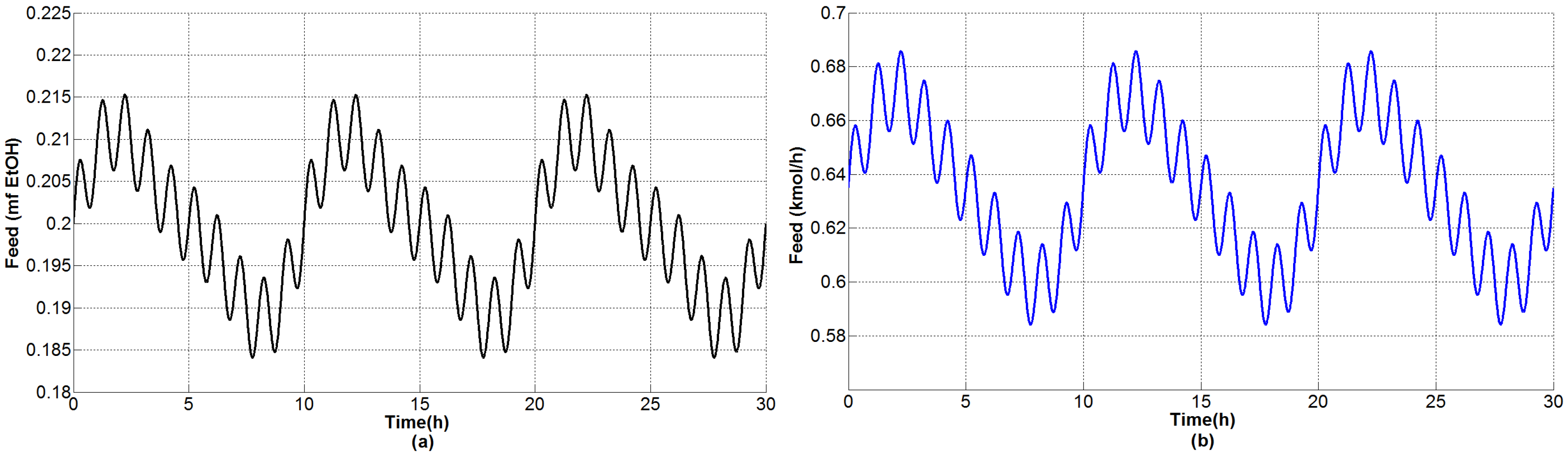

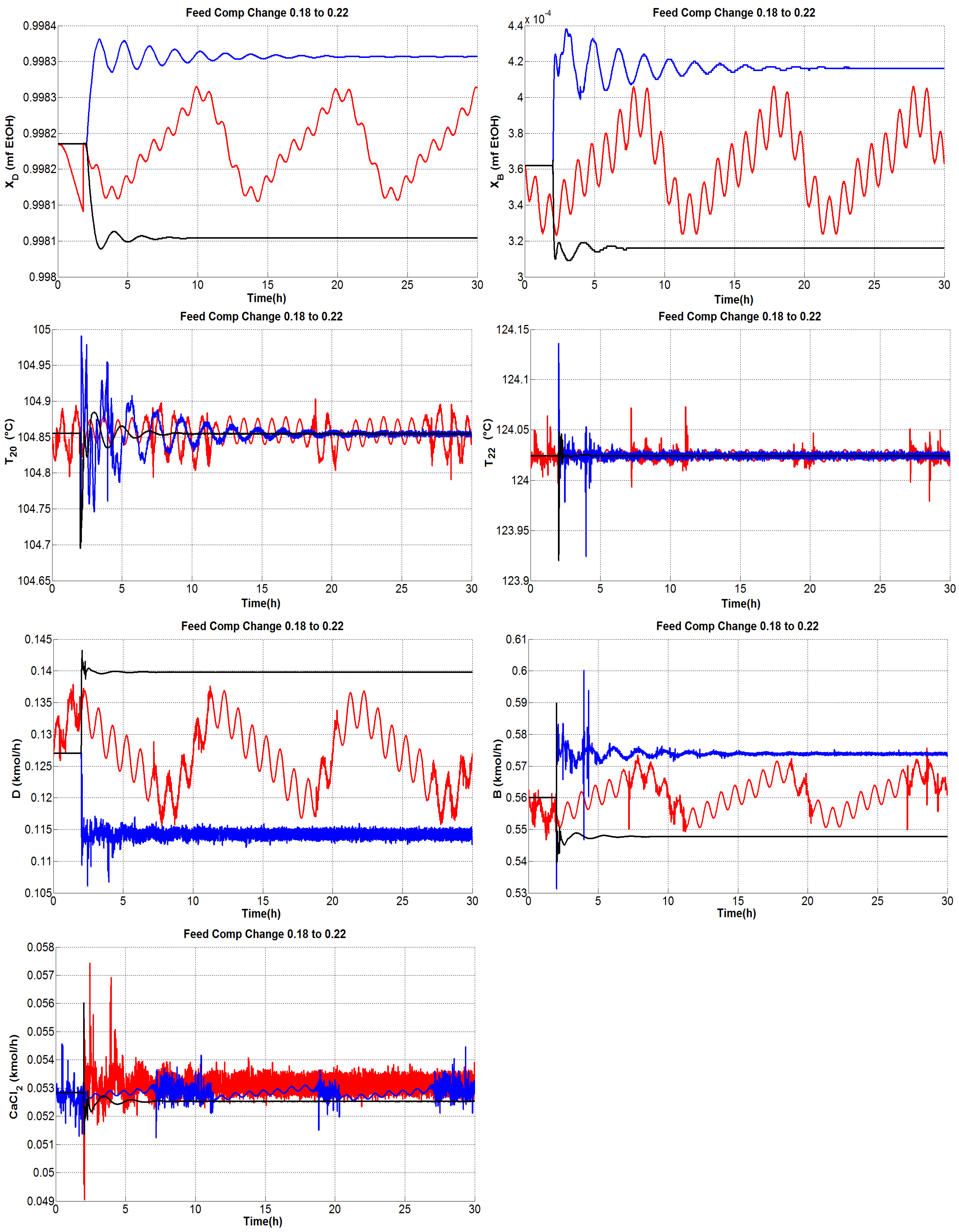

On the basis of a reliable steady-state simulator, we designed an ethanol dehydration pilot plant, and we present its operating configuration in

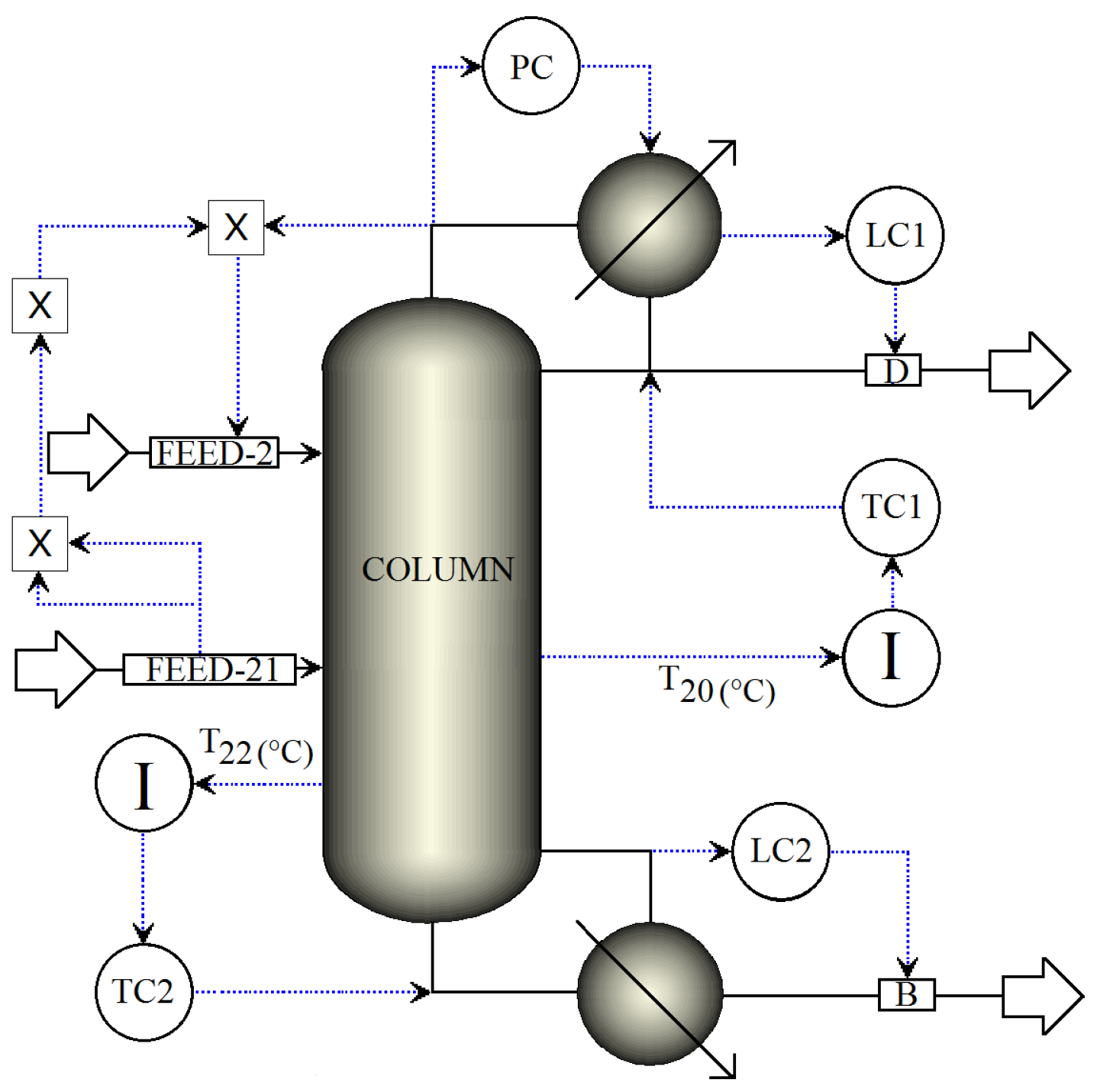

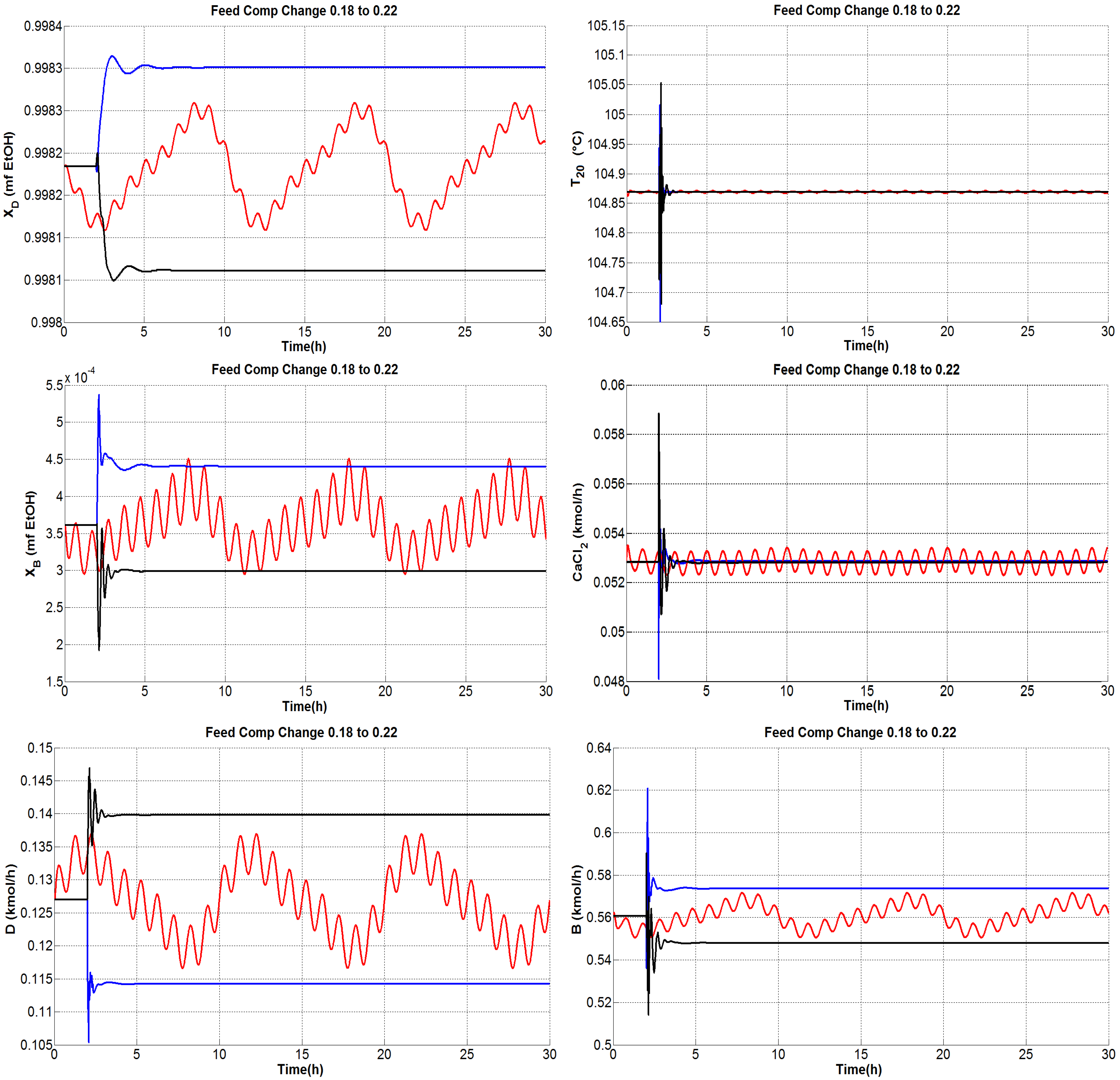

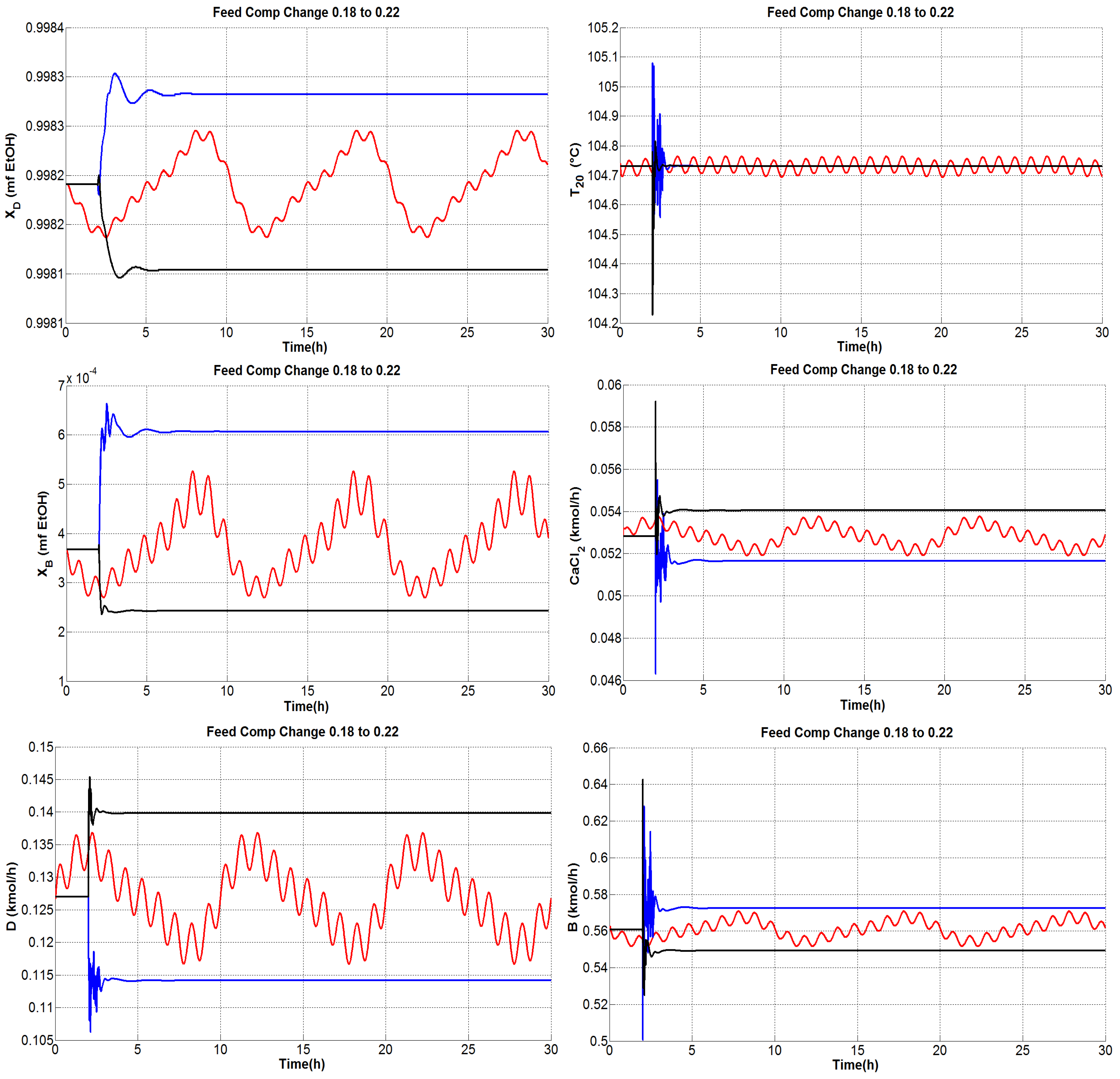

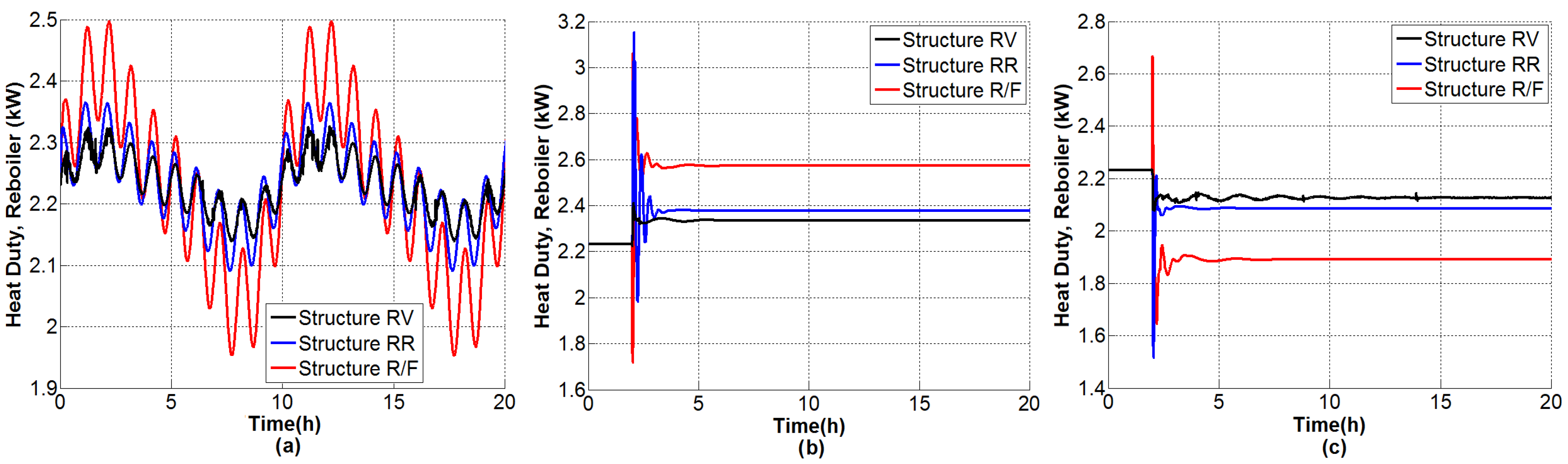

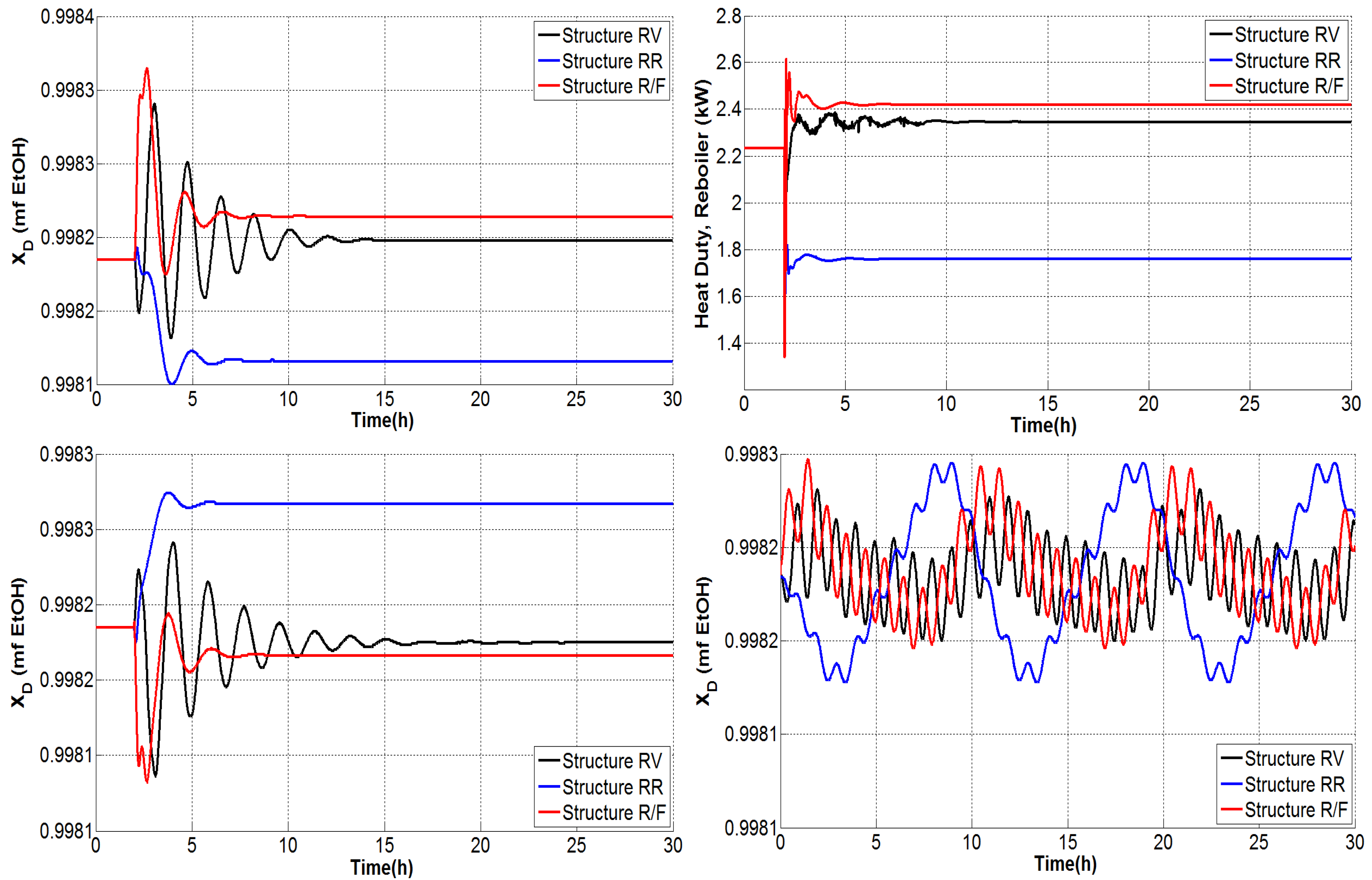

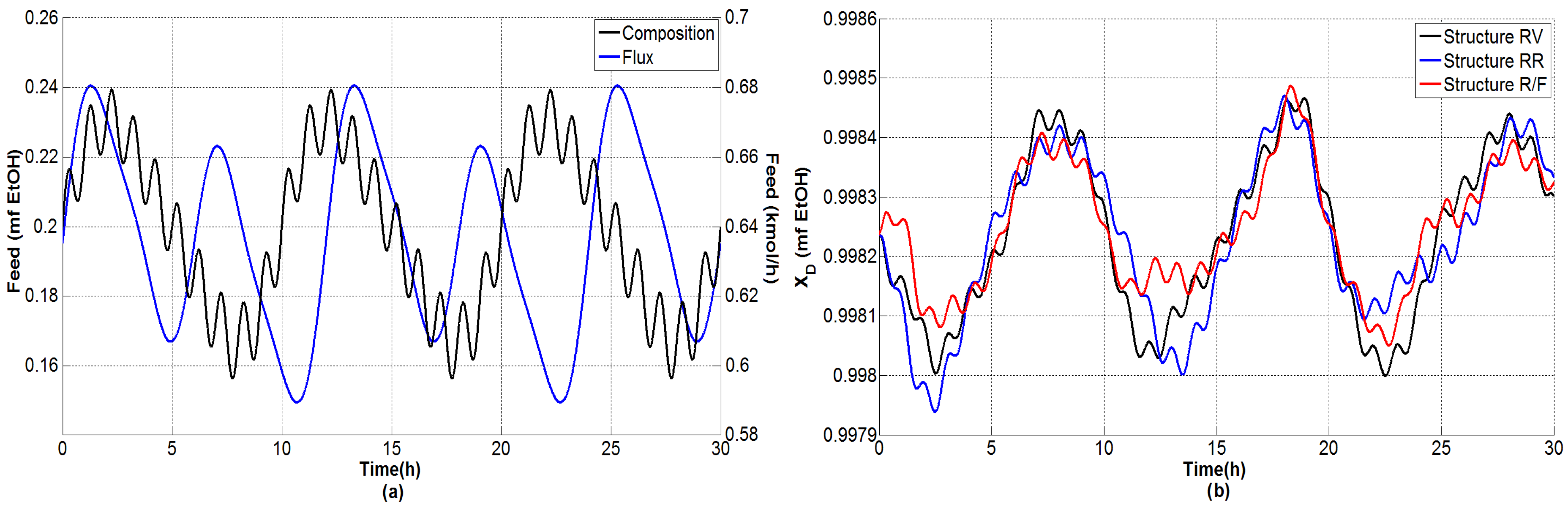

Section 2.3. As part of a flow-driven dynamic simulation carried-out in Aspen-Dynamics, following on from this design, we decided to prove three control structures (which are described in

Section 3); then, we evaluated and compared their performances by means of different criteria (in

Section 4). Here, we define the deterministic indicators: Integral time-weighted absolute error (ITAE), measuring persistent errors, Equation (4), Integral absolute error (IAE), Equation (3) and integral squared error (ISE), measuring large errors, Equation (2) that we used in addition to other classic performance indicators:

where the signal error

is the difference between the set-point or steady-state and the analyzed measured signal over time (

t).

2.2. Vapor–Liquid Equilibrium Prediction

The reliability of the distillation simulation depends on the validity of the phase equilibrium prediction, which is a demanding task owing to the non-ideal and electrolytic nature of the system. The Calcium Chloride (CaCl) is an effective separating agent in extractive distillation of mixtures composed of ethanol and water, and this electrolyte has an experimentally proved salting-out effect on the ethanol–water VLE. When a small quantity of CaCl is added to the binary mixture, the salt is dissociated in solution by the water at the same time that the relative volatility of ethanol increases to such an extent that the ethanol–water azeotrope is broken.

The VLE data of the ethanol–water–CaCl

system must be consistently expressed either, in terms of [

26]:

The true mole fractions

with

. Equation (5) defining the composition of the quaternary system: ethanol[1]-water[2]-Ca

[3]-Cl

[4]:

The apparent mole fractions or stoichiometric fractions

with

. Equation (6) defining the composition of the ternary system: ethanol[1]-water[2]-CaCl

[3]:

Or, on a salt-free basis mole fractions defining a pseudo-binary mixture: ethanol/CaCl

[1]–water/CaCl

[2]. Herein,

with

are the liquid phase salt-free mole fraction corresponding to the vapor phase mole fraction of ethanol

and the vapor phase mole fraction of water

. The salt concentration is calculated as indicated in Equation (7):

where

,

and

are the molecular weights of the ethanol (46.07

/

), water (18.02

/

) and CaCl

(110.99

/

), respectively, and

is the molecular weight of the binary mixture Equation (8).

We used the Electrolyte NRTL model to fit the experimental VLE data reported by Nishi [

23] for the ethanol–water–CaCl

mixture with CaCl

concentration of 16.7 wt % on a salt-free basis; therefore, the composition of the salt in the distillation column stages should be kept as close as possible to this value.

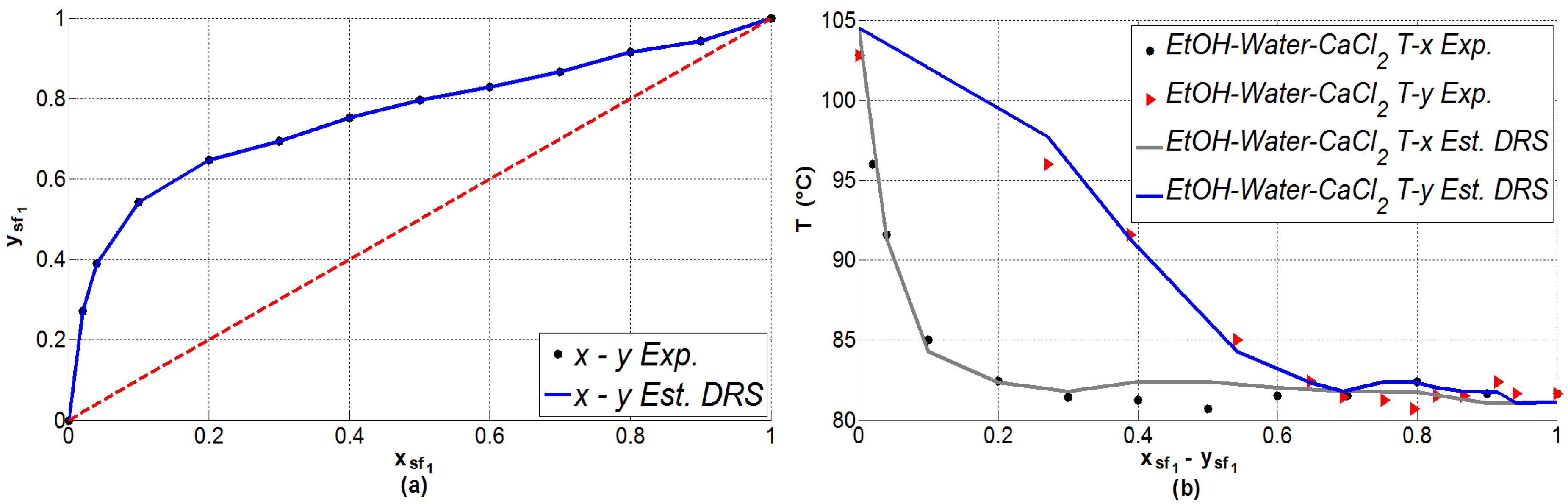

The interaction parameters of the Electrolyte NRTL model serve to estimate the activity coefficients. Both the procedure for obtaining the model parameters and the final tuning of the thermodynamic model are presented in

Section 2.1. The prediction of the

and

diagrams are depicted in

Figure 3 and

Table 2. The absolute mean error of estimation is 0.871129 for the temperature regression and 1.21765 × 10

−6 for the vapor composition fitting.

The VLE of the nonideal ternary system is estimated as if it were a pseudo-binary mixture. The fact that there is a point at which bubble and dew point temperatures intersect in

Figure 3 does not mean that an azeotrope arises, since the vapor and liquid do not coexist in the same composition. The point of intersection corresponds approximately to a temperature of 81.5

; in this condition the vapor and liquid compositions are 0.867 and 0.7, respectively. This condition, experimentally determined, has been commented on in references [

26,

50].

2.3. Steady-State Design

We considered two well-known case studies of ethanol dehydration as a basis to design a saline extractive distillation pilot plant with CaCl

as separating agent: the experimental study by Hashemi [

27] and the steady-state modeling study by Llano-Restrepo and Aguilar-Arias [

26], who estimated the ethanol–water-CaCl

VLE using the Wilson-E and the NRTL-E models, respectively. Similarly to the industrial practice, these works considered the separation of a slightly pre-concentrated mixture.

As pointed out by Llano-Restrepo and Aguilar-Arias, the simulation of the process should be conducted by keeping the concentration of CaCl

in the column as close as possible to 16.7 wt % on a salt free basis, since the experimental VLE data used to correlate the phase equilibrium model was obtained for this concentration [

23]. A saturated vapor mixture of ethanol–water feeding the column should guarantee this condition; however, an appropriate salt flow should also enter at the top of the column. Llano-Restrepo and Aguilar-Arias developed a steady-state equilibrium model of a saline extractive distillation process and simulated a column with 22 equilibrium stages, treating 100 kmol/h of a mixture of 20% ethanol and 80% water on a molar basis, fed at 94.5

and 1.01325 bar, a flow of CaCl

equal to 8.315 kmol/h at 78.3

keeps the salt concentration close to 16.7 wt %. The two operating specifications are a reflux ratio of 6.42 and a distillate flow of 20 kmol/h. We used their results to validate the ethanol dehydration simulation in Aspen-Plus, and the validation results are reported in

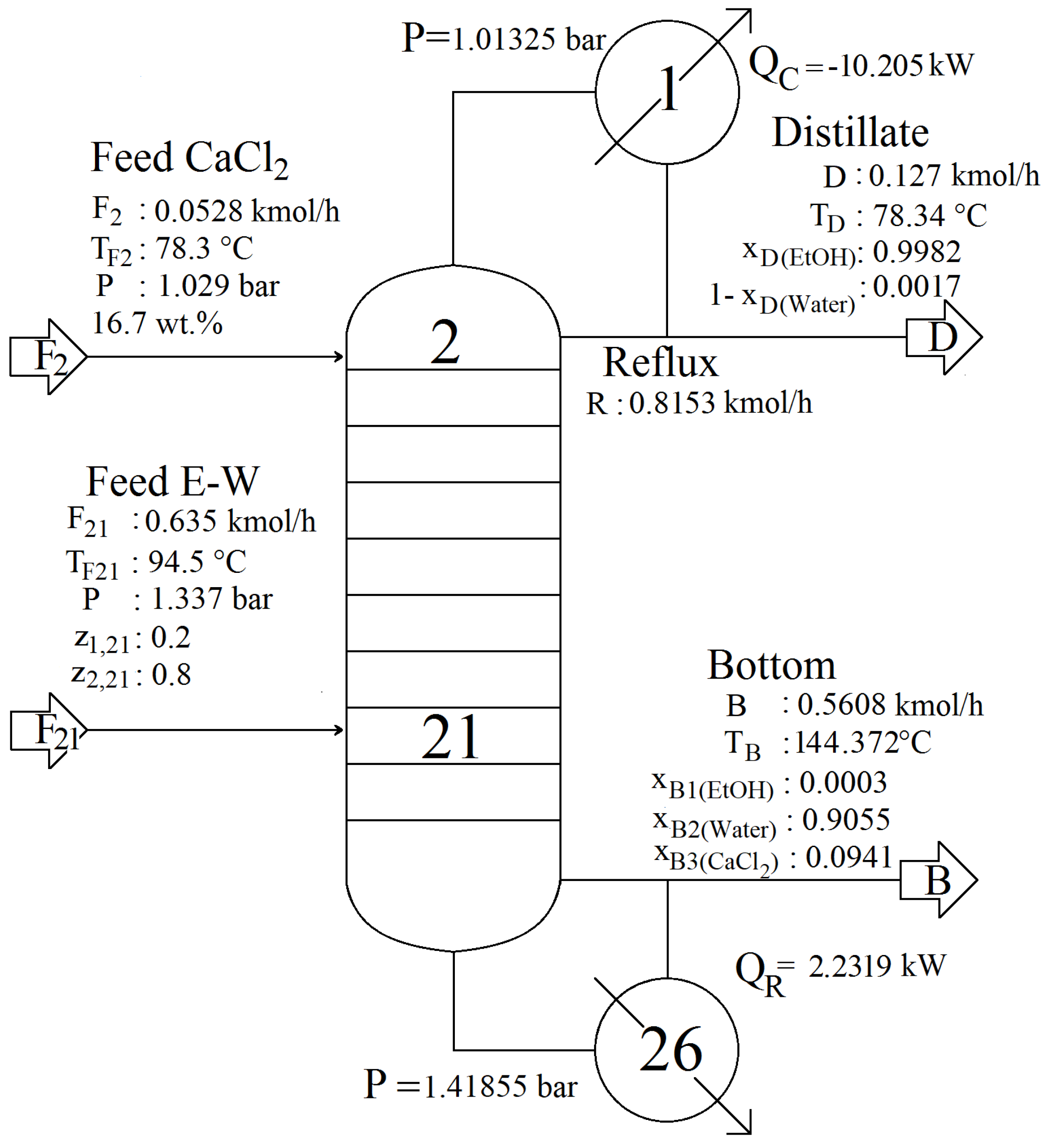

Section 2.1.

Taking as a starting point the described process, we designed a distillation pilot plant with flow specification of 0.635 kmol/h or 15 kg/h, which is the minimum flow for a pilot plant production (according to a quotation of Sulzer Chemtech Ltd, Sulzerallee 48, 8404 Winterthur Switzerland). Moreover, a rough approximation of the column efficiency is also assumed for simulating the process, thereby the number of trays increases with respect to the original design. The column efficiency estimated from the empirical O’Connell correlation was 40%; on the other hand, Barba et al. [

19] estimated a column efficiency of 70% for a packed column with three sections. As a crude estimation, an intermediate value of efficiency was assumed (50%).

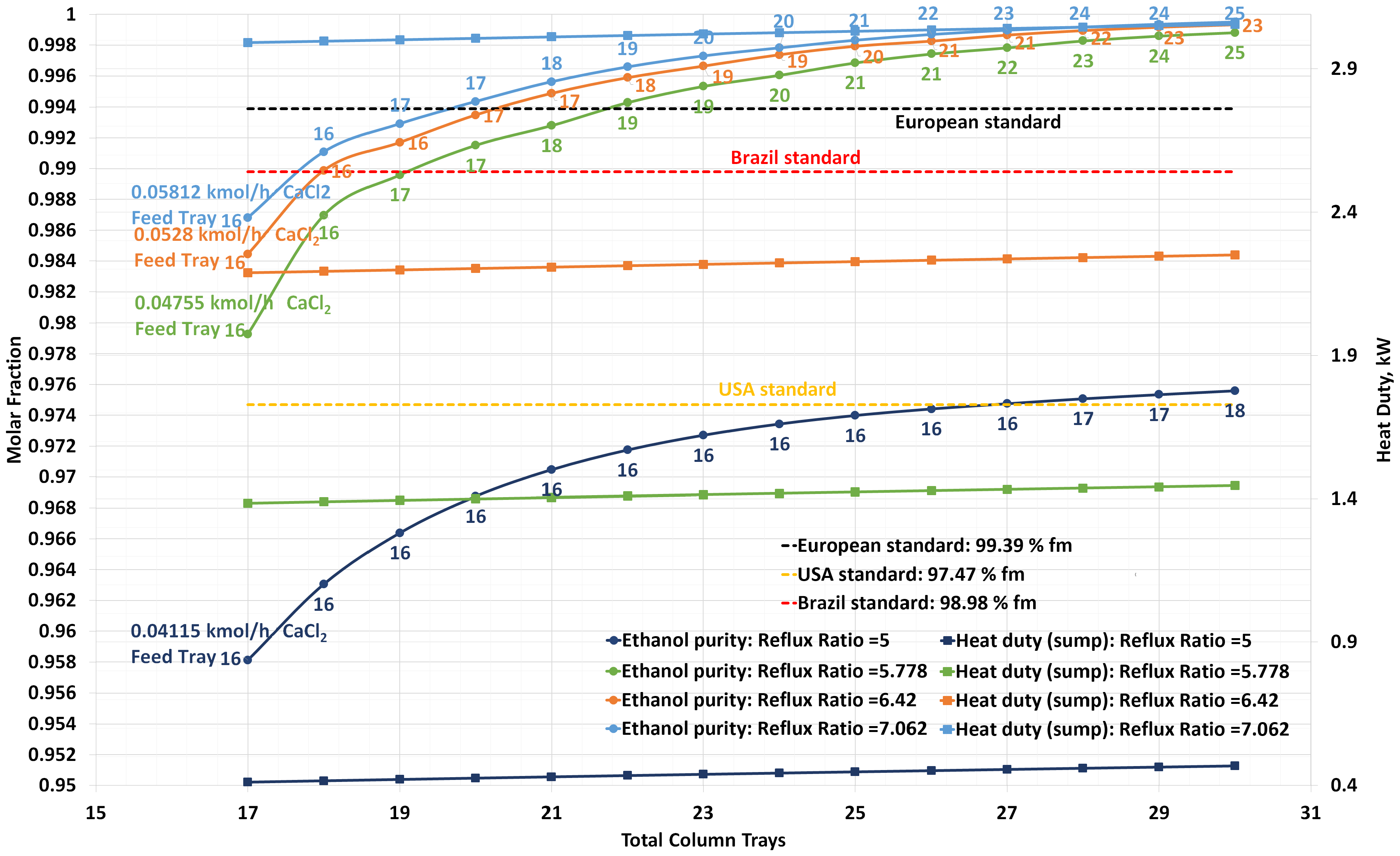

We performed a sensitivity analysis using the rigorous distillation model to determine the total number of stages of the column and the feed tray for a reflux ratio of 6.42. Simulations were done with reflux ratios between 5 and 7, in order to additionally investigate the influence of the operating conditions on both the product purity and energy consumption in the reboiler. Results provide useful insights for appropriately reconfiguring the column to different specifications of product or introducing energy consumption constrains, and for giving an early indication of the allowable tolerance to variation of the reflux ratio if desiring to conserve product quality within specifications. Thus, the results of the analysis are discussed to make evident the fulfillment of the described purposes.

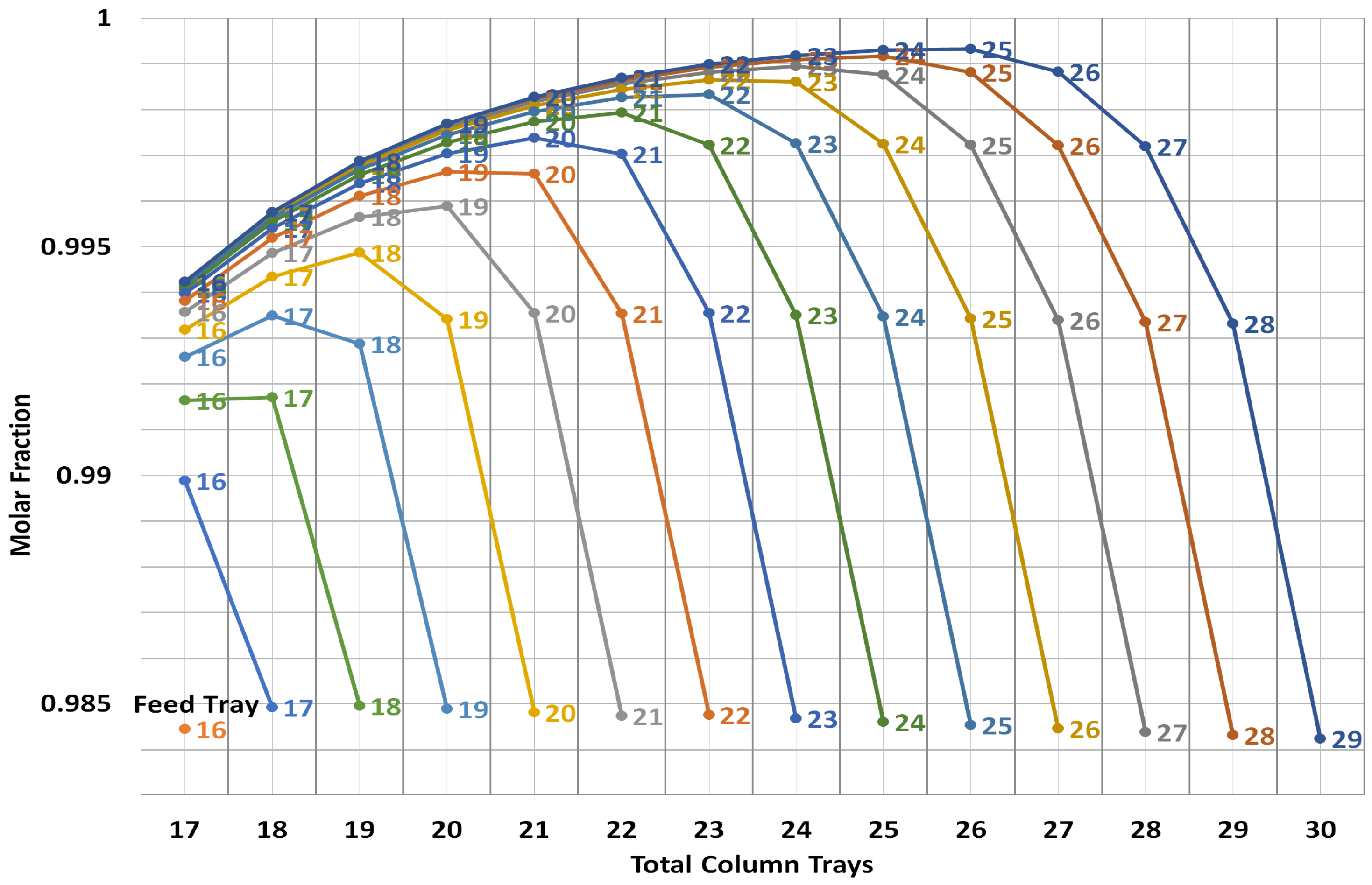

We examined how the purity of the distillate product depends on the feed tray location for a different number of stages in the column, including the condenser and the column base, considering four reflux ratios: 5, 5.778, 6.420 and 7.062. We firstly present

Figure 4 to show these relationships considering the nominal reflux ratio since the simulations with other reflux ratios have similar behaviors.

For a fixed reflux ratio and total number of stages, the relationship between purity and feed tray location is clearly nonlinear. The optimal stage for feeding the ethanol-water mixture is the tray for which the maximum purity is achieved. The feeding of the mixture before and after that tray produces purity drop, but the slope of the reduction curves is steeper for greater numbers of total stages.

Afterwards, the information extracted from the simulations carried out with different reflux ratios served to build

Figure 5, which shows the location of the feed tray that allows the maximum ethanol purity in columns with total number of trays between 17 and 30. The corresponding reboiler heat duty is also showed. Different issues are discussed below.

The effect of the reflux ratio on the ethanol purity is nonlinear: the purity increases with the reflux ratio, but the growing trend slows down for large reflux ratios. Instead, the energy consumed in the reboiler augments proportionally to the reflux ratio. Thus, considering the design reflux ratio (6.42) as a baseline, the gain in the purity of the product is minor when increasing the reflux ratio from 6.42 to 7.062 (0.066%), while the reboiler energy requirement augments to a larger extent (36.5%). Then, a drop in product purity occurs when reducing the reflux ratio from 6.42 to 5.778 (0.1316%), and the purity drop is stiffer as the reflux ratio diminishes, but the reboiler heat duty decreases by the same proportion (36.2%). The percentages provided were computed by considering a column with minimum 23 trays, in order to fulfill the European standard even for a reflux ratio of 5.778.

Both the purity of the product and the reboiler heat duty also depend on the total number of trays, but the effect of varying the number of trays is lower compared with the effect of changing the reflux ratio. For a constant reflux ratio, a larger number of total trays improves purity, but also increases the energy consumption.

A trade-off between purity and energy consumption should be established when defining the reflux ratio and the total number of trays, but an additional criterion is the fulfillment of technical specifications for fuel ethanol quality. The European standard (CEN EN 15376:2014, European Committee for Standardization) requires the ethanol to contain a maximum of 0.24 vol % water, the USA standard requires a maximum water content of 1 vol %, whereas the Brazil ANP (National agency of petroleum) Resolution 36, 0.4 vol % [

51]. Thereby, the considered minimum ethanol content product specifications are 99.76 vol % (99.39% mole), 99.0 vol % (97.47% mole) and 99.6 vol % (98.98% mole), respectively.

Given a reflux ratio of 5, the distillation provides a product with a maximum purity of 0.976. The product meets the minimum ethanol content set by the American standard only with columns composed of at least 27 total stages. For higher values of reflux ratios, at least 22 stages are required to meet the three quality standards reported in this paper.

Given a reflux ratio of 6.42, the three quality standards are met for a minimum of 22 stages, but the range of variation of the ethanol mole fraction would be very restrictive and would be difficult for achieving the operational objective of the control. Then, the decision is to use a column with 26 total stages, selecting tray 21 to feed the ethanol-water mixture to be treated.

Control structures that exhibit variation of the reflux ratio should not have a problem tolerating changes of at least ±10% (from 5.778 to 7.062) of the nominal value because, in the operating region, the product purity is less sensitive to changes of the reflux ratio and the purity is quite high there; moreover, a large margin exists with respect to the quality standards. On the other hand, the reboiler heat duty, as mentioned before, is more affected by the reflux ratio changes. The process design is specified in

Table 3, which includes the input nominal operating conditions. The flowsheet of the process is depicted in

Figure 6.