An Improved Optimization Function for Maximizing User Comfort with Minimum Energy Consumption in Smart Homes

Abstract

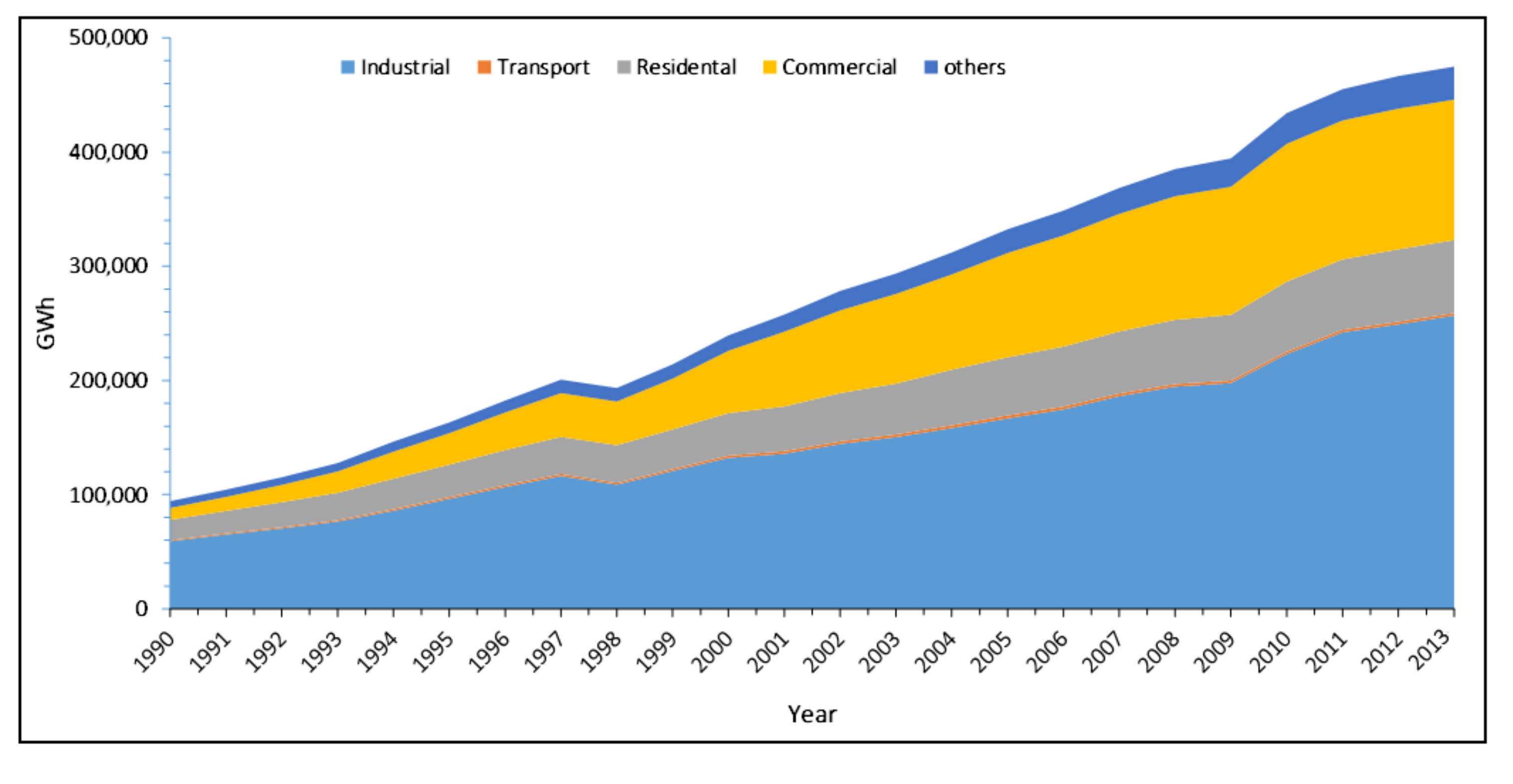

:1. Introduction

2. Related Work

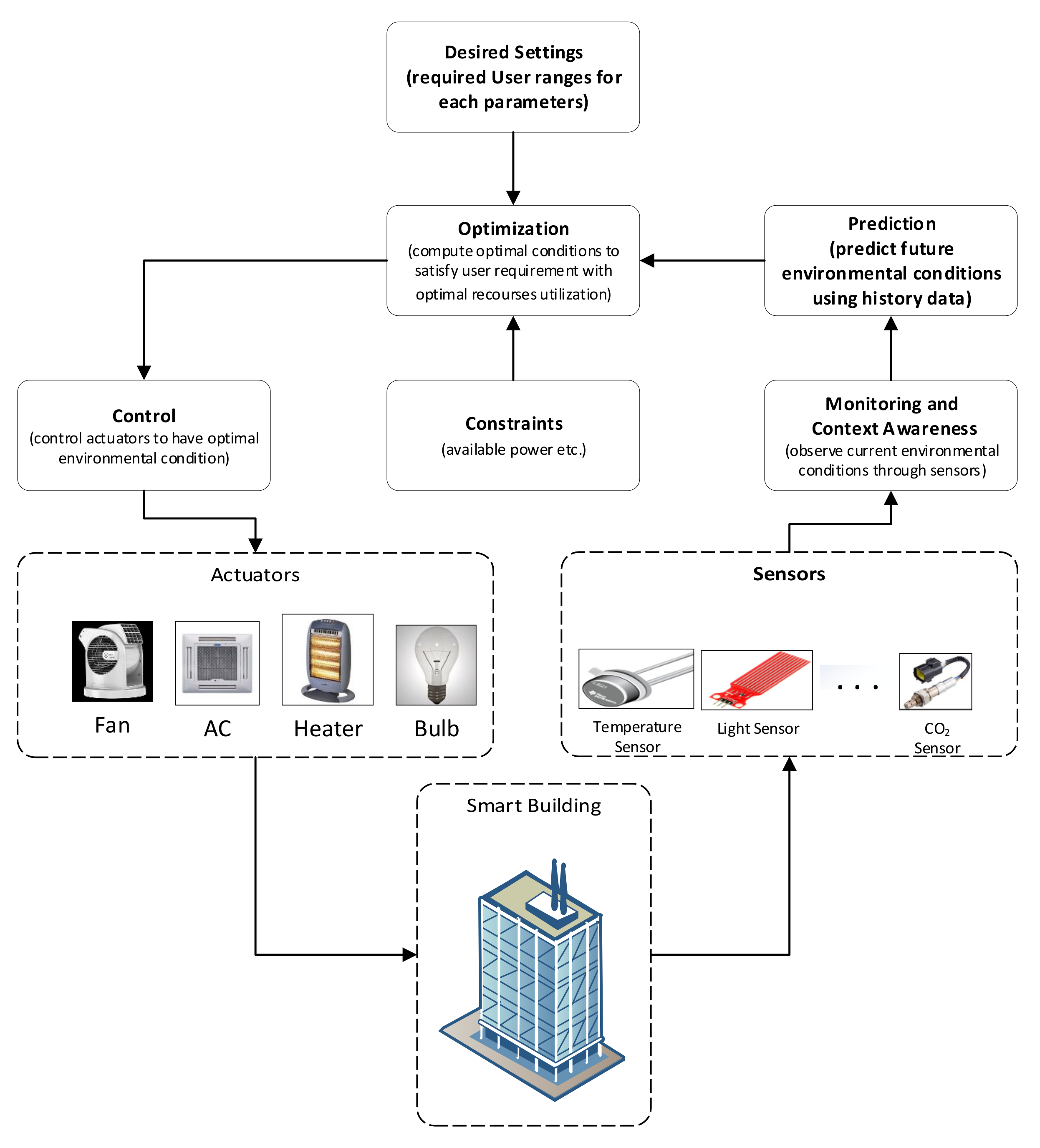

3. Proposed Conceptual Design for the Smart Energy Management System

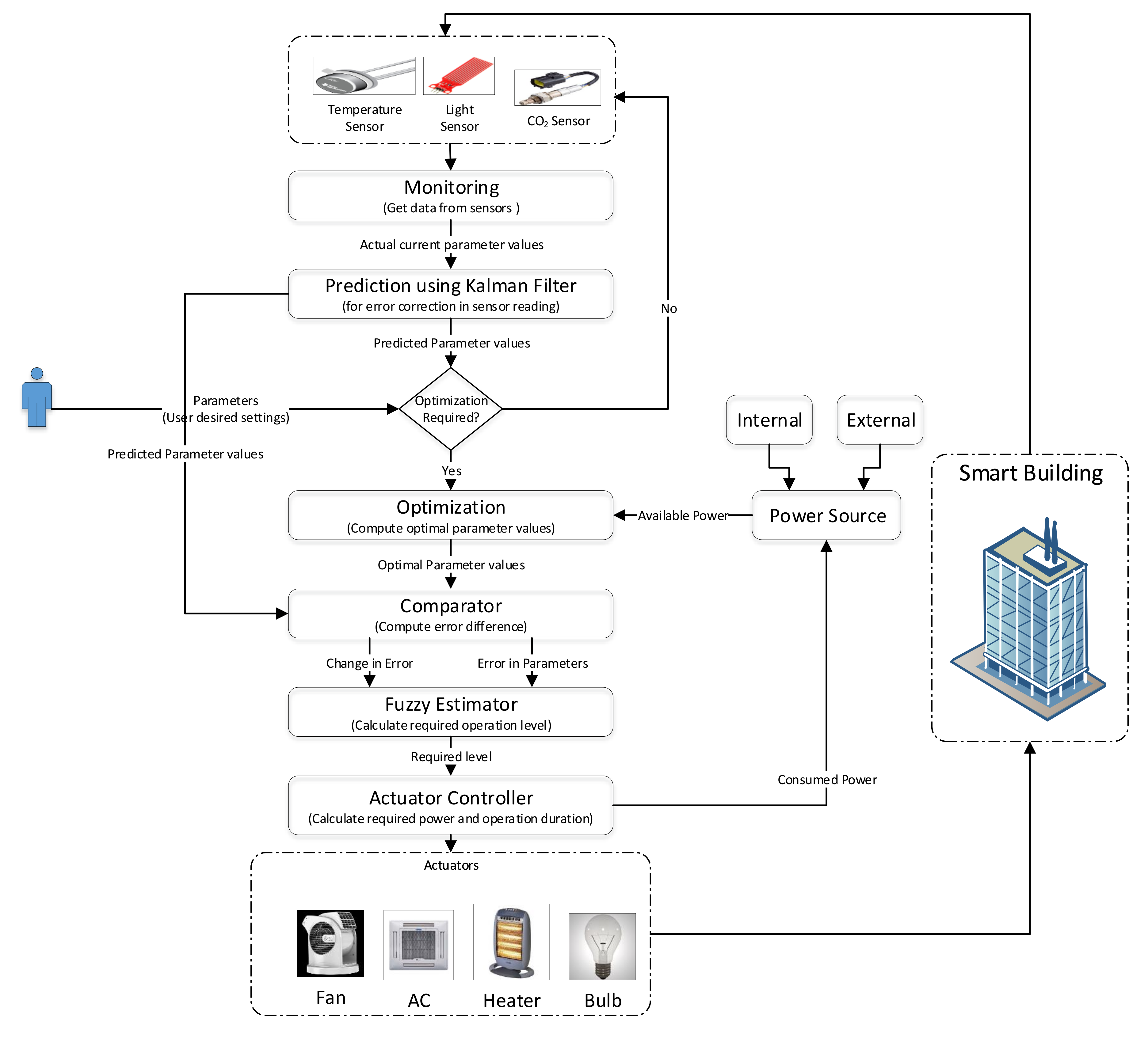

4. Problem Formulation for Optimization

5. Experimental Results and Discussion

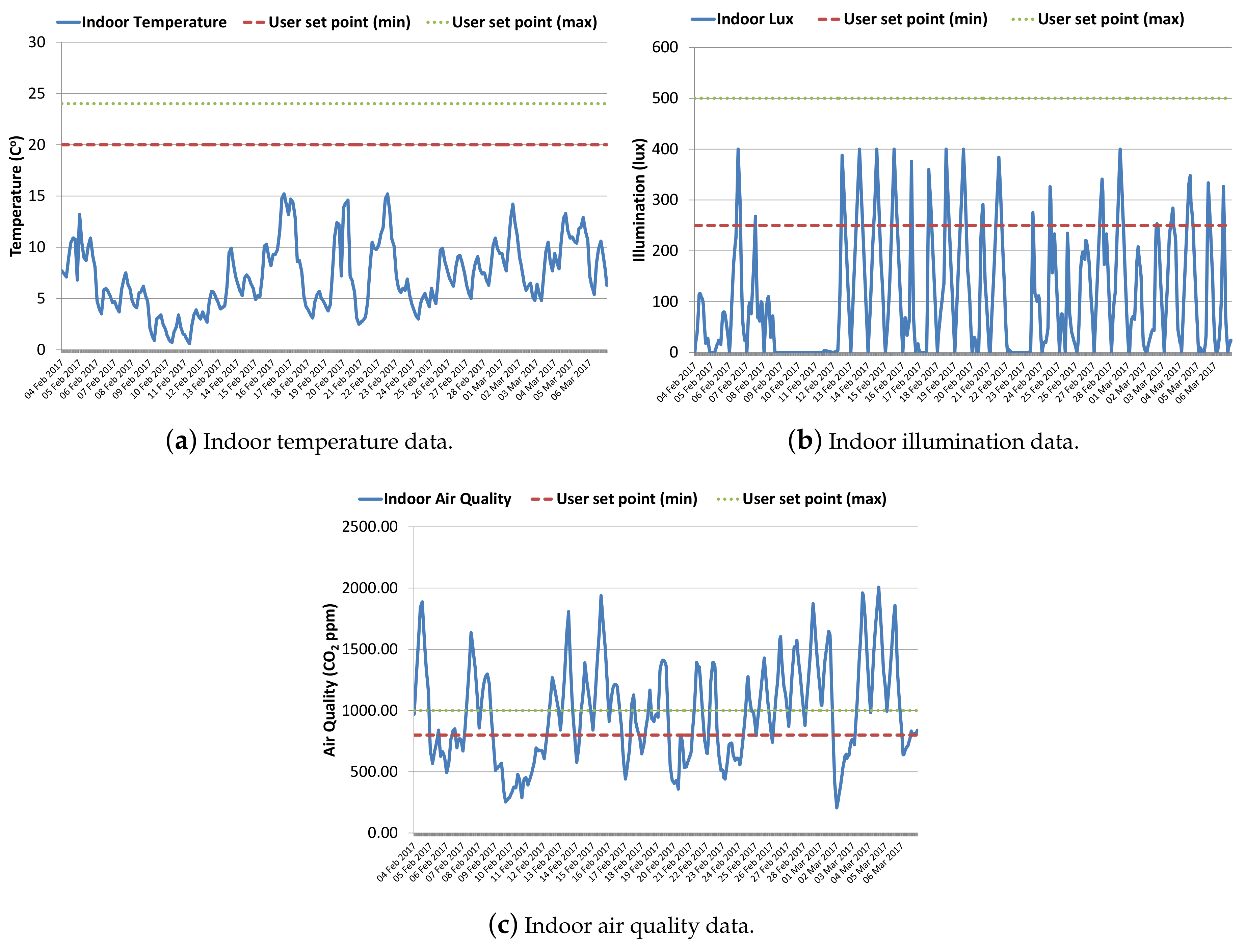

5.1. Experimental Setup

5.2. Implementation

5.2.1. Genetic Algorithm

- Initial random population of size S

- Calculate the fitness of each individual using Equation (13)

- Choose T best individuals

- Perform single-point crossover with probability among selected individuals to generate new solutions (offspring)

- Perform mutation with rate

- Calculate the fitness of new offspring using Equation (13)

- Combine the populations of Steps (3) and (5)

- Goto Step 2 until the required number of iterations

- Return the best fitted chromosome as the optimal solution

5.2.2. Particle Swarm Optimization

- Initialize

- Randomly initialize particle positions

- Randomly initialize particle velocities

- Optimize

- Calculate the fitness of each particle using Equation (13)

- Find the global and local best particle

- If the stopping condition is satisfied, then go to Step 3

- Update each particle velocity and position vector using the global and local best particles

- Go to Step 2

- Return the best particle as the solution

5.2.3. No-Optimization Scheme

5.3. Proposed System Results Analysis

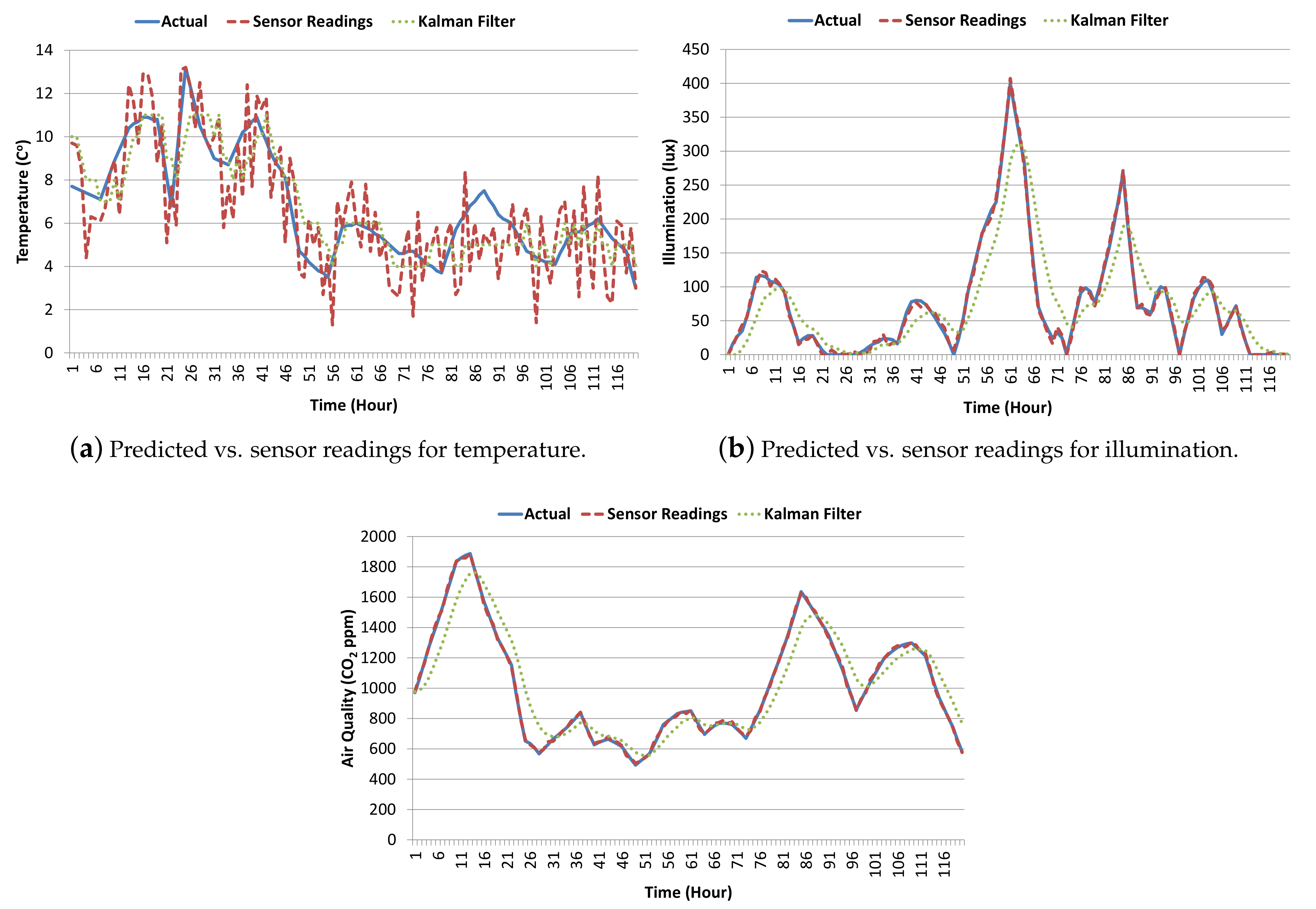

5.3.1. Analysis of the Prediction Part Based on the Kalman Filter

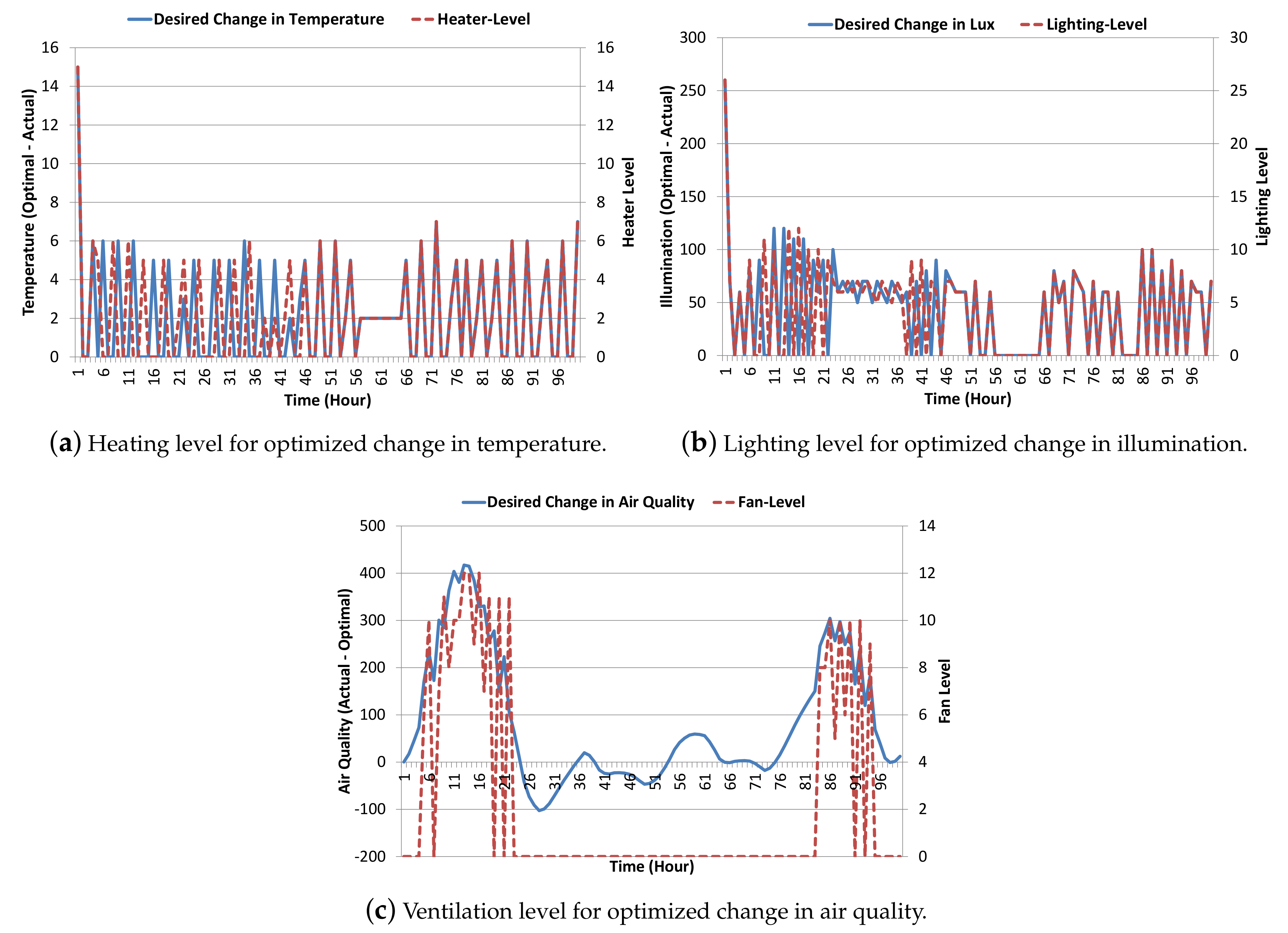

5.3.2. Analysis of the Optimization Part

5.3.3. Analysis of the Actuators’ Operations

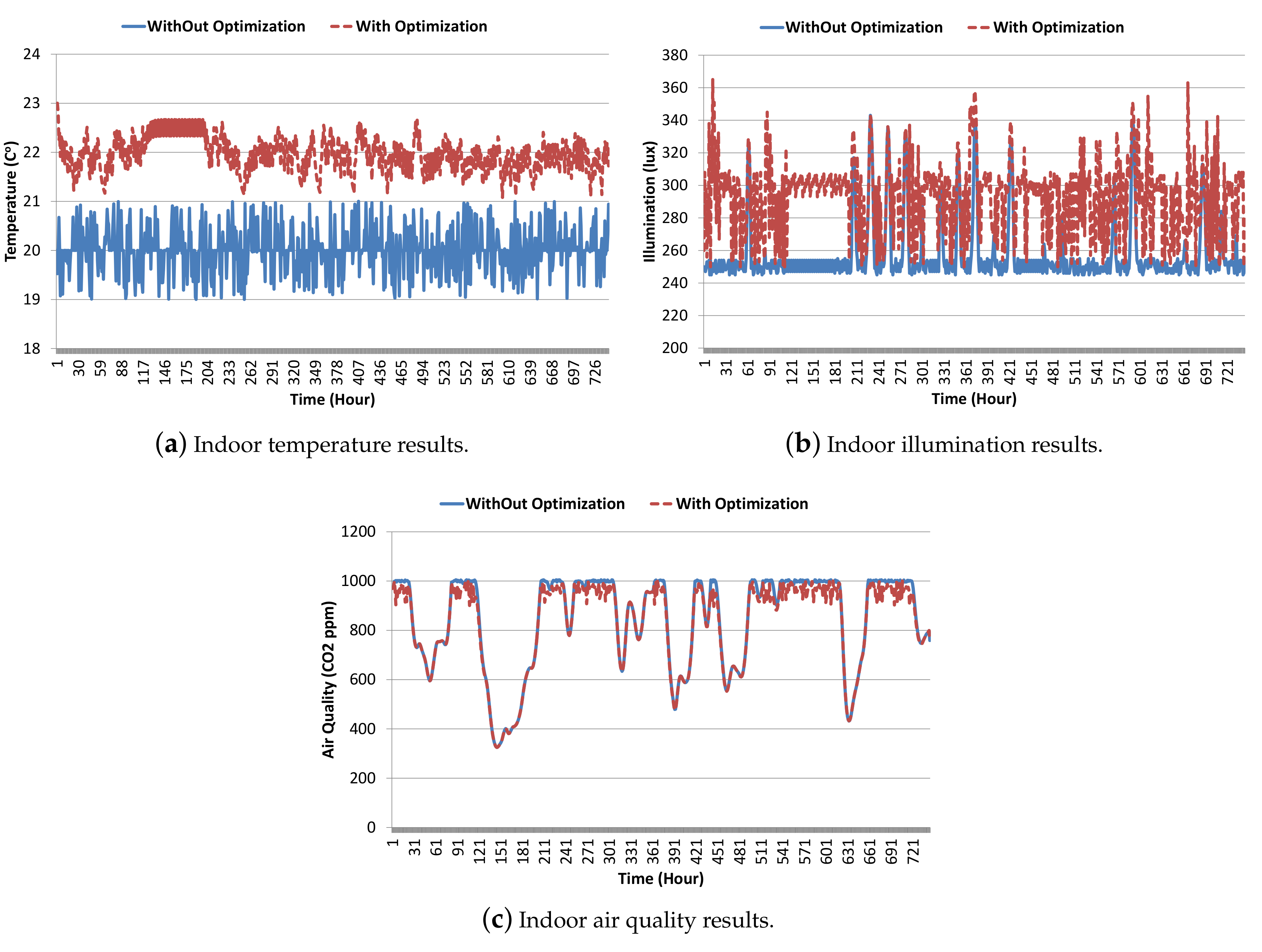

5.4. Comparative Analysis

6. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Modifications of the Equations for the Cooling Case

- Case 1: When the current temperature is below the user-desired range, then heating will be required. The formulation for this scenario is covered in the paper’s main text. The constraint given in Expression (14) covers this case.

- Case 2: When the current temperature is above the user-desired range, then cooling will be required. The formulation for this scenario will require minor adjustments in certain equations, which are given here.If , then cooling will be required, and we need to choose at optimal temperature through optimization where . The equation for total required energy for maintaining settings with optimal parameters will change as below:Above is the total required power for maintaining optimal settings where cooling is required for temperature. Similarly, calculations for possible minimum and maximum power consumption in this case will also change as below:The equation for the computation of user comfort gain will also change as below:The constraint for the second case is given below:Note: when the current temperature is inside the desired user range, i.e., , then no optimization is required for temperature.

References

- Kim, S.; Kim, S. A multi-criteria approach toward discovering killer IoT application in Korea. Technol. Forecast. Soc. Chang. 2016, 102, 143–155. [Google Scholar] [CrossRef]

- Korea Energy Statistical Information System. Available online: http://www.kesis.net/main/mainEng.jsp (accessed on 9 October 2017).

- Dounis, A.I.; Caraiscos, C. Advanced control systems engineering for energy and comfort management in a building environment—A review. Renew. Sustain. Energy Rev. 2009, 13, 1246–1261. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, R.; Wang, L. Multi-agent control system with intelligent optimization for smart and energy-efficient buildings. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 Novomber 2010; pp. 1144–1149. [Google Scholar]

- Emmerich, S.J.; Persily, A.K. State-of-the-Art Review of CO2 Demand Controlled Ventilation Technology and Application; Diane Publishing: Collingdale, PA, USA, 2003. [Google Scholar]

- Ali, S.; Kim, D. Optimized power control and comfort management in building environment. In Proceedings of the 2013 FTRA International Conference on Advanced IT, engineering and Management (FTRA AIM-13), Seoul, Korea, 21–23 Febuary 2013; pp. 145–146. [Google Scholar]

- Ali, S.; Kim, D.H. Effective and comfortable power control model using Kalman filter for building energy management. Wirel. Pers. Commun. 2013, 73, 1439–1453. [Google Scholar] [CrossRef]

- Levermore, G.J. Building Energy Management Systems: Applications to Low-Energy HVAC and Natural Ventilation Control; Taylor & Francis: Abingdon, UK, 2000. [Google Scholar]

- Benard, C.; Guerrier, B.; Rosset-Louerat, M. Optimal building energy management: Part 2—Control. J. Sol. Energy Eng. 1992, 114, 13–22. [Google Scholar] [CrossRef]

- Curtiss, P.S.; Kreider, J.; Shavit, G. Neural Networks Applied to Buildings—A Tutorial and Case Studies in Prediction and Adaptive Control; Technical Report; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 1996. [Google Scholar]

- Tang, K.S.; Man, K.F.; Chen, G.; Kwong, S. An optimal fuzzy PID controller. IEEE Trans. Ind. Electr. 2001, 48, 757–765. [Google Scholar] [CrossRef]

- Kolokotsa, D.; Stavrakakis, G.; Kalaitzakis, K.; Agoris, D. Genetic algorithms optimized fuzzy controller for the indoor environmental management in buildings implemented using PLC and local operating networks. Eng. Appl. Artif. Intell. 2002, 15, 417–428. [Google Scholar] [CrossRef]

- Kusiak, A.; Li, M.; Zhang, Z. A data-driven approach for steam load prediction in buildings. Appl. Energy 2010, 87, 925–933. [Google Scholar] [CrossRef]

- Širokỳ, J.; Oldewurtel, F.; Cigler, J.; Prívara, S. Experimental analysis of model predictive control for an energy efficient building heating system. Appl. Energy 2011, 88, 3079–3087. [Google Scholar] [CrossRef]

- Lin, B.; Li, S.; Xiao, Y. Optimal and learning-based demand response mechanism for electric water heater system. Energies 2017, 10, 1722. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Dounis, A.I.; Yang, R. Multi-agent control system with information fusion based comfort model for smart buildings. Appl. Energy 2012, 99, 247–254. [Google Scholar] [CrossRef]

- Edwards, R.E.; New, J.; Parker, L.E. Predicting future hourly residential electrical consumption: A machine learning case study. Energy Build. 2012, 49, 591–603. [Google Scholar] [CrossRef]

- Winkelmann, F.; Birdsall, B.; Buhl, W.; Ellington, K.; Erdem, A.; Hirsch, J.; Gates, S. DOE-2 Supplement: Version 2.1E; Technical Report; Lawrence Berkeley Lab.: Berkeley, CA, USA; Hirsch (James J.) and Associates: Camarillo, CA, USA, 1993. [Google Scholar]

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.F.; Huang, Y.J.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J.; et al. EnergyPlus: Creating a new-generation building energy simulation program. Energy Build. 2001, 33, 319–331. [Google Scholar] [CrossRef]

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef] [Green Version]

- Karatasou, S.; Santamouris, M.; Geros, V. Modeling and predicting building’s energy use with artificial neural networks: Methods and results. Energy Build. 2006, 38, 949–958. [Google Scholar] [CrossRef]

- Li, K.; Su, H.; Chu, J. Forecasting building energy consumption using neural networks and hybrid neuro-fuzzy system: A comparative study. Energy Build. 2011, 43, 2893–2899. [Google Scholar] [CrossRef]

- Bluyssen, P.M.; Aries, M.; van Dommelen, P. Comfort of workers in office buildings: The European HOPE project. Build. Environ. 2011, 46, 280–288. [Google Scholar] [CrossRef]

- Marino, C.; Nucara, A.; Pietrafesa, M. Proposal of comfort classification indexes suitable for both single environments and whole buildings. Build. Environ. 2012, 57, 58–67. [Google Scholar] [CrossRef]

- Yumurtaci, R. Role of energy management in hybrid renewable energy systems: Case study-based analysis considering varying seasonal conditions. Turk. J. Electr. Eng. Comput. Sci. 2013, 21, 1077–1091. [Google Scholar] [CrossRef]

- Wright, J.A.; Loosemore, H.A.; Farmani, R. Optimization of building thermal design and control by multi-criterion genetic algorithm. Energy Build. 2002, 34, 959–972. [Google Scholar] [CrossRef]

- Abido, M. Optimal design of power-system stabilizers using particle swarm optimization. IEEE Trans. Energy Convers. 2002, 17, 406–413. [Google Scholar] [CrossRef]

- Huang, W.; Lam, H. Using genetic algorithms to optimize controller parameters for HVAC systems. Energy Build. 1997, 26, 277–282. [Google Scholar] [CrossRef]

- Obara, S.; Kudo, K. Multiple-purpose operational planning of fuel cell and heat pump compound system using genetic algorithm. Trans. Soc. Heat. Air Cond. Sanit. Eng. Japan 2003, 65–76. [Google Scholar]

- Li, H.; Nalim, R.; Haldi, P.A. Thermal-economic optimization of a distributed multi-generation energy system—A case study of Beijing. Appl. Therm. Eng. 2006, 26, 709–719. [Google Scholar] [CrossRef]

- Ferdyn-Grygierek, J.; Grygierek, K. Multi-variable optimization of building thermal design using genetic algorithms. Energies 2017, 10, 1570. [Google Scholar] [CrossRef]

- Delgarm, N.; Sajadi, B.; Kowsary, F.; Delgarm, S. Multi-objective optimization of the building energy performance: A simulation-based approach by means of particle swarm optimization (PSO). Appl. Energy 2016, 170, 293–303. [Google Scholar] [CrossRef]

- Hakimi, S.; Tafreshi, S.M.; Kashefi, A. Unit sizing of a stand-alone hybrid power system using particle swarm optimization (PSO). In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; pp. 3107–3112. [Google Scholar]

- Shaikh, P.H.; Nor, N.B.M.; Nallagownden, P.; Elamvazuthi, I.; Ibrahim, T. A review on optimized control systems for building energy and comfort management of smart sustainable buildings. Renew. Sustain. Energy Rev. 2014, 34, 409–429. [Google Scholar] [CrossRef]

- United States Department of Labor. Safety and health regulations for construction. In 29 Code of Federal Regulation, Part 1926; Occupational Safety and Health Administration, United States Department of Labor: Washington, DC, USA, 2003. [Google Scholar]

- ASHRAE. Standard 62.1—2016 Ventilation for Acceptable Indoor Air Quality; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2016. [Google Scholar]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Kennedy, J.; Eberhart, R.C. Particle swarm optimization. In Proceedings of the IEEE International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995. [Google Scholar]

| Notation | Description |

|---|---|

| Current temperature (°C). | |

| Current illumination (lux). | |

| Current air quality (ppm). | |

| Optimal temperature (°C). | |

| Optimal illumination (lux). | |

| Optimal air quality (ppm). | |

| Desired user set points. | |

| User-desired temperature range. | |

| User-desired illumination range. | |

| User-desired air quality range. | |

| Required power for per unit change in temperature (kWh). | |

| Required power for per unit level change in illumination (kWh). | |

| Required power for per unit level change in air quality (kWh). | |

| Required energy for optimal change in indoor parameters (kWh). | |

| Gain in user comfort. | |

| Gain in energy savings. | |

| User preference for comfort and energy savings. | |

| User preference for temperature, illumination and air quality. |

| Parameter | Max | Min | Avg. | User Set Points |

|---|---|---|---|---|

| Temperature | 15.20 | 0.60 | 7.19 | [20, 24] |

| Illumination | 400.00 | 0.00 | 108.33 | [250, 500] |

| Air Quality | 2007.27 | 205.91 | 982.19 | [800, 1000] |

| Parameter | Values/Range |

|---|---|

| Process noise covariance matrix (Q) | 1 |

| Sensing noise covariance matrix (R) | 10 |

| Error in temperature sensor reading | ±3 |

| Error in illumination sensor reading | ±10 |

| Error in CO sensor reading | ±20 |

| Parameter | Values/Range |

|---|---|

| 0.5 | |

| 0.5 | |

| 0.4 | |

| 0.3 | |

| 0.3 | |

| 5 | |

| 1 | |

| 1 |

| Optimization Scheme | User Comfort Index (avg.) | Total Power Consumption (kWh) |

|---|---|---|

| No-optimization scheme | 0.87 | 15,969 |

| Particle Swarm Optimization (PSO) | 0.967 | 12,130 |

| Genetic Algorithm (GA) | 0.964 | 11,632 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, I.; Kim, D. An Improved Optimization Function for Maximizing User Comfort with Minimum Energy Consumption in Smart Homes. Energies 2017, 10, 1818. https://doi.org/10.3390/en10111818

Ullah I, Kim D. An Improved Optimization Function for Maximizing User Comfort with Minimum Energy Consumption in Smart Homes. Energies. 2017; 10(11):1818. https://doi.org/10.3390/en10111818

Chicago/Turabian StyleUllah, Israr, and DoHyeun Kim. 2017. "An Improved Optimization Function for Maximizing User Comfort with Minimum Energy Consumption in Smart Homes" Energies 10, no. 11: 1818. https://doi.org/10.3390/en10111818