Experimental Investigation of the Effect of Biodiesel Blends on a DI Diesel Engine’s Injection and Combustion

Abstract

:1. Introduction

- Measurement of combustion process by analysis of engine indicator diagrams;

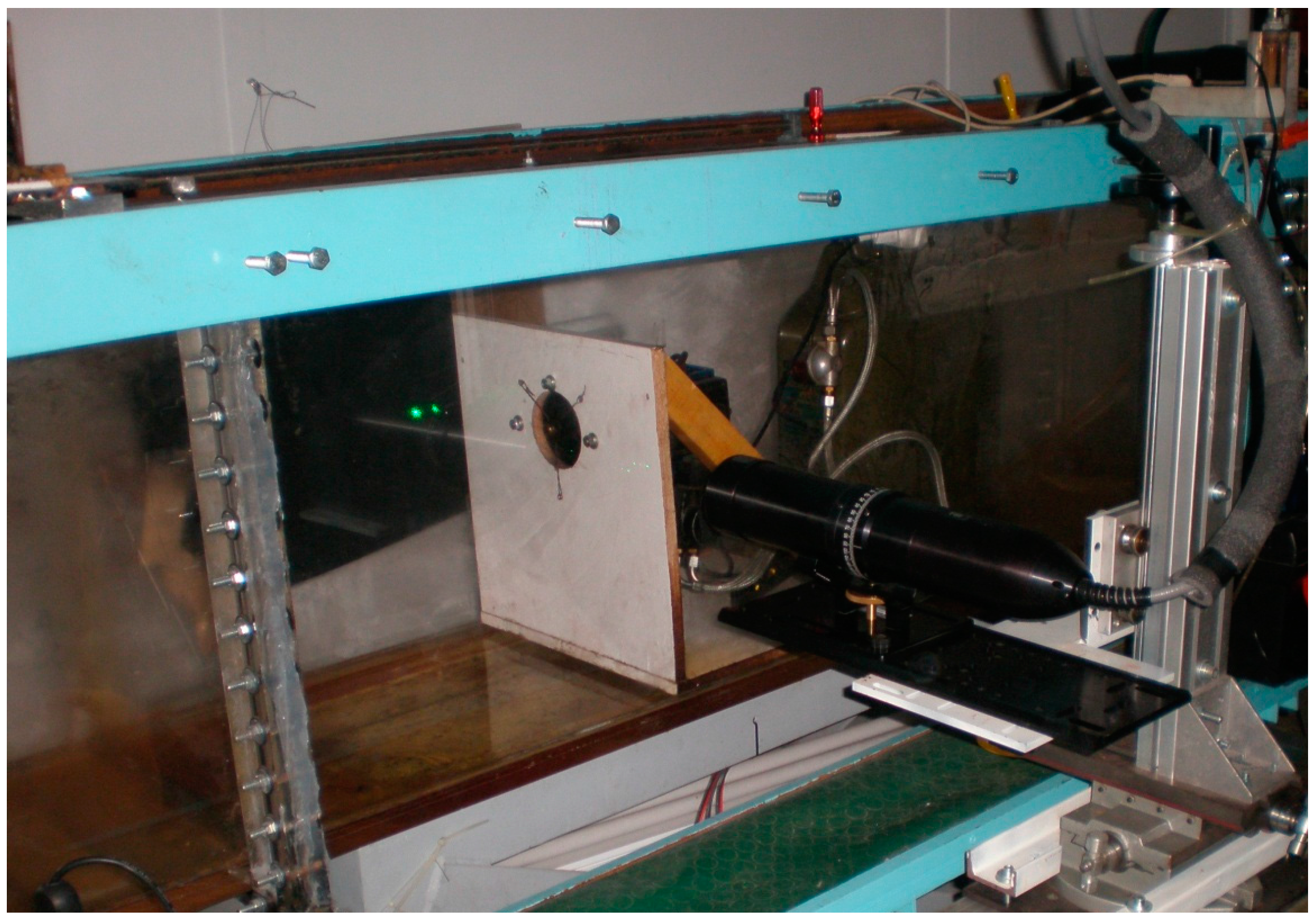

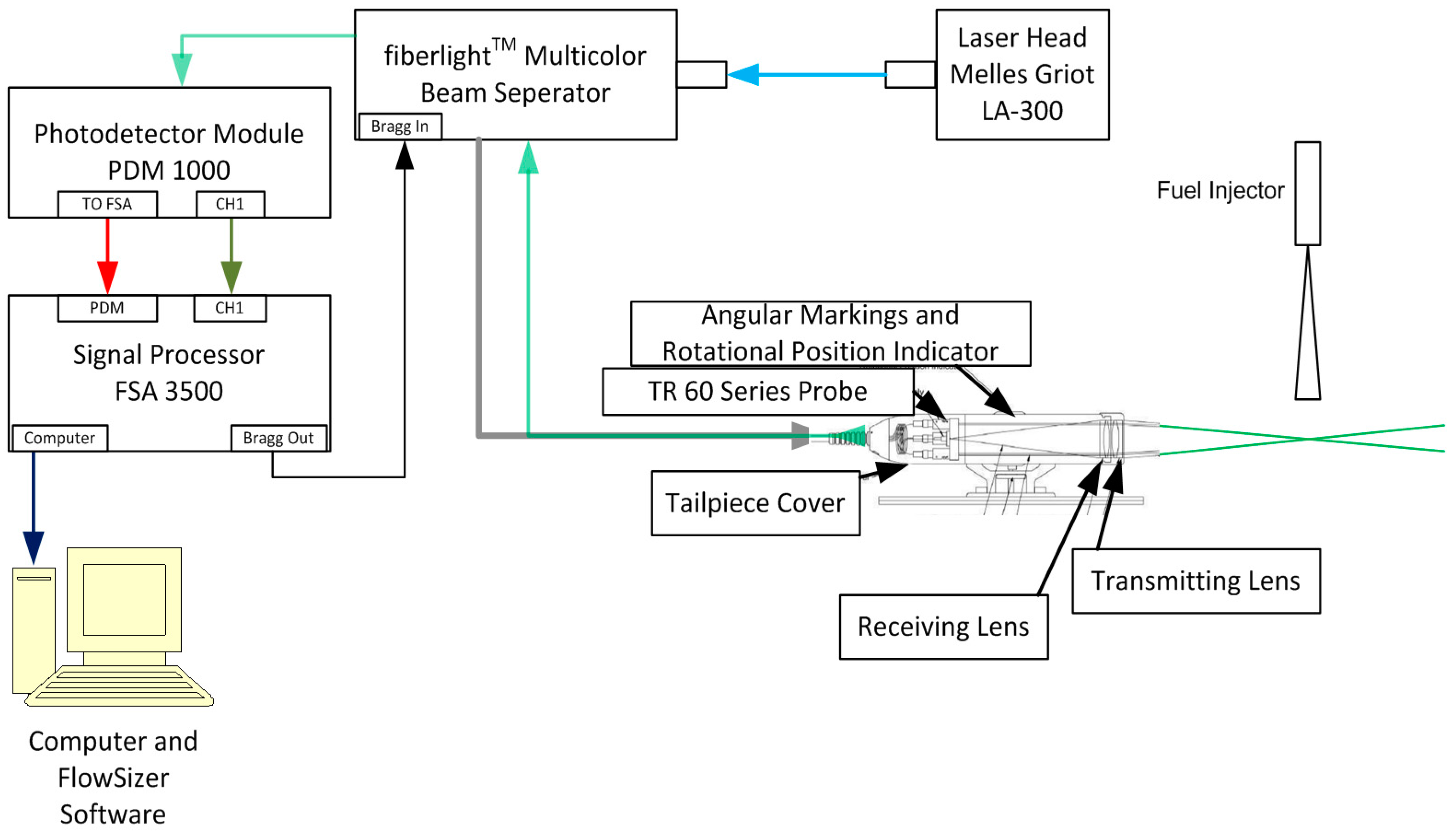

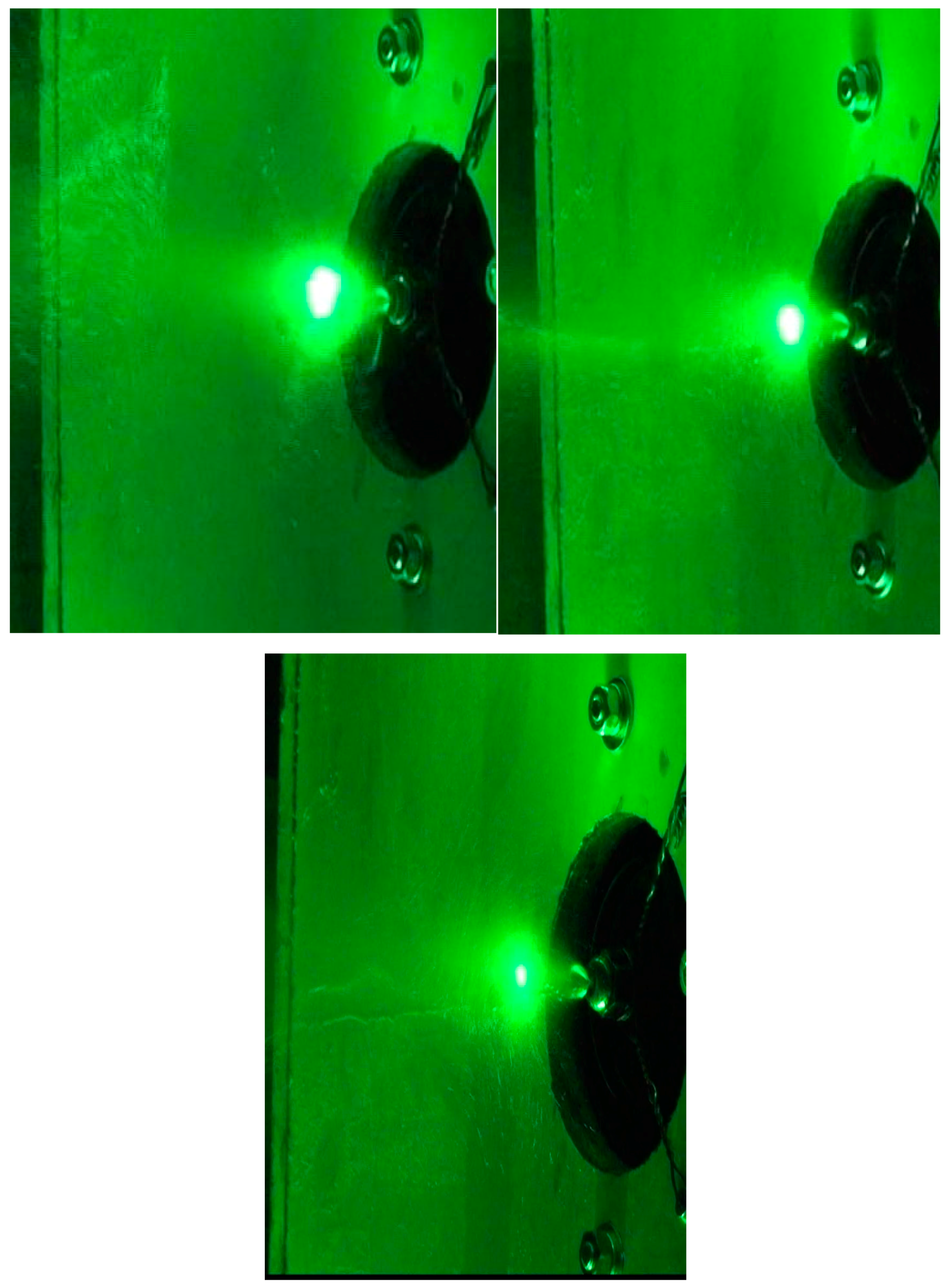

- Spray visualization at low and standard injection pressures by use of a laser sheet visualization system;

- Comparative measurements of atomization characteristics (mean droplet velocity, Sauter mean diameter (SMD), droplet velocity and diameter distributions) at low injection pressures by Laser Doppler Velocimetry.

2. Experimental Setup

2.1. Engine Test Equipment and Procedure

2.2. Diesel Spray Test Equipment and Experimental Procedure

2.3. Properties of Fuels and Blending

3. Results and Discussion

3.1. Calculation of Injection Timing Advance

3.2. Cycle-to-Cycle Variation

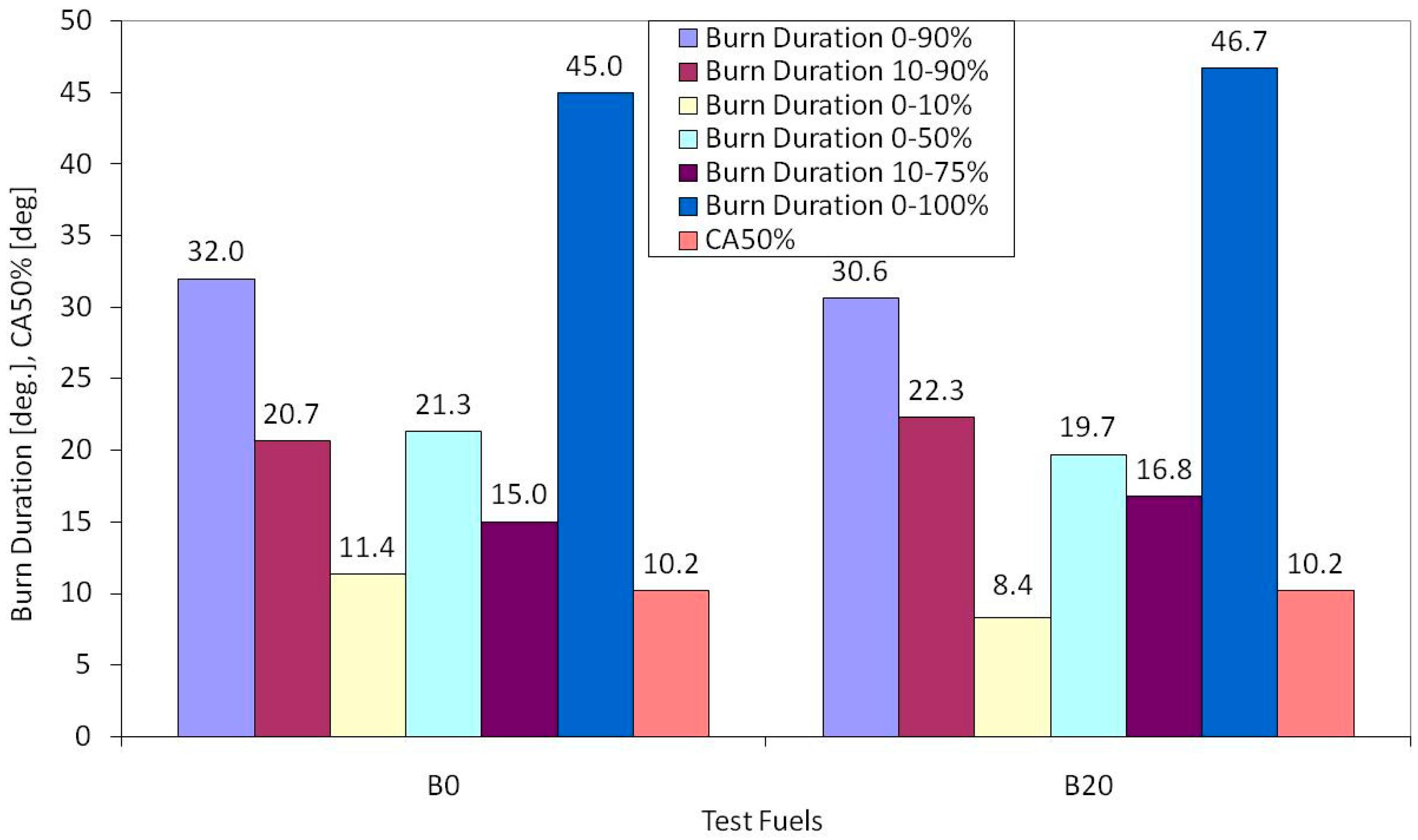

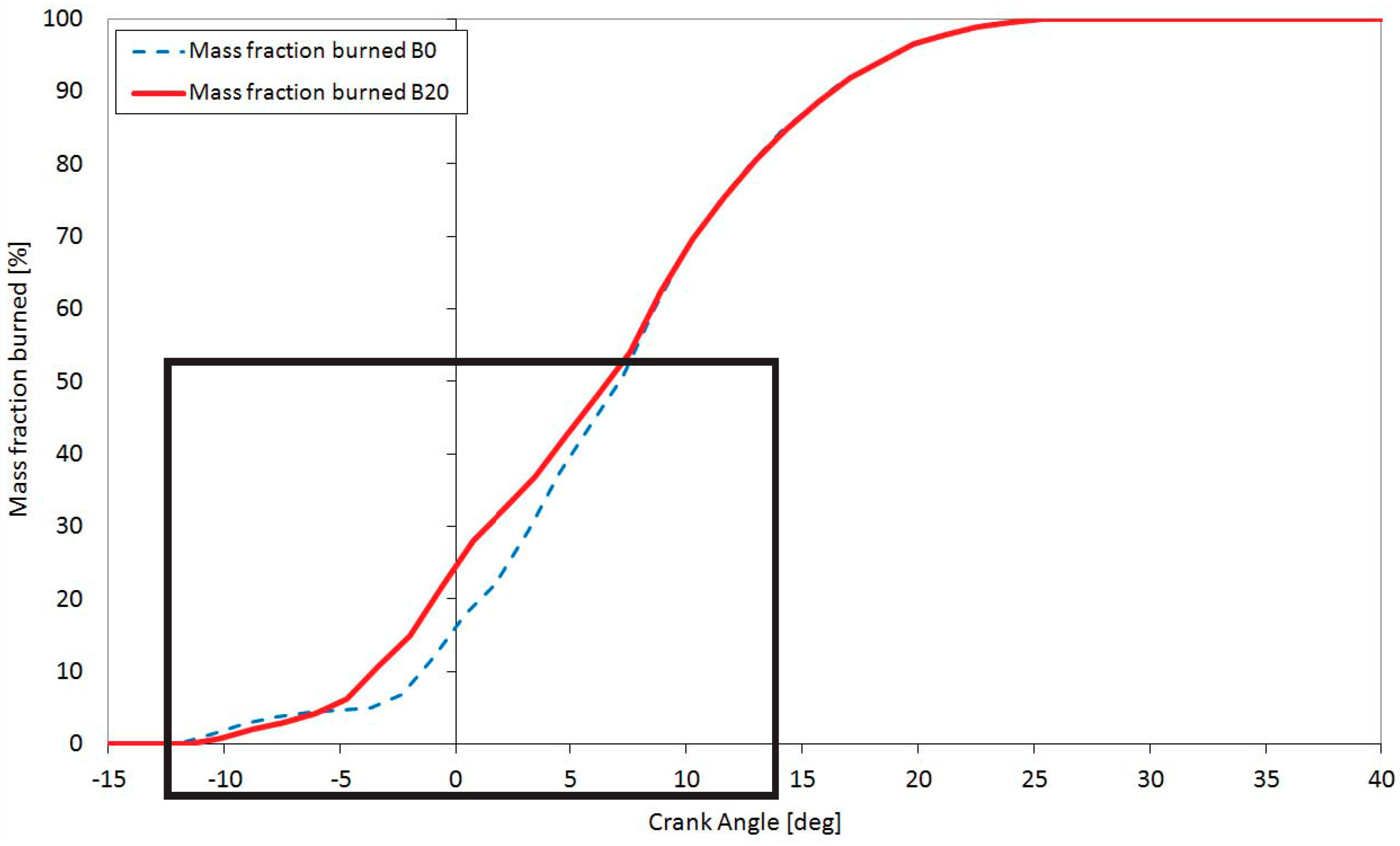

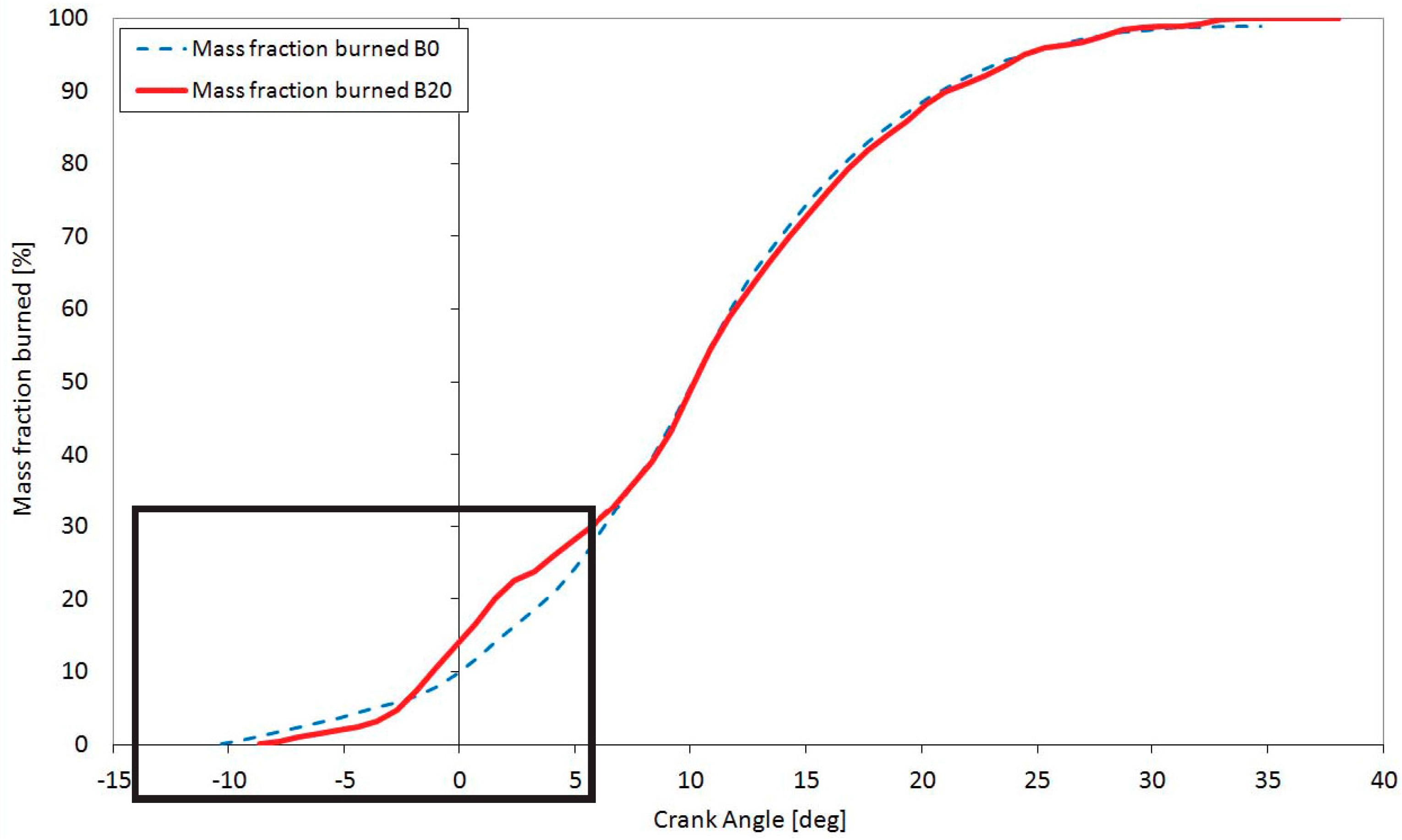

3.3. Combustion Characteristics

3.4. Injection Characteristics

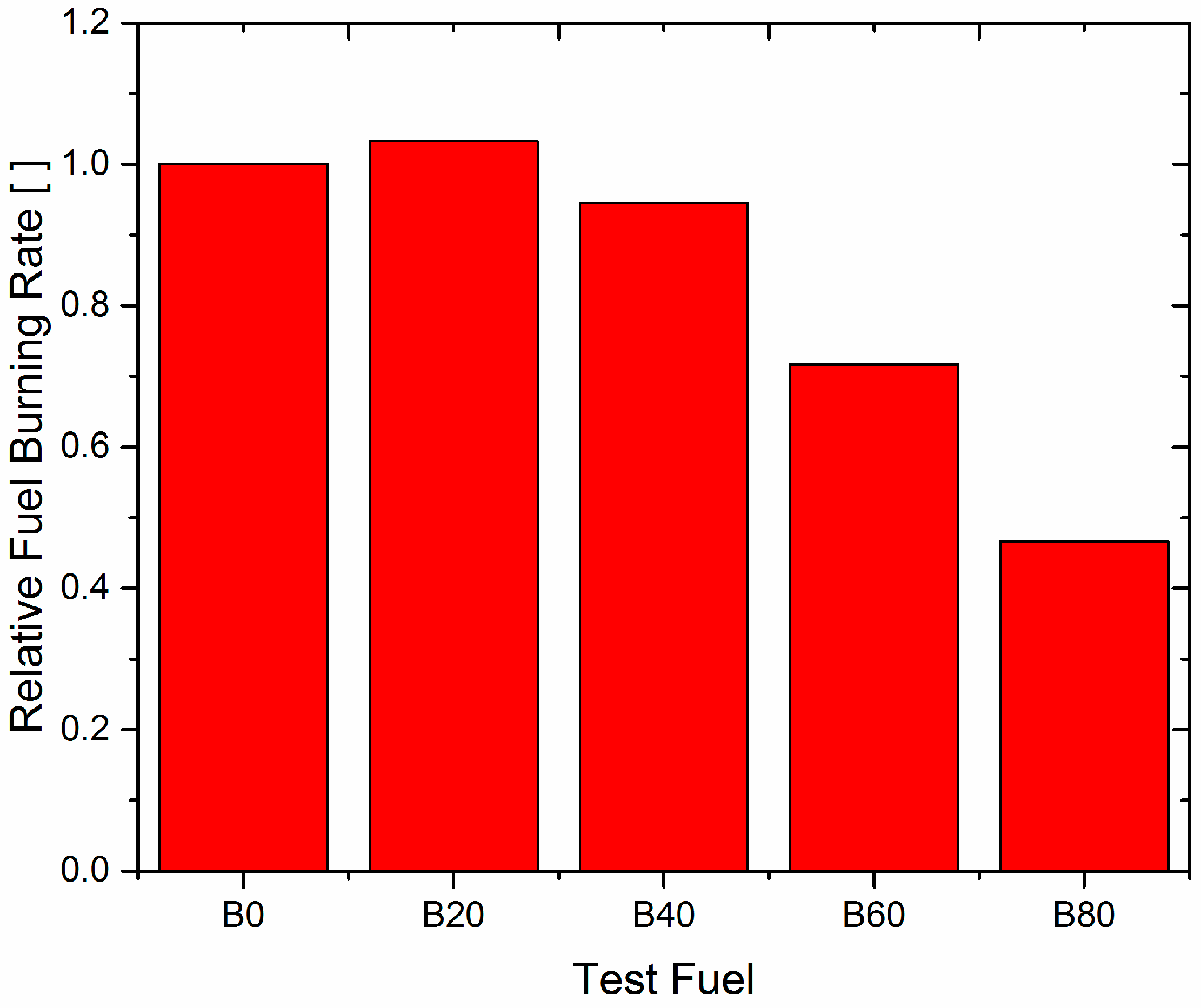

3.5. Fuel Atomization Characteristics

3.6. Spray and Combustion Evolution

4. Conclusions

- Combustion of B20 and B40 in the unmodified engine with pump-line-nozzle injection system resulted in modification in the evolution of combustion compared to B0. The ignition delay was reduced, while the fuel burning rate in the initial premixed combustion phase was higher.

- However, the total combustion duration for the B20 blend was higher.

- The increase of the biodiesel blending ratio appears to increase the COVimep from 8.6% (B0) to 8.8% (B20) and 9.4% (B40).

- The kinematic viscosity and surface tension become higher as the mixing ratio of the biodiesel increases, thus modifying the atomization characteristics of blended fuels.

- The surface tension of the biodiesel is higher than that of commercial diesel, which gives a lower Weber number (less strong breakup tendency).

- The SMD, VMD and arithmetic mean diameter (AMD) of diesel and biodiesel blended fuels decreased with an increase in the axial distance due to the fuel atomization process.

- Comparison of SMD values between blends show that the biodiesel blends present increasingly higher SMD than the conventional diesel fuel. The VMD and AMD values have similar trends.

- Comparison of approximate fuel burning rates for different samples of 60,000 droplets each clearly indicate a decrease in fuel burning rate for B20 and higher blends.

- The higher viscosity of biodiesel can become a factor in a lower axial mean velocity because it increases the friction (and wear) between the nozzle surface and fuel.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| AMD | Area mean diameter [m] |

| A/F | Air to Fuel ratio |

| B | Spalding number |

| CA | Crank angle [°] |

| COV | Coefficient of variation [·] |

| cp,g | Specific heat capacity of gas phase [kJ/kg·K] |

| DI | Direct injection |

| F | Frequency [Hz] |

| FAME | Fatty acid methyl ester |

| FBR | Fuel burning rate [s−1] |

| imep | indicated mean effective pressure [MPa] |

| ITA | Injection timing advance [°] |

| LDV | Laser Doppler Velocimetry |

| LHV | Lower heating value [MJ/kg] |

| Oh | Ohnesorge number |

| p | pressure [Pa] |

| Po | Power [kW] |

| PLN | Pump in line nozzle |

| Rej | Jet Reynolds number |

| SiC | Silicon carbide |

| SMD | Sauter mean diameter [m] |

| VMD | Volume mean diameter [m] |

| Wej | Jet Weber number |

| θ | crankangle [deg] |

| λ | wavelength [m] |

| λg | thermal conductivity of gas phase [W/mK] |

| density of liquid phase [kg/m3] |

References

- Maghbouli, A.; Yang, W.; An, H.; Li, J.; Shafee, S. Effects of injection strategies and fuel injector configuration on combustion and emission characteristics of a DI diesel engine fueled by bio-diesel. Renew. Energy 2015, 76, 687–698. [Google Scholar] [CrossRef]

- Shameer, M.P.; Ramesh, K.; Sakthivel, R.; Purnachandran, R. Effects of fuel injection parameters on emission characteristics of diesel engines operating on various biodiesel: A review. Renew. Sustain. Energy Rev. 2017, 67, 1267–1281. [Google Scholar] [CrossRef]

- Gülüm, M.; Bilgin, A. Measurements and empirical correlations in predicting biodiesel-diesel blends’ viscosity and density. Fuel 2017, 199, 567–577. [Google Scholar] [CrossRef]

- Kegl, B. Numerical analysis of injection characteristics using biodiesel fuel. Fuel 2006, 85, 2377–2387. [Google Scholar] [CrossRef]

- Wu, Z.; Zhu, Z.; Huang, Z. An experimenal study on the spray structure of oxygenated fuel using laser-based visualization and particle image velocimetry. Fuel 2006, 85, 1458–1464. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Jayaraj, S.; Muraleedharan, C. Use of vegetable as IC engine fuels: A review. Renew. Energy 2004, 29, 727–742. [Google Scholar] [CrossRef]

- Lee, C.S.; Park, S.W. An experimental and numerical study on fuel atomization characteristics of high-pressure diesel injection sprays. Fuel 2002, 81, 2417–2423. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A.; Gupta, J.G.; Kim, W.; Lee, C.S.; Park, S. Effect of fuel injection pressure and injection timing on spray characteristics and particulate size-number distribution in a biodiesel fuelled common rail direct injection diesel engine. Appl. Energy 2014, 130, 212–221. [Google Scholar] [CrossRef]

- Charalampous, G.; Hardalupas, Y. How do liquid fuel physical properties affect liquid jet development in atomisers? Phys. Fluids 2016, 28, 102106. [Google Scholar] [CrossRef]

- Reif, K. Diesel Engine Management Systems and Components; Springer Vieweg: Wiesbaden, Germany, 2014. [Google Scholar]

- TSI Software Manual; Texas Success Initiative (TSI): Austin, TX, USA, 2007.

- Automotive Fuels—Fatty Acid Methylesters (FAME) for Diesel Engines—Requirements and Test Methods. Available online: http://agrifuelsqcs-i.com/attachments/1598/en14214.pdf (accessed on 10 June 2017).

- Tat, M.E.; Van Gerpen, J.H. Measurement of Biodiesel Speed of Sound and Its Impact on Injection Timing. Available online: http://www.nrel.gov/docs/fy03osti/31462.pdf (accessed on 10 June 2017).

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Zhang, Y.; Boehman, A.L. Impact of biodiesel on NOx emissions in a common rail direct injection diesel engine. Energy Fuels 2007, 21, 2003–2012. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engines Fundamentals. Available online: https://2k9meduettaxila.files.wordpress.com/2012/09/internal-combustion-engines-fundamentals-heywood.pdf (accessed on 10 June 2017).

- Help Navigator; Gamma Technologies Inc.: Westmont, IL, USA, 2009.

- Grech, N.; Mehdi, A.; Zachos, P.K.; Pachidis, V.; Singh, R. Effect of combustor geometry on performance of airblast atomizer under sub-atomizer conditions. Eng. Appl. Comput. Fluid Mech. 2012, 6, 203–213. [Google Scholar] [CrossRef]

- Tziourtzioumis, D. Experimental Investigation of the Steady State and Transient Operation of Diesel Engines Fuelled by High Percentage Biodiesel Blends; University of Thessaly: Volos, Greece, 2012. [Google Scholar]

- Lee, C.S.; Reitz, R.D. Effect of liquid properties on the breakup mechanism of high-speed liquid drops. At. Sprays 2001, 11, 1–19. [Google Scholar]

- Available online: http://www.borgwarner.com/ (accessed on 10 July 2017).

- Kousoulidou, M.; Fontaras, G.; Ntziachristos, L.; Samaras, Z. Biodiesel blend effects on common-rail diesel combustion and emissions. Fuel 2010, 89, 3442–3449. [Google Scholar] [CrossRef]

- Fang, T.; Lee, C.F. Bio-diesel effects on combustion processes in an HSDI diesel engine using advanced injection strategies. Proc. Combust. Inst. 2009, 32, 2785–2792. [Google Scholar] [CrossRef]

- Hamasaki, K.; Kinoshita, E.; Tajima, H.; Takasaki, K.; Morita, D. Combustion characteristics of diesel engines with waste vegetable oil methyl ester. In Proceedings of the 5th International Symposium on Diagnostics and Modeling of Combustion in Internal Combustion Engines, Nagoya, Japan, 1–4 July 2001. [Google Scholar]

- Yehliu, K.; Boehman, A.L.; Armas, O. Emissions from different alternative diesel fuels operating with single and split fuel injection. Fuel 2010, 89, 423–437. [Google Scholar] [CrossRef]

| Experimental Setup | RF91 DI Diesel Engine | LDV (Low Injection Pressure Setup) | ||||

|---|---|---|---|---|---|---|

| Fuel | Injection Timing Advance | Cycle-to-Cycle Variation | Indicator Diagram Analysis | Injection Characteristics | Fuel Atomization Characteristics | Spay Evolution |

| B0 | ||||||

| B20 | ||||||

| B40 | ||||||

| B60 | ||||||

| B80 | ||||||

| B100 | ||||||

| Engine Type | DI 4 Stroke Naturally Aspirated Diesel Engine |

|---|---|

| Engine model | RF91 |

| Number of cylinders | 1 |

| Bore | 90 mm |

| Stroke | 75 mm |

| Rated power | 8.1 kW, 3600 rpm |

| Rated torque | 25 Nm, 2500 rpm |

| Compression ratio | 18.5:1 |

| Diesel particulate filter | IBIDEN SiC filter |

| Injection System Type | New Diesel Pump-in-Line Nozzle Injection System |

|---|---|

| Needle diameter | 4 mm |

| Number and diameter of nozzle holes | 4 × 0.24 mm |

| Nozzle hole length | 0.6 mm |

| Pin height | 0.125–0.175 mm |

| Sump volume | 0.36 mm3 |

| Opening pressure | 210 bar |

| Pump plunger diameter | 7 mm |

| Drive rod length | 65.8–66 mm |

| High pressure line length | 400 mm |

| Specifications/Ranges | B0 | B20 | B40 | B60 | B80 | B100 |

|---|---|---|---|---|---|---|

| Density (15 °C) (kg/m3) | 825 | 840 | 852 | 864 | 876 | 885 |

| Viscosity (40 °C) (cSt) | 2.493 | 3.039 | 3.384 | 3.730 | 4.075 | 4.720 |

| Surface tension (N/m) | 0.02600 | 0.02637 | 0.02674 | 0.02711 | 0.02748 | 0.02800 |

| Cetane number | 50 | - | - | - | - | 55 |

| Stoichiometric A/F ratio | 14.5 | 14.10 | 13.69 | - | - | 12.48 |

| Lower heating value [MJ/kg] | 43.3 | 42.18 | 41.06 | - | - | 37.7 |

| Variable | Value |

|---|---|

| Crankshaft rotation required to reach the NOP-B0 [CA] | 10.22 |

| Crankshaft rotation required to reach the NOP-B20 [CA] | 10.0 |

| Crankshaft rotation required to reach the NOP-B40 [CA] | 9.8 |

| Crankshaft rotation required to reach the NOP-B100 [CA] | 9.12 |

| Engine Speed [rpm] | Time [ms]/CA | Total CA for B0 Case-PtN Time | Total CA for B20 Case-PtN Time | Total CA for B40 Case-PtN Time | Total CA for B100 Case-PtN Time |

|---|---|---|---|---|---|

| 1600 | 0.1042 | 2.95 | 2.93 | 2.91 | 2.86 |

| 1700 | 0.0980 | 3.13 | 3.11 | 3.09 | 3.03 |

| 1800 | 0.0926 | 3.32 | 3.30 | 3.28 | 3.21 |

| 1900 | 0.0877 | 3.50 | 3.48 | 3.46 | 3.39 |

| 2000 | 0.0833 | 3.69 | 3.66 | 3.64 | 3.57 |

| 2100 | 0.0794 | 3.87 | 3.85 | 3.82 | 3.75 |

| 2200 | 0.0758 | 4.06 | 4.03 | 4.00 | 3.93 |

| 2300 | 0.0725 | 4.24 | 4.21 | 4.19 | 4.10 |

| 2400 | 0.0694 | 4.42 | 4.40 | 4.37 | 4.28 |

| 2500 | 0.0667 | 4.61 | 4.58 | 4.55 | 4.46 |

| 2600 | 0.0641 | 4.79 | 4.76 | 4.73 | 4.64 |

| 2700 | 0.0617 | 4.98 | 4.95 | 4.91 | 4.82 |

| 2800 | 0.0595 | 5.16 | 5.13 | 5.10 | 5.00 |

| 2900 | 0.0575 | 5.35 | 5.31 | 5.28 | 5.17 |

| 3000 | 0.0556 | 5.53 | 5.49 | 5.46 | 5.35 |

| 3100 | 0.0538 | 5.71 | 5.68 | 5.64 | 5.53 |

| 3200 | 0.0521 | 5.90 | 5.86 | 5.82 | 5.71 |

| 3250 | 0.0513 | 5.99 | 5.95 | 5.91 | 5.80 |

| 3300 | 0.0505 | 6.08 | 6.04 | 6.01 | 5.89 |

| 3400 | 0.0490 | 6.27 | 6.23 | 6.19 | 6.07 |

| 3500 | 0.0476 | 6.45 | 6.41 | 6.37 | 6.25 |

| 3600 | 0.0463 | 6.64 | 6.59 | 6.55 | 6.42 |

| Test Fuel | B0 | B20 | B40 | B60 | B80 | B100 |

|---|---|---|---|---|---|---|

| Mean droplet velocity [m/s] | 25.31 | 24.95 | 24.60 | 24.25 | 23.92 | 23.81 |

| Wej (Jet Weber number) | 5.91 | 5.66 | 5.43 | 5.21 | 4.50 | 4.86 |

| Rej (Jet Reynolds number) | 1879 | 1642 | 1453 | 1300 | 1174 | 1078 |

| Oh (Ohnesorge number) | 0.034 | 0.038 | 0.043 | 0.047 | 0.051 | 0.055 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tziourtzioumis, D.N.; Stamatelos, A.M. Experimental Investigation of the Effect of Biodiesel Blends on a DI Diesel Engine’s Injection and Combustion. Energies 2017, 10, 970. https://doi.org/10.3390/en10070970

Tziourtzioumis DN, Stamatelos AM. Experimental Investigation of the Effect of Biodiesel Blends on a DI Diesel Engine’s Injection and Combustion. Energies. 2017; 10(7):970. https://doi.org/10.3390/en10070970

Chicago/Turabian StyleTziourtzioumis, Dimitrios N, and Anastassios M Stamatelos. 2017. "Experimental Investigation of the Effect of Biodiesel Blends on a DI Diesel Engine’s Injection and Combustion" Energies 10, no. 7: 970. https://doi.org/10.3390/en10070970