Adaptable Optical Fiber Displacement-Curvature Sensor Based on a Modal Michelson Interferometer with a Tapered Single Mode Fiber

Abstract

:1. Introduction

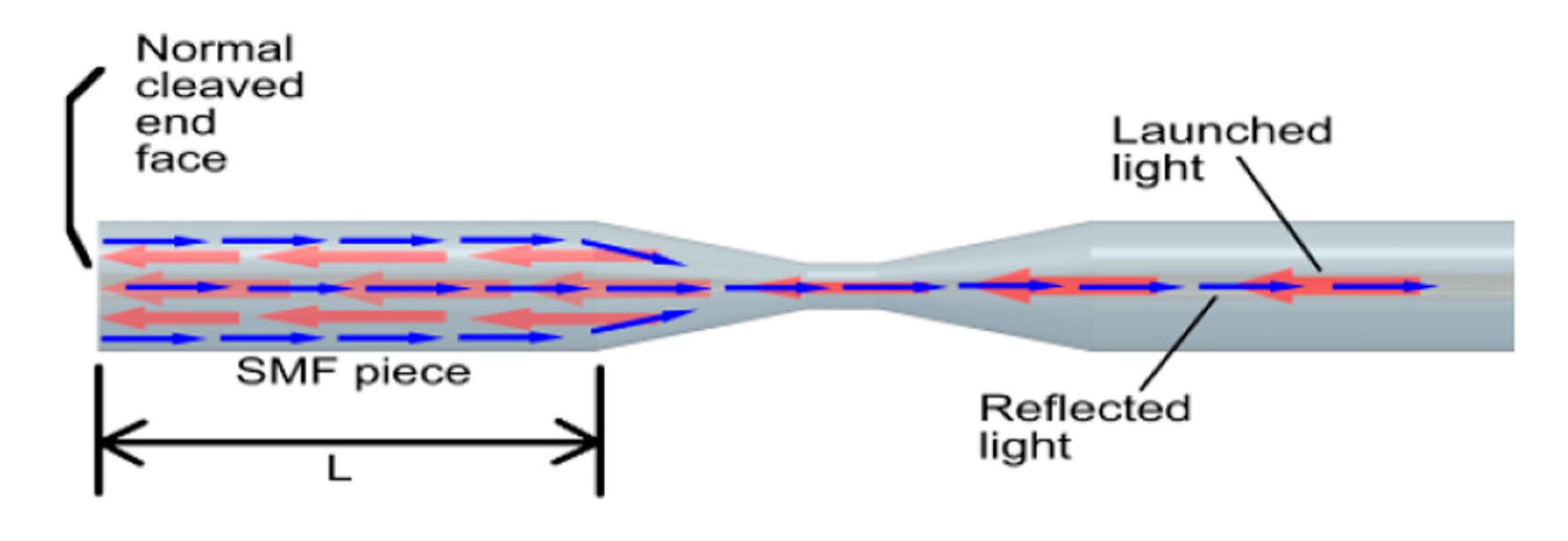

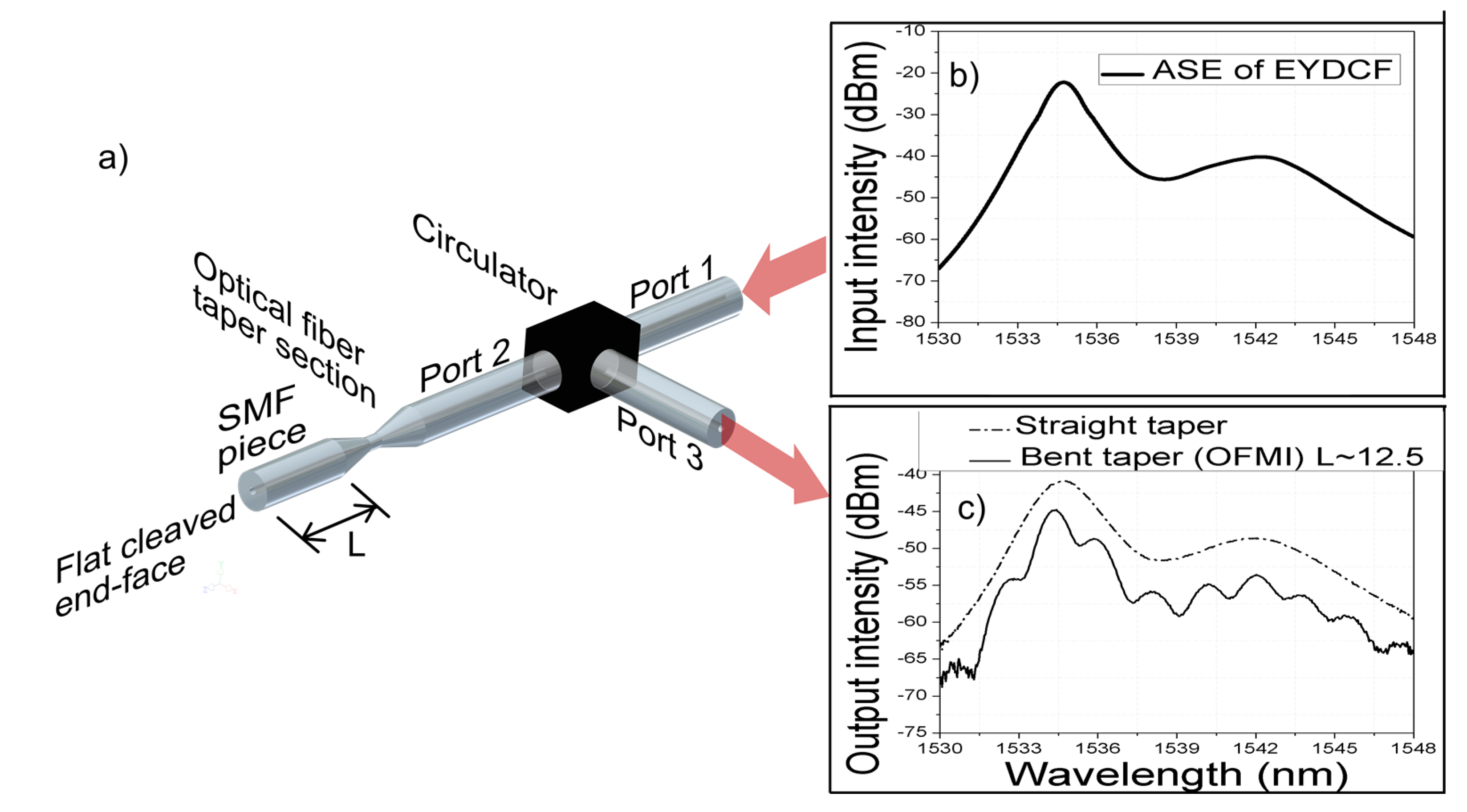

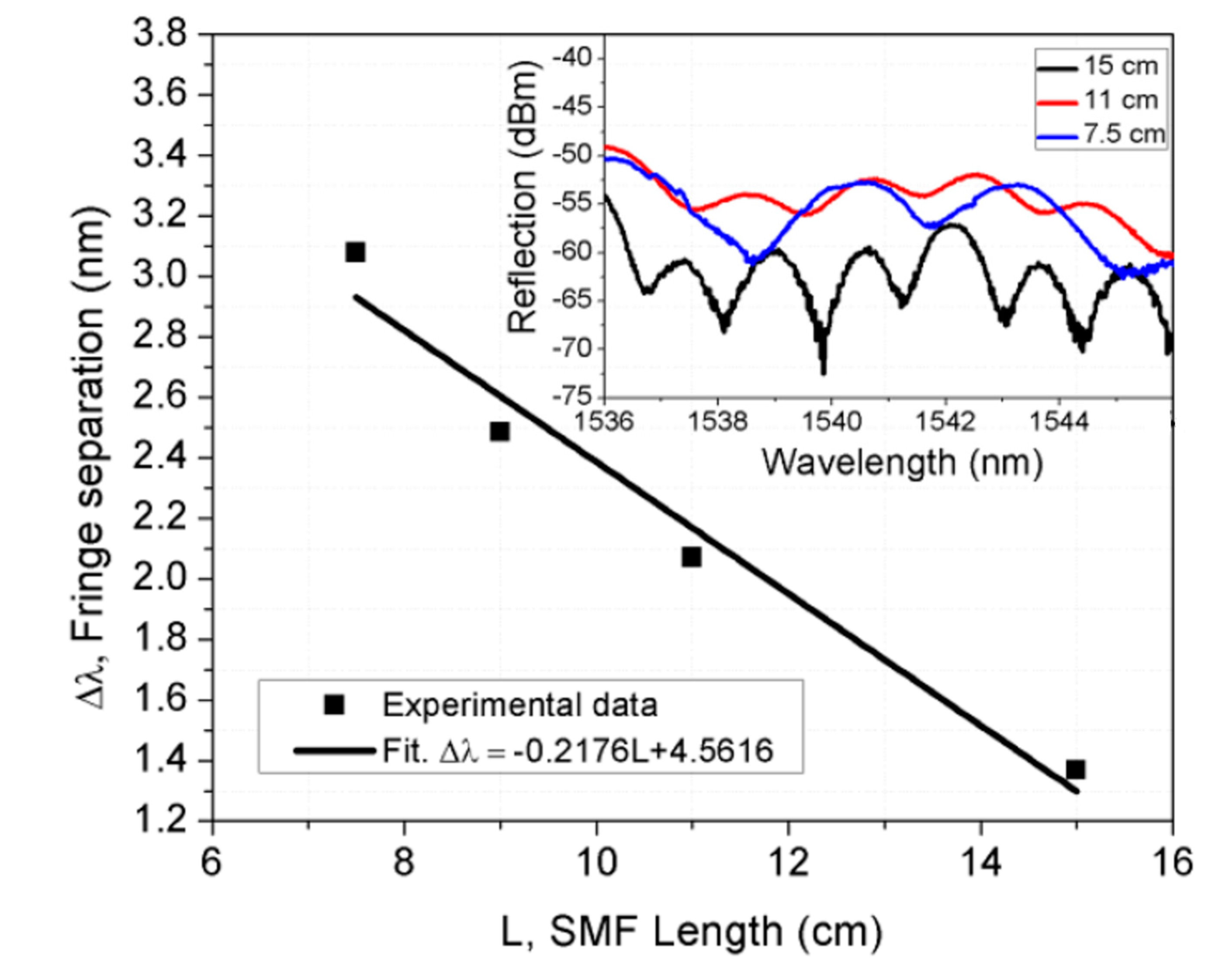

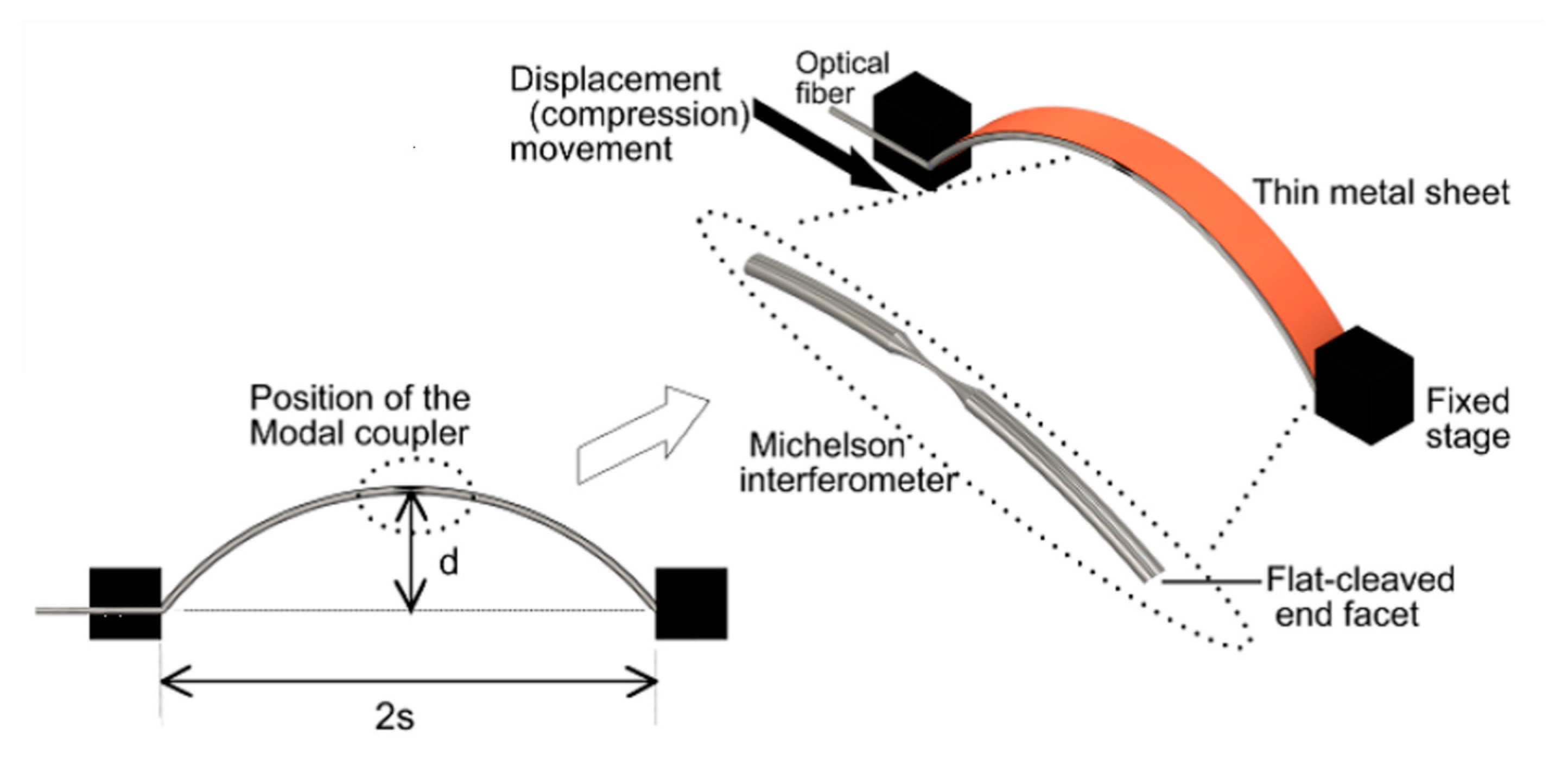

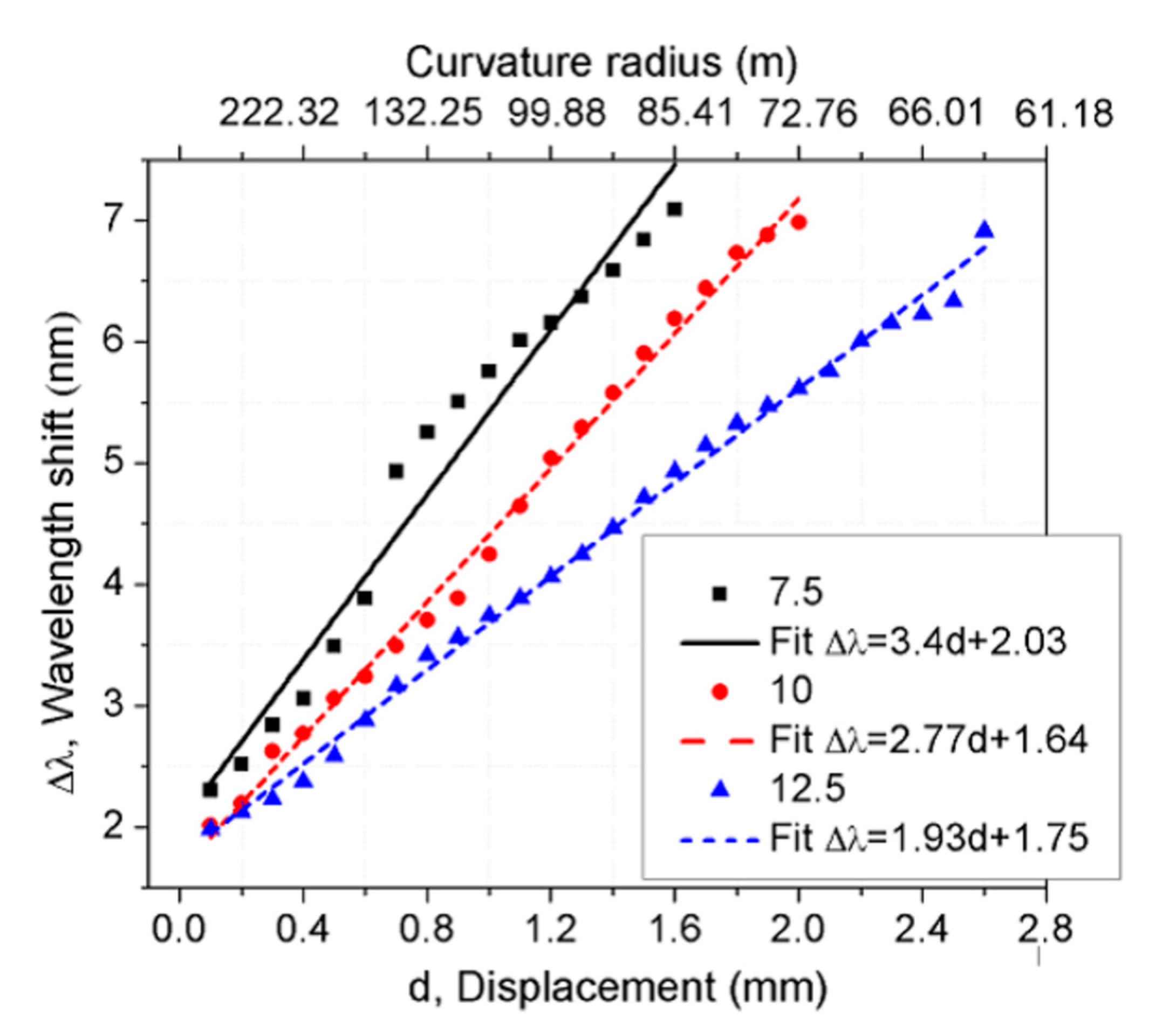

2. Structure and Working Principle of the Proposed Optical Fiber Michelson Interferometer (OFMI)

3. Analysis and Experimental Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, Z.Z.; Yu-Ming, G.; Shin-Tson, W.; Shug-June, H. Ultra-sensitive curvature sensor based on liquid crystal-infiltrated fiber interferometer. J. Appl. Phys. 2016, 50, 1–6. [Google Scholar] [CrossRef]

- Wang, X.; Chen, D.; Li, H.; Feng, G.; Yang, J. In line Mach-Zehnder interferometric sensor based on a seven-core optical fiber. IEEE Sens. J. 2017, 17, 100–104. [Google Scholar] [CrossRef]

- Xiong, M.; Gong, H.; Wang, Z.; Zhao, C.-L.; Dong, X. Fiber curvature sensor based on spherical-shape structures and long-period grating. Opt. Lasers Eng. 2016, 86, 356–359. [Google Scholar] [CrossRef]

- Zhao, Y.; Cai, L.; Li, X.-G. Temperature-Insensitive optical fiber curvature sensor based on SMF-MMF-TCSMF-MMF-SMF Structure. IEEE Trans. Instrum. Meas. 2017, 66, 141–147. [Google Scholar] [CrossRef]

- Raji, Y.M.; Lin, H.S.; Ibrahim, S.A.; Mokhtar, M.R.; Yusoff, Z. Intensity-modulated abrupt tapered fiber Mach-Zehnder Interferometer for the simultaneous sensing of temperature and curvature. Opt. Laser Technol. 2016, 86, 8–13. [Google Scholar] [CrossRef]

- Hu, H.-F.; Sun, S.-J.; Lv, R.-Q.; Zhao, Y. Design and experiment of an optical micro bend sensor for respiration monitoring. Sens. Actuators A Phys. 2016, 251, 126–133. [Google Scholar] [CrossRef]

- Monteiro, C.S.; Ferreira, M.S.; Silvia, S.O.; Kobelke, J.; Schuster, K.; Bierlich, J.; Frazao, O. Fiber Fabry-Perot interferometer for curvature sensing. Photonic Sens. 2016, 6, 339–344. [Google Scholar] [CrossRef]

- Monzon-Hernandez, D.; Martinez-Rios, A.; Torres-Gomez, I.; Salceda-Delgado, G. Compact optical fiber curvature sensor based on concatenating two tapers. Opt. Lett. 2011, 36, 4380–4382. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Gong, H.; Qian, Z.; Jin, Y.; Dong, X. Fiber curvature sensor based on Mach-Zehnder interferometer using up-taper cascaded long-period grating. Microw. Opt. Technol. Lett. 2015, 58, 246–248. [Google Scholar] [CrossRef]

- Feng, D.; Qiao, X.; Albert, J. Off-axis ultraviolet-written fiber Bragg gratings for directional bending measurements. Opt. Lett. 2016, 41, 1201–1204. [Google Scholar] [CrossRef] [PubMed]

- Salceda-Delgado, G.; Monzon-Hernandez, D.; Martinez-Rios, A.; Cardenas-Sevilla, G.A.; Villatoro, J. Optical microfiber mode interferometer for temperature-independent refractometric sensing. Opt. Lett. 2012, 37, 1974–1976. [Google Scholar] [CrossRef] [PubMed]

- Salceda-Delgado, G.; van Newkirk, A.; Antonio-Lopez, J.E.; Martinez-Rios, A.; Schulzgen, A.; Amezcua-Correa, R. Compact fiber-optic curvature sensor based on super-mode interference in a seven-core fiber. Opt. Lett. 2015, 40, 1468–1471. [Google Scholar] [CrossRef] [PubMed]

- Villatoro, J.; Minkovich, V.P.; Zubia, J. Photonic crystal fiber interferometric vector bending sensor. Opt. Lett. 2015, 40, 3113–3116. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.; Yam, S.; Loock, H.P. Refractive index sensor based on an abrupt taper Michelson interferometer in a single-mode fiber. Opt. Lett. 2008, 33, 1105–1107. [Google Scholar] [CrossRef] [PubMed]

- Tan, X.; Geng, Y.; Li, X. High-birefringence photonic crystal fiber Michelson interferometer with cascaded fiber Bragg grating for pressure and temperature discrimination. Opt. Eng. 2016, 55, 090508. [Google Scholar] [CrossRef]

- Duan, L.; Zhang, P.; Tang, M.; Wang, R.; Zhao, Z.; Fu, S.; Gan, L.; Zhu, B.; Tong, W.; Liu, D.; et al. Heterogeneous all-solid multicore fiber based multipath Michelson interferometer for high temperature sensing. Opt. Exp. 2016, 24, 20210–20218. [Google Scholar] [CrossRef] [PubMed]

- Hua, L.; Song, Y.; Huang, J.; Lan, X.; Li, Y.; Xiao, H. Microwave interrogated large core fused silica fiber Michelson interferometer for strain sensing. Appl. Opt. 2015, 54, 7181–7187. [Google Scholar] [CrossRef] [PubMed]

- Salceda-Delgado, G.; Martinez-Rios, A.; Monzon-Hernandez, D. Tailoring Mach–Zehnder Comb-Filters Based on Concatenated Tapers. J. Lightwave Technol. 2013, 31, 761. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salceda-Delgado, G.; Martinez-Rios, A.; Selvas-Aguilar, R.; Álvarez-Tamayo, R.I.; Castillo-Guzman, A.; Ibarra-Escamilla, B.; Durán-Ramírez, V.M.; Enriquez-Gomez, L.F. Adaptable Optical Fiber Displacement-Curvature Sensor Based on a Modal Michelson Interferometer with a Tapered Single Mode Fiber. Sensors 2017, 17, 1259. https://doi.org/10.3390/s17061259

Salceda-Delgado G, Martinez-Rios A, Selvas-Aguilar R, Álvarez-Tamayo RI, Castillo-Guzman A, Ibarra-Escamilla B, Durán-Ramírez VM, Enriquez-Gomez LF. Adaptable Optical Fiber Displacement-Curvature Sensor Based on a Modal Michelson Interferometer with a Tapered Single Mode Fiber. Sensors. 2017; 17(6):1259. https://doi.org/10.3390/s17061259

Chicago/Turabian StyleSalceda-Delgado, G., A. Martinez-Rios, R. Selvas-Aguilar, R. I. Álvarez-Tamayo, A. Castillo-Guzman, B. Ibarra-Escamilla, V. M. Durán-Ramírez, and L. F. Enriquez-Gomez. 2017. "Adaptable Optical Fiber Displacement-Curvature Sensor Based on a Modal Michelson Interferometer with a Tapered Single Mode Fiber" Sensors 17, no. 6: 1259. https://doi.org/10.3390/s17061259