A Novel Caving Model of Overburden Strata Movement Induced by Coal Mining

Abstract

:1. Introduction

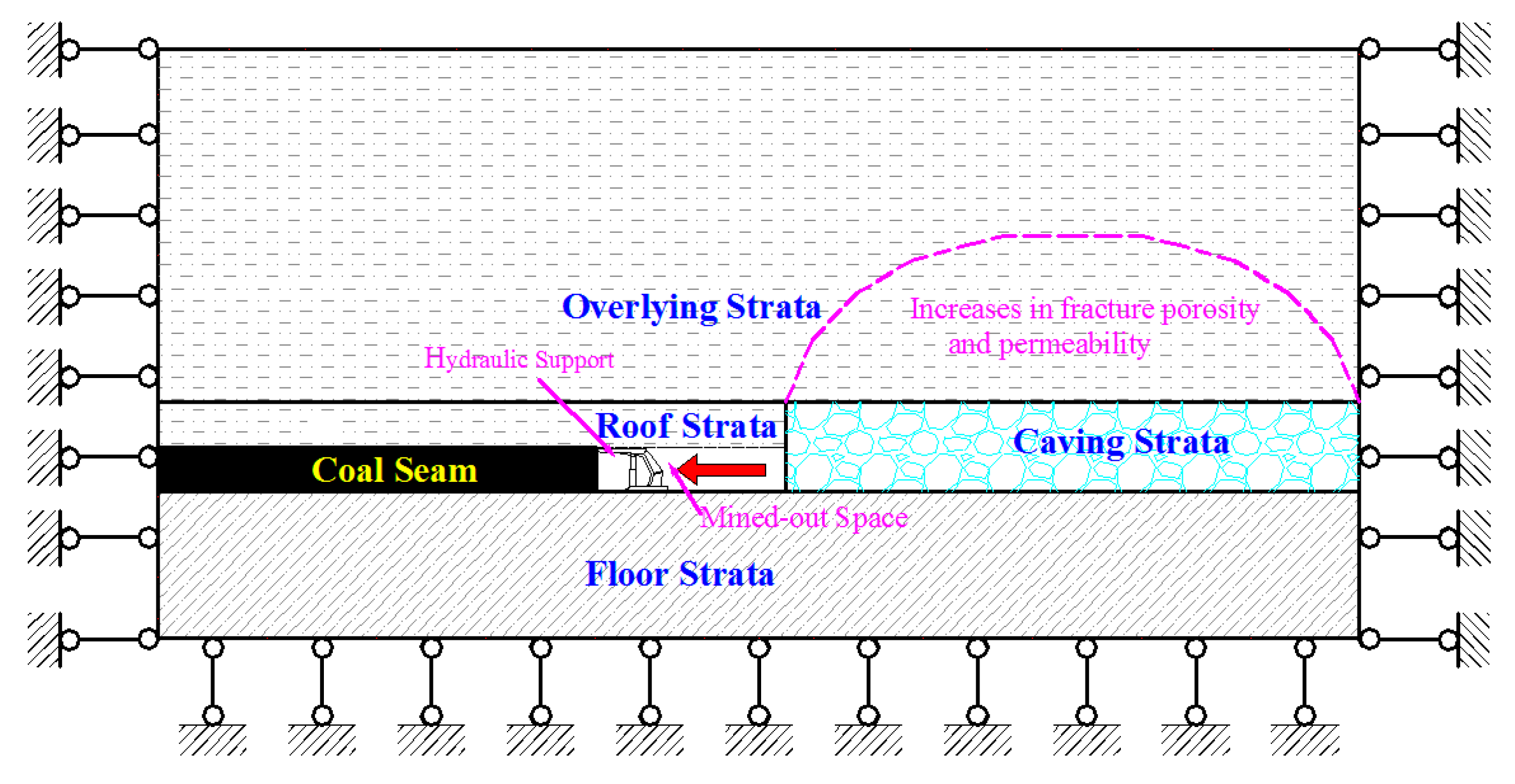

2. Background Concerning Mining Effects

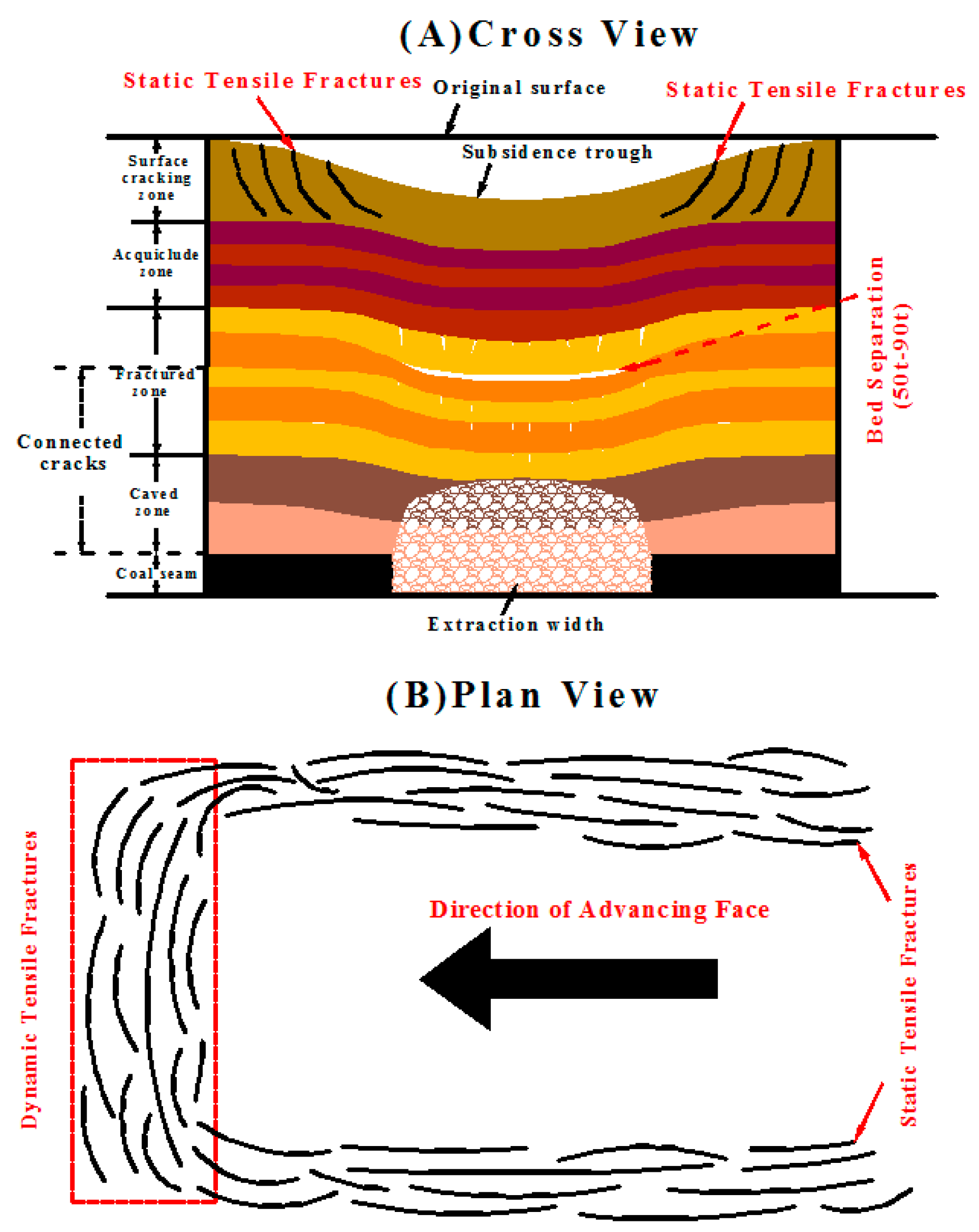

2.1. Fractures Changes Due to Longwall Mining

2.2. Effects on Subsidence of Longwall Mining

2.3. Interactions between Subsidence and Water Bodies

3. Trapezoid Broken Model to Calculate Mining-Induced Fracture Parameters

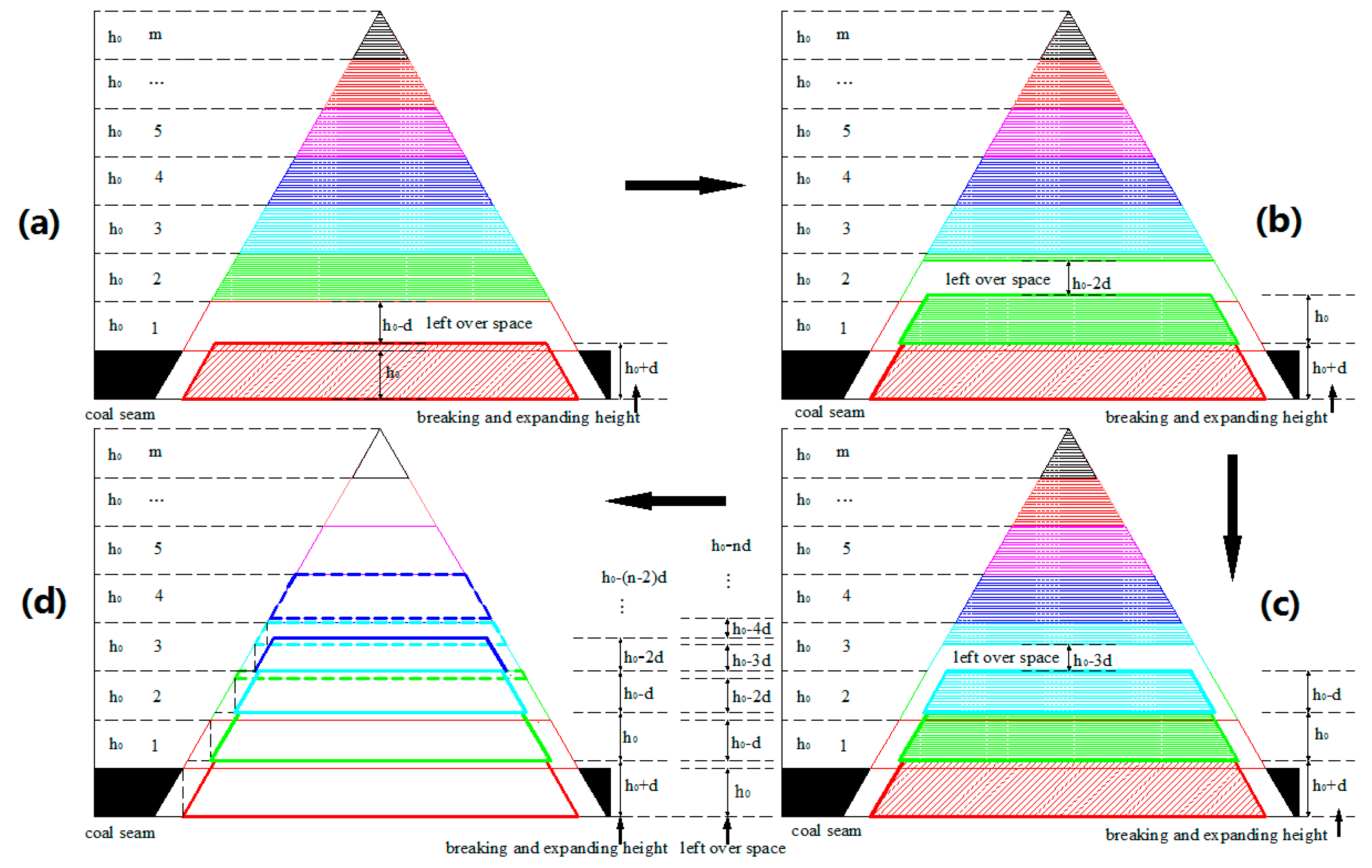

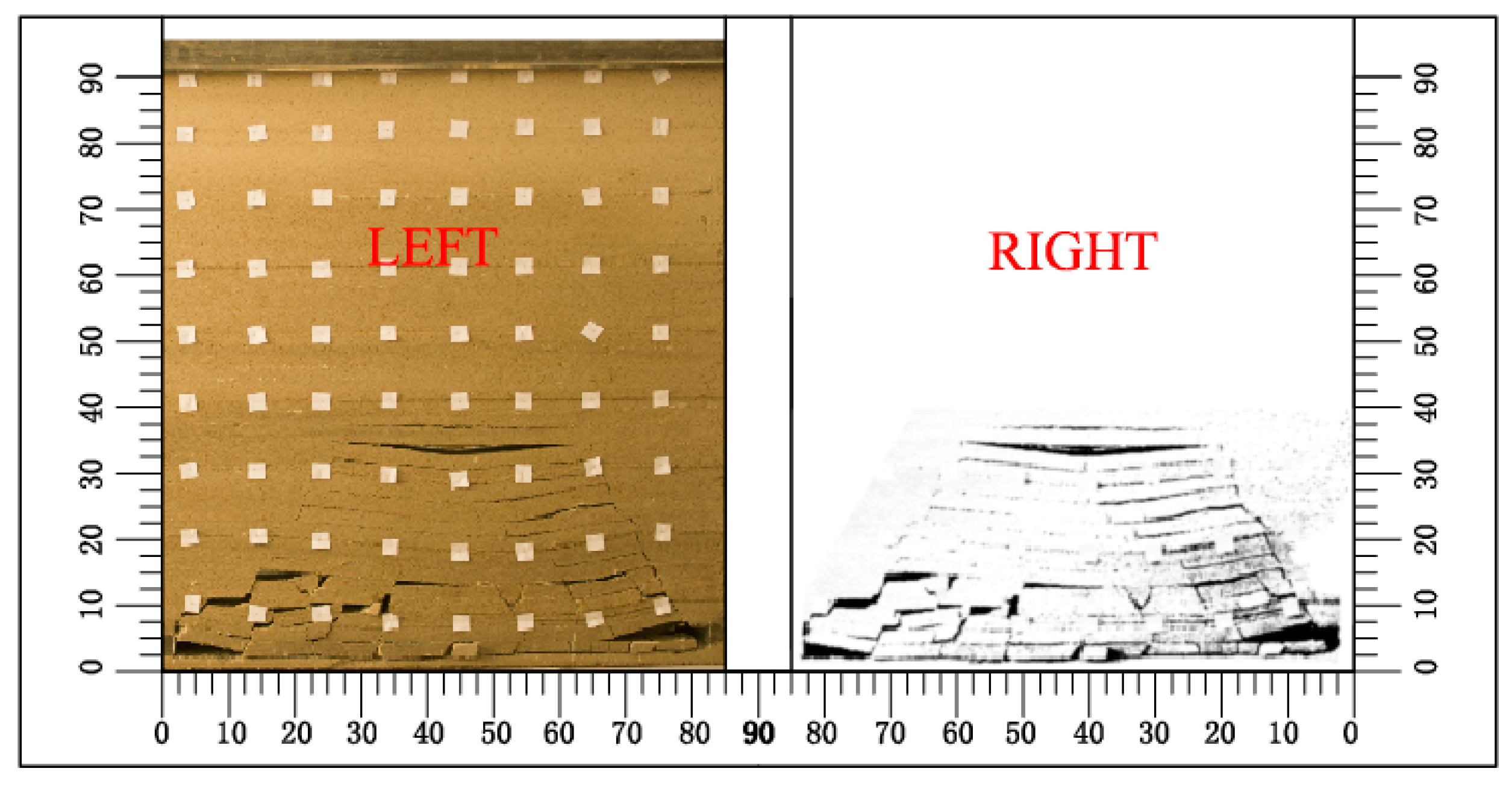

3.1. Model Study I

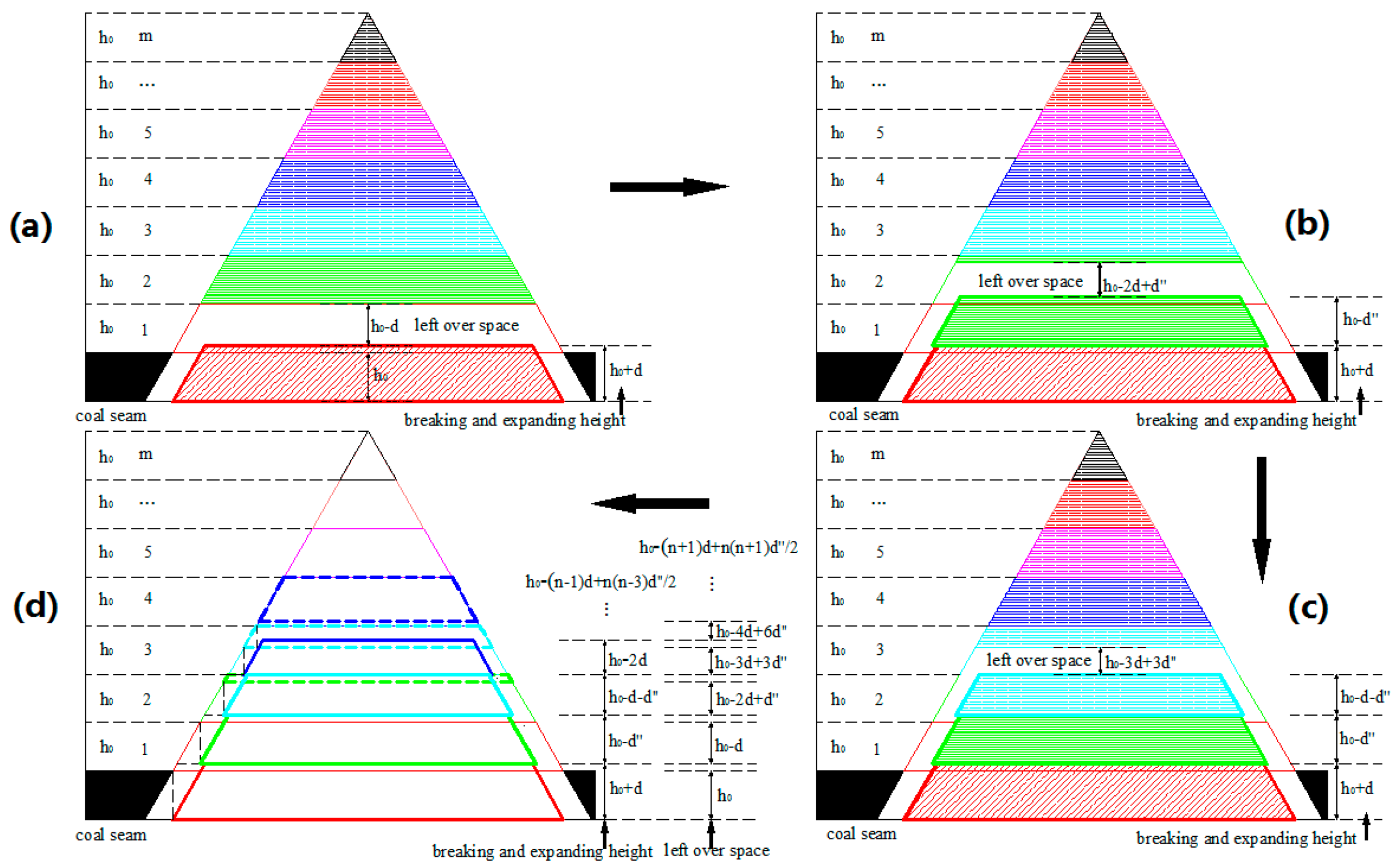

3.2. Model Study II

3.3. Model Study III

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bahuguna, P.P.; Srivastava, A.M.C.; Saxena, N.C. A critical review of mine subsidence prediction methods. J. Min. Sci. Technol. 1991, 13, 369–382. [Google Scholar] [CrossRef]

- Bárdossy, A.; Hörning, S. Gaussian and non-Gaussian inverse modeling of groundwater flow using copulas and random mixing. Water Resour. Res. 2016, 52. [Google Scholar] [CrossRef]

- Bayram, A.; Önsoy, H. Sand and gravel mining impact on the surface water quality: A case study from the city of Tirebolu (Giresun Province, NETurkey). Environ. Earth Sci. 2015, 73, 1997–2011. [Google Scholar] [CrossRef]

- Booth, C.J.; Spande, E.D.; Pattee, C.T.; Miller, J.D.; Bertsch, L.P. Positive and negative impacts of longwall mine subsidence on a sandstone aquifer. Environ. Geol. 1998, 34, 223–233. [Google Scholar] [CrossRef]

- Booth, C.J. Groundwater as an environmental constraint of longwall coal mining. Environ. Geol. 2006, 49, 796–803. [Google Scholar] [CrossRef]

- Booth, C.J. Confined-unconfined changes above longwall coal mining due to increases in fracture porosity. Environ. Eng. Geosci. 2007, 13, 355–367. [Google Scholar] [CrossRef]

- Booth, C.J. Strata-movement concepts and the hydrogeological impact of underground coal mining. Ground Water 1986, 24, 507–515. [Google Scholar] [CrossRef]

- Chang, J.; Leung, D.Y.C.; Wu, C.Z.; Yuan, Z.H. A review on the energy production, consumption, and prospect of renewable energy in China. Renew. Sustain. Energy Rev. 2003, 7, 453–468. [Google Scholar] [CrossRef]

- Franks, C.A.M.; Geddes, J.D. Subsidence on steep slopes due to longwall mining. Geotech. Geol. Eng. 1986, 4, 291–301. [Google Scholar] [CrossRef]

- Gordalla, B.C.; Ewers, U.; Frimmel, F.H. Hydraulic fracturing: A toxicological threat for groundwater and drinking-water? Environ. Earth Sci. 2013, 70, 3875–3893. [Google Scholar] [CrossRef]

- Gregory, K.B.; Vidic, R.D.; Dzombak, D.A. Water management challenges associated with the production of shale gas by hydraulic fracturing. Elements 2011, 7, 181–186. [Google Scholar] [CrossRef]

- Hill, J.G.; Price, D.R. The impact of deep mining on an overlying aquifer in western Pennsylvania. Ground Water Monit. Remediat. 1983, 3, 138–143. [Google Scholar] [CrossRef]

- Howladar, M.F. Coal mining impacts on water environs around the Barapukuria coal mining area, Dinajpur, Bangladesh. Environ. Earth Sci. 2012, 70, 215–226. [Google Scholar] [CrossRef]

- Howladar, M.F.; Hasan, K. A study on the development of subsidence due to the extraction of 1203 slice with its associated factors around Barapukuria underground coal mining industrial area, Dinajpur, Bangladesh. Environ. Earth Sci. 2014, 72, 3699–3713. [Google Scholar] [CrossRef]

- Islam, M.R.; Hayashi, D.; Kamruzzaman, A.B.M. Finite element modeling of stress distributions and problems for multi-slice longwall mining in Bangladesh, with special reference to the Barapukuria coal mine. Int. J. Coal Geol. 2009, 78, 91–109. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Goodman, G. Hydraulic conductivity changes and influencing factors in longwall overburden determined by slug tests in gob gas ventholes. Int. J. Rock Mech. Min. 2009, 46, 1162–1174. [Google Scholar] [CrossRef]

- Karaman, A.; Seyhan, T.; Işık, M.F. Detecting the footprint of a longwall mine panel claimed to infringe on a permit boundary at the Soma–Darkale coalfield (Manisa, Turkey) using surface fractures and microgravity measurements. Environ. Earth Sci. 2013, 70, 1895–1902. [Google Scholar] [CrossRef]

- Lee, D.K.; Mojtabai, N.; Lee, H.B.; Song, W.K. Assessment of the influencing factors on subsidence at abandoned coal mines in South Korea. Environ. Earth Sci. 2013, 68, 647–654. [Google Scholar] [CrossRef]

- Li, G.Y.; Zhou, W.F. Impact of karst water on coal mining in North China. Environ. Geol. 2006, 49, 449–457. [Google Scholar] [CrossRef]

- Liu, J.; Elsworth, D. Three-dimensional effects of hydraulic conductivity enhancement and desaturation around mined panels. Int. J. Rock Mech. Min. 1997, 34, 1139–1152. [Google Scholar] [CrossRef]

- Ma, L.Q.; Zhang, D.S.; Li, X.; Fan, G.W.; Zhao, Y.F. Technology of groundwater reservoir construction in goafs of shallow coalfields. Int. J. Min. Sci. Technol. 2009, 19, 730–735. [Google Scholar] [CrossRef]

- Majdi, A.; Hassani, F.P.; Nasiri, M.Y. Prediction of the height of destressed zone above the mined panel roof in longwall coal mining. Int. J. Coal Geol. 2012, 98, 62–72. [Google Scholar] [CrossRef]

- Mehnert, B.B.; Van-Roosendaal, D.J.; Bauer, R.A.; DeMaris, P.J.; Kawamura, N. Final Report of Subsidence Investigations at the Rend Lake Site, Jefferson County, Illinois; Coop Agreement CO267001; Illinois State Geological Survey, US Department of the Interior: Quincy, IL, USA, 1994. [Google Scholar]

- Mills, C.E. Ground movement and subsidence at the United Verde mine. Trans. AIME 1934, 109, 153–172. [Google Scholar]

- Molson, J.; Aubertin, M.; Bussière, B. Reactive transport modelling of acid mine drainage within discretely fractured porous media: Plume evolution from a surface source zone. Environ. Model. Softw. 2012, 38, 259–270. [Google Scholar] [CrossRef]

- Osborn, S.G.; Vengosh, A.; Warner, N.R.; Jackson, R.B. Methane contamination of drinking water accompanying gas-well drilling and hydraulic fracturing. Proc. Natl. Acad. Sci. USA 2011, 108, 8172–8176. [Google Scholar] [CrossRef] [PubMed]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 2003, 44, 28–38. [Google Scholar]

- Palchik, V. Application of Mohr–Coulomb failure theory to very porous sandy shales. Int. J. Rock Mech. Min. Sci. 2006, 43, 1153–1162. [Google Scholar] [CrossRef]

- Panthulu, T.V.; Krishnaiah, C.; Shirke, J.M. Detection of seepage paths in earth dams using self-potential and electrical resistivity methods. Eng. Geol. 2001, 59, 281–295. [Google Scholar] [CrossRef]

- Peksezer-Sayit, A.; Cankara-Kadioglu, C.; Yazicigil, H. Assessment of dewatering requirements and their anticipated effects on groundwater resources: A case study from the Caldag Nickel Mine, Western Turkey. Mine Water. Environ. 2015, 34, 122–135. [Google Scholar] [CrossRef]

- Saloustros, S.; Pelà, L.; Cervera, M. A crack-tracking technique for localized cohesive-frictional damage. Eng. Fract. Mech. 2015, 150, 96–114. [Google Scholar] [CrossRef]

- Singh, B.K.; Dhar, B.B. Sinkhole subsidence due to mining. Geotech. Geol. Eng. 1997, 15, 327–341. [Google Scholar] [CrossRef]

- Society of Mining Engineers. Mine Subsidence; Singh, M.M., Ed.; Society of Mining Engineers, American Institute of Mining: New York, NY, USA, 1986; pp. 73–143. [Google Scholar]

- Soliman, M.M.; LaMoreaux, P.E.; Memon, B.A.; LaMoreaux, J.W.; Assaad, F.A. Environmental Hydrogeology, 2nd ed.; IWA Publishers: London, UK, 2008; pp. 81–101. [Google Scholar]

- Tammetta, B.P. Estimation of the height of complete groundwater drainage above mined longwall panels. Ground Water 2014, 52, 923–935. [Google Scholar] [CrossRef] [PubMed]

- Tammetta, B.P. Estimation of the change in hydraulic conductivity above mined longwall panels. Ground Water 2014, 53, 122–129. [Google Scholar] [CrossRef] [PubMed]

- Trevits, M.A.; Matetic, R.J. A study of the relationship between saturated zone response and longwall mining-induced ground strain. In Proceedings of the NWWA Fifth National Outdoor Action Conference on Aquifer Restoration, Ground Water Monitoring, and Geophysical Methods, Las Vegas, NV, USA, 13–16 May 1991; pp. 1101–1109. [Google Scholar]

- White, E.K.; Peterson, T.J.; Costelloe, J.; Western, A.W.; Carrara, E. Can we manage groundwater? A method to determine the quantitative testability of groundwater management plans. Water. Resour. Res. 2016, 52. [Google Scholar] [CrossRef]

- Whittaker, B.N.; Reddish, D.J. Subsidence: Occurrence, Prediction and Control: Developments in Geotechnical Engineering; Elsevier: New York, NY, USA, 1989; Volume 56, p. 528. [Google Scholar]

- Wu, J.Y.; Cervera, M. On the equivalence between traction- and stress-based approaches for the modeling of localized failure in solids. J. Mech. Phys. Solids 2015, 82, 137–163. [Google Scholar] [CrossRef]

- Wu, Q.Y.; Pang, J.W.; Qi, S.Z.; Li, Y.P.; Han, C.C.; Liu, T.X.; Huang, L.M. Impacts of coal mining subsidence on the surface landscape in Longkou city, Shandong province of China. Environ. Geol. 2009, 59, 783–791. [Google Scholar]

- Xu, D.J.; SPeng, P.; Xiang, S.Y.; Liang, M.X.; Liu, W.M. The effects of caving of a coal mine’s immediate roof on floor strata failure and water inrush, Mine. Water. Environ. 2016, 35, 337–349. [Google Scholar] [CrossRef]

- Yang, Y.K.; Kang, T.H.; Hao, X.L.; Zheng, T.B.; Wang, A. Research on in-situ purification technique of mine water in Shendong mining area. Energy Educ. Sci. Technol. 2012, 29, 209–216. [Google Scholar]

- Yang, T.H.; Liu, J.; Zhu, W.C.; Elsworth, D.; Tham, L.G.; Tang, C.A. A coupled flow-stress-damage model for groundwater outbursts from an underlying aquifer into mining excavations. Int. J. Rock Mech. Min. 2007, 44, 87–97. [Google Scholar] [CrossRef]

- Yu, S.W.; Wei, Y.M. Prediction of China’s coal production-environmental pollution based on a hybrid genetic algorithm-system dynamics model. Energy Policy 2012, 42, 521–529. [Google Scholar] [CrossRef]

- Vukelić, Ž.; Dervarič, E.; Šporin, J.; Vižintin, G. The development of dewatering predictions of the velenje coalmine. Energies 2016, 9, 702. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, D.S.; Wu, L.X.; Wang, H.Z. On-site radon detection of mining-induced fractures from overlying strata to the surface: A case study of the Baoshan coal mine in China. Energies 2014, 7, 8483–8507. [Google Scholar] [CrossRef]

- Zhang, D.S.; Fan, G.W.; Liu, Y.D.; Ma, L.Q. Field trials of aquifer protection in longwall mining of shallow coal seams in China. Int. J. Rock Mech. Min. 2010, 47, 908–914. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, D.S.; Wu, L.X.; Wang, X.F. Numerical simulation on dynamic development features of mining induced fractures in overlying strata during shallow coal seam mining. Electron. J. Geotech. Eng. 2013, 18, 5531–5543. [Google Scholar]

- Zhang, D.S.; GFan, W.; Ma, L.Q.; Wang, X.F. Aquifer protection during longwall mining of shallow coal seams: A case study in the Shendong coalfield of China. Int. J. Coal Geol. 2011, 86, 190–196. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Li, F.M. Monitoring analysis of fissure development evolution and height of overburden failure of high tension fully-mechanized caving mining, Chinese. J. Rock Mech. Eng. 2011, 30, 2994–3001. [Google Scholar]

- Zipper, C.; Balfour, W.; Roth, R.; Randolph, J. Domestic water supply impacts by underground coal mining in Virginia, USA. Environ. Geol. 1997, 29, 84–93. [Google Scholar] [CrossRef]

| Number of Caving Strata | Length of Long Side | Length of Short Side | Passageway Width | Passageway Area |

|---|---|---|---|---|

| 0 | ||||

| 1 | ||||

| 2 | ||||

| n − 2 | ||||

| n − 1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, D.; Peng, S.; Xiang, S.; He, Y. A Novel Caving Model of Overburden Strata Movement Induced by Coal Mining. Energies 2017, 10, 476. https://doi.org/10.3390/en10040476

Xu D, Peng S, Xiang S, He Y. A Novel Caving Model of Overburden Strata Movement Induced by Coal Mining. Energies. 2017; 10(4):476. https://doi.org/10.3390/en10040476

Chicago/Turabian StyleXu, Dongjing, Suping Peng, Shiyao Xiang, and Yunlan He. 2017. "A Novel Caving Model of Overburden Strata Movement Induced by Coal Mining" Energies 10, no. 4: 476. https://doi.org/10.3390/en10040476