Surfactant-Assisted Perovskite Nanofillers Incorporated in Quaternized Poly (Vinyl Alcohol) Composite Membrane as an Effective Hydroxide-Conducting Electrolyte

Abstract

:1. Introduction

2. Results and Discussion

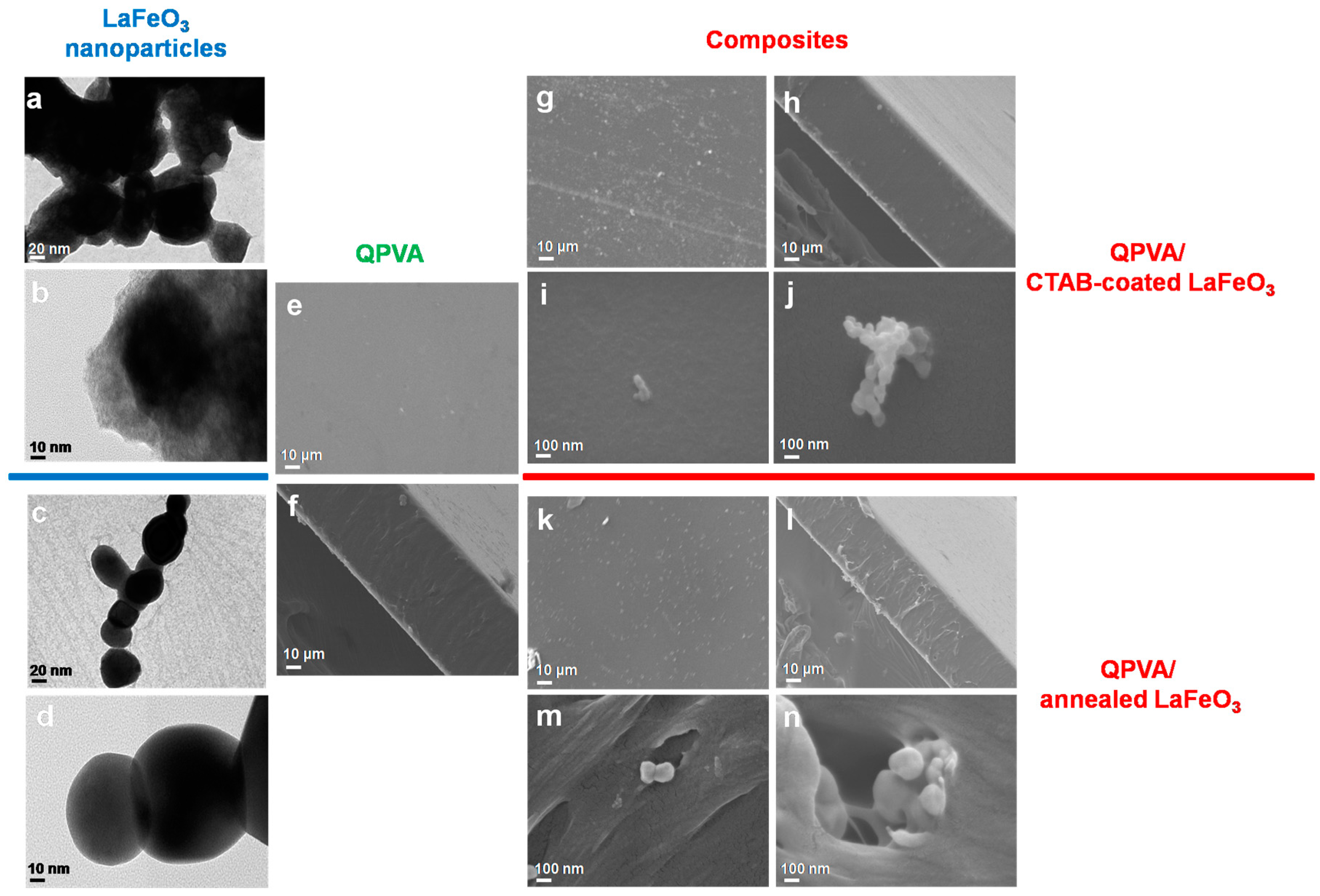

2.1. Perovskite Reaction Mechanism and Morphological Analysis

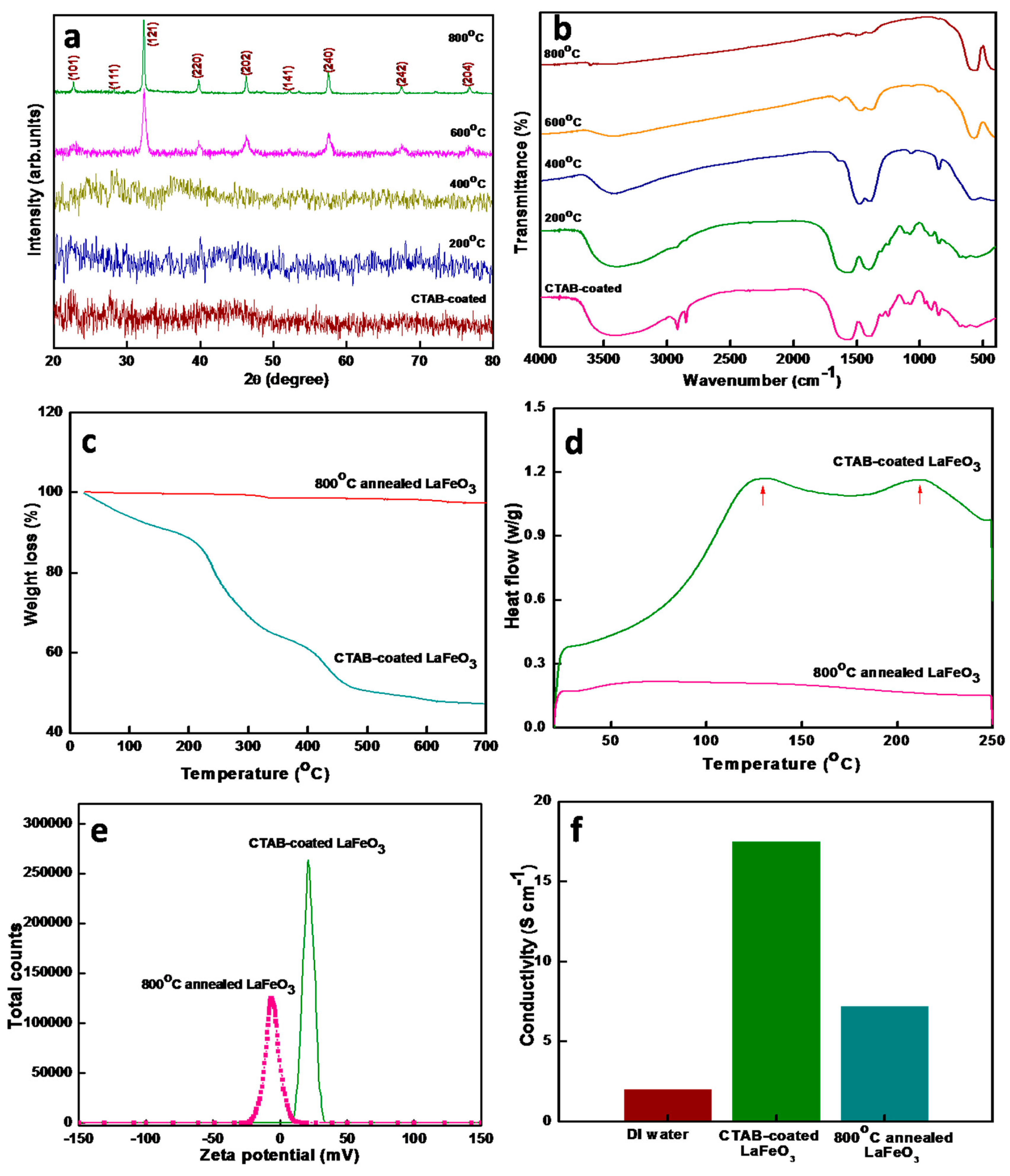

2.2. Physicochemical Characterization of Nanoparticles

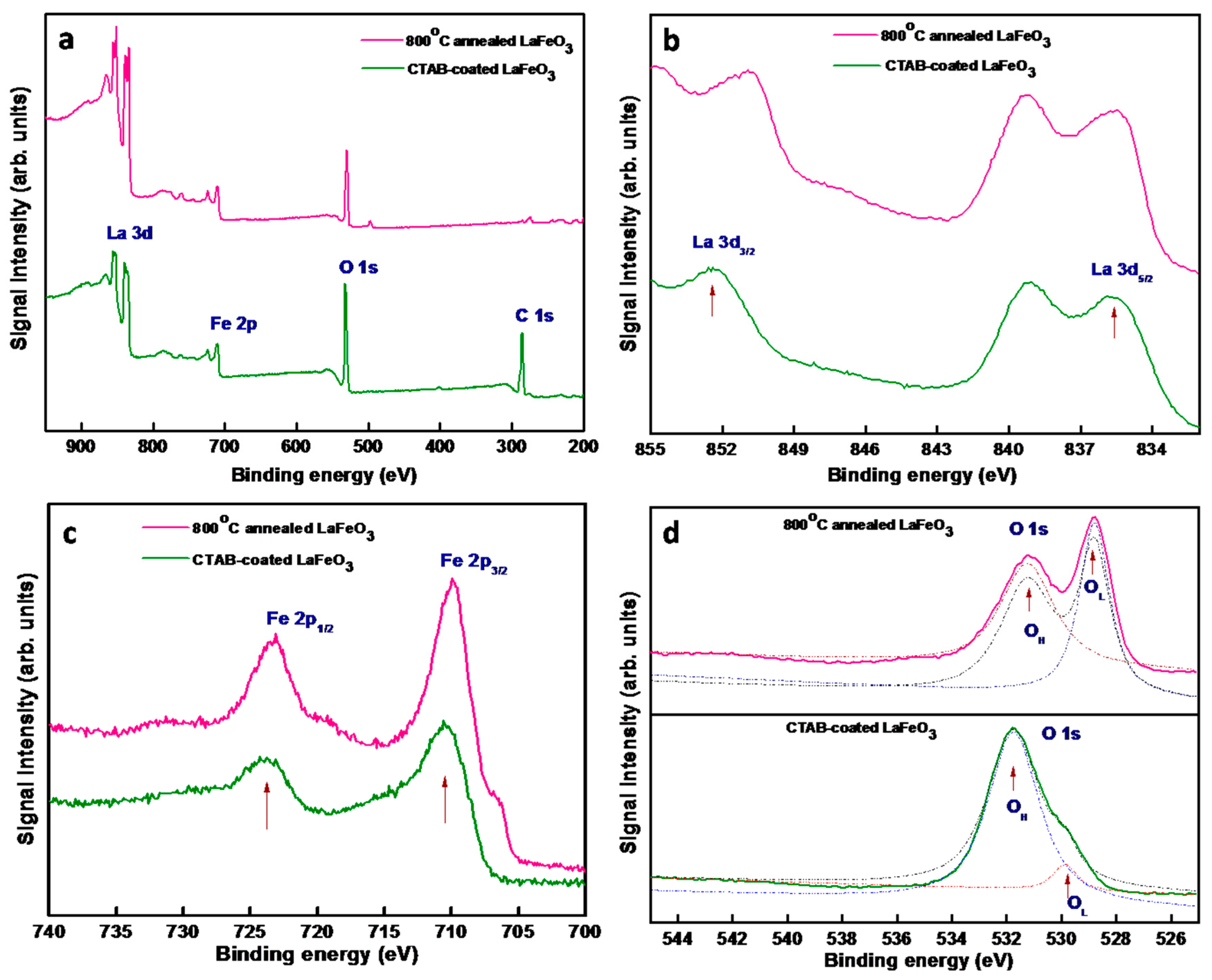

2.3. Compositional Analysis of Nanoparticles

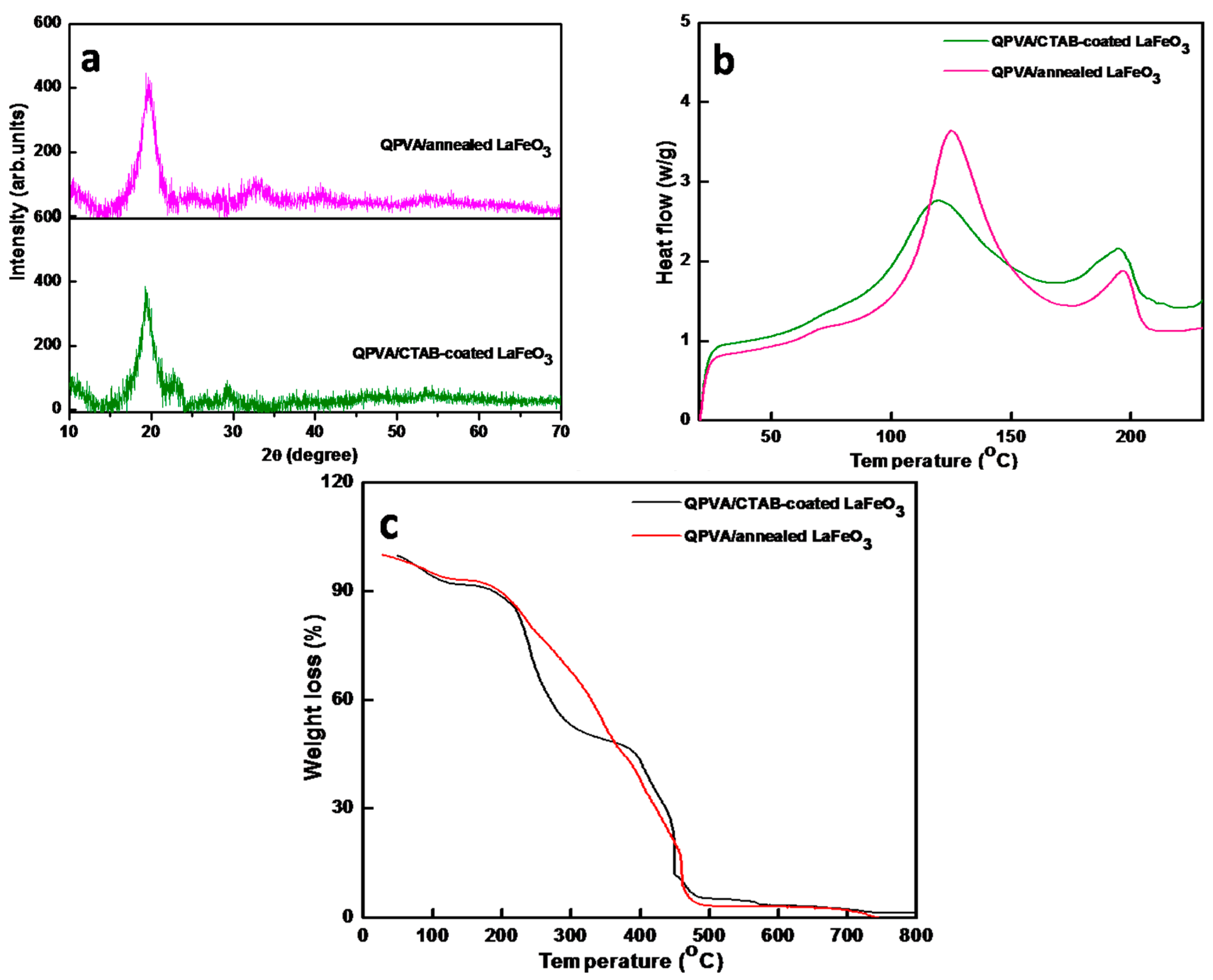

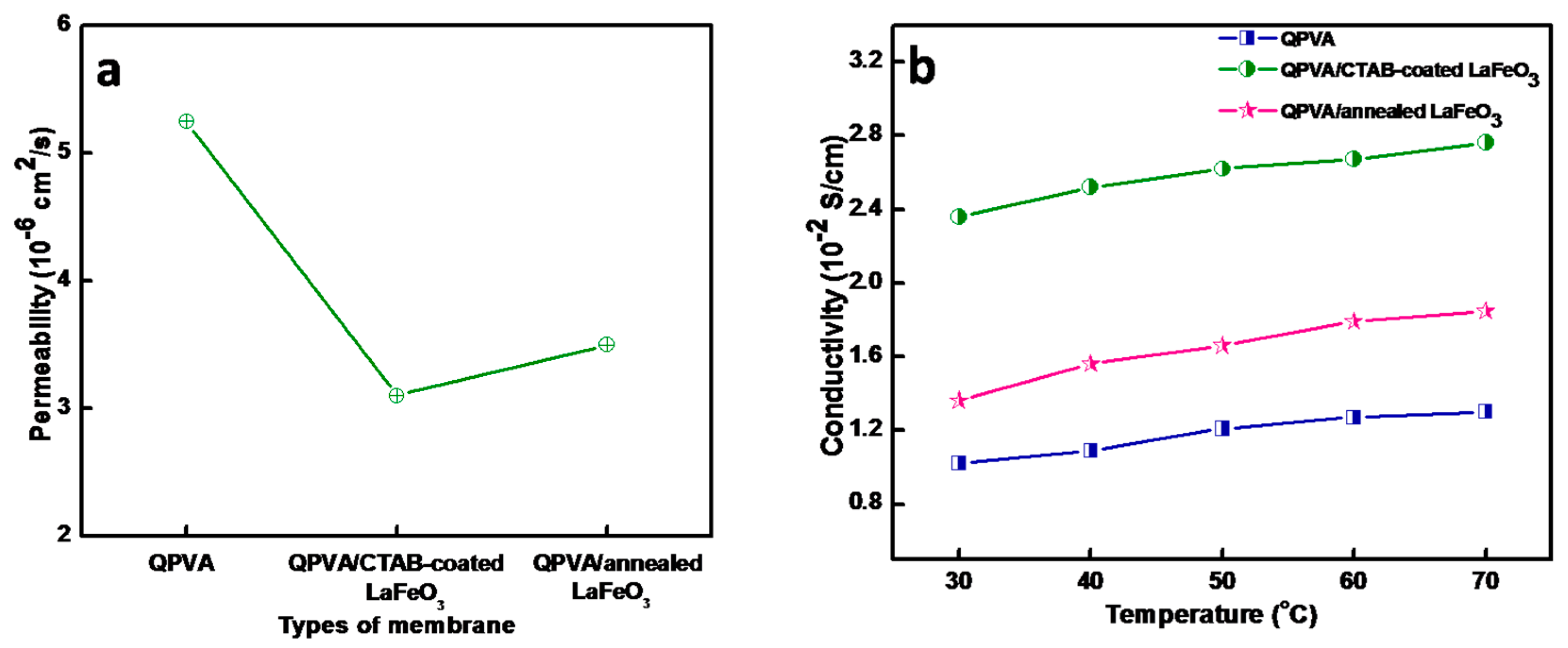

2.4. Nanocomposite Membrane Characterizations

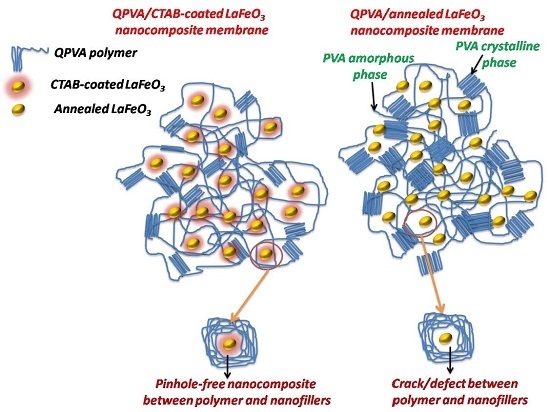

2.5. Role of CTAB Surfactant

2.6. Direct Alkaline Methanol Fuel Cell Performance

3. Materials and Methods

3.1. Preparation of QPVA

3.2. Preparation of LaFeO3 Nanoparticles and QPVA/LaFeO3 Nanocomposite Membranes

3.3. Physicochemical Properties of Nanoparticles and Nanocomposite Membranes

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, Y.-J.; Zhao, N.; Fang, B.; Li, H.; Bi, X.T.; Wang, H. Carbon-supported Pt-based alloy electrocatalysts for the oxygen reduction reaction in polymer electrolyte membrane fuel cells: Particle size, shape, and composition manipulation and their impact to activity. Chem. Rev. 2015, 115, 3433–3467. [Google Scholar] [CrossRef] [PubMed]

- García-Cruz, L.; Casado-Coterillo, C.; Iniesta, J.; Montiel, V.; Irabien, Á. Chitosan: Poly(vinyl) alcohol composite alkaline membrane incorporating organic ionomers and layered silicate materials into a PEM electrochemical reactor. J. Membr. Sci. 2016, 498, 395–407. [Google Scholar] [CrossRef]

- Si, Z.; Qiu, L.; Dong, H.; Gu, F.; Li, Y.; Yan, F. Effects of substituents and substitution positions on alkaline stability of imidazolium cations and their corresponding anion-exchange membranes. ACS Appl. Mater. Interfaces 2014, 6, 4346–4355. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Shao, R.; Chen, S.; He, X.; Qiao, J.; Zhang, J. A review of radiation-grafted polymer electrolyte membranes for alkaline polymer electrolyte membrane fuel cells. J. Power Sources 2015, 293, 946–975. [Google Scholar] [CrossRef]

- Li, X.; Yu, Y.; Meng, Y. Novel Quaternized Poly(arylene ether sulfone)/nano-ZrO2 composite anion exchange membranes for alkaline fuel cells. ACS Appl. Mater. Interfaces 2013, 5, 1414–1422. [Google Scholar] [CrossRef] [PubMed]

- Lue, S.J.; Mahesh, K.P.O.; Wang, W.-T.; Chen, J.-Y.; Yang, C.-C. Permeant transport properties and cell performance of potassium hydroxide doped poly(vinyl alcohol)/fumed silica nanocomposites. J. Membr. Sci. 2011, 367, 256–264. [Google Scholar] [CrossRef]

- Yang, C.-C.; Chiu, S.-S.; Kuo, S.-C.; Liou, T.-H. Fabrication of anion-exchange composite membranes for alkaline direct methanol fuel cells. J. Power Sources 2012, 199, 37–45. [Google Scholar] [CrossRef]

- Lue, S.J.; Pan, W.-H.; Chang, C.-M.; Liu, Y.-L. High-performance direct methanol alkaline fuel cells using potassium hydroxide-impregnated polyvinyl alcohol/carbon nano-tube electrolytes. J. Power Sources 2012, 202, 1–10. [Google Scholar] [CrossRef]

- Wang, Y.-J.; Qiao, J.; Baker, R.; Zhang, J. Alkaline polymer electrolyte membranes for fuel cell applications. Chem. Soc. Rev. 2013, 42, 5768–5787. [Google Scholar] [CrossRef] [PubMed]

- Lue, S.J.; Wang, W.-T.; Mahesh, K.P.O.; Yang, C.-C. Enhanced performance of a direct methanol alkaline fuel cell (DMAFC) using a polyvinyl alcohol/fumed silica/KOH electrolyte. J. Power Sources 2010, 195, 7991–7999. [Google Scholar] [CrossRef]

- Sheibley, D.W.; Manzo, M.A. Polyvinyl Alcohol Membrances as Alkaline Battery Separetors. Available online: http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19830001865.pdf (accessed on 1 January 1982).

- Fang, J.; Qiao, J.; Wilkinson, D.P.; Zhang, J. Electrochemical Polymer Electrolyte Membranes; CRC Press, Taylor & Francis Group: London, UK, 2015. [Google Scholar]

- Fu, J.; Lee, D.U.; Hassan, F.M.; Yang, L.; Bai, Z.; Park, M.G.; Chen, Z. Flexible high-energy polymer-electrolyte-based rechargeable zinc–air batteries. Adv. Mater. 2015, 27, 5617–5622. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Qiao, J.; Wang, X.; Ma, J.; Okada, T. Alkali doped poly(vinyl alcohol) for potential fuel cell applications. Synth. Met. 2010, 160, 193–199. [Google Scholar] [CrossRef]

- Stoševski, I.; Krstić, J.; Vokić, N.; Radosavljević, M.; Popović, Z.K.; Miljanić, Š. Improved Poly(vinyl alcohol) (PVA) based matrix as a potential solid electrolyte for electrochemical energy conversion devices, obtained by gamma irradiation. Energy 2015, 90, 595–604. [Google Scholar] [CrossRef]

- Fu, J.; Qiao, J.; Lv, H.; Ma, J.; Yuan, X.-Z.; Wang, H. Alkali doped poly(vinyl alcohol) (PVA) for anion-exchange membrane fuel cells: Ionic conductivity, chemical stability and FT-IR characterizations. ECS Trans. 2010, 25, 15–23. [Google Scholar]

- Liao, G.-M.; Yang, C.-C.; Hu, C.-C.; Pai, Y.-L.; Lue, S.J. Novel quaternized polyvinyl alcohol/quaternized chitosan nano-composite as an effective hydroxide-conducting electrolyte. J. Membr. Sci. 2015, 485, 17–29. [Google Scholar] [CrossRef]

- Liao, G.-M.; Li, P.-C.; Lin, J.-S.; Ma, W.-T.; Yu, B.-C.; Li, H.-Y.; Liu, Y.-L.; Yang, C.-C.; Shih, C.-M.; Lue, S.J. Highly conductive quasi-coaxial electrospun quaternized polyvinyl alcohol nanofibers and composite as high-performance solid electrolytes. J. Power Sources 2016, 304, 136–145. [Google Scholar] [CrossRef]

- Yang, C.-C. Synthesis and characterization of the cross-linked PVA/TiO2 composite polymer membrane for alkaline DMFC. J. Membr. Sci. 2007, 288, 51–60. [Google Scholar] [CrossRef]

- Lo, C.-F.; Wu, J.-F.; Li, H.-Y.; Hung, W.-S.; Shih, C.-M.; Hu, C.-C.; Liu, Y.-L.; Lue, S.J. Novel polyvinyl alcohol nanocomposites containing carbon nano-tubes with Fe3O4 pendants for alkaline fuel cell applications. J. Membr. Sci. 2013, 444, 41–49. [Google Scholar] [CrossRef]

- Yang, C.-C.; Chiu, S.-J.; Chien, W.-C.; Chiu, S.-S. Quaternized poly(vinyl alcohol)/alumina composite polymer membranes for alkaline direct methanol fuel cells. J. Power Sources 2010, 195, 2212–2219. [Google Scholar] [CrossRef]

- Merle, G.; Wessling, M.; Nijmeijer, K. Anion exchange membranes for alkaline fuel cells: A review. J. Membr. Sci. 2011, 377, 1–35. [Google Scholar] [CrossRef]

- Rajesh Kumar, S.; Juan, C.-H.; Liao, G.-M.; Lin, J.-S.; Yang, C.-C.; Ma, W.-T.; You, J.-H.; Jessie Lue, S. Fumed silica nanoparticles incorporated in quaternized poly(vinyl alcohol) nanocomposite membrane for enhanced power densities in direct alcohol alkaline fuel cells. Energies 2016, 9, 15. [Google Scholar] [CrossRef]

- Lin, J.-S.; Ma, W.-T.; Shih, C.-M.; Yu, B.-C.; Teng, L.-W.; Wang, Y.-C.; Cheng, K.-W.; Chiu, F.-C.; Lue, S. Reorientation of magnetic graphene oxide nanosheets in crosslinked quaternized polyvinyl alcohol as effective solid electrolyte. Energies 2016, 9, 1003. [Google Scholar] [CrossRef]

- Mehta, S.; Kumar, S.; Chaudhary, S.; Bhasin, K.; Gradzielski, M. Evolution of ZnS nanoparticles via facile CTAB aqueous micellar solution route: A study on controlling parameters. Nanoscale Res. Lett. 2008, 4, 17. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Jing, L.; Shi, K.; Yao, C.; Fu, H. Synthesis of large surface area LaFeO3 nanoparticles by SBA-16 template method as high active visible photocatalysts. J. Nanopart. Res. 2010, 12, 967–974. [Google Scholar] [CrossRef]

- Ekrami-Kakhki, M.-S.; Yavari, Z.; Saffari, J.; Ekrami-Kakhki, S.A. Perovskite-type LaFeO3 and LaFeO3-CNTs nanocrystals as active anode for methanol oxidation in alkaline solutions. J. Electr. Eng. 2016, 4, 88–99. [Google Scholar]

- Xuefeng Zhu, W.Y. Mixed Conducting Ceramic Membranes: Fundamentals, Materials and Applications; Springer: Berlin, Germany, 2017; Volume 1, pp. 1–367. [Google Scholar]

- Royer, S.; Duprez, D.; Can, F.; Courtois, X.; Batiot-Dupeyrat, C.; Laassiri, S.; Alamdari, H. Perovskites as substitutes of noble metals for heterogeneous catalysis: Dream or reality. Chem. Rev. 2014, 114, 10292–10368. [Google Scholar] [CrossRef] [PubMed]

- Thirumalairajan, S.; Girija, K.; Mastelaro, V.R.; Ponpandian, N. Investigation on magnetic and electric properties of morphologically different perovskite LaFeO3 nanostructures. J. Mater. Sci. Mater. Electron. 2015, 26, 8652–8662. [Google Scholar] [CrossRef]

- Mizusaki, J.; Yoshihiro, M.; Yamauchi, S.; Fueki, K. Nonstoichiometry and defect structure of the perovskite-type oxides La1−xSrxFeO3−°. J. Solid State Chem. 1985, 58, 257–266. [Google Scholar] [CrossRef]

- Spinicci, R.; Tofanari, A.; Delmastro, A.; Mazza, D.; Ronchetti, S. Catalytic properties of stoichiometric and non-stoichiometric LaFeO3 perovskite for total oxidation of methane. Mater. Chem. Phys. 2002, 76, 20–25. [Google Scholar] [CrossRef]

- Tsipis, E.V.; Kiselev, E.A.; Kolotygin, V.A.; Waerenborgh, J.C.; Cherepanov, V.A.; Kharton, V.V. Mixed conductivity, Mossbauer spectra and thermal expansion of (La,Sr)(Fe,Ni)O3−δ perovskites. Solid State Ion. 2008, 179, 2170–2180. [Google Scholar] [CrossRef]

- Dai, Z.; Lee, C.-S.; Kim, B.-Y.; Kwak, C.-H.; Yoon, J.-W.; Jeong, H.-M.; Lee, J.-H. Honeycomb-like periodic porous LaFeO3 thin film chemiresistors with enhanced gas-sensing performances. ACS Appl. Mater. Interfaces 2014, 6, 16217–16226. [Google Scholar] [CrossRef] [PubMed]

- Unemoto, A.; Kaimai, A.; Sato, K.; Kitamura, N.; Yashiro, K.; Matsumoto, H.; Mizusaki, J.; Amezawa, K.; Kawada, T. High-temperature protonic conduction in LaFeO3–SrFeO3−δ–SrZrO3 solid solutions. J. Electrochem. Soc. 2011, 158, B180–B188. [Google Scholar] [CrossRef]

- Cordero, F.; Craciun, F.; Trequattrini, F. Ionic mobility and phase transitions in perovskite oxides for energy application. Challenges 2017, 8, 5. [Google Scholar] [CrossRef]

- Chen, D.; Chen, C.; Baiyee, Z.M.; Shao, Z.; Ciucci, F. Nonstoichiometric oxides as low-cost and highly-efficient oxygen reduction/evolution catalysts for low-temperature electrochemical devices. Chem. Rev. 2015, 115, 9869–9921. [Google Scholar] [CrossRef] [PubMed]

- Dhinesh Kumar, R.; Jayavel, R. Facile hydrothermal synthesis and characterization of LaFeO3 nanospheres for visible light photocatalytic applications. J. Mater. Sci. Mater. Electron. 2014, 25, 3953–3961. [Google Scholar] [CrossRef]

- Huang, K.; Yuan, L.; Feng, S. Crystal facet tailoring arts in perovskite oxides. Inorgan. Chem. Front. 2015, 2, 965–981. [Google Scholar] [CrossRef]

- Liu, Y.; Tourbin, M.; Lachaize, S.; Guiraud, P. Silica nanoparticles separation from water: Aggregation by cetyltrimethylammonium bromide (CTAB). Chemosphere 2013, 92, 681–687. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhao, X.; Meng, W.; Wang, P.; Wu, F.; Tang, Z.; Han, X.; Giesy, J.P. Cetyltrimethylammonium bromide-coated Fe3O4 magnetic nanoparticles for analysis of 15 trace polycyclic aromatic hydrocarbons in aquatic environments by ultraperformance, liquid chromatography with fluorescence detection. Anal. Chem. 2015, 87, 7667–7675. [Google Scholar] [CrossRef] [PubMed]

- Cheng, W.; Dong, S.; Wang, E. Synthesis and Self-Assembly of Cetyltrimethylammonium Bromide-Capped Gold Nanoparticles. Langmuir 2003, 19, 9434–9439. [Google Scholar] [CrossRef]

- Wang, H.-Q.; Wei, X.; Wang, K.-X.; Chen, J.-S. Controlled synthesis of magnetic Pd/Fe3O4 spheres via an ethylenediamine-assisted route. Dalton Trans. 2012, 41, 3204–3208. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Liu, T.; Xu, Y.; Zhao, J.; He, Y. Effects of PVA content on the synthesis of LaFeO3 via sol–gel route. Ceram. Int. 2011, 37, 1203–1207. [Google Scholar] [CrossRef]

- Hudspeth, J.M.; Stewart, G.A.; Studer, A.J.; Goossens, D.J. Crystal and magnetic structures in Perovskite-related (x = 0.2, 0.33). J. Phys. Chem. Solids 2011, 72, 1543–1547. [Google Scholar] [CrossRef]

- Thirumalairajan, S.; Girija, K.; Mastelaro, V.R.; Ponpandian, N. Photocatalytic degradation of organic dyes under visible light irradiation by floral-like LaFeO3 nanostructures comprised of nanosheet petals. New J. Chem. 2014, 38, 5480–5490. [Google Scholar] [CrossRef]

- Tesquet, G.; Faye, J.; Hosoglu, F.; Mamede, A.-S.; Dumeignil, F.; Capron, M. Ethanol reactivity over La1+x FeO3+δ perovskites. Appl. Catal. A Gen. 2016, 511, 141–148. [Google Scholar] [CrossRef]

- Li, S.; Jin, W.; Xu, N.; Shi, J. Synthesis and oxygen permeation properties of La0.2Sr0.8Co0.2Fe0.8O3−δ membranes. Solid State Ion. 1999, 124, 161–170. [Google Scholar] [CrossRef]

- Pishahang, M.; Bakken, E.; Stølen, S.; Thomas, C.I.; Dahl, P.I. Oxygen non-stoichiometry, redox thermodynamics, and structure of LaFe1−xCoxO3−δ. Ionics 2013, 19, 869–878. [Google Scholar] [CrossRef]

- Delmastro, A.; Mazza, D.; Ronchetti, S.; Vallino, M.; Spinicci, R.; Brovetto, P.; Salis, M. Synthesis and characterization of non-stoichiometric LaFeO3 perovskite. Mater. Sci. Eng. B 2001, 79, 140–145. [Google Scholar] [CrossRef]

- Li, P.; Hu, X.; Zhang, L.; Dai, H.; Zhang, L. Sol-gel nanocasting synthesis of patterned hierarchical LaFeO3 fibers with enhanced catalyticCO oxidation activity. Nanoscale 2011, 3, 974–976. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.-Y.; Yun, H.J.; Yoon, J.-W. Characterization and magnetic properties of LaFeO3 nanofibers synthesized by electrospinning. J. Alloys Compd. 2014, 583, 320–324. [Google Scholar] [CrossRef]

- Lue, S.J.; Lee, D.-T.; Chen, J.-Y.; Chiu, C.-H.; Hu, C.-C.; Jean, Y.C.; Lai, J.-Y. Diffusivity enhancement of water vapor in poly(vinyl alcohol)–fumed silica nano-composite membranes: Correlation with polymer crystallinity and free-volume properties. J. Membr. Sci. 2008, 325, 831–839. [Google Scholar] [CrossRef]

- Pan, W.-H.; Lue, S.J.; Chang, C.-M.; Liu, Y.-L. Alkali doped polyvinyl alcohol/multi-walled carbon nano-tube electrolyte for direct methanol alkaline fuel cell. J. Membr. Sci. 2011, 376, 225–232. [Google Scholar] [CrossRef]

- Jessie Lue, S.; Chen, J.Y.; Ming Yang, J. Crystallinity and stability of poly(vinyl alcohol)-fumed silica mixed matrix membranes. J. Macromol. Sci. Part B 2007, 47, 39–51. [Google Scholar]

- Wu, J.-F.; Lo, C.-F.; Li, L.-Y.; Li, H.-Y.; Chang, C.-M.; Liao, K.-S.; Hu, C.-C.; Liu, Y.-L.; Lue, S.J. Thermally stable polybenzimidazole/carbon nano-tube composites for alkaline direct methanol fuel cell applications. J. Power Sources 2014, 246, 39–48. [Google Scholar] [CrossRef]

- Emmanuel, K.; Cheng, C.; Erigene, B.; Mondal, A.N.; Hossain, M.M.; Khan, M.I.; Afsar, N.U.; Liang, G.; Wu, L.; Xu, T. Imidazolium functionalized anion exchange membrane blended with PVA for acid recovery via diffusion dialysis process. J. Membr. Sci. 2016, 497, 209–215. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Lin, J.-S.; Pan, W.-H.; Shih, C.-M.; Liu, Y.-L.; Lue, S.J. Alkaline direct ethanol fuel cell performance using alkali-impregnated polyvinyl alcohol/functionalized carbon nano-tube solid electrolytes. J. Power Sources 2016, 303, 267–277. [Google Scholar] [CrossRef]

- Li, P.-C.; Liao, G.M.; Kumar, S.R.; Shih, C.-M.; Yang, C.-C.; Wang, D.-M.; Lue, S.J. Fabrication and Characterization of Chitosan Nanoparticle-Incorporated Quaternized Poly(Vinyl Alcohol) Composite Membranes as Solid Electrolytes for Direct Methanol Alkaline Fuel Cells. Electrochim. Acta 2016, 187, 616–628. [Google Scholar] [CrossRef]

- Wang, B.-Y.; Lin, H.-K.; Liu, N.-Y.; Mahesh, K.P.O.; Lue, S.J. Cell performance modeling of direct methanol fuel cells using proton-exchange solid electrolytes: Effective reactant diffusion coefficients in porous diffusion layers. J. Power Sources 2013, 227, 275–283. [Google Scholar] [CrossRef]

- Gi Hong, J.; Glabman, S.; Chen, Y. Effect of inorganic filler size on electrochemical performance of nanocomposite cation exchange membranes for salinity gradient power generation. J. Membr. Sci. 2015, 482, 33–41. [Google Scholar] [CrossRef]

- Watanabe, H.; Takahashi, H.; Takeguchi, T.; Yamanaka, T.; Ueda, W. Performance of Solid Alkaline Fuel Cells Employing Layered Perovskite-Type Oxides as Electrolyte. ECS Trans. 2010, 33, 1825–1829. [Google Scholar]

- Yang, C.-C. Alkaline direct methanol fuel cell based on a novel anion-exchange composite polymer membrane. J. Appl. Electrochem. 2012, 42, 305–317. [Google Scholar] [CrossRef]

- Thirumalairajan, S.; Girija, K.; Ganesh, V.; Mangalaraj, D.; Viswanathan, C.; Ponpandian, N. Novel Synthesis of LaFeO3 Nanostructure Dendrites: A Systematic Investigation of Growth Mechanism, Properties, and Biosensing for Highly Selective Determination of Neurotransmitter Compounds. Cryst. Growth Des. 2013, 13, 291–302. [Google Scholar] [CrossRef]

- Mihai, O.; Raaen, S.; Chen, D.; Holmen, A. Preparation of stable cubic LaFeO3 nanoparticles using carbon nanotubes as templates. J. Mater. Chem. A 2013, 1, 7006–7011. [Google Scholar] [CrossRef]

- Jing, L.; Qu, Y.; Su, H.; Yao, C.; Fu, H. Synthesis of High-Activity TiO2-Based Photocatalysts by Compounding a Small Amount of Porous Nanosized LaFeO3 and the Activity-Enhanced Mechanisms. J. Phys. Chem. C 2011, 115, 12375–12380. [Google Scholar] [CrossRef]

- Wang, J.; Huang, S.-p.; Hu, K.; Zhou, K.-c.; Sun, H. Effect of cetyltrimethylammonium bromide on morphology and porous structure of mesoporous hydroxyapatite. Trans. Nonferr. Met. Soc. China 2015, 25, 483–489. [Google Scholar] [CrossRef]

- Micellisation of Cetyltrimethyl Ammonium Bromide in Aqueous-Organic Media. Available online: http://astonjournals.com/manuscripts/Vol2012/CSJ-52_Vol2012.pdf (accessed on 2 March 2017).

- Krevelen, D.W.V. Properties of Polymers: Their Correlation with Chemical Structure; Their Numerical Estimation and Prediction from Additive Group Contributions, 3rd ed.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1990. [Google Scholar]

- Ramasubramanian, K.; Severance, M.A.; Dutta, P.K.; Ho, W.S.W. Fabrication of zeolite/polymer multilayer composite membranes for carbon dioxide capture: Deposition of zeolite particles on polymer supports. J. Coll. Interface Sci. 2015, 452, 203–214. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Han, Q.; Zhou, Q.; Du, X.; Xue, L. Molecular sieving effect of zeolites on the properties of PVA based composite membranes for total heat recovery in ventilation systems. RSC Adv. 2016, 6, 66767–66773. [Google Scholar] [CrossRef]

- Yang, C.; Wang, S.; Ma, W.; Jiang, L.; Sun, G. Comparison of alkaline stability of quaternary ammonium- and 1,2-methylimidazolium-based alkaline anion exchange membranes. J. Membr. Sci. 2015, 487, 12–18. [Google Scholar] [CrossRef]

- Lue, S.J.; Pai, Y.-L.; Shih, C.-M.; Wu, M.-C.; Lai, S.-M. Novel bilayer well-aligned Nafion/graphene oxide composite membranes prepared using spin coating method for direct liquid fuel cells. J. Membr. Sci. 2015, 493, 212–223. [Google Scholar] [CrossRef]

- Chien, H.-C.; Tsai, L.-D.; Huang, C.-P.; Kang, C.-y.; Lin, J.-N.; Chang, F.-C. Sulfonated graphene oxide/Nafion composite membranes for high-performance direct methanol fuel cells. Int. J. Hydrogen Energy 2013, 38, 13792–13801. [Google Scholar] [CrossRef]

- Yang, J.-M.; Wang, N.-C.; Chiu, H.-C. Preparation and characterization of poly(vinyl alcohol)/sodium alginate blended membrane for alkaline solid polymer electrolytes membrane. J. Membr. Sci. 2014, 457, 139–148. [Google Scholar] [CrossRef]

- Li, L.-Y.; Yu, B.-C.; Shih, C.-M.; Lue, S.J. Polybenzimidazole membranes for direct methanol fuel cell: Acid-doped or alkali-doped? J. Power Sources 2015, 287, 386–395. [Google Scholar] [CrossRef]

- Chou, F.-Y.; Lai, J.-Y.; Shih, C.-M.; Tsai, M.-C.; Lue, S.J. In vitro biocompatibility of magnetic thermo-responsive nanohydrogel particles of poly(N-isopropylacrylamide-co-acrylic acid) with Fe3O4 cores: Effect of particle size and chemical composition. Coll. Surf. B Biointerfaces 2013, 104, 66–74. [Google Scholar] [CrossRef] [PubMed]

- Lue, S.J.; Chen, B.-W.; Shih, C.-M.; Chou, F.-Y.; Lai, J.-Y.; Chiu, W.-Y. Micron- and Nano-sized Poly(N-isopropylacrylamide-co-acrylic acid) Latex Syntheses and Their Applications for Controlled Drug Release. J. Nanosci. Nanotechnol. 2013, 13, 5305–5315. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.-C.; Liu, Y.-L.; Pan, W.-H.; Chang, C.-M.; Shih, C.-M.; Chu, H.-Y.; Chien, C.-H.; Juan, C.-H.; Lue, S.J. Direct borohydride fuel cell performance using hydroxide-conducting polymeric nanocomposite electrolytes. J. Polym. Sci. Part B Polym. Phys. 2013, 51, 1779–1789. [Google Scholar] [CrossRef]

| Properties | QPVA | QPVA/CTAB-Coated LaFeO3 | QPVA/Annealed LaFeO3 |

|---|---|---|---|

| Elongation (%) | 143 | 99 | 54 |

| Young’s modulus (MPa) | 22.3 | 12.3 | 6.9 |

| Ion exchange capacity (mmol g−1) | 0.75 ± 0.02 | 1.06 ± 0.04 | 0.95 ± 0.01 |

| Total KOH solution Uptake (g g−1) a | 2.14 ± 0.01 | 1.43 ± 0.02 | 1.30 ± 0.01 |

| Partial KOH uptake (g g−1) a | 0.48 | 0.78 | 0.58 |

| Partial water uptake (g g−1) a | 1.66 | 0.65 | 0.72 |

| In-plane swelling (%) a | 25.0 | 6.3 | 10.0 |

| Through-plane swelling (%) a | 66.7 | 44.4 | 51.1 |

| Membrane Electrolyte | Nano-Filler Loading (wt %) | Cond. (mS cm−1) | Meth. Perm. (×10−6 cm2 s−1) | Operating Conditions | Pmax (mW cm−2) | References | |||

|---|---|---|---|---|---|---|---|---|---|

| Anode Catalyst (Loading in mg cm−2) | Cathode Catalyst (Loading in mg cm−2) | Temp. (°C) | MeOH conc./KOH conc. | ||||||

| QPVA/PECH | 25 | 8.8 | 46 | Pt-Ru/C (4) | MnO2/C (4) | 25 | 2 M/4 M | 22.3 | Yang et al. [63] |

| QPVA/Al2O3 | 10 | 11 | 67 | Pt-Ru/C (4) | MnO2/C (4) | 25 | 4 M/4 M | 36.1 | Yang et al. [21] |

| PVA/TiO2 | 10 | 31 | -a | Pt-Ru/C (4) | Pt/C (4) | 60 | 2 M/2 M | 7.5 | Yang et al. [19] |

| QPVA/CTAB-coated LaFeO3 | 0.1 | 24 | 3.10 | Pt-Ru/C (2) | Pt/C (1) | 30 | 4 M/6 M | 112 | This work |

| QPVA/annealed LaFeO3 | 0.1 | 14 | 3.50 | Pt-Ru/C (2) | Pt/C (1) | 30 | 4 M/6 M | 100 | This work |

| QPVA/Q-SiO2 | 20 | 19 | 81 | Pt-Ru/C (4) | MnO2/C (4) | 50 | 2 M/8 M | 35.1 | Yang et al. [7] |

| QPVA/chitosan | 10 | 27 | 6.7 | Pt-Ru/C (6) | Pt/C (5) | 80 | 1 M/6 M | 67 | Li et al. [59] |

| QPVA/Q-chitosan | 5 | 4.8 | 3.0 | Pt-Ru/C (6) | Pt/C (5) | 60 | 2 M/6 M | 73 | Liao et al. [17] |

| PVA/CNT | 0.1 | 11.7 | 30 | Pt-Ru/C (6) | Pt/C (5) | 60 | 2 M/6 M | 68.1 | Lue et al. [8] |

| PVA/Fe3O4-CNT | 10 | 48 | 8.9 | Pt-Ru/C (6) | Pt/C (5) | 60 | 2 M/6 M | 87.8 | Lo et al. [20] |

| Electrospun QPVA | -a | 41 | 5.2 | Pt-Ru/C (6) | Pt/C (5) | 60 | 2 M/6 M | 54 | Liao et al. [18] |

| QPVA/fumed silica | 5 | 35 | 4.6 | Pt-Ru/C (6) | Pt/C (5) | 60 | 2 M/6 M | 88.4 | Kumar et al. [23] |

| QPVA/GO-Fe3O4 | 0.1 | 1.01 | 29 | Pt-Ru/C (6) | Pt/C (5) | 60 | 2 M/6 M | 55.4 | Lin et al. [24] |

| QPVA/CTAB-coated LaFeO3 | 0.1 | 27 | -a | Pt-Ru/C (2) | Pt/C (1) | 60 | 4 M/6 M | 272 | This work |

| QPVA/annealed LaFeO3 | 0.1 | 18 | -a | Pt-Ru/C (2) | Pt/C (1) | 60 | 4 M/6 M | 254 | This work |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajesh Kumar, S.; Ma, W.-T.; Lu, H.-C.; Teng, L.-W.; Hsu, H.-C.; Shih, C.-M.; Yang, C.-C.; Lue, S.J. Surfactant-Assisted Perovskite Nanofillers Incorporated in Quaternized Poly (Vinyl Alcohol) Composite Membrane as an Effective Hydroxide-Conducting Electrolyte. Energies 2017, 10, 615. https://doi.org/10.3390/en10050615

Rajesh Kumar S, Ma W-T, Lu H-C, Teng L-W, Hsu H-C, Shih C-M, Yang C-C, Lue SJ. Surfactant-Assisted Perovskite Nanofillers Incorporated in Quaternized Poly (Vinyl Alcohol) Composite Membrane as an Effective Hydroxide-Conducting Electrolyte. Energies. 2017; 10(5):615. https://doi.org/10.3390/en10050615

Chicago/Turabian StyleRajesh Kumar, Selvaraj, Wei-Ting Ma, Hsin-Chun Lu, Li-Wei Teng, Hung-Chun Hsu, Chao-Ming Shih, Chun-Chen Yang, and Shingjiang Jessie Lue. 2017. "Surfactant-Assisted Perovskite Nanofillers Incorporated in Quaternized Poly (Vinyl Alcohol) Composite Membrane as an Effective Hydroxide-Conducting Electrolyte" Energies 10, no. 5: 615. https://doi.org/10.3390/en10050615