Quantitative Index and Abnormal Alarm Strategy Using Sensor-Dependent Vibration Data for Blade Crack Identification in Centrifugal Booster Fans

Abstract

:1. Introduction

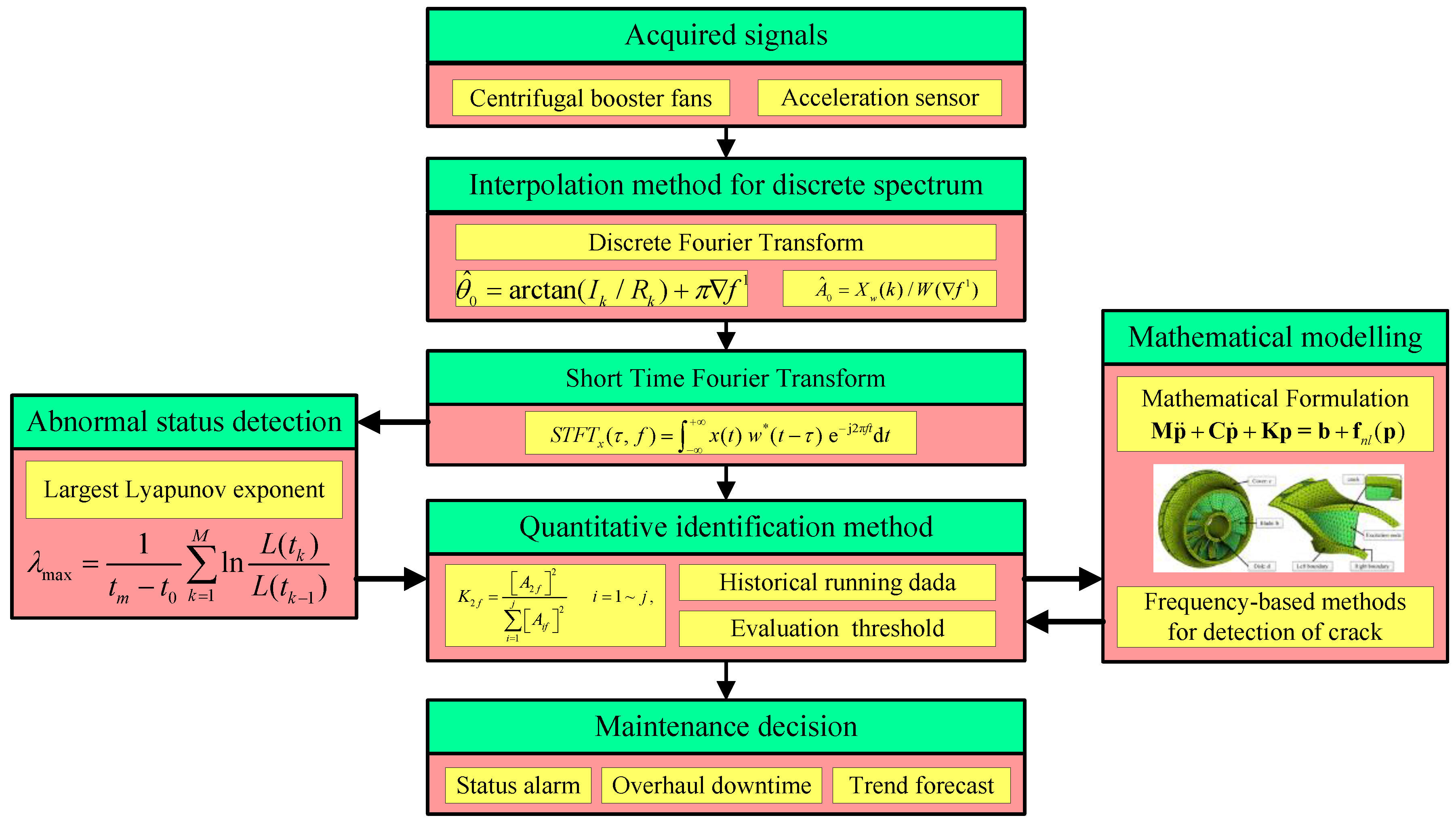

2. Fault Identification Method for Thermal Generator Sets

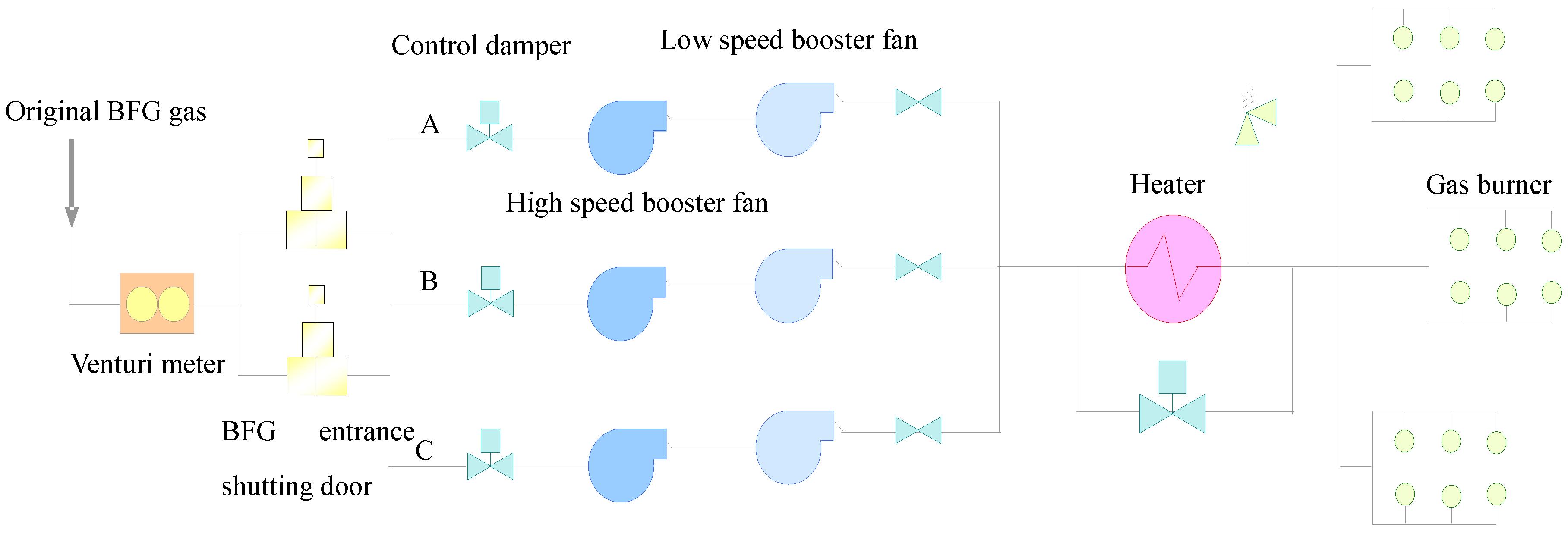

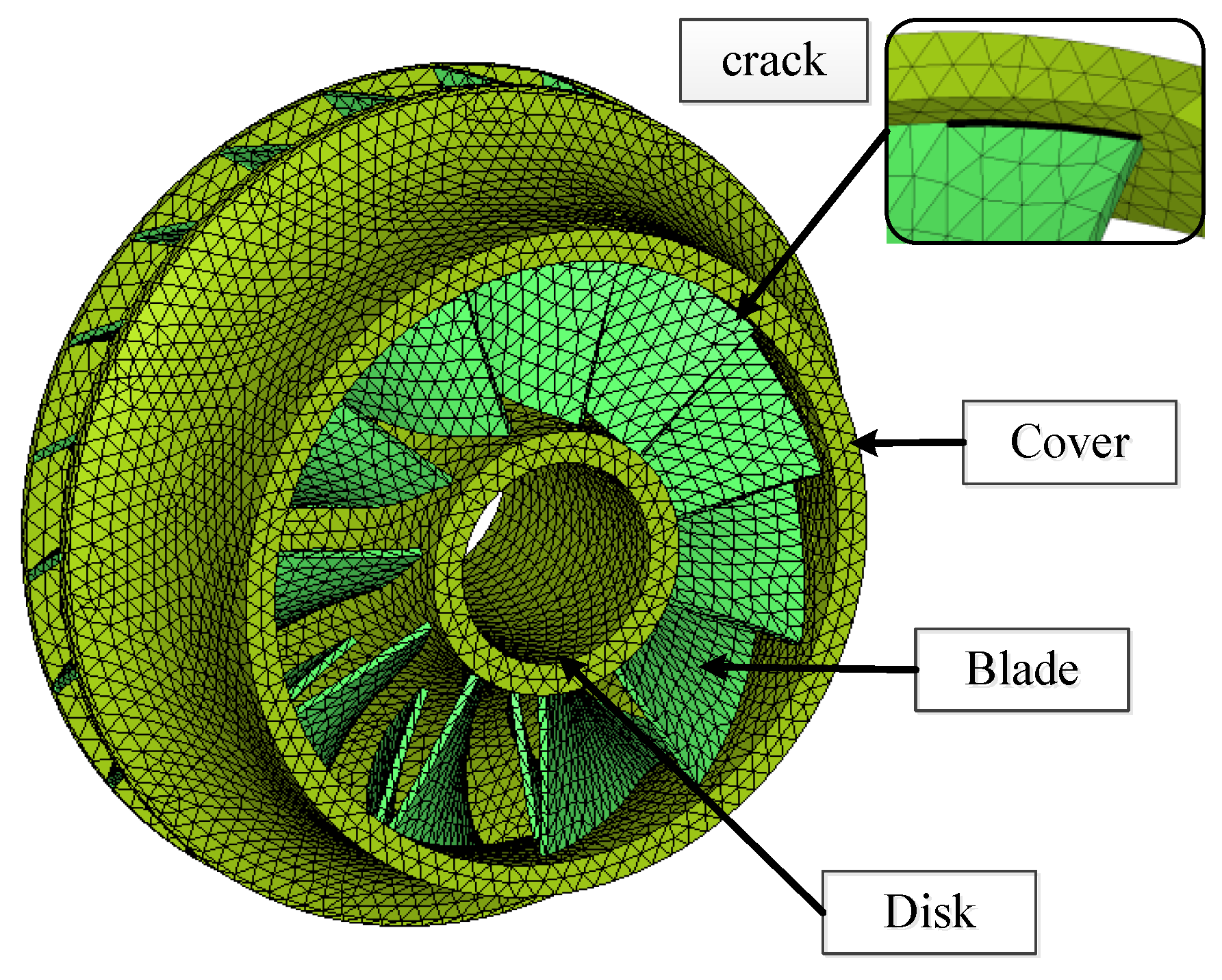

2.1. Centrifugal Booster Fans in Thermal Generator Sets

The original BFG gas from the the Department of Energy and Environment Protection → Venturi meter → BFG entrance shutting door → BFG booster fan entrance control damper → three BFG booster fans → BFG booster fan exit isolation damper → Heater and its bypass → BFG gas burners.

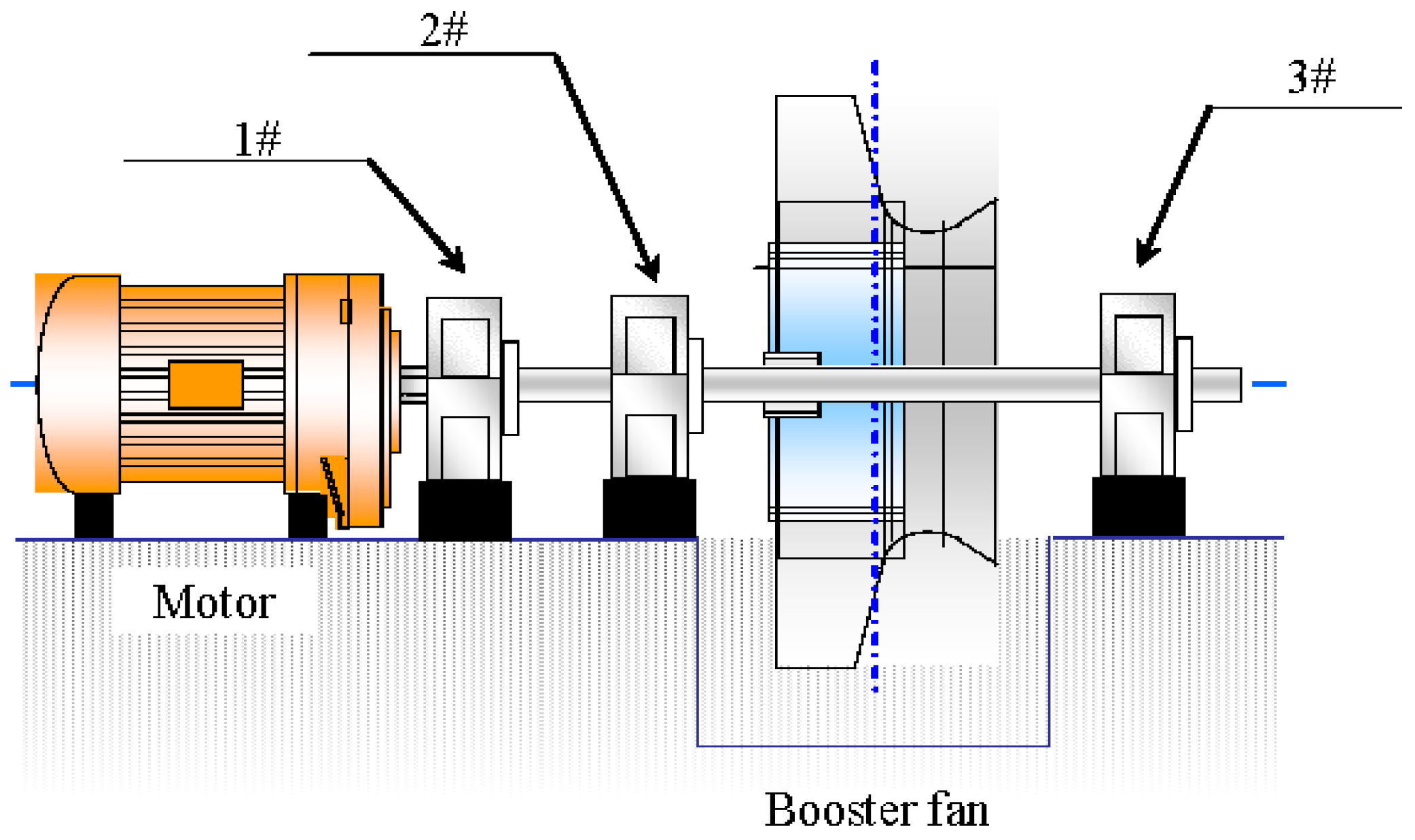

2.2. Condition Data Acquisition Testing Framework

2.3. Fault Feature Extraction Method

2.3.1. Discrete Spectrum Interpolation Method

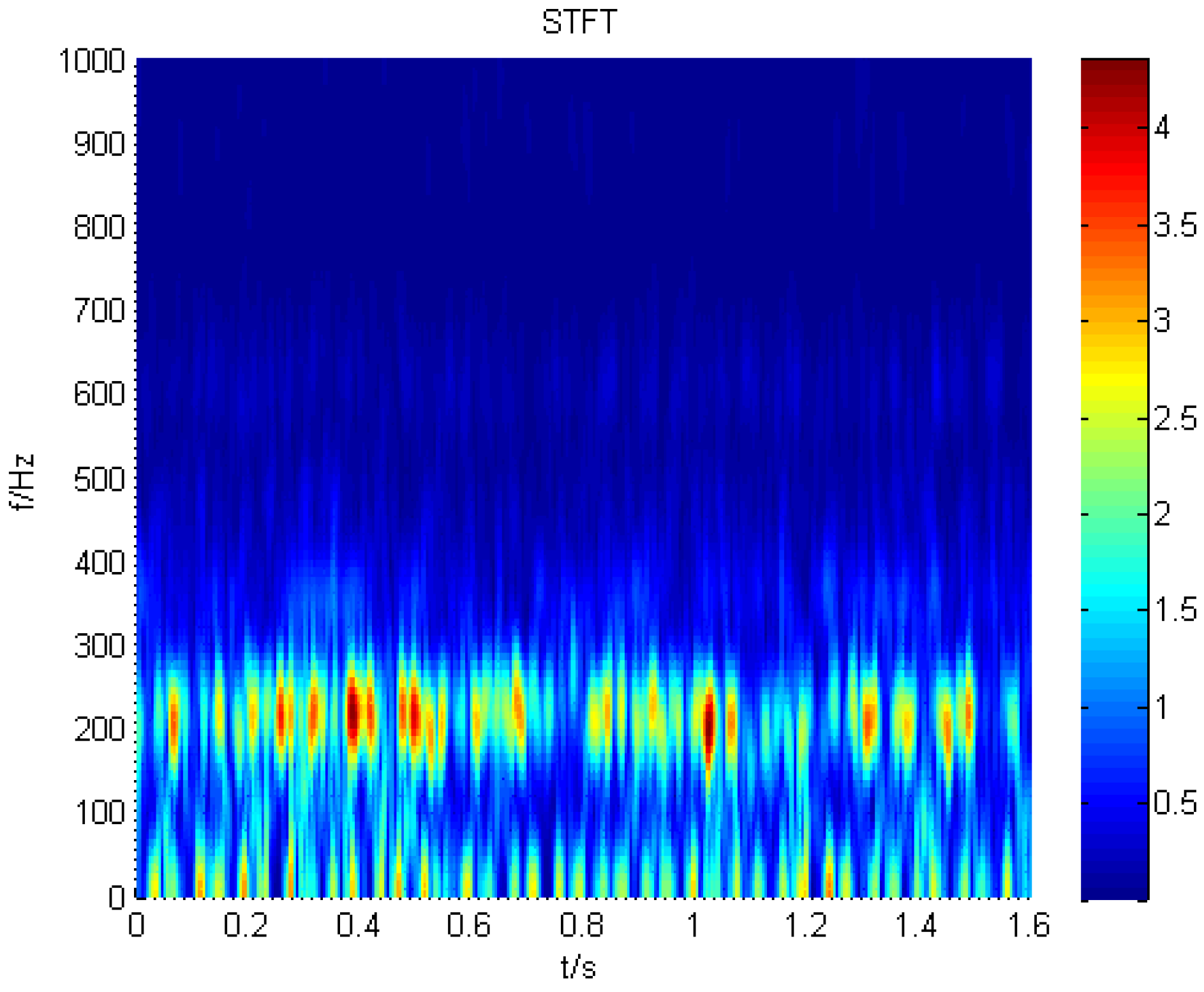

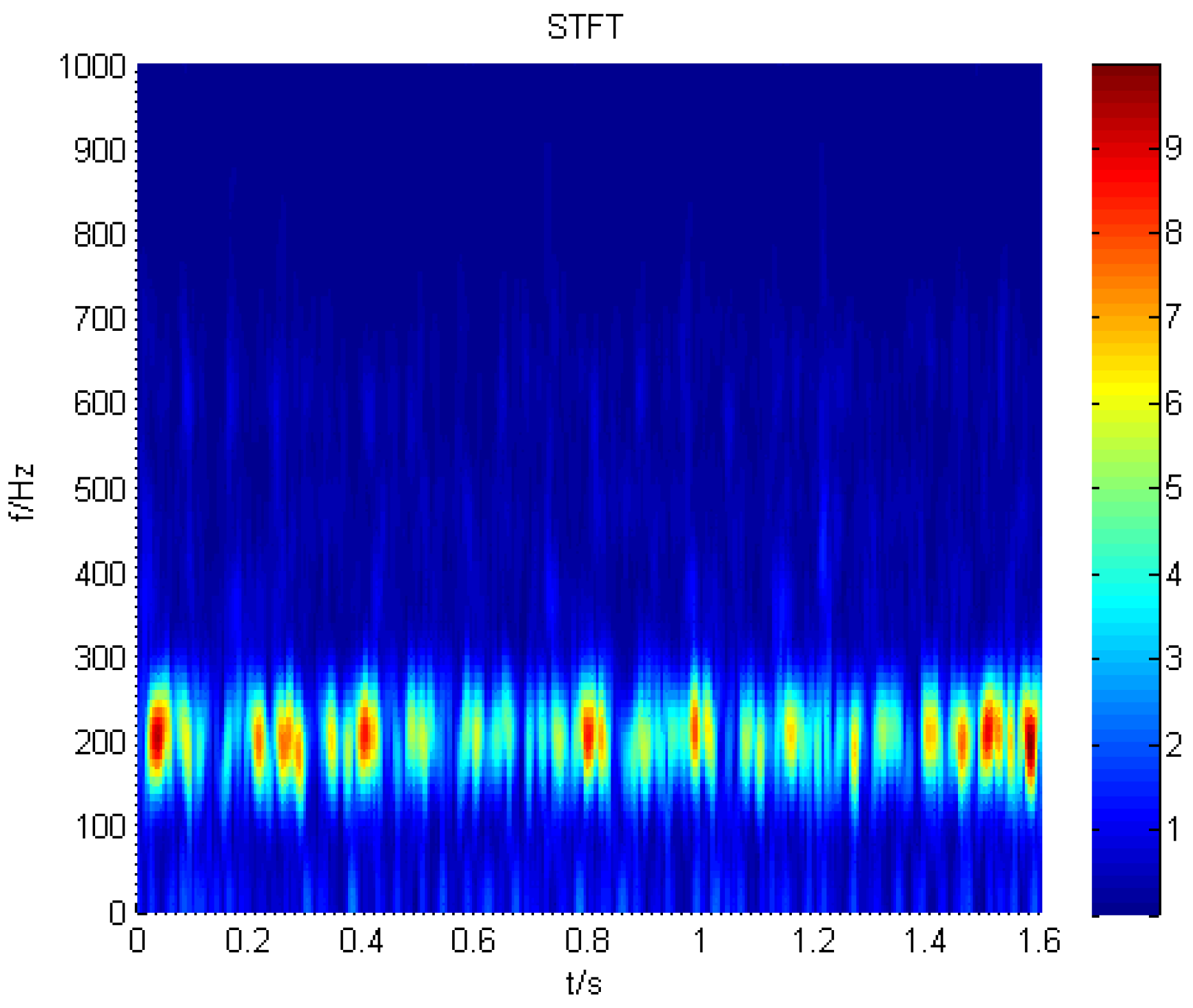

2.3.2. Short Time Fourier Transform

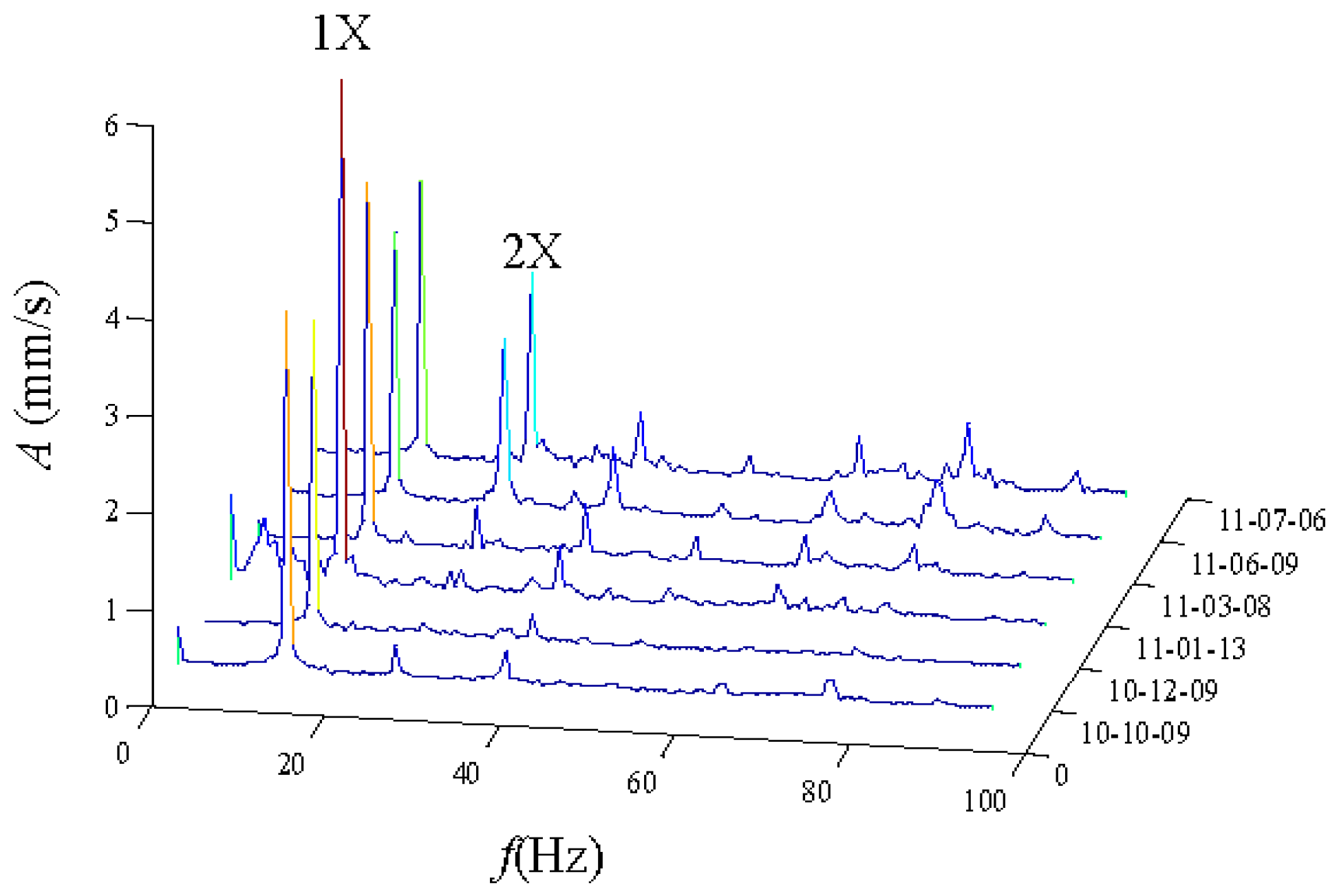

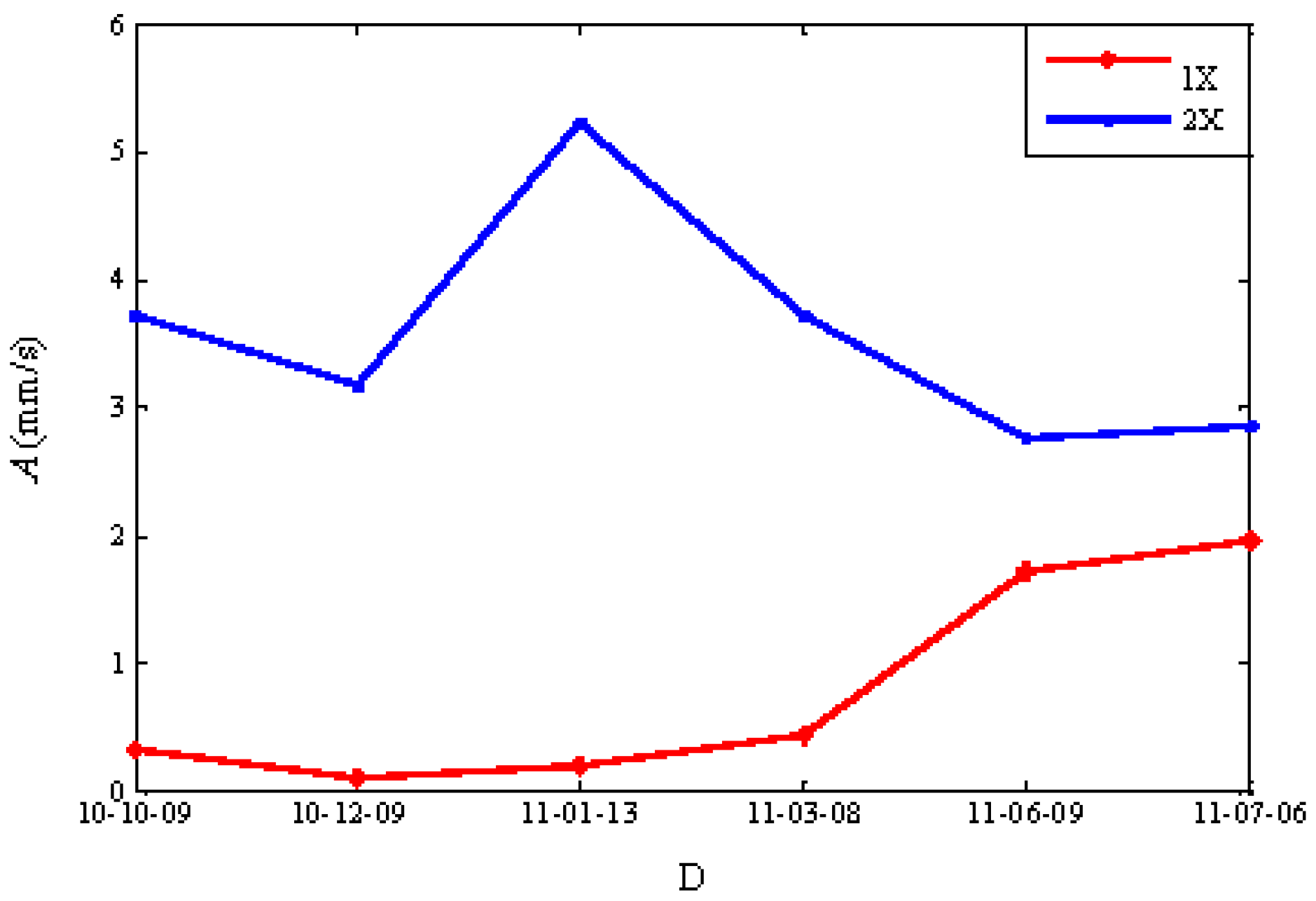

3. Case Study via Blade Crack Fault of a Centrifugal Booster Fan

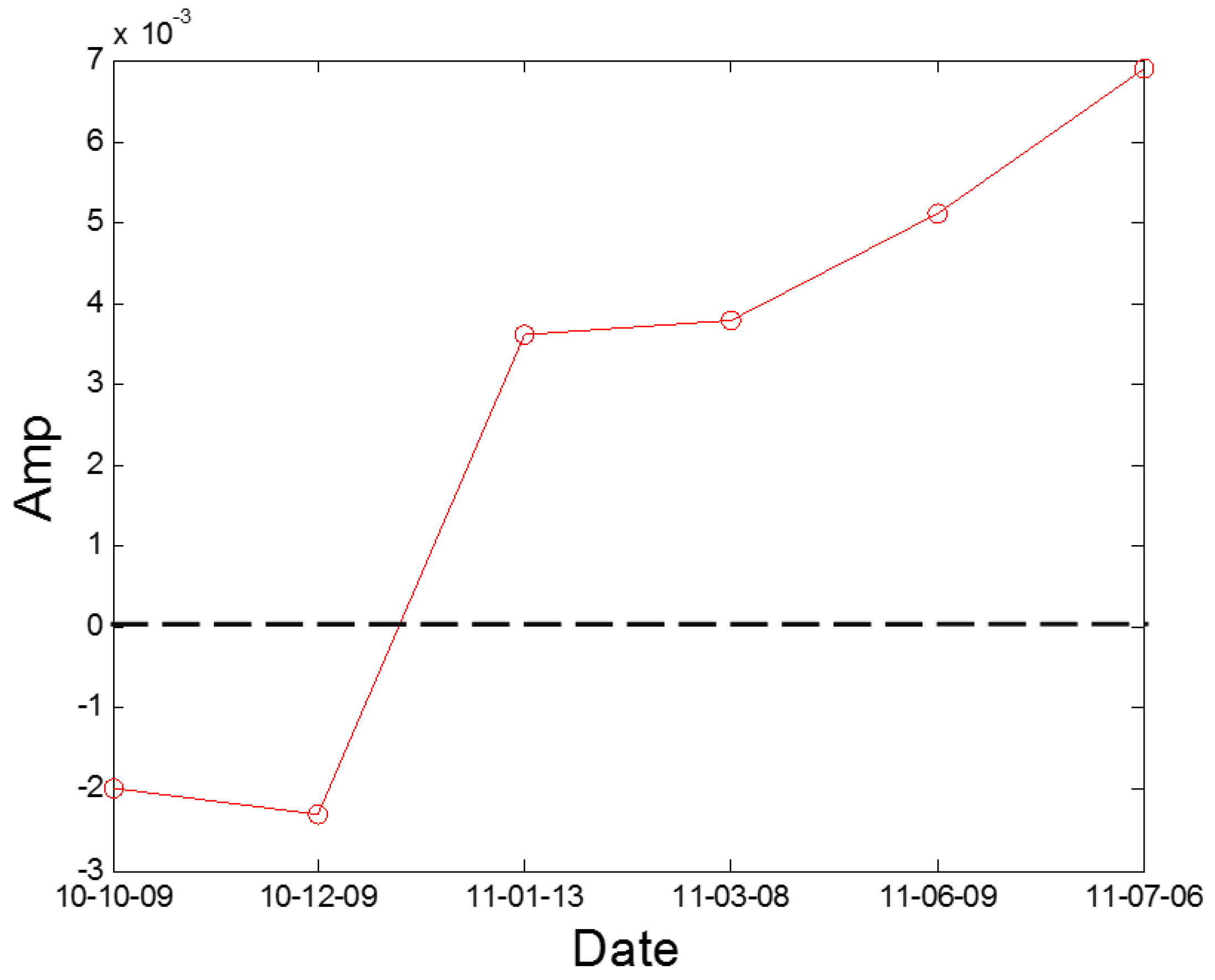

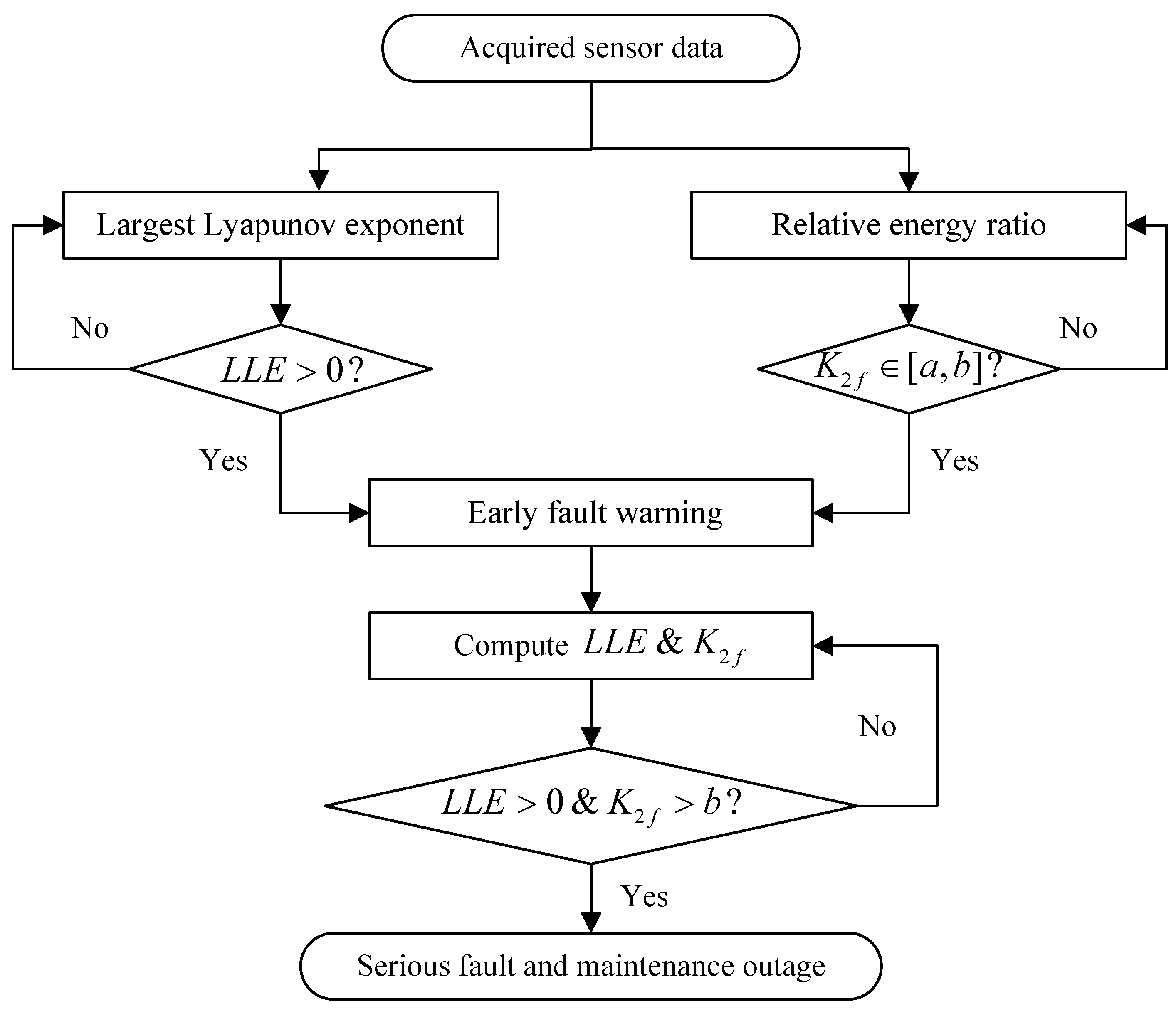

4. Quantitative Identification and Abnormality Alarm Strategy for Blade Crack Faults

4.1. The Proposed Quantitative Identification Method

4.1.1. Largest Lyapunov Exponent Algorithm

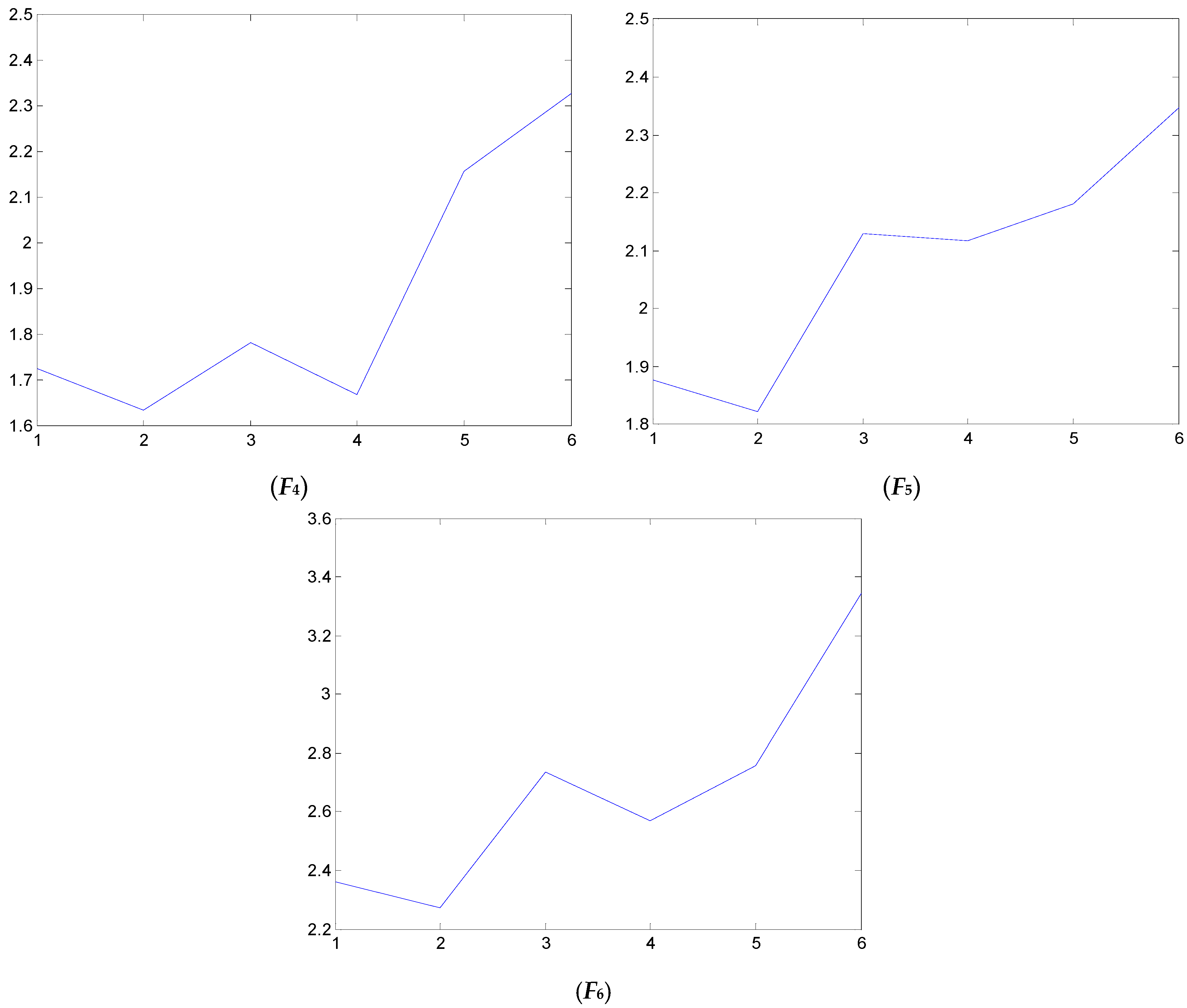

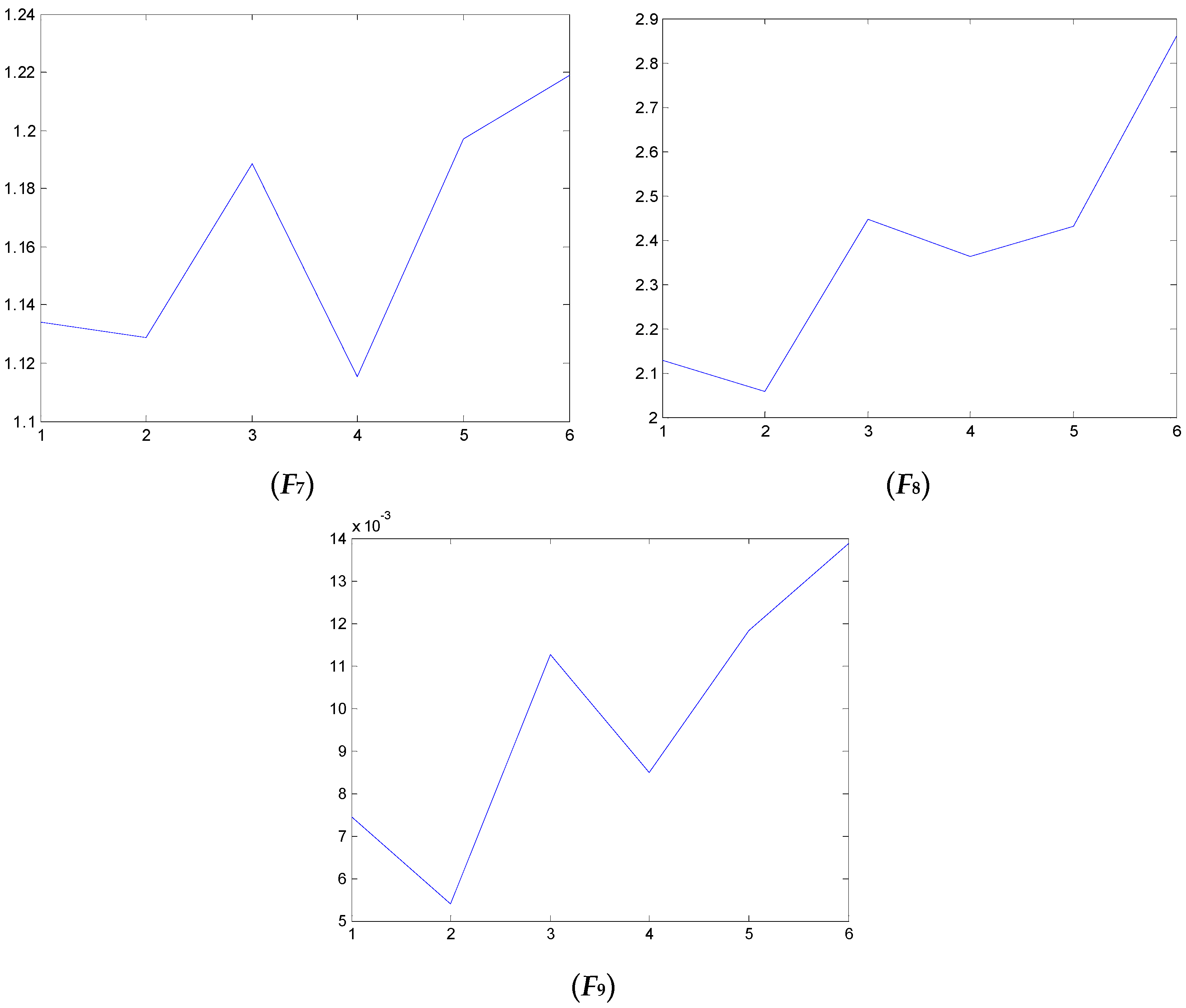

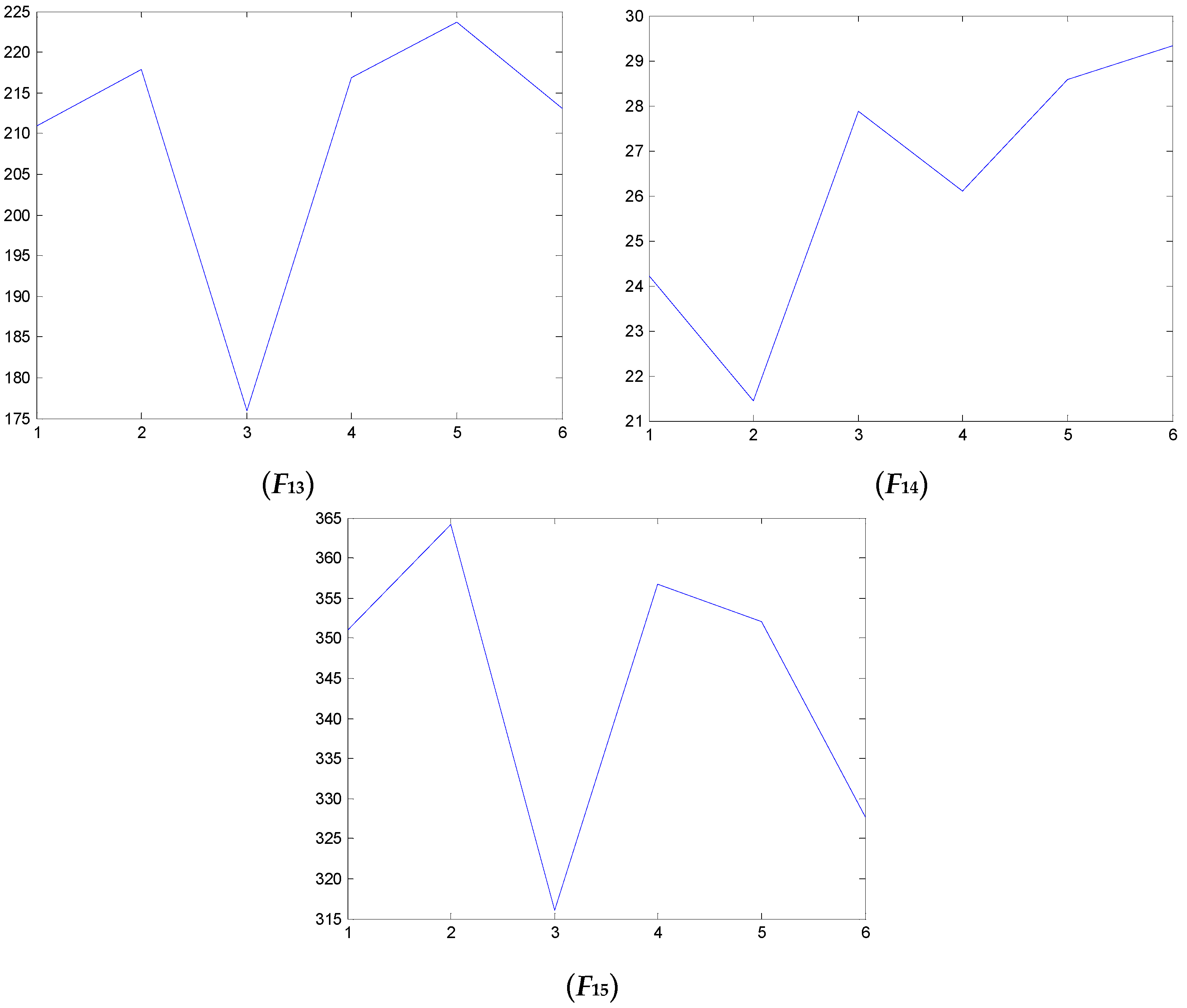

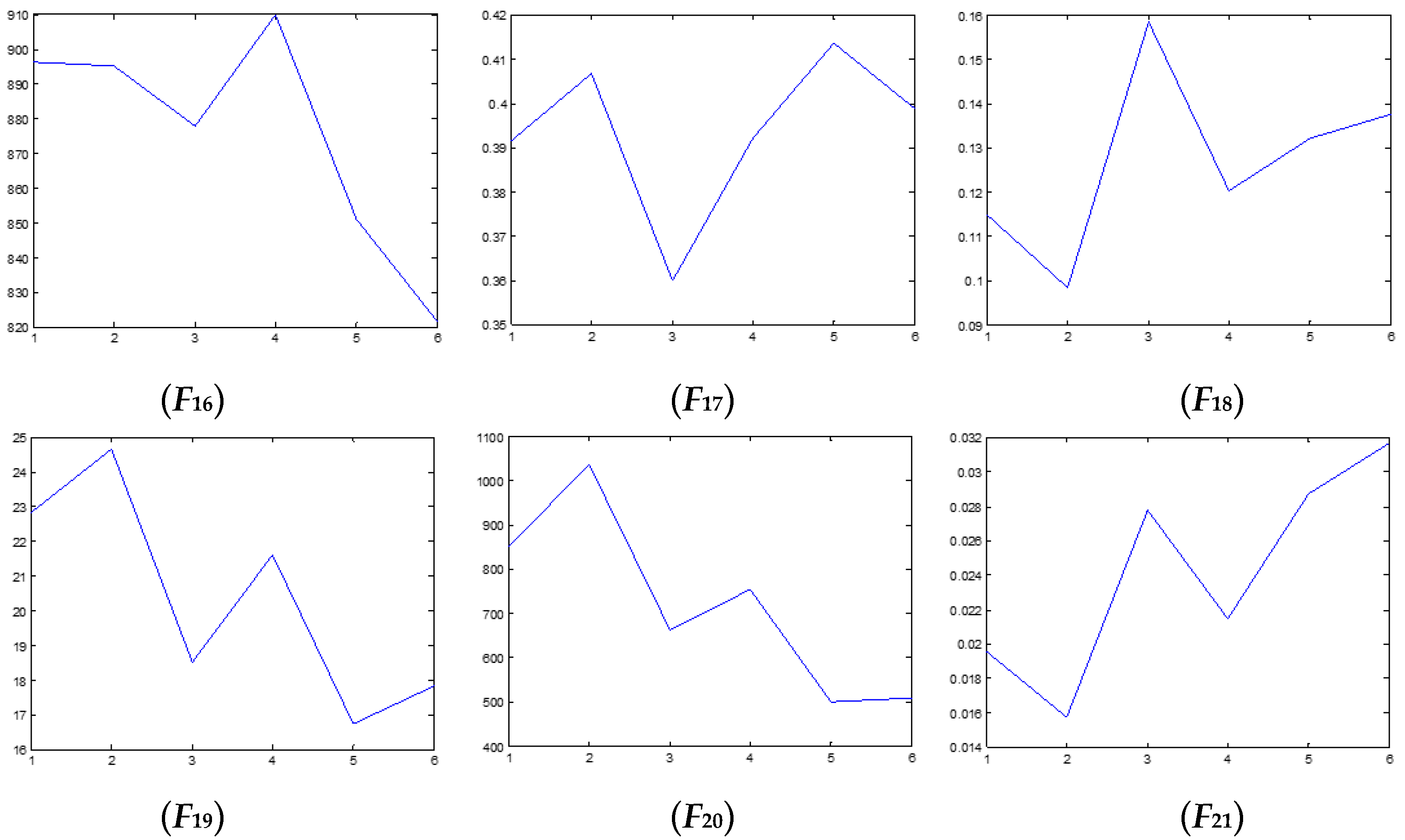

4.1.2. Relative Energy Ratio at Second Harmonic Frequency Component

- (1)

- 0 ≤ K2f < a : Normal condition, the rotor works well;

- (2)

- a ≤ K2f ≤ b: Incipient fault, a crack appears, but is small;

- (3)

- K2f > b: Serious fault, many cracks appear.

- (1)

- Collect the sensor-dependent running condition vibration data;

- (2)

- Pre-process this vibration data using the discrete spectrum interpolation method and STFT;

- (3)

- Compute the LLE and the relative energy ratio K2f.

- (4)

- Confirm the degree of blade crack fault(s) of the centrifugal booster fan;

- (5)

- Conduct the corresponding maintenance management activities based on the fault degree.

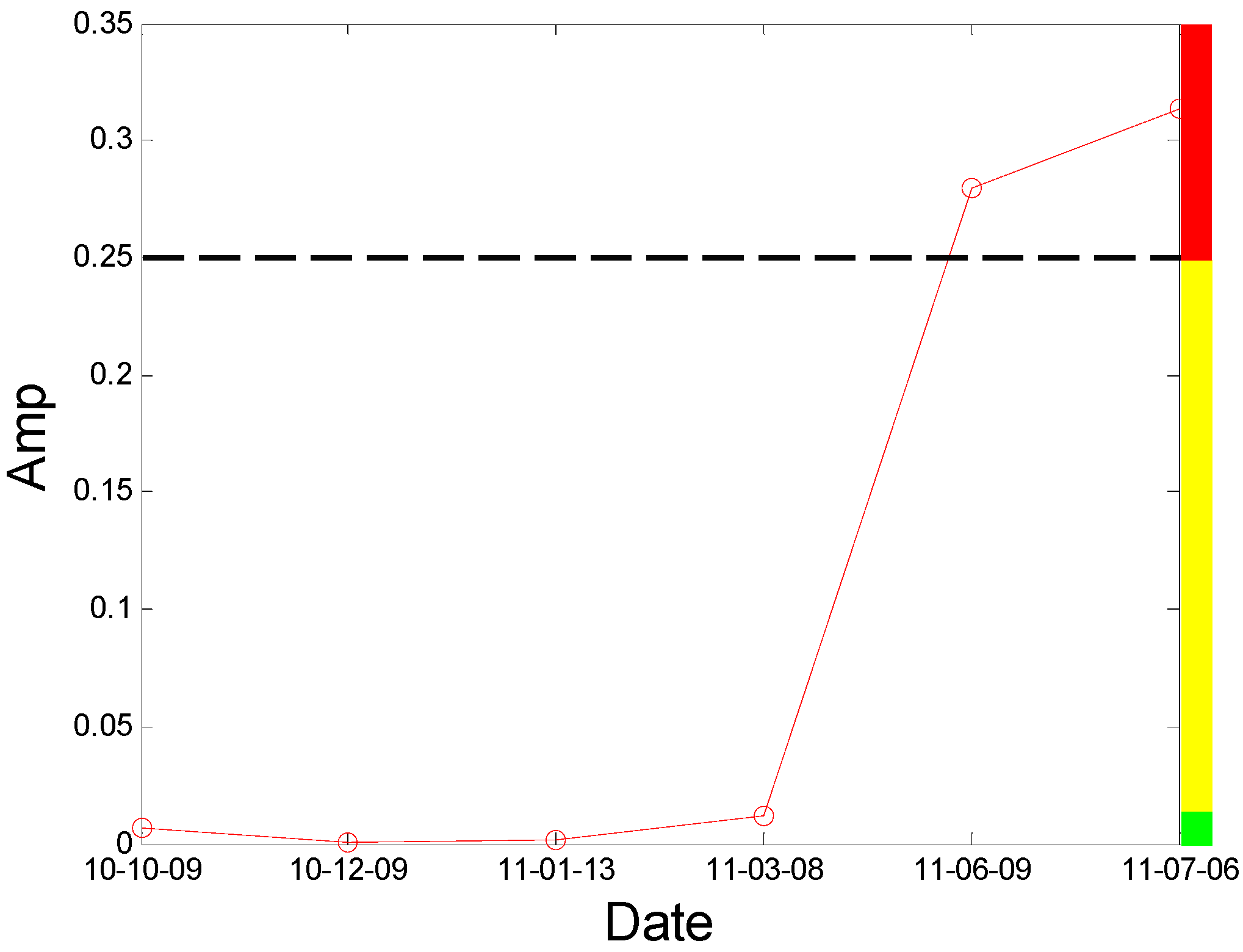

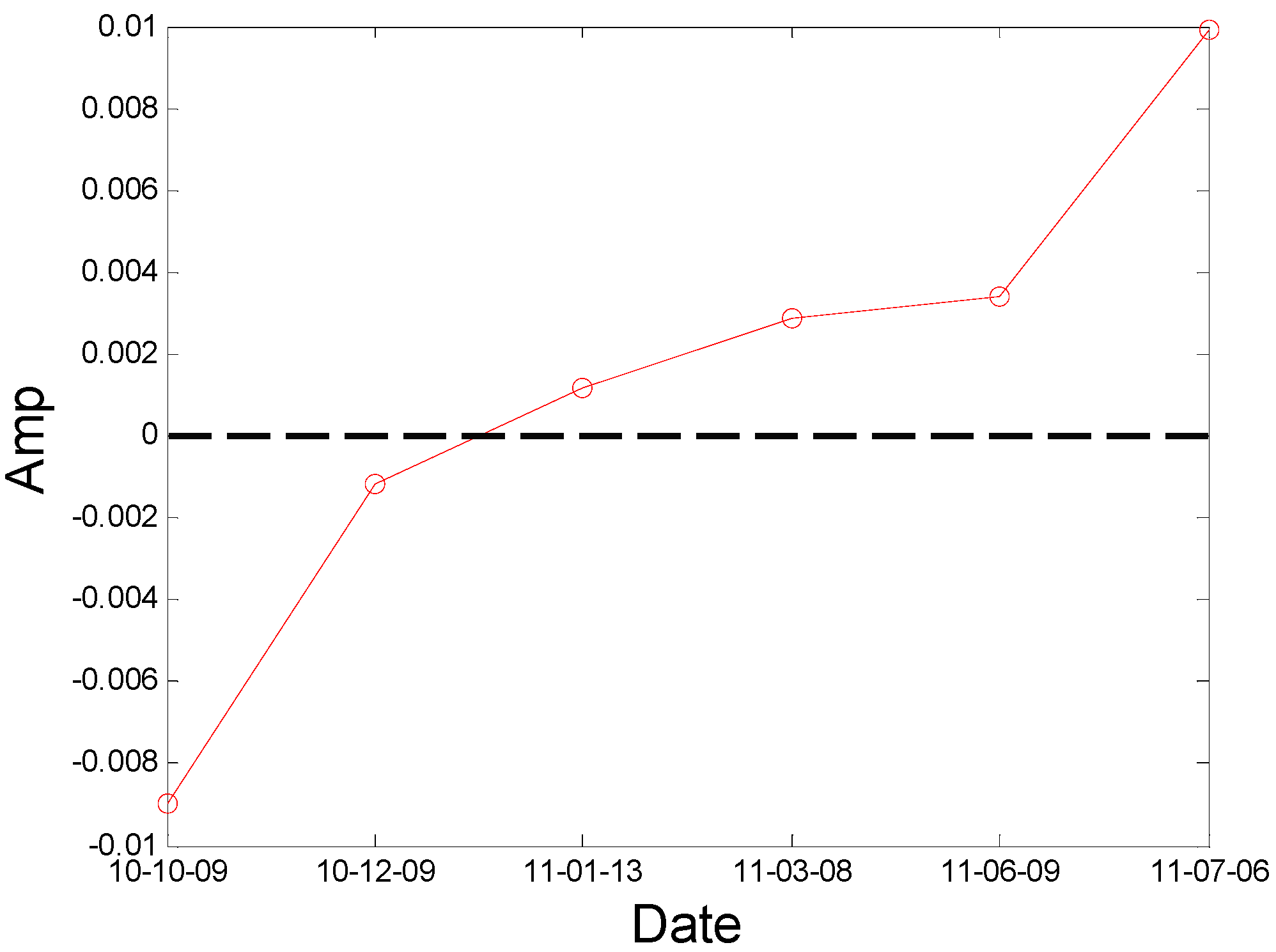

4.2. Test and Validation

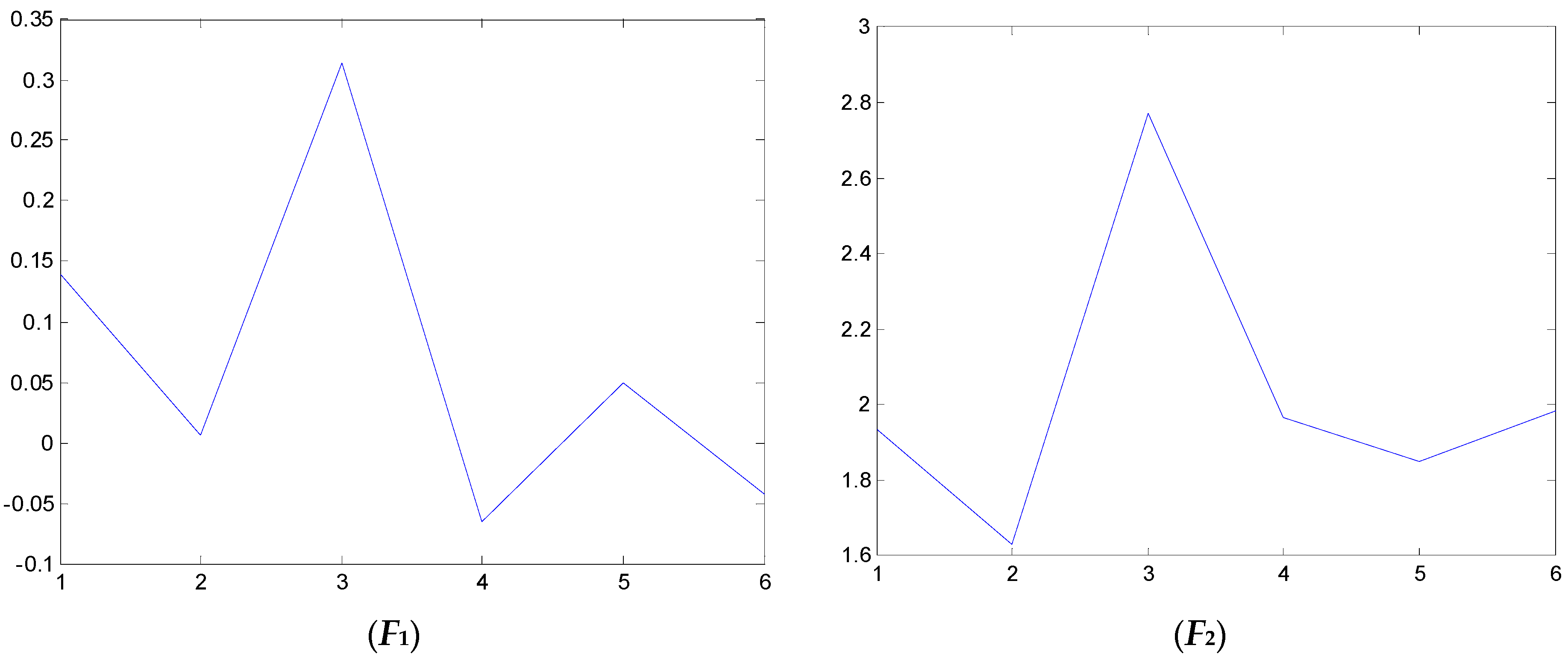

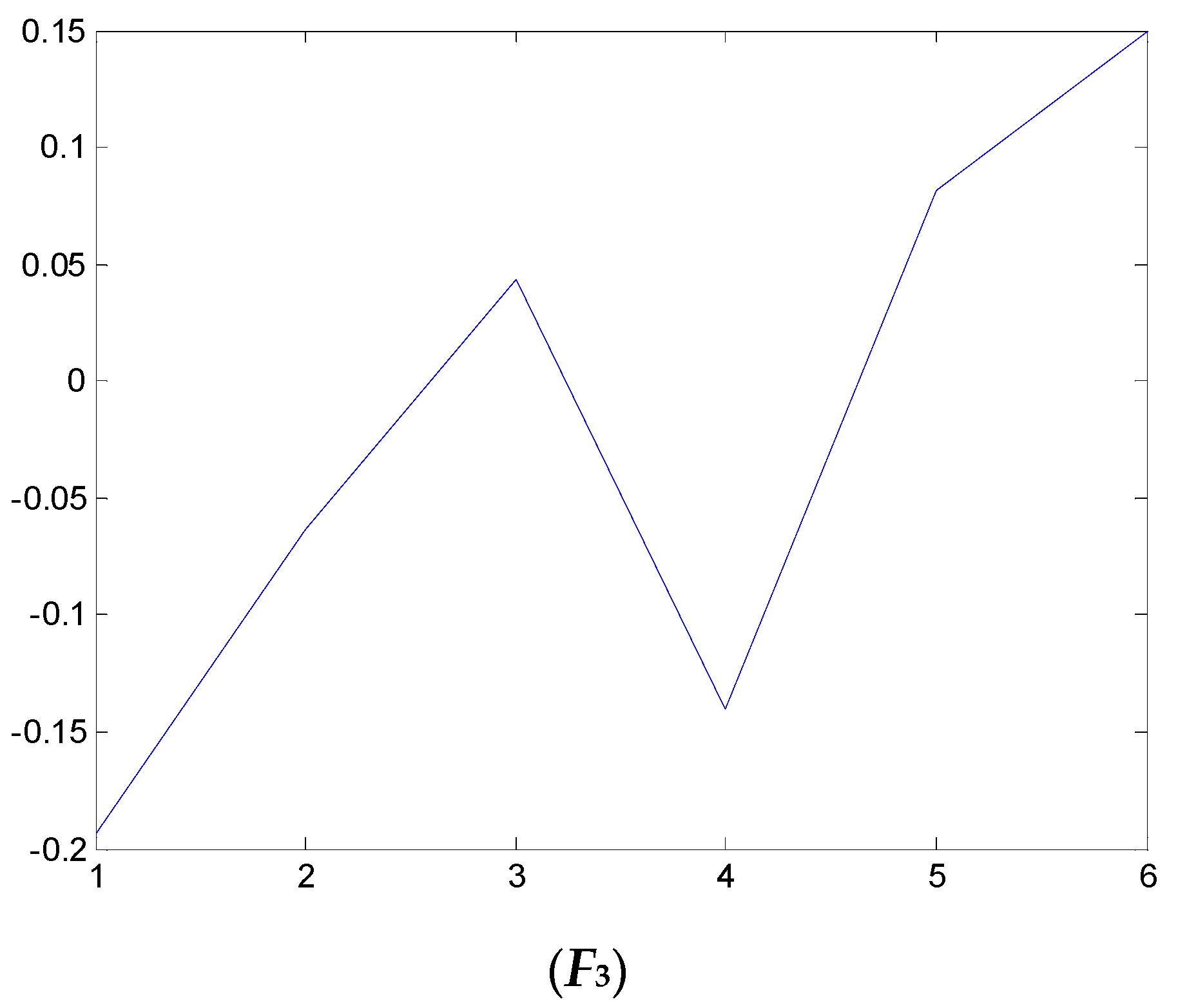

5. Mathematical Modelling for Revealing Vibration Signal Properties

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhao, J.; Wang, W.; Liu, Y.; Pedrycz, W. A two-stage online prediction method for a blast furnace gas system and its application. IEEE Trans. Control Syst. Technol. 2011, 19, 507–520. [Google Scholar] [CrossRef]

- Steer, J.M.; Marsh, R.; Greenslade, M.; Robinson, A. Opportunities to improve the utilisation of granulated coals for blast furnace injection. Fuel 2015, 151, 40–49. [Google Scholar] [CrossRef]

- Wan, Z.G.; Cao, H.R.; Zi, Y.Y.; He, W.P.; He, Z.J. An improved time-varying mesh stiffness algorithm and dynamic modeling of gear-rotor system with tooth root crack. Eng. Fail. Anal. 2014, 42, 157–177. [Google Scholar] [CrossRef]

- Luo, Y.G.; Zhang, S.H.; Wu, B.; Hu, H.Y. Stability analysis of nonlinear stiffness rotor-bearing system with pedestal looseness fault. Appl. Mech. Mater. 2013, 483, 285–288. [Google Scholar] [CrossRef]

- Corbetta, M.; Sbarufatti, C.; Manes, A.; Giglio, M. Real-time prognosis of crack growth evolution using sequential Monte Carlo methods and statistical model parameters. IEEE Trans. Reliabil. 2015, 64, 736–753. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, Z.S.; Guo, T. A novel manifold–manifold distance index applied to looseness state assessment of viscoelastic sandwich structures. Smart Mater. Struct. 2014, 23, 065019. [Google Scholar] [CrossRef]

- Liu, C.; Jiang, D.X.; Chu, F.L. Influence of alternating loads on nonlinear vibration characteristics of cracked blade in rotor system. J. Sound Vib. 2015, 353, 205–219. [Google Scholar] [CrossRef]

- Wang, Y.F.; Liang, M.; Xiang, J.W. Damage detection method for wind turbine blades based on dynamics analysis and mode shape difference curvature information. Mech. Syst. Signal Process. 2014, 48, 351–367. [Google Scholar] [CrossRef]

- Yang, B.; Sun, D.B. Testing, inspecting and monitoring technologies for wind turbine blades: A survey. Renew. Sustain. Energy Rev. 2013, 22, 515–526. [Google Scholar] [CrossRef]

- Kubiak, J.; Urquiza, G.; Rodriguez, J.A.; González, G.; Rosales, I.; Castillo, G.; Nebradt, J. Failure analysis of the 150 MW gas turbine blades. Eng. Fail. Anal. 2009, 16, 1794–1804. [Google Scholar] [CrossRef]

- Li, F.; Wang, J.X.; Chyu, M.K.; Tang, B.P. Weak fault diagnosis of rotating machinery based on feature reduction with Supervised Orthogonal Local Fisher Discriminant Analysis. Neurocomputing 2015, 168, 505–519. [Google Scholar] [CrossRef]

- Zhang, X.L.; Wang, B.J.; Chen, X.F. Operational safety assessment of turbo generators with wavelet rényi entropy from sensor-dependent vibration signals. Sensors 2015, 15, 8898–8918. [Google Scholar] [CrossRef] [PubMed]

- Witek, L. Crack propagation analysis of mechanically damaged compressor blades subjected to high cycle fatigue. Eng. Fail. Anal. 2011, 18, 1223–1232. [Google Scholar] [CrossRef]

- Infante, V.; Silva, J.M. Case studies of computational simulations of fatigue crack propagation using finite elements analysis tools. Eng. Fail. Anal. 2011, 18, 616–624. [Google Scholar] [CrossRef]

- Lin, L.; Chu, F.L. HHT-based AE characteristics of natural fatigue cracks in rotating shafts. Mech. Syst. Signal Process. 2012, 26, 181–189. [Google Scholar] [CrossRef]

- Fang, D.; Zivanovic, R. Condition Monitoring of an Induction Motor Stator Windings Via Global Optimization Based on the Hyperbolic Cross Points. IEEE Trans. Ind. Electron. 2015, 62, 1826–1834. [Google Scholar]

- Qiao, W.; Lu, D. A survey on wind turbine condition monitoring and fault diagnosis. IEEE Trans. Ind. Electron. 2015, 99, 6536–6545. [Google Scholar] [CrossRef]

- Liu, K.; Zhu, Z.Q. Position-offset-based parameter estimation using the adaline NN for condition monitoring of permanent-magnet synchronous machines. IEEE Trans. Ind. Electron. 2015, 62, 2372–2383. [Google Scholar] [CrossRef]

- Seungdeog, C.; Pazouki, E.; Baek, J.; Bahrami, H.R. Iterative condition monitoring and fault diagnosis scheme of electric motor for harsh industrial application. IEEE Trans. Ind. Electron. 2015, 62, 1760–1769. [Google Scholar]

- Chen, J.L.; Zhang, C.L.; Zhang, Y.Y.Z.X.Y.; He, S.L.; Yang, Z. Planetary gearbox condition monitoring of ship-based satellite communication antennas using ensemble multiwavelet analysis method. Mech. Syst. Signal Process. 2015, 54–55, 277–292. [Google Scholar] [CrossRef]

- Gao, Z.W.; Ding, S.X.; Cecati, C. Real-time fault diagnosis and fault-tolerant control. IEEE Trans. Ind. Electron. 2015, 62, 3752–3756. [Google Scholar] [CrossRef]

- Gao, Z.W.; Cecati, C.; Ding, S.X. A survey of fault diagnosis and fault-tolerant techniques—Part II: Fault diagnosis with knowledge-based and hybrid/active approaches. IEEE Trans. Ind. Electron. 2015, 62, 3768–3774. [Google Scholar] [CrossRef]

- Sun, H.L.; Zi, Y.Y.; He, Z.J.; Chen, B.Q.; Liu, H. Feature extraction and its application for nonstationary features of the blade crack in centrifugal booster fans. J. Vib. Shock 2012, 31. [Google Scholar]

- Sun, H.L. Theory and Applications of Adaptive Multiwavelets in Quantitative Fault Diagnosis for Key Mechanical Equipments. Ph.D. Dissertation, Xi’an Jiaotong University, Xi’an, China, 2013.

- Kim, Y.H.; Youn, Y.W.; Hwang, D.H.; Sun, J.H.; Kang, D.S. High-Resolution Parameter Estimation Method to Identify Broken Rotor Bar Faults in Induction Motors. IEEE Trans. Ind. Electron 2013, 60, 4103–4116. [Google Scholar] [CrossRef]

- Amar, M.; Gondal, I.; Wilson, C. Vibration spectrum imaging: A novel bearing fault classification Approach. IEEE Trans. Ind. Electron 2015, 62, 494–502. [Google Scholar] [CrossRef]

- Lin, H.B.; Ding, K. Energy based signal parameter estimation method and a comparative study of different frequency estimators. Mech. Syst. Signal Process. 2011, 25, 452–462. [Google Scholar]

- Sharma, G.K.; Kumar, A.; Rao, C.B.; Jayakumar, T.; Raj, B. Short time fourier transform analysis for understanding frequency dependent attenuation in austenitic stainless steel. NDT E Int. 2013, 53, 1–7. [Google Scholar] [CrossRef]

- Wang, J.Z.; Jia, R.L.; Zhao, W.G.; Wu, J.; Dong, Y. Application of the largest Lyapunov exponent and non-linear fractal extrapolation algorithm to short-term load forecasting. Chaos Solitons Fractals 2012, 45, 1277–1287. [Google Scholar] [CrossRef]

- Wolf, A.; Swift, J.B.; Swinney, H.L.; Vastano, J.A. Determining Lyapunov exponents from A time series. Phys. D Nonlinear Phenom. 1985, 16, 285–317. [Google Scholar] [CrossRef]

- Chen, B.Q. Overcomplete Frame Expansion Based on Wavelet Tight Frame and Its Applications to Machinery Fault Detection and Diagnosis. Ph.D. Dissertation, Xi’an Jiaotong University, Xi’an, China, 2013.

- Chen, B.Q.; Zhang, Z.S.; Zi, Y.Y.; He, Z.J.; Sun, C. Detecting of transient vibration signatures using an improved fast spatial-spectral ensemble kurtosis kurtogram and its applications to mechanical signature analysis of short duration data from rotating machinery. Mech. Syst. Signal Process. 2013, 40, 1–37. [Google Scholar] [CrossRef]

- Chen, J.L.; Zi, Y.Y.; He, Z.J.; Wang, X.D. Adaptive redundant multiwavelet denoising with improved neighboring coefficients for gearbox fault detection. Mech. Syst. Signal Process. 2013, 38, 549–568. [Google Scholar] [CrossRef]

- Wang, S.; Zi, Y.Y.; Li, B.; Zhang, C.L.; He, Z.J. Reduced-order modeling for mistuned centrifugal impellers with crack damages. J. Sound Vib. 2014, 333, 6979–6995. [Google Scholar] [CrossRef]

- Kuang, J.; Huang, B. The effect of blade crack on mode localization in rotating bladed disks. J. Sound Vib. 1999, 227, 85–103. [Google Scholar] [CrossRef]

- Fang, X.; Tang, J.; Jordan, E.; Murphy, K. Crack induced vibration localization in simplified bladed-disk structures. J. Sound Vib. 2006, 291, 395–418. [Google Scholar] [CrossRef]

- Wang, S.; Zi, Y.Y.; Wan, Z.G.; Li, B.; He, Z.J. Effects of multiple cracks on the forced response of centrifugal impellers. Mech. Syst. Signal Process. 2015, 60–61, 326–3438. [Google Scholar] [CrossRef]

| No. | Date | 2# | 3# | ||||

|---|---|---|---|---|---|---|---|

| A | H | V | A | H | V | ||

| mm/s | mm/s | GE | mm/s | mm/s | GE | ||

| 1 | 10-08-04 | D | D | D | D | D | D |

| 2 | 10-10-09 | D | D | D | D | D | D |

| 3 | 10-12-09 | D | D | D | D | D | D |

| 4 | 11-01-13 | D | D | D | D | D | D |

| 5 | 11-03-08 | D | D | D | D | D | D |

| 6 | 11-04-07 | Dh | Dh | Dh | Dh | Dh | Dh |

| 7 | 11-04-12 | Dh | Dh | Dh | Dh | Dh | Dh |

| 8 | 11-05-11 | D | D | D | D | D | D |

| 9 | 11-06-09 | D | D | D | D | D | D |

| 10 | 11-07-06 | D | D | D | D | D | D |

| Category | Parameter |

|---|---|

| Time-Domain index | |

| Frequency-Domain index | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Sun, H.; Wang, S.; He, Z. Quantitative Index and Abnormal Alarm Strategy Using Sensor-Dependent Vibration Data for Blade Crack Identification in Centrifugal Booster Fans. Sensors 2016, 16, 632. https://doi.org/10.3390/s16050632

Chen J, Sun H, Wang S, He Z. Quantitative Index and Abnormal Alarm Strategy Using Sensor-Dependent Vibration Data for Blade Crack Identification in Centrifugal Booster Fans. Sensors. 2016; 16(5):632. https://doi.org/10.3390/s16050632

Chicago/Turabian StyleChen, Jinglong, Hailiang Sun, Shuai Wang, and Zhengjia He. 2016. "Quantitative Index and Abnormal Alarm Strategy Using Sensor-Dependent Vibration Data for Blade Crack Identification in Centrifugal Booster Fans" Sensors 16, no. 5: 632. https://doi.org/10.3390/s16050632