All-Polyamide Composite Coated-Fabric as an Alternative Material of Construction for Textile-Bioreactors (TBRs)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Composite Material and Reactor Design

Characterization of the Reactor Material

2.3. Yeast Fermentation

2.4. Fungi Cultivation

2.5. Fermentation Analyses

2.6. Economic Analysis

3. Results and Discussion

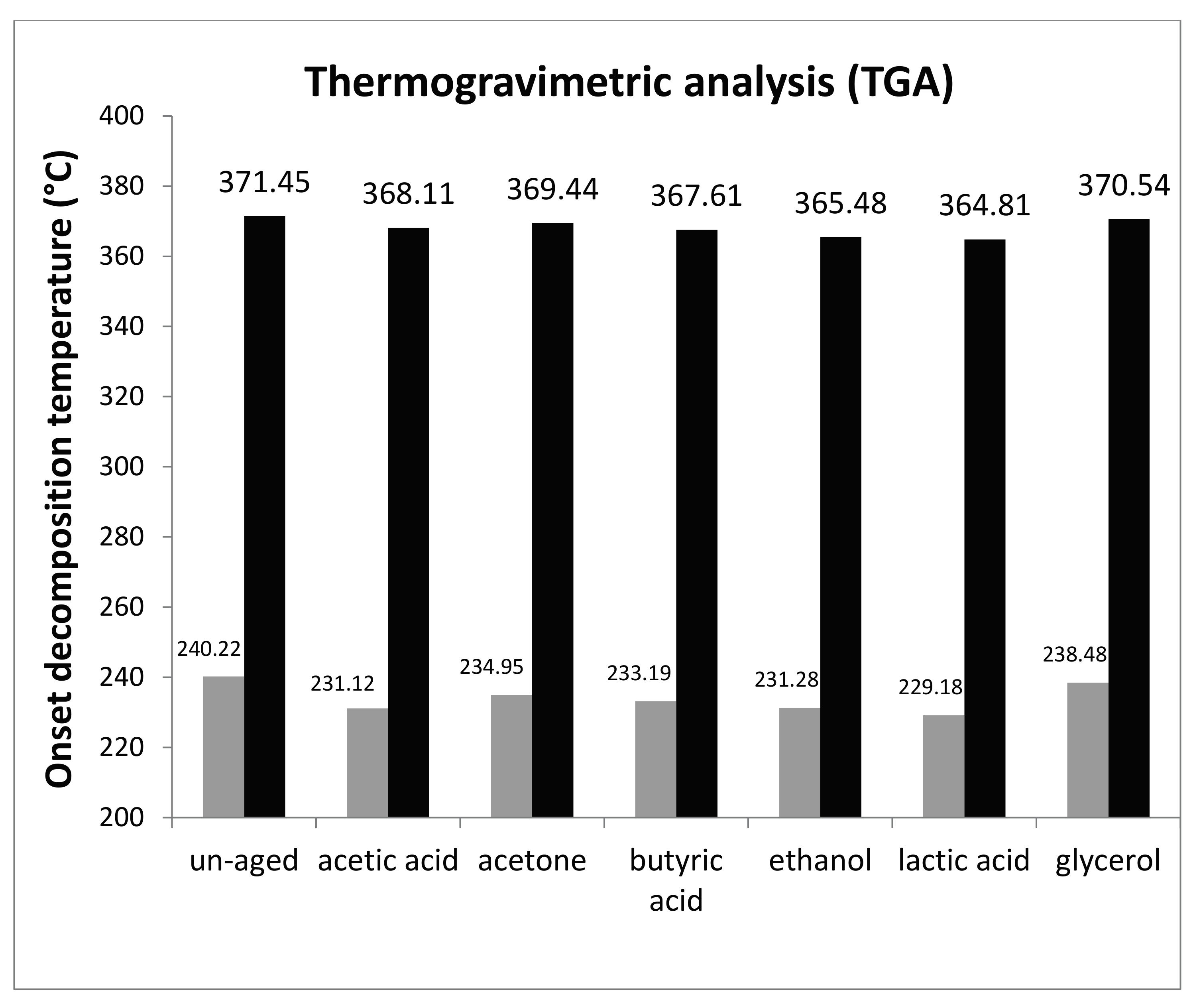

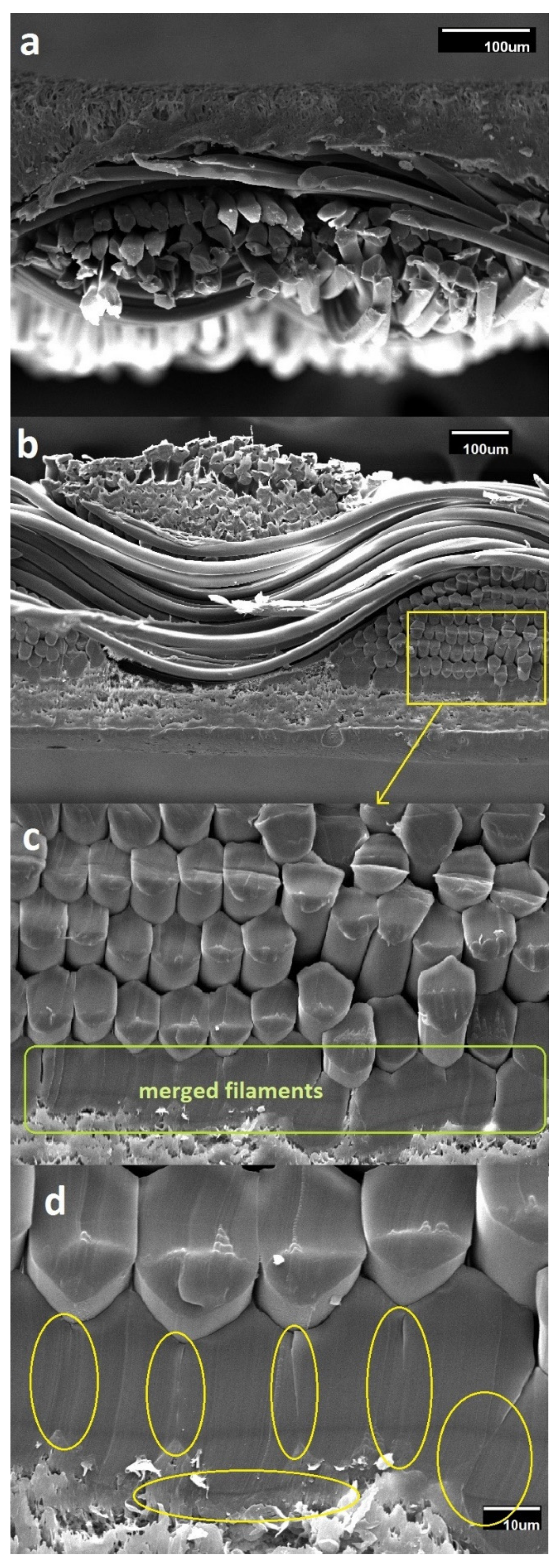

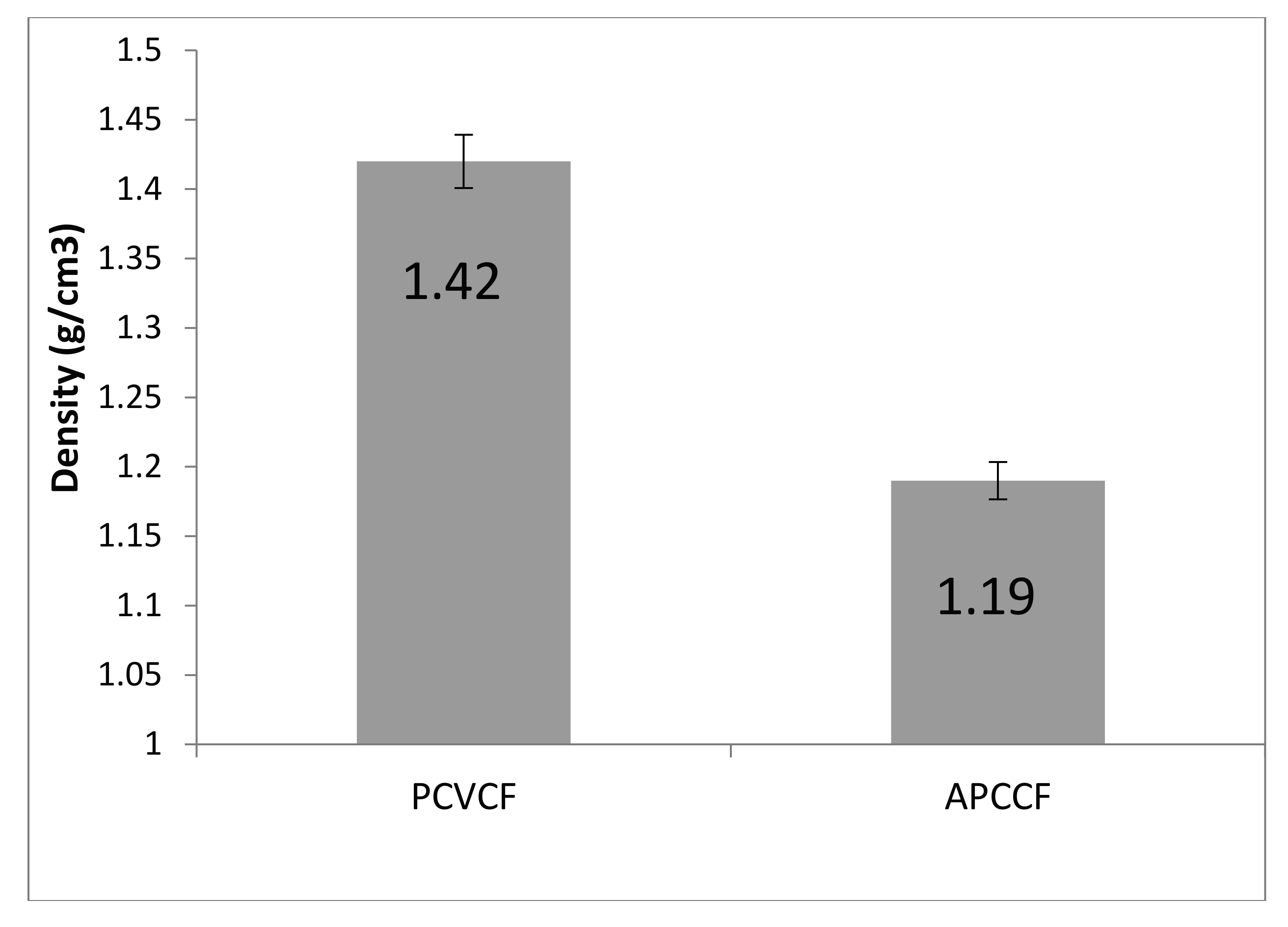

3.1. Material Development

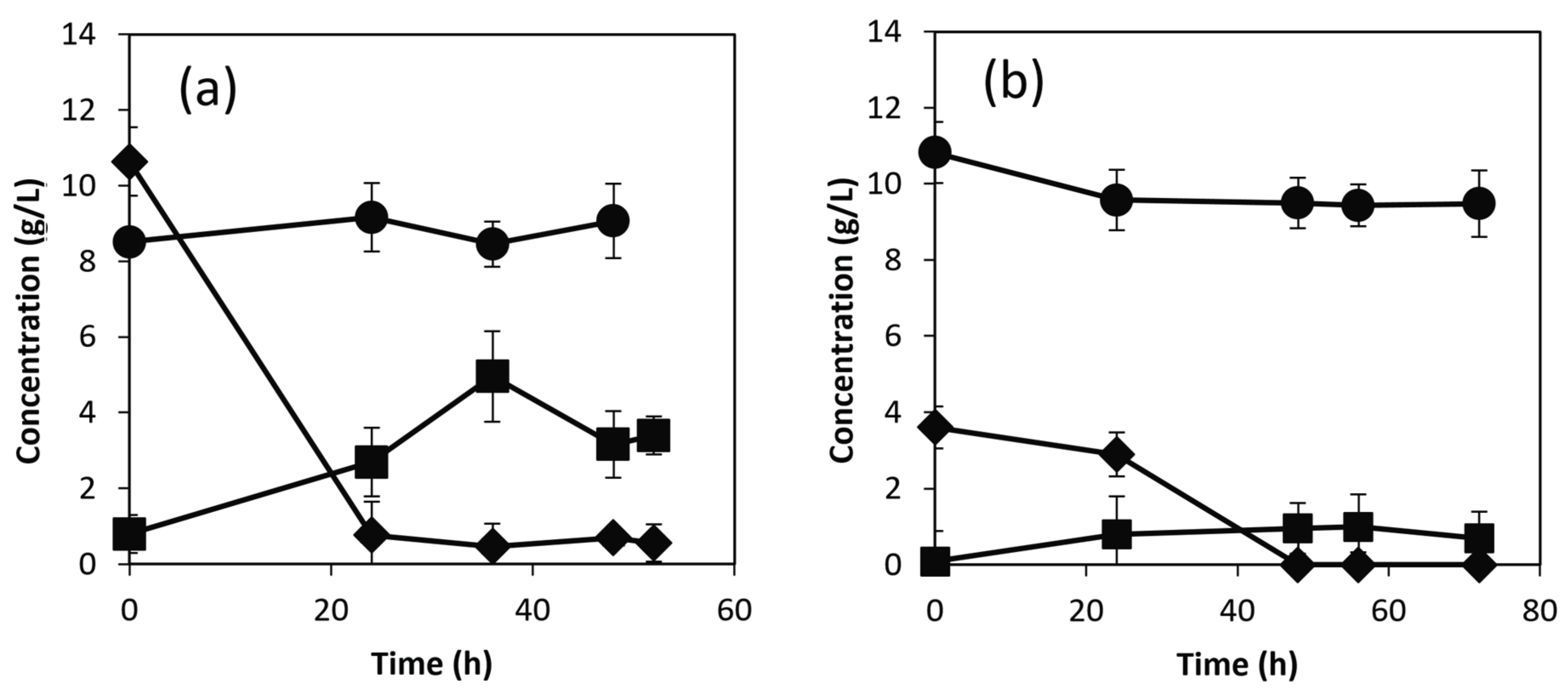

3.2. APCCF Bioreactor for Valorization of Waste-Stream from Conventional Ethanol Industries

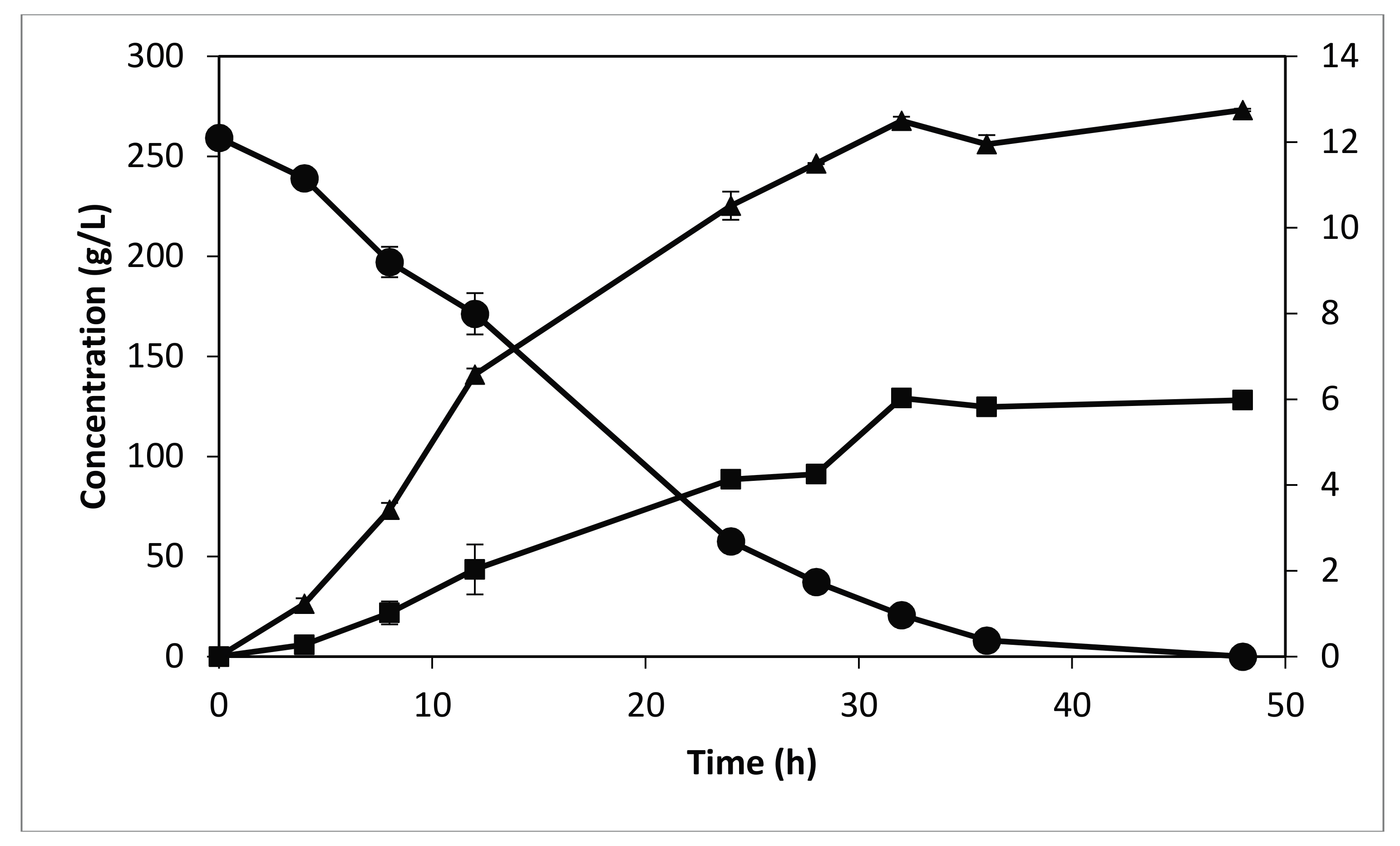

3.3. APCCF Bioreactor for Conventional Ethanol Production

3.4. Economic Evaluation and Cost Comparisons

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wilson, D.G. Energy supplies and future engines for land, sea, and air. J. Air Waste Manag. Assoc. 2012, 62, 607–624. [Google Scholar] [CrossRef] [PubMed]

- Arteconi, A.; Hewitt, N.J.; Polonara, F. Domestic demand-side management (dsm): Role of heat pumps and thermal energy storage (tes) systems. Appl. Therm. Eng. 2013, 51, 155–165. [Google Scholar] [CrossRef]

- Osadolor, O.A.; Lennartsson, P.R.; Taherzadeh, M.J. Introducing textiles as material of construction of ethanol bioreactors. Energies 2014, 7, 7555–7567. [Google Scholar] [CrossRef]

- Palacios-Bereche, R.; Ensinas, A.; Modesto, M.; Nebra, S.A. New alternatives for the fermentation process in the ethanol production from sugarcane: Extractive and low temperature fermentation. Energy 2014, 70, 595–604. [Google Scholar] [CrossRef]

- Blakebrough, N. Fundamentals of fermenter design. Pure Appl. Chem. 1973, 36, 305–316. [Google Scholar] [CrossRef]

- Osadolor, O.A.; Lundin, M.; Lennartsson, P.R.; Taherzadeh, M.J. Membrane stress analysis of collapsible tanks and bioreactors. Biochem. Eng. J. 2016, 114, 62–69. [Google Scholar] [CrossRef]

- Chernukhina, A.I.; Gabrielyan, G.A. Thermostabilization of aliphatic polyamides and fibres on their base (review). Khimicheskie Volokna 1993, 30–34. [Google Scholar]

- Jabbari, M.; Åkesson, D.; Skrifvars, M.; Taherzadeh, M.J. Novel lightweight and highly thermally insulative silica aerogel-doped poly(vinyl chloride)-coated-fabric composite. J. Reinf. Plast. Compos. 2015, 34. [Google Scholar] [CrossRef]

- Jabbari, M.; Skrifvars, M.; Åkesson, D.; Taherzadeh, M.J. Introducing all-polyamide composite coated-fabrics: A method to produce fully recyclable single-polymer composite coated-fabrics. J. Appl. Polym. Sci. 2016, 133, 42829. [Google Scholar] [CrossRef]

- Angelov, R.R.; Georgieva, B.C.; Karashanova, D.B. Films of recycled polyethylene terephthalate, obtained by electrospraying, for paper and textile impregnation. Bulg. Chem. Commun. 2016, 48, 156–160. [Google Scholar]

- Riley, K.; Williams, J.; Waldron, D. End of life opportunities for textiles in the UK healthcare sector. J. Fiber Bioeng. Inform. 2009, 709–717. [Google Scholar]

- Sommers, J.; Kho, H.S.; Al-Ghamedi, R.; Low, I.M.; Davies, I.J.; Latella, B.A. Mechanical and physical properties of recycled cellulose fibre-reinforced epoxy eco-composites. Adv. Mater. Res. 2008, 41–42, 317–322. [Google Scholar] [CrossRef]

- Low, I.M.; Somers, J.; Kho, H.S.; Davies, I.J.; Latella, B.A. Fabrication and properties of recycled cellulose fibre-reinforced epoxy composites. Compos. Interfaces 2009, 16, 659–669. [Google Scholar] [CrossRef]

- Ferreira, J.A.; Lennartsson, P.R.; Taherzadeh, M.J. Production of ethanol and biomass from thin stillage by neurospora intermedia: A pilot study for process diversification. Eng. Life Sci. 2015, 15, 751–759. [Google Scholar] [CrossRef]

- Couper, J.R.; Penney, W.R.; Fair, J.R.; Walas, S.M. Costs of individual equipment. In Chemical Process Equipment; Elsevier Inc.: Amsterdam, The Netherlands, 2005; pp. 663–669. [Google Scholar]

- Mignard, D. Correlating the chemical engineering plant cost index with macro-economic indicators. Chem. Eng. Res. Des. 2014, 92, 285–294. [Google Scholar] [CrossRef]

- Bergeron, P. Bioethanol market forces. In Handbook on Bioethanol: Production and Utilization; Wyman, C., Ed.; CRC Press: Boca Raton, FL, USA, 1996; pp. 61–88. [Google Scholar]

- Vinken, E.; Terry, A.E.; Spoelstra, A.B.; Koning, C.E.; Rastogi, S. Influence of superheated water on the hydrogen bonding and crystallography of piperazine-based (co)polyamides. Langmuir 2009, 25, 5294–5303. [Google Scholar] [CrossRef] [PubMed]

- Behler, K.; Havel, M.; Mattia, D.; Gogotsi, Y. Self-assembled multi-walled carbon nanotube coatings. In Proceedings of the Materials Research Society (MRS) Fall Meeting, Boston, MA, USA, 1–5 December 2008; pp. 133–138. [Google Scholar]

- Sathitsuksanoh, N.; George, A.; Zhang, Y.H.P. New lignocellulose pretreatments using cellulose solvents: A review. J. Chem. Technol. Biotechnol. 2013, 88, 169–180. [Google Scholar] [CrossRef]

- Chen, F.; Chang, W.V. Applicability study of a new acid-base interaction-model in polypeptides and polyamides. Langmuir 1991, 7, 2401–2404. [Google Scholar] [CrossRef]

- Carey, F.A.; Sundberg, R.J. Advanced Organic Chemistry; Springer Science & Business Media: Berlin, Germany, 2000. [Google Scholar]

- Herrero, M.; Tiemblo, P.; Reyes-Labarta, J.; Mijangos, C.; Reinecke, H. PVC modification with new functional groups. Influence of hydrogen bonds on reactivity, stiffness and specific volume. Polymer 2002, 43, 2631–2636. [Google Scholar] [CrossRef]

- Bao, Y.; Weng, Z.; Huang, Z.; Pan, Z. The crystallinity of pvc and its effect on physical properties. Int. Polym. Process. 1996, 11, 369–372. [Google Scholar] [CrossRef]

- Gilbert, M. Importance of crystallinity in pvc. Prog. Rubber Plast. Technol. 1993, 9, 143–158. [Google Scholar]

- Rathi, S.; Dahiya, J.B. Effect on thermal behaviour of polyamide 66/clay nanocomposites with inorganic flame retardant additives. Indian J. Chem. A 2012, 51, 1677–1685. [Google Scholar]

- Buckley, R.W. Polymer Enhancement of Technical Textiles; iSmithers Rapra Publishing: Akron, OH, USA, 2003. [Google Scholar]

- Sargent, J.G.; Lee, J.S.; Reynaud, E.; Gilbert, M.D.; Sloan, J.M. Study of selectively permeable coatings to textiles. In Proceedings of the 2010 Materials Research Society (MRS) Fall Meeting, Boston, MA, USA, 29 November–2 December 2011; pp. 497–502. [Google Scholar]

- Rohwerder, M.; Stratmann, M. From molecular aspects of delamination to new polymeric coating. Macromol. Symp. 2002, 187, 35–42. [Google Scholar] [CrossRef]

- Lodi, P.C.; De Souza Bueno, B.; Vilar, O.M. The effects of weathering exposure on the physical, mechanical, and thermal properties of high-density polyethylene and poly (vinyl chloride). Mater. Res. 2013, 16, 1331–1335. [Google Scholar] [CrossRef]

- Basso, L.C.; Basso, T.O.; Rocha, S.N. Ethanol production in brazil: The industrial process and its impact on yeast fermentation. Biofuel Prod. Recent Dev. Prospects 2011, 86–100. [Google Scholar]

- Rajoka, M.I.; Ferhan, M.; Khalid, A.M. Kinetics and thermodynamics of ethanol production by a thermotolerant mutant of saccharomyces cerevisiae in a microprocessor-controlled bioreactor. Lett. Appl. Microbiol. 2005, 40, 316–321. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, K.; Aslanzadeh, S.; Johansson, F.; Taherzadeh, M.J. Experimental and economical evaluation of a novel biogas digester. Energy Convers. Manag. 2013, 74, 183–191. [Google Scholar] [CrossRef]

| Medium | PVCCF | ∆ (%) | APCCF | ∆ (%) |

|---|---|---|---|---|

| un-aged | 57.2 ± 2.19 | n.d. | 68.6 ± 1.77 * | n.d. |

| acetic acid | 49.8 ± 1.71 | 12.9 | 63.2 ± 1.21 | 7.9 |

| acetone | 52.5 ± 2.3 | 8.2 | 67.3 ± 1.9 | 1.9 |

| butyric acid | 53.1 ± 1.8 | 7.2 | 65.7 ± 1.61 | 4.2 |

| ethanol | 55.3 ± 1.6 | 3.3 | 67.4 ± 1.2 | 1.7 |

| lactic acid | 51.2 ± 1.4 | 10.5 | 63.1 ± 2.1 | 8.0 |

| glycerol | 55.1 ± 1.7 | 3.7 | 68.1 ± 1.4 | 0.7 |

| Reactor Size (m3) | Purchase Cost of Developed TBR ($) | Purchase Cost of 304 SSBR ($) |

|---|---|---|

| 100 | 25,000 | 108,000 |

| 200 | 35,000 | 137,000 |

| 300 | 45,000 | 160,000 |

| 400 | 58,000 | 181,000 |

| 500 | 66,000 | 200,000 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jabbari, M.; Osadolor, O.A.; Nair, R.B.; Taherzadeh, M.J. All-Polyamide Composite Coated-Fabric as an Alternative Material of Construction for Textile-Bioreactors (TBRs). Energies 2017, 10, 1928. https://doi.org/10.3390/en10111928

Jabbari M, Osadolor OA, Nair RB, Taherzadeh MJ. All-Polyamide Composite Coated-Fabric as an Alternative Material of Construction for Textile-Bioreactors (TBRs). Energies. 2017; 10(11):1928. https://doi.org/10.3390/en10111928

Chicago/Turabian StyleJabbari, Mostafa, Osagie A. Osadolor, Ramkumar B. Nair, and Mohammad J. Taherzadeh. 2017. "All-Polyamide Composite Coated-Fabric as an Alternative Material of Construction for Textile-Bioreactors (TBRs)" Energies 10, no. 11: 1928. https://doi.org/10.3390/en10111928