Electric Propulsion Concepts for an Inverted Joined Wing Airplane Demonstrator

Abstract

:1. Introduction

2. Inverted Joined Wing Concept

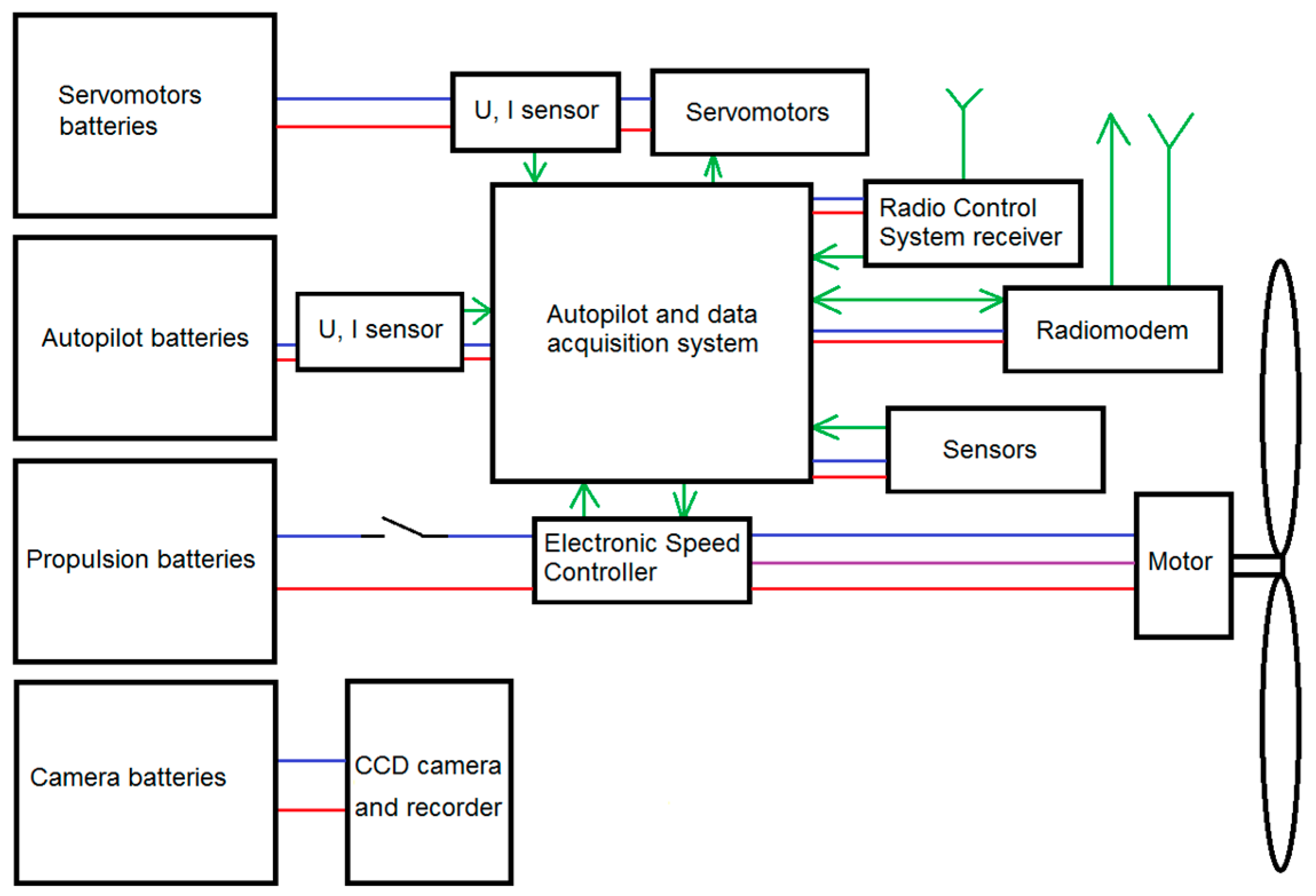

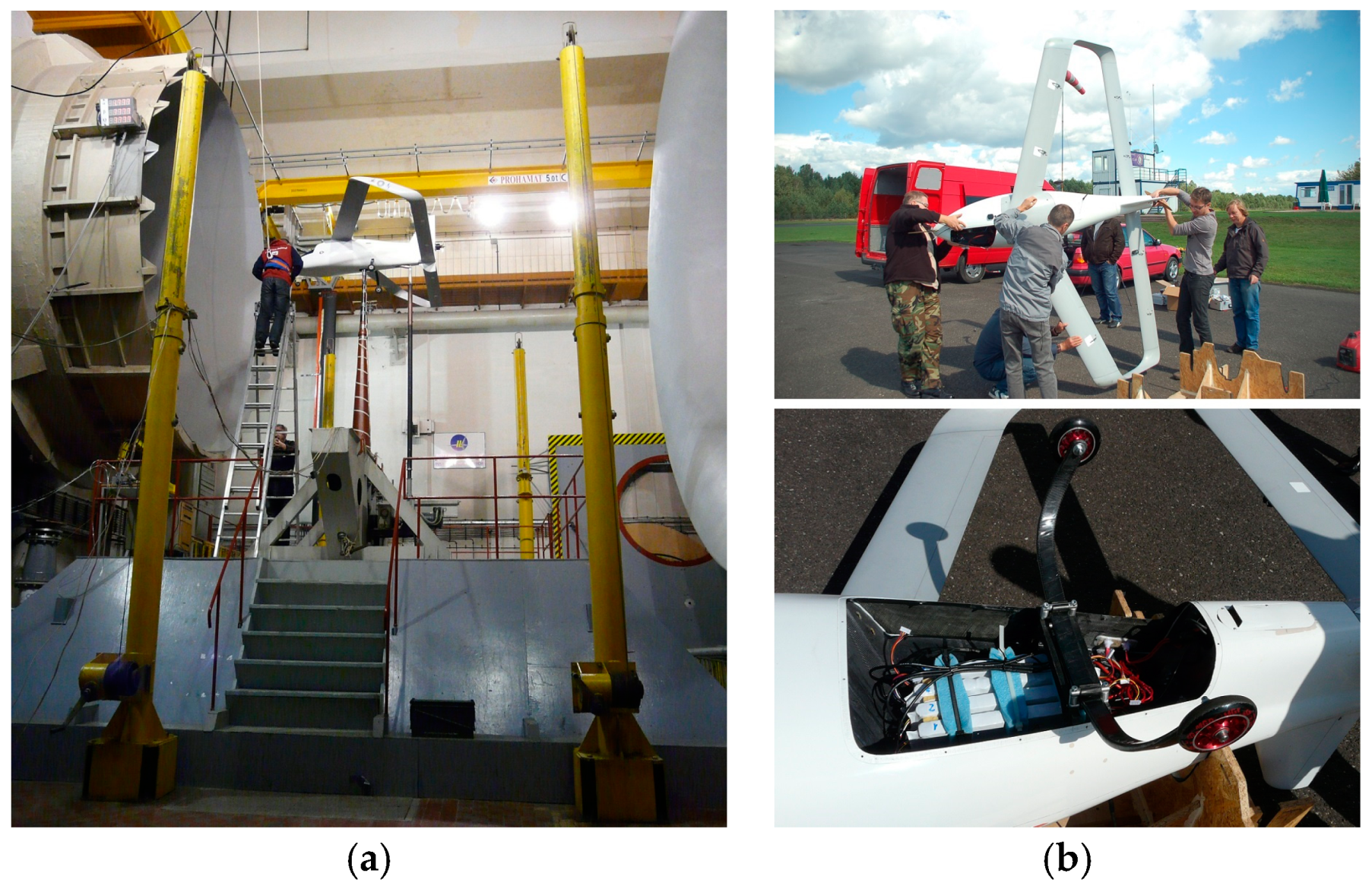

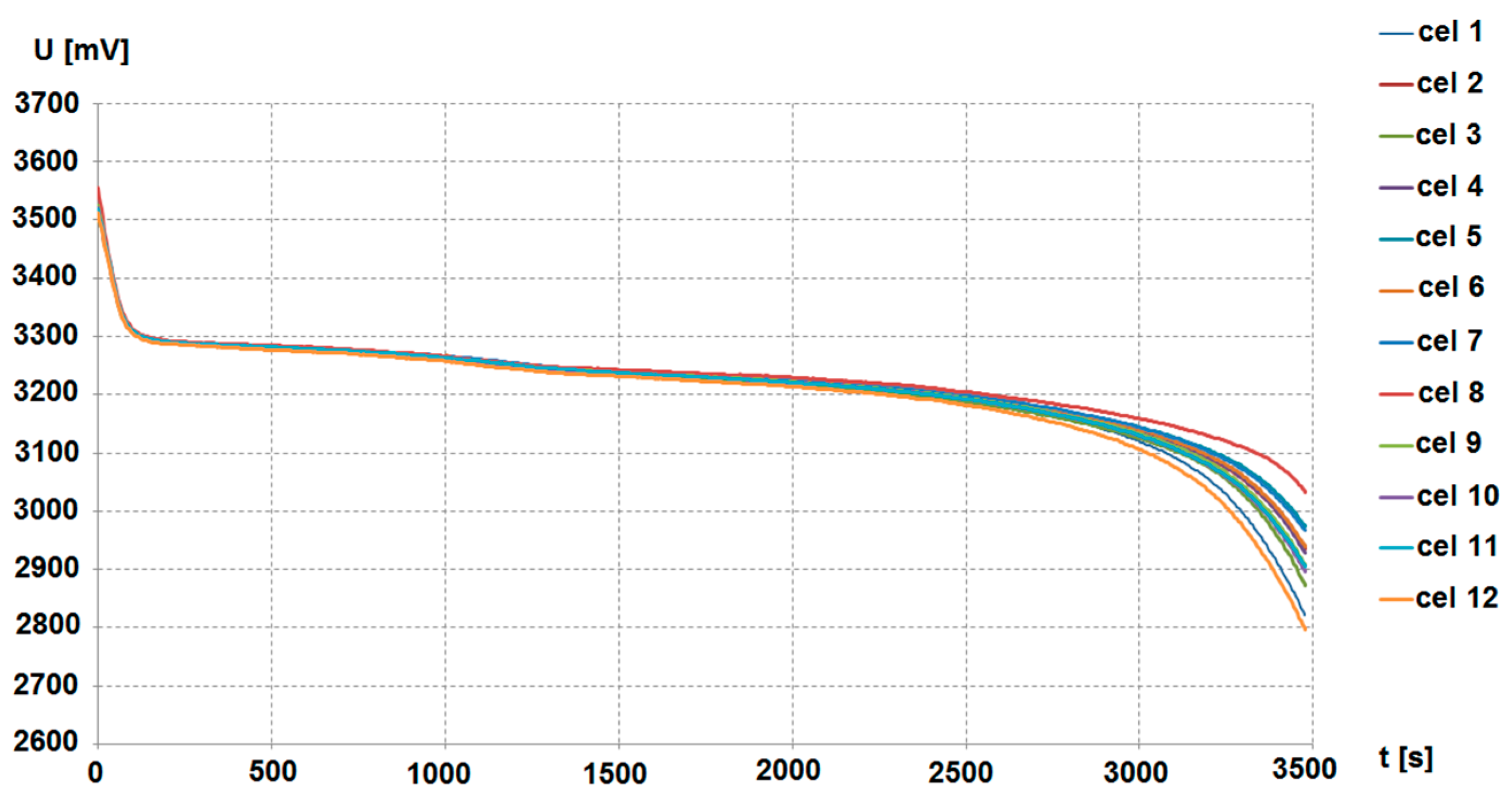

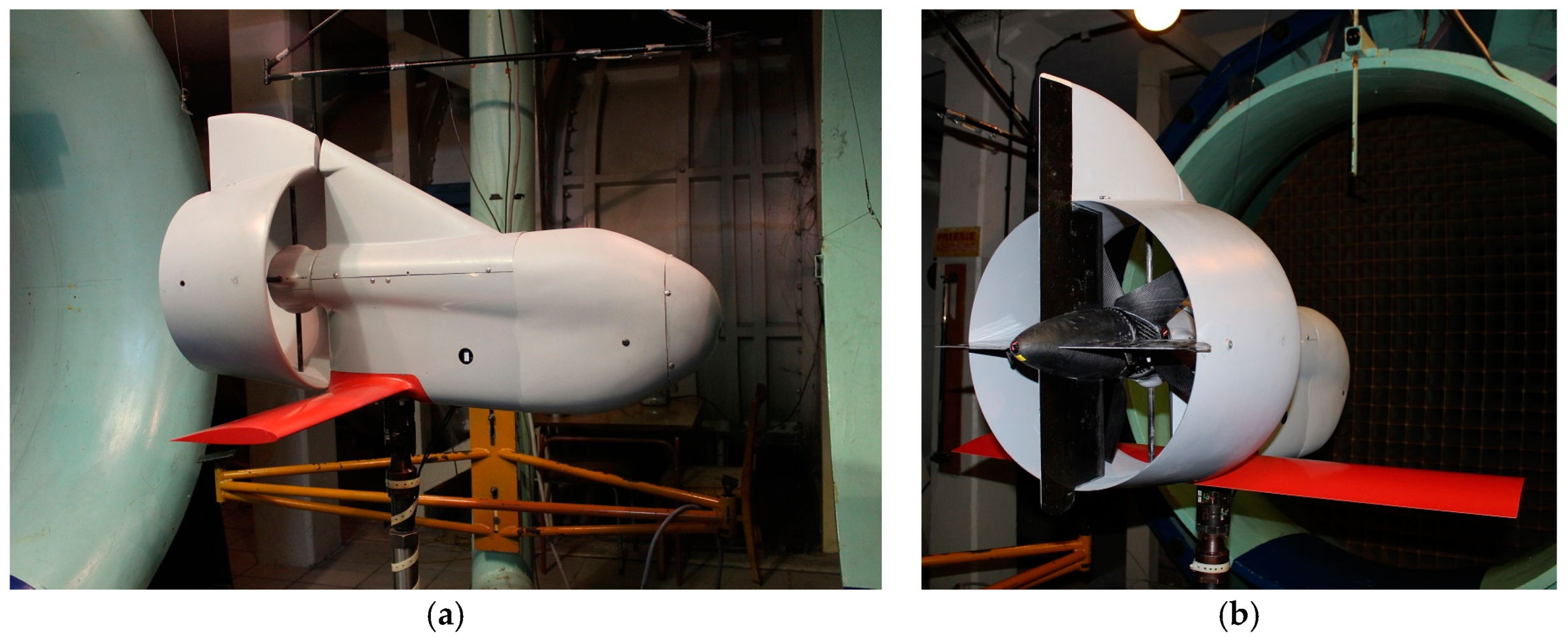

3. Electrical System Architecture in the Current Demonstrator

4. Project Implementation and Results

5. Performance Improvement Analysis

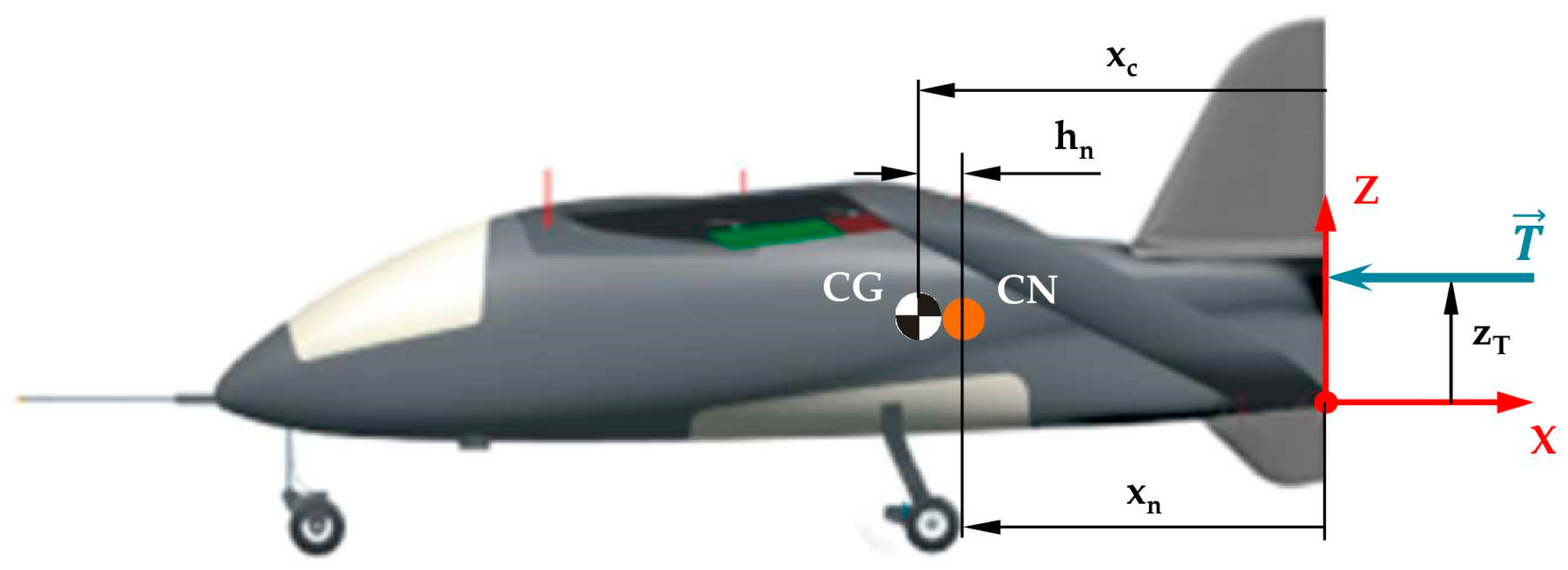

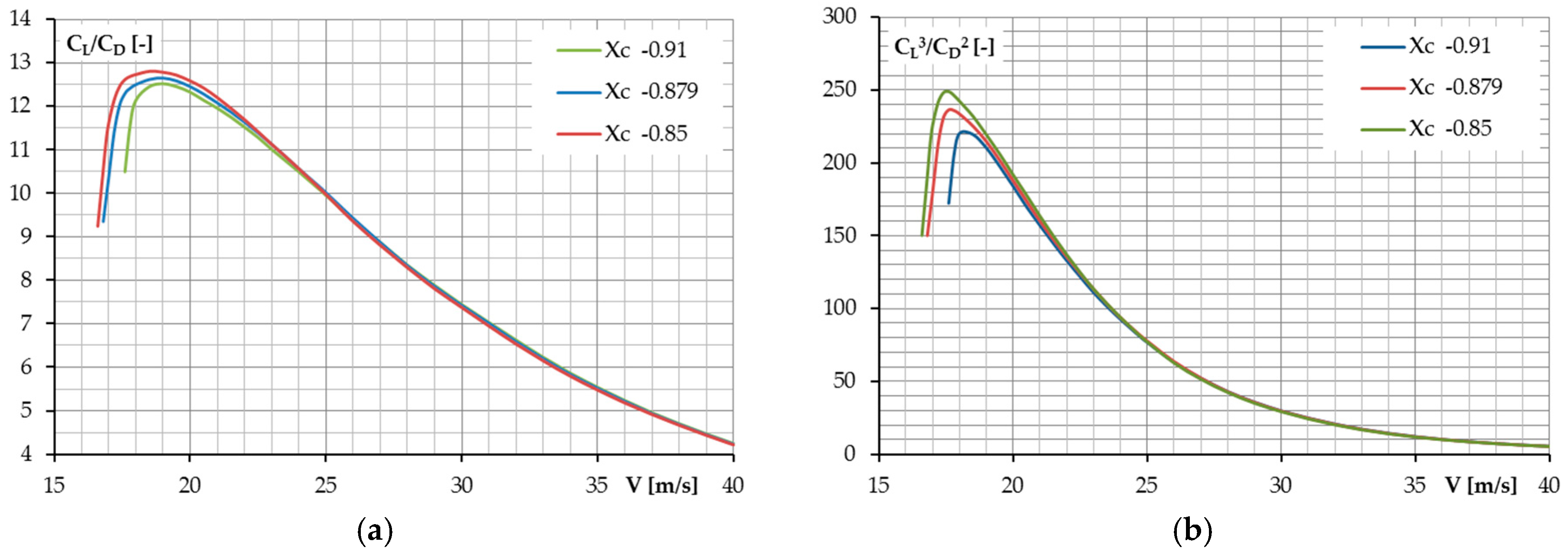

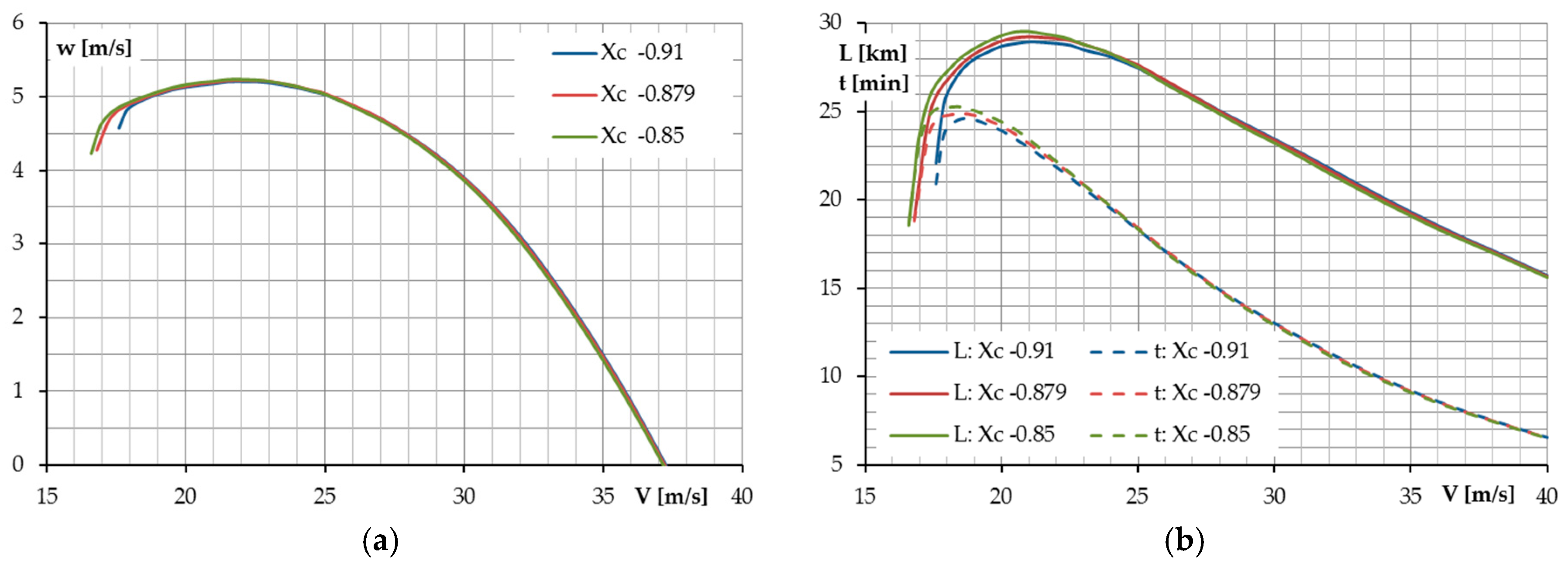

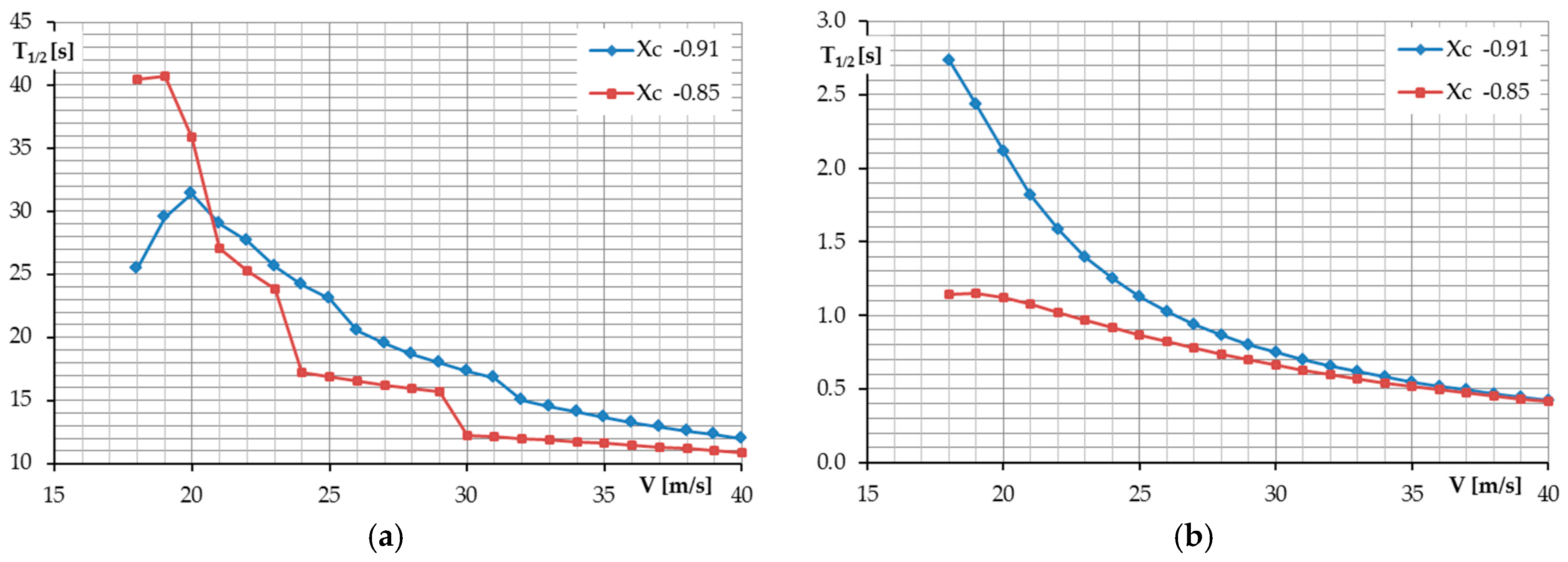

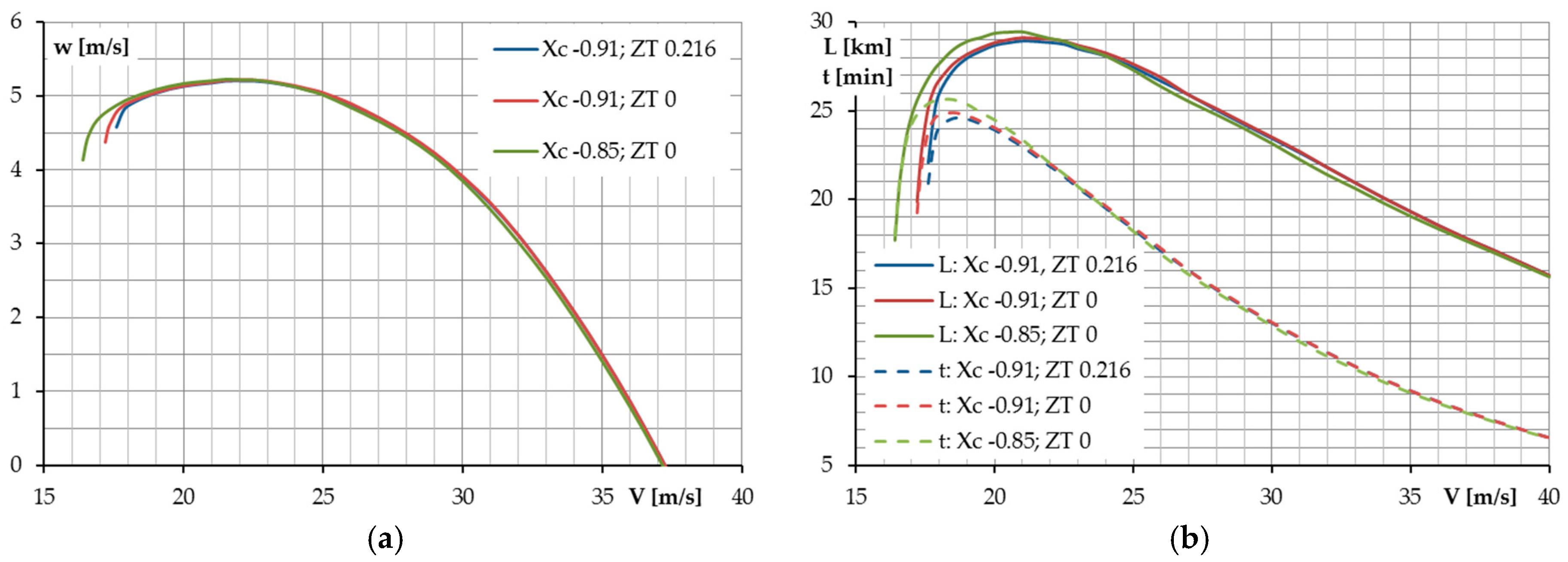

5.1. Center of Gravity Position Impact on the Airplane Performance

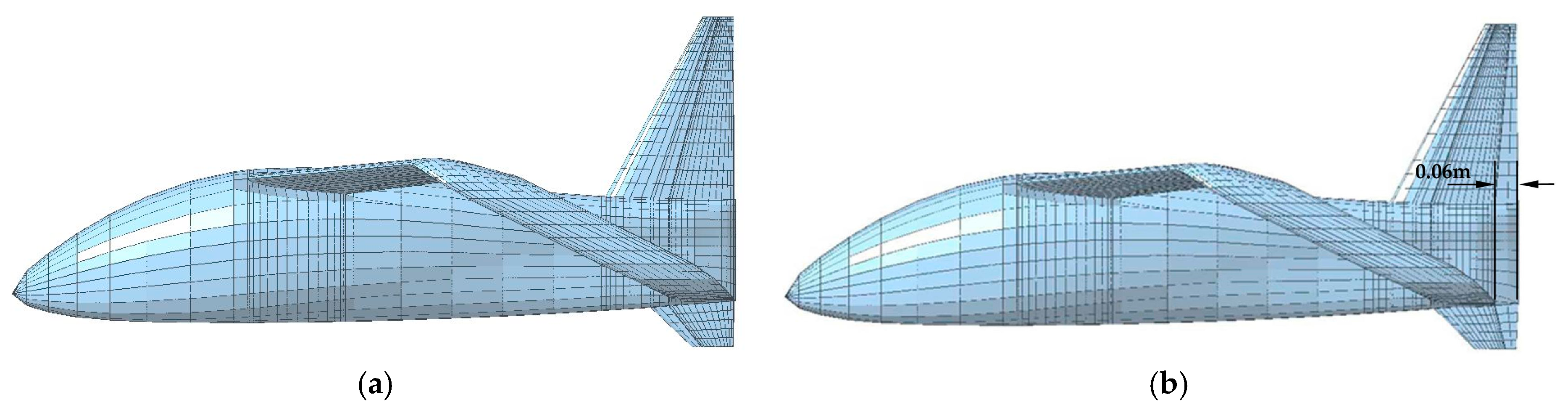

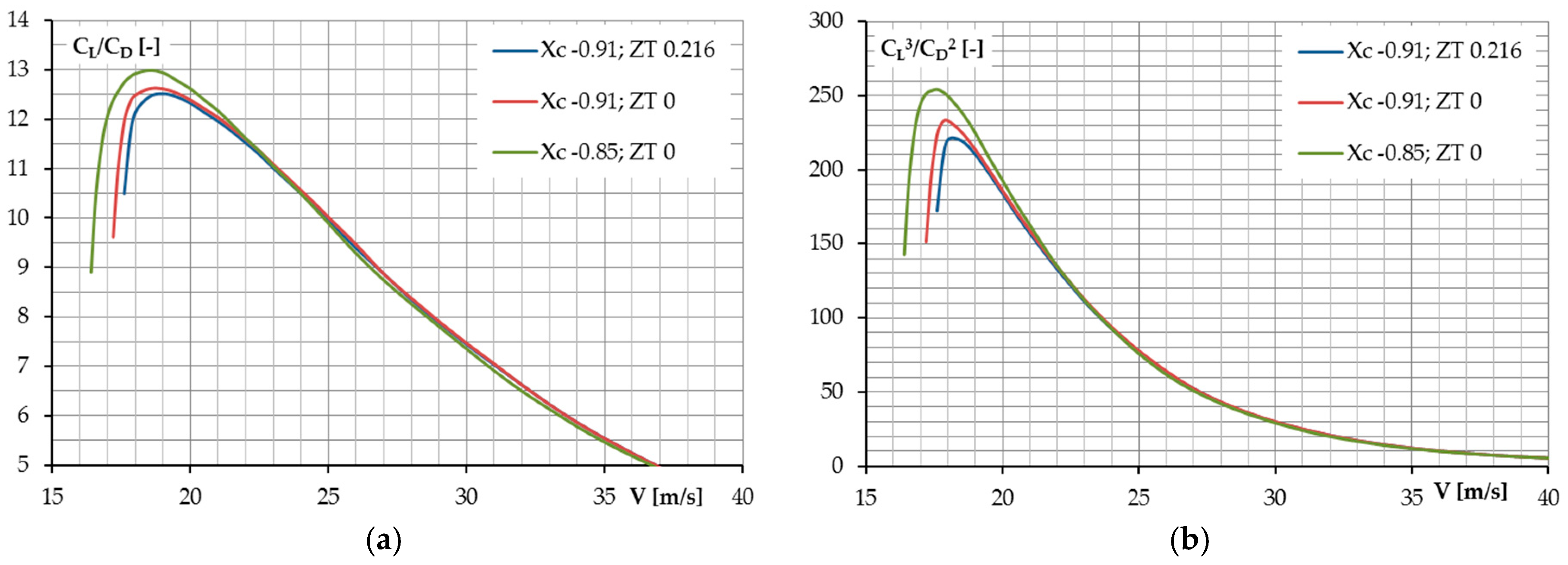

5.2. Thrust Vector Position Impact on the Airplane Performance

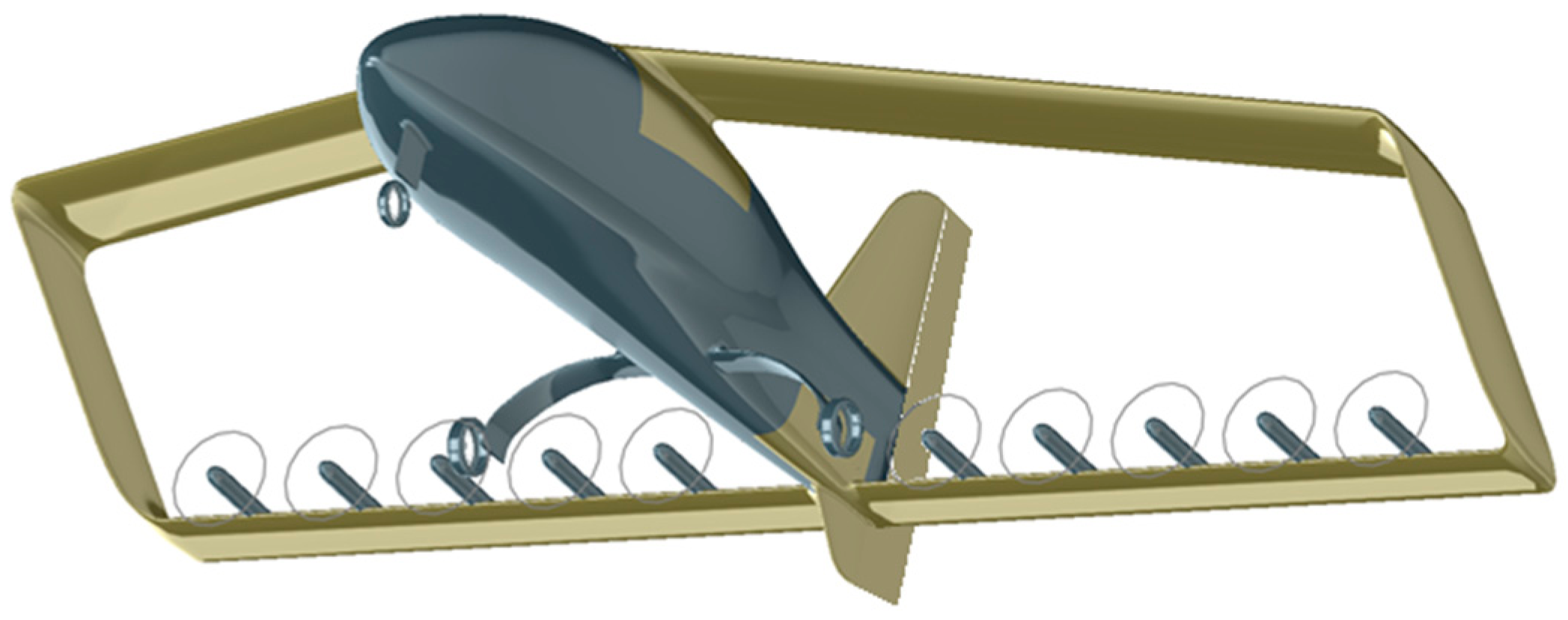

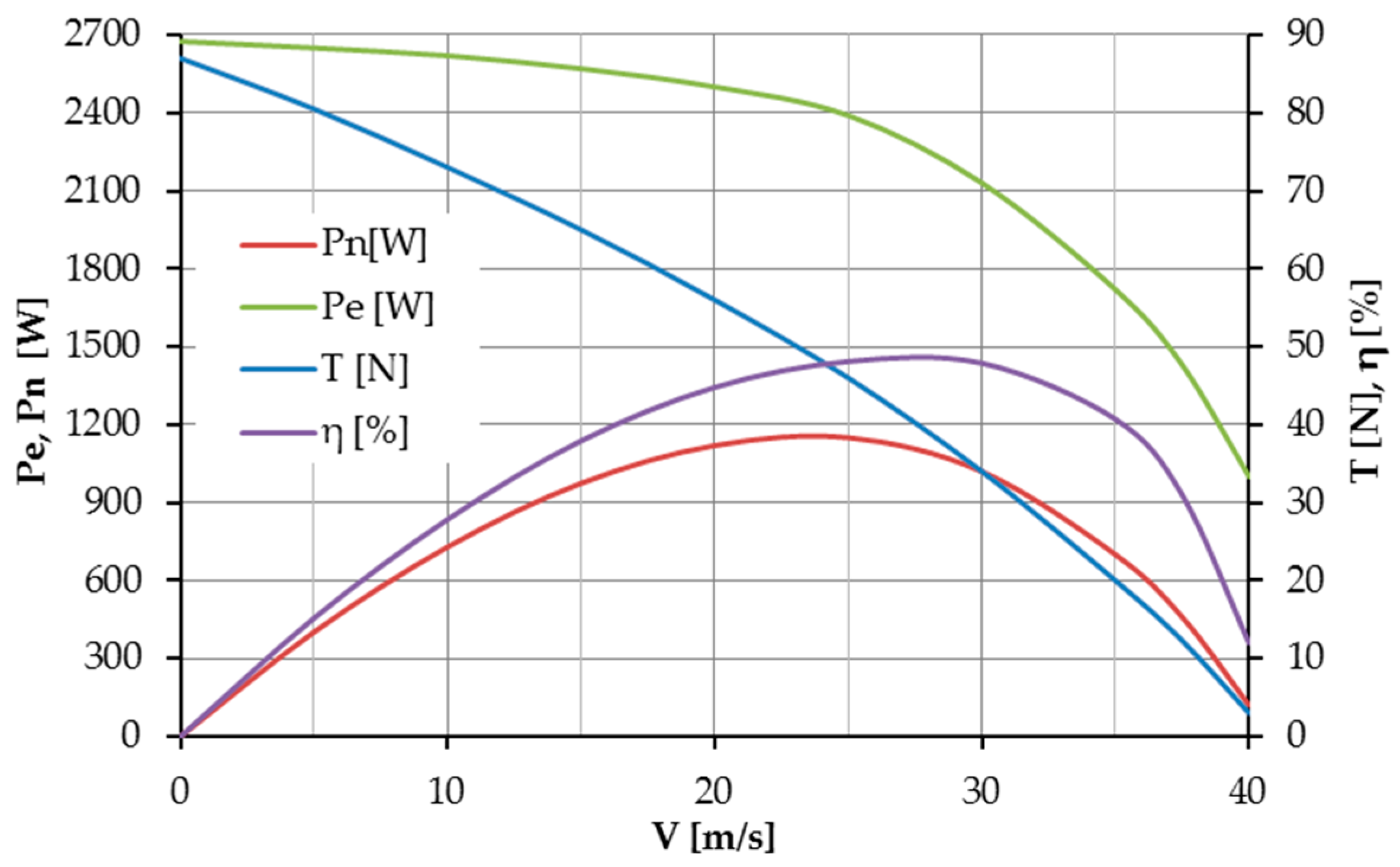

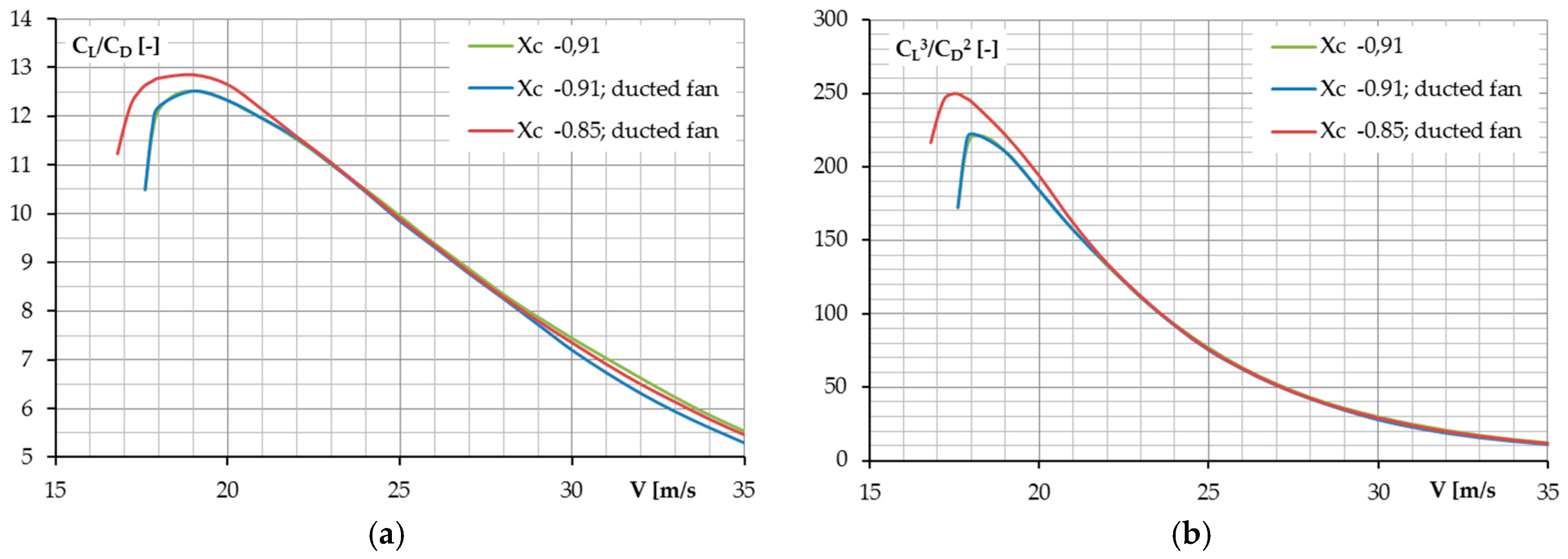

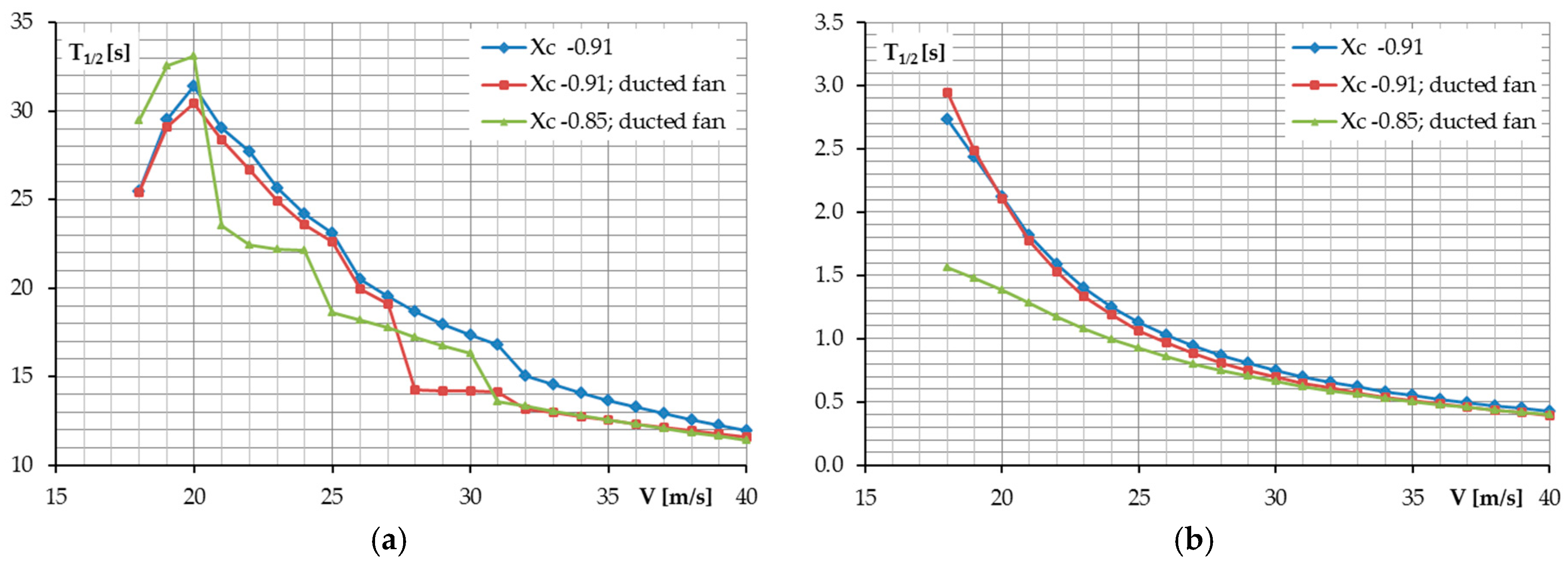

5.3. The Airplane Performance with the Ducted Fan Propulsion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Munk, M. The Minimum Induced Drag of Aerofoils; NACA-TR-121; National Aeronautics and Space Administration (NASA): Washington, DC, USA, 1923.

- Prandtl, L. Induced Drag of Multiplanes; NACA-TN-182; National Aeronautics and Space Administration (NASA): Washington, DC, USA, 1924.

- Lange, R.H.; Cahill, J.F.; Bradley, E.S.; Eudaily, R.R.; Jenness, C.M.; MacWilkinson, D.G. Feasibility Study of the Transonic Biplane Concept for Transport Aircraft Application; NASA-CR-132462; Lockheed-Georgia Company: Marietta, GA, USA, 1974. [Google Scholar]

- Wolkovitch, J. The joined wing—An overview. J. Aircr. 1986, 23, 161–178. [Google Scholar] [CrossRef]

- Frediani, A.; Cipolla, V.; Rizzo, E. The PrandtlPlane Configuration: Overview on Possible Applications to Civil Aviation, Variational Analysis and Aerospace Engineering: Mathematical Challenges for Aerospace Design; Springer: New York, NY, USA, 2012; Volume 66, pp. 179–210. [Google Scholar]

- Cavallaro, R.; Demasi, L. Challenges, ideas, and innovations of joined-wing configurations: A concept from the past, an opportunity for the future. Prog. Aerosp. Sci. 2016, 87, 1–93. [Google Scholar] [CrossRef]

- Demasi, L.; Monegato, G.; Dipace, A.; Cavallaro, R. Minimum induced drag theorems for joined wings, closed systems, and generic biwings: Theory. J. Optim. Theory Appl. 2016, 169, 200–235. [Google Scholar] [CrossRef]

- Demasi, L.; Monegato, G.; Rizzo, E.; Cavallaro, R.; Dipace, A. Minimum induced drag theorems for joined wings, closed systems, and generic biwings: Applications. J. Optim. Theory Appl. 2016, 169, 236–261. [Google Scholar] [CrossRef]

- Cavallaro, R.; Nardini, M.; Demasi, L. Amphibious PrandtlPlane: Preliminary Design Aspects Including Propellers Integration and Ground Effect. In Proceedings of the 56th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar] [CrossRef]

- Cipolla, V.; Frediani, A.; Lonigro, E. Aerodynamic design of a light amphibious PrandtlPlane: Wind tunnel tests and CFD validation. Aerotec. Missili Spazi. 2016, 94, 113–123. [Google Scholar] [CrossRef]

- Cipolla, V.; Frediani, A.; Oliviero, F.; Rossi, R.; Rizzo, E.; Pinucci, M. Ultralight amphibious PrandtlPlane: The final design. Aerotec. Missili Spazi. 2016, 95, 125–135. [Google Scholar] [CrossRef]

- Ligetti-Stratos.com. Available online: http://ligeti-stratos.com/ (accessed on 1 December 2017).

- The History of the SUNNY-Boxwing. Available online: http://www.sunny-boxwing.de/ (accessed on 1 December 2017).

- Danilecki, S. Zamknięte Skrzydło—Zalety i Wady (I); Technika Lotnicza i Astronautyczna, No. 9; Oficyna Wydawnicza SIMP Simpress: Warszawa, Poland, 1988; pp. 4–6. (In Polish) [Google Scholar]

- Danilecki, S. Zamknięte Skrzydło—Zalety i Wady (II); Technika Lotnicza i Astronautyczna, No. 10; Oficyna Wydawnicza SIMP Simpress: Warszawa, Poland, 1988; pp. 8–10. (In Polish) [Google Scholar]

- Galinski, C. Results of Testing of Models of Joined-Wing Utility Class Aircraft; SAE Paper No. 921013; SAE International: Warrendale, PA, USA, 1992. [Google Scholar]

- Mamla, P.; Galinski, C. Basic induced drag study of the joined-wing aircraft. J. Aircr. 2009, 46, 1438–1440. [Google Scholar] [CrossRef]

- Livne, E.; Weisshaar, T.A. Aeroelasticity of nonconventional airplane configurations—Past and future. J. Aircr. 2003, 40, 1047–1065. [Google Scholar] [CrossRef]

- Rasmussen, C.C.; Canfield, R.A.; Blair, M. Joined-wing sensor-craft configuration design. J. Aircr. 2006, 43, 1470–1478. [Google Scholar] [CrossRef]

- Cavalaro, R.; Demasi, L.; Passariello, A. Nonlinear analysis of PrandtlPlane joined wings: Effects of anisotropy. AIAA J. 2014, 52, 964–980. [Google Scholar] [CrossRef]

- Goraj, Z.; Kulicki, P.; Lasek, M. Aircraft stability analysis for strongly coupled aerodynamic configuration. J. Theor. Appl. Mech. 1997, 35, 137–158. [Google Scholar]

- Galiński, C.; Hajduk, J. Assumptions of the joined wing flying model programme. Trans. Inst. Aviat. 2015, 238, 7–21. [Google Scholar] [CrossRef]

- Galinski, C.; Hajduk, J.; Kalinowski, M.; Seneńko, K. The concept of the joined wing scaled demonstrator programme. In Proceedings of the CEAS ’2013 Conference, Linkoping, Sweden, 16–18 September 2013; pp. 244–253. [Google Scholar]

- Galiński, C.; Stalewski, W.; Lis, M.; Hajduk, J. Overview of the Inverted Joined Wing Scaled Demonstrator Programme. In Proceedings of the ICAS ’2016 Conference, Daejeon, Korea, 25–30 September 2016. [Google Scholar]

- Stalewski, W. Parametric modelling of aerodynamic objects—The key to successful design and optimisation. Aerotec. Missili Spazi. 2012, 91, 23–31. [Google Scholar]

- Stalewski, W.; Żółtak, J. The preliminary design of the air-intake system and the nacelle in the small aircraft-engine integration process. Aircr. Eng. Aerosp. Technol. 2014, 86, 250–258. [Google Scholar]

- Stalewski, W.; Żółtak, J. Design of a turbulent wing for small aircraft using multidisciplinary optimization. Arch. Mech. 2014, 66, 185–201. [Google Scholar]

- Goetzendorf-Grabowski, T.; Mieloszyk, J.; Mieszalski, D. MADO—Software Package for High Order Multidyscyplinary Aircraft Design and Optimisation. In Proceedings of the ICAS 2012, Brisbane, Australia, 23–28 September 2012. [Google Scholar]

- Mieloszyk, J. Handling Optimization Problems on an Example of Micro UAV. In Proceedings of the 3rd CEAS Air & Space Conference, Venice, Italy, 24–28 October 2011. [Google Scholar]

- Kalinowski, M. Structural optimization of box wing aircraft. Arch. Mech. Eng. 2015, LXII, 45–60. [Google Scholar] [CrossRef]

- Galiński, C.; Bartkiewicz, P.; Hajduk, J.; Lamers, P. Results of the J-5 Marco Dynamic Similar Model Flight Tests Program; SAE Paper No. 975551; SAE International: Warrendale, PA, USA, 1997. [Google Scholar]

- Goraj, Z.; Szender, M. Badania modelu samolotu w locie na dużych kątach natarcia. In Proceedings of the VI Konferencja “Metody i Technika Badań Statków Powietrznych w Locie”, Mrągowo, Poland, 15–18 June 2004; pp. 143–153. (In Polish). [Google Scholar]

- Goraj, Z.; Szender, M. Techniques and critical technologies applied for small and mini UAVs—State of the art and development perspectives. Trans. Inst. Aviat. 2005, 183, 41–49. [Google Scholar]

- Goraj, Z.; Kittmann, K.; Voit-Nitschmann, R.; Szender, M. Design and Integration of Flexi-Bird—A Low Cost Sub-Scale Research Aircraft for Safety and Environmental Issues. In Proceedings of the ICAS Congress 2012, Brisbane, Australia, 23–28 September 2012. [Google Scholar]

- Piwek, K.; Wiśniowski, W. Small air transport aircraft entry requirements evoked by FlightPath 2050. Aircr. Eng. Aerosp. Technol. 2016, 88, 341–347. [Google Scholar] [CrossRef]

- Iwaniuk, A.; Wiśniowski, W.; Żółtak, J. Multi-Disciplinary Optimisation Approach for a Light Turboprop Aircraft-Engine Integration and Improvement. Aircr. Eng. Aerosp. Technol. 2016, 88, 348–355. [Google Scholar] [CrossRef]

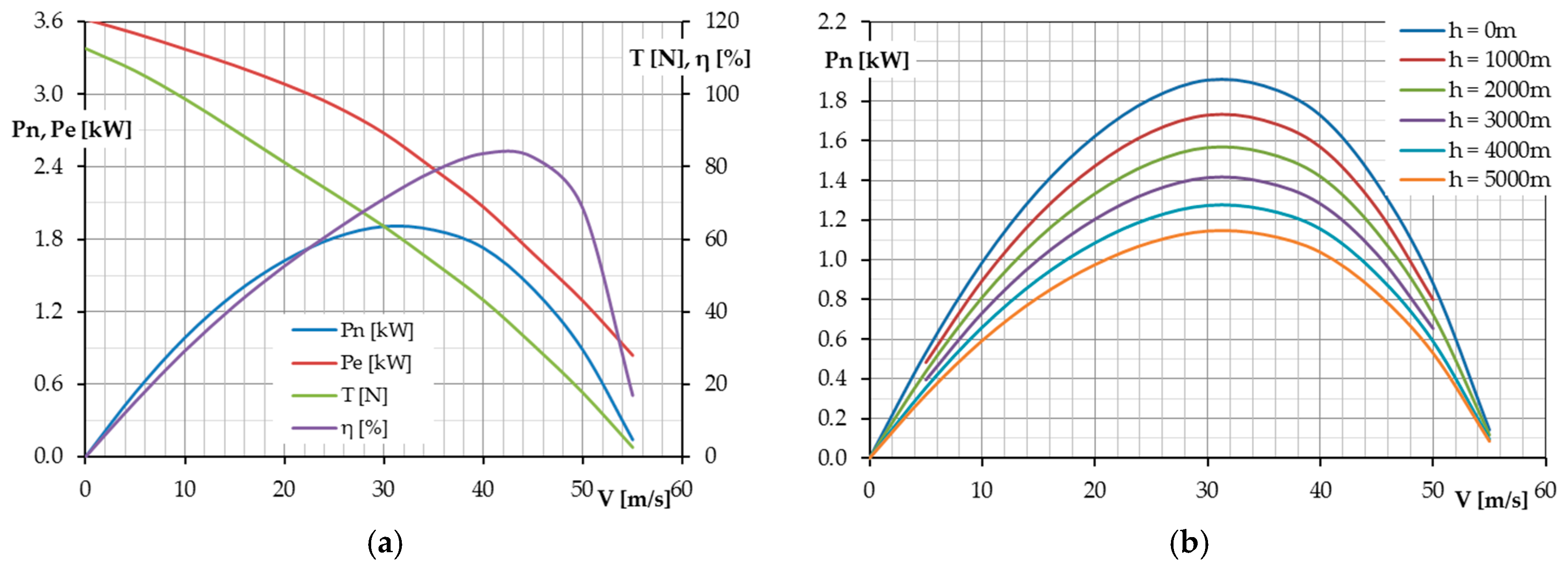

- Lis, M.; Galinski, C. Predicted performance of the inverted joined wing scaled demonstrator. Aviation 2015, 19, 123–132. [Google Scholar] [CrossRef]

- Lis, M.; Dziubiński, A.; Galinski, C.; Krysztofiak, G.; Ruchała, P.; Surmacz, K. Predicted Flight Characteristics of the Inverted Joined Wing Scaled Demonstrator. In Proceedings of the ICAS ’2014 Conference, St. Petersburg, Russia, 7–12 September 2014. [Google Scholar]

- Dziubiński, A.; Kuprianowicz, S.; Surmacz, K.; Galinski, C.; Żółtak, J. The Joined Wing Scaled Demonstrator Results of CFD. In Proceedings of the ICAS ’2014 Conference, St. Petersburg, Russia, 7–12 September 2014. [Google Scholar]

- Galinski, C.; Krysztofiak, G.; Miller, M.; Ruchala, P.; Kalski, M.; Lis, M.; Dziubinski, A.; Bogdanski, K.; Stefanek, Ł.; Hajduk, J. Wind tunnel test results of the inverted joined wing airplane flying model. Aircr. Eng. Aerosp. Technol. 2016, in press. [Google Scholar]

- Stalewski, W. Aerodynamic Optimisation of Joined-Wing Aeroplane. In Proceedings of the 6th International Conference on 6th Experiments/Process/SystemModelling/Simulation/Optimization, Athens, Greece, 8–11 July 2015. [Google Scholar]

- Kalinowski, M. Automatic Design and Sizing of Inverted Joined-Wing Aircraft. In Proceedings of the 58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Mieloszyk, J. Practical problems of numerical optimization in aerospace sciences. Aircr. Eng. Aerosp. Technol. 2017, 89. [Google Scholar] [CrossRef]

- Sieradzki, A.; Dziubinski, A.; Galinski, C. Performance comparison of the optimized inverted joined wing airplane concept and classical configuration airplanes. Arch. Mech. Eng. 2016, 63, 455–470. [Google Scholar]

- Bogdański, K.; Krusz, W.; Rodzewicz, M.; Rutkowski, M. Design and Optimization of Low Speed Ducted Fan for a New Generation of Joined Wing Aircraft. In Proceedings of the 29th Congress of the International Council of the Aeronautical Sciences (ICAS), St. Petersburg, Russia, 7–12 September 2014. [Google Scholar]

- Rodzewicz, M.; Bogdański, K.; Ruchała, P.; Miller, M. Koncepcja i Realizacja Badań Zespołu Napędowego W Tunelu Aerodynamicznym. In Proceedings of the XVI Konferencji Mechanika w Lotnictwie, Kazimierz Dolny, Poland, 26–29 May 2014. (In Polish). [Google Scholar]

- Głowacki, D. Rodzewicz, Badania Dynamiczne Wirnika Napędu Otunelowanego Samolotu MOSUPS. In Proceedings of the XVI Konferencji Mechanika w Lotnictwie, Kazimierz Dolny, Poland, 26–29 May 2014. (In Polish). [Google Scholar]

- Bogdański, K.; Głowacki, D.; Rodzewicz, M. Research on the rotor of a ducted fan propulsion system of MOSUPS aircraft taking into account self balance during operation. Solid State Phenom. 2016, 240, 191–197. [Google Scholar]

- Bogdański, K.; Rodzewicz, M.; Ruchała, P. Characteristics of Locked and Free Wheeling Ducted Fan Based on Wind Tunnel Tests and CFD Analyses. In Proceedings of the 5th CEAS Air & Space Conference Challenges in European Aerospace, Delft, The Netherlands, 7–11 September 2015. [Google Scholar]

- Ruchala, P. Wind tunnel tests of the pusher propeller—An assessment of accuracy. J. KONES Powertrain Transp. 2016, 23, 309–315. [Google Scholar] [CrossRef]

- Turnigy RotoMax 1.60 Brushless Outrunner Motor. Available online: https://hobbyking.com/en_us/turnigy-rotomax-1-60-brushless-outrunner-motor.html (accessed on 29 May 2017).

- HobbyKing YEP 120A HV (4~14S) Brushless Speed Controller (OPTO). Available online: https://hobbyking.com/en_us/hobbyking-yep-120a-hv-4-14s-brushless-speed-controller-opto.html (accessed on 29 May 2017).

- Fiala. Available online: http://vrtule-fiala.cz/en/ (accessed on 29 May 2017).

- Galinski, C.; Sieradzki, A.; Kalinowski, M. Propulsion configuration effect on performance of an inverted joined wing airplane. J. KONES Powertrain Transp. 2016, 23, 136–141. [Google Scholar]

- Burtton, K. The buzz over batteries. Aerosp. Am. 2016, 54, 16–22. [Google Scholar]

- SDSA. Dynamic Stability Analyser. Available online: https://www.meil.pw.edu.pl/add/ADD/Teaching/Software/SDSA (accessed on 29 May 2017).

- Goetzendorf-Grabowski, T.; Mieszalski, D.; Marcinkiewicz, E. Stability analysis using SDSA tool. Prog. Aerosp. Sci. 2011, 47, 636–646. [Google Scholar] [CrossRef]

- PANUKL. Package to Compute the Aerodynamic Characteristics of an Aircraft Using Low Order Panel Method. Available online: https://www.meil.pw.edu.pl/add/ADD/Teaching/Software/PANUKL (accessed on 29 May 2017).

- Blair, M.; Robinson, J.; McClelland, W.A.; Bowmann, J.C. A Joined Wing Flight Experiment; AFRL-RB-WP-TR-2008-3101; Air Force Research Laboratory: Dayton, OH, USA, 2008.

- Oliviero, F.; Zanetti, D.; Cipolla, V. Flight dynamics model for preliminary design of PrandtlPlane wing configuration with sizing of the control surfaces. Aerotec. Missili Spazi. 2016, 95, 201–210. [Google Scholar] [CrossRef]

| Motor: Turnigy RotoMax 1.60 [51] | Voltage (V) | 37 |

| Maximum current (A) | 80 | |

| Mass (g) | 849 | |

| Nominal power/RPM | 2960/8550 | |

| Electronic Speed Controller: YEP 120 [52] | Maximum Continuous Current (A) | 120 |

| Mass (g) | 100 | |

| Battery: Li-Fe 4p12s (48 Cell) | Nominal Voltage (V) | 39.6 |

| Capacity (Ah) | 9.6 | |

| Maximum Continuous Current (A) | 200 | |

| Mass (g) | 4100 | |

| Propeller: Fiala 20 × 10 E [53] | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galinski, C.; Lis, M.; Hajduk, J. Electric Propulsion Concepts for an Inverted Joined Wing Airplane Demonstrator. Energies 2017, 10, 762. https://doi.org/10.3390/en10060762

Galinski C, Lis M, Hajduk J. Electric Propulsion Concepts for an Inverted Joined Wing Airplane Demonstrator. Energies. 2017; 10(6):762. https://doi.org/10.3390/en10060762

Chicago/Turabian StyleGalinski, Cezary, Mateusz Lis, and Jaroslaw Hajduk. 2017. "Electric Propulsion Concepts for an Inverted Joined Wing Airplane Demonstrator" Energies 10, no. 6: 762. https://doi.org/10.3390/en10060762