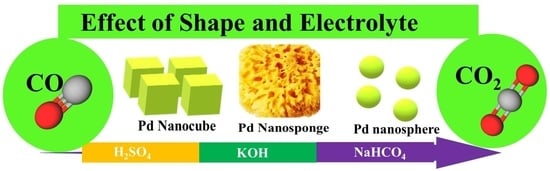

Self-Standing Pd-Based Nanostructures for Electrocatalytic CO Oxidation: Do Nanocatalyst Shape and Electrolyte pH Matter?

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Materials/Chemicals

3.2. Preparation of Pd Nanocube

3.3. Preparation of Pd Nanosponge

3.4. Material Characterization

3.5. Electrochemical COOxid Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gamal, A.; Eid, K.; El-Naas, M.H.; Kumar, D.; Kumar, A. Catalytic Methane Decomposition to Carbon Nanostructures and COx-Free Hydrogen: A Mini-Review. Nanomaterials 2021, 11, 1226. [Google Scholar] [CrossRef]

- Gamal, A.; Eid, K.; Abdullah, A.M. Engineering of Pt-based nanostructures for efficient dry (CO2) reforming: Strategy and mechanism for rich-hydrogen production. Int. J. Hydrogen Energy 2022, 47, 5901–5928. [Google Scholar] [CrossRef]

- Lu, Q.; Eid, K.; Li, W. Heteroatom-Doped Porous Carbon-Based Nanostructures for Electrochemical CO2 Reduction. Nanomaterials 2022, 12, 2379. [Google Scholar] [CrossRef] [PubMed]

- Udry, G.A.O.; Tiessler-Sala, L.; Pugliese, E.; Urvoas, A.; Halime, Z.; Maréchal, J.-D.; Mahy, J.-P.; Ricoux, R. Photo-catalytic Hydrogen Production and Carbon Dioxide Reduction Catalyzed by an Artificial Cobalt Hemoprotein. Int. J. Mol. Sci. 2022, 23, 14640. [Google Scholar] [CrossRef]

- Eid, K.; Lu, Q.; Abdel-Azeim, S.; Soliman, A.; Abdullah, A.M.; Abdelgwad, A.M.; Forbes, R.P.; Ozoemena, K.I.; Varma, R.S.; Shibl, M.F. Highly exfoliated Ti3C2Tx MXene nanosheets atomically doped with Cu for efficient electrochemical CO2 reduction: An experimental and theoretical study. J. Mater. Chem. A 2022, 10, 1965–1975. [Google Scholar] [CrossRef]

- Tenno, T.; Rikmann, E.; Uiga, K.; Zekker, I.; Mashirin, A.; Tenno, T. A novel proton transfer model of the closed equilibrium system H2O–CO2–CaCO3–NHX. Proc. Est. Acad. Sci. 2018, 67, 260–270. [Google Scholar] [CrossRef]

- Zekker, I.; Rikmann, E.; Tenno, T.; Saluste, A.; Tomingas, M.; Menert, A.; Loorits, L.; Lemmiksoo, V.; Tenno, T. Achieving nitritation and anammox enrichment in a single moving-bed biofilm reactor treating reject water. Environ. Technol. 2012, 33, 703–710. [Google Scholar] [CrossRef]

- Tenno, T.; Uiga, K.; Mashirin, A.; Zekker, I.; Rikmann, E. Modeling closed equilibrium systems of H2O–dissolved CO2–solid CaCO3. J. Phys. Chem. A 2017, 121, 3094–3100. [Google Scholar] [CrossRef]

- Ahsan, M.A.; He, T.; Eid, K.; Abdullah, A.M.; Sanad, M.F.; Aldalbahi, A.; Alvarado-Tenorio, B.; Du, A.; Puente Santiago, A.R.; Noveron, J.C. Controlling the interfacial charge polarization of MOF-derived 0D–2D vdW architectures as a unique strategy for bifunctional oxygen electrocatalysis. ACS Appl. Mater. Interfaces 2022, 14, 3919–3929. [Google Scholar] [CrossRef]

- Lu, Q.; Abdelgawad, A.; Li, J.; Eid, K. Non-Metal-Doped Porous Carbon Nitride Nanostructures for Photocata-lytic Green Hydrogen Production. Int. J. Mol. Sci. 2022, 23, 15129. [Google Scholar]

- Abdu, H.I.; Eid, K.; Abdullah, A.M.; Sliem, M.H.; Elzatahry, A.; Lu, X. Dry ice-mediated rational synthesis of edge-carboxylated crumpled graphene nanosheets for selective and prompt hydrolysis of cellulose and eucalyptus lignocellulose under ambient reaction conditions. Green Chem. 2020, 22, 5437–5446. [Google Scholar] [CrossRef]

- Eid, K.; Sliem, M.H.; Al-Ejji, M.; Abdullah, A.M.; Harfouche, M.; Varma, R.S. Hierarchical Porous Carbon Nitride-Crumpled Nanosheet-Embedded Copper Single Atoms: An Efficient Catalyst for Carbon Monoxide Oxidation. ACS Appl. Mater. Interfaces 2022, 14, 40749–40760. [Google Scholar] [PubMed]

- Lebechi, A.K.; Ipadeola, A.K.; Eid, K.; Abdullah, A.M.; Ozoemena, K.I. Porous Spinel-type Transition metal oxides Nanostructures as Emergent Electrocatalysts for Oxygen Reduction Reaction. Nanoscale 2022, 14, 10717–10737. [Google Scholar] [CrossRef] [PubMed]

- Rehman, J.; Eid, K.; Ali, R.; Fan, X.; Murtaza, G.; Faizan, M.; Laref, A.; Zheng, W.; Varma, R.S. Engineering of Transition Metal Sulfide Nanostructures as Efficient Electrodes for High-Performance Supercapacitors. ACS Appl. Energy Mater. 2022, 5, 6481–6498. [Google Scholar] [CrossRef]

- Ipadeola, A.K.; Abdelgawad, A.; Salah, B.; Ghanem, A.; Chitt, M.; Abdullah, A.M.; Eid, K. Self-standing foam-like Pd-based alloys nanostructures for efficient electrocatalytic ethanol oxidation. Int. J. Hydrogen Energy 2023. [Google Scholar] [CrossRef]

- Ipadeola, A.K.; Eid, K.; Lebechi, A.K.; Abdullah, A.M.; Ozoemena, K.I. Porous multi-metallic Pt-based nanostructures as efficient electrocatalysts for ethanol oxidation: A mini-review. Electrochem. Commun. 2022, 140, 107330. [Google Scholar] [CrossRef]

- Lu, Q.; Li, J.; Eid, K.; Gu, X.; Wan, Z.; Li, W.; Al-Hajri, R.S.; Abdullah, A.M. Facile one-step aqueous-phase synthesis of porous PtBi nanosponges for efficient electrochemical methanol oxidation with a high CO tolerance. J. Electroanal. Chem. 2022, 916, 116361. [Google Scholar] [CrossRef]

- Wu, F.; Eid, K.; Abdullah, A.M.; Niu, W.; Wang, C.; Lan, Y.; Elzatahry, A.A.; Xu, G. Unveiling one-pot template-free fabrication of exquisite multidimensional PtNi multicube nanoarchitectonics for the efficient electro-chemical oxidation of ethanol and methanol with a great tolerance for CO. ACS Appl. Mater. Interfaces 2020, 12, 31309–31318. [Google Scholar] [CrossRef]

- Li, S.; Cai, G.; Wu, S.; Raut, A.; Borges, W.; Sharma, P.R.; Sharma, S.K.; Hsiao, B.S.; Rafailovich, M. Sustainable Plant-Based Biopolymer Membranes for PEM Fuel Cells. Int. J. Mol. Sci. 2022, 23, 15245. [Google Scholar] [CrossRef]

- Biz, C.; Gracia, J.; Fianchini, M. Review on Magnetism in Catalysis: From Theory to PEMFC Applications of 3d Metal Pt-Based Alloys. Int. J. Mol. Sci. 2022, 23, 14768. [Google Scholar] [CrossRef]

- Bhowmick, G.D.; Ghangrekar, M.M.; Zekker, I.; Kibena-Põldsepp, E.; Tammeveski, K.; Wilhelm, M.; Banerjee, R. Ultrafiltration membrane bio-fuel cell as an energy-efficient advanced wastewater treatment system. Int. J. Energy Res. 2022, 46, 20216–20227. [Google Scholar] [CrossRef]

- Almeida, C.V.; Tremiliosi-Filho, G.; Eguiluz, K.I.; Salazar-Banda, G.R. Improved ethanol electro-oxidation at Ni@ Pd/C and Ni@ PdRh/C core–shell catalysts. J. Catal. 2020, 391, 175–189. [Google Scholar] [CrossRef]

- Abdelgawad, A.; Salah, B.; Eid, K.; Abdullah, A.M.; Al-Hajri, R.S.; Al-Abri, M.; Hassan, M.K.; Al-Sulaiti, L.A.; Ahmadaliev, D.; Ozoemena, K.I. Pt-Based Nanostructures for Electrochemical Oxidation of CO: Unveiling the Effect of Shapes and Electrolytes. Int. J. Mol. Sci. 2022, 23, 15034. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, T.; Ji, Z.; Song, Y.; Li, Y.; Liu, J.; Hu, W. Spatial decoupling of dehydrogenation and CO oxidation by Ni-Co-Ti hierarchical trimetallic catalyst for electrocatalytic oxidation of methanol. Appl. Catal. B Environ. 2023, 320, 122024. [Google Scholar] [CrossRef]

- Yuan, W.; Ma, Y.; Wu, H.; Cheng, L. Single-atom catalysts for CO oxidation, CO2 reduction, and O2 electrochemistry. J. Energy Chem. 2022, 65, 254–279. [Google Scholar] [CrossRef]

- Shin, S.; Kwon, T.; Lee, Y. Palladium-rhodium binary oxide composite nanofibers with various composition ratios for highly efficient electrochemical sensing of carbon monoxide in neutral aqueous media. Appl. Surf. Sci. 2022, 598, 153847. [Google Scholar] [CrossRef]

- Eid, K.; Gamal, A.; Abdullah, A.M. Graphitic carbon nitride-based nanostructures as emergent catalysts for carbon monoxide (CO) oxidation. Green Chem. 2023, 25, 1276–1310. [Google Scholar] [CrossRef]

- Yun, Q.; Lu, Q.; Li, C.; Chen, B.; Zhang, Q.; He, Q.; Hu, Z.; Zhang, Z.; Ge, Y.; Yang, N.; et al. Synthesis of PdM (M = Zn, Cd, ZnCd) Nanosheets with an Unconventional Face-Centered Tetragonal Phase as Highly Efficient Electrocatalysts for Ethanol Oxidation. ACS Nano 2019, 13, 14329–14336. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Y.; Ma, Y.; Zheng, Y.; Zhang, H.; Tang, M.; Dai, Y. Ultrathin samarium-doped palladium nanocrystals with exotic shapes for efficient electrocatalytic ethanol oxidation. Catal. Today 2023, 409, 63–70. [Google Scholar] [CrossRef]

- Eid, K.; Sliem, M.H.; Abdullah, A.M. Unraveling template-free fabrication of carbon nitride nanorods co-doped with Pt and Pd for efficient electrochemical and photoelectrochemical carbon monoxide oxidation at room temperature. Nanoscale 2019, 11, 11755–11764. [Google Scholar] [CrossRef]

- Eid, K.; Sliem, M.H.; Al-Kandari, H.A.; Sharaf, M.A.; Abdullah, A.M. Rational Synthesis of Porous Graphitic-like Carbon Nitride Nanotubes Co-doped with Au and Pd as an Efficient Catalyst for Carbon Monoxide Oxidation. Langmuir 2019, 35, 3421–3431. [Google Scholar] [CrossRef] [PubMed]

- Fang, L.-L.; Tao, Q.; Li, M.-F.; Liao, L.-W.; Chen, D.; Chen, Y.-X. Determination of the Real Surface Area of Palladium Electrode. Chin. J. Chem. Phys. 2010, 23, 543–548. [Google Scholar] [CrossRef]

- Huang, H.; Blackman, O.F.; Celorrio, V.; Russell, A.E. Isolating the contributions of surface Sn atoms in the bi-functional behaviour of PtSn CO oxidation electrocatalysts. Electrochim. Acta 2021, 390, 138811. [Google Scholar] [CrossRef]

- Ma, T.Y.; Dai, S.; Qiao, S.Z. Self-supported electrocatalysts for advanced energy conversion processes. Mater. Today 2016, 19, 265–273. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Yan, Z.; Liu, F.; Xu, W.; Cheng, F.; Chen, J. Self-Supported Transition-Metal-Based Electrocatalysts for Hydrogen and Oxygen Evolution. Adv. Mater. 2020, 32, 1806326. [Google Scholar] [CrossRef]

- Celorrio, V.; Sebastián, D.; Calvillo, L.; García, A.; Fermin, D.J.; Lázaro, M.J. Influence of thermal treatments on the stability of Pd nanoparticles supported on graphitised ordered mesoporous carbons. Int. J. Hydrogen Energy 2016, 41, 19570–19578. [Google Scholar] [CrossRef] [Green Version]

- Asmussen, R.M.; Adams, B.D.; Chen, S.; Shah, B.; Chen, A. Synthesis and electrochemical study of PtPd nanodendrites. J. Electroanal. Chem. 2013, 688, 151–157. [Google Scholar] [CrossRef]

- Ulas, B.; Kivrak, A.; Aktas, N.; Kivrak, H.; Nanotubes; Nanostructures, C. Carbon monoxide and formic acid electrooxidation study on Au decorated Pd catalysts prepared via microwave assisted polyol method. Fuller. Nano-tub. Carbon Nanostructures 2019, 27, 545–552. [Google Scholar] [CrossRef]

- Wang, Y.; Nguyen, T.S.; Liu, X.; Wang, X. Novel palladium-lead (Pd-Pb/C) bimetallic catalysts for electrooxidation of ethanol in alkaline media. J. Power Sources 2010, 195, 2619–2622. [Google Scholar] [CrossRef]

- Yang, D.; Carpena-Núnez, J.; Fonseca, L.F.; Biaggi-Labiosa, A.; Hunter, G.W. Shape-controlled synthesis of palladium and copper superlattice nanowires for high-stability hydrogen sensors. Sci. Rep. 2014, 4, 3773. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Sun, T.; Chen, C.; Xiao, F.; Gong, Z.; Wang, S. Bifunctional Nanocatalyst Based on Three-Dimensional Carbon Nanotube—Graphene Hydrogel Supported Pd Nanoparticles: One-Pot Synthesis and Its Catalytic Properties. ACS Appl. Mater. Interfaces 2014, 6, 21035–21040. [Google Scholar] [CrossRef] [PubMed]

- Lei, H.; Li, X.; Sun, C.; Zeng, J.; Siwal, S.S.; Zhang, Q. Galvanic Replacement—Mediated Synthesis of Ni-Supported Pd Nanoparticles with Strong Metal—Support Interaction for Methanol Electro-oxidation. Small 2019, 15, 1804722. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Zhang, L.; Lv, T.; Ruditskiy, A.; Liu, J.; Ye, Z.; Xia, Y. Five-Fold Twinned Pd Nanorods and Their Use as Templates for the Synthesis of Bimetallic or Hollow Nanostructures. Chemnanomat 2015, 1, 246–252. [Google Scholar] [CrossRef]

- Kettemann, F.; Wuithschick, M.; Caputo, G.; Kraehnert, R.; Pinna, N.; Rademann, K.; Polte, J. Reliable palladium nanoparticle syntheses in aqueous solution: The importance of understanding precursor chemistry and growth mechanism. Crystengcomm 2015, 17, 1865–1870. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Peng, H.-C.; Liu, J.; Huang, C.Z.; Xia, Y. Use of Reduction Rate as a Quantitative Knob for Controlling the Twin Structure and Shape of Palladium Nanocrystals. Nano Lett. 2015, 15, 1445–1450. [Google Scholar] [CrossRef]

- Vidal-Iglesias, F.J.; Arán-Ais, R.M.; Solla-Gullón, J.; Garnier, E.; Herrero, E.; Aldaz, A.; Feliu, J.M. Shape-dependent electrocatalysis: Formic acid electrooxidation on cubic Pd nanoparticles. Phys. Chem. Chem. Phys. 2012, 14, 10258–10265. [Google Scholar] [CrossRef]

- Ipadeola, A.K.; Eid, K.; Abdullah, A.M.; Ozoemena, K.I. Pd-Nanoparticles Embedded Metal—Organic Frame-work-Derived Hierarchical Porous Carbon Nanosheets as Efficient Electrocatalysts for Carbon Monoxide Oxidation in Different Electrolytes. Langmuir 2022, 38, 11109–11120. [Google Scholar] [CrossRef]

- Ipadeola, A.K.; Haruna, A.B.; Abdullah, A.M.; Al-Hajri, R.; Viter, R.; Ozoemena, K.I.; Eid, K. Ternary PdNiO Nanocrystals Ornamented Porous CeO2/Onion-like Carbon for Electrooxidation of Carbon Monoxide: Unveiling the Effect of Supports and Electrolytes. Catal. Sci. Technol. 2023, 13, 3035–3046. [Google Scholar]

- Ipadeola, A.K.; Eid, K.; Abdullah, A.M.; Al-Hajri, R.S.; Ozoemena, K.I. Pd/Ni-metal-organic framework-derived porous carbon nanosheets for efficient CO oxidation over a wide pH range. Nanoscale Adv. 2022, 4, 5044–5055. [Google Scholar] [CrossRef]

- Salah, B.; Eid, K.; Abdelgwad, A.M.; Ibrahim, Y.; Abdullah, A.M.; Hassan, M.K.; Ozoemena, K.I. Titanium Car-bide (Ti3C2Tx) MXene Ornamented with Palladium Nanoparticles for Electrochemical CO Oxidation. Electroanalysis 2022, 34, 677–683. [Google Scholar] [CrossRef]

- Navaladian, S.; Viswanathan, B.; Varadarajan, T.; Viswanath, R. A rapid synthesis of oriented palladium nanoparticles by UV irradiation. Nanoscale Res. Lett. 2009, 4, 181–186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, B.S.; Amali, A.J.; Pitchumani, K. Fabrication of Pd nanoparticles embedded C@ Fe3O4 core—Shell hybrid nanospheres: An efficient catalyst for cyanation in aryl halides. ACS Appl. Mater. Interfaces 2015, 7, 22907–22917. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Eid, K.; Wang, H.; Deng, Y.; Lu, S.; Li, X.; Wang, L.; Gu, H. One-pot synthesis of bimetallic PdCu nanoframes as an efficient catalyst for the methanol oxidation reaction. New J. Chem. 2018, 42, 798–801. [Google Scholar] [CrossRef]

- Ipadeola, A.K.; Salah, B.; Ghanem, A.; Ahmadaliev, D.; Sharaf, M.A.; Abdullah, A.M.; Eid, K. Unveiling the effect of shapes and electrolytes on the electrocatalytic ethanol oxidation activity of self-standing Pd nanostructures. Heliyon 2023, 9, e16890. [Google Scholar] [CrossRef]

- Jin, M.; Zhang, H.; Xie, Z.; Xia, Y. Palladium nanocrystals enclosed by {100} and {111} facets in controlled pro-portions and their catalytic activities for formic acid oxidation. Energy Environ. Sci. 2012, 5, 6352–6357. [Google Scholar] [CrossRef] [Green Version]

- Eid, K.; Ahmad, Y.H.; Yu, H.; Li, Y.; Li, X.; AlQaradawi, S.Y.; Wang, H.; Wang, L. Rational one-step synthesis of porous PtPdRu nanodendrites for ethanol oxidation reaction with a superior tolerance for CO-poisoning. Nanoscale 2017, 9, 18881–18889. [Google Scholar] [CrossRef]

- Weir, M.G.; Myers, V.S.; Frenkel, A.I.; Crooks, R.M. In situ X-ray absorption analysis of ∼1.8 nm dendrimer-encapsulated Pt nanoparticles during electrochemical CO oxidation. ChemPhysChem 2010, 11, 2942–2950. [Google Scholar] [CrossRef]

- Jurzinsky, T.; Cremers, C.; Pinkwart, K.; Tübke, J. On the influence of Ag on Pd-based electrocatalyst for methanol oxidation in alkaline media: A comparative differential electrochemical mass spectrometry study. Electrochim. Acta 2016, 199, 270–279. [Google Scholar] [CrossRef]

- Matsui, T.; Fujiwara, K.; Okanishi, T.; Kikuchi, R.; Takeguchi, T.; Eguchi, K. Electrochemical oxidation of CO over tin oxide supported platinum catalysts. J. Power Sources 2006, 155, 152–156. [Google Scholar] [CrossRef]

| Catalysts | EOnset (V) | EOxid (V) | IAnode mA cm−2 @ 50 mV/s | Slope (IAnode vs. υ 1/2) | ECSA (m2/g) | Charge of COads (μC) | Mass/Specific Activity (mA·mg−1/mA·cm−1) |

|---|---|---|---|---|---|---|---|

| Acid (0.1 M H2SO4) | |||||||

| Pd Nanocube | 0.360 | 0.755 | 5.92 | 0.92 | 22.88 | 930.0 | 19.85/0.090 |

| Pd Nanosponge | 0.410 | 0.715 | 4.00 | 1.25 | 23.64 | 955.5 | 14.13/0.060 |

| Pd/C | 0.750 | 0.878 | 1.59 | 0.34 | 11.11 | 265.0 | 18.7/0.095 |

| Alkaline (0.1 M KOH) | |||||||

| Pd Nanocube | −0.133 | −0.086 | 1.63 | 0.31 | 2.86 | 110.0 | 5.75/0.200 |

| Pd Nanosponge | −0.170 | −0.090 | 3.20 | 0.54 | 15.07 | 602.0 | 11.30/0.075 |

| Pd/C | −0.217 | −0.185 | 1.48 | 0.29 | 2.78 | 99.5 | 17.40/0.620 |

| Neutral (0.5 M NaHCO3) | |||||||

| Pd Nanocube | 0.200 | 0.371 | 0.578 | 0.196 | 6.23 | 130.0 | 2.04/0.065 |

| Pd Nanosponge | −0.049 | 0.249 | 0.977 | 0.279 | 10.11 | 211.5 | 3.45/0.068 |

| Pd/C | 0.341 | 0.451 | 0.52 | 0.13 | -3.16 | 64.4 | 6.12/0.110 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salah, B.; Ipadeola, A.K.; Abdullah, A.M.; Ghanem, A.; Eid, K. Self-Standing Pd-Based Nanostructures for Electrocatalytic CO Oxidation: Do Nanocatalyst Shape and Electrolyte pH Matter? Int. J. Mol. Sci. 2023, 24, 11832. https://doi.org/10.3390/ijms241411832

Salah B, Ipadeola AK, Abdullah AM, Ghanem A, Eid K. Self-Standing Pd-Based Nanostructures for Electrocatalytic CO Oxidation: Do Nanocatalyst Shape and Electrolyte pH Matter? International Journal of Molecular Sciences. 2023; 24(14):11832. https://doi.org/10.3390/ijms241411832

Chicago/Turabian StyleSalah, Belal, Adewale K. Ipadeola, Aboubakr M. Abdullah, Alaa Ghanem, and Kamel Eid. 2023. "Self-Standing Pd-Based Nanostructures for Electrocatalytic CO Oxidation: Do Nanocatalyst Shape and Electrolyte pH Matter?" International Journal of Molecular Sciences 24, no. 14: 11832. https://doi.org/10.3390/ijms241411832