1. Introduction

Maritime transport accounts for a large proportion of the transportation industry. However, the resulting gaseous and particle emissions from ships pose a threat to public health and the environment [

1,

2]. The emissions of ships considerably contribute to the levels of ambient air pollutants [

3,

4,

5]. This is especially the case with the recent usage of low-grade heavy fuel oil (HFO), which has the advantage of low price compared to other types of fuel. HFO includes some sulfur and is mainly used to power ships that have low-speed diesel engines installed. The SO

2 and particulate matter (PM) are mainly derived from HFO combustion due to the high fuel sulfur content (FSC) [

6,

7]. The sulfate and bound water were the main chemical species contributing to the mass of PM [

8]. In addition to substantial SO

2 and PM emissions, high amounts of NO

x and polycyclic aromatic hydrocarbons (PAHs) are generated, which also have hazardous effects on health [

9,

10]. The quality and type of fuel can affect the emissions of harmful substances [

11]. The NO

x-reduction method involves selective catalytic reduction (SCR) technology, which is a widely recognized technology applied in ships. The PAHs are usually attached to the surface of PM, such as elemental carbon (EC), organic carbon (OC), and sulfate [

12,

13]. The PAHs, OC, and EC are usually affected by engine loads [

14]. PM emissions are largely dependent on the operating conditions of engines as well as fuel type [

15,

16]. According to some opinions, optimizing the combustion conditions of engines and changing the fuel type can solve the emission problem in ships [

17]. It was assumed that a reduction in the fuel sulfur content (FSC) will considerably reduce the emissions of particulate matter (PM). The difference between the high sulfur oil and low sulfur oil for PM emissions was minimal, with the amount of coarse PM and of particles emitted remaining unchanged.

The International Maritime Organization Marine Environment Protection (IMO MEPC) and other countries have stated that sulfur emission regulations and PM from ship emissions will likely exceed that of regulations in the future [

18,

19]. Many regions have also set sulfur emission-controlled areas (SECAs), such as in the Caribbean of United States, Baltic Sea, North Sea, North America, Hong Kong, and the eastern coastal areas of China. Among these areas, the emission-controlled areas (ECA) of the Caribbean of United States and North Sea also have strict requirements for NO

x and PM emissions. The sulfur content has to be 3.5% (m/m) in non-ECA before 2020 and 0.5% (m/m) after 2020. In ECAs, the content has to still be 0.1% (m/m) according to the regulations of the IMO [

20,

21]. To solve the sulfur and PM emission problems in ships, using low-sulfur fuel oil (or LNG and other cleaning fuels) [

22,

23] or installing exhaust gas cleaning (EGC) systems have been suggested. Compared to using only HFO, the two methods—using low-sulfur fuel and installing a scrubber—can add the total cost of shipping. The price of the low-sulfur fuel is much higher than HFO with additional modification costs for the fuel conversion system. The EGC systems include the initial investment in the system, maintenance cost, and employee wages. The EGC technologies can significantly reduce the emission of PM [

24]. The diesel filter would not be suitable for the low-power, low-speed marine diesel engine due to back pressure [

25]. The EGC technologies include closed-loop, open-loop, and hybrid systems [

26]. The open-loop system uses seawater to remove SO

2 in the exhaust gas based on natural alkaline of seawater and waste water. After scrubbing, this water is discharged into the sea. However, it can cause secondary pollution and contribute to the greenhouse effect due to the release of carbon dioxide. Furthermore, it has high energy consumption [

27,

28,

29]. The closed-loop system uses fresh water or seawater as the carrier in addition to sodium hydroxide as the absorbent to remove SO

2 in exhaust gas. It has the advantages of high desulfurization efficiency, low energy consumption, and no CO

2 emissions. The closed-loop system is the most suitable technology for the exhaust gas desulfurization technology of ships [

30,

31,

32].

This study presents the impact of the after-treatment technology exhaust gas cleaning (EGC) system on marine diesel engine emissions and the advantages in terms of cost compared to using low-sulfur fuel oil. The emission factors of various pollutants from low-speed two-stroke marine diesel engines were also investigated. Using the EGC system and using low sulfur oil also complies with the new FSC limit in ECAs or non-ECAs before and after 2020. The aim of this study was to investigate and predict the removal efficiency of SO2 and PM for the EGC system. The economic comparison of using the EGC system and low-sulfur oil was also a major research goal.

2. Material and Methods

2.1. Engine and Test Cycle

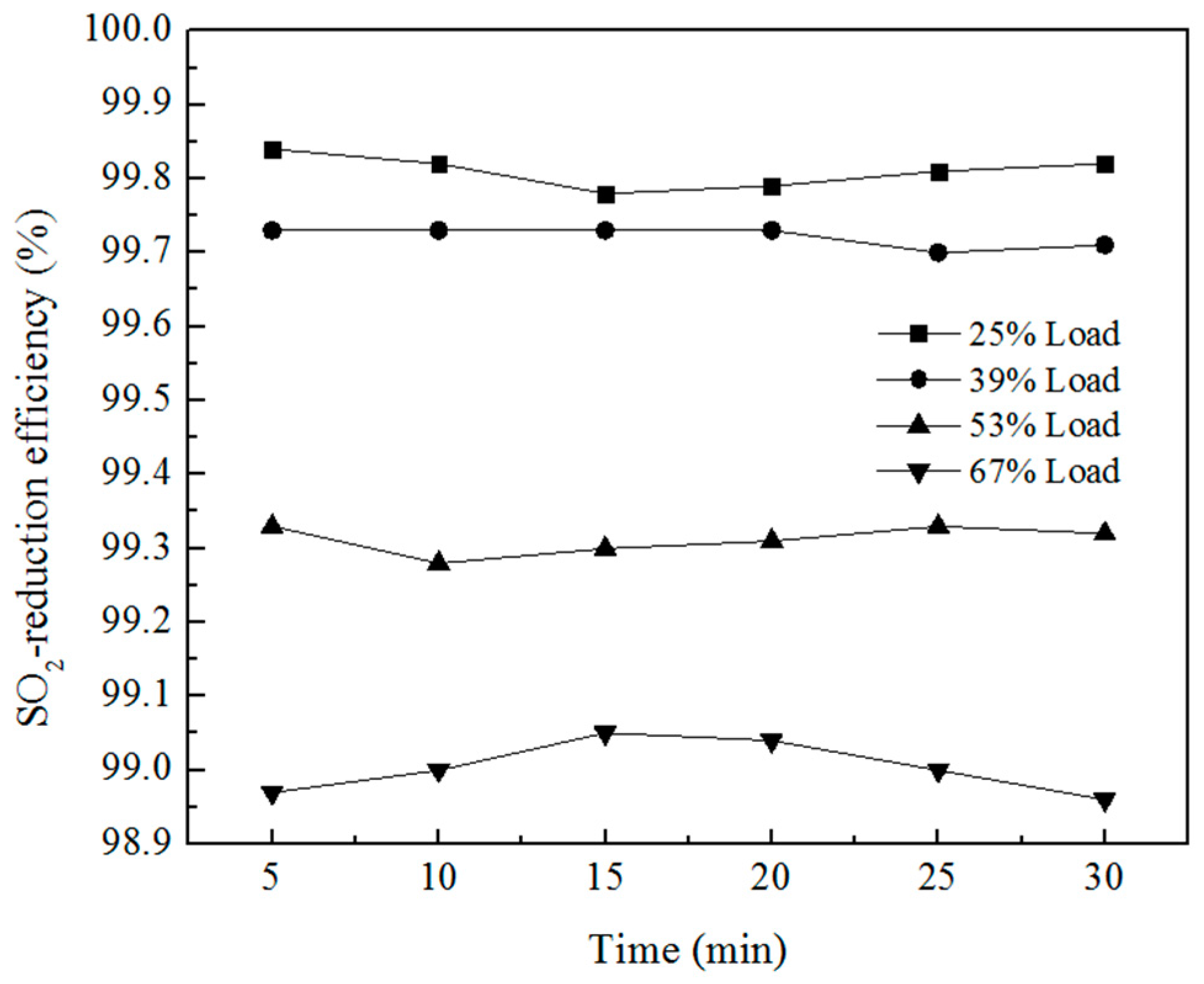

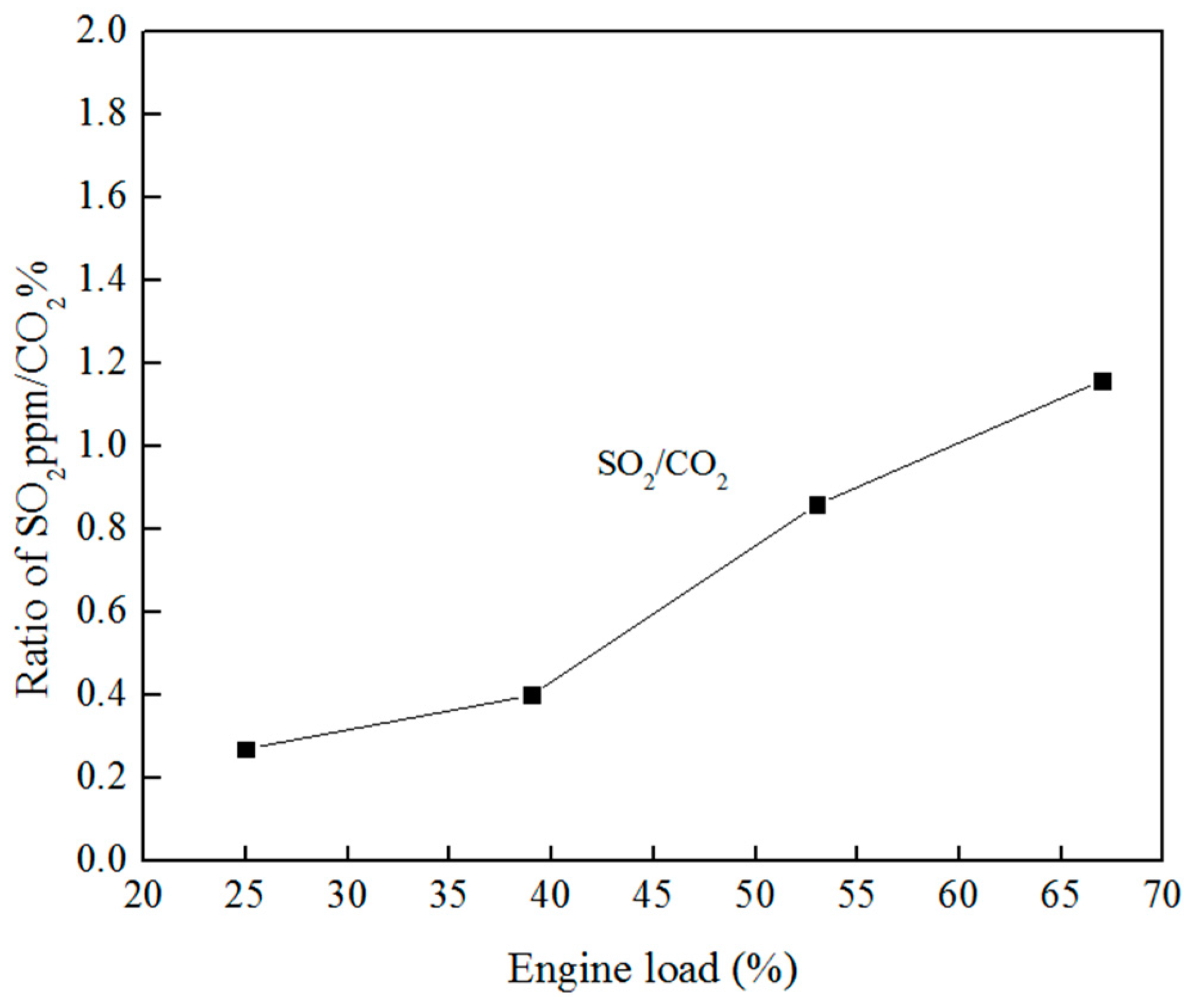

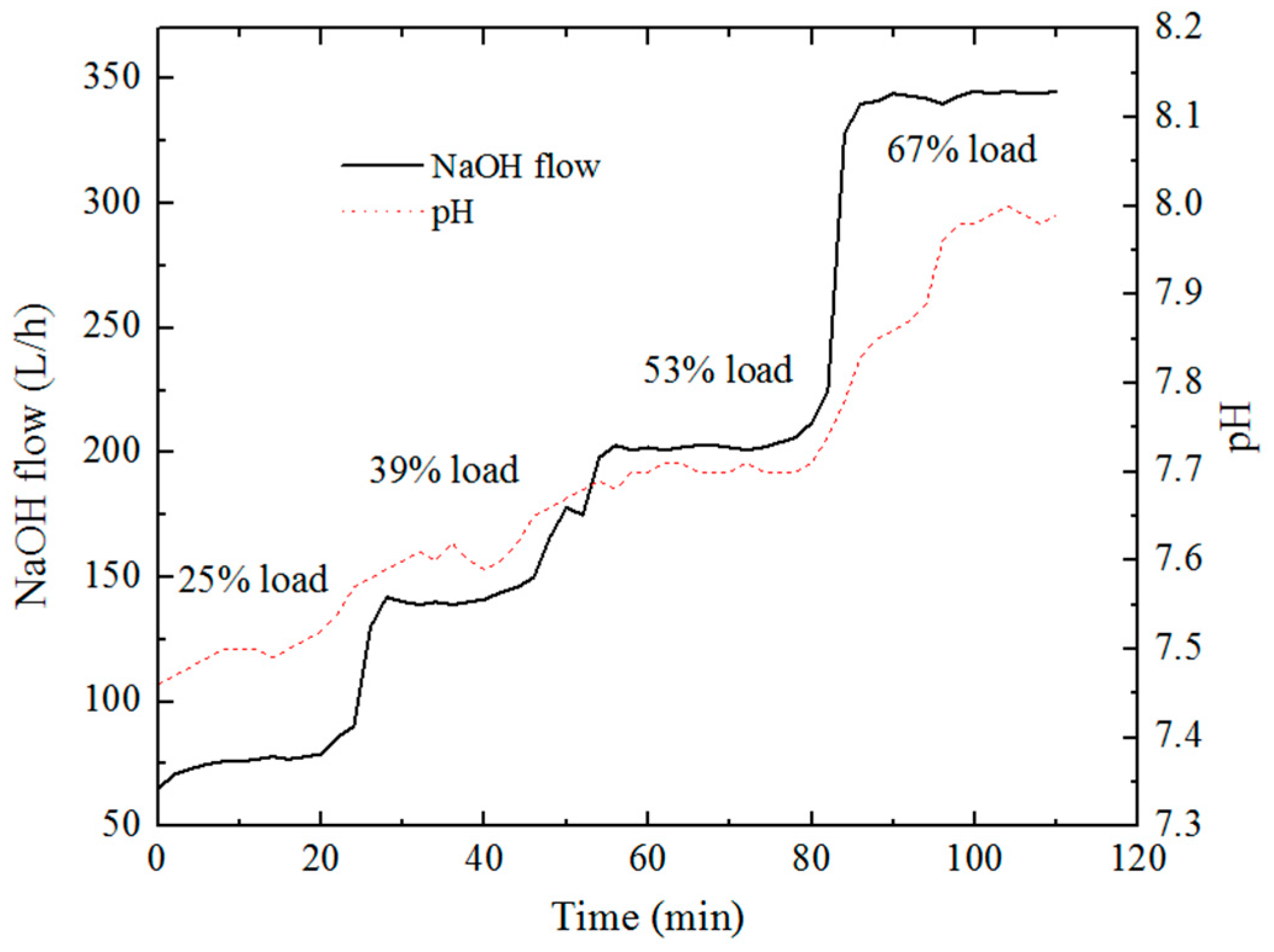

The study engine in this real test was a two-stroke, slow-speed marine diesel engine. The engine ran at 6160 kW and 99 rpm. During the study, loads were assigned with the main engine (ME) running at 25, 39, 53, and 67%. The test cycle is shown in

Table 1.

2.2. Fuel Properties

The study engine was run with high sulfur oil (3.36 wt % of S) and low-sulfur oil <0.1 wt % of S). The sulfurous organic material was added into the diesel oil to adjust the sulfur fuel content according to the content of HFO. The selected properties are in

Table 2.

2.3. EGC System Description

This EGC system was designed in accordance with a maximum power of 4200 kW, while the body material of this tower was stainless steel. It was 2.2 m in diameter and 6 m high. The ratio of liquid to gas was 2 L/m3, while the ratio of sodium to sulfur was about 0.8–0.9 when operating. The scrubber included a two-spray layer and demister structure. The required desulfurization efficiency was greater than 97.15%, which corresponds with the 0.1% fuel sulfur content limit. It consisted of a tower shell, spray system, mist eliminator, external steel structure, and so on. All parts of the scrubber were made of corrosion-resistant stainless steel. It could withstand SO2 and ultrafine particle corrosion in addition to meeting the requirement of anti-corrosion. The EGC system included the required temperature, pressure measuring points, and so on. The operation mode of the EGC system was a closed-loop cycle.

Alkali was fed to the scrubbing water pipes to maintain the pH value and ensured desulfurization efficiency. Generally, 50% NaOH was used for the supplementary alkali. As the low condensation point of 20% NaOH solution is –30 °C, 20% NaOH solution was also chosen as supplementary alkali in some situations.

The EGC system included a scrubber system and wastewater treatment system. The desulfurization byproduct included sulfite, sulfate, hydrosulfite, polycyclic aromatic hydrocarbon (PAH), and sludge. There was an oxidizing fan in the wastewater treatment system, which was used to make sulfite into sulfate. The wastewater treatment system also included a buffer tank, coagulant, monitoring system, and separator. The requirements of IMO included the pH value, turbidity, and PAH concentration. The nitrate will be detected by the inspection department of the ship at the scene.

2.4. Measurement and Analysis

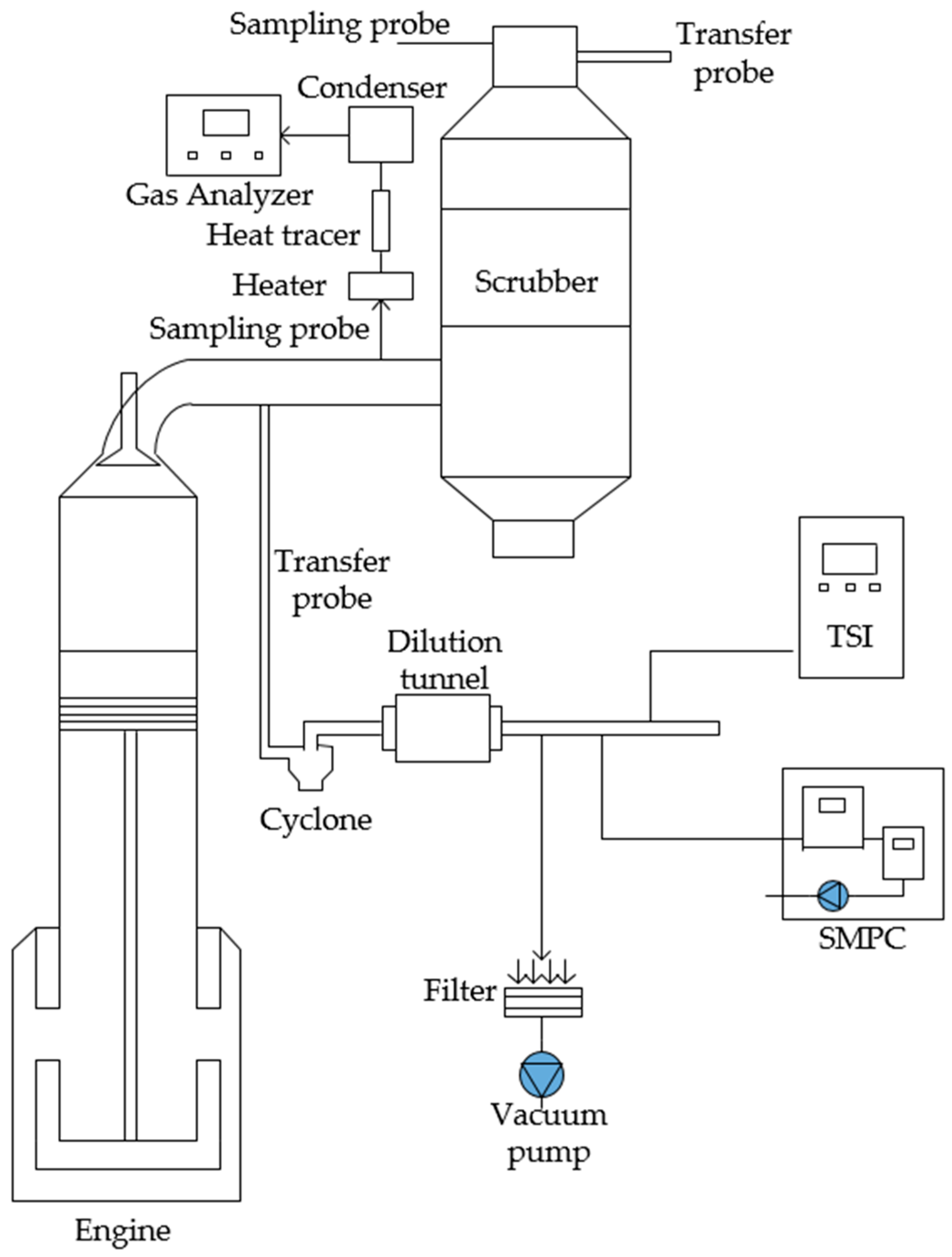

The analyzed exhaust gas from the engine was sampled from the pipes before and after the scrubber. The principle diagram showing a schematic of the engine test system can be found in

Figure 1.

Figure 2 is a photograph of the experimental setup for a scrubber in a marine diesel engine.

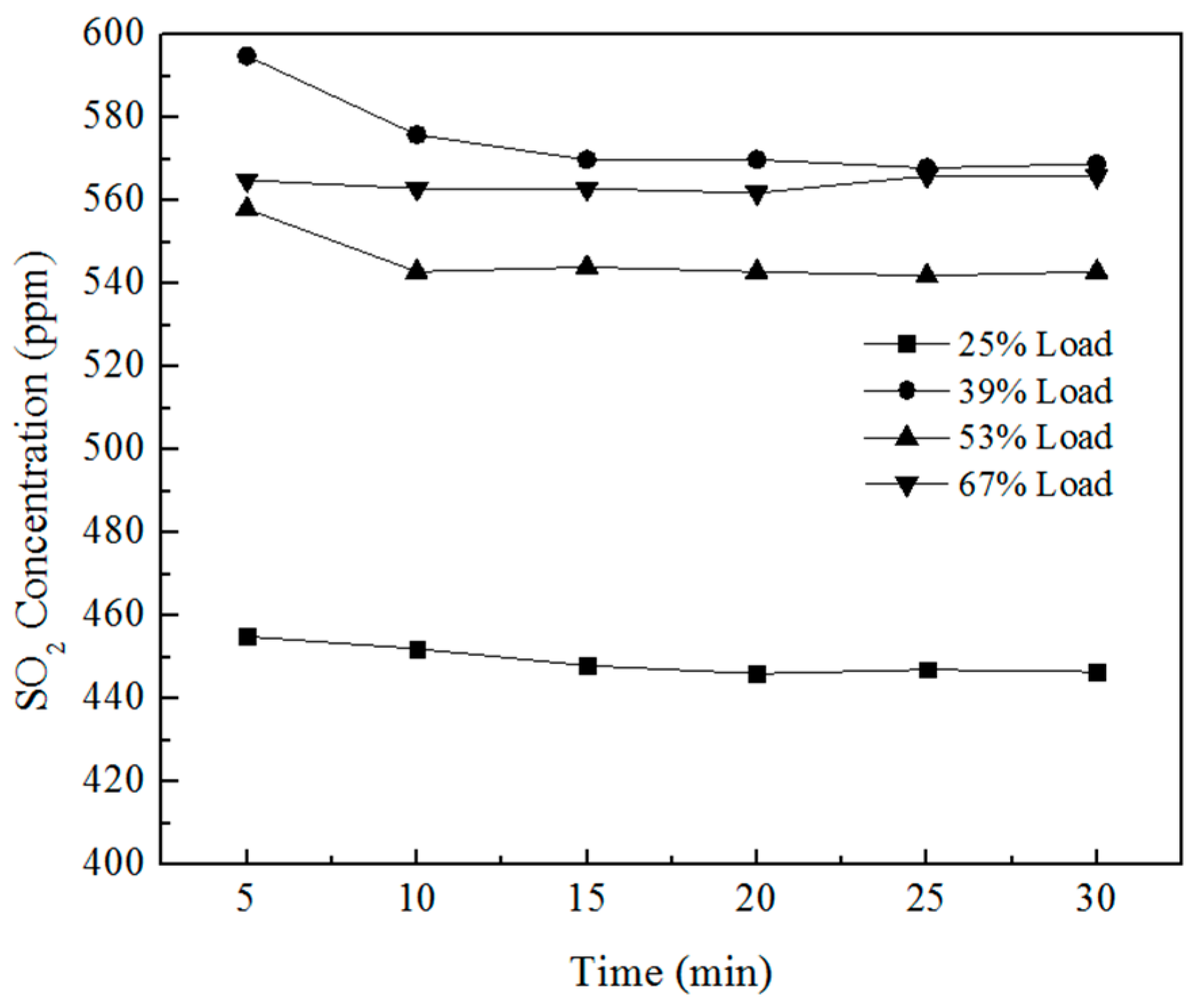

2.4.1. Gas Measurement

SO2, NOx, O2, CO2, and CO were measured by exhaust gas analyzers (PG-350, Horiba, Japan). The analyzers were equipped with chemiluminescence detection (CLD), non-dispersive infrared sensor (NDIR), and zirconia sensor. NOx was measured by CLD with fluid modulation. SO2 and CO were analyzed by NDIR with fluid modulation. CO2 was measured by NDIR with light source modulation. O2 was measured by a zirconia oxygen analyzer. The measurement was to be carried out at each mode point after the engine was stabilized. When stabilized for at least 5 min, the output of the analyzer was to be recorded on a strip chart recorder or a data acquisition system. The duration for every mode was 30 min and the recording period was not to be less than 10 min. For data acquisition systems of PG-350, the sampling frequency was 12 per minute.

2.4.2. PM Measurement

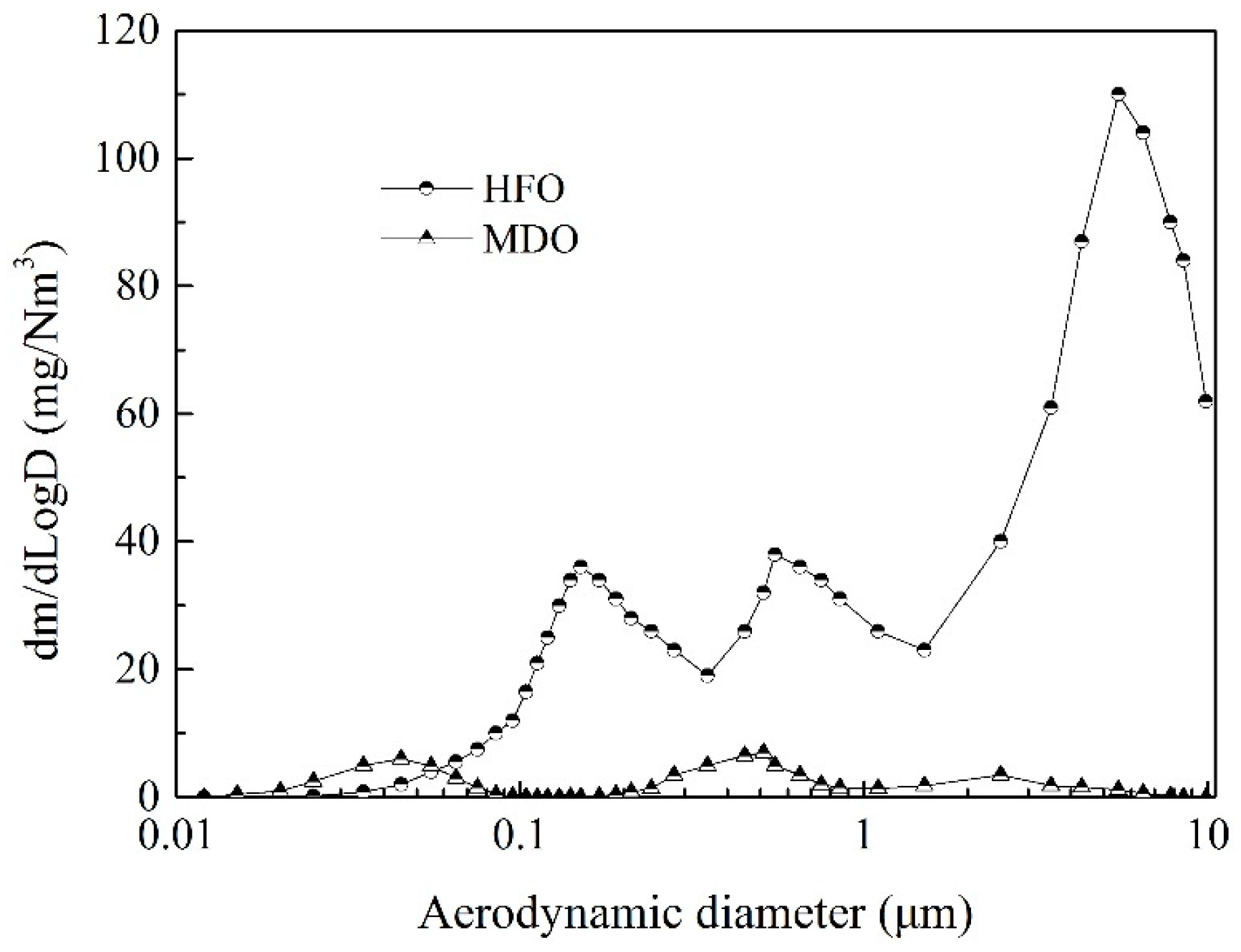

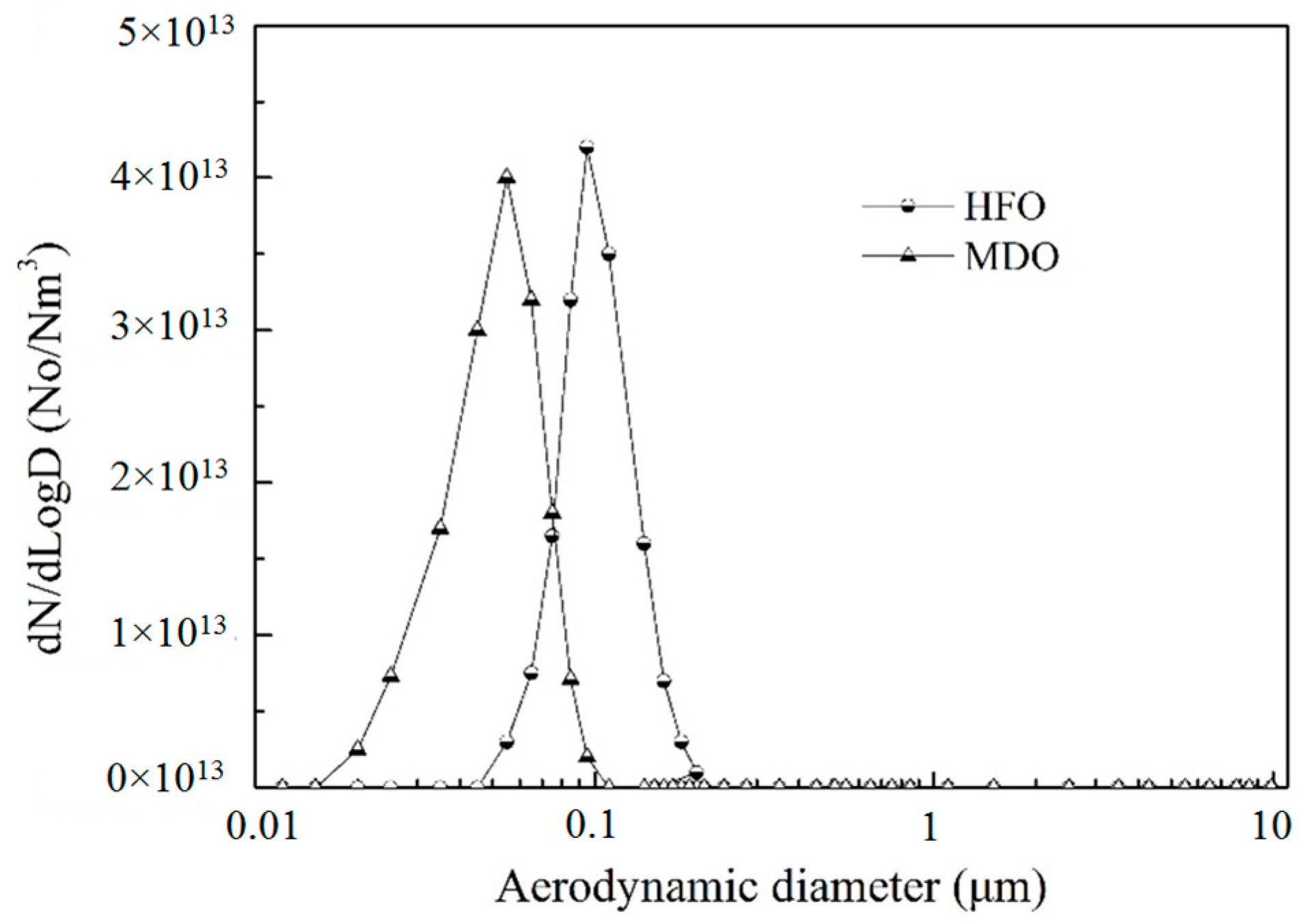

The sampling for PM analyzers and filter collections was taken from the pipe after dilution. The cyclone can remove particulate matter of a large diameter. The dilution ratio ranged from 500 to 800. PM filter samples were collected on a quarts filter with diameter of 47 mm (Zefluor, Pall, NY, USA). The quartz filters need to be heated in the muffle furnace at 500 °C for 4h to remove carbon impurities before sampling. Before and after collection, the filters were conditioned for 24 h in an environmentally-controlled space (ratio of humidity (RH) = 40%, T = 25 °C). The particles on the were measured using microbalance (XS105, Mettler-Toledo, Columbus, OH, USA). The NanoScan SMPS (Model 3910, 10 to 420 nm, TSI, USA) and Engine Exhaust Particle Sizers (Model 3330, 0.3–10 μm, TSI, Shoreview, MN, USA) were used to measure the particle size distribution.

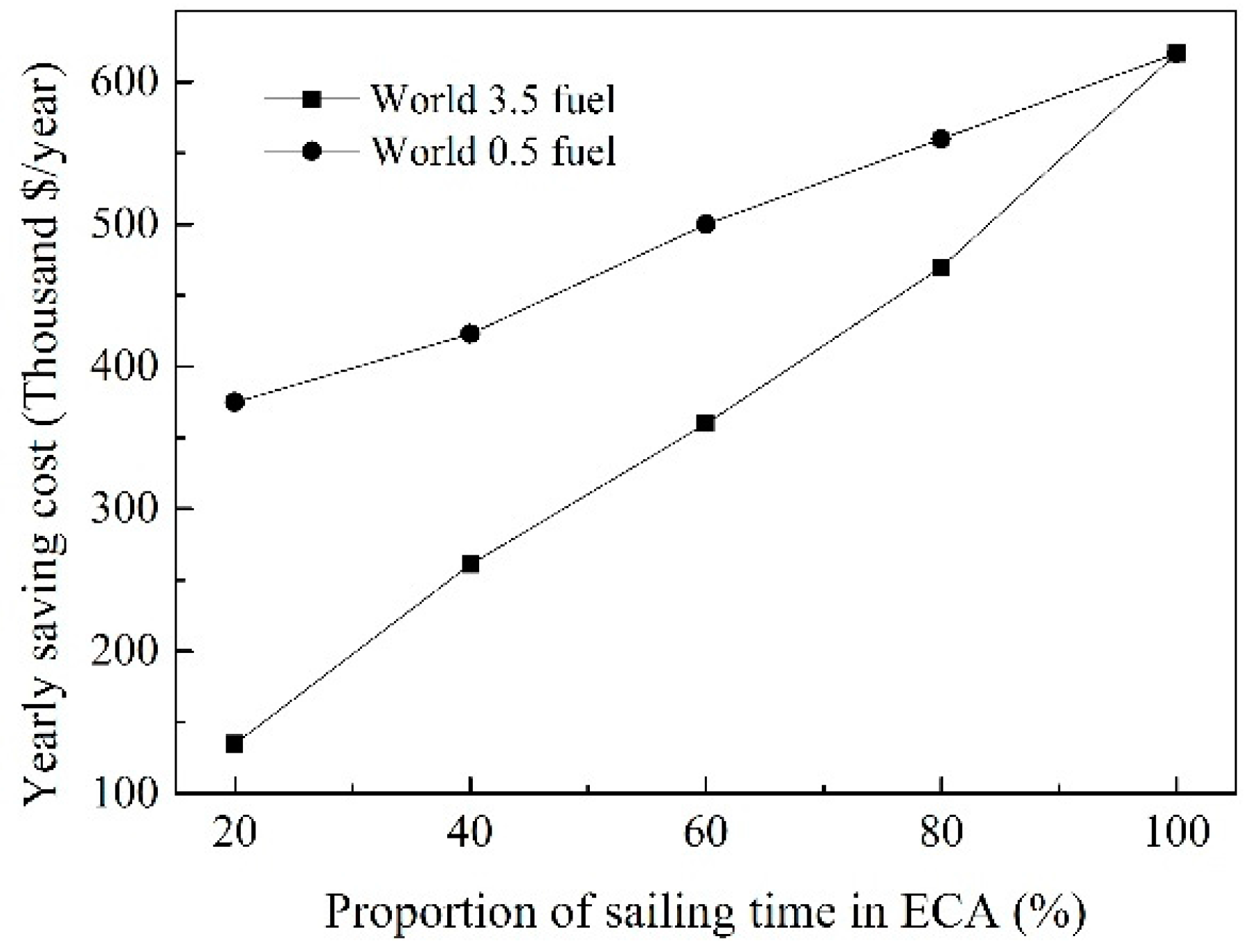

4. Economic Study

The sulfur content is 3.5% (m/m) in non-ECA before 2020 and 0.5% (m/m) after 2020. In ECA, the content remains at 0.1% (m/m) according to the regulations of IMO. Therefore, one of the two methods using low-sulfur fuel and installing a scrubber must be selected. The following shows the consumption and economic analysis of the EGC system. Furthermore, a comparison between using low-sulfur fuel oil and a scrubber was also made. The calculated data for a closed-loop EGC system on a 6S35MC MAN B&W marine diesel engine (CSSC Marine Power CO., LTD, Zhenjiang, China) is provided in the rest of this section.

The initial investment of the EGC system mainly includes the system equipment cost, production and processing cost, ship modification cost, maintenance cost, and employee wages. When using low-sulfur fuel oil, the initial investment includes equipment and modification cost of the fuel conversion system and maintenance cost. For the scrubber, the installation cost was 10% of the equipment procurement cost, while the maintenance costs were 4% of the equipment procurement cost. Employee expenses were based on the international average wage level. According to the initial investment of this EGC system, the equipment procurement cost was $1,500,000, while the total initial investment was $2,400,000. Along with the advancement in the scrubber industrialization, the initial cost will be reduced. The initial investment of the EGC system was higher than using low-sulfur fuel oil, with the initial cost difference between installing a scrubber and using low-sulfur fuel oil being $2,000,000. All prices of consumables—such as fuel, chemical production, and other costs—were analyzed according to the prices in 2016. The initial cost of this scrubber is equivalent to the cost of around a 5 MW two-stroke engine, although one of the two methods must be used to meet the emission regulations of IMO and the initial costs will not have large fluctuations with an increase in engine power. The economic data was from the test and emission project guide of MAN Diesel & Turbo. The NaOH consumption from this test and fuel oil consumption was due to SFOC and the engine power. Furthermore, the initial investment and running costs of the EGC system were calculated according to the requirements of IMO and other references.

The engine load and sailing time in ECAs and non-ECAs can affect the total consumption. The absolute consumption according to the load profile is shown in

Table 4.

The yearly consumptions and running costs of installing the scrubber and using low-sulfur fuel oil were analyzed according to the emission regulations after the year of 2020 in

Table 5 and

Table 6. The sulfur content of fuel is required to be at 0.5% (m/m) in non-ECAs and 0.1% (m/m) in ECAs. The ship sailing time was presumed to be 2000 hours in ECAs with a running scrubber and 4000 hours in non-ECAs without a scrubber.

When HFO and a scrubber were used in the ships, the yearly running cost of the EGC system was

$619,000/year and the results are presented in

Table 5.

Table 6 shows the yearly running cost in USD of using low-sulfur fuel without a scrubber. The yearly running cost of using low-sulfur fuel was

$1,035,000/year. The results show that compared to using low-sulfur fuel oil, using a scrubber could reduce the yearly running cost of ships and the saving cost is a key factor influencing the cost payback period of installing a scrubber. The difference of

$416,000/year was a result of the high price of low-sulfur fuel oil and the value was also defined as the yearly saving cost from using a scrubber.

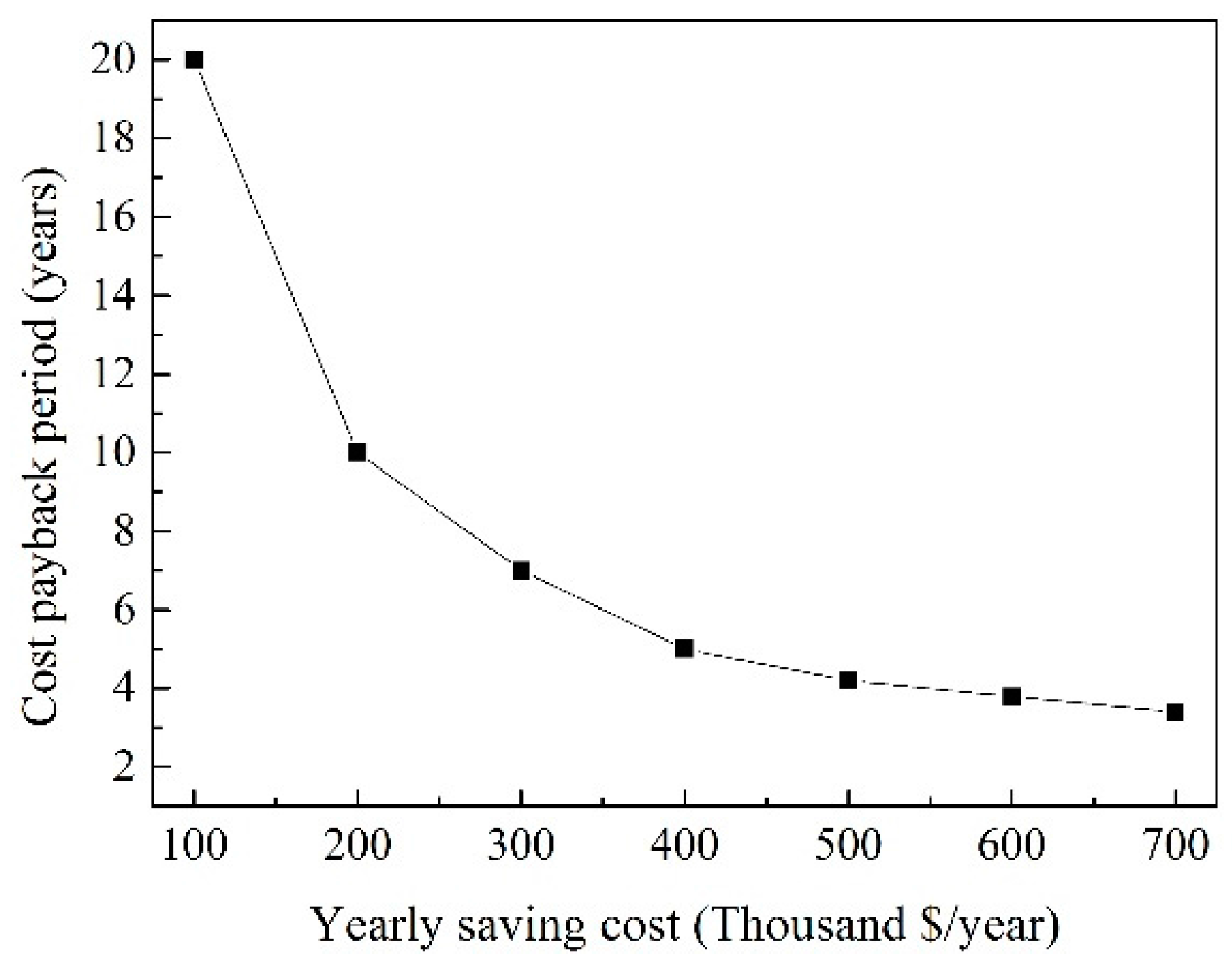

The yearly running cost of a scrubber was related to the sailing time of ship in ECAs, with the total sailing time supposed to be 6000 h annually. The relationship between yearly saving cost and sailing time in ECAs for using a scrubber is presented in

Figure 11, while the relationship between cost payback period and yearly saving cost is presented in

Figure 12. The yearly saving cost is the difference in value of the yearly running costs between using low-sulfur fuel oil and using a scrubber. Under the regulations, the saving in cost increases and the cost payback shortens with an increase in sailing time in ECAs. Therefore, compared to using low-sulfur fuel oil, installing a scrubber was more advantageous and the advantages will be more evident after 2020. The increase in the emissions control area and sailing time in ECAs will also intensify the advantages of the EGC system.

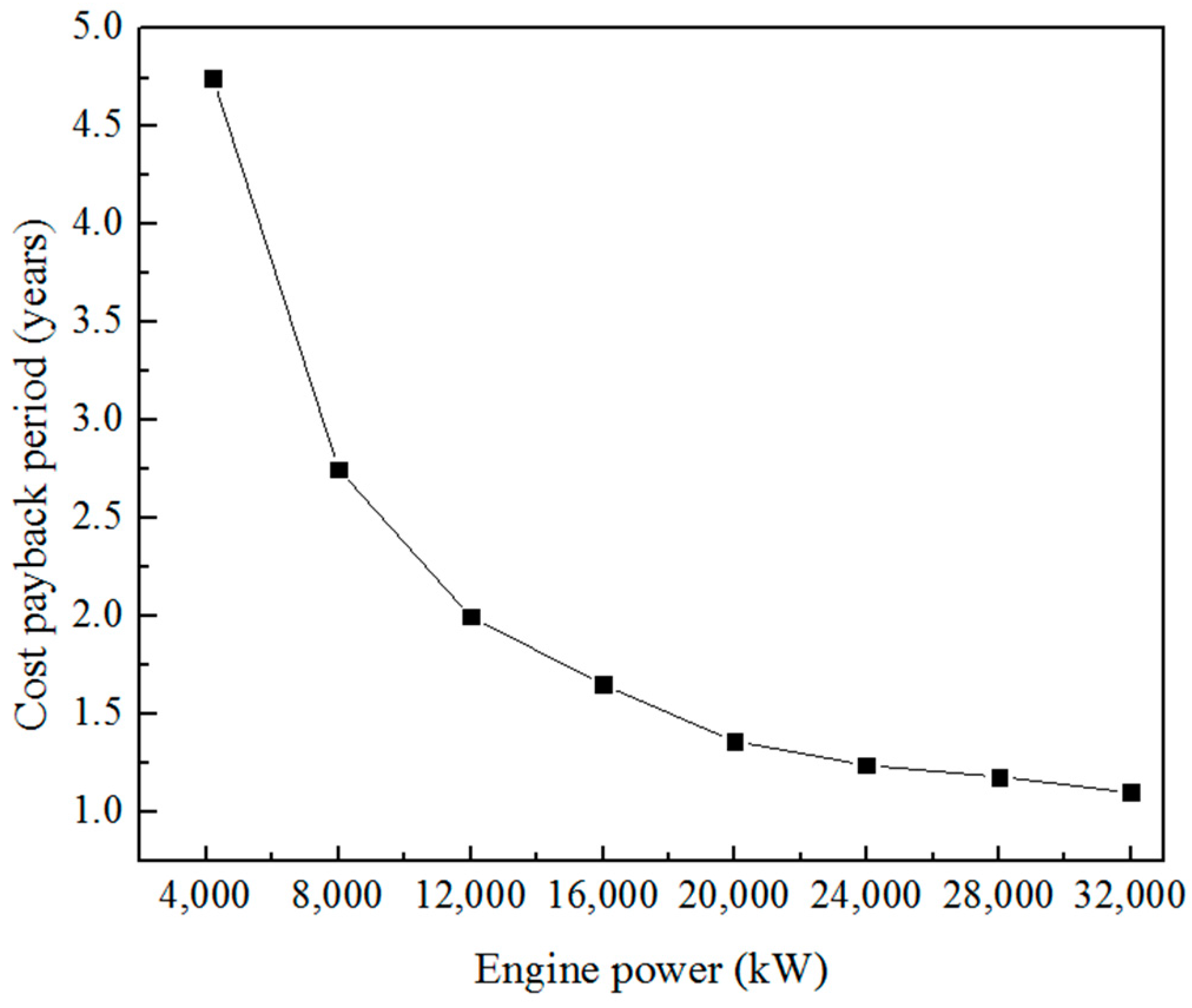

The large price difference between HFO and low-sulfur fuel oil would lead to a shortened payback period for larger power engines. The engine power could affect the difference in the value of the yearly running cost from using a scrubber and using low-sulfur fuel oil. The results are shown in

Figure 13, with the difference being the yearly saving cost of using a scrubber. The relationship between engine power and cost payback period with a scrubber is presented in

Figure 14. As shown in

Figure 13 and

Figure 14, the savings in increased cost and cost payback period sharply shortens with an increase in engine power. In particular, when engine power rose from 4 MW to 12 MW, the cost payback period was shortened from five years to two years. The above results fully demonstrate the cost advantage of scrubber installation for ships.

Although the fuel price has declined in recent years, the supply of low-sulfur fuel oil is limited in the long-term because of the limitation of fuel oil refining capacity. The development of the shipping industry would inevitably lead to an increase in fuel price, with the running cost of ships also increasing. The cost advantage of scrubber installation would become more prominent. Therefore, the EGC system was more suitable for an engine with higher power as the initial cost will not change considerably with an increase in engine power. Due to the stringent emission regulations of the IMO, one of the two methods must be selected and used to meet the emission requirements. Using LNG (Liquefied Natural Gas) is an alternative, but it also has several disadvantages, such as cost of modifications, refueling problems, and sailing endurance. Therefore, the EGC system is recommended.