Combustion, Performance, and Emission Evaluation of a Diesel Engine with Biodiesel Like Fuel Blends Derived From a Mixture of Pakistani Waste Canola and Waste Transformer Oils

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples Collection

2.2. Transesterification Process

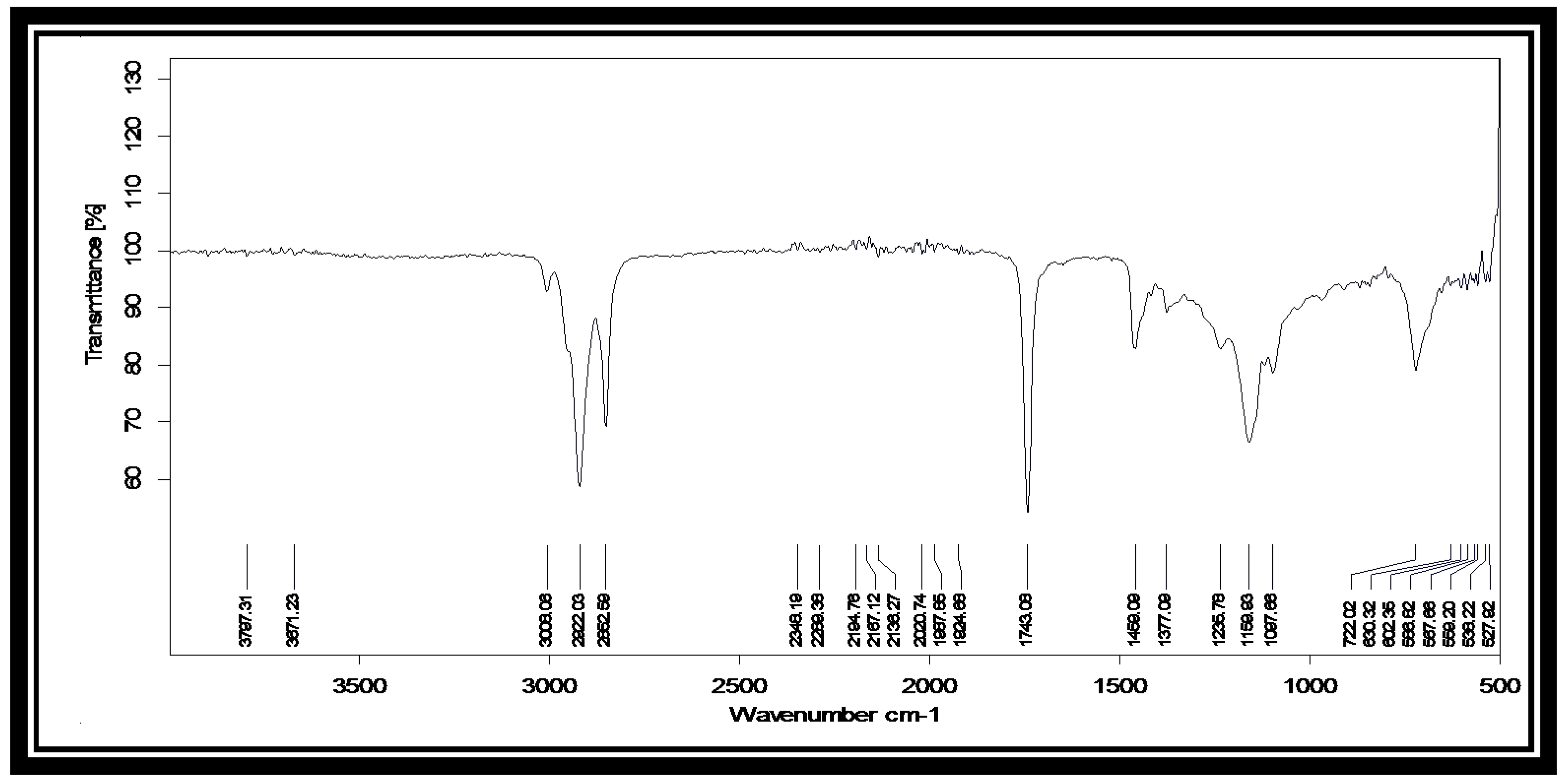

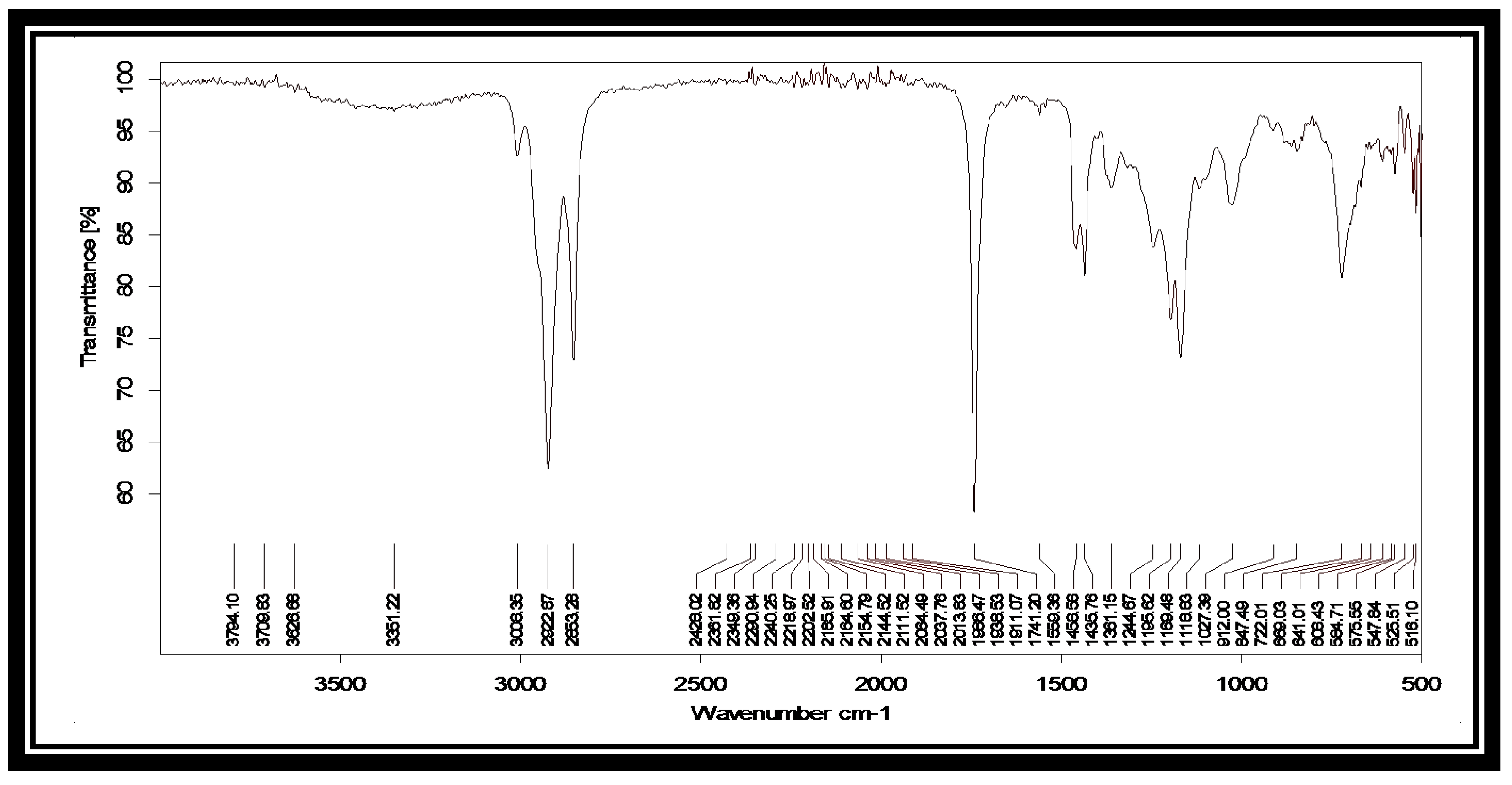

2.3. FTIR Analysis

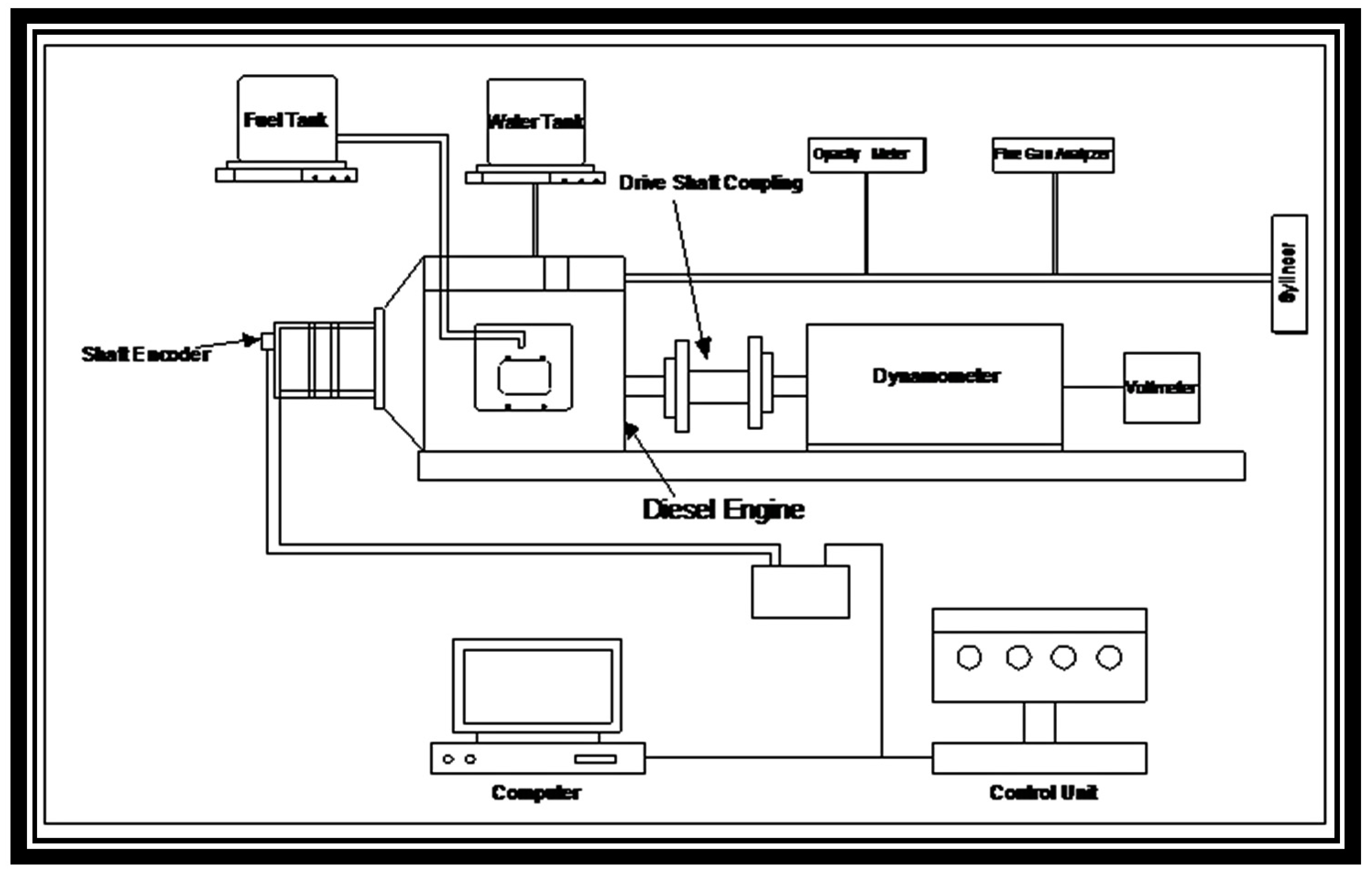

2.4. Engine Setup

3. Results and Discussions

3.1. Fuel Properties

3.2. Combustion and Engine Performance

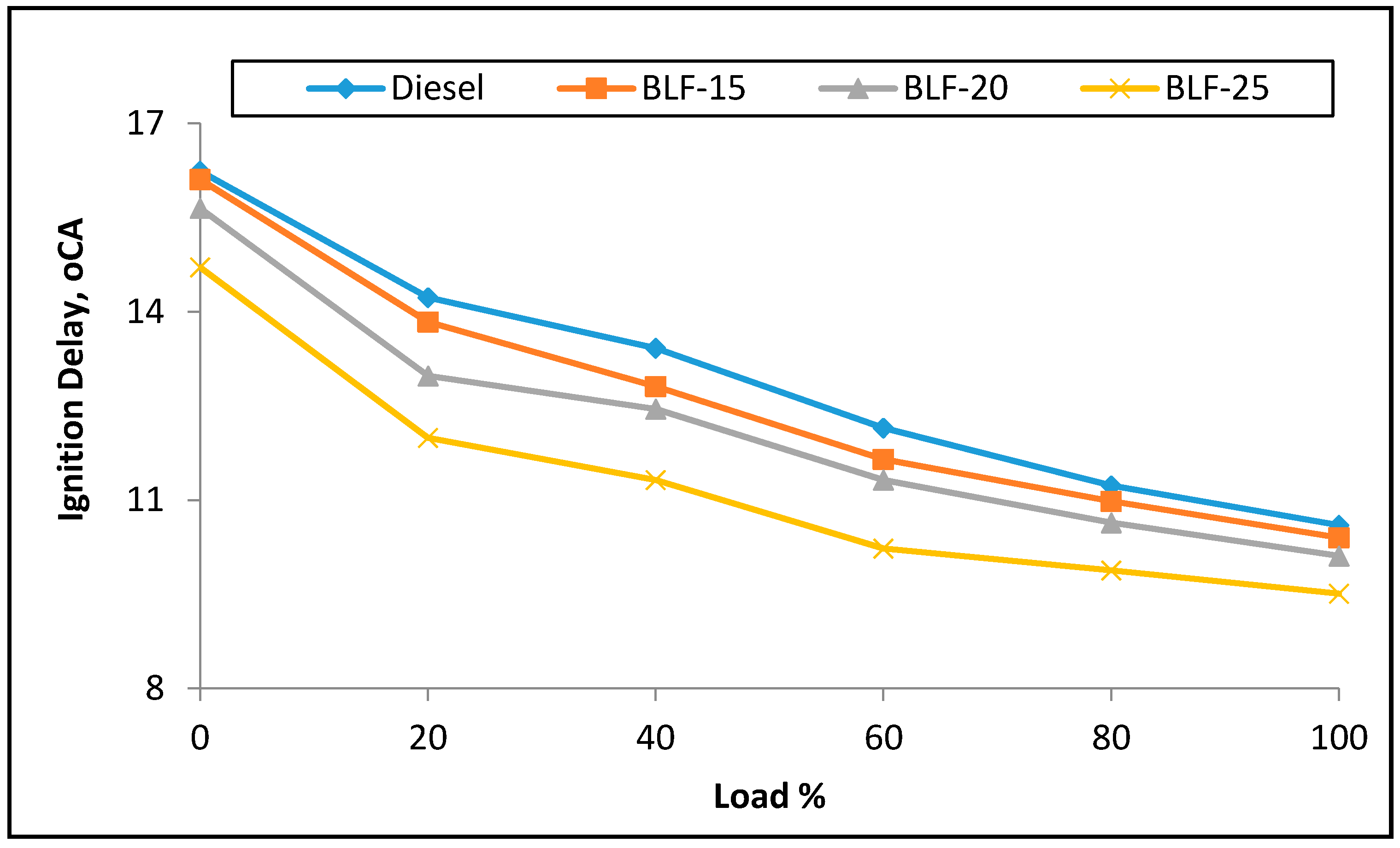

3.2.1. Ignition Delay

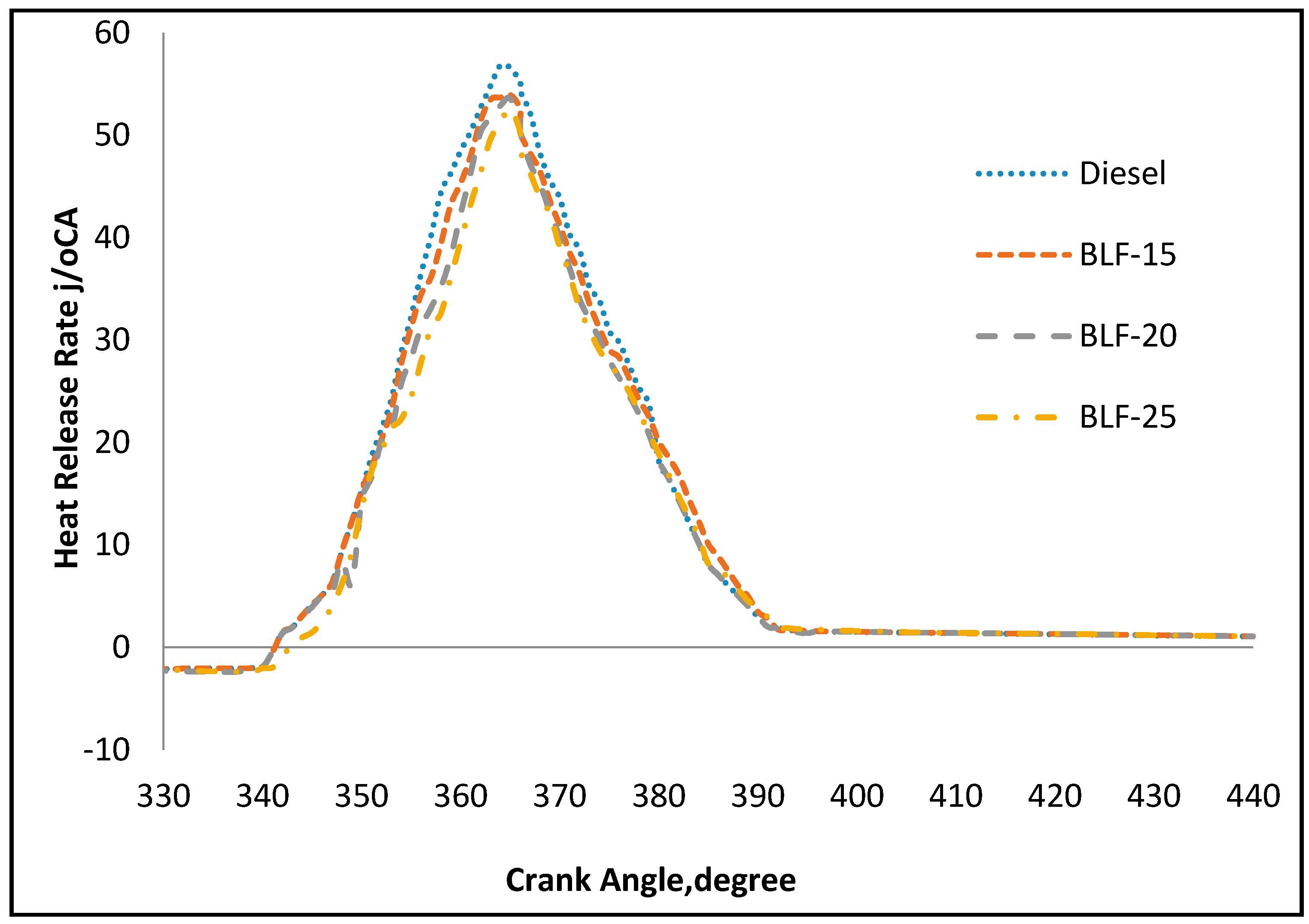

3.2.2. Heat Release Rate

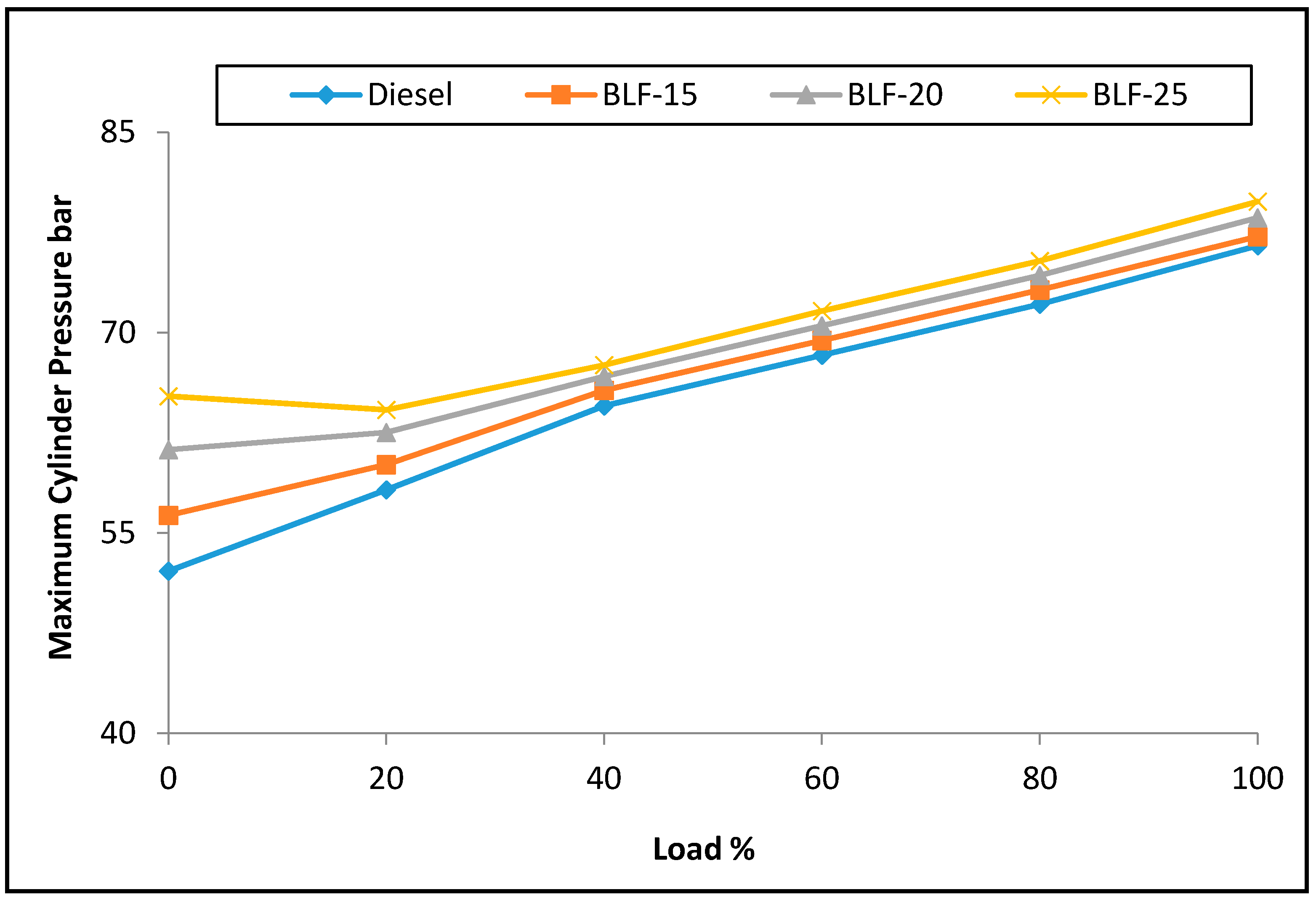

3.2.3. Maximum Cylinder Pressure

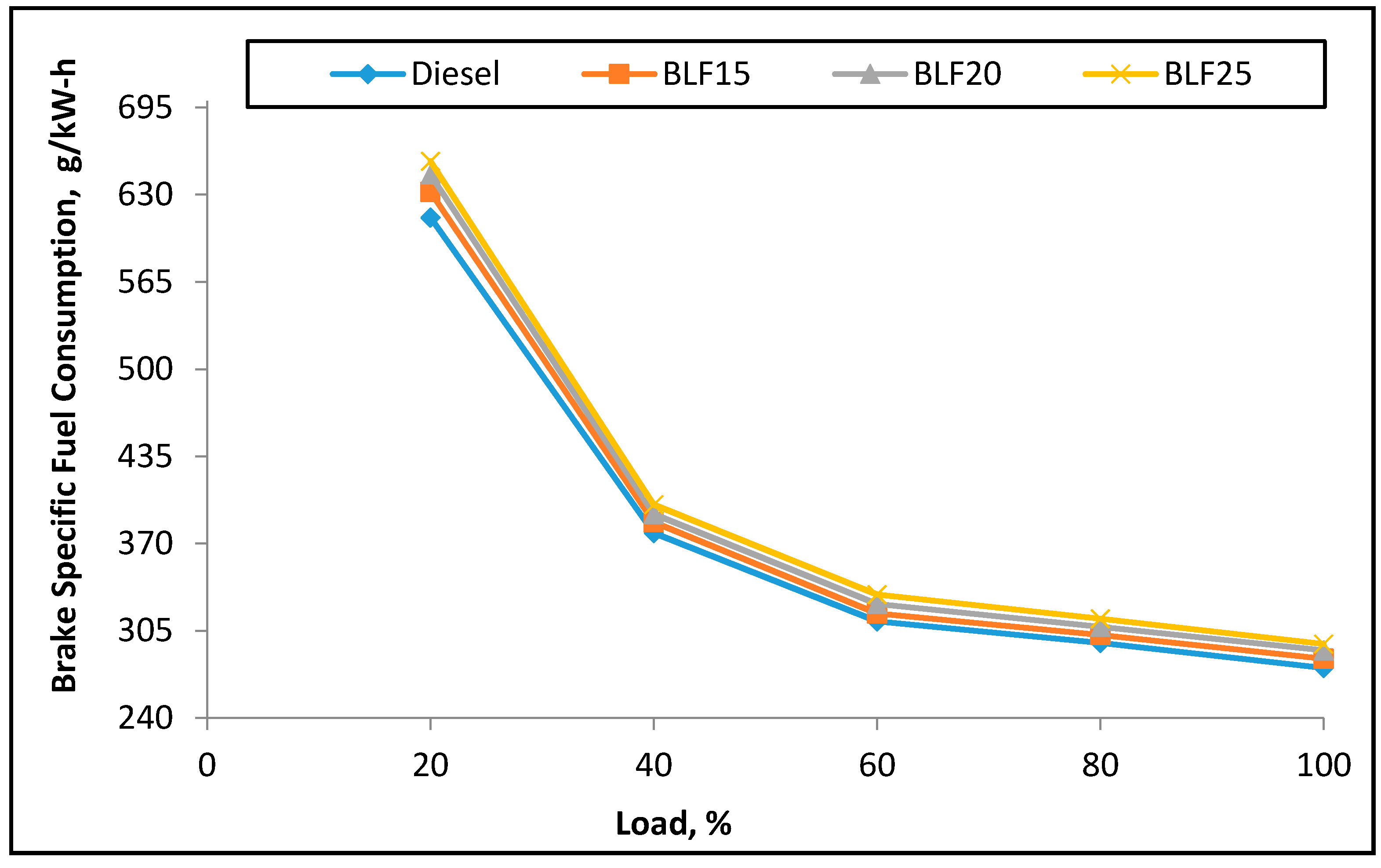

3.2.4. Brake Specific Fuel Consumption (BSFC)

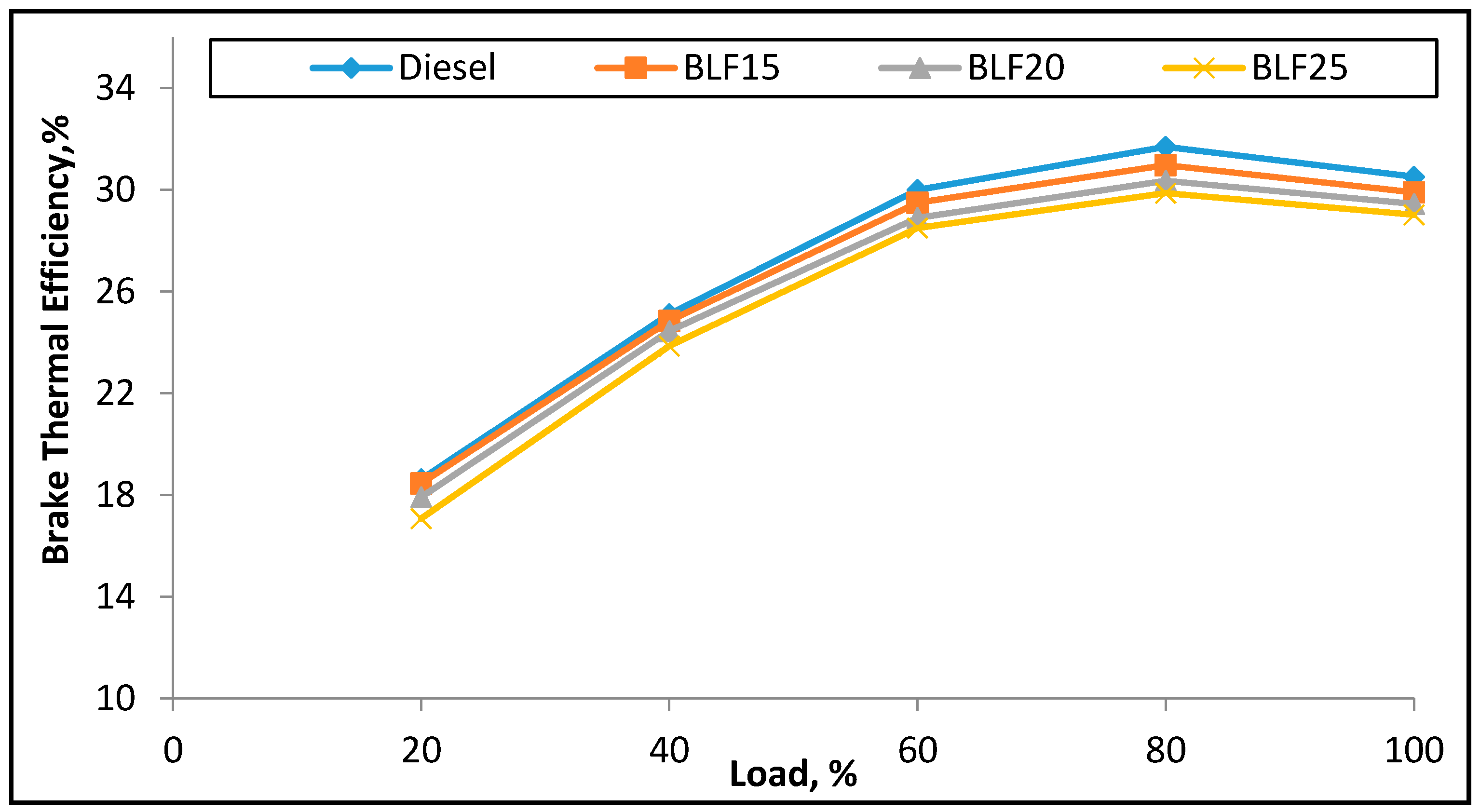

3.2.5. Brake Thermal Efficiency (BTE)

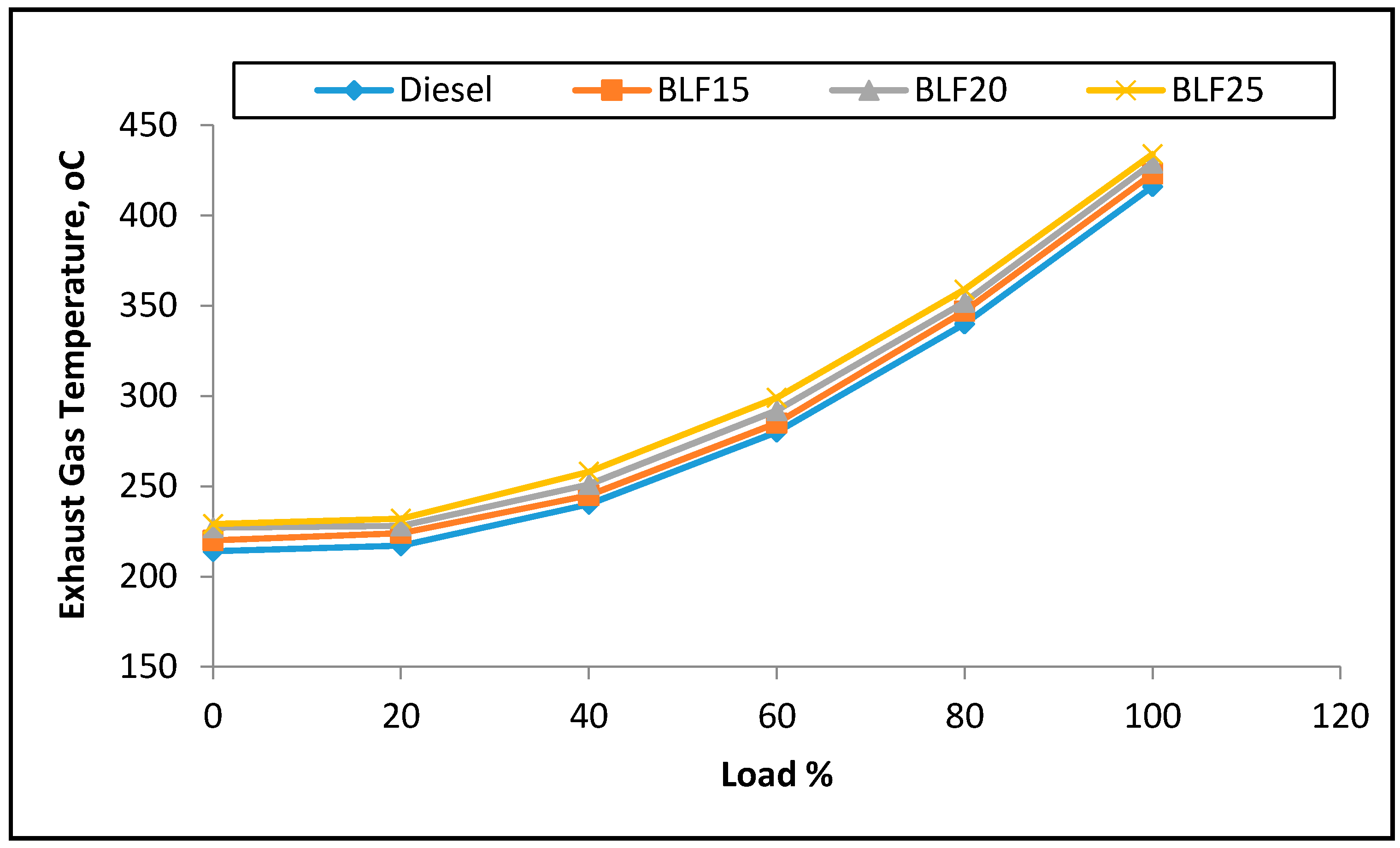

3.2.6. Exhaust Gas Temperature (EGT)

3.3. Engine Emissions

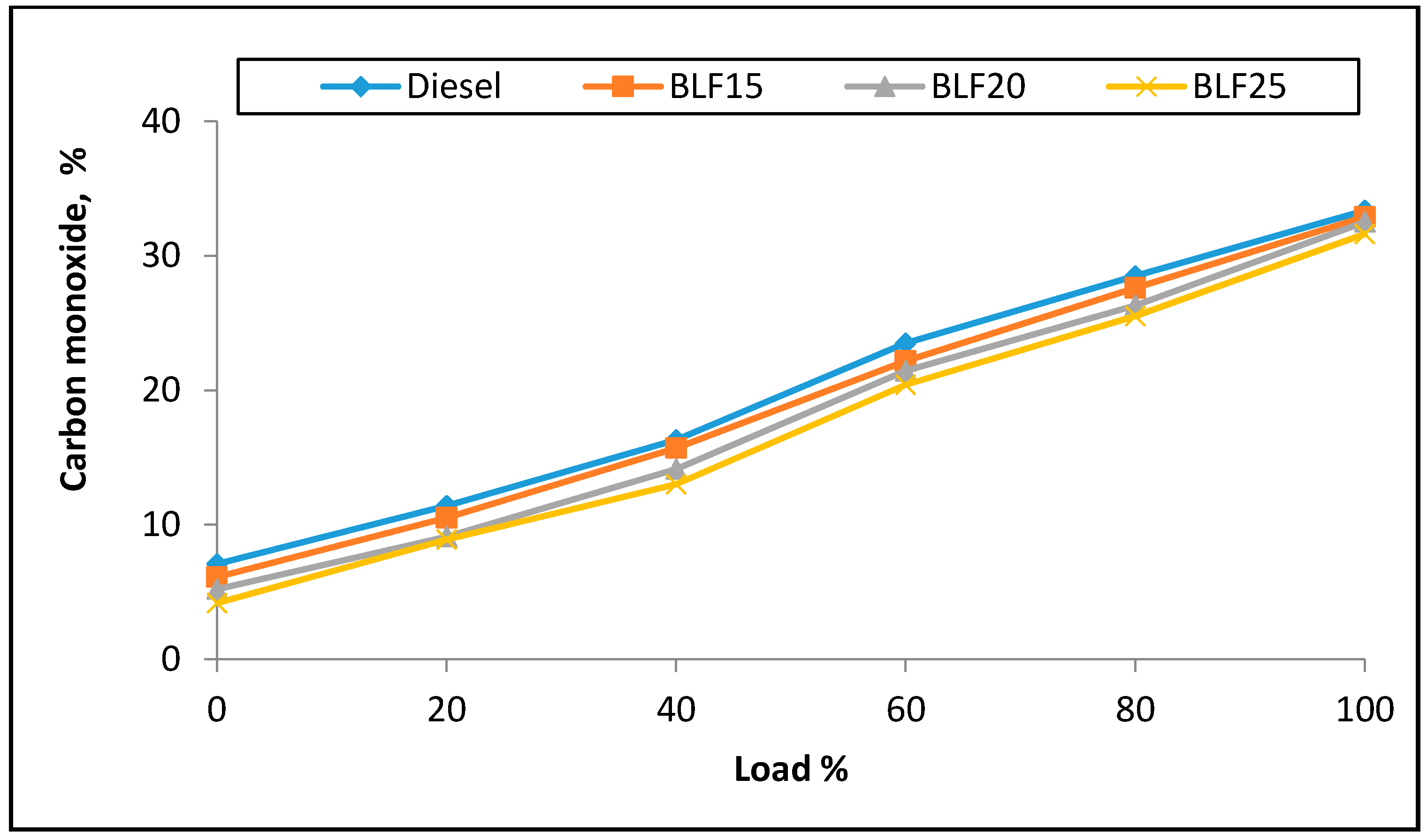

3.3.1. Carbon Monoxide (CO)

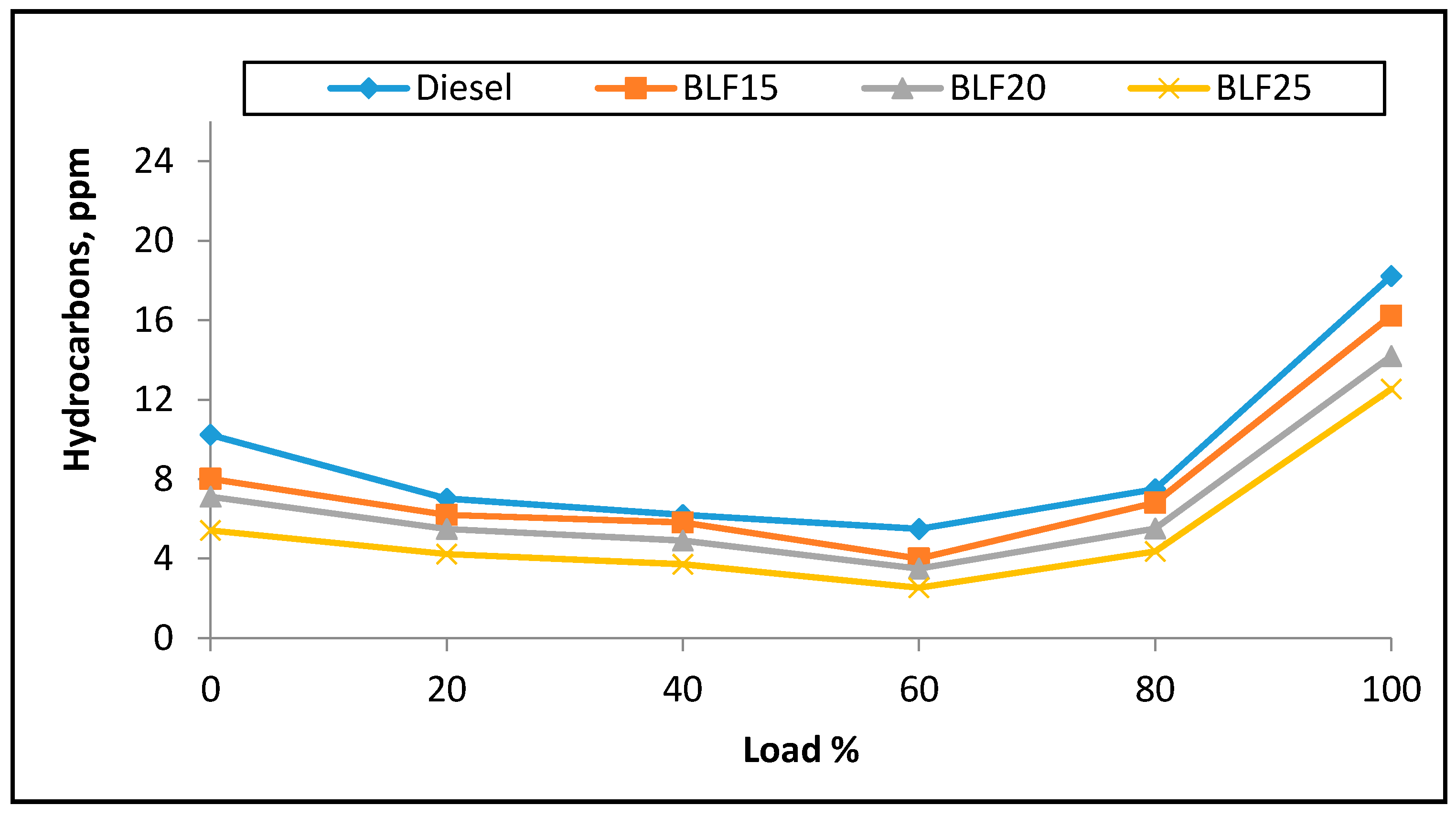

3.3.2. Hydrocarbons (HC)

3.3.3. Oxides of Nitrogen (NOx)

3.3.4. Smoke Opacity

4. Conclusions

- The results of FTIR analysis have confirmed that BLF fuel has similar characteristics to that of petroleum diesel showing saturated alkane structures.

- It is observed that fuelobtained from the mixture of transesterified waste transformer oil (TWTO) and waste canola oil methyl esters (WCOME) have fuel properties comparable to petroleum diesel and were found within the international specified standard (EN 14214, BIS 15607 and ASTM 6751-03) limits of biodiesel fuel.

- In comparison to diesel, a shorter ignition delay was observed BLF fuel blends. This was a good indication for better combustion of the proposed fuel blends.

- EGT and BSFC of BLF fuel blends were found to increase 1.68–4.33% and 2.48–6.45%, respectively, as compared to petroleum diesel at maximum load conditions, however, BTE decreased 1.99–4.91% with the increase in BLF concentrations in the fuel blend. BLF15 has a lower fuel consumption value (632.02 g/kW·h), higher BTE (29.91%), and lower EGT (224 °C at minimum engine load) as compared to BLF20 and BLF25 fuel blends.

- HC and CO emissions of the diesel engine with BLF fuel blends were observed to reduce by 10.92–31.17% and 3.80–6.32%, respectively, as compared to those of diesel fuel. The smoke density was reduced by 1.39–5.21%, whereas NOx emissions were found to increase by 3.16–7.78% in relation to diesel fuel.

- Minimum decrease of CO, HC, smoke value, and minimum increase of NOx emissions were found with BLF15. BSFC, EGT, and BTE values of the BLF15 fuel blend are closer to those of petroleum diesel. It is, therefore, suggested that this fuel blend may be used in diesel engines without any engine modifications.

- Pakistani waste transformer and waste canola oils have been successfully converted into fuel which might boost the country’s economy by saving its crude oil import bills. Additionally, the outcome of this research work is to minimize the environmental problems arising from the waste oil disposals.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Agarwal, A.K. Biofuels (alcohols and biodiesels) application as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Demirbas, A. Progress and recent trends in biofuels. Prog. Energy Combust. Sci. 2007, 33, 1–18. [Google Scholar] [CrossRef]

- Graboski, M.S.; McCormick, R.L. Combustion of fat and vegetable oil derived fuels in diesel engines. Prog. Energy Combust. Sci. 1998, 24, 125–164. [Google Scholar] [CrossRef]

- McCormick, R.L.; Tennant, C.J.; Hayes, R.R.; Black, S.; Ireland, J.; McDaniel, T.; Williams, A.; Frailey, M.; Sharp, C.A. Regulated emissions from biodiesel tested in heavy duty engines meeting 2004 emission standards. In Proceedings of the 2005 SAE Brasil Fuels & Lubricants Meeting, Rio De Janeiro, Brazil, 11–13 May 2005. [Google Scholar]

- Yoon, S.H.; Park, S.H.; Lee, C.S. Experimental investigation on the fuel properties of biodiesel and its blends at various temperatures. Energy Fuels 2008, 22, 652–656. [Google Scholar] [CrossRef]

- Yoon, S.H.; Lee, C.S. Experimental investigation on the combustion and exhaust emission characteristics of biogas-biodiesel dual-fuel combustion in a CI engine. Fuel Process. Technol. 2011, 92, 992–1000. [Google Scholar] [CrossRef]

- Yoon, S.H.; Cha, P.J.; Lee, C.S. An investigation of the effects of spray angle and injection strategy on dimethyl ether (DME) combustion and exhaust emission characteristics in a common-rail diesel engine. Fuel Process. Technol. 2010, 91, 1364–1372. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Wang, Z.; Xiao, J.H. Combustion and emission characteristics of diesel engine fueled with diesel/biodiesel/pentanol fuel blends. Fuel 2015, 15, 211–218. [Google Scholar] [CrossRef]

- Kalantar, A.; Levin, M. Factors affecting the dissolution of copper in transformer oils. Lubr. Sci. 2008, 20, 223–240. [Google Scholar] [CrossRef]

- Hara, I. Health status and PCBs in blood of workers exposed to PCBs and of their children. Environ. Health Perspect. 1985, 59, 85–90. [Google Scholar] [CrossRef] [PubMed]

- Gustavsson, P.; Hogstedt, C. A cohort study of swedish capacitor manufacturing workers exposed to polychlorinated biphenyls (PCBs). Am. J. Ind. Med. 1997, 32, 234–239. [Google Scholar] [CrossRef]

- Lobeiras, A.; Sabau, J. Particle counting of insoluble decay products in mineral insulating oils. In Proceedings of the 2000 Symposium of the American Society for Testing and Materials (ASTM), Toronto, ON, Canada, 2000. [Google Scholar]

- Sierota, A.; Rungis, J. Electrical insulating oils. Part-1: Characterization and pre-treatment of new transformer oils. IEEE Electr. Insul. Mag. 1995, 11, 8–20. [Google Scholar] [CrossRef]

- Pullagura, G.; Kumar, K.R.; Verma, P.C.; Jaiswal, A. Experimental investigation of hydrogen enrichment on performance and emission behavior of CI engine. Int. J. Eng. Sci. Technol. 2012, 4, 1223–1232. [Google Scholar]

- Kurki, A.; Hill, A.; Morris, M. Biodiesel: The Sustainability Dimensions; ATTRA Publication: Butte, MT, USA, 2006; pp. 1–12. Available online: http://attra.ncat.org/attra-pub/PDF/biodiesel_sustainable.pdf (accessed on 1 January 2017).

- Khan, M.I.; Chhetri, A.B.; Islam, M.R. Analyzing Sustainability of Community Based Energy Technologies. Energy Sources 2007, 2, 403–419. [Google Scholar] [CrossRef]

- Abdullah, N.H.; Hassan, S.H.; Yusoff, N.R.M. Biodiesel production based on waste cooking oil (WCO). Int. J. Mater. Sci. Eng. 2013, 1, 94–99. [Google Scholar] [CrossRef]

- Kaanagbara, L.; Inyang, H.I.; Wu, J.; Hilger, H. Aromatic and aliphatichydrocarbon balance in electric transformer oils. Fuel 2010, 89, 3114–3118. [Google Scholar] [CrossRef]

- Murugan, S.; Ramaswamy, M.C.; Nagarajan, G. The use of tyre pyrolysis oil in diesel engines. J. Waste Manag. 2008, 28, 2743–2749. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.J.; Liu, Y.-C.; Mwangi, F.K.; Chen, W.-H.; Lin, S.-L.; Fukushima, Y.; Liao, C.-N.; Wang, L.-C. Assessment of energy performance and airpollutant emissions in a diesel engine generator fueled withwater-containing ethanol–biodiesel–diesel blend of fuels. Energy 2011, 36, 5591–5599. [Google Scholar] [CrossRef]

- Mani, M.; Subash, C.; Nagarajan, G. Performance, emission and combustioncharacteristics of a CI diesel engine using waste plastic oil. Appl. Therm. Eng. 2009, 29, 2738–2744. [Google Scholar] [CrossRef]

- Arpa, O.; Yumrutaş, R.; Argunhan, Z. Experimental investigation of the effects ofdiesel-like fuel obtained from waste lubrication oil on engineperformance and exhaust emission. Fuel Process. Technol. 2010, 91, 1241–1249. [Google Scholar] [CrossRef]

- Rakopoulos, C.; Hountalas, D.T.; Giakoumis, E.G.; Andritsakis, E.C. Performance and emissions of bus engineusing blends of diesel fuel with bio-diesel of sunflower orcottonseed oils derived from Greek feedstock. Fuel 2008, 87, 147–157. [Google Scholar] [CrossRef]

- Recep, Y.; Mehmet, H.A.; Hakan, Ö.; Önder, K. Investigation of purified sulphates turpentine on engine performance and exhaust emission. Fuel 2008, 87, 252–259. [Google Scholar]

- Arpa, O.; Yumrutaş, R.; Kaşka, Ö. Desulfurization of diesel-like fuel produced fromwaste lubrication oil and its utilization on engine performanceand exhaust emission. Appl. Therm. Eng. 2013, 58, 374–381. [Google Scholar] [CrossRef]

- Behera, P.; Murugan, S.; Nagarajan, G. Dual fuel operation of Used Transformer Oil with acetylene in a DI diesel engine. Energy Convers. Manag. 2014, 87, 840–847. [Google Scholar] [CrossRef]

- Prasanna, S.; Saravanan, C.G.; Kannan, M. Influence of injection timing on DI diesel engine characteristics fuelled with waste transformer oil. Alex. Eng. J. 2015, 54, 881–888. [Google Scholar]

- International Standard Organization. ISO 3046 Reciprocating Internal Combustion Engines—Performance; International Standard Organization: Geneva, Switzerland, 1996. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Inc.: New York, NY, USA, 1988; pp. 509–510. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamental; McGraw Hill Publications: New York, NY, USA, 1988; pp. 491–667. [Google Scholar]

- Raheman, H.; Prakash Jena, C.; Snehal, S.J. Performance of a diesel engine with blends of biodiesel (from a mixture of oils) and high speed diesel. Int. J. Energy Environ. 2013, 6, 1–9. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M. A study on the performance and emission of a diesel engine fuelled with Jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Performance, emissions and combustion characteristics of Karanja biodiesel in a transportation engine. Fuel 2014, 119, 70–80. [Google Scholar] [CrossRef]

- Hirkude, J.B.; Padalkar, A.S. Performance and emission analysis of acompression ignition: Engine operated on waste fried oil methyl esters. Appl. Energy 2012, 90, 68–72. [Google Scholar] [CrossRef]

- Kakati, J.; Gogoi, T.K. Biodiesel production from Kutkura (Meyna spinosa Roxb. Ex.) fruit seed oil: Its characterization and engine performance evaluation with 10% and 20% blends. Energy Convers. Manag. 2016, 121, 152–161. [Google Scholar] [CrossRef]

- Khiari, K.; Awad, S.; Loubar, K.; Tarabet, L.; Mahmoud, R.; Tazerout, M. Experimental investigation of Pistacialentiscus biodiesel as a fuel For directin injection diesel engine. Energy Convers. Manag. 2016, 108, 392–399. [Google Scholar] [CrossRef]

- Lapuerta, M.; Jose, O.A.; Ferna´ndez, R. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M. Determination of performance and combustion characteristics of a diesel engine fueled with canola and waste palm oil methyl esters. Energy Convers. Manag. 2011, 52, 108–116. [Google Scholar] [CrossRef]

- Usta, N. An experimental study on performance and exhaust emissions of a diesel engine fuelled with tobacco seed oil methyl ester. Energy Convers. Manag. 2005, 46, 2373–2386. [Google Scholar] [CrossRef]

- Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I.; Silitonga, A.S.; Chong, W.T.; Leong, K.Y. Optimization of biodiesel production and engine performance from high free fatty acid Calophyllum inophyllum oil in CI diesel engine. Energy Convers. Manag. 2014, 81, 30–40. [Google Scholar] [CrossRef]

- Chuah, L.F.; Rashid, A.; Aziz, A.; Yusup, S.; Bokhari, A.; Klemeš, J.J.; Abdullah, M.Z. Performance and emission of diesel engine fuelled by waste cooking oil methyl ester derived from palm oil using hydro dynamic cavitation. Clean Technol. Environ. Policy 2015, 15, 2229–2241. [Google Scholar] [CrossRef]

- Raheman, H.; Ghadge, S.V. Performance of compression ignition engine with mahua (Madhuca indica) biodiesel. Fuel 2007, 86, 2568–2573. [Google Scholar] [CrossRef]

- Gumus, M.; Kasifoglu, S. Performance and emission evaluation of a compression ignition engine using a biodiesel (apricot seed kernel oil methyl ester) and its blends with diesel fuel. Biomass Bioenergy 2010, 34, 134–139. [Google Scholar] [CrossRef]

| Sr. No. | Fuel Type | BLF Composition | BLF-Diesel Blends Description | ||

|---|---|---|---|---|---|

| TWTO Volume | WCOME Volume | BLF Volume | Diesel Volume | ||

| 1 | Diesel (BLF0) | - | - | 0 mL | 1000 mL |

| 2 | BLF100 | 500 mL | 500 mL | 1000 mL | 0 mL |

| 3 | BLF15 | 500 mL | 500 mL | 150 mL | 850 mL |

| 4 | BLF20 | 500 mL | 500 mL | 200 mL | 800 mL |

| 5 | BLF25 | 500 mL | 500 mL | 250 mL | 750 mL |

| Diesel | BLF | ||||

|---|---|---|---|---|---|

| Frequency Range (cm−1) | Bond Types | Family | Frequency Range (cm−1) | Bond Types | Family |

| 2922.03–2852.59 | C–H stretch | Alkanes | 2922.87–2853.26 | C–H stretch | Alkanes |

| 1459.09 | C–H bend | Alkanes | 1458.58 | C–H bend | Alkanes |

| 1377.09 | C–X | Flouride | 1361.15 | C–X | Fluoride |

| 722.01 | C–H bend | Alkanes | 722.02 | C–H bend | Alkanes |

| Particulars | Details | |

|---|---|---|

| Engine | Model | Kirolaskar TAF-1 |

| Maximum power (kW) | 5.5 | |

| Type | Water-cooled, four stroke | |

| Rated speed (rpm) | 1600 | |

| Number of cylinders | 1 | |

| Bore | 87.5 mm | |

| Stroke | 110 mm | |

| Compression ratio | 17.5:1 | |

| Combustion | Direct injection (DI) and naturally aspirated | |

| Injection timing | 23° before TDC | |

| Gas analyzer | Model | AVL Di Gas 444 |

| HC (ppm) | - | |

| Accuracy | ±4% | |

| Range | 0 to 30,000 | |

| Resolution | 1 | |

| CO (%) | - | |

| Accuracy | ±0.06 | |

| Range | 0 to 15 | |

| Data resolution | 0.001 | |

| NOx (ppm) | - | |

| Range | 0 to 5000 | |

| Accuracy | ±2% | |

| Resolution | 1 | |

| Smoke meter | - | AVL 437 |

| Accuracy | ±1% | |

| Range | 0–100% | |

| Alarming signal temperataure | 70 °C | |

| Light Source | Halogen Lamp, 12 V |

| Properties | Units | Method ASTM | Diesel | BLF100 | BLF15 | BLF20 | BLF25 | ASTM 6751 | EN 14214 | BIS 15607 |

|---|---|---|---|---|---|---|---|---|---|---|

| Density at 15 °C | (Kg/m3) | D-1298 | 834 | 886 | 836 | 841 | 845 | - | 860–900 | 860–900 |

| Kin.Viscosity at 40 °C | cSt | D-445 | 2.96 | 5.56 | 3.18 | 3.24 | 3.31 | 1.9–6.0 | 3.5–5.0 | 2.5–6.0 |

| Heating Value | KJ/kg | D-240-17 | 43,400 | 39,500 | 42,800 | 42,000 | 41,400 | - | - | - |

| Flash Point | °C | D-93 | 60 | 166 | 71 | 83 | 88 | >130 | >120 | >120 |

| Pour Point | °C | D-97 | −12 | 6 | −9 | −6 | −3 | - | - | - |

| Cetane Number | - | D-976 | 53 | 54 | 54.5 | 55 | 55.5 | - | - | - |

| Acid Value | mgKOH/g | D-664 | - | 0.39 | 0.16 | 0.18 | 0.21 | <0.80 | <0.50 | <0.50 |

| Water Contents | mg L−1 | D-95 | 70 | 430 | 185 | 210 | 255 | <500 | <500 | <500 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qasim, M.; Ansari, T.M.; Hussain, M. Combustion, Performance, and Emission Evaluation of a Diesel Engine with Biodiesel Like Fuel Blends Derived From a Mixture of Pakistani Waste Canola and Waste Transformer Oils. Energies 2017, 10, 1023. https://doi.org/10.3390/en10071023

Qasim M, Ansari TM, Hussain M. Combustion, Performance, and Emission Evaluation of a Diesel Engine with Biodiesel Like Fuel Blends Derived From a Mixture of Pakistani Waste Canola and Waste Transformer Oils. Energies. 2017; 10(7):1023. https://doi.org/10.3390/en10071023

Chicago/Turabian StyleQasim, Muhammad, Tariq Mahmood Ansari, and Mazhar Hussain. 2017. "Combustion, Performance, and Emission Evaluation of a Diesel Engine with Biodiesel Like Fuel Blends Derived From a Mixture of Pakistani Waste Canola and Waste Transformer Oils" Energies 10, no. 7: 1023. https://doi.org/10.3390/en10071023