1. Introduction

With China’s rapid economic development, the inland shipping industry has made great progress [

1]. As the economic center of China, Shanghai is also China’s major port city. Haze phenomena have occurred frequently in recent years, and the air quality problem is becoming more and more serious [

2]. Large amounts of inland ship emissions form one of the leading causes of air pollution in the port city. According to a report by the Shanghai Environmental Monitoring Center in 2014, the proportion of pollutant emissions from inland river ships at Shanghai waters is as follows: 11% PM

; 12% PM

; 17% NO

; 2% SO

; 28% CO; 29% HC; 25% CO

and 29% N

O [

3,

4]. To regulate sea haze phenomena, the government has advocated the use of novel technologies to reduce the energy consumption and emissions from ships, and published the “Shanghai port ship pollution prevention and control measures” in June 2015. Therefore, the development of new ships with low consumption which produce low emission has become an important task for China’s shipbuilding industry. The hybrid electric propulsion system is one of the latest technologies to achieve the goals of saving energy and reducing emissions. Hybrid ships use two or more different powers to drive propellers, and transform one of them into electricity. Compared with classical diesel–electric propulsion, hybrid technology pays more attention to the impact on the environment, including emissions, waste and noise pollution from ships in navigation and berth.

With hybrid power systems being an excellent method for saving energy and reduction of emissions, an easy and reasonable control strategy is very important. Some scholars have studied energy management strategies for ships. In [

5], Saravana et al. studied a multi energy system consisting of batteries and ultra capacitors (UCs) and applied it to a hybrid electric ship. The control strategy was designed to benefit the fast charge and discharge capability of UCs in order to reduce the battery stress due to the instantaneous power demands. Because of the small volume of inland vessels, the installation of both the UCs and batteries on the ship greatly increase the weight and cost of shipbuilding. Dynamic system mathematic models have been established, and an optimal control strategy of hybrid power ships was proposed based on a dynamic programming algorithm under different working conditions in [

6,

7]. However, the dynamic programming method has a large computational burden, therefore, it is not suitable for real-time control of actual ships. In [

8], Seenumani et al. proposed a hierarchical optimal control strategy for the power management of the hybrid power system for an electric ship. The strategy was only applied to support critical missions such as weapon or aircraft launches. In [

9], Zhu et al. studied a ship energy management strategy based on fuzzy logic control, and verified the results obtained through simulation. However, the strategy lacks practical verification and is difficult to realize for real-time control.

The Suzhou River plays an important transportation role in the water transportation network of Shanghai. This river has narrow channel and numerous vessels. According to the characteristics of the Suzhou River and its environmental protection requirements, a hybrid electric boat (HEB) series, used for monitoring the water environment and controlling the pollution, is considered in this paper. The HEB navigates several round-trips through the whole urban area, therefore the highest level environmental protection is required, including a reduction of emissions and noise, as well as fuel savings. The HEB designed in this paper should meet the requirements of the environmental inspection of the Suzhou River, and in addition, it is necessary to consider the ship reliability for the busy channel. From the analysis of structure and principle of the power train, the parameter design for its key devices is described, and a new energy control strategy is proposed. The control strategy proposed in the paper is simple, with few calculations. It is easy to realize, and can also guarantee the reliability of the actual ship, ensure ship safety and reduce its emissions. The proposed parameter design method and energy control strategy are verified based on a real sailing experiment of a law enforcement boat on the Suzhou River.

2. Power System Structure

Different types of ship hybrid power systems have specific characteristics. The choice of the system depends on a variety of factors, such as water environment, navigation conditions, economic costs, etc. In this paper, the series structure of inland ship hybrid power system is considered. A HEB (HU HUANJIAN13) is shown in the left picture, with a structure presented in the right picture inside the rectangle of

Figure 1. When the HEB berths at the dock, the boat is supplied by the shore power. The hybrid system is mainly composed of a diesel generator set, lithium iron phosphate power batteries, a bi-directional DC/DC converter, inverter including AC/DC rectifier and DC/AC converter, a transformer, auxiliary equipment, and propulsion motor, etc.

The diesel generator (G) outputs three-phase alternating current (AC), which is sent to the AC/DC rectifier, and then to the inverter’s DC bus. The power from the DC bus is transformed into AC power by the DC/AC inverter, which supplies power to the AC asynchronous motor (M). The motor drives the propeller. The power batteries output DC, which goes through DC/DC conversion, and then to the inverter’s DC bus. Furthermore, the DC from the batteries is transformed into AC power by another DC/AC inverter. The AC power through the transformer outputs 220 V, and supplies power to the auxiliary equipment such as air-conditioning, lighting and so on. The generator and batteries can provide energy for the propulsion motor in a mixed or separated way. In addition, when the HEB is berthing, the power is supplied by the shore, and the battery is charged by the charger of the shore. The series hybrid power system has the following features: there is no mechanical connection between the diesel engine and propeller, which enhances the power system layout flexibility. With the diesel engine being completely decoupled from the propeller, its operation is not affected by the navigation condition of the ship. The diesel engine can be controlled in friendly working area. This power system has the advantages of simple structure, easy control and low cost.

3. Power System Parameter Design

3.1. Main Parameters of the Boat

The object of this study is a cruise boat sailing in the Suzhou River of Shanghai. The main task of the boat is to monitor the river water quality and control the pollution. The length of the whole channel is about 8.4 km. The main parameters of the boat’s power system are listed in

Table 1.

3.2. Parameters of the Diesel Generator Set

According to the rules recommended by the boat inspection organism, the generator type should be a marine three-phase synchronous diesel generator set. In a HEB, during the peak propulsion power, the generator and the power battery should provide together the electrical energy to drive the propeller and meet the power requirements of the auxiliary equipment. The basic principle of the generator power rating design is that the power demand of the propeller propulsion and auxiliary equipment should be satisfied under the cruising speed when the boat is supplied only by the generator:

In (

1)

is the rated power of the generator,

is the required propulsion power during cruising,

is the required auxiliary power, and

is the power headroom coefficient of the generator set. Therefore, the rated power of the generator is calculated as:

The rated power of the generator is determined as 30 kW. The main parameters are shown in

Table 2.

3.3. Propulsion Motor Parameters

The main propulsion motor driving the propeller should meet the relevant requirements or standards imposed by the marine inspection organism, which include the marine motor, motor protection class, insulation level and other technical indicators, etc. In addition, the motor should be able to operate normally in humid air, salt mist, oil mist and mold environment. The motor should have one-minute overload capacity to avoid the accident of the motor blocking caused by propeller winding. The speed range of the motor should meet the requirement of the propeller, generally not less than 1:10, and the rated output torque at low speed.

The AC three-phase squirrel cage asynchronous motor is simple, solid, durable, low cost, etc. Using the modern AC speed regulation technology, the asynchronous motor’s capacity, low-speed large torque and regulated speed range completely meet the requirements of the main propulsion motor. Therefore, the marine variable frequency asynchronous motor is selected for the propulsion motor. The rated power of the motor should meet the propulsion rated power under the condition of maximum speed. Because the motor speed is much faster than that of the propeller, the four-pole motor with gear box can meet the requirements of propeller speed. The main technical parameters of the motor are shown in

Table 3.

3.4. Parameter of the Battery

Compared with the lead–acid battery and nickel–metal hydride battery, the iron lithium battery has high energy density, charge and discharge capacity and the longest lifespan [

10]. The iron lithium battery adopted in this study is used to store the electrical energy. The basic constraints of parameter design of battery are to meet the maximum speed propulsion power and auxiliary equipment power requirement of the boat with the maximum discharge power; and the stored power of the battery should autonomously satisfy the time duration requirement of the boat under cruising speed. Therefore, we have the three following design requirements.

(1) Maximum discharge power of the battery in short time,

In (

3)

is the battery rated power,

is the maximum propulsion power, and

is the average battery power discharge efficiency set to be 0.97.

(2) The effective energy of the power battery:

where T is the duration time of the boat supplied only by the battery, and it is assumed that the power demand is constant during

T time period.

(3) The total energy stored in the battery [

11],

where

is the effective energy discharged by the battery when its state of charge (SOC) is between

and

.

is the minimum required state of charge of the battery and is set to be 0.25,

is the state of charge when the battery is fully charged and set to be 0.98, and

is the total energy stored by the power battery.

Therefore, the power battery should be composed of elementary modules in a series, and the capacity is of 110 Ah and the voltage is of 12.8 V for each individual module. The main technical parameters are shown in

Table 4.

The test of the above designed power battery shows that total power battery voltage is 486.4 V and capacity is 110 Ah. It can output maximum power of 35.1 kW, and the discharge current is:

As the discharge current is 72.16 A under the maximum power discharge, it is less than the discharge rate of 0.7 C, which allows for guaranteeing the performance and life-time of the power battery.

4. Energy Control Strategy

The performance of a hybrid system is not only related to the structure of the power system, but is also closely related to the control strategy and navigation conditions.

4.1. Basic Principles

Under the condition that the propulsion dynamic performance of the boat is satisfied, the control strategy of the power system should be able to harmoniously distribute and efficiently coordinate two kinds of energy according to the characteristics and operating conditions of the generator set and the power battery, in order to obtain the optimum energy economy and lowest possible emissions [

12,

13]. The following basic principles should be followed when designing the energy control strategy of a hybrid electric inland waterway boat.

- (1)

Power battery is exhausted. The high-capacity power battery in the HEB has a long battery life, and it should be mostly charged in the dock of the shore during the berthing. Usually the energy stored in the battery is almost used at the end of the boat sailing.

- (2)

Propeller propulsion power is the priority. According to the conditions of boat sailing and the constraint of the various power components, the requirement of power propeller propulsion should be always satisfied to ensure the normal navigation of the boat. Under this condition, two kinds of energy due to the generator and power battery should be distributed harmoniously to ensure that the generator set works in its most efficient area for getting the best fuel economy.

- (3)

Energy recovery of regenerative braking. When the propeller is decelerating or reversing rapidly in the driving, the propeller is in the turbine state due to the hydrodynamic effect. The regenerative braking energy is generated by the propulsion motor. The energy control system should be able to recover the braking energy and store it in the power battery.

4.2. Battery Charge-Depleting and Charge-Sustaining Periods

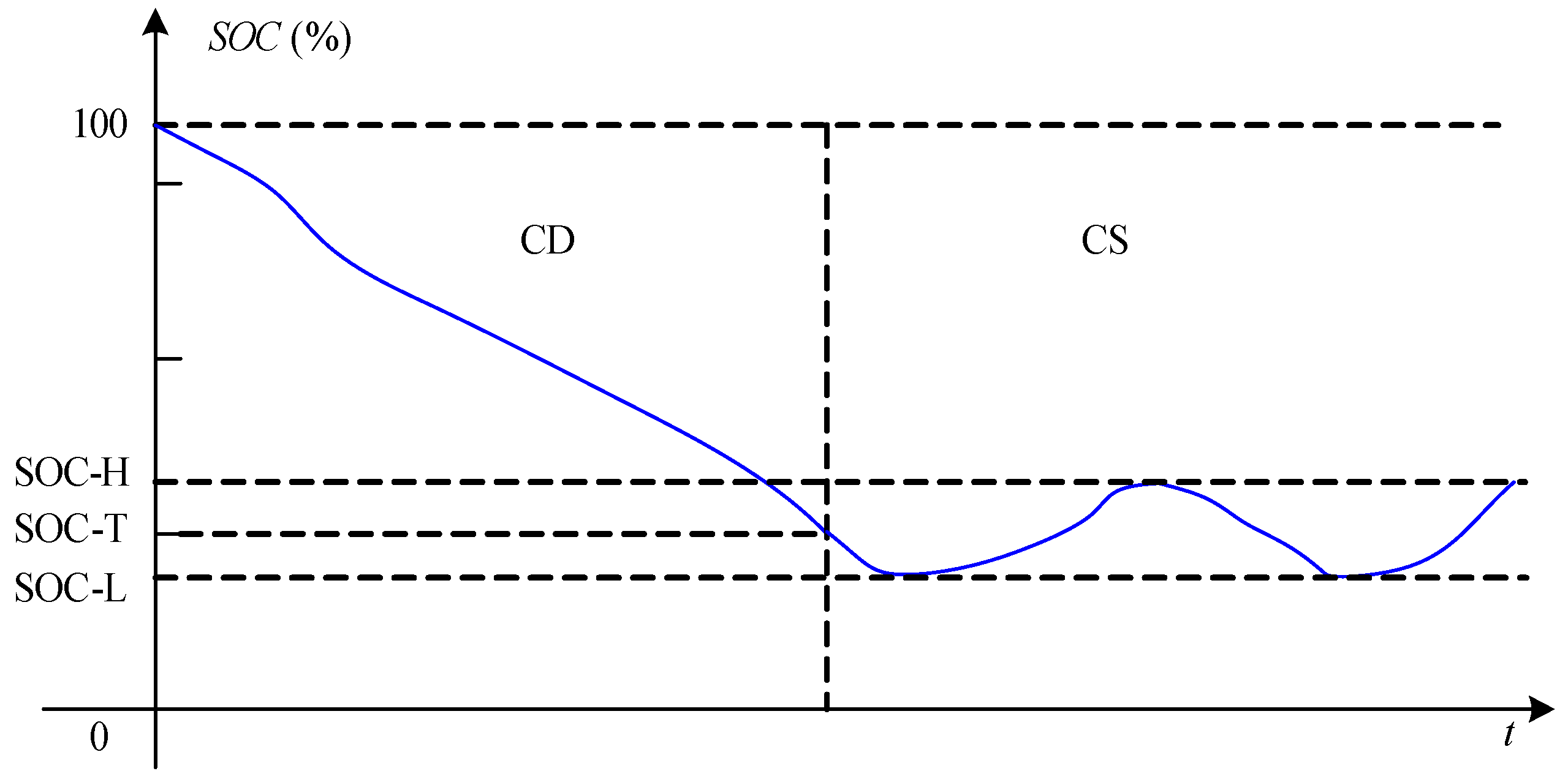

During the process of the HEB sailing, the power battery can be divided into two stages, charge depleting (CD) and charge sustaining (CS), according to the value of its SOC, as shown in

Figure 2. During the CD period, the SOC of the power battery continues to drop to SOC-T. In the CS period, the SOC is kept in the range of SOC-L and SOC-H.

According to the characteristics of the power system of HEB and the propulsion power requirement of boat in navigation, an energy control strategy based on the CD period and CS period is proposed in the following.

4.3. Control Strategy in the Charge-Depleting Period

The power battery of HEB can be recharged not only by the generator of the boat during the navigation, but also by the shore power during the docking. Generally speaking, to reduce the diesel engine’s fuel consumption and emissions, the power battery should be completely recharged by shore power during the berthing of the boat. The power capacity of the power battery of hybrid electric system proposed in this paper is 110 Ah. If the discharge current is 110 A and discharge rated current is supplied with 1 C, the power supplied by the power battery is kWh, which is much more than the required maximum propulsion power of the propeller. Therefore, the control strategy of the power battery during the CD period is to use only the battery to satisfy the power requirement of propulsion motor and auxiliary equipment, which will result in the continually decreasing of SOC of the power battery until the SOC is dropped to the target value of SOC-T (30%). Then the power battery will enter to the battery CS period.

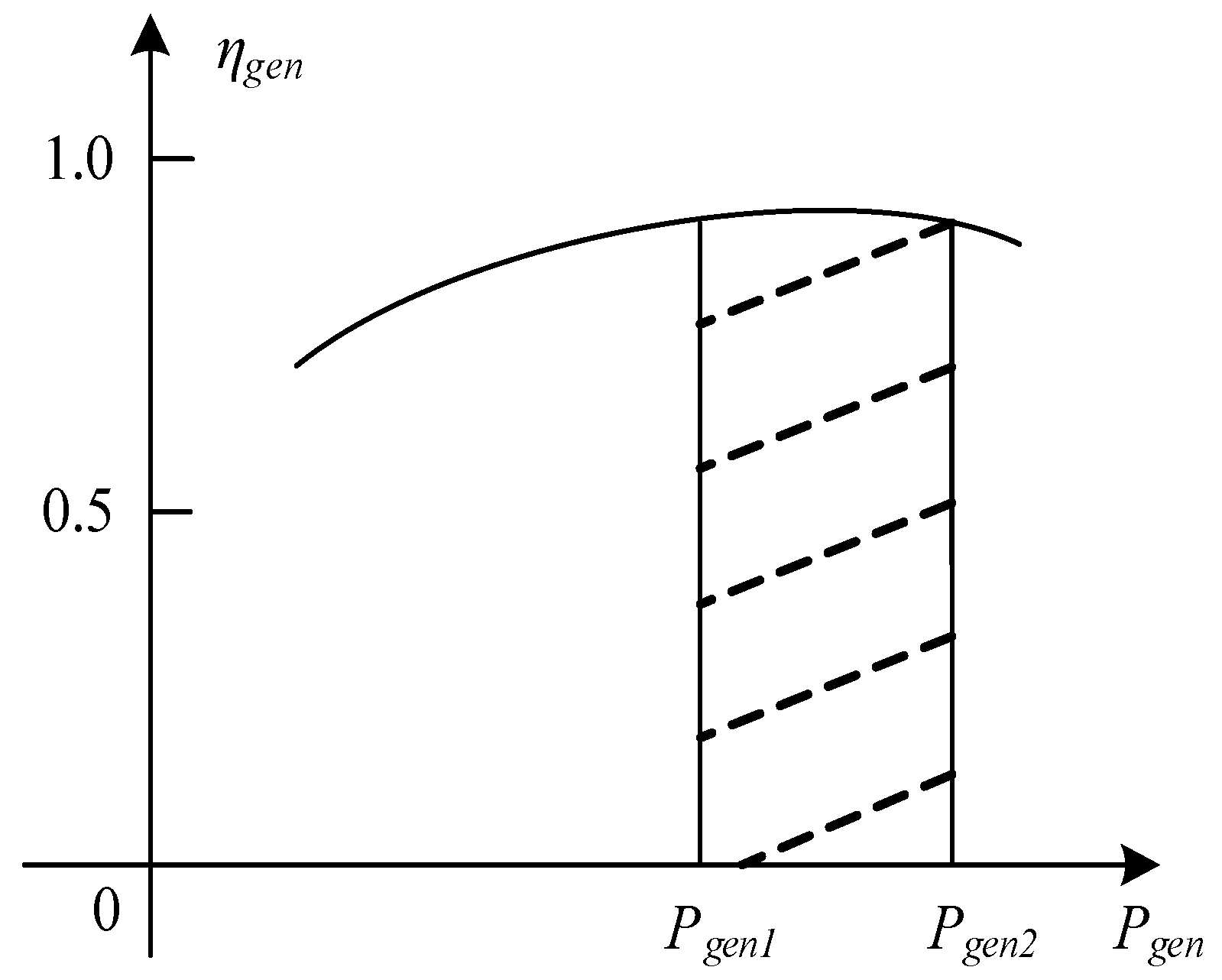

4.4. Control Strategy in Charge-Sustaining Period

During the battery CS period, the system controls the state of the generator set and that of the charge/discharge of the battery according to the demand of the propulsion power and value of the SOC of the battery. The goal is to maintain the SOC at a level between SOC-L (25%) and SOC-H (35%) while ensuring the power requirement of the boat. In order to improve the operation efficiency, the output power of the generator should be maintained between the

and

area, as shown in

Figure 3.

According to the characteristics of the boat sailing conditions and the parameter configuration of the hybrid electric system, we propose a battery CS period control strategy, described in

Table 5.

In

Table 5,

is the required propulsion power,

is the lower limit of the generator’s efficient area and

the corresponding upper limit.

5. Experimental and Analysis

In order to verify the performance of the proposed parameter design method for the power system and control strategy, two kinds of navigation conditions have been tested and analyzed on the HEB, which are variable-speed navigation and constant-speed cruising.

5.1. Variable-Speed Navigation

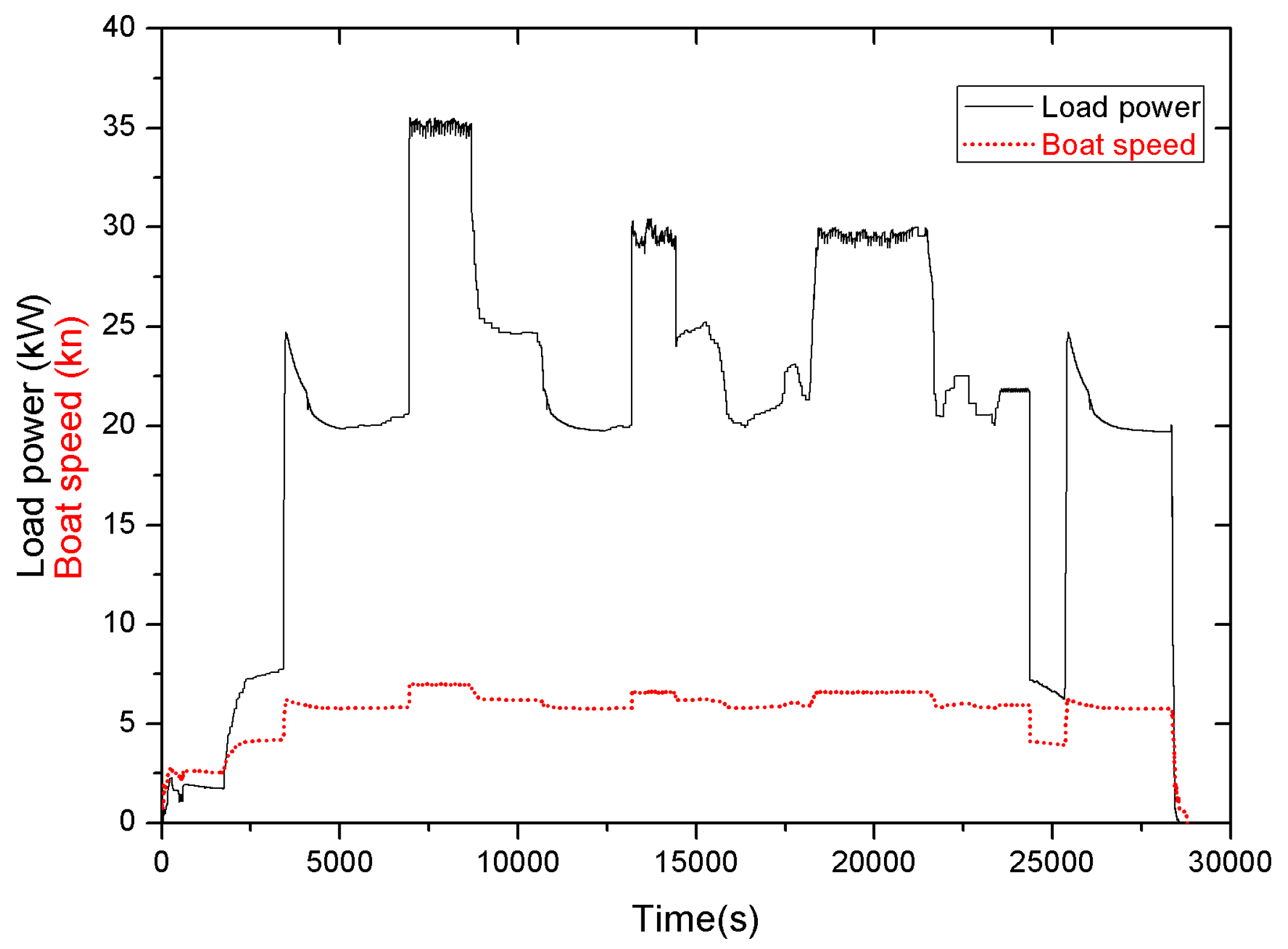

The power and boat speed under variable speed condition profiles are shown in

Figure 4. The length of the whole channel of the Suzhou River of Shanghai is about 8.4 km and the boat is sailing in the river to make several round-trips during 8 h per day. We have selected one of navigation data of the boat for experimentation. The boat has navigated for about five round-trips corresponding to 84 km from the starting point to the ending point of the collected data. The collected data are described in

Table 6.

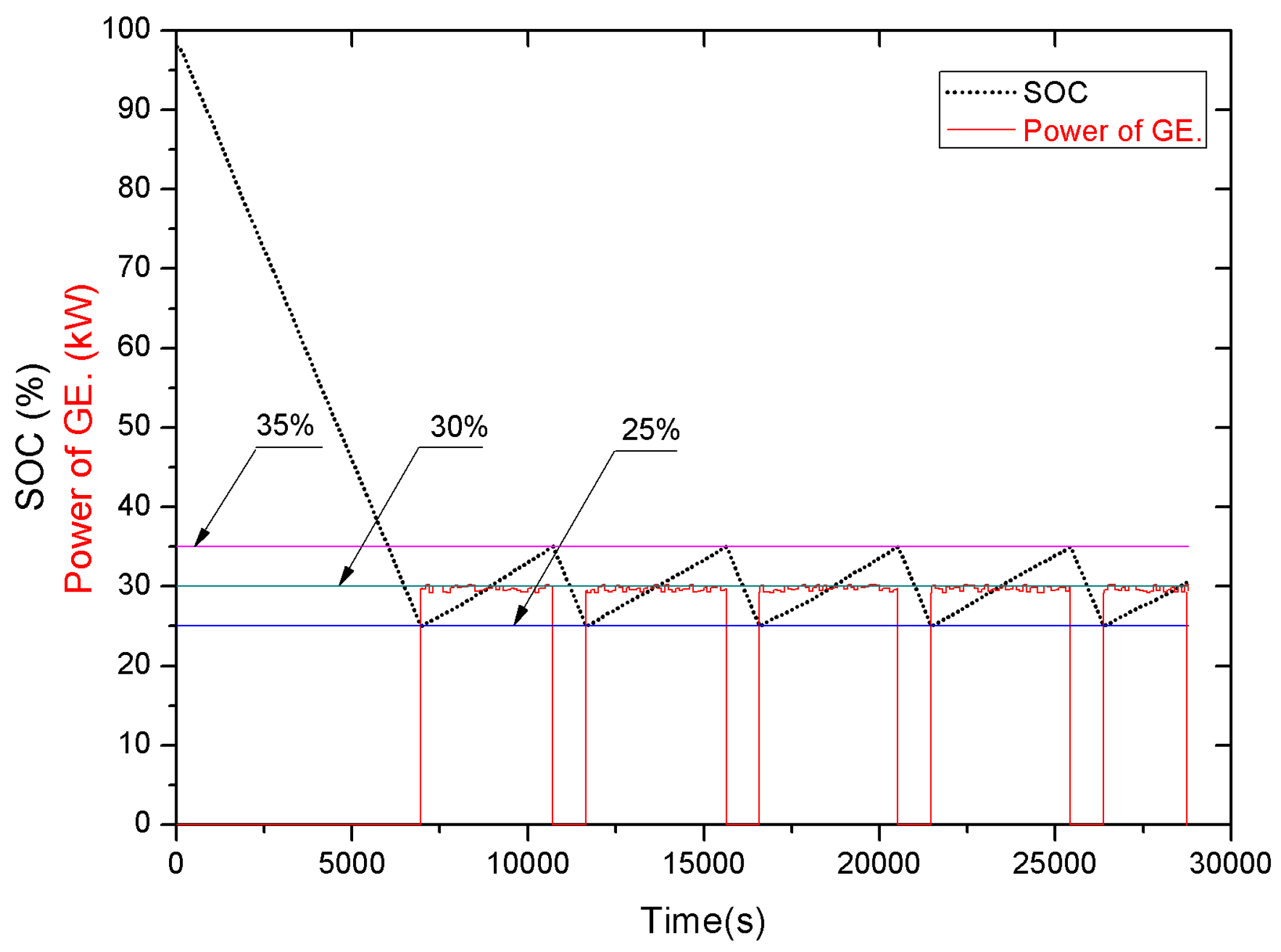

It can be seen that the navigation process includes the starting, accelerating, normal sailing and decelerating steps. The boat is principally at the state of maneuvering, the propulsion power often changes greatly. The maximum load power is about 35 kW at full speed. According to the energy control strategy, the power battery SOC curve and generator work curve are shown in

Figure 5.

As shown in

Figure 5, when the boat is starting to sail, the power battery is almost full whose SOC is close to 100%. During the CD period, the power system is supplied only by the power battery that results in a continuous drop of the SOC with a descending rate depending on the propulsion power. At about 8900 s, the SOC drops to the target value SOC-T (30%). After that, the battery changes from the battery CD period to the CS period; the SOC is maintained between SOC-L (25%) and SOC-H (35%) by the proposed control strategy. Comparing

Figure 5 and

Figure 6, it is obvious that, during the CD period, the whole power system is only supplied by the power battery, while the generator set is in a stop state, and during the CS period, the SOC drops to SOC-L (25%) at about 9300 s and the generator starts working to drive the propulsion motor and at the same time to charge the battery. At about 12,300 s, the SOC rises to SOC-H (35%) and the generator stops running. In the whole CS period, the work state of generator is decided based on the control strategy.

5.2. Constant-Speed Cruising

The power and boat speed under constant-speed condition profiles are shown in

Figure 6. The boat makes several round-trips during 8 h per day in the river, and the average speed of the boat is about 6.27 Kn. It can be seen that the HEB is cruising with constant speed, and the load power is from 23 to 25 kW. The power battery SOC curve and the generator work curve are shown in

Figure 7.

We can see that in more than 8 h of navigation, the demand for propulsion power is fully met to ensure the boat’s navigation safety. During the cruising, the generator and power battery are used harmoniously. In addition, the boat makes full use of the shore power stored in the battery. The distance of boat sailing exceeds the power battery life duration. It is also active to maintain the SOC of the battery in balance to prevent the battery from overdischarging. At the end of the travel, the SOC of the battery fluctuates around the target value SOC-T, and the stored electric energy is almost used. The fuel economy is improved, the cost of the navigation and pollution emission are reduced.

5.3. Analysis

Under the same load power, propulsion power, boat speed and distance, and without considering the cost of the weight of the battery, we compare the power consumption of the HEB and a diesel propulsion boat (DB). The comparison results are shown in

Table 7 and

Table 8 for variable-speed navigation and constant-speed cruising, respectively. The data used for the comparison are described as follows: the boat navigates 8 h per day (several round-trips in the river) for 360 days per year on the Suzhou River. In 2017, the price of diesel oil in China is 6.5 CNY/L. The electricity price is 0.8 CNY/kWh, so the cost of the electrical energy corresponding to a complete battery charging on shore is 0.8

= 0.8 × 53 = 42.4 CNY.

Converting the cost of the electrical energy to equivalent diesel oil gives 42.4/6.5 = 6.5 L.

The average output power is 21 kW, based on the load power profile in variable-speed navigation in

Figure 4. If the generator is on, the output power is about 30 kW based on the working curve of the generator set in variable-speed navigation in

Figure 5. The engine’s fuel consumption at 30 kW is 7 L/h and at 21 kW it is 6 L/h from engine performance data sheet for generator sets provided by manufacturer. From these analyses, we get the comparison results of HEB and DB in variable-speed navigation given in

Table 7.

The average output power is 24 kW, based on the load power profile in constant-speed cruising in

Figure 6. If the generator is on, the output power is about 30 kW based on the working curve of generator set in constant-speed cruising in

Figure 7. The engine’s fuel consumption at 24 kW is 6.5 L per hour from engine performance data sheet for generator sets provided by manufacturer. From these analyses, we get the comparison results of HEB and DB in constant-speed cruising given in

Table 8.

According to the above results, the use of hybrid technology can save ship oil and reduce pollution emissions and the capacity of diesel generator, resulting in a significant reduction in the costs of shipbuilding. Even though the weight of boat is increased due to the battery, the capacity of the generator and the fuel carried by the boat as well as the volume and weight of fuel tank will be decreased. As such, the capacity of HEB to reduce pollutant emissions remains predominant.

6. Conclusions

In order to reduce pollutant emissions from inland river ships and therefore improve air quality, this paper presents a series hybrid power system according to the characteristics of the inland river ships. The typical power supply modes are analyzed. The hybrid power system parameter design method is proposed based on the power requirements for ship propulsion and the auxiliary equipment. A hybrid energy control strategy for inland river ships is established. The experimental results show that the proposed system parameter design technique and control strategy of the hybrid power system are satisfactory; the power capacity completely meets the requirements for ship navigation. The energy savings and emission reductions are obvious.

Acknowledgments

The authors would like to acknowledge the financial support of National Natural Science Foundation of China under Contract number 61304186, 61673260 and the Natural Science Foundation of Shanghai under Contract number 16ZR1414300.

Author Contributions

Diju Gao designed the power system structure and parameter of HEB, drafted the manuscript, and also participated in the R & D of the HEB. Wei Zhang carried out the data acquisition, data analysis and manuscript preparation. Aidi Shen proposed the energy control strategy of HEB and the experiment design. Yide Wang provided theoretical knowledge in the data analysis and also reviewed and refined the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Song, J. Current situation and countermeasures of air pollution in inland river ships. Marit. Manag. Pap. China 2016, 10, 101–106. (In Chinese) [Google Scholar]

- Zhuang, N.; Zhu, K.Z. Research on prevention and control technologies of harbor pollution. In Proceedings of the International Conference on Energy and Environment Technology, Guilin, China, 16–18 October 2009; Volume 10, pp. 713–716. [Google Scholar]

- Wang, F.F.; Bao, H.B.; Thomas, K. Emission inventory assessment for a container vessel. In Proceedings of the IEEE International Symposium on Sustainable Systems and Technology, Tempe, AZ, USA, 18–20 May 2009; Volume 5, pp. 1–6. [Google Scholar]

- Luo, N. Analysis on characteristics of sulfur emissions from ships in Shanghai port. J. Transp. Manag. Inst. Minist. Transp. 2014, 2, 3–6. (In Chinese) [Google Scholar]

- Saravana, S.; Naveen Prabhu, S.; Lenin Pugalhanthi, P. PI Controller for Energy Management System in Hybrid Electric Ship. In Proceedings of the 2014 IEEE International Conference on Innovations in Engineering and Technology, Tamil Nadu, India, 21–22 March 2014; Volume 3, pp. 770–776. [Google Scholar]

- Bolognani, S.; Faggion, A.; Sgarbossa, L. Power flow management design for an electric propulsion system of a hybrid catamaran. In Proceedings of the 14th European Conference on Power Electronics and Applications, Birmingham, UK, 30 August–1 September 2011; Volume 9, pp. 1–9. [Google Scholar]

- Dupriez-Robin, F.; Loron, L.; Claveau, F.; Chevrel, P. Design and optimization of an hybrid sailboat by a power modeling approach. In Proceedings of the IEEE Electric Ship Technologies Symposium, Baltimore, MD, USA, 20–22 April 2009; Volume 4, pp. 270–277. [Google Scholar]

- Seenumani, G.; Sun, J.; Peng, H. A hierarchical optimal control strategy for power management of hybrid power systems in all electric ships applications. In Proceedings of the 49th IEEE Conference on Decision and Control, Atlanta, GA, USA, 15–17 December 2010; Volume 12, pp. 3972–3977. [Google Scholar]

- Zhu, L.S.; Han, J.G.; Peng, D.K.; Wang, T.Z.; Tang, T.H.; Charpentier, J.-F. Fuzzy logic based energy management strategy for a fuel cell battery ultra capacitor hybrid ship. In Proceedings of the First International Conference on Green Energy, Sfax, Tunisia, 25–27 March 2014; Volume 11, pp. 107–112. [Google Scholar]

- Mukherjee, N.; Strickland, D. Analysis and comparative study of different converter modes in modular second-life hybrid battery energy storage systems. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 2, 547–563. [Google Scholar] [CrossRef]

- Peng, Z.Y.; Qing, D.T.; Yang, Y.L.; Duan, Z.H. Operation mode analysis and parameter matching design of a Noval hybrdi electric vehicle. China Mech. Eng. May 2012, 9, 1122–1128. (In Chinese) [Google Scholar]

- Gutierrez, C.; Meana, D. Application of hybrid-electric power supply system in fishing vessels. In Proceedings of the Second International Symposium on Fishing Vessel Energy Efficiency E-Fishing, Vigo, Spain, 22–24 May 2012; Volume 5, pp. 1–8. [Google Scholar]

- Yaakob, O.; Mukti, M.A.A.; Nasirudin, A.; Lazim, T.M.; Ghani, M.P.A.; Ghani, K.B. A Low Wash Hullform and Pollutant Free Inland Waterways Leisure Craft. In Proceedings of the 3rd International Conference on Maritime and Naval Science and Engineering, Constantza, Romania, 3–5 September 2010; Volume 6, pp. 212–216. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).