Optimization of Reducing Sugar Production from Manihot glaziovii Starch Using Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrate and Enzymes

2.2. Methodology

2.2.1. Composition of Manihot glaziovii Substrate

2.2.2. Analysis of Sugars and Ethanol as by-Products

2.2.3. Hydrolysis Process

2.2.4. Optimization of Hydrolysis Process

2.2.5. Yeast Culturing Media Preparation

2.2.6. Fermentation Process

2.2.7. Fermentation Kinetics

2.2.8. Distillation Process

2.2.9. Fourier Transform Infrared Spectroscopy

2.2.10. Physical and Chemical Properties of the Manihot glaziovii Bioethanol

3. Results and Discussion

3.1. Composition of Manihot glaziovii Substrate

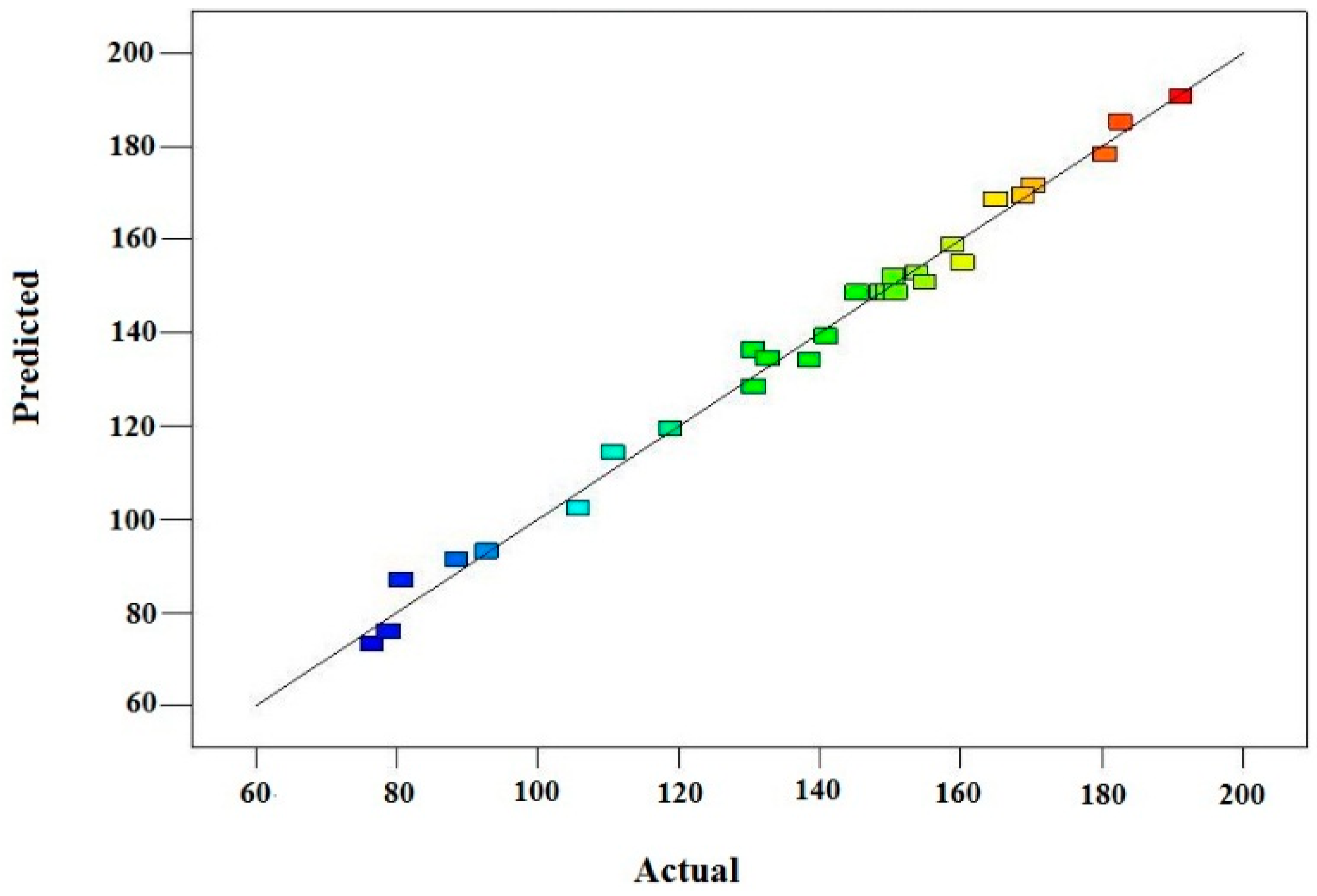

3.2. Optimization of Starch Hydrolysis Process Operating Parameters

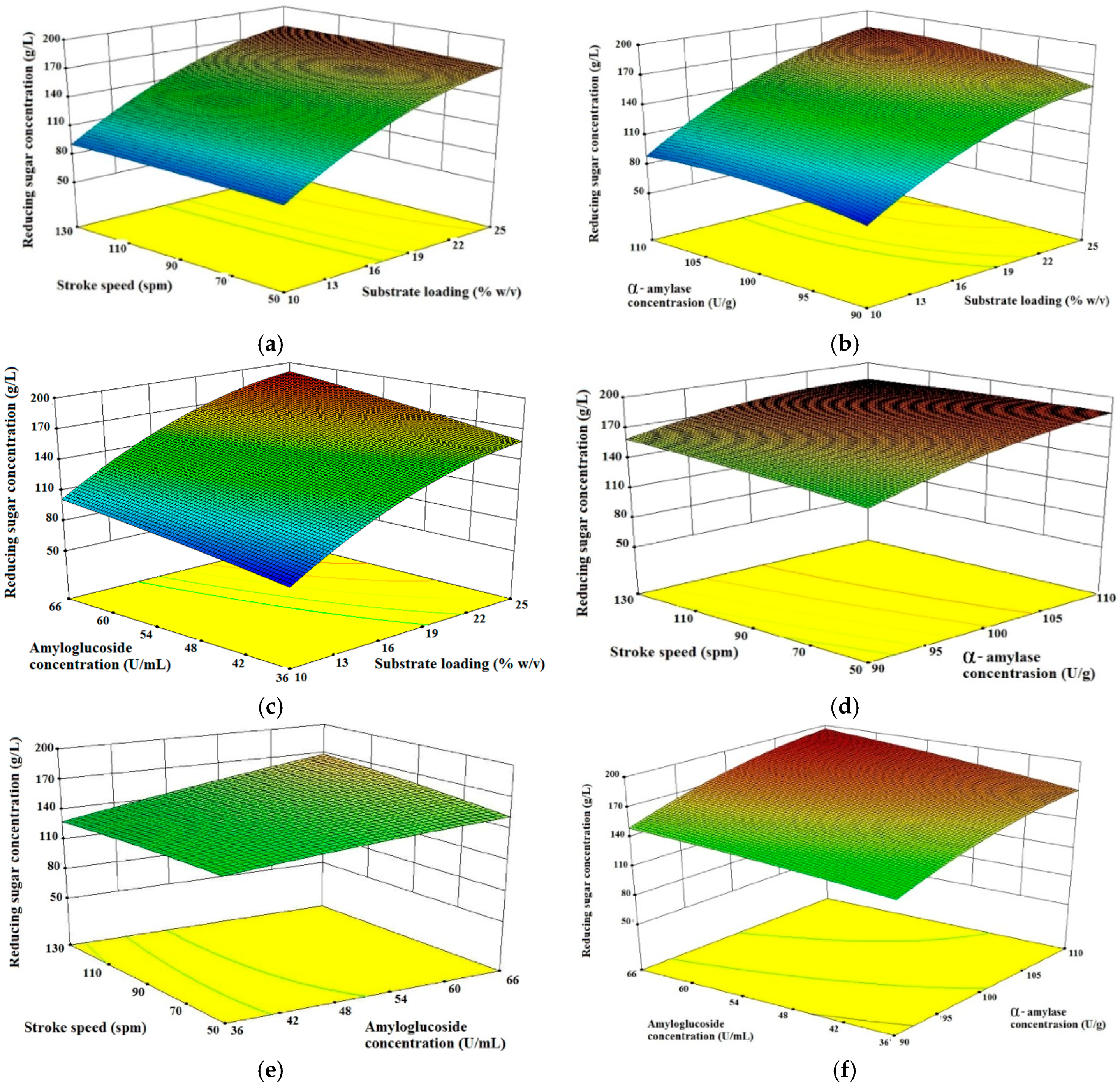

3.3. Relationship between the Independent Variables of the Starch Hydrolysis Process

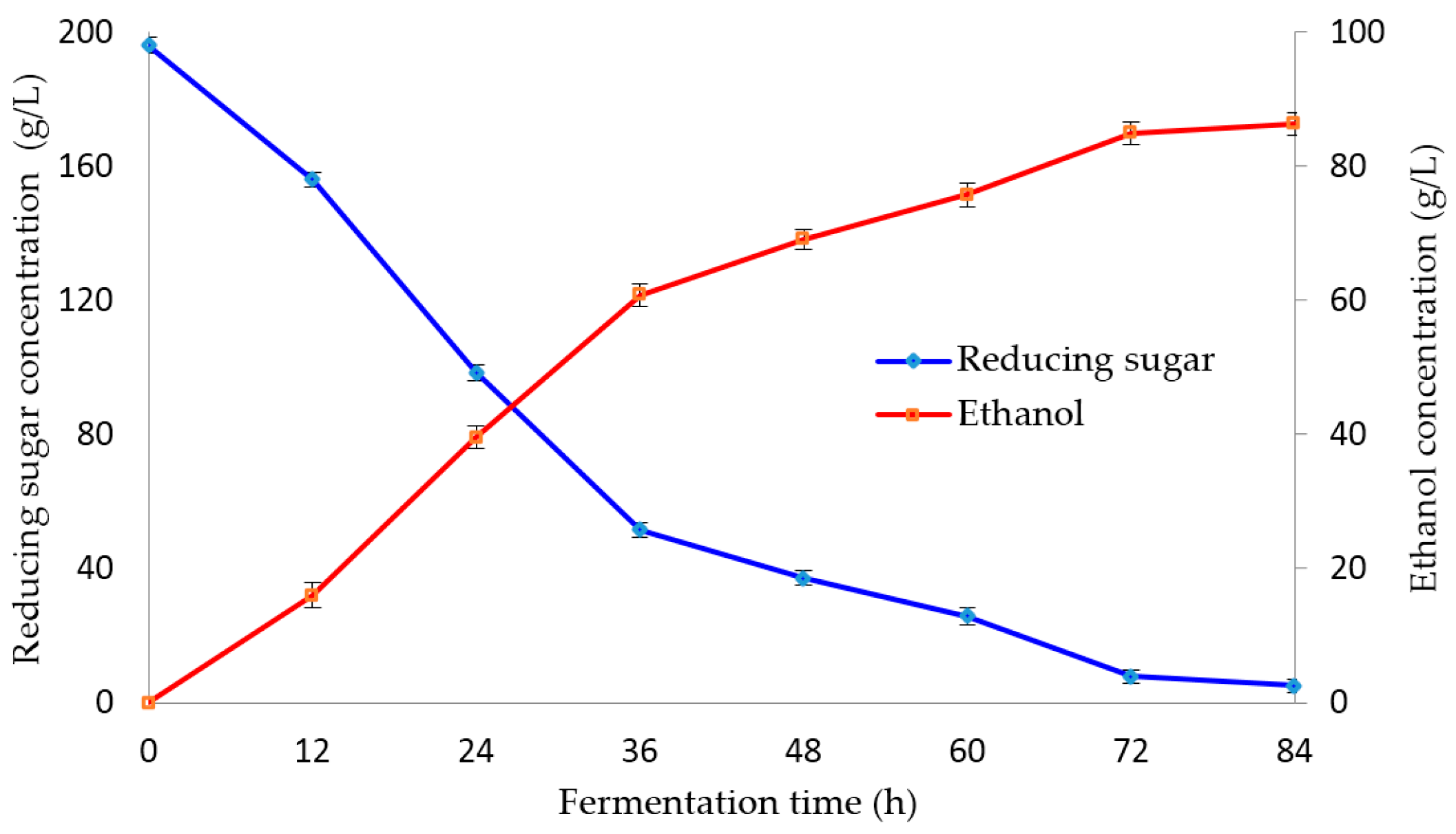

3.4. Ethanol Production from Manihot glaziovii

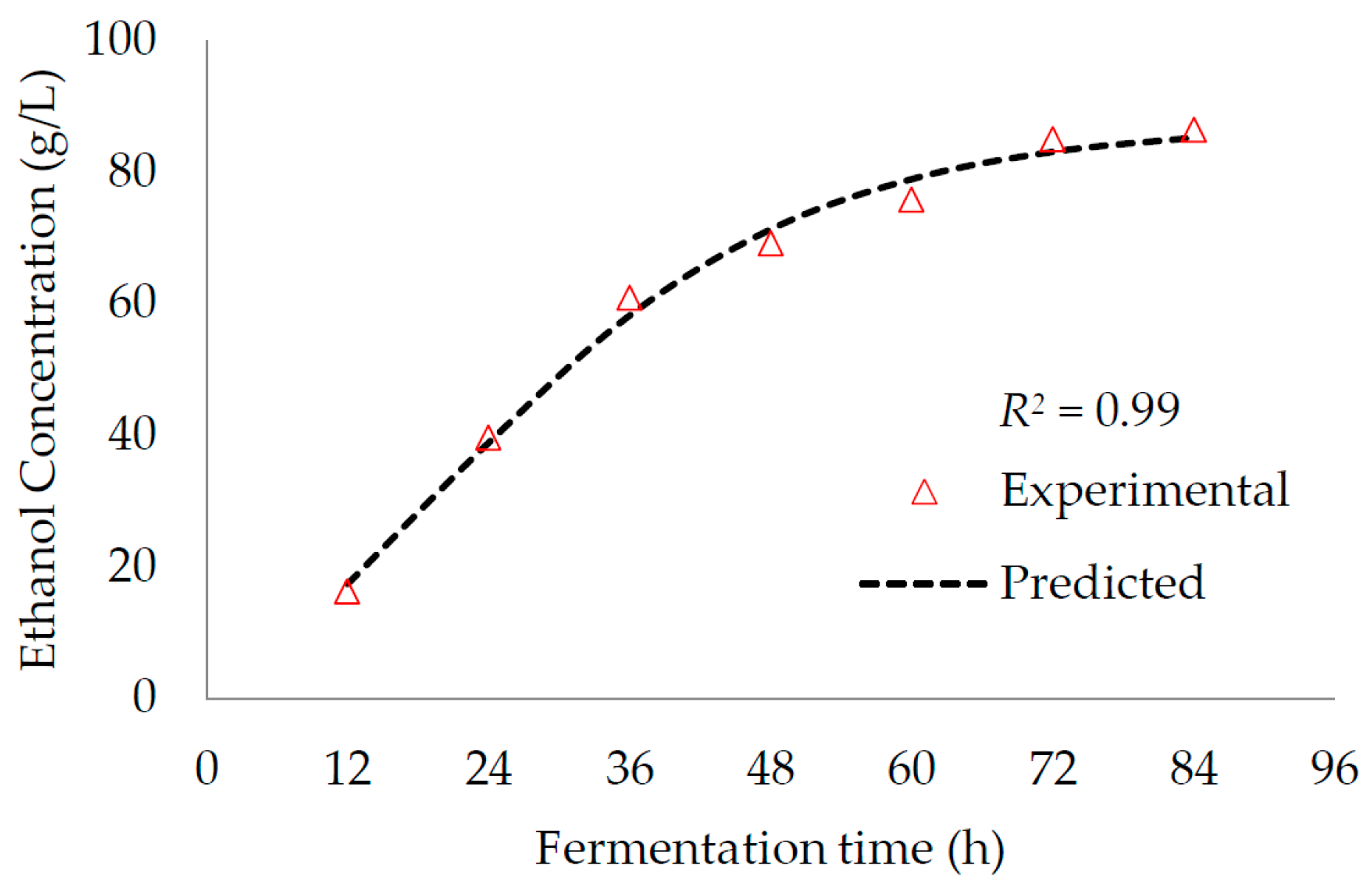

3.5. Fermentation Kinetics

3.6. Distillation and Dehydration

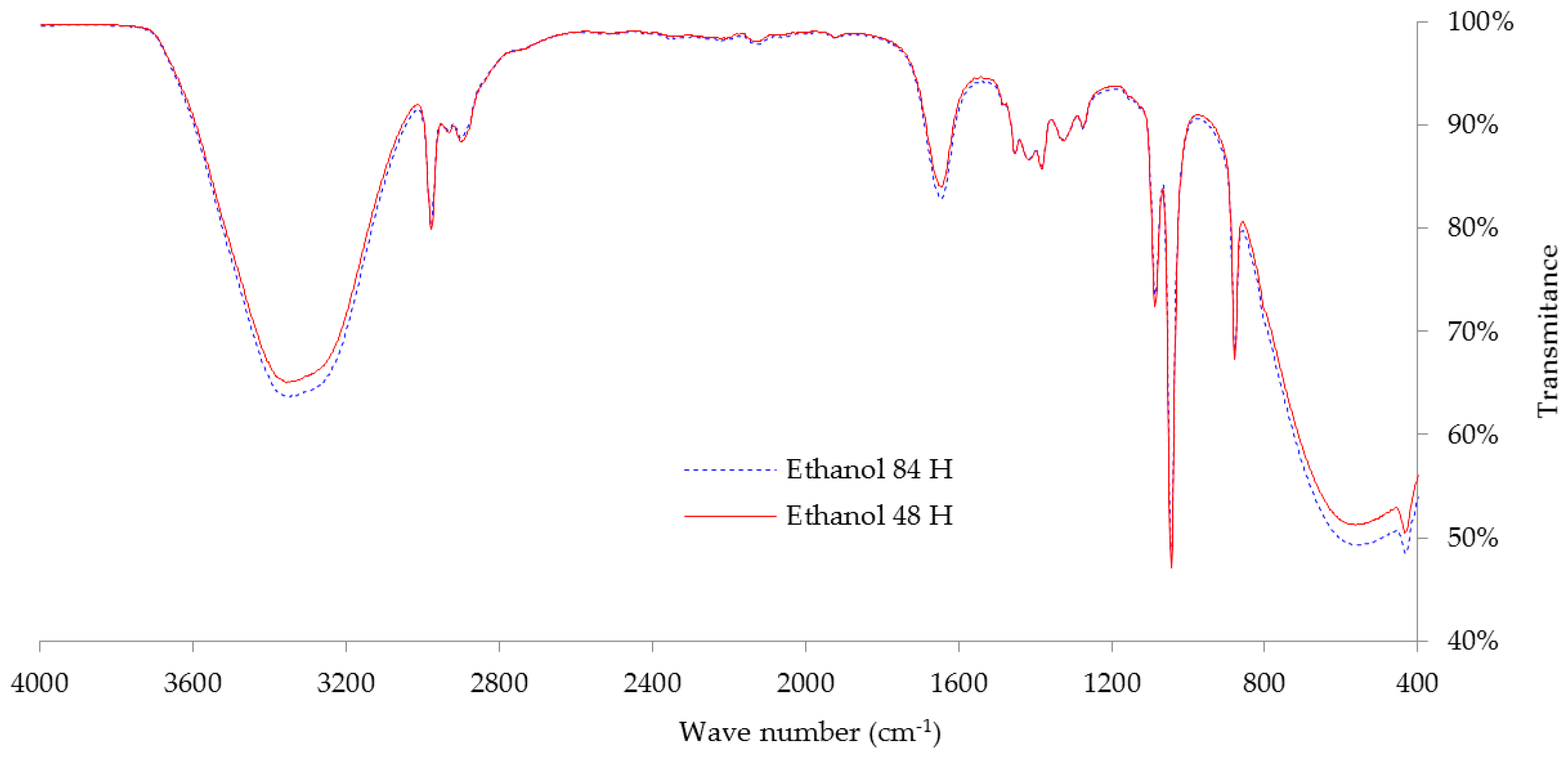

3.7. Fourier Transform Infrared Spectroscopy of Manihot glaziovii Bioethanol

3.8. Physical and Chemical Properties of Manihot glaziovii Bioethanol

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liguori, R.; Soccol, C.; De Souza Vandenberghe, L.P.; Woiciechowski, A.; Faraco, V. Second generation ethanol production from brewers’ spent grain. Energies 2015, 8, 2575–2586. [Google Scholar] [CrossRef]

- Renó, M.L.G.; Olmo, O.A.D.; Palacio, J.C.E.; Lora, E.E.S.; Venturini, O.J. Sugarcane biorefineries: Case studies applied to the brazilian sugar-alcohol industry. Energy Convers. Manag. 2014, 86, 981–991. [Google Scholar] [CrossRef]

- Pejin, J.D.; Mojović, L.V.; Pejin, D.J.; Kocić-Tanackov, S.D.; Savić, D.S.; Nikolić, S.B.; Djukić-Vuković, A.P. Bioethanol production from triticale by simultaneous saccharification and fermentation with magnesium or calcium ions addition. Fuel 2015, 142, 58–64. [Google Scholar] [CrossRef]

- Hansdah, D.; Murugan, S.; Das, L.M. Experimental studies on a DI diesel engine fueled with bioethanol-diesel emulsions. Alexandria Eng. J. 2013, 52, 267–276. [Google Scholar] [CrossRef]

- Wang, J.; Kim, Y.M.; Rhee, H.S.; Lee, M.W.; Park, J.M. Bioethanol production from mannitol by a newly isolated bacterium, Enterobacter sp. JMP3. Bioresour. Technol. 2013, 135, 199–206. [Google Scholar] [CrossRef] [PubMed]

- Balat, M. Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energy Convers. Manag. 2011, 52, 858–875. [Google Scholar] [CrossRef]

- Küüt, A.; Ritslaid, K.; Olt, J. Study of potential uses for farmstead ethanol as motor fuel. Agron. Res. 2011, 9, 125–134. [Google Scholar]

- Mahalaxmi, S.; Williford, C. Biochemical conversion of biomass to fuels. In Handbook of Climate Change Mitigation; Springer: Berlin, Germany, 2012; pp. 965–999. [Google Scholar]

- Sebayang, A.H.; Masjuki, H.H.; Ong, H.C.; Dharma, S.; Silitonga, A.S.; Mahlia, T.M.I.; Aditiya, H.B. A perspective on bioethanol production from biomass as alternative fuel for spark ignition engine. RSC Adv. 2016, 6, 14964–14992. [Google Scholar] [CrossRef]

- Yangcheng, H.; Jiang, H.; Blanco, M.; Jane, J.-L. Characterization of normal and waxy corn starch for bioethanol production. J. Agric. Food Chem. 2013, 61, 379–386. [Google Scholar] [CrossRef] [PubMed]

- Brunschwig, C.; Moussavou, W.; Blin, J. Use of bioethanol for biodiesel production. Prog. Energy Combust. Sci. 2012, 38, 283–301. [Google Scholar] [CrossRef]

- Ahmed, I.N.; Nguyen, P.L.T.; Huynh, L.H.; Ismadji, S.; Ju, Y.-H. Bioethanol production from pretreated Melaleuca leucadendron shedding bark—Simultaneous saccharification and fermentation at high solid loading. Bioresour. Technol. 2013, 136, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.-Y.; Jiang, B.-H.; Duan, K.-J. Production of bioethanol from carrot pomace using the thermotolerant yeast kluyveromyces marxianus. Energies 2013, 6, 1794–1801. [Google Scholar] [CrossRef]

- Moshi, A.P.; Hosea, K.M.M.; Elisante, E.; Mamo, G.; Mattiasson, B. High temperature simultaneous saccharification and fermentation of starch from inedible wild cassava (Manihot glaziovii) to bioethanol using caloramator boliviensis. Bioresour. Technol. 2015, 180, 128–136. [Google Scholar] [CrossRef] [PubMed]

- Moshi, A.P.; Crespo, C.F.; Badshah, M.; Hosea, K.M.M.; Mshandete, A.M.; Mattiasson, B. High bioethanol titre from Manihot glaziovii through fed-batch simultaneous saccharification and fermentation in automatic gas potential test system. Bioresour. Technol. 2014, 156, 348–356. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Zhu, M. A consolidated bio-processing of ethanol from cassava pulp accompanied by hydrogen production. Bioresour. Technol. 2011, 102, 10471–10479. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Lin, Y.; Zhang, Q.; Wang, X.; Wu, D.; Kong, H. Optimisation of simultaneous saccharification and fermentation of wheat straw for ethanol production. Fuel 2013, 112, 331–337. [Google Scholar] [CrossRef]

- Dharma, S.; Masjuki, H.H.; Ong, H.C.; Sebayang, A.H.; Silitonga, A.S.; Kusumo, F.; Mahlia, T.M.I. Optimization of biodiesel production process for mixed Jatropha curcas–Ceiba pentandra biodiesel using response surface methodology. Energy Convers. Manag. 2016, 115, 178–190. [Google Scholar] [CrossRef]

- Ali, O.; Mamat, R.; Najafi, G.; Yusaf, T.; Safieddin Ardebili, S. Optimization of biodiesel-diesel blended fuel properties and engine performance with ether additive using statistical analysis and response surface methods. Energies 2015, 8, 14136–14150. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, J.; Jönsson, P.G.; Zhao, Z. Improvement and optimization of the growth quality of upright ZnO rod arrays by the response surface methodology. Appl. Surf. Sci. 2015, 351, 451–459. [Google Scholar] [CrossRef]

- Moshi, A.P.; Crespo, C.F.; Badshah, M.; Hosea, K.M.M.; Mshandete, A.M.; Elisante, E.; Mattiasson, B. Characterisation and evaluation of a novel feedstock, Manihot glaziovii, Muell. Arg, for production of bioenergy carriers: Bioethanol and biogas. Bioresour. Technol. 2014, 172, 58–67. [Google Scholar] [CrossRef] [PubMed]

- Gumienna, M.; Szwengiel, A.; Lasik, M.; Szambelan, K.; Majchrzycki, D.; Adamczyk, J.; Nowak, J.; Czarnecki, Z. Effect of corn grain variety on the bioethanol production efficiency. Fuel 2016, 164, 386–392. [Google Scholar] [CrossRef]

- Meinita, M.D.N.; Marhaeni, B.; Winanto, T.; Setyaningsih, D.; Hong, Y.-K. Catalytic efficiency of sulfuric and hydrochloric acids for the hydrolysis of Gelidium latifolium (Gelidiales, Rhodophyta) in bioethanol production. J. Ind. Eng. Chem. 2015, 27, 108–114. [Google Scholar] [CrossRef]

- Tasić, M.B.; Konstantinović, B.V.; Lazić, M.L.; Veljković, V.B. The acid hydrolysis of potato tuber mash in bioethanol production. Biochem. Eng. J. 2009, 43, 208–211. [Google Scholar] [CrossRef]

- Naguleswaran, S.; Li, J.; Vasanthan, T.; Bressler, D.; Hoover, R. Amylolysis of large and small granules of native triticale, wheat and corn starches using a mixture of α-amylase and glucoamylase. Carbohydr. Polym. 2012, 88, 864–874. [Google Scholar] [CrossRef]

- Masum, B.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Palash, S.M.; Abedin, M.J. Effect of ethanol-gasoline blend on NOx emission in SI engine. Renew. Sustain. Energy Rev. 2013, 24, 209–222. [Google Scholar] [CrossRef]

- Miller, G.L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Dodić, J.M.; Vučurović, D.G.; Dodić, S.N.; Grahovac, J.A.; Popov, S.D.; Nedeljković, N.M. Kinetic modelling of batch ethanol production from sugar beet raw juice. Appl. Energy 2012, 99, 192–197. [Google Scholar] [CrossRef]

- Moshi, A.P.; Temu, S.G.; Nges, I.A.; Malmo, G.; Hosea, K.M.M.; Elisante, E.; Mattiasson, B. Combined production of bioethanol and biogas from peels of wild cassava Manihot glaziovii. Chem. Eng. J. 2015, 279, 297–306. [Google Scholar] [CrossRef]

- Sivamani, S.; Baskar, R. Optimization of bioethanol production from cassava peel using statistical experimental design. Environ. Prog. Sustain. Energy 2015, 34, 567–574. [Google Scholar] [CrossRef]

- Yadira, P.-S.B.; Sergio, S.-T.; Fernando, S.E.L.; Sebastian, P.J.; Eapen, D. Bioethanol production from coffee mucilage. Energy Procedia 2014, 57, 950–956. [Google Scholar] [CrossRef]

| Parameter | Unit | Range and Levels | ||

|---|---|---|---|---|

| −1 | 0 | +1 | ||

| Substrate loading (X1) | % (w/v) | 10 | 17.5 | 25 |

| α-amylase concentration (X2) | U/g | 90 | 100 | 110 |

| Amyloglucosidase concentration (X3) | U/mL | 36 | 51 | 66 |

| Stroke speed (X4) | spm | 50 | 90 | 130 |

| Property | Equipment | Standard Method [9,26] |

|---|---|---|

| Kinematic viscosity | Lovis 2000 M/ME micro viscometer and micro density meter (Anton Paar) | DIN 53015 |

| Density | ISO 12058 | |

| Elemental analysis for carbon (C), hydrogen (H) and oxygen (O) | CE-440 CHN Elemental Analyzer (EIA) | ASTM D5291 |

| Calorific value | IKA C2000 basic, automatic bomb calorimeter | ASTM D240 |

| Ethanol content | Gas chromatograph, Agilent 7890A | ASTM D4806 |

| Parameter | Unit | M. glaziovii |

|---|---|---|

| carbohydrates | wt % | 74.8 |

| proteins | wt % | 6.62 |

| lipids | wt % | 3.12 |

| Ash | wt % | 5.15 |

| fibers | wt % | 1.70 |

| moisture content | wt % | 8.61 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F | Remarks |

|---|---|---|---|---|---|---|

| Model | 28,689.87 | 14 | 2049.28 | 115.29 | <0.0001 | significant |

| A-Substrate loading (X1) | 22,057.47 | 1 | 22,057.47 | 1240.98 | <0.0001 | - |

| B-α-amylase (X2) | 2041.02 | 1 | 2041.02 | 114.83 | <0.0001 | - |

| C-Amyloglucosidase (X3) | 2528.51 | 1 | 2528.51 | 142.26 | <0.0001 | - |

| D-Stroke speed (X4) | 91.69 | 1 | 91.69 | 5.16 | 0.0394 | - |

| AB | 39.38 | 1 | 39.38 | 2.22 | 0.1588 | - |

| AC | 7.54 | 1 | 7.54 | 0.42 | 0.5255 | - |

| AD | 1.37 | 1 | 1.37 | 0.077 | 0.7854 | - |

| BC | 16.61 | 1 | 16.61 | 0.93 | 0.3502 | - |

| BD | 92.54 | 1 | 92.54 | 5.21 | 0.0387 | - |

| CD | 124.21 | 1 | 124.21 | 6.99 | 0.0193 | - |

| A2 | 1498.9 | 1 | 1498.9 | 84.33 | <0.0001 | - |

| B2 | 348.88 | 1 | 348.88 | 19.63 | 0.0006 | - |

| C2 | 14.11 | 1 | 14.11 | 0.79 | 0.3879 | - |

| D2 | 12.09 | 1 | 12.09 | 0.68 | 0.4234 | - |

| Residual | 248.84 | 14 | 17.77 | - | - | - |

| Lack of Fit | 231.66 | 10 | 23.17 | 5.39 | 0.0593 | not significant |

| Pure Error | 17.18 | 4 | 4.3 | - | - | - |

| Cor Total | 28,938.71 | 28 | - | - | - | - |

| R-Squared | 0.9914 | - | Adj R-Squared a | 0.9828 | - | - |

| C.V. b % | 3.05 | - | - | - | - | - |

| Sample No | Substrate Loading (% w/v) (X1) | α-Amylase Concentration (U/g) (X2) | Amyloglucosidase Concentration (U/mL) (X3) | Stroke Speed (spm) (X4) | Reducing Sugar (g/L) | |

|---|---|---|---|---|---|---|

| Experiment | Predicted | |||||

| 1 | 25 | 90 | 51 | 90 | 153.84 | 152.78 |

| 2 | 10 | 100 | 36 | 90 | 78.84 | 75.92 |

| 3 | 10 | 100 | 51 | 130 | 88.48 | 91.36 |

| 4 | 17.5 | 90 | 36 | 90 | 110.68 | 114.29 |

| 5 | 25 | 100 | 51 | 130 | 180.52 | 178.27 |

| 6 | 17.5 | 100 | 36 | 50 | 138.46 | 134.07 |

| 7 | 17.5 | 110 | 51 | 50 | 160.28 | 155.00 |

| 8 | 17.5 | 100 | 51 | 90 | 149.64 | 148.62 |

| 9 | 17.5 | 100 | 66 | 130 | 164.94 | 168.63 |

| 10 | 17.5 | 100 | 66 | 50 | 150.48 | 151.96 |

| 11 | 25 | 100 | 51 | 50 | 170.28 | 171.57 |

| 12 | 17.5 | 100 | 36 | 130 | 130.63 | 128.45 |

| 13 | 17.5 | 90 | 51 | 50 | 118.82 | 119.30 |

| 14 | 17.5 | 110 | 66 | 90 | 168.84 | 169.40 |

| 15 | 17.5 | 90 | 51 | 130 | 132.64 | 134.45 |

| 16 | 17.5 | 100 | 51 | 90 | 148.58 | 148.62 |

| 17 | 17.5 | 100 | 51 | 90 | 145.24 | 148.62 |

| 18 | 10 | 110 | 51 | 90 | 92.75 | 93.11 |

| 19 | 25 | 100 | 36 | 90 | 158.85 | 158.92 |

| 20 | 17.5 | 100 | 51 | 90 | 150.78 | 148.62 |

| 21 | 17.5 | 100 | 51 | 90 | 148.84 | 148.62 |

| 22 | 17.5 | 110 | 51 | 130 | 154.86 | 150.91 |

| 23 | 25 | 110 | 51 | 90 | 182.64 | 185.13 |

| 24 | 25 | 100 | 66 | 90 | 191.25 | 190.70 |

| 25 | 17.5 | 110 | 36 | 90 | 130.49 | 136.30 |

| 26 | 17.5 | 90 | 66 | 90 | 140.88 | 139.24 |

| 27 | 10 | 100 | 51 | 50 | 80.58 | 87.00 |

| 28 | 10 | 90 | 51 | 90 | 76.5 | 73.30 |

| 29 | 10 | 100 | 66 | 90 | 105.75 | 102.21 |

| Fuel Properties | M. glaziovii Bioethanol | Gasoline [26] | Ethanol ASTM D4806 [26] |

|---|---|---|---|

| Formula | C2H5OH | C5–C12 | C2H5OH |

| Carbon-fraction | 56.1 | 85–88 | 52.2 |

| Hydrogen-fraction | 12.5 | 12–15 | 13 |

| Oxygen-fraction | 35.1 | 0 | 34.7 |

| C/H (atom ratio) | 0.37 | 0.56 | 0.33 |

| Viscosity at 20 °C (mm/s2) | 1.28 | 0.5–0.6 | 1.2–1.5 |

| Density at 15 °C (kg/m3) | 803.7 | 750–765 | 785–809.9 |

| Higher heating value (MJ/kg) | 30.26 | 47.30 | 29.7 |

| Lower heating value MJ/kg | 28.98 | 44 | 26.9 |

| Ethanol content (%vol. min) | 95.6 | – | 92.1 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sebayang, A.H.; Hassan, M.H.; Ong, H.C.; Dharma, S.; Silitonga, A.S.; Kusumo, F.; Mahlia, T.M.I.; Bahar, A.H. Optimization of Reducing Sugar Production from Manihot glaziovii Starch Using Response Surface Methodology. Energies 2017, 10, 35. https://doi.org/10.3390/en10010035

Sebayang AH, Hassan MH, Ong HC, Dharma S, Silitonga AS, Kusumo F, Mahlia TMI, Bahar AH. Optimization of Reducing Sugar Production from Manihot glaziovii Starch Using Response Surface Methodology. Energies. 2017; 10(1):35. https://doi.org/10.3390/en10010035

Chicago/Turabian StyleSebayang, Abdi Hanra, Masjuki Haji Hassan, Hwai Chyuan Ong, Surya Dharma, Arridina Susan Silitonga, Fitranto Kusumo, Teuku Meurah Indra Mahlia, and Aditiya Harjon Bahar. 2017. "Optimization of Reducing Sugar Production from Manihot glaziovii Starch Using Response Surface Methodology" Energies 10, no. 1: 35. https://doi.org/10.3390/en10010035

APA StyleSebayang, A. H., Hassan, M. H., Ong, H. C., Dharma, S., Silitonga, A. S., Kusumo, F., Mahlia, T. M. I., & Bahar, A. H. (2017). Optimization of Reducing Sugar Production from Manihot glaziovii Starch Using Response Surface Methodology. Energies, 10(1), 35. https://doi.org/10.3390/en10010035