Sliding Mode and Neural Network Control of Sensorless PMSM Controlled System for Power Consumption and Performance Improvement

Abstract

:1. Introduction

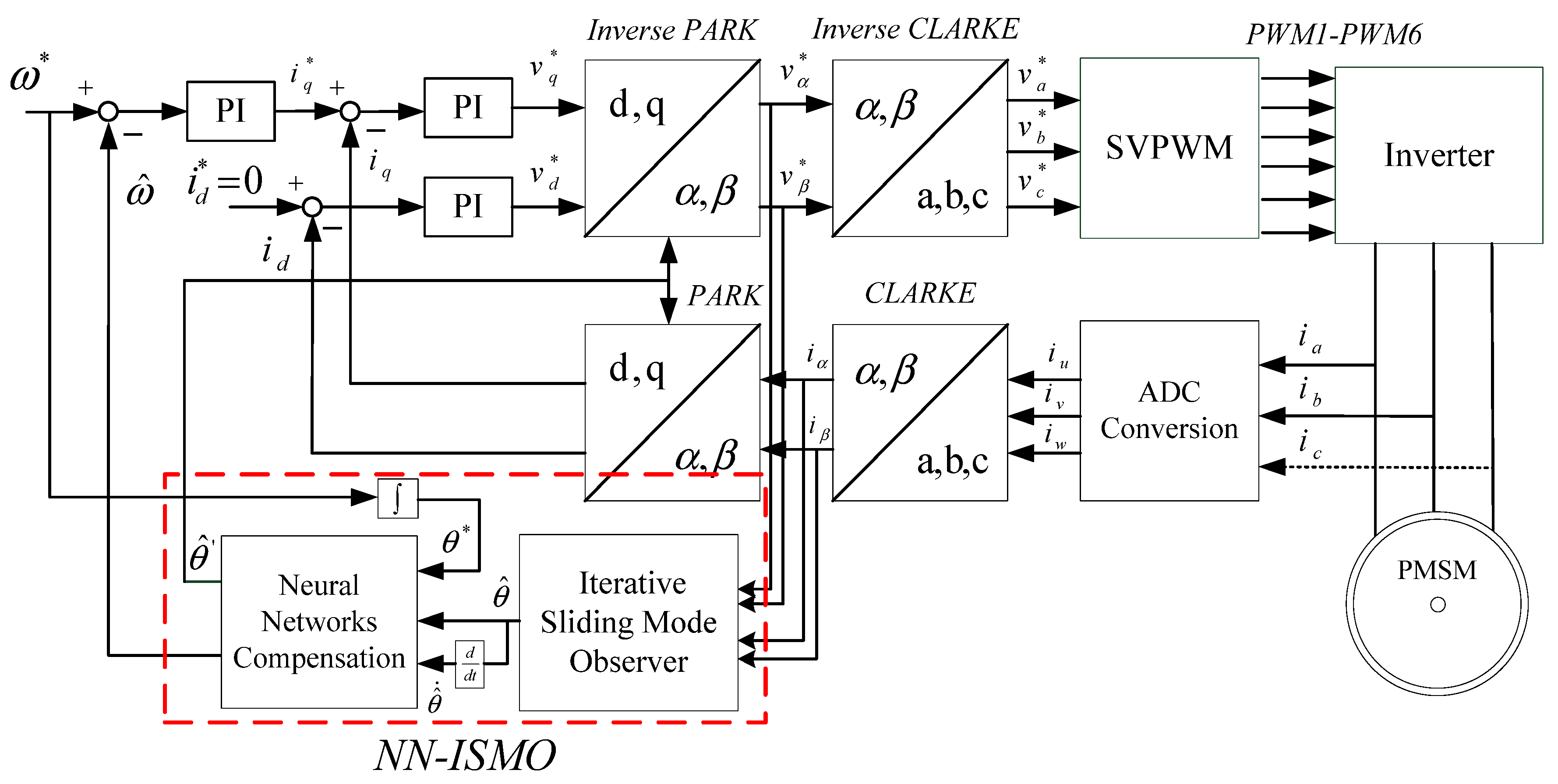

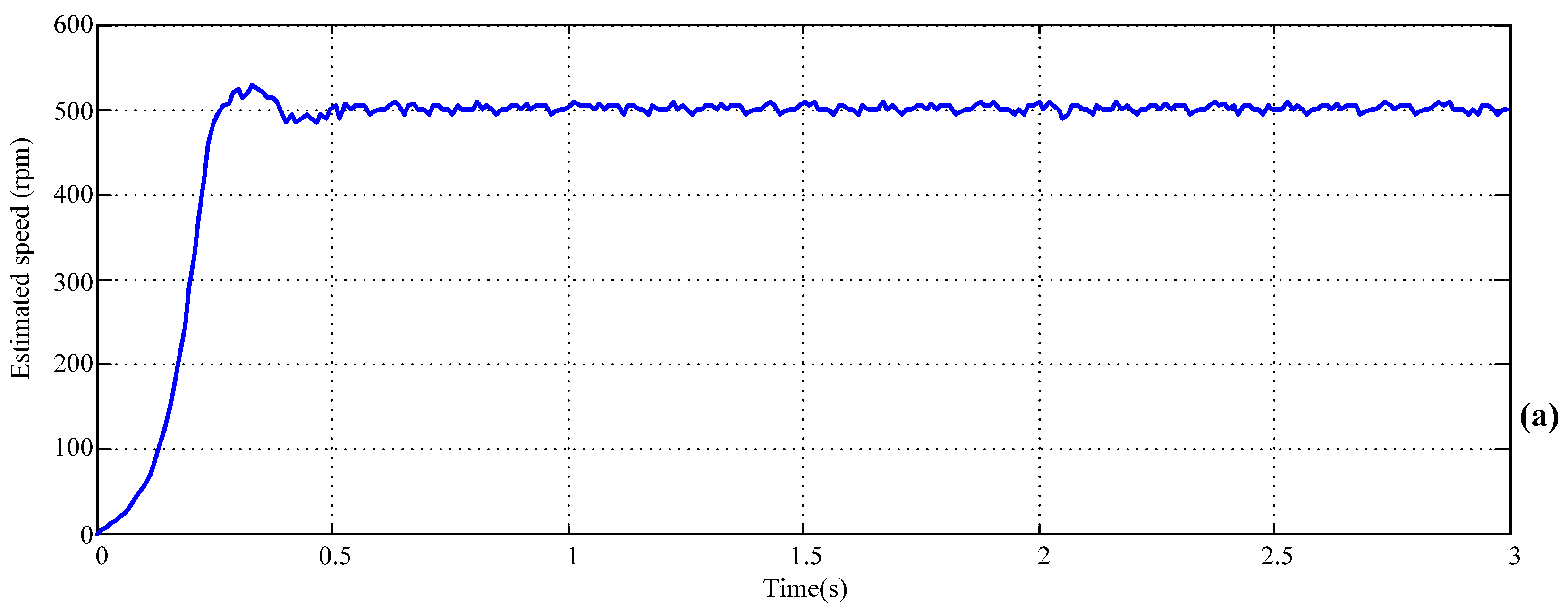

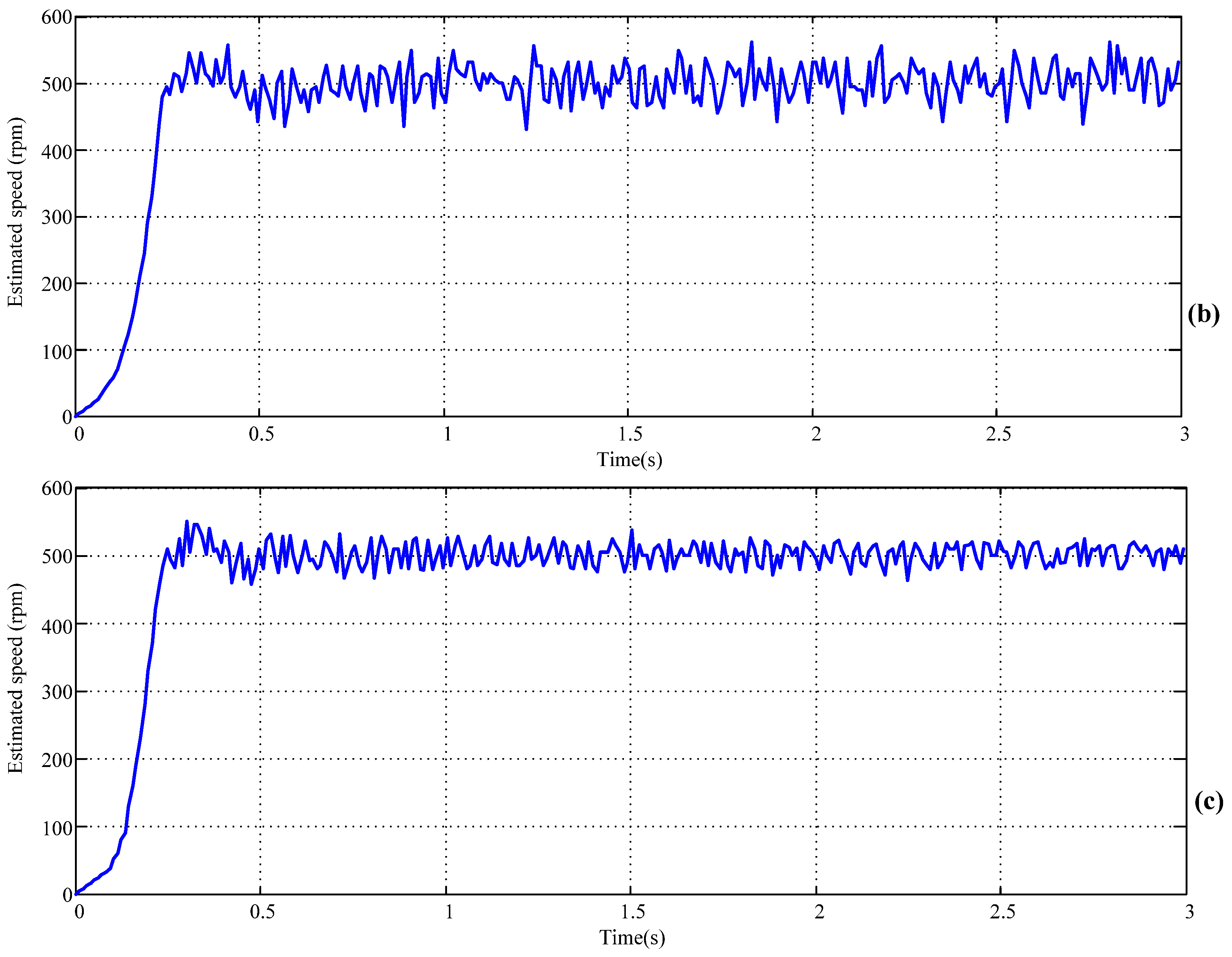

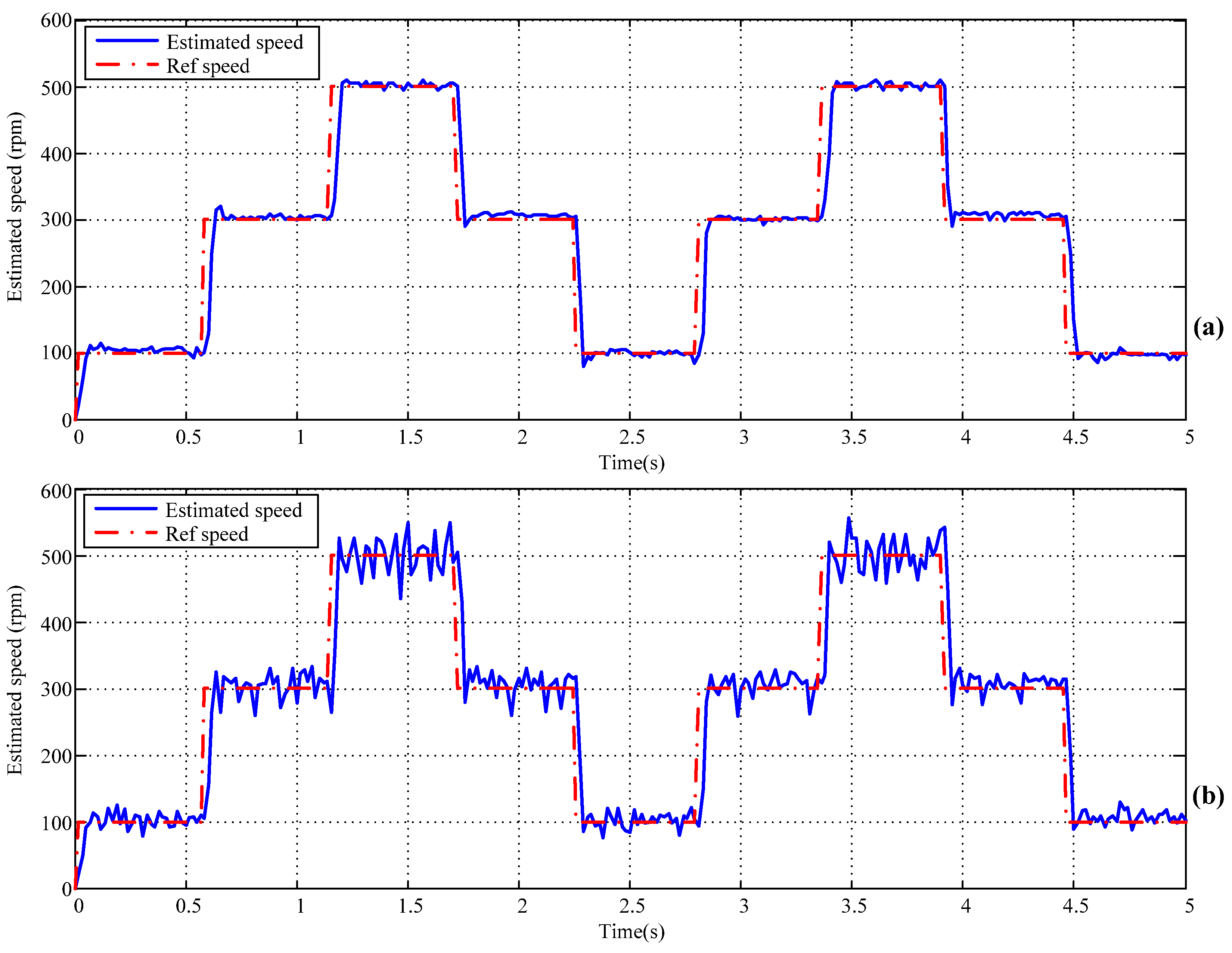

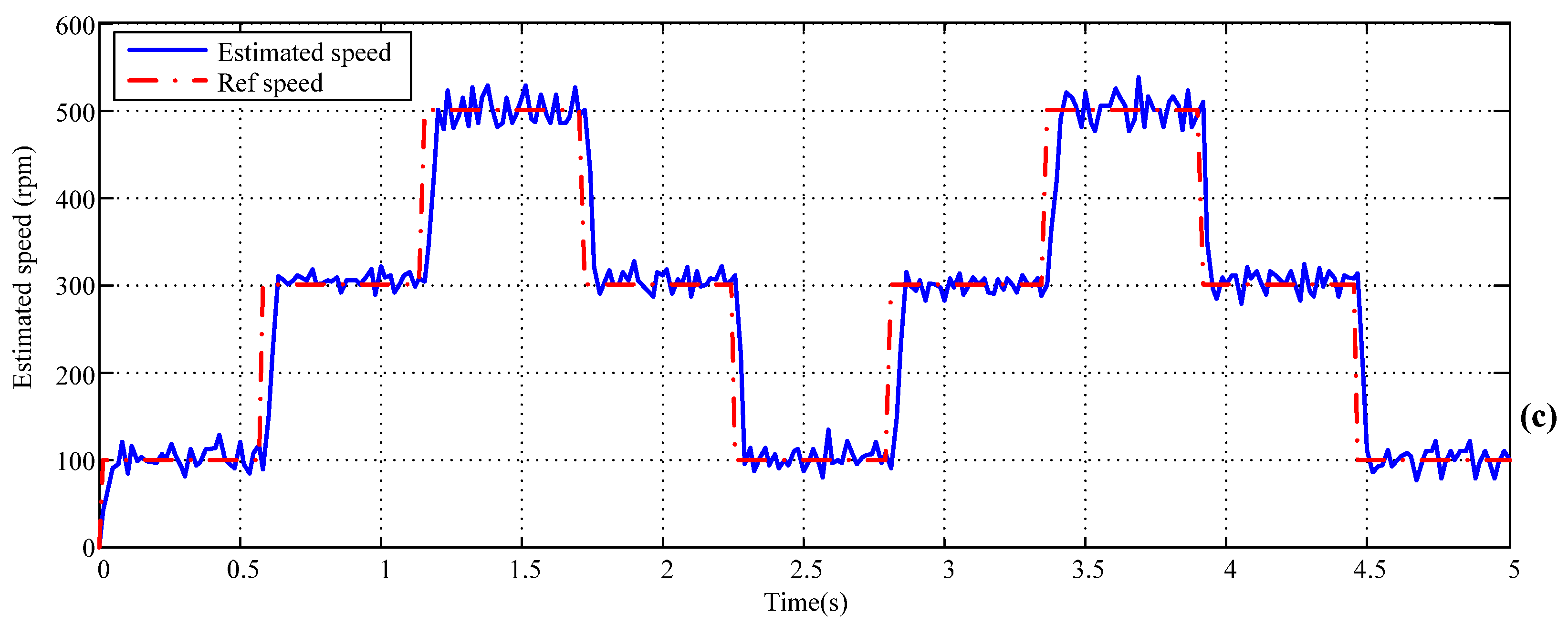

2. Servo System Design

2.1. PMSM Modeling

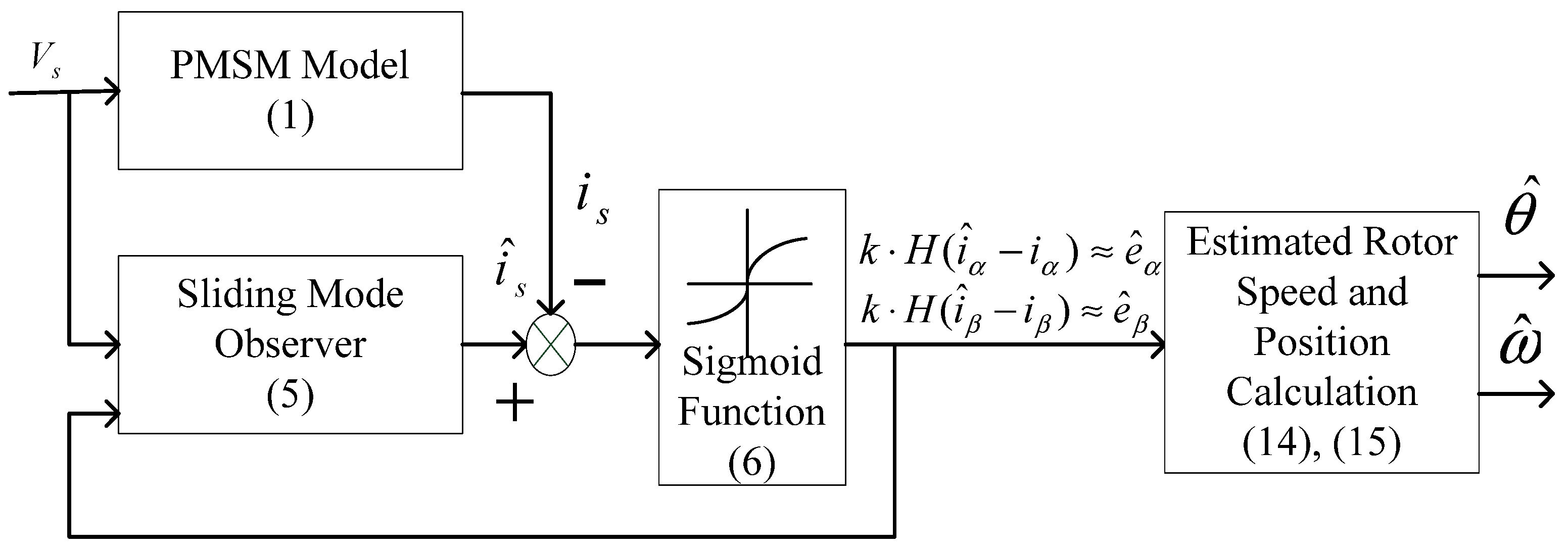

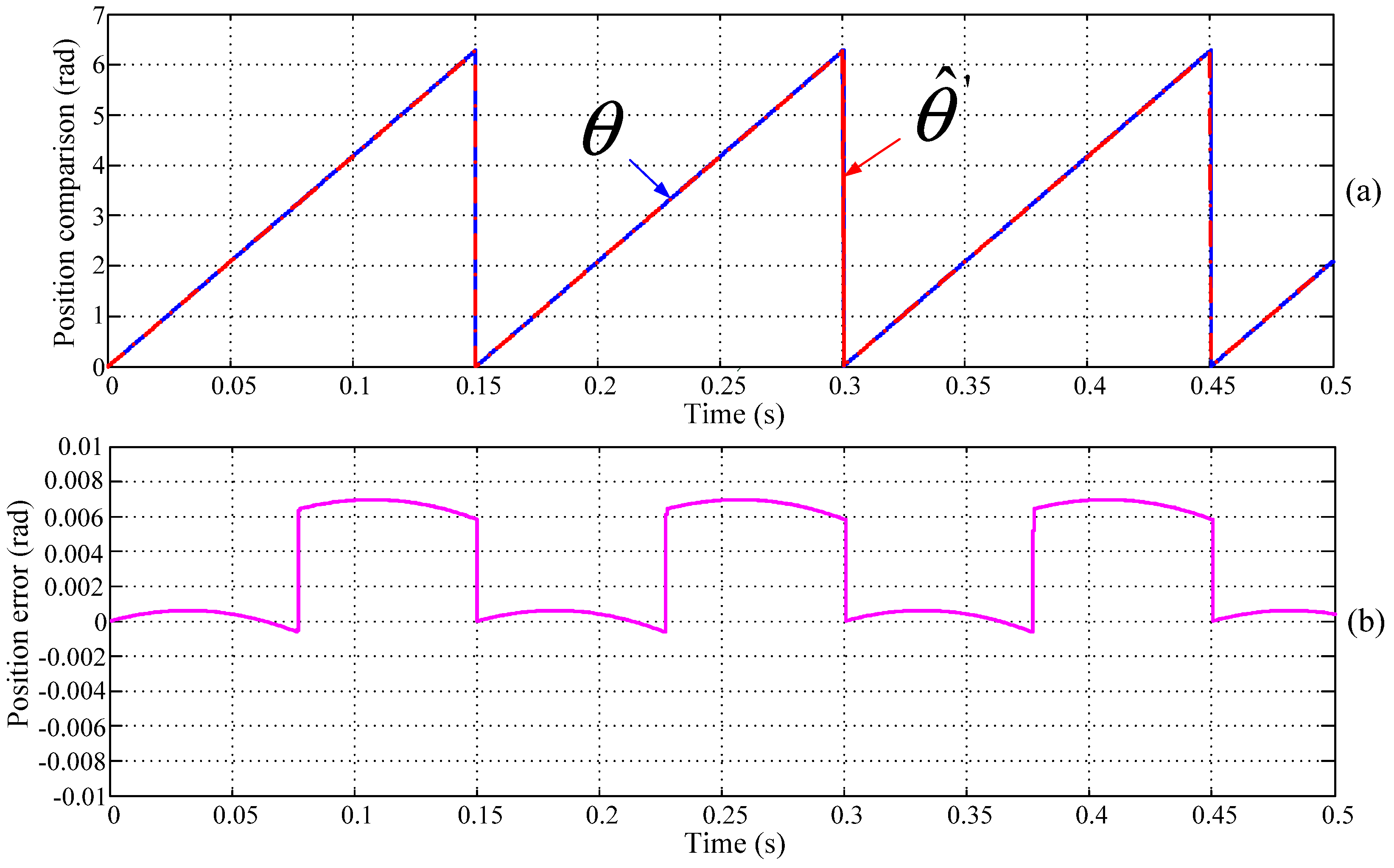

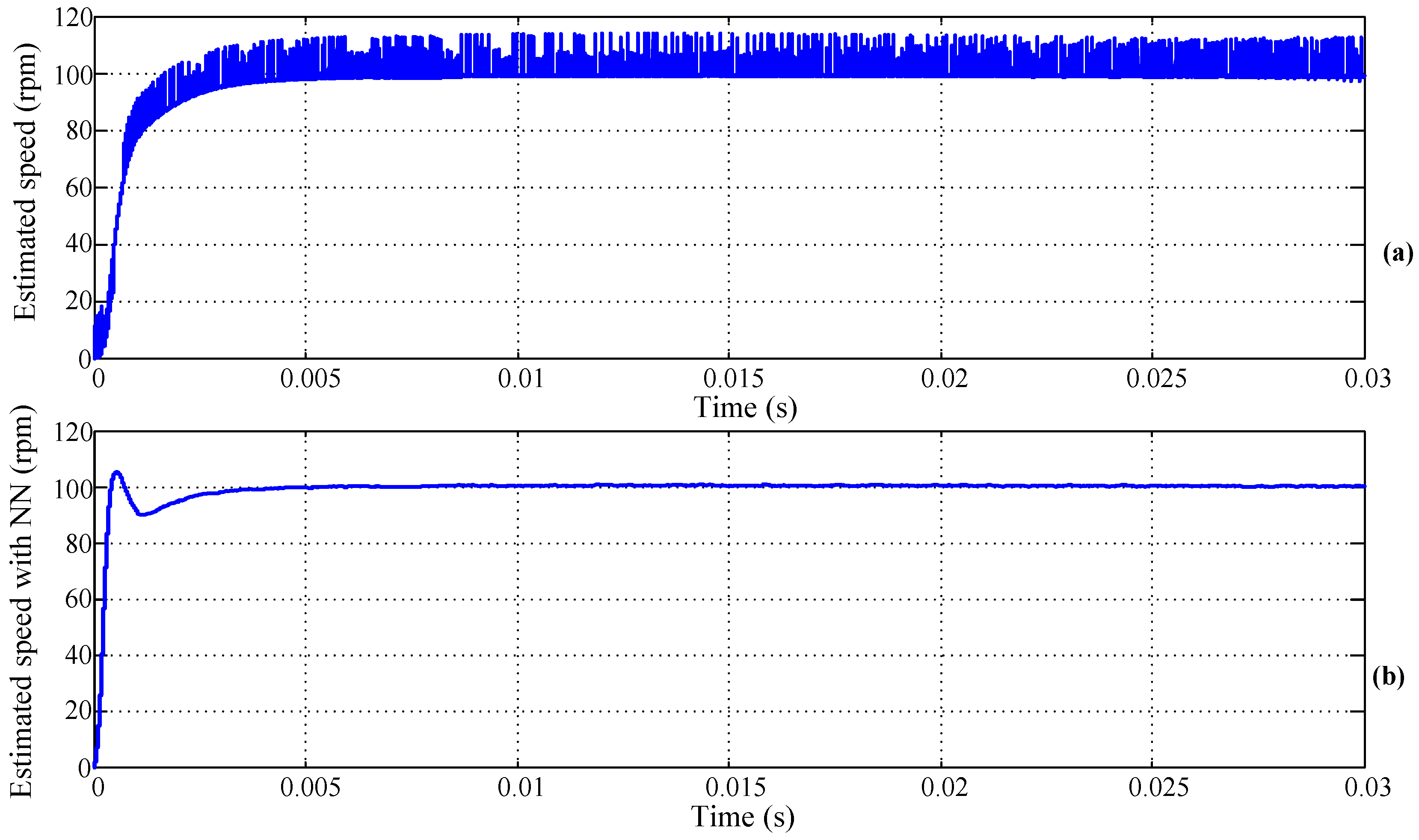

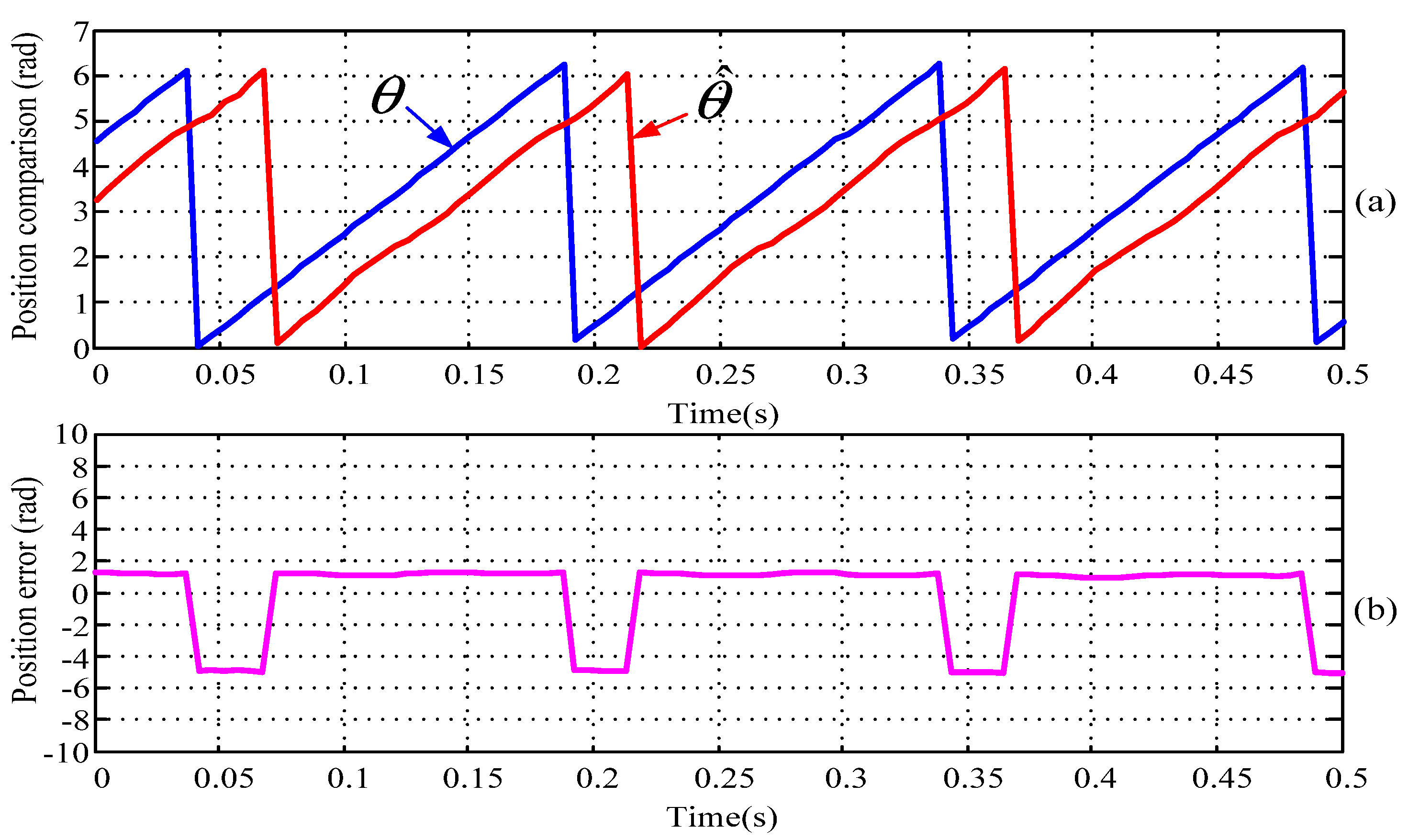

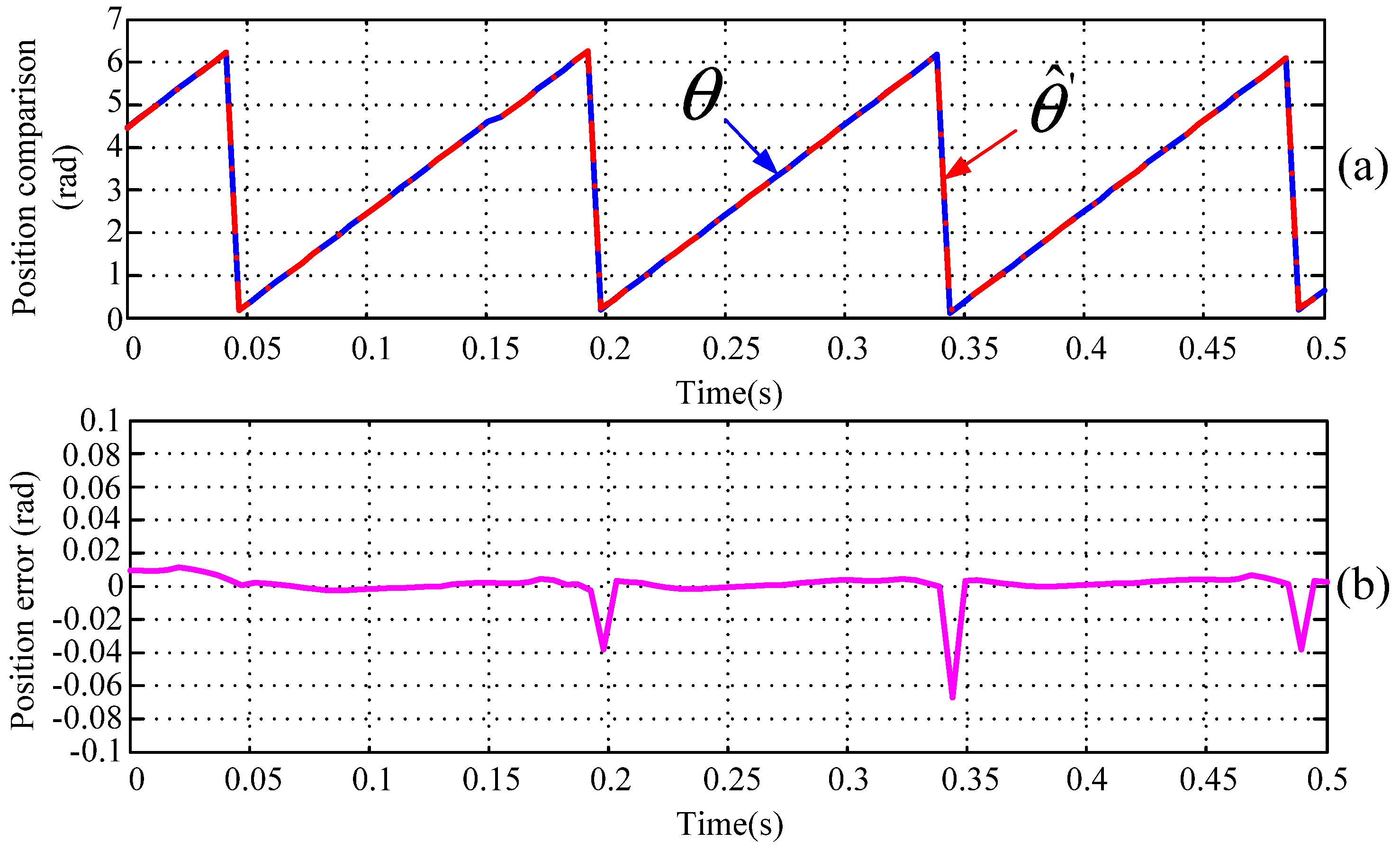

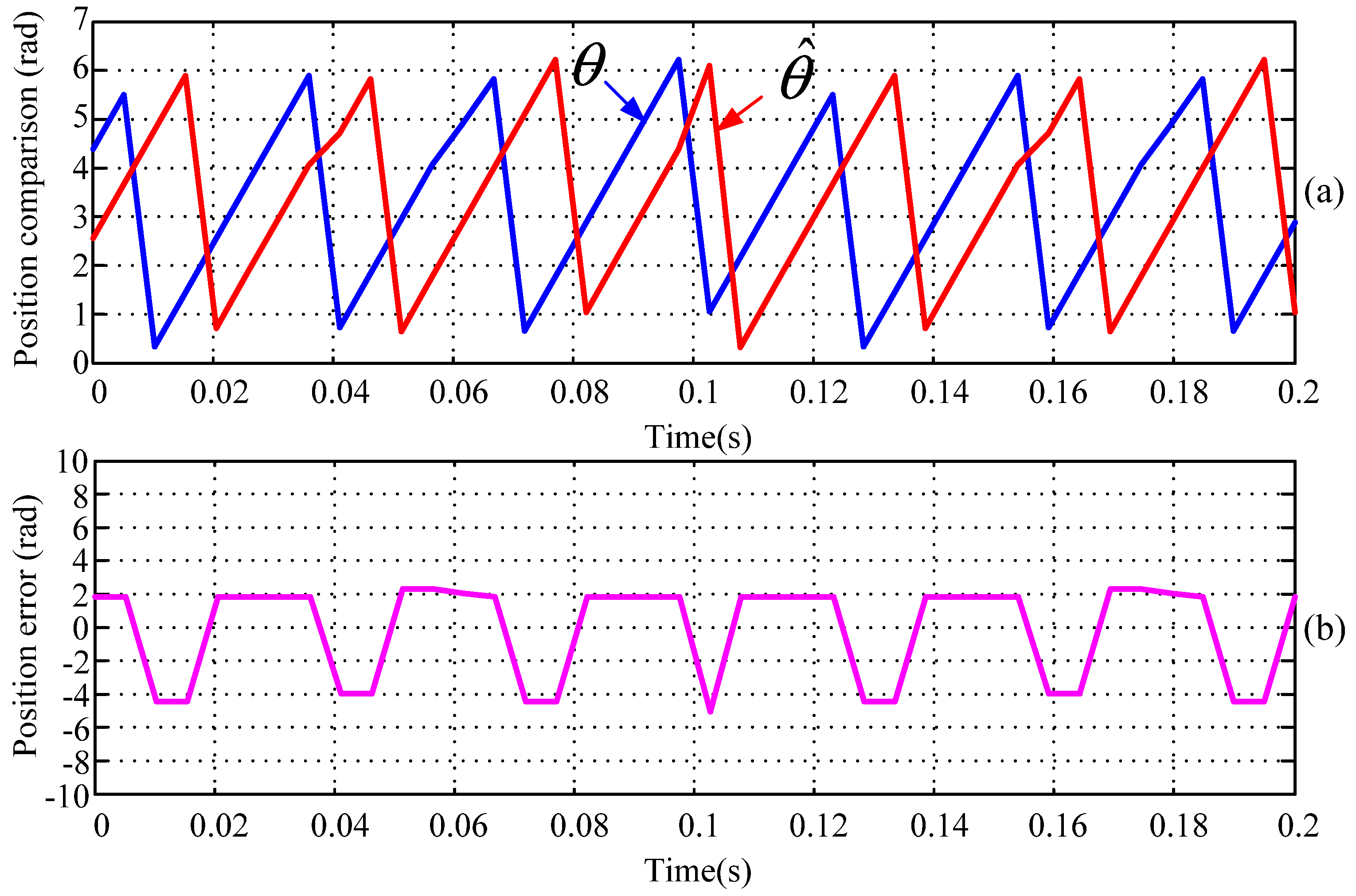

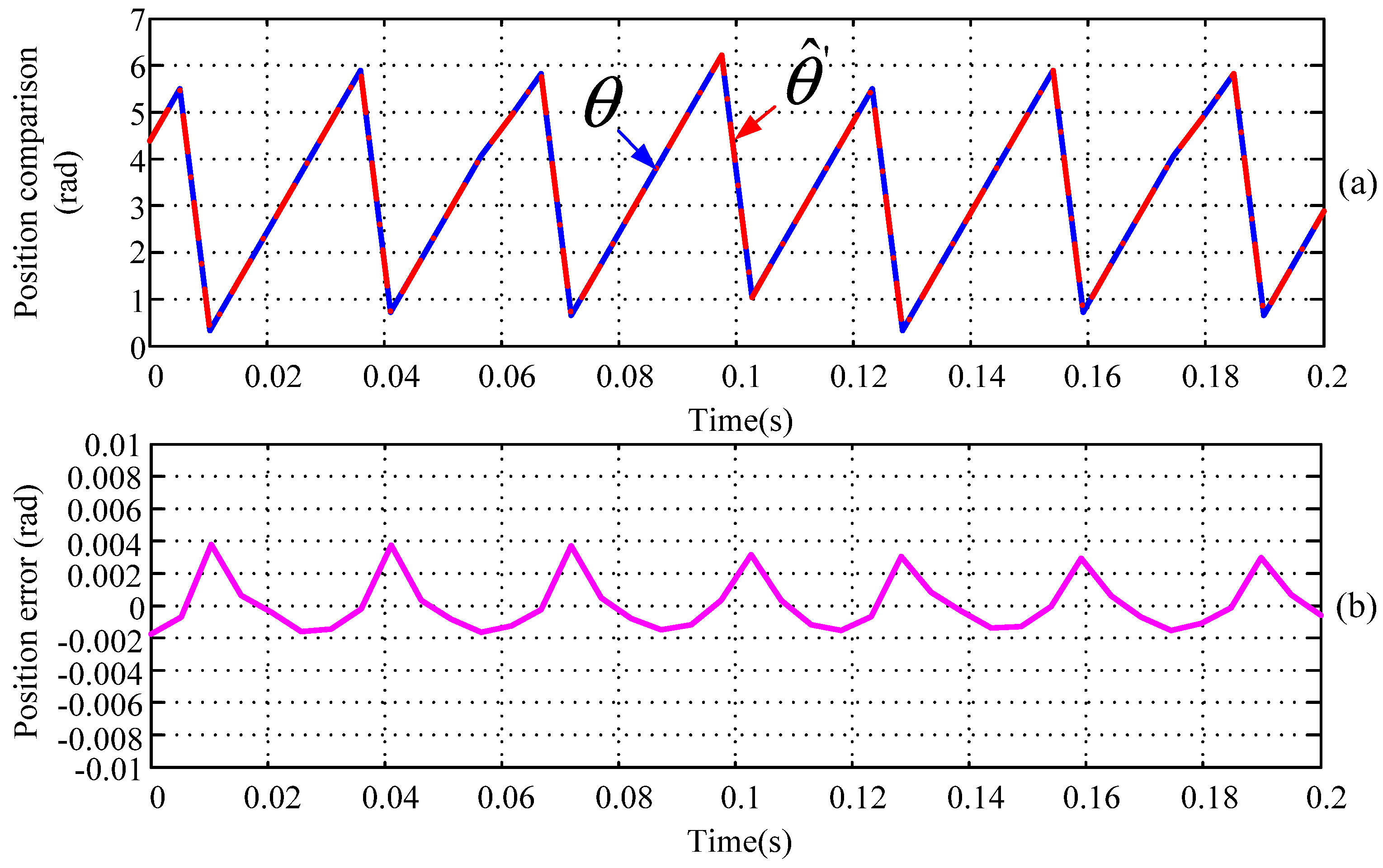

2.2. Iterative Sliding Mode Observer

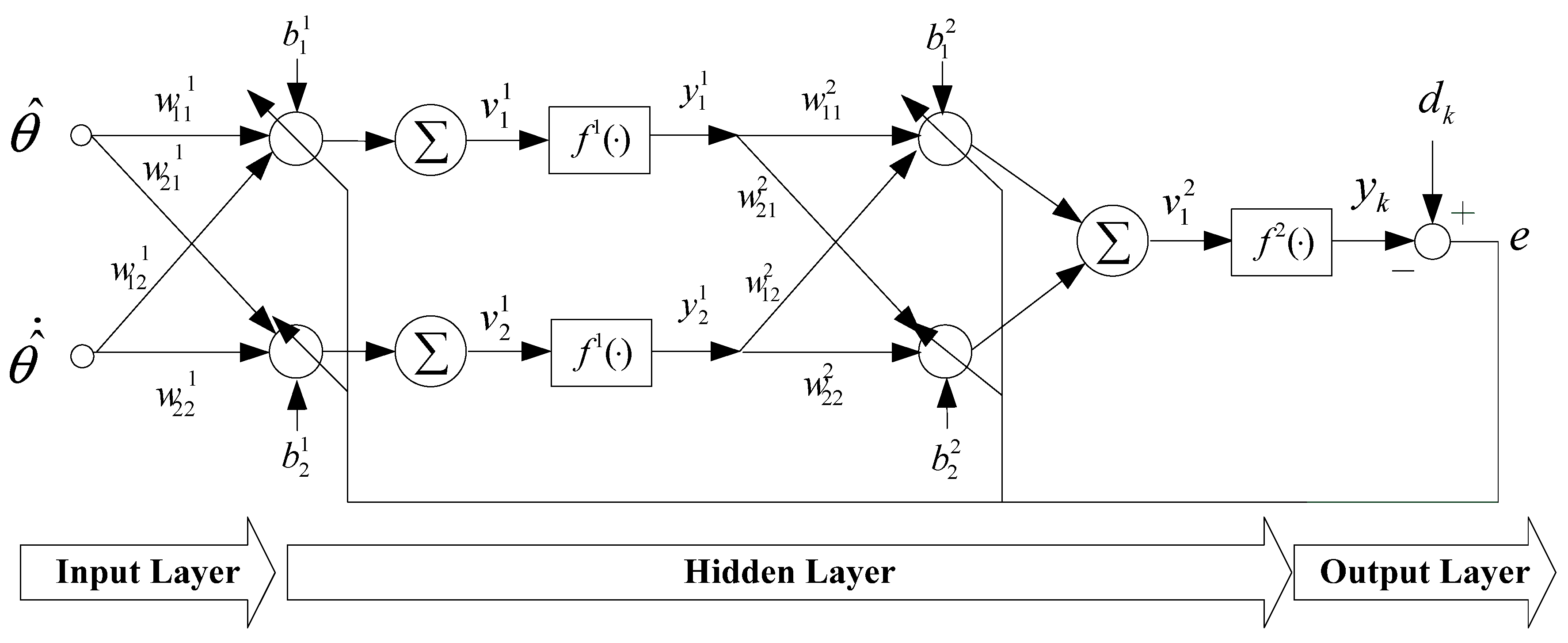

2.3. Neural Networks Compensation

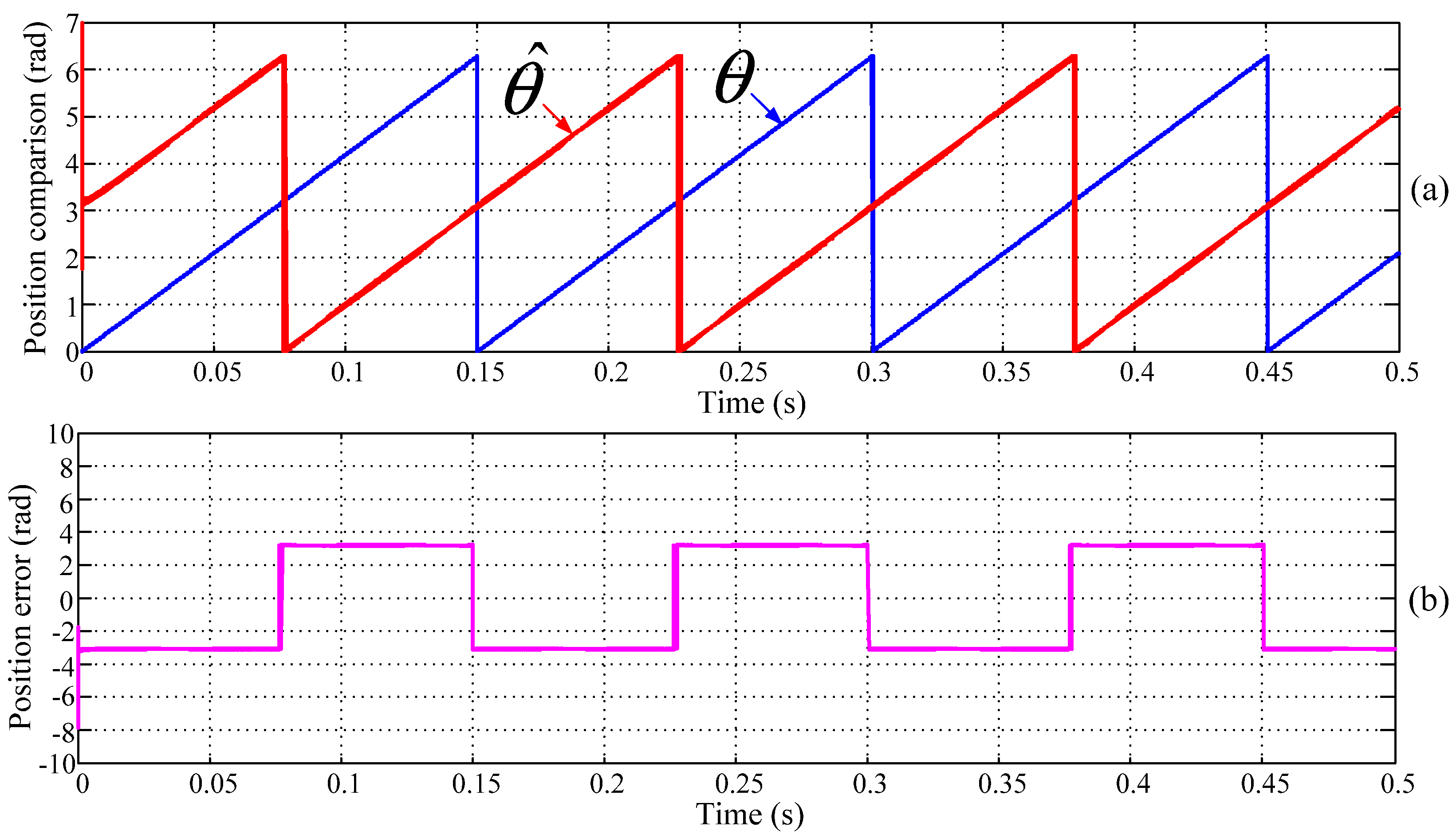

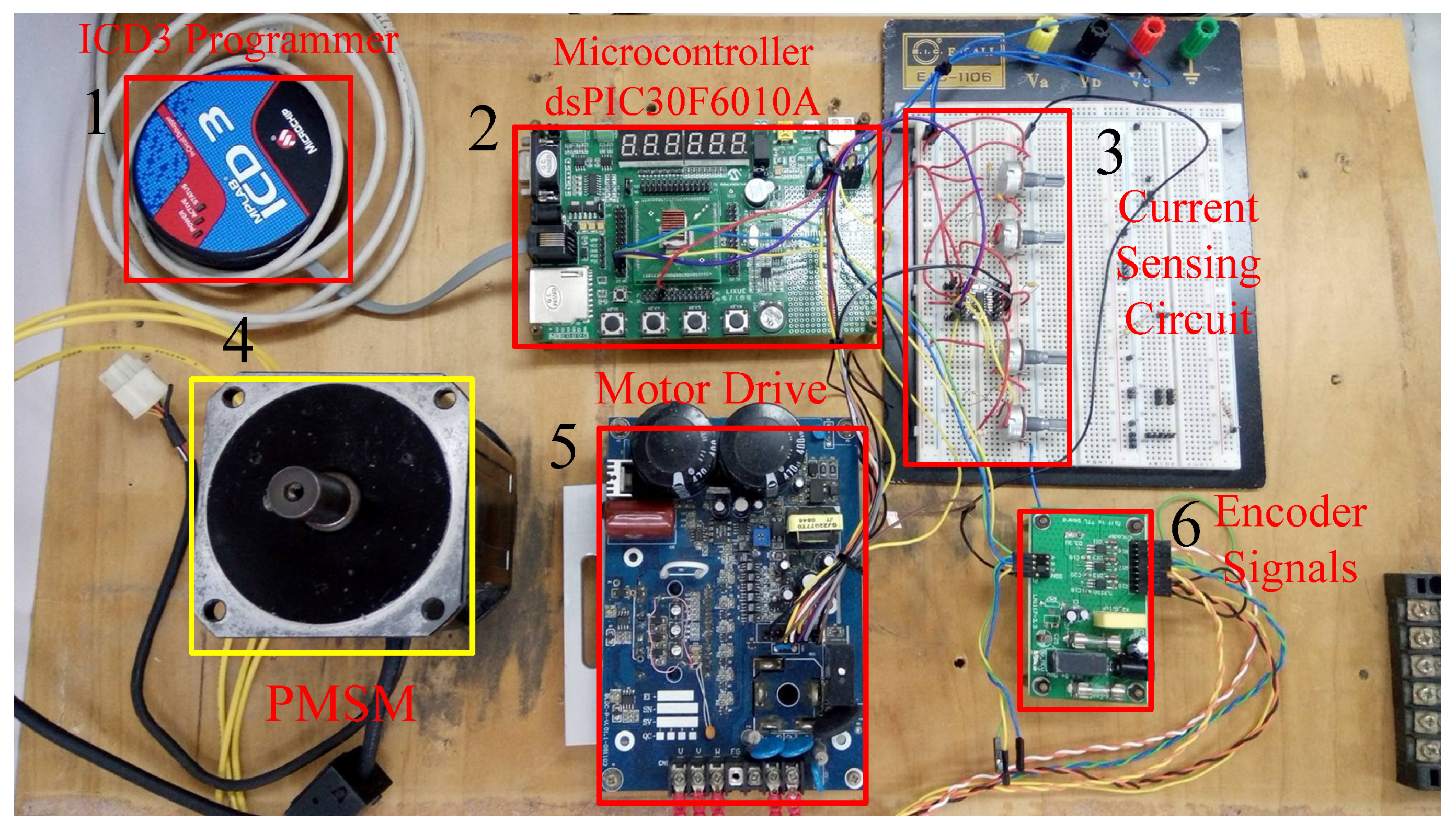

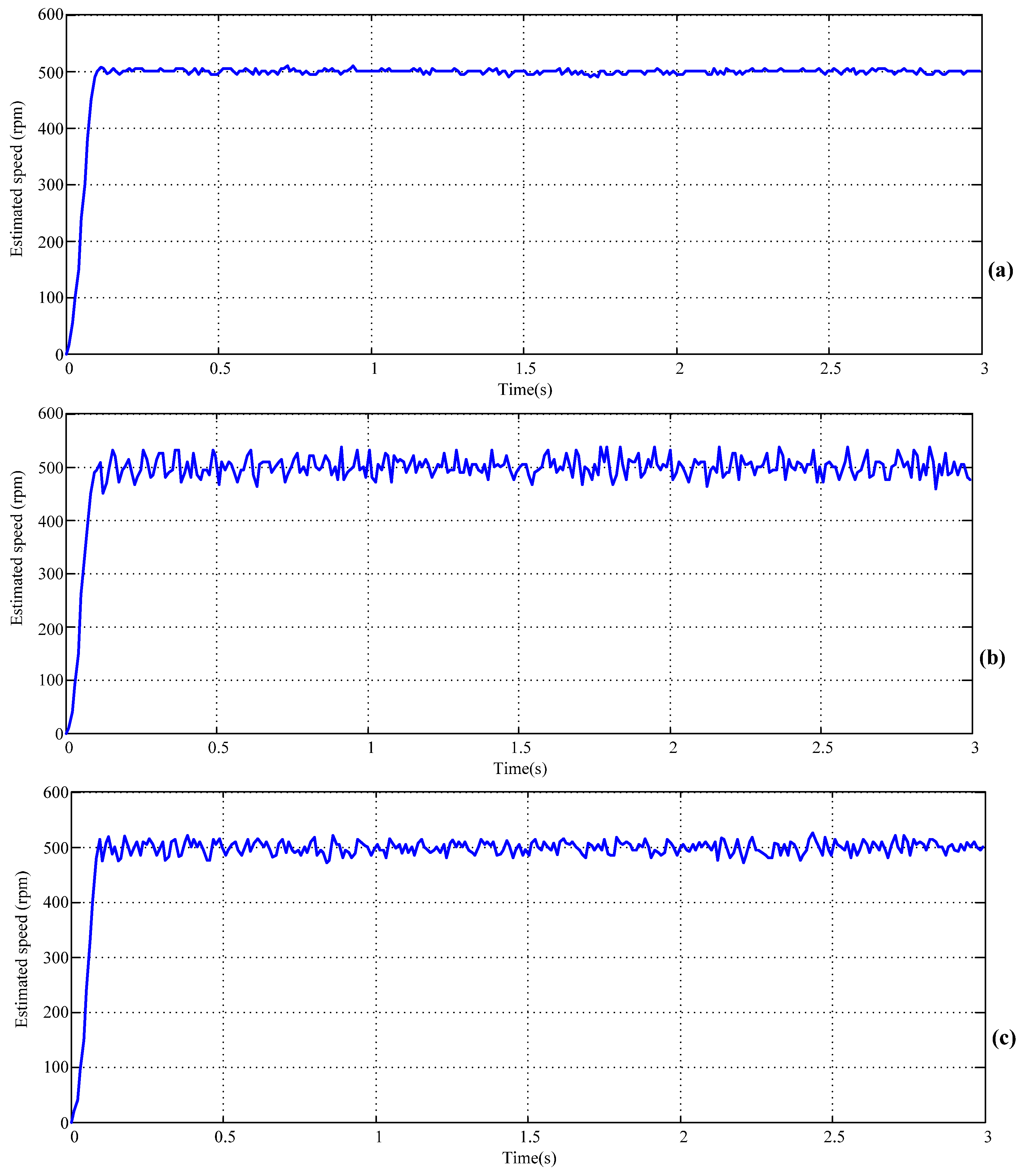

3. Simulation and Experimental Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems. Available online: http://www.iea.org/publications/freepublications/publication/ee_for_electricsystems.pdf (accessed on 15 February 2017).

- Wu, R.; Slemon, G. A permanent magnet motor drive without a shaft sensor. IEEE Trans. Ind. Appl. 1991, 27, 1005–1011. [Google Scholar] [CrossRef]

- Rafaq, M.S.; Mwasilu, F.; Kim, J.; Choi, H.H.; Jung, J.-W. Online Parameter Identification for Model-Based Sensorless Control of Interior Permanent Magnet Synchronous Machine. IEEE Trans. Power Electron. 2017, 32, 4631–4643. [Google Scholar] [CrossRef]

- Piippo, A.; Hinkkanen, M.; Luomi, J. Sensorless control of PMSM drives using a combination of voltage model and HF signal injection. In Proceedings of the Conference Record of the 2004 IEEE Industry Applications Conference, 39th IAS Annual Meeting, Seattle, WA, USA, 3–7 October 2004; pp. 964–970. [Google Scholar]

- Liu, J.M.; Zhu, Z.Q. Novel sensorless control strategy with injection of high frequency pulsating carrier signal into stationary reference frame. IEEE Trans. Ind. Appl. 2013, 50, 2574–2583. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Gong, L.M. Investigation of effectiveness of sensorless operation in carrier-signal-injection-based sensorless-control methods. IEEE Trans. Ind. Electron. 2011, 58, 3431–3439. [Google Scholar] [CrossRef]

- Seilmeier, M.; Ebersberger, S.; Piepenbreier, B. HF Test Current Injection-Based Self-Sensing Control of PMSM for Low- and Zero-Speed Range Using Two-Degree-of-Freedom Current Control. IEEE Trans. Ind. Appl. 2015, 51, 2268–2278. [Google Scholar] [CrossRef]

- Moon, C.; Kwon, Y.A. Sensorless speed control of permanent magnet synchronous motor by unscented Kalman filter using various scaling parameters. J. Electr. Eng. Technol. 2016, 11, 347–352. [Google Scholar] [CrossRef]

- Tomei, P.; Verrelli, C.M. Observer-based speed tracking control for sensorless permanent magnet synchronous motors with unknown load torque. IEEE Trans. Autom. Control 2011, 56, 1484–1488. [Google Scholar] [CrossRef]

- Kim, H.; Son, J.; Lee, J. A high-speed sliding-mode observer for the sensorless speed control of a PMSM. IEEE Trans. Ind. Electron. 2011, 58, 4069–4077. [Google Scholar]

- Lee, H.; Lee, J. Design of Iterative Sliding Mode Observer for Sensorless PMSM Control. IEEE Trans. Control Syst. Technol. 2013, 21, 1394–1399. [Google Scholar] [CrossRef]

- Qiao, Z.; Shi, T.; Wang, Y.; Yan, Y.; Xia, C.; He, X. New Sliding-Mode Observer for Position Sensorless Control of Permanent-Magnet Synchronous Motor. IEEE Trans. Ind. Electron. 2013, 60, 710–719. [Google Scholar] [CrossRef]

- Chen, S.Y.; Liu, T.S. Intelligent tracking control of a PMLSM using self-evolving probabilistic fuzzy neural network. IET Electr. Power Appl. 2017, 11, 1043–1054. [Google Scholar] [CrossRef]

- Lin, F.J.; Sun, I.F.; Yang, K.J.; Chang, J.K. Recurrent Fuzzy Neural Cerebellar Model Articulation Network Fault-Tolerant Control of Six-Phase Permanent Magnet Synchronous Motor Position Servo Drive. IEEE Trans. Fuzzy Syst. 2016, 24, 153–167. [Google Scholar] [CrossRef]

- Sun, X.; Chen, L.; Jiang, H.; Yang, Z.; Chen, J.; Zhang, W. High-Performance Control for a Bearingless Permanent-Magnet Synchronous Motor Using Neural Network Inverse Scheme Plus Internal Model Controllers. IEEE Trans. Ind. Electron. 2016, 63, 3479–3488. [Google Scholar] [CrossRef]

- Liu, S.; Guo, X.; Zhang, L. Robust Adaptive Backstepping Sliding Mode Control for Six-Phase Permanent Magnet Synchronous Motor Using Recurrent Wavelet Fuzzy Neural Network. IEEE Access. 2017, 5, 14502–14515. [Google Scholar]

- Wang, M.S.; Syamsiana, I.N.; Lin, F.C. Sensorless Speed Control of Permanent Magnet Synchronous Motors by Neural Network Algorithm. Math. Probl. Eng. 2014. [Google Scholar] [CrossRef]

- Schimmack, M.; Feistauer, E.E.; Amancio-Filhoand, S.T.; Mercorelli, P. Hysteresis Analysis and Control of a Metal-Polymer Hybrid Soft Actuator. Energies 2017, 10, 508. [Google Scholar] [CrossRef]

- Ginoya, D.; Shendge, P.D.; Phadke, S.B. Sliding Mode Control for Mismatched Uncertain Systems Using an Extended Disturbance Observer. IEEE Trans. Ind. Electron. 2014, 61, 1983–1992. [Google Scholar] [CrossRef]

- Chaudhari, P.; Sharma, V.; Shendge, P.D.; Phadke, S.B. Disturbance observer based sliding mode control for anti-lock braking system. In Proceedings of the IEEE International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 4–6 July 2016; pp. 1–5. [Google Scholar]

- Haus, B.; Mercorelli, P.; Werner, N. A Robust Adaptive Self-tuning Sliding Mode Control for a Hybrid Actuator in Camless Internal Combustion Engines. In Advances and Applications in Sliding Mode Control Systems; Azar, A.T., Zhu, Q., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 107–136. [Google Scholar]

- Veluvolu, K.C.; Soh, Y.C. High-Gain Observers with Sliding Mode for State and Unknown Input Estimations. IEEE Trans. Ind. Electron. 2009, 56, 3386–3393. [Google Scholar] [CrossRef]

- Mercorelli, P. An Anti-Saturating Adaptive Pre-action and a Slide Surface to Achieve Soft Landing Control for Electromagnetic Actuators. IEEE/ASME Trans. Mechatron. 2012, 17, 76–85. [Google Scholar] [CrossRef]

- Mercorelli, P. A Two-Stage Sliding-Mode High-Gain Observer to Reduce Uncertainties and Disturbances Effects for Sensorless Control in Automotive Applications. IEEE Trans. Ind. Electron. 2015, 62, 5929–5940. [Google Scholar] [CrossRef]

- Su, Y.; Zheng, C.; Mercorelli, P. Global Finite-Time Stabilization of Planar Linear Systems with Actuator Saturation. IEEE Trans. Circuits Syst. II Express Briefs 2017, 8, 947–951. [Google Scholar] [CrossRef]

- Antonio, L.M.; Hugo, V.B.; Josep, M.B.-M.; Javier, M.-A.; Luis, M.-S. Sliding-mode-control-based boost converter for high-voltage-low-power applications. IEEE Trans. Ind. Electron. 2015, 62, 229–237. [Google Scholar]

- Biricik, S.; Komurcugil, H. Optimized sliding mode control to maximize existence region for single-phase dynamic voltage restorers. IEEE Trans. Ind. Inform. 2016, 12, 1486–1497. [Google Scholar] [CrossRef]

- Pisano, A.; Tanelli, M.; Ferrara, A. Switched/time-based adaptation for second-order sliding mode control. Automatica 2016, 64, 126–132. [Google Scholar] [CrossRef]

- Precup, R.E.; Radac, M.B.; Roman, R.C.; Petriu, E.M. Model-free sliding mode control of nonlinear systems: Algorithms and experiments. Inf. Sci. 2017, 381, 176–192. [Google Scholar] [CrossRef]

- Ellis, G. Control System Design Guide, 2nd ed.; Academic Press: San Diego, CA, USA, 2000; pp. 105–106. ISBN 2-12-237465-7. [Google Scholar]

| Parameters | Unit | Value |

|---|---|---|

| P | W | 750 |

| V | V | 149.4 |

| T | N·m | 2.931 |

| I | A | 3.4 |

| N | Rpm | 3000 |

| K | N·m/A | 0.776 |

| J | Kg·cm2 | 2.449 |

| Rs | Ω | 3.27 |

| Ls | mH | 10.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.-S.; Tsai, T.-M. Sliding Mode and Neural Network Control of Sensorless PMSM Controlled System for Power Consumption and Performance Improvement. Energies 2017, 10, 1780. https://doi.org/10.3390/en10111780

Wang M-S, Tsai T-M. Sliding Mode and Neural Network Control of Sensorless PMSM Controlled System for Power Consumption and Performance Improvement. Energies. 2017; 10(11):1780. https://doi.org/10.3390/en10111780

Chicago/Turabian StyleWang, Ming-Shyan, and Tse-Ming Tsai. 2017. "Sliding Mode and Neural Network Control of Sensorless PMSM Controlled System for Power Consumption and Performance Improvement" Energies 10, no. 11: 1780. https://doi.org/10.3390/en10111780

APA StyleWang, M.-S., & Tsai, T.-M. (2017). Sliding Mode and Neural Network Control of Sensorless PMSM Controlled System for Power Consumption and Performance Improvement. Energies, 10(11), 1780. https://doi.org/10.3390/en10111780