A Real-Time Digital Solver for Smart Substation Based on Orders

Abstract

:1. Introduction

- (1)

- The equivalent model of the inlet-outlet line unit is established, which can reduce the scale of the substation real-time simulation and improve the simulation speed by pre-storing the equivalent conductivity and voltage coefficients.

- (2)

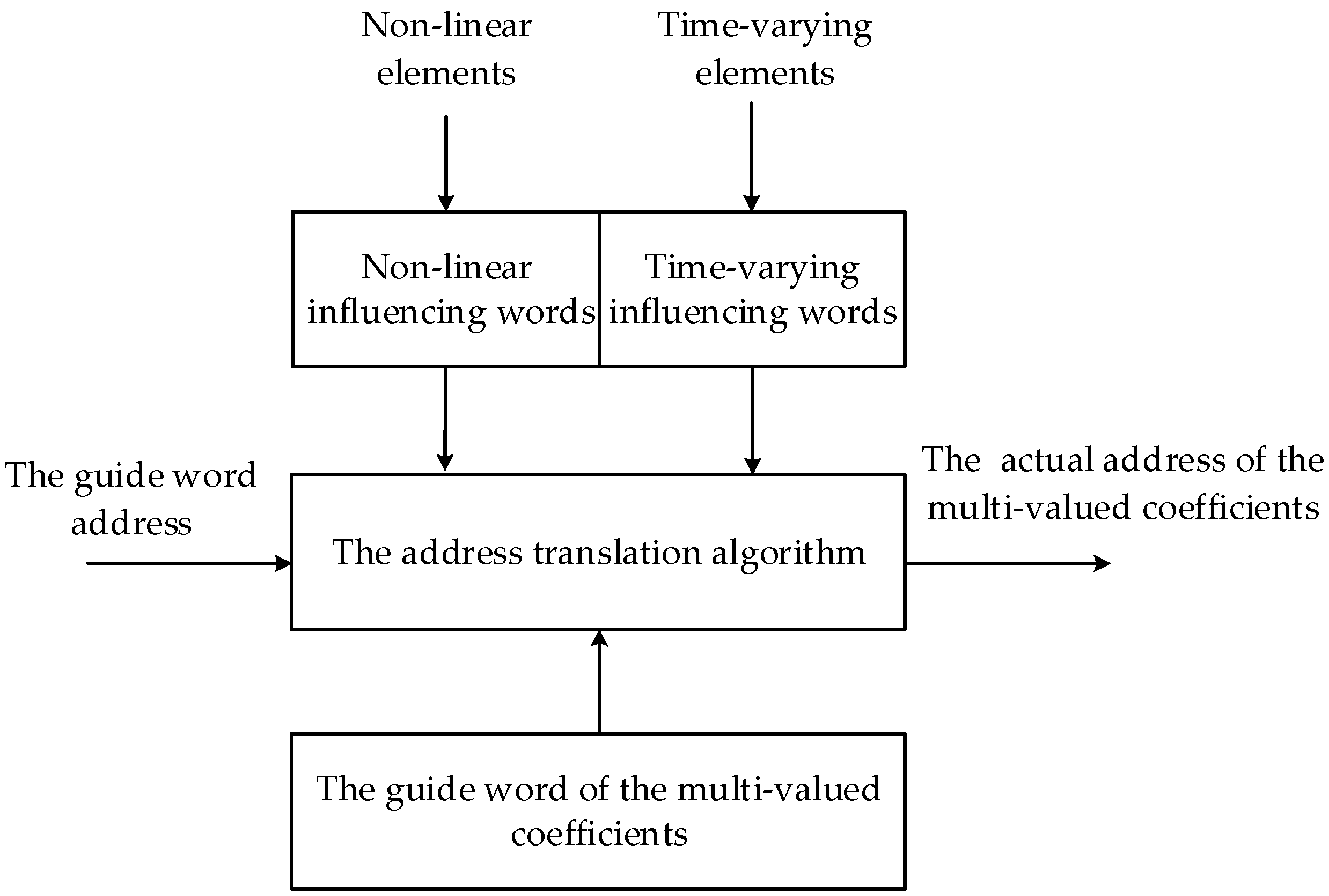

- The special address query circuit of the multivalued coefficients is designed, which associates the address transformation algorithm with the multivalued coefficients guide word. This addressing process is completed in the orders, which is independent of the simulation calculation, with a good scalability.

- (3)

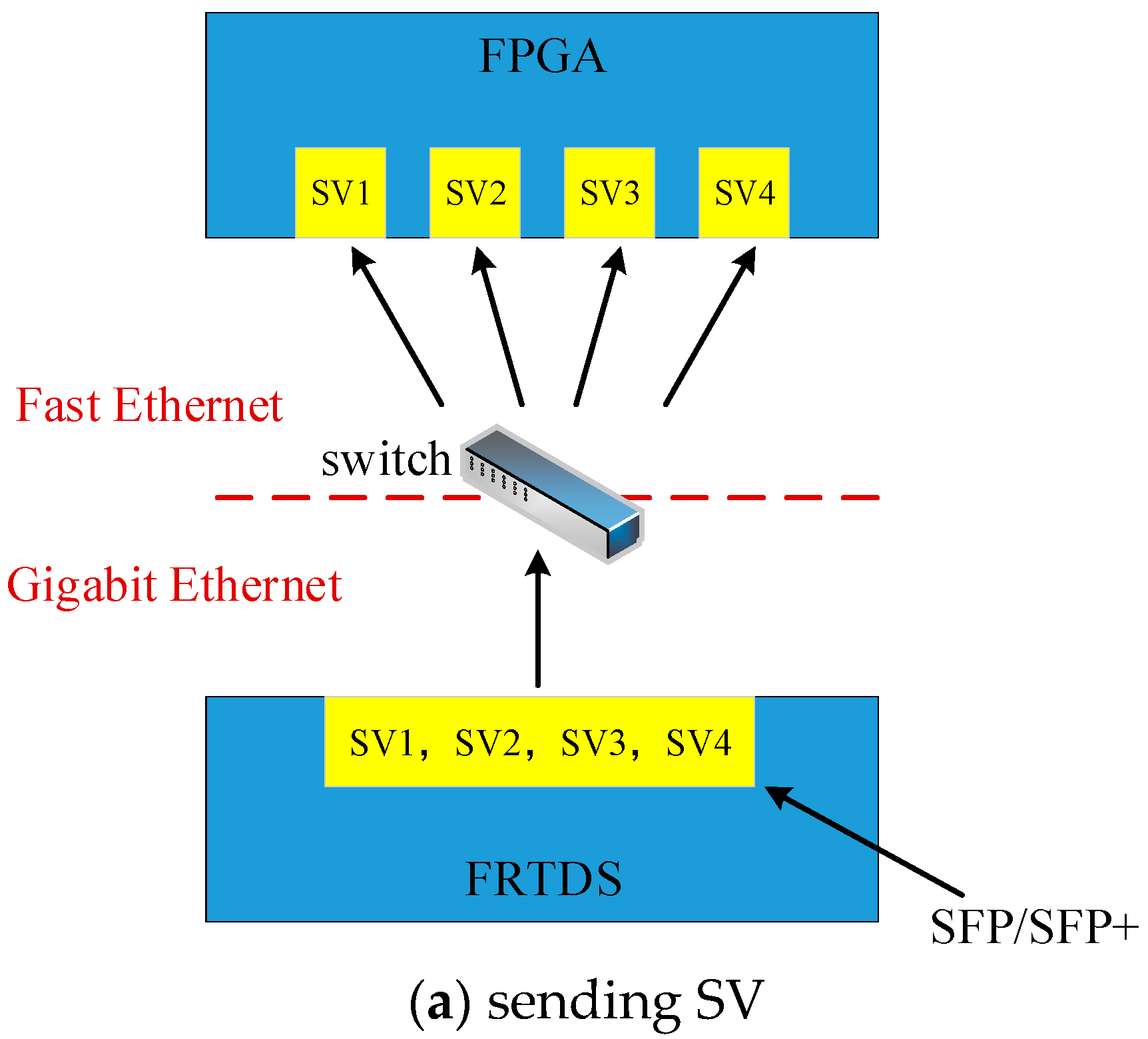

- The formation of SV packet and the resolution of GOOSE packet are implemented in FRTDS in the form of orders. The template modification service module and the state extraction service module are designed to solve the uncertainty of SV and GOOSE packet structure.

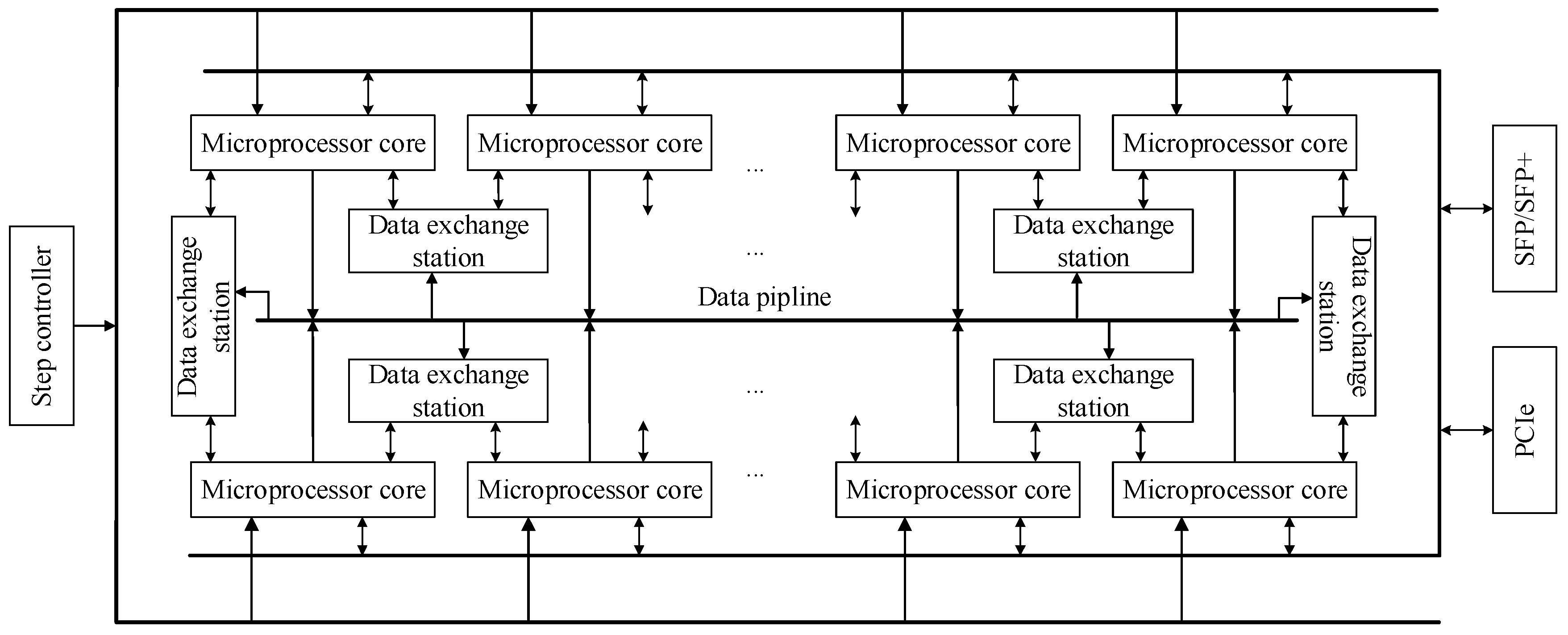

2. FRTDS

2.1. Microprocessor Core

2.2. The Overall Structure

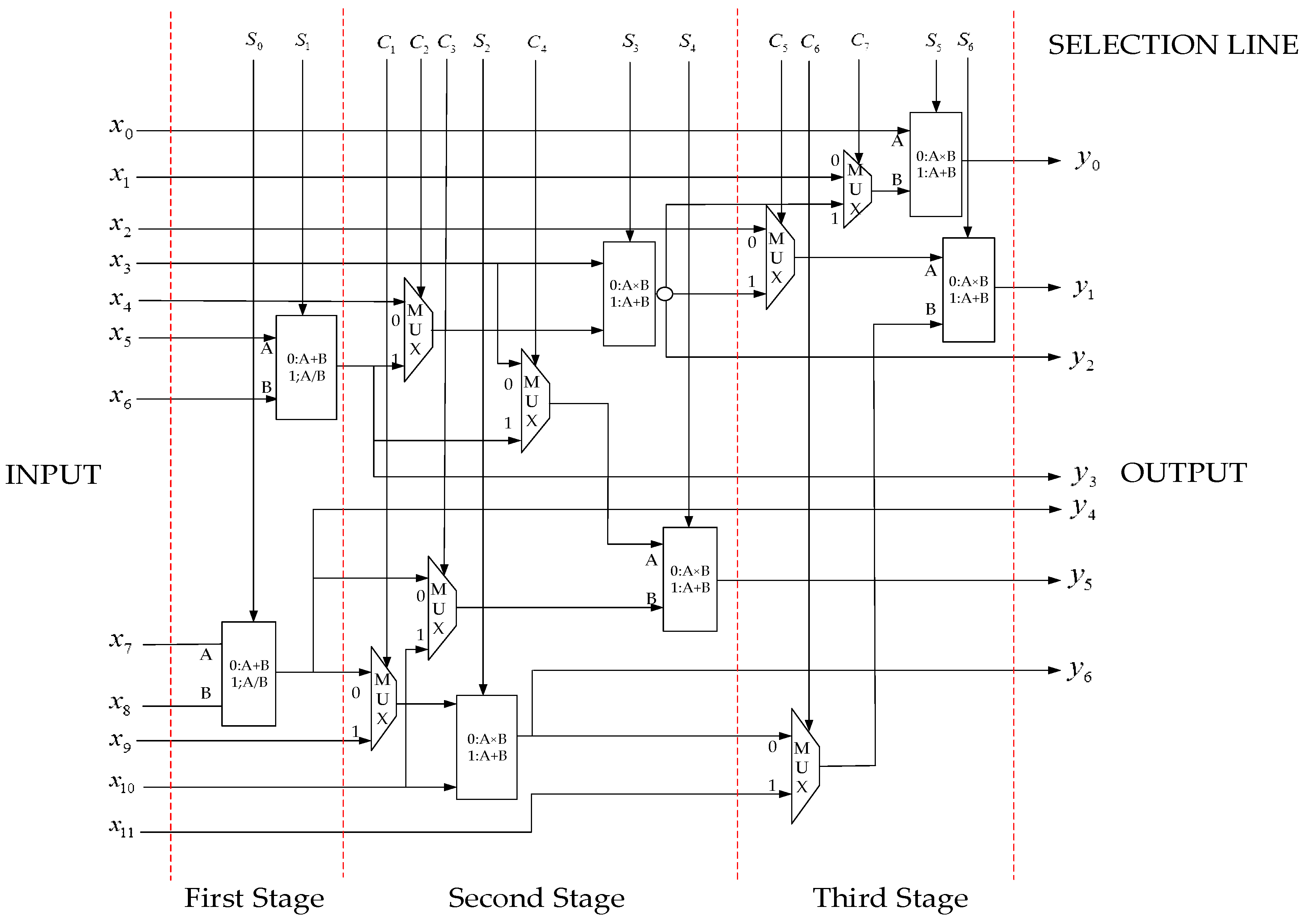

2.3. The Order Generator

3. The Method of Multivalued Coefficients Pre-Storage

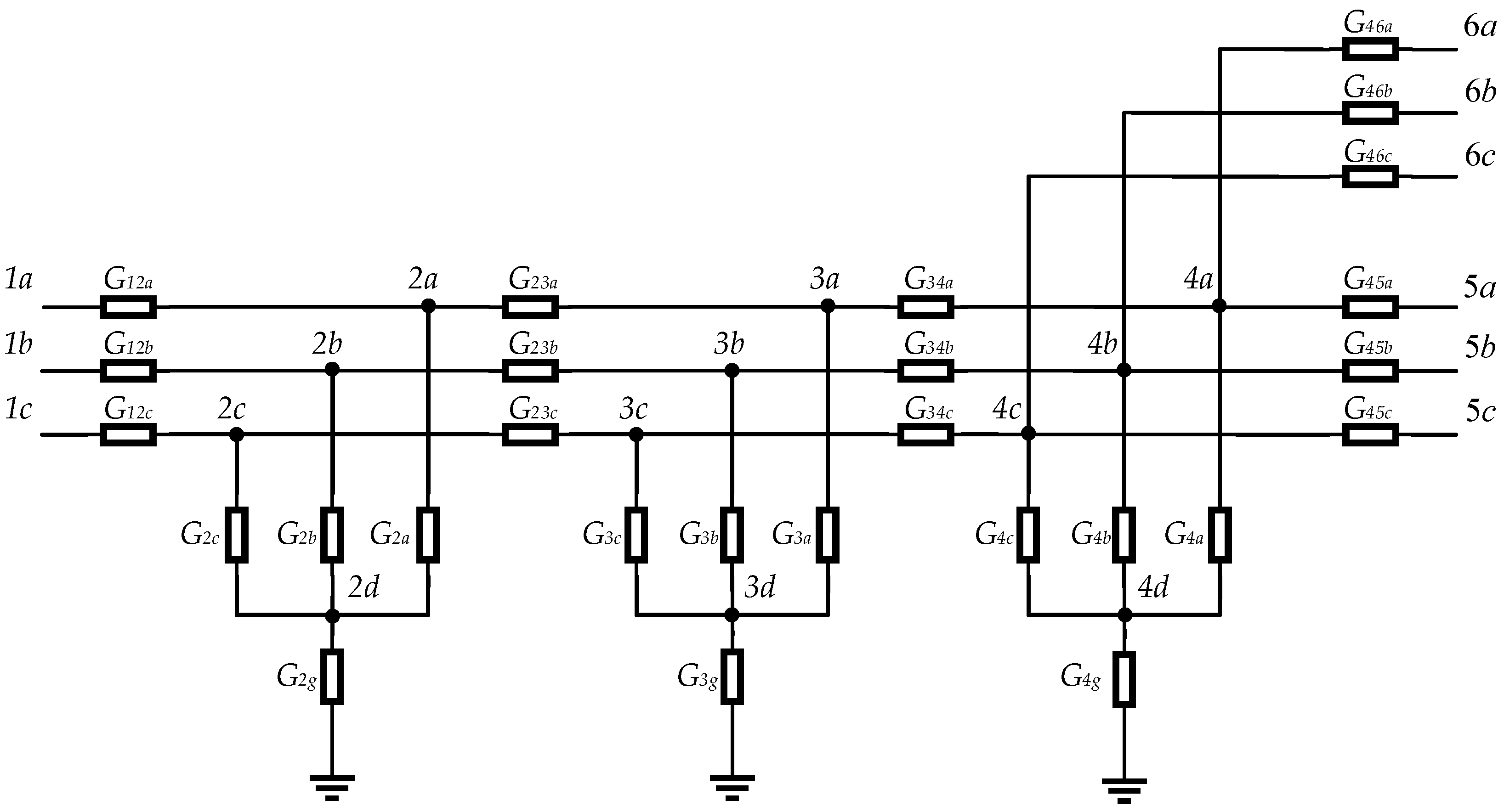

3.1. Time-Varying Conductance

3.2. Nonlinear Inductance

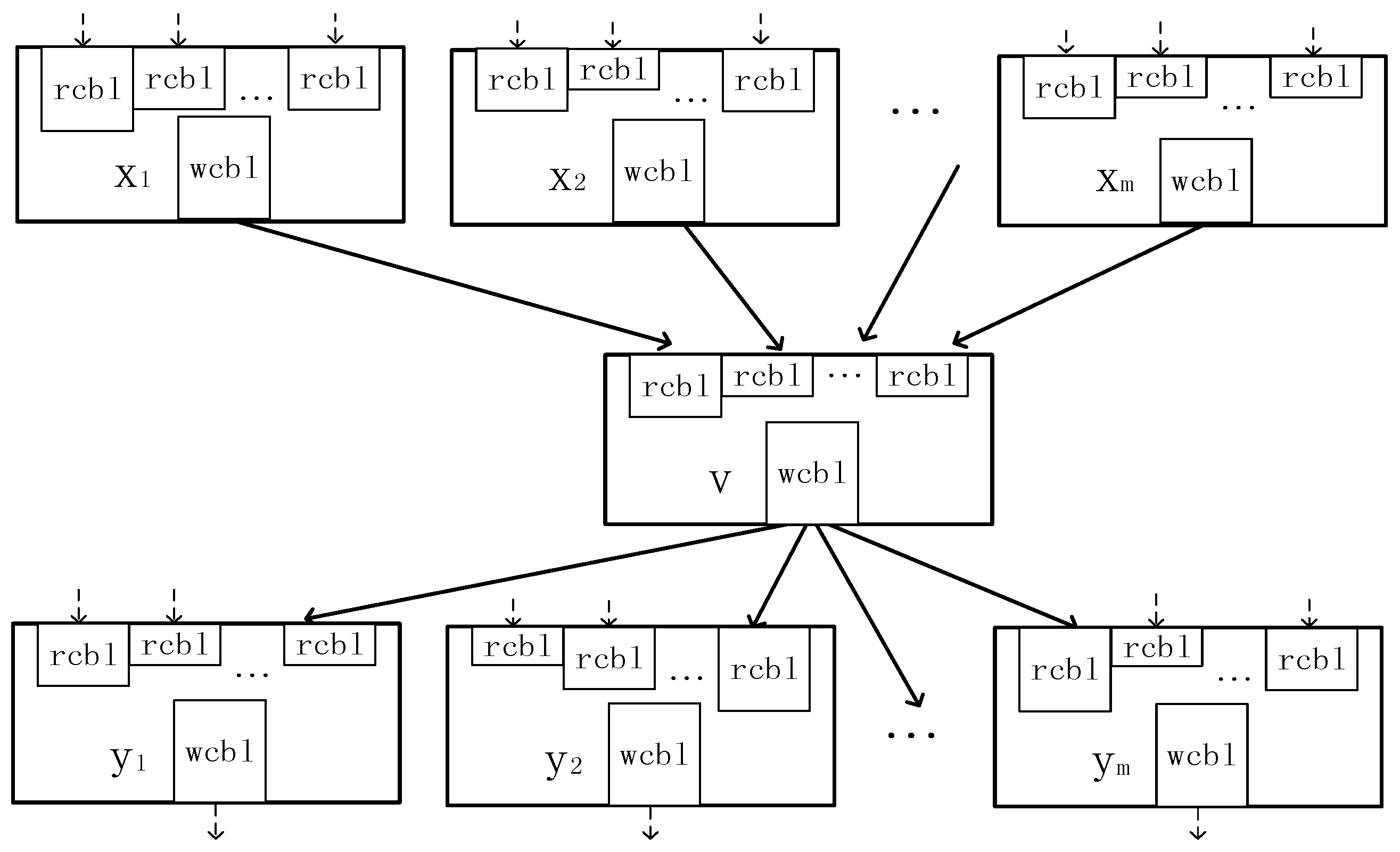

3.3. The Local Equivalence of the Network

3.4. The Query of the Multivalued Coefficients

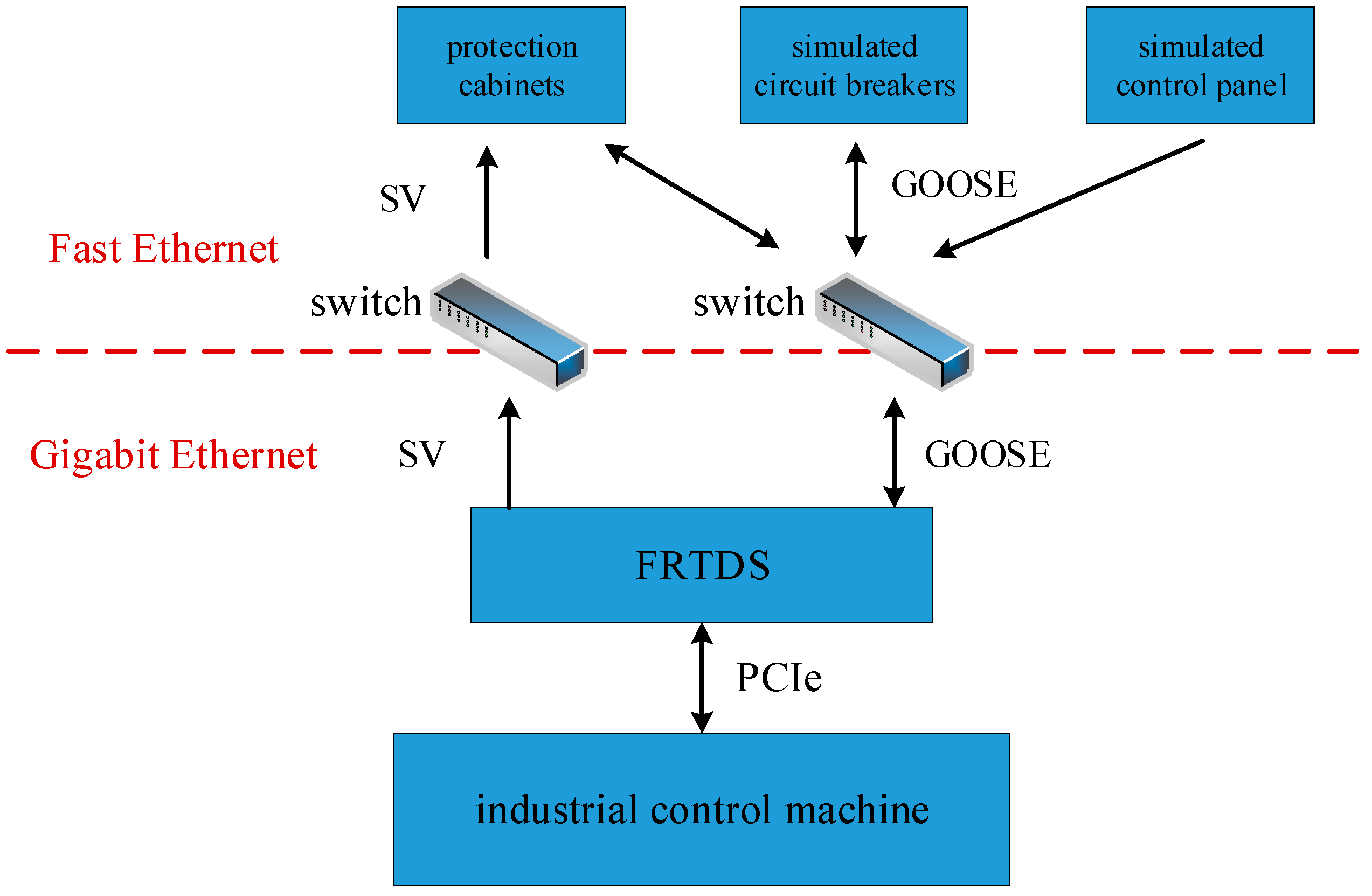

4. Network Communication of Process Layer

4.1. Communication Interface

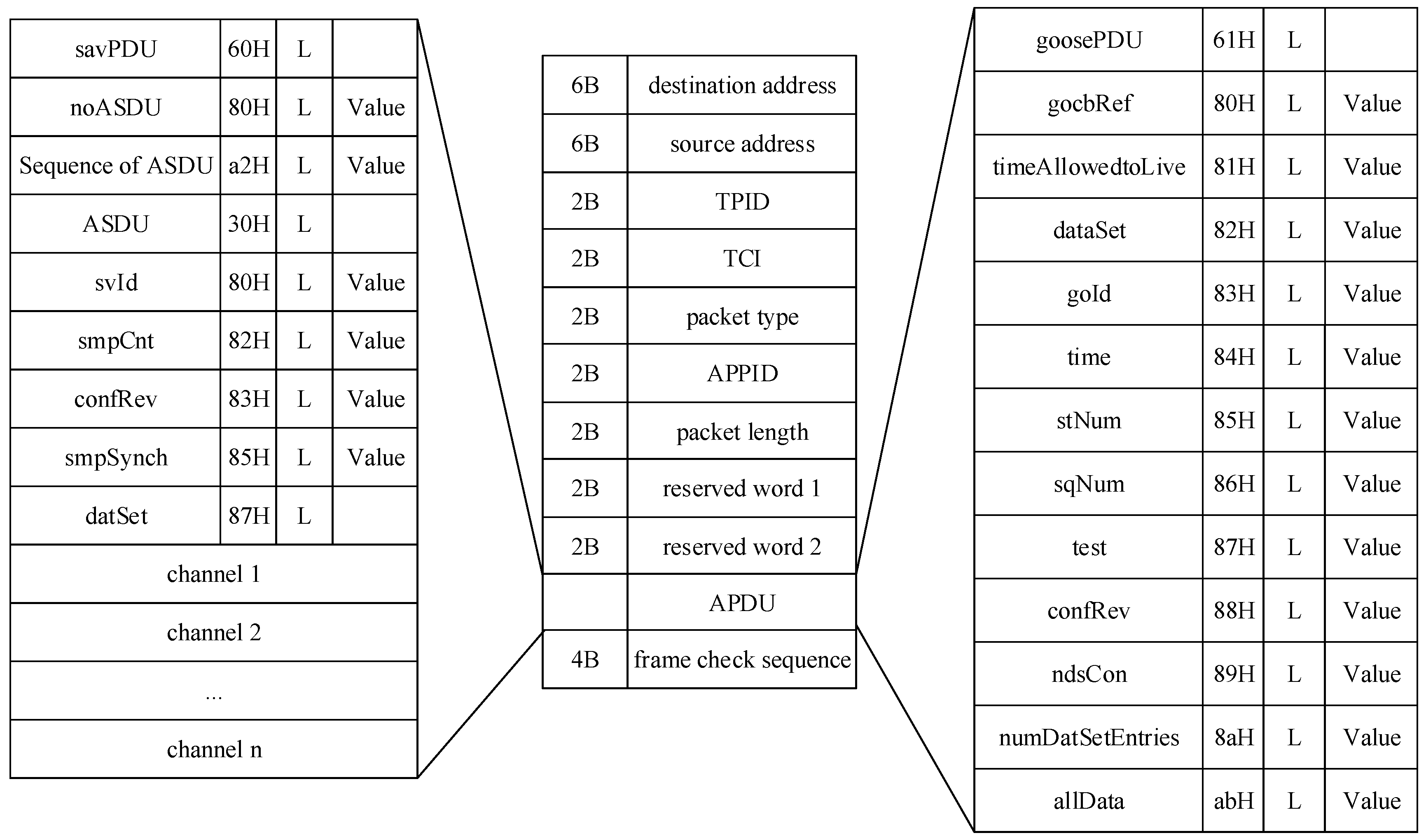

4.2. Formation of SV Packet

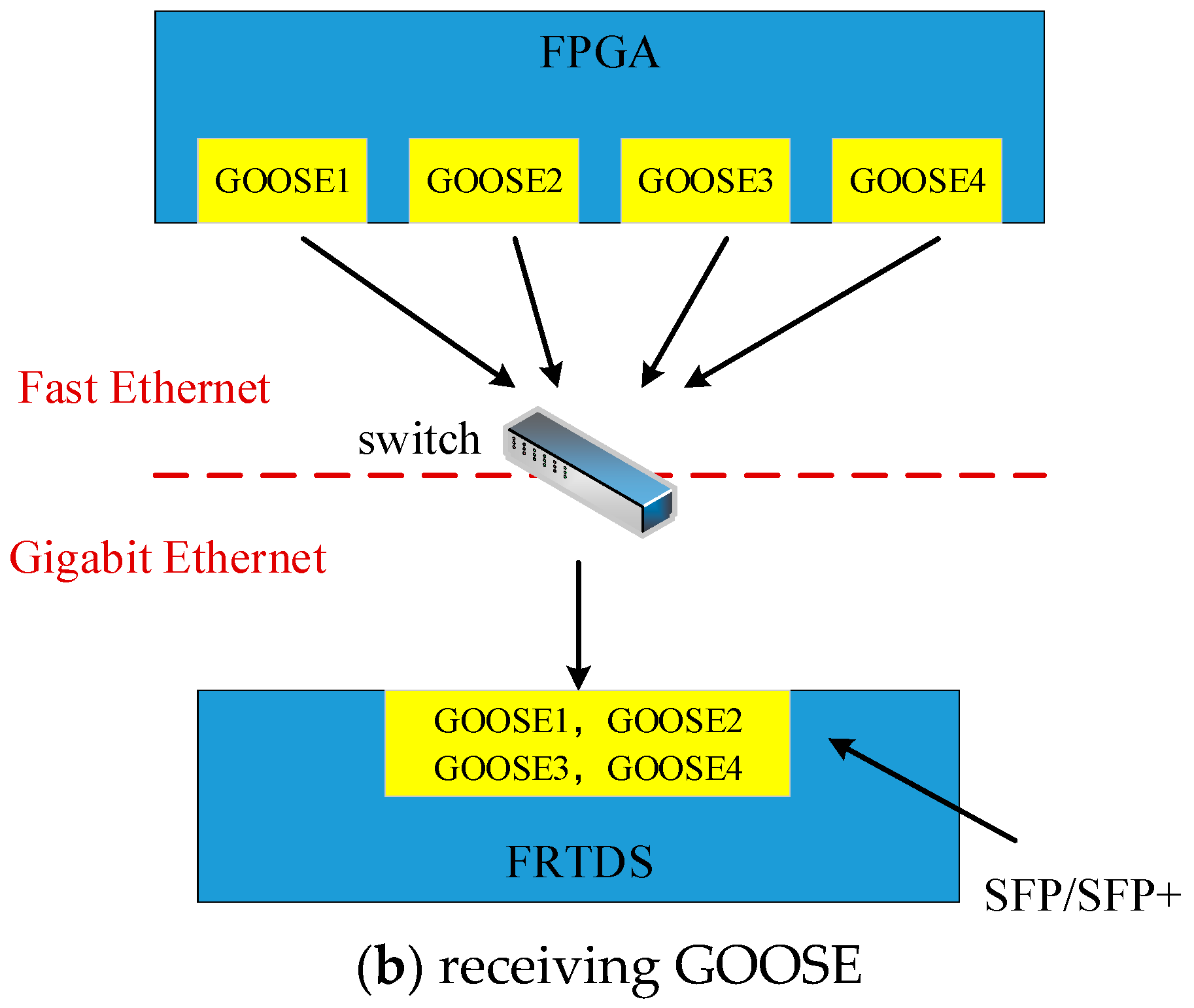

4.3. Resolution of GOOSE Packet

5. Case Study

5.1. Simulation Calculating Capacity

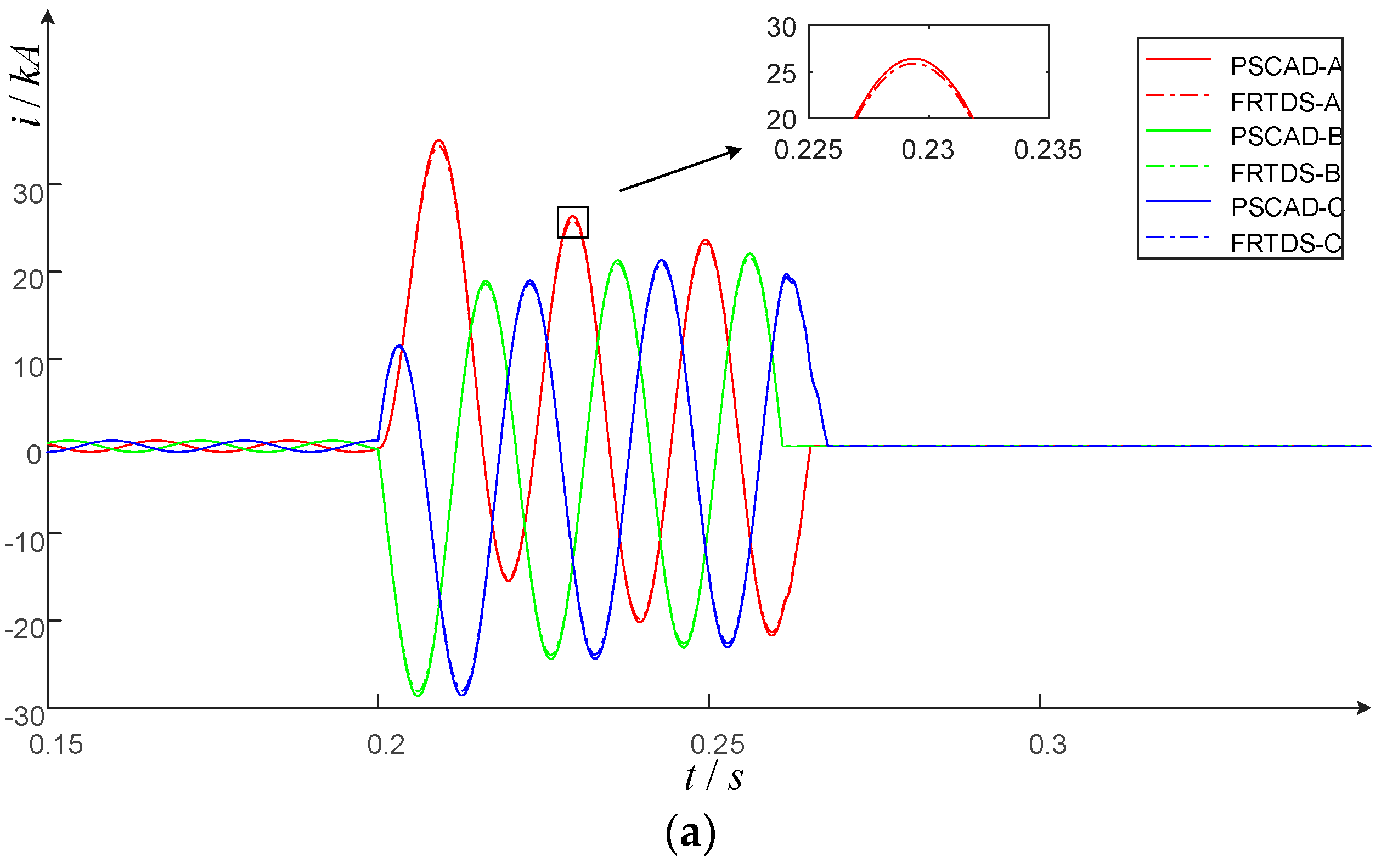

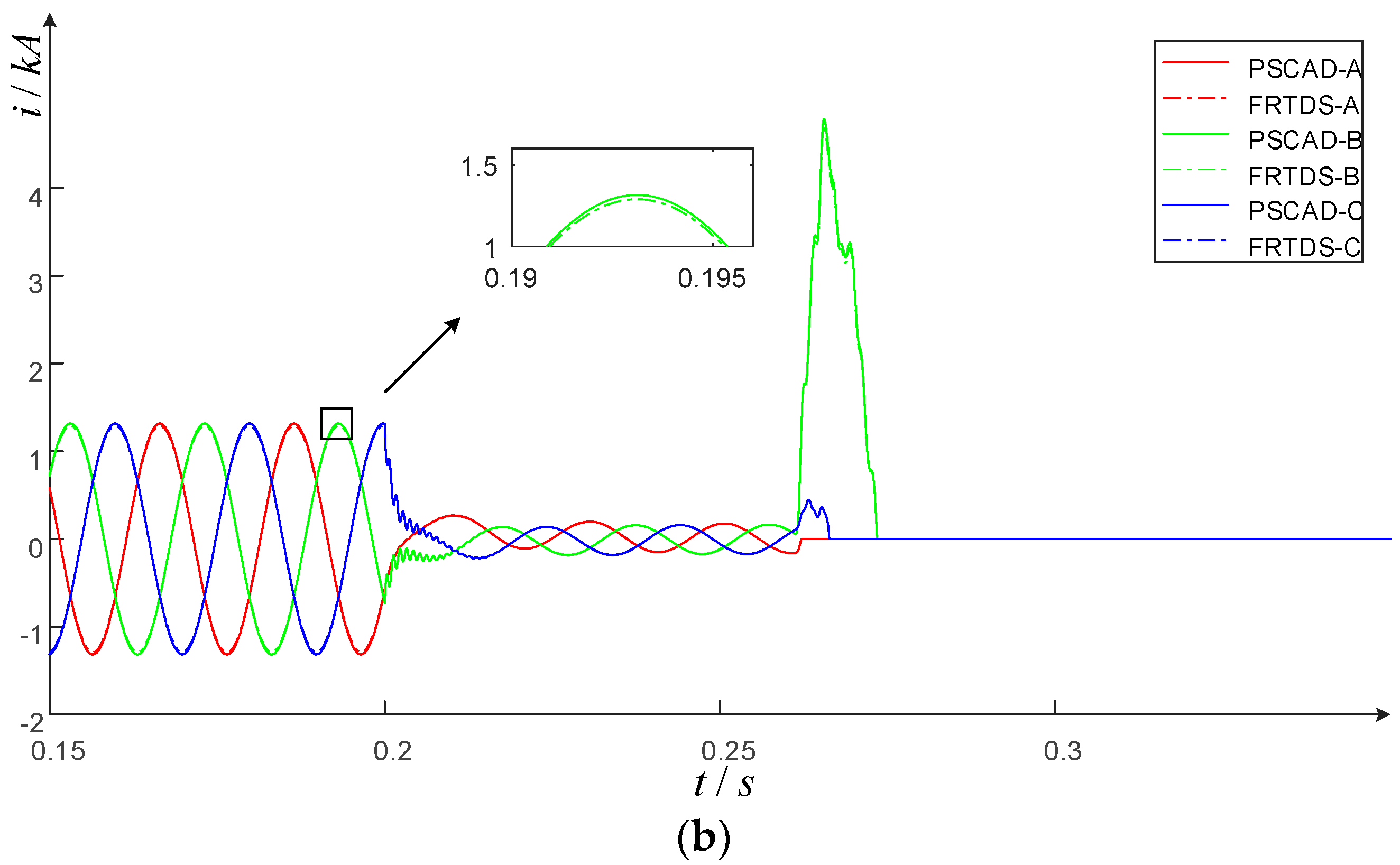

5.2. Haredware-in-the-Loop Ability

6. Conclusions

- (1)

- The proposed inlet-outlet line unit described by the 0/108 S conductance has disconnection between nodes and network symmetry. The number of equivalent conductance and voltage coefficients is much less than that described by the 10−8/108 S conductance. This allows for FRTDS to perform electromagnetic transient simulations with the equivalent model of inlet-outlet line unit and significantly reduce the simulation calculations to expand the scale.

- (2)

- The address transformation algorithm is designed according to the characteristics of the influencing words, which is associated with the multivalued coefficients guide word, so that the multivalued coefficients address query circuit has good expansibility. At the same time, this circuit works independently of the PE, which effectively reduces the computational burden of the PE.

- (3)

- By using the field fixed location in the same APPID packet and orders design concept. The development of the template modification service module and the state extraction service module to solve the uncertainty of SV and GOOSE packet structure, which makes FRTDS easy for smart substation hardware-in-loop real-time simulation platform.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jing, S.; Huang, Q.; Wu, J.; Zhen, W. A Novel Whole-View Test Approach for Onsite Commissioning in Smart Substation. IEEE Trans. Power Deliv. 2013, 28, 1715–1722. [Google Scholar] [CrossRef]

- Huang, Q.; Jing, S.; Li, J.; Huang, Q.; Jing, S.; Cai, D.; Wu, J.; Zhen, W. Smart Substation: State of the Art and Future Development. IEEE Trans. Power Deliv. 2017, 32, 1098–1105. [Google Scholar] [CrossRef]

- Song, Q.; Sheng, W.; Kou, L.; Zhao, D.; Wu, Z.; Fang, H.; Zhao, X. Smart substation integration technology and its application in distribution power grid. CSEE J. Power Energy Syst. 2016, 2, 31–36. [Google Scholar] [CrossRef]

- He, X.; Jiang, X.; Zhang, P.; Gao, X. Availability Analysis of Smart Substation Protection System Considering Maintenance Strategies. Power Syst. Technol. 2015, 39, 1121–1128. [Google Scholar] [CrossRef]

- Liu, H.; Hu, J.; Li, F.; Qi, Z. Design and Implementation of Simulation Test System for Substation Automation. Autom. Electr. Power Syst. 2012, 36, 109–112. [Google Scholar] [CrossRef]

- Peng, F.; Gao, H.; Liu, Y.; Kong, F. Practical test technology and solution based on RTDS-GTNET for protective equipment in smart substation. Electr. Power Autom. Equip. 2016, 36, 160–165. [Google Scholar] [CrossRef]

- Meng, H.; Liang, X.; Liu, Y.; Zhao, Y. Research on Closed Loop Real Time Simulation System of Relay Protection for Digital Substation. Power Syst. Technol. 2010, 34, 198–203. [Google Scholar] [CrossRef]

- Razzaghi, R.; Mitjans, M.; Rachidi, F.; Paolone, M. An automated FPGA real-time simulator for power electronics and power systems electromagnetic transient applications. Electr. Power Syst. Res. 2016, 141, 147–156. [Google Scholar] [CrossRef]

- Ouldbachir, T.; Blanchette, H.; Al-Haddad, K. A Network Tearing Technique for FPGA-Based Real-Time Simulation of Power Converters. IEEE Trans. Ind. Electr. 2015, 62, 3409–3418. [Google Scholar] [CrossRef]

- Chen, Y.; Dinavahi, V. Hardware Emulation Building Blocks for Real-Time Simulation of Large-Scale Power Grids. IEEE Trans. Ind. Inform. 2013, 10, 373–381. [Google Scholar] [CrossRef]

- Wang, C.; Ding, C.; Li, P.; Yu, H. Real-time Transient Simulation for Distribution Systems Based on FPGA, Part I: Module Realization. Proc. CSEE 2014, 34, 161–167. [Google Scholar] [CrossRef]

- Wang, C.; Ding, C.; Li, P.; Yu, H. Real-time Transient Simulation for Distribution Systems Based on FPGA, Part II: System Architecture and Algorithm Verification. Proc. CSEE 2014, 34, 628–634. [Google Scholar] [CrossRef]

- Chen, Y.; Dinavahi, V. Multi-FPGA digital hardware design for detailed large-scale real-time electromagnetic transient simulation of power systems. IET Gener. Trans. Distrib. 2013, 7, 451–463. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, D.; Jin, Z.; Wu, Y. Multivalued Coefficient Pre-storage and Block Parallel Method for Real-Time Simulation of Micro-grid on FRTDS. Energies 2017, 10, 1248. [Google Scholar] [CrossRef]

- Chen, Y.; Dinavahi, V. FPGA-Based Real-Time EMTP. IEEE Trans. Power Deliv. 2009, 24, 892–902. [Google Scholar] [CrossRef]

| Equivalent Conductance | Quantity | Equivalent Conductance | Quantity |

|---|---|---|---|

| G1a,2d | 17 | G3d,6a | 13 |

| G1a,3d | 9 | G4d,5a | 15 |

| G2a,3d | 9 | G4d,6a | 15 |

| G1a,4d | 13 | G5a,6a | 15 |

| G1a,5a | 13 | G1a,1a | 19 |

| G1a,6a | 13 | G2a,2d | 19 |

| G2d,4d | 13 | G3d,3d | 17 |

| G2d,5a | 13 | G4d,4d | 25 |

| G2d,6a | 13 | G5a,5a | 25 |

| G3d,4d | 13 | G6a,6a | 25 |

| G2d,5a | 13 | - | - |

| Voltage Coefficients | Quantity | Voltage Coefficients | Quantity |

|---|---|---|---|

| K2a,1a | 19 | K3a,4d | 25 |

| K2a,2d | 19 | K3a,5a | 25 |

| K2a,3d | 13 | K3a,6a | 25 |

| K2a,4d | 19 | K4a,1a | 17 |

| K2a,5a | 19 | K4a,2d | 17 |

| K2a,6a | 19 | K4a,3d | 17 |

| K3a,1a | 17 | K4a,4d | 25 |

| K3a,2d | 17 | K4a,5a | 25 |

| K3a,3d | 17 | K4a,6a | 25 |

| Method | Simulation Time (μs) |

|---|---|

| 1 | 56.145 |

| 2 | 53.465 |

| 3 | 48.115 |

| Method | Simulation Node | The Storage of Multivalued Coefficients (kb) | Simulation Time (μs) |

|---|---|---|---|

| Before | 352 | 768 | 48.115 |

| After | 226 | 975 | 37.465 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Wu, Y.; Jin, Z.; Wang, Y. A Real-Time Digital Solver for Smart Substation Based on Orders. Energies 2017, 10, 1795. https://doi.org/10.3390/en10111795

Zhang B, Wu Y, Jin Z, Wang Y. A Real-Time Digital Solver for Smart Substation Based on Orders. Energies. 2017; 10(11):1795. https://doi.org/10.3390/en10111795

Chicago/Turabian StyleZhang, Bingda, Yanjie Wu, Zhao Jin, and Yang Wang. 2017. "A Real-Time Digital Solver for Smart Substation Based on Orders" Energies 10, no. 11: 1795. https://doi.org/10.3390/en10111795