Characterization and Effects of the Shock Losses in a Parallel Fan Station in the Underground Mine

Abstract

:1. Introduction

2. Model Development

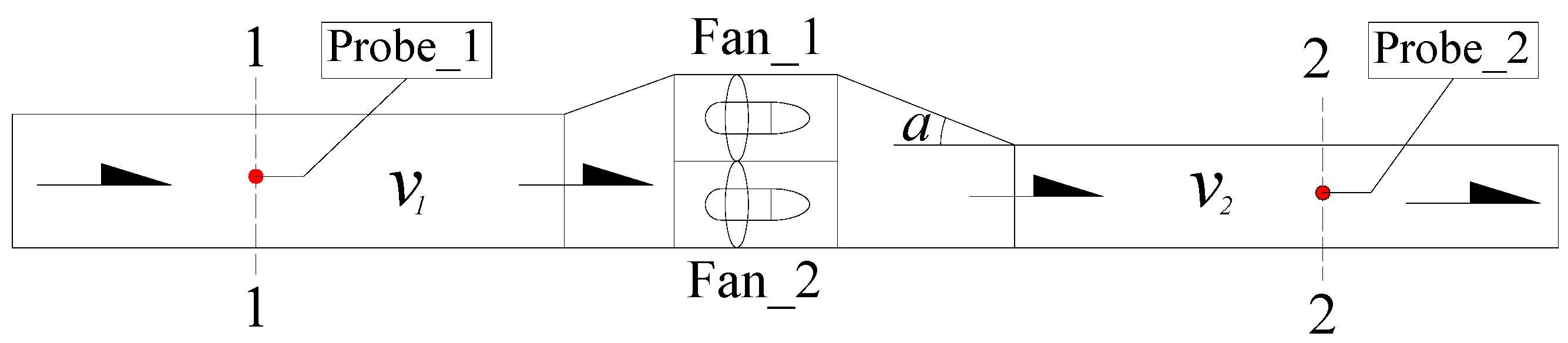

2.1. Field Measurement

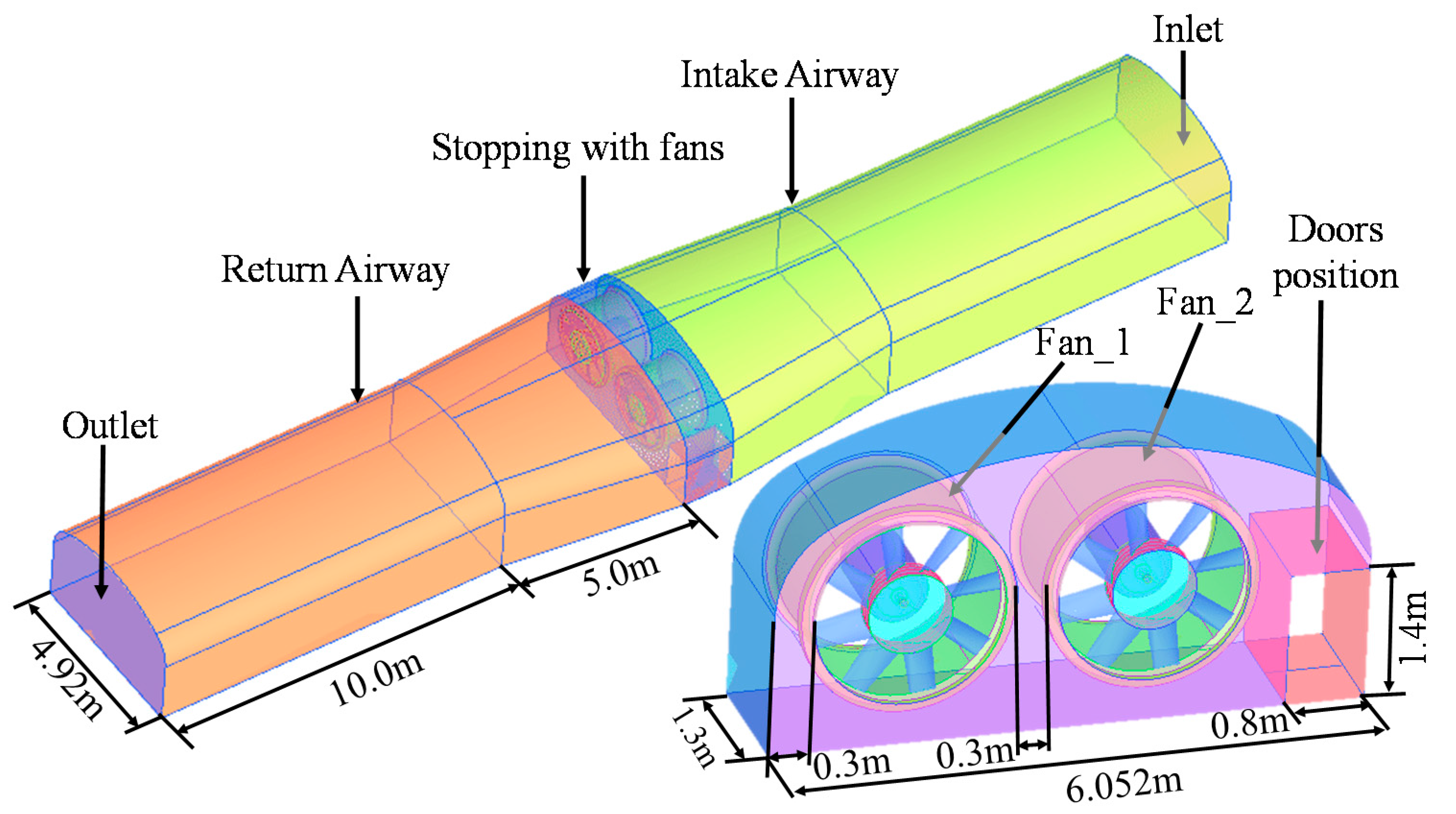

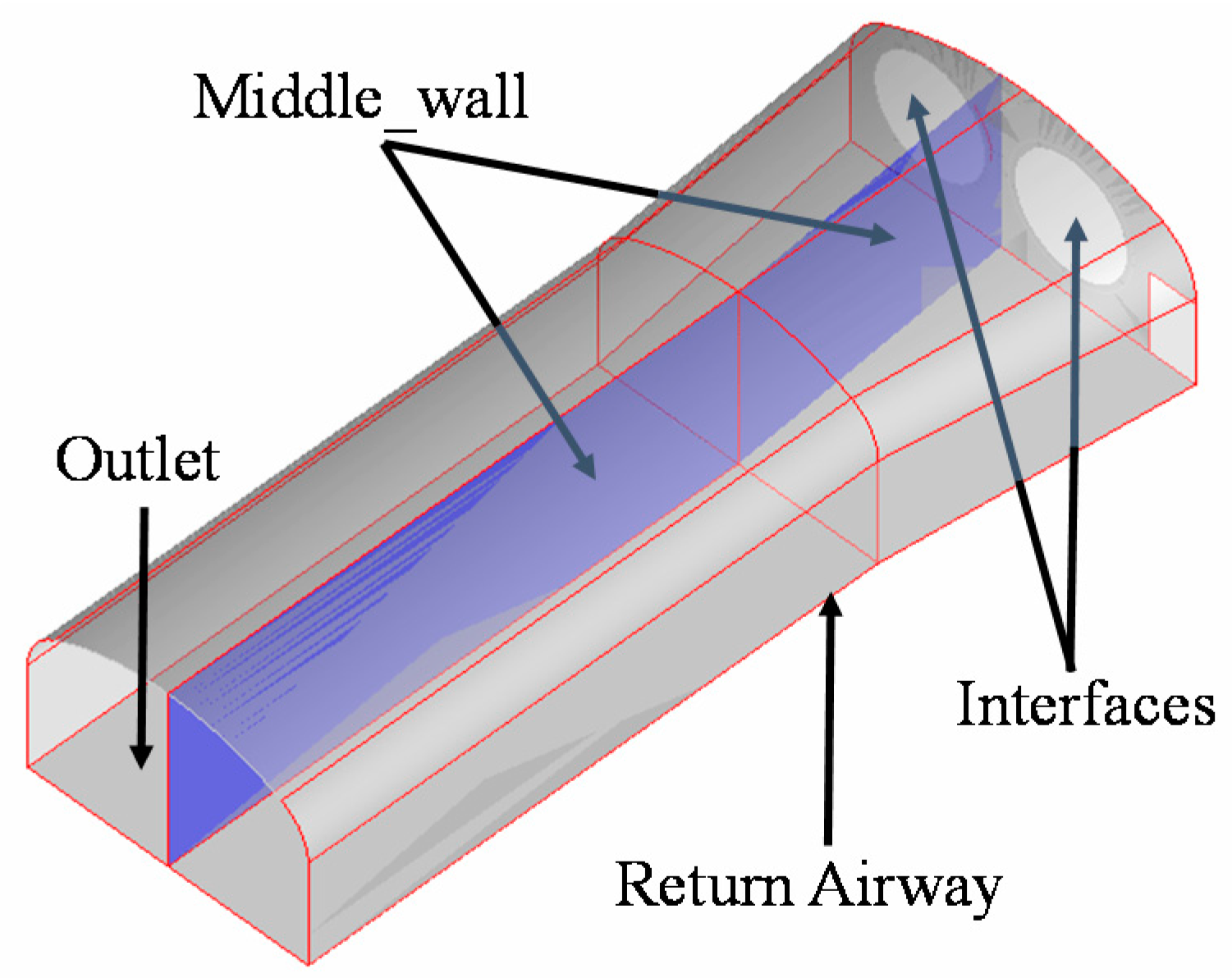

2.2. Physical Model

2.3. Governing Equations

2.4. Computational Method and Boundary Conditions

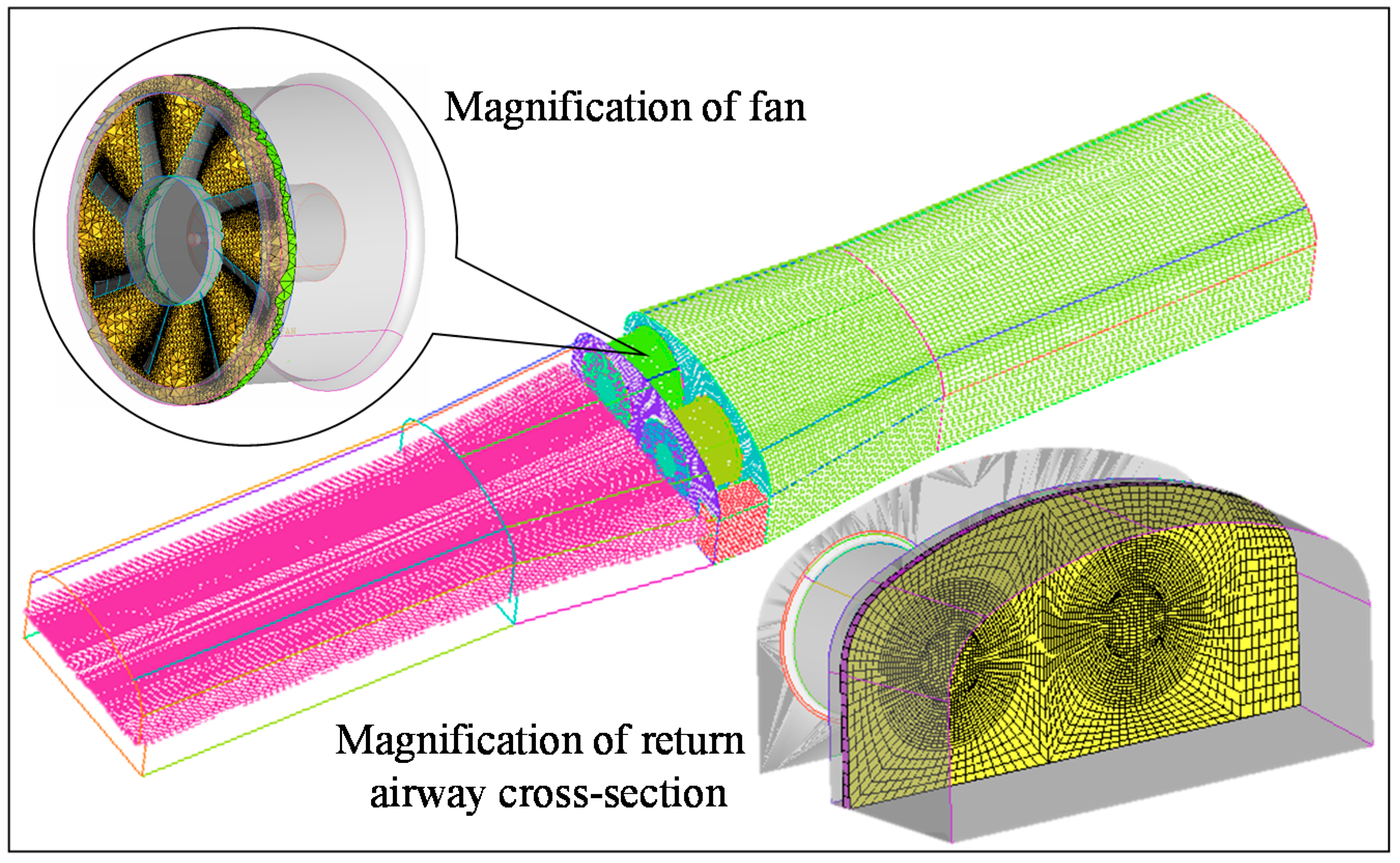

2.5. Mesh Generation

3. Results and Discussion

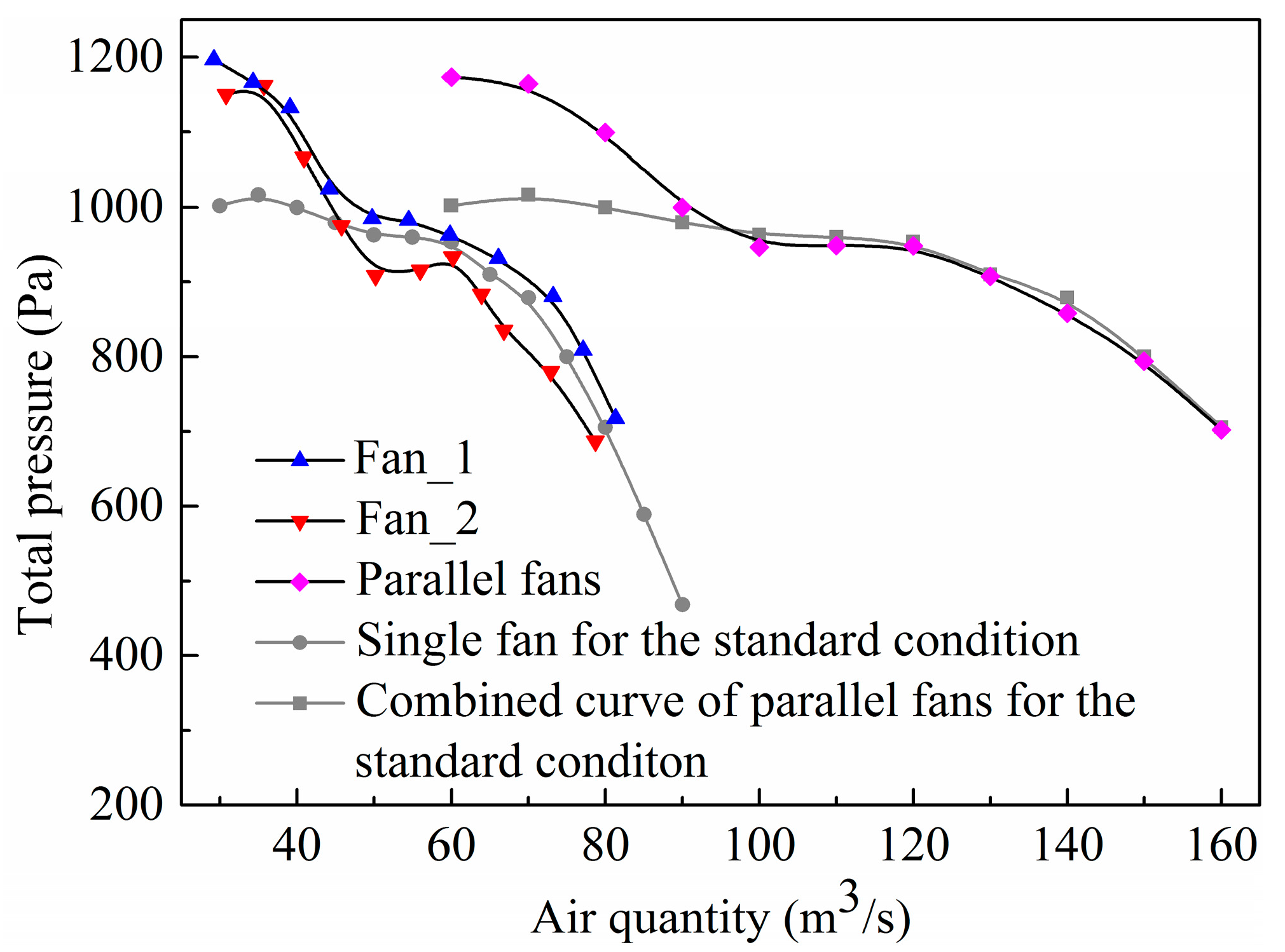

3.1. Validation

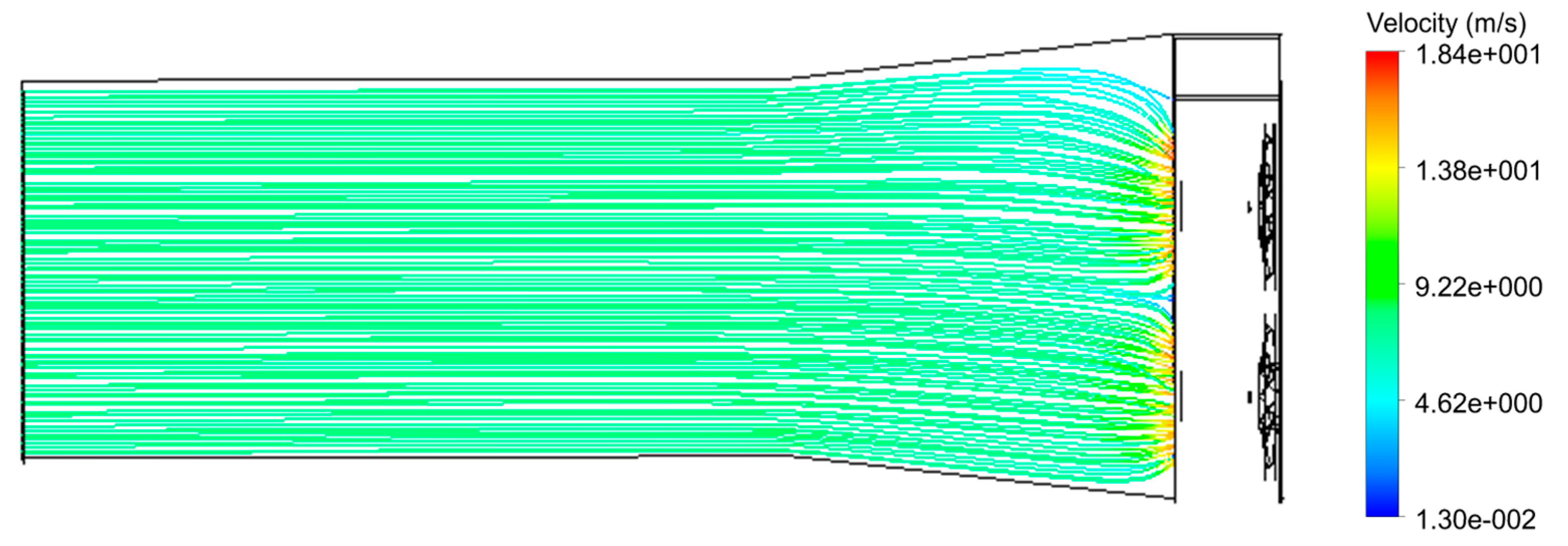

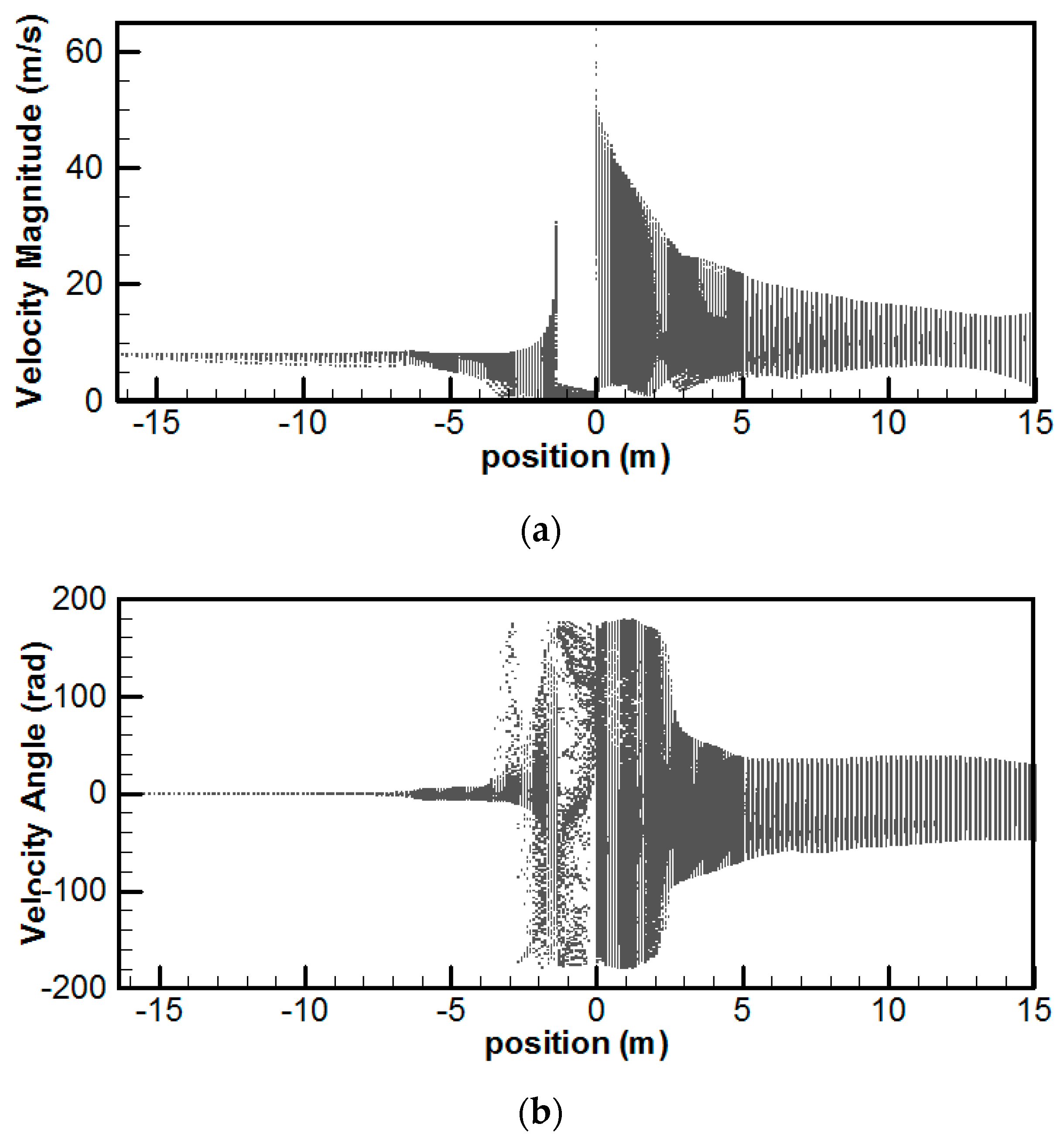

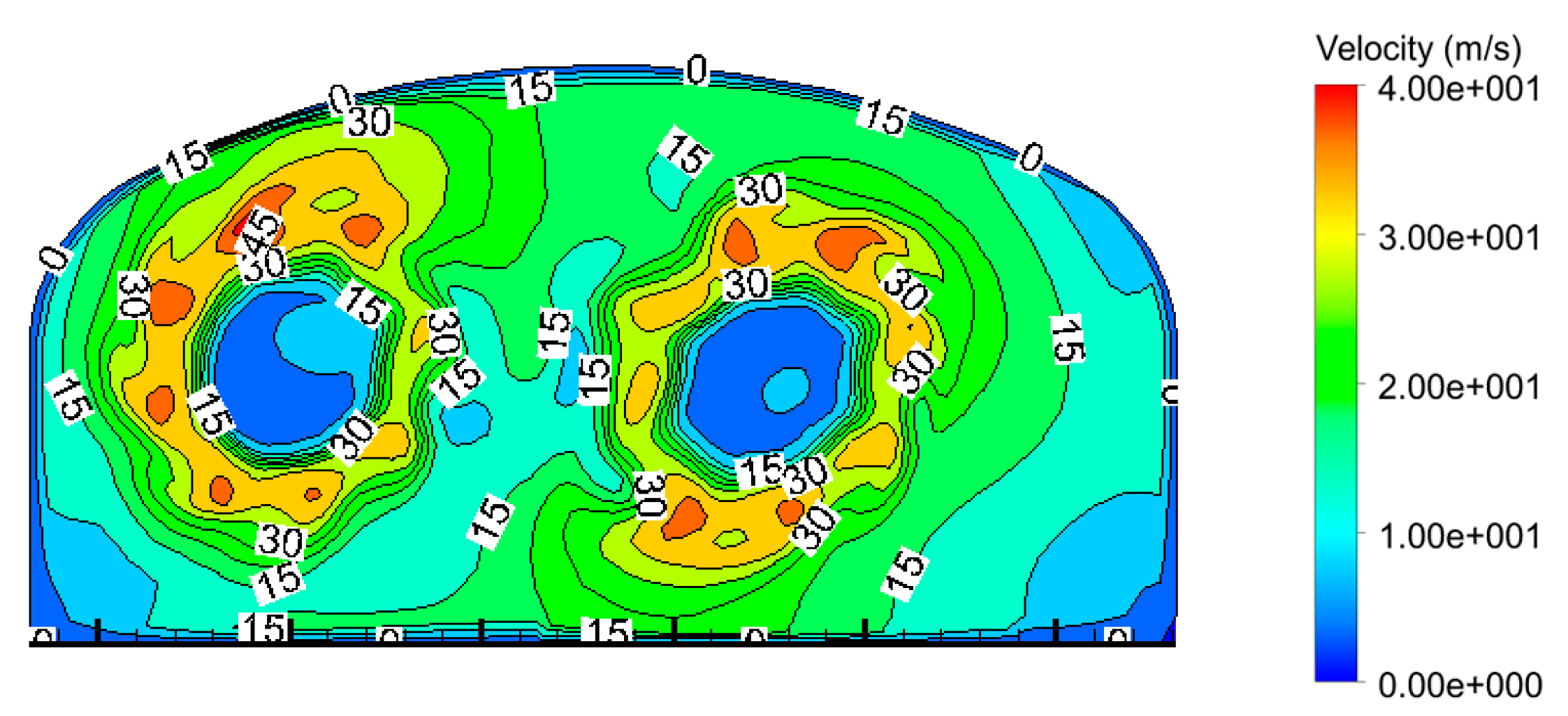

3.2. Airflow Characteristic in PFS

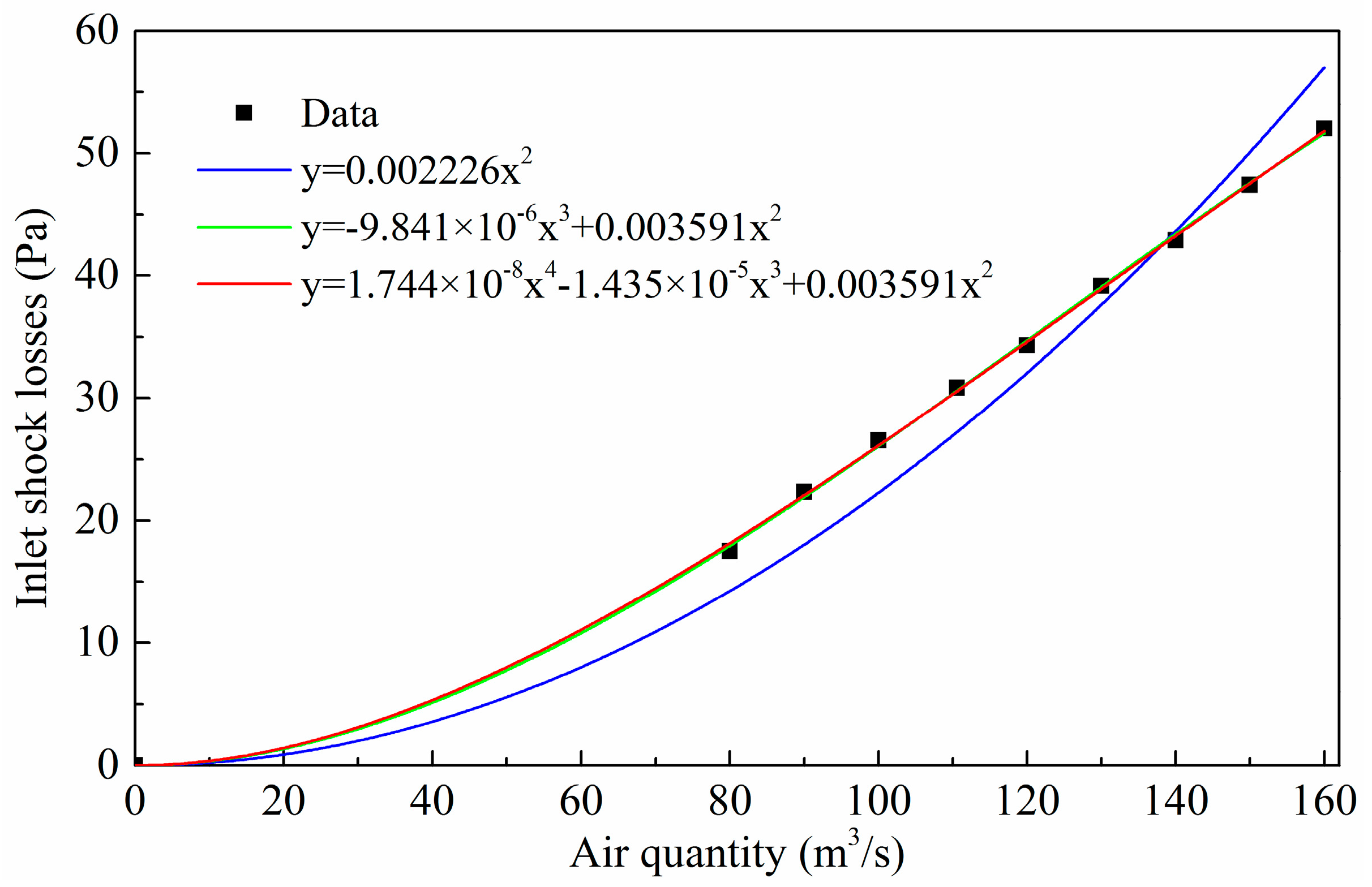

3.3. Inlet Shock Losses in PFS

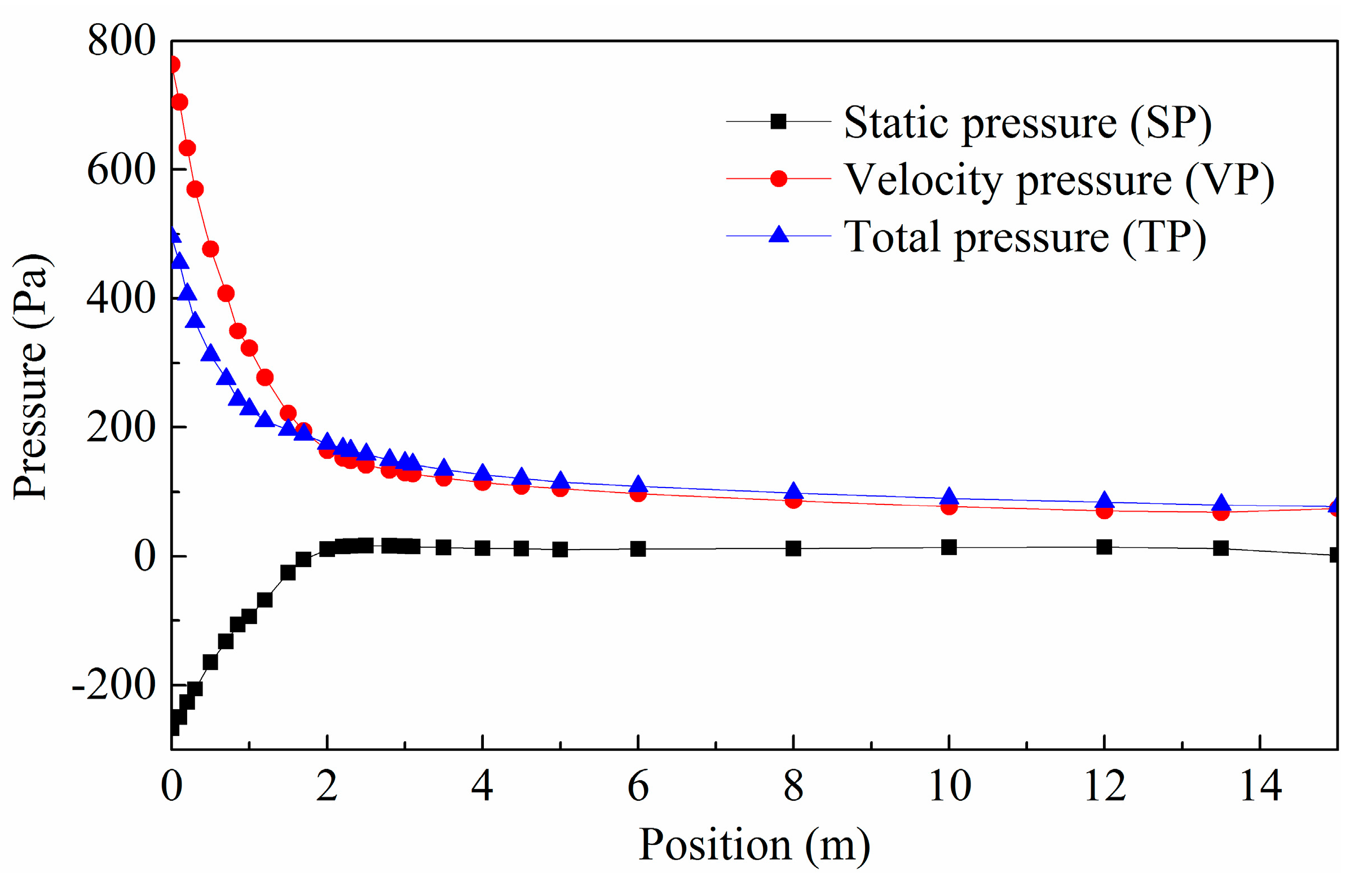

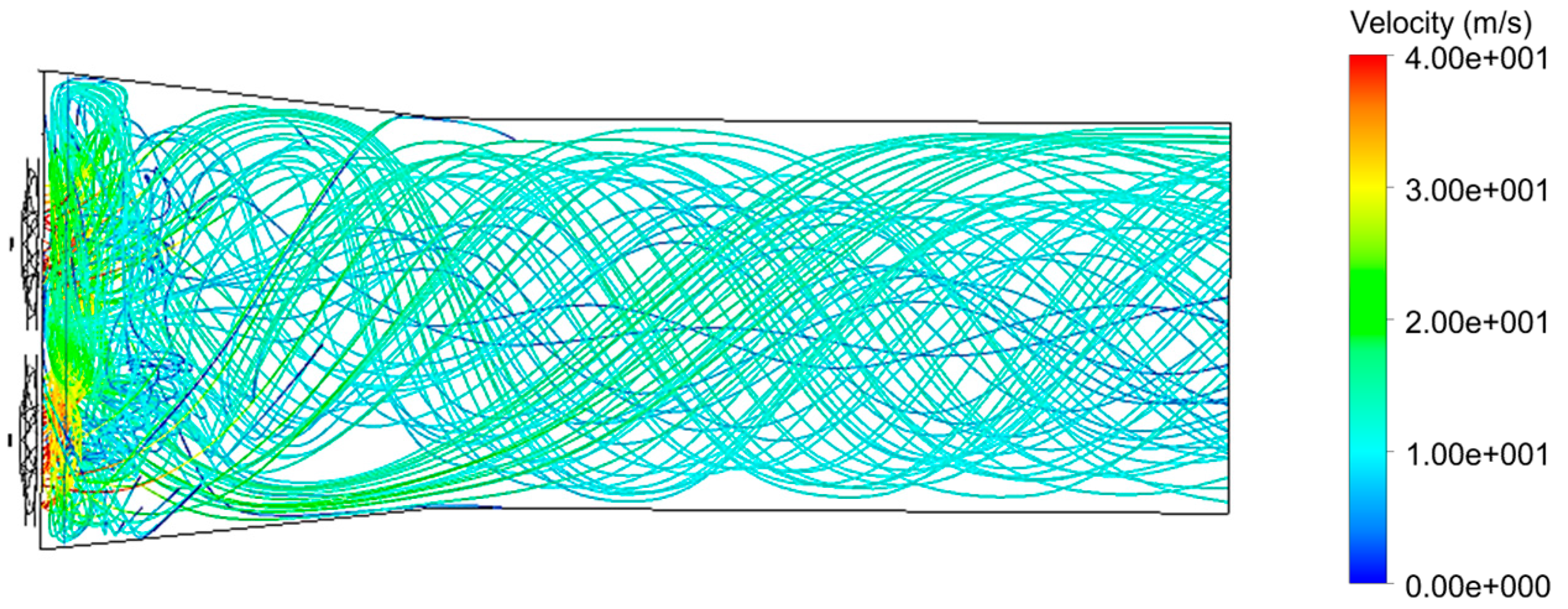

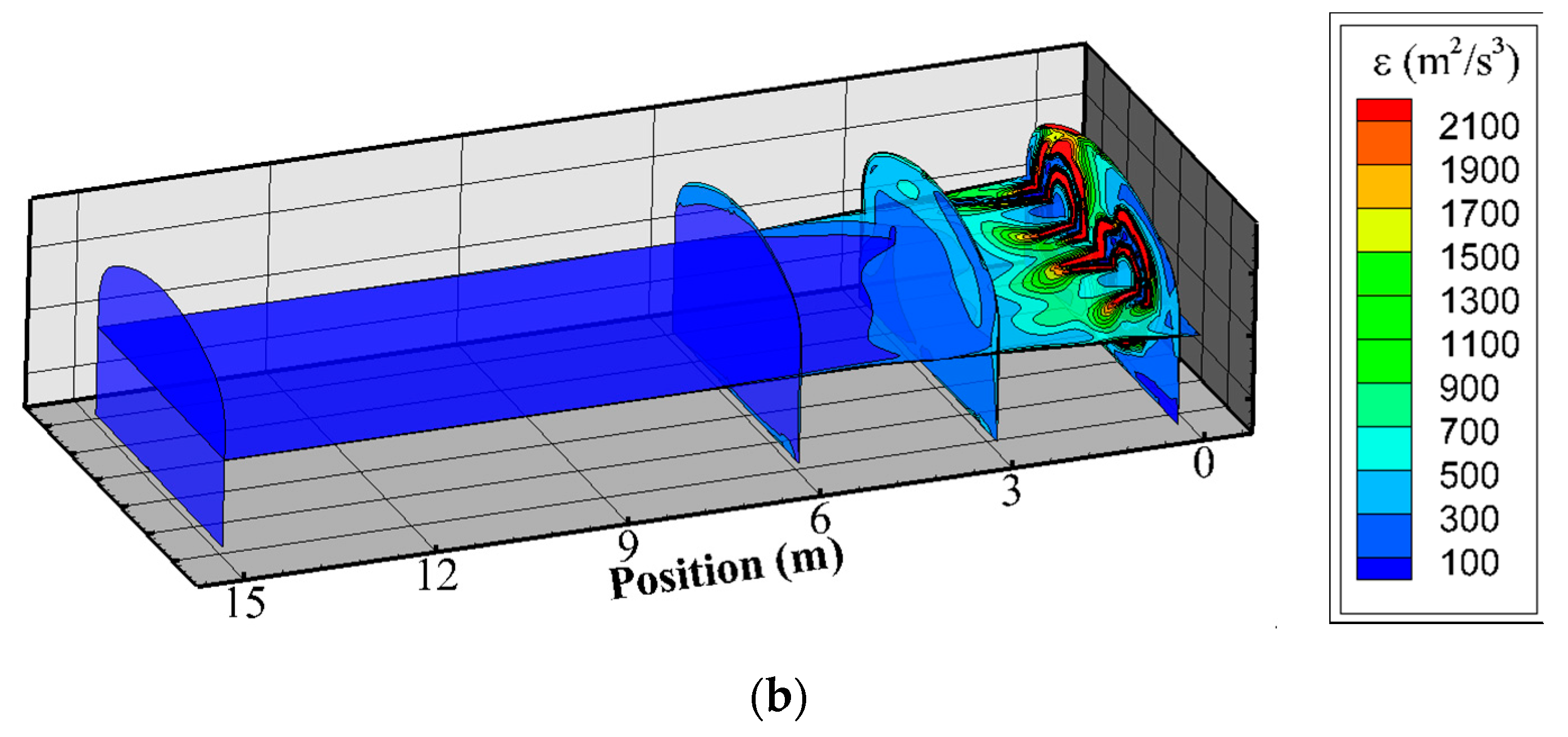

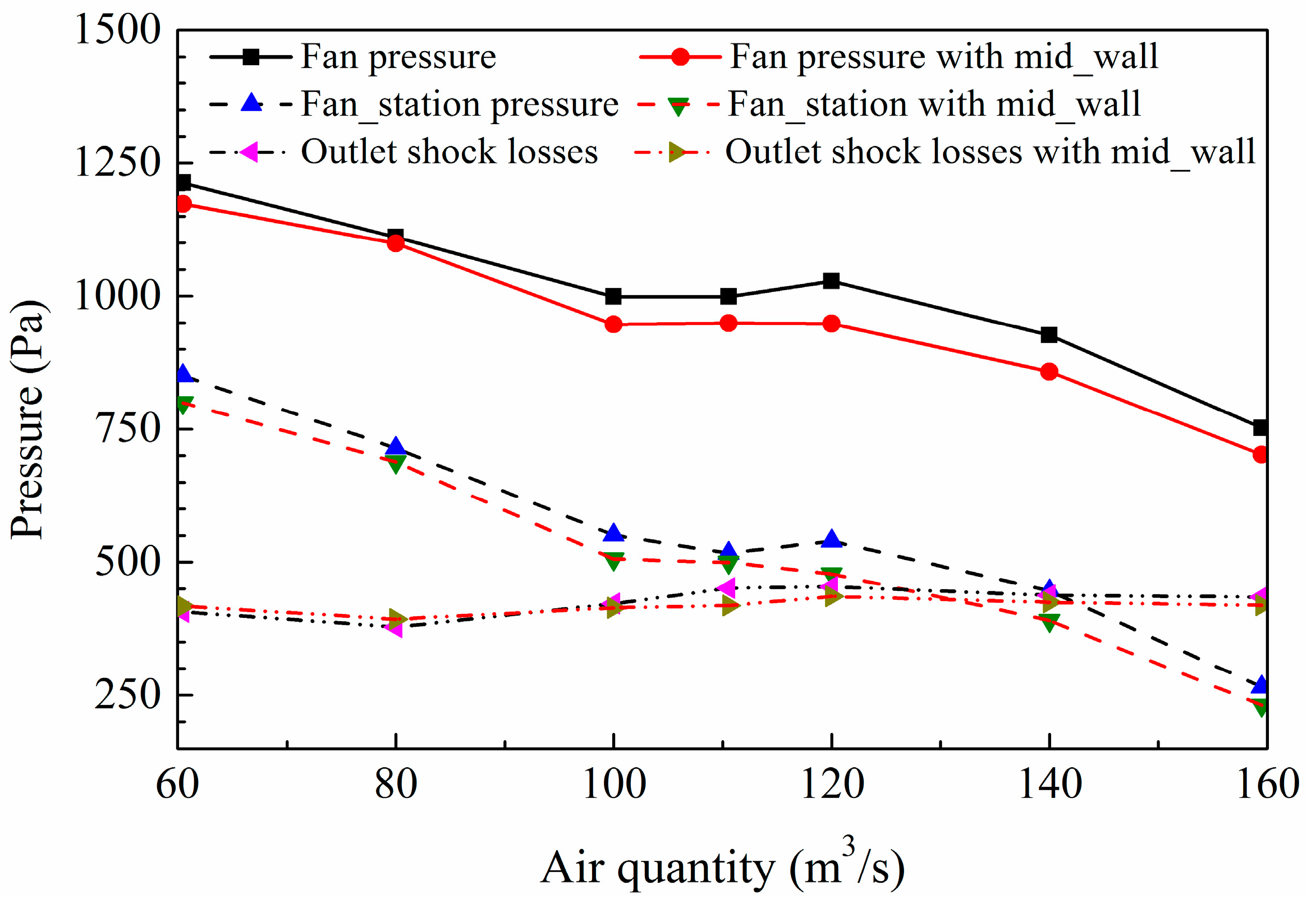

3.4. Outlet Shock Losses in PFS

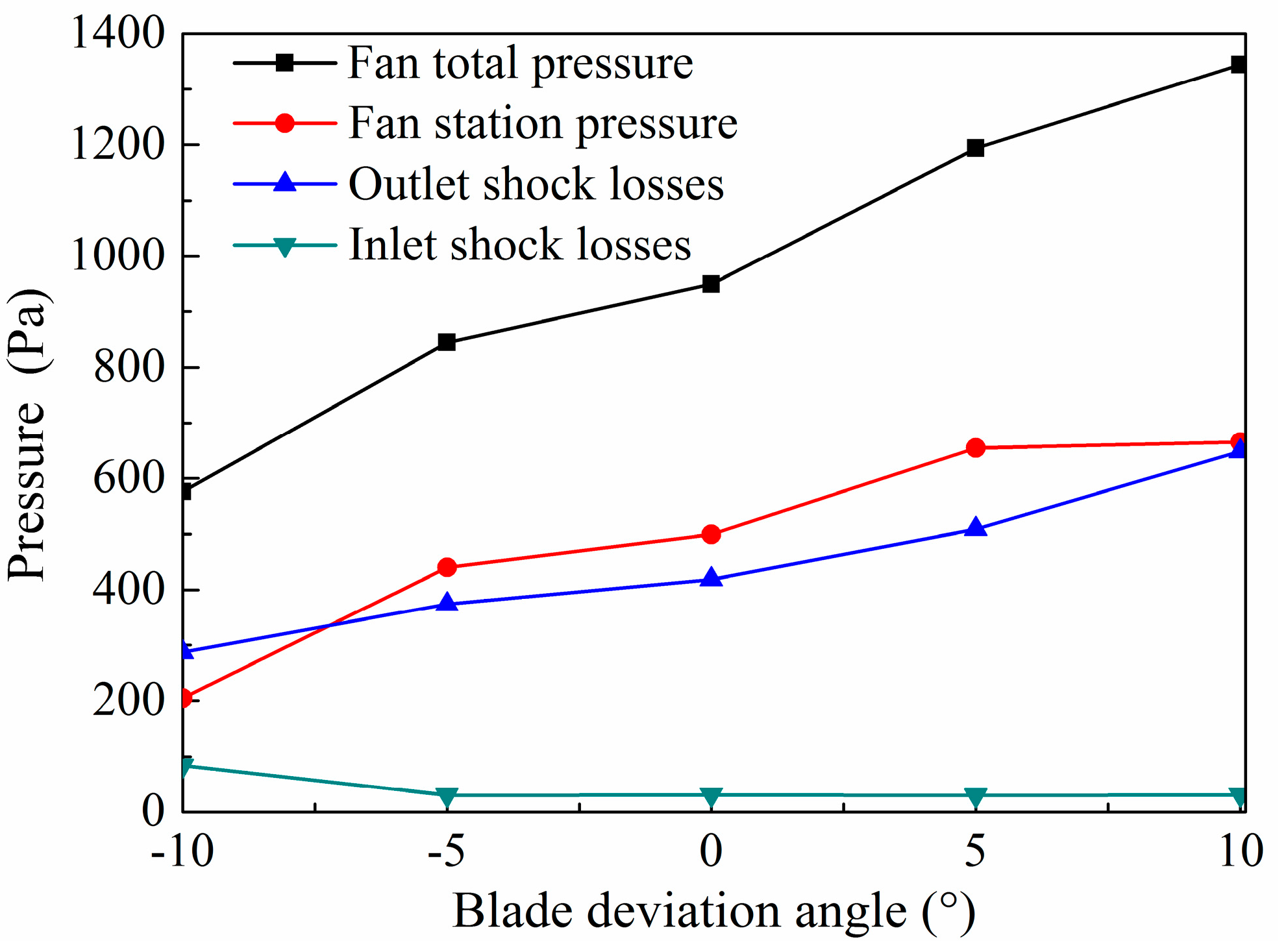

3.5. Effect of Factors

3.5.1. Effect of Blade Installation Angle

3.5.2. Effect of Airflow Mutual Interference

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chatterjee, A.; Zhang, L.; Xia, X. Optimization of mine ventilation fan speeds according to ventilation on demand and time of use tariff. Appl. Energy 2015, 146, 65–73. [Google Scholar] [CrossRef]

- Panigrahi, D.C.; Mishra, D.P. CFD simulations for the selection of an appropriate blade profile for improving energy efficiency in axial flow mine ventilation fans. J. Sustain. Min. 2014, 13, 15–21. [Google Scholar] [CrossRef]

- De Souza, E. Improving the energy efficiency of mine fan assemblages. Appl. Therm. Eng. 2015, 90, 1092–1097. [Google Scholar] [CrossRef]

- Karacan, C.Ö. Development and application of reservoir models and artificial neural networks for optimizing ventilation air requirements in development mining of coal seams. Int. J. Coal Geol. 2007, 72, 221–239. [Google Scholar] [CrossRef]

- Abdelaziz, E.A.; Saidur, R.; Mekhilef, S. A review on energy saving strategies in industrial sector. Renew. Sustain. Energy Rev. 2011, 15, 150–168. [Google Scholar] [CrossRef]

- Ghoreishi-Madiseh, S.A.; Sasmito, A.P.; Hassani, F.P.; Amiri, L. Performance evaluation of large scale rock-pit seasonal thermal energy storage for application in underground mine ventilation. Appl. Energy 2017, 185, 1940–1947. [Google Scholar] [CrossRef]

- Cheng, J.W.; Zhou, F.B.; Qin, Y.; Li, J.L. System dynamic based simulation experiments for evaluating performances of mine ventilation system—A case study. Disaster Adv. 2013, 6, 358–374. [Google Scholar]

- Wang, T.J.; Xie, X.P.; Li, J.G.; Tan, X.Y.; Yin, X.Y.; Su, M.W.; Luo, W.G.; Cui, C. Optimization of monitoring points’ layout for the multi-fan and multi-station ventilation system. Polit. Relig. 2014, 614, 590–612. [Google Scholar] [CrossRef]

- Liu, J.; Xie, X. Principle of energy saving of multi-fan and multistage fan station ventilation system. Nonferrous Met. 2010, 62, 71–74. [Google Scholar]

- Chen, Y. Research on optimization design method for mine multi-stage fan station ventilation system. Met. Min. 2008, 379, 121–124. [Google Scholar]

- Hu, P.H.; Li, X.J. Analysis of radon reduction and ventilation systems in uranium mines in china. J. Radiol. Prot. 2012, 32, 289–300. [Google Scholar] [CrossRef] [PubMed]

- Don, Z.M. Discussion on the problems on ventilation technology of multistage fan stations. Express Inf. Min. Ind. 2001, 366, 1–4. [Google Scholar]

- Haghighat, A. Analysis of A Ventilation Network in A Multiple Fans Limestone Mine. Master’s Thesis, Massouri University of Science and Technology, Rolla, MO, USA, 2014. [Google Scholar]

- Hurtado, J.P.; Díaz, N.; Acuña, E.I.; Fernández, J. Shock losses characterization of ventilation circuits for block caving production levels. Tunn. Undergr. Space Technol. 2014, 41, 88–94. [Google Scholar] [CrossRef]

- Wu, C. Mine Ventilation and Air Conditioning; Central South University Press: Changsha, China, 2008. [Google Scholar]

- Pan, J. Study on the local ventilation resistance of multistage fan station. Met. Min. 2001, 9, 49–51. [Google Scholar]

- Cheng, L.S.; Li, G.Q.; Shen, Y.W. Study on the resistance of multi fan station in underground. Ind. Saf. Environ. Protect. 1987, 2, 13–18. [Google Scholar]

- Li, Y.L.; Cheng, L.S.; Li, G.Q. Study on reducing the local resistance and the reasonable structure of the machine station. In Proceedings of the National Symposium on Mine Ventilation and Safety, Ma’anshan, China, 15 July 1987. [Google Scholar]

- Liang, Y.; Li, J.; Tian, H. Study on flow fields and losses of the stationary components in an axial flow fan. J. Xian Jiaotong Univ. 2008, 3, 269–272. [Google Scholar]

- Basara, B.; Alajbegovic, A.; Beader, D. Simulation of single- and two-phase flows on sliding unstructured meshes using finite volume method. Int. J. Numer. Methods Fluids 2004, 45, 1137–1159. [Google Scholar] [CrossRef]

- Diego, I.; Torno, S.; Toraño, J.; Menéndez, M.; Gent, M. A practical use of CFD for ventilation of underground works. Tunn. Undergr. Space Technol. 2011, 26, 189–200. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. Simulation of a novel intermittent ventilation system for underground mines. Tunn. Undergr. Space Technol. 2014, 42, 206–215. [Google Scholar] [CrossRef]

- Sasmito, A.P.; Birgersson, E.; Ly, H.C.; Mujumdar, A.S. Some approaches to improve ventilation system in underground coal mines environment—A computational fluid dynamic study. Tunn. Undergr. Space Technol. 2013, 34, 82–95. [Google Scholar] [CrossRef]

- Heerden, J.; Sullivan, P. The application of CFD for evaluation of dust suppression and auxiliary ventilating systems used with continuous miners. In Proceedings of the 6th US Mine Ventialtion Symposium, Littleton, CO, USA; 1993; pp. 293–297. [Google Scholar]

- Hurtado, J.P.; Acuña, E.I. CFD analysis of 58 adit main fans parallel installation for the 2015–2019 underground developments of the new level mine project. Appl. Therm. Eng. 2015, 90, 1109–1118. [Google Scholar] [CrossRef]

- Xu, G.; Jong, E.C.; Luxbacher, K.D.; Ragab, S.A.; Karmis, M.E. Remote characterization of ventilation systems using tracer gas and CFD in an underground mine. Saf. Sci. 2015, 74, 140–149. [Google Scholar] [CrossRef]

- Li, C.; Lin, Q.; Ding, X.; Ye, X. Performance, aeroacoustics and feature extraction of an axial flow fan with abnormal blade angle. Energy 2016, 103, 322–339. [Google Scholar] [CrossRef]

- Gou, Y.G. Efficiency Improvement and Consumption Reduction Studies of Complex Multi-Stage Fan Station Ventilation System in Deep Mine. Master’s Thesis, Central South University, Changsha, China, 2016. [Google Scholar]

- Ye, X.; Li, P.; Li, C.; Ding, X. Numerical investigation of blade tip grooving effect on performance and dynamics of an axial flow fan. Energy 2015, 82, 556–569. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Li, P.; Ye, X. Numerical investigation of impeller trimming effect on performance of an axial flow fan. Energy 2014, 75, 534–548. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Chen, Q.; Yang, C. Feasibility of recycling ultrafine leaching residue by backfill: Experimental and CFD approaches. Minerals 2017, 7, 54. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Hassani, F.P.; Mujumdar, A.S. Introduction and evaluation of a novel hybrid brattice for improved dust control in underground mining faces: A computational study. Int. J. Min. Sci. Technol. 2015, 25, 537–543. [Google Scholar] [CrossRef]

- ANSYS. Ansys Fluent 15.0 Users Guide Manual; ANSYS Inc.: Canonsburg, PA, USA, 2014. [Google Scholar]

- ANSYS. Ansys Icem CFD 14.5 Tutorial Manual; ANSYS Inc.: Canonsburg, PA, USA, 2014. [Google Scholar]

- SIWEI. Axial Flow Fan Comprehensive Parameters Instruction Manual; Nanchang SIWEI Ventilation Mashion Factory: Nanchang, China, 2013. [Google Scholar]

- GB/T1236-2000. Industrial Fans Performance Testing Using Standardized Airways; State Bureau of Quality and Technical Supervision: Shanghai, China, 2000. [Google Scholar]

- Wang, C.; Ye, J.H. Fan performance test system design and research. In Proceedings of the International Conference on Electric Information & Control Engineering, Lushan, China, 6–8 April 2012; pp. 714–716. [Google Scholar]

- Sasmito, A.P.; Kurnia, J.C.; Birgersson, E.; Mujumdar, A.S. Computational evaluation of thermal management strategies in an underground mine. Appl. Therm. Eng. 2015, 90, 1144–1150. [Google Scholar] [CrossRef]

- McPherson, M.J. Subsurface Ventilation and Environmental Engineering; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

| Station Site | Fan Name | Fan Model | Rated Power (kW) | Measured Air Quantity (m3/s) | TP (Pa) | Measured Input Power (kW) | Measured Efficiency (%) | Measured Pressure Loss Rate (%) | |

|---|---|---|---|---|---|---|---|---|---|

| Rated | Measured | ||||||||

| 450 m station | 450A | K40(C)-22 | 110 | 80.67 | 900 | 610 | 79.4 | 34.8 | 32.22 |

| 450B | 671 | 77.5 | 39.2 | 25.44 | |||||

| 250 m station | 250A | K40(B)-19 | 110 | 103.5 | 929 | 520 | 72.4 | 41.8 | 44.02 |

| 250B | 525 | 83.3 | 36.3 | 43.48 | |||||

| 50 m station | 50A | K40(B)-19 | 110 | 110.56 | 963 | 619 | 107.8 | 35.7 | 35.7 |

| 50B | 620 | 101.0 | 38.1 | 35.6 | |||||

| Air Quantity (m3/s) | Total Fan Pressure (Pa) | Fan Station Pressure (Pa) | Shock Losses (Pa) | Outlet Pressure Loss Rate (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Difference | Inlet | Outlet | Difference | Inlet | Outlet | ||||

| 60.00 | −703.22 | 470.11 | 1173.33 | 746.80 | 52.90 | 799.70 | −43.58 | 417.21 | 35.56 | ||

| 70.00 | −702.35 | 461.99 | 1164.34 | 706.58 | 65.96 | 772.54 | −4.23 | 396.03 | 34.01 | ||

| 80.00 | −631.05 | 468.18 | 1099.23 | 613.54 | 74.99 | 688.53 | 17.51 | 393.19 | 35.77 | ||

| 90.00 | −528.73 | 471.11 | 999.84 | 506.41 | 86.08 | 592.49 | 22.32 | 385.03 | 38.51 | ||

| 100.00 | −467.27 | 479.49 | 946.76 | 440.76 | 65.56 | 506.32 | 26.51 | 413.93 | 43.72 | ||

| 110.56 | −453.39 | 495.53 | 948.92 | 422.55 | 76.93 | 499.48 | 30.84 | 418.60 | 44.11 | ||

| 120.00 | −427.92 | 520.26 | 948.18 | 393.61 | 84.57 | 478.18 | 34.31 | 435.69 | 45.95 | ||

| 130.00 | −396.51 | 511.05 | 907.55 | 357.36 | 87.88 | 445.24 | 39.15 | 423.17 | 46.63 | ||

| 140.00 | −348.96 | 509.00 | 857.96 | 306.08 | 84.44 | 390.52 | 42.88 | 424.56 | 49.48 | ||

| 150.00 | −278.64 | 515.64 | 794.28 | 231.22 | 97.35 | 328.57 | 47.42 | 418.29 | 52.66 | ||

| 160.00 | −158.45 | 543.66 | 702.10 | 106.44 | 124.61 | 231.05 | 52.01 | 419.05 | 59.68 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gou, Y.; Shi, X.; Zhou, J.; Qiu, X.; Chen, X. Characterization and Effects of the Shock Losses in a Parallel Fan Station in the Underground Mine. Energies 2017, 10, 785. https://doi.org/10.3390/en10060785

Gou Y, Shi X, Zhou J, Qiu X, Chen X. Characterization and Effects of the Shock Losses in a Parallel Fan Station in the Underground Mine. Energies. 2017; 10(6):785. https://doi.org/10.3390/en10060785

Chicago/Turabian StyleGou, Yonggang, Xiuzhi Shi, Jian Zhou, Xianyang Qiu, and Xin Chen. 2017. "Characterization and Effects of the Shock Losses in a Parallel Fan Station in the Underground Mine" Energies 10, no. 6: 785. https://doi.org/10.3390/en10060785