Antioxidant Potential of Hemp and Flax Fibers Depending on Their Chemical Composition

Abstract

:1. Introduction

2. Results and Discussion

2.1. Chemical Analysis

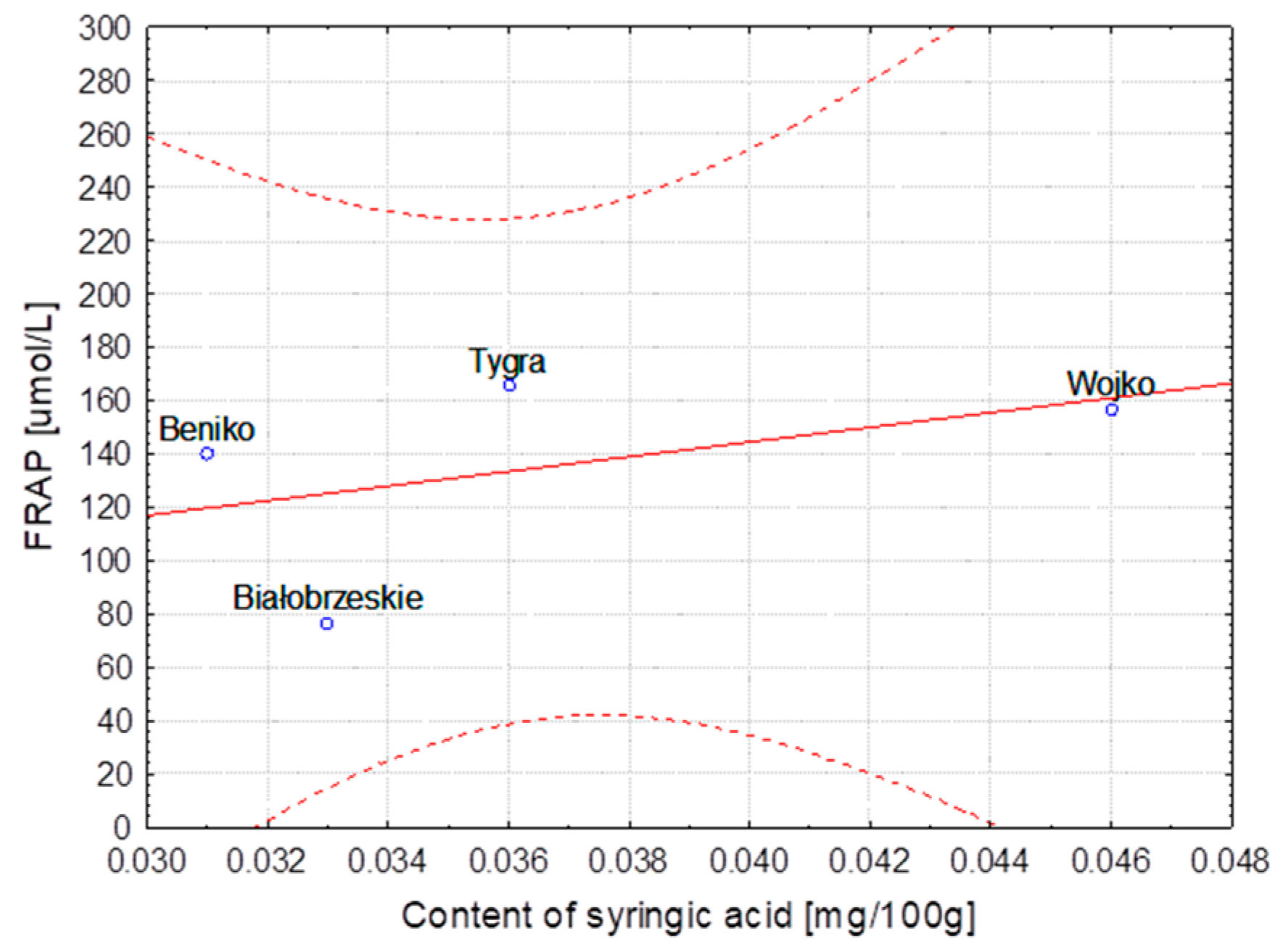

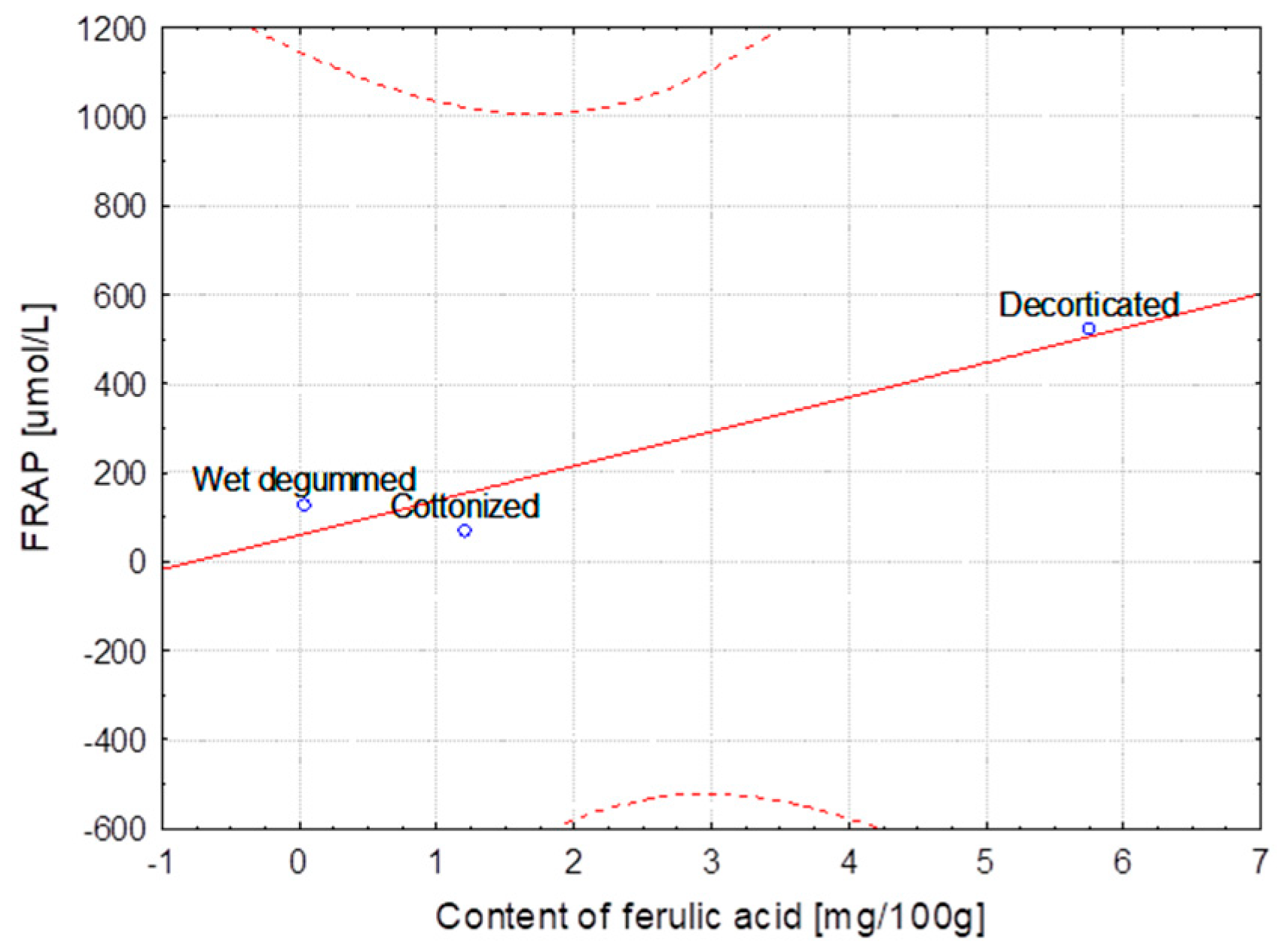

2.2. Antioxidant Activity

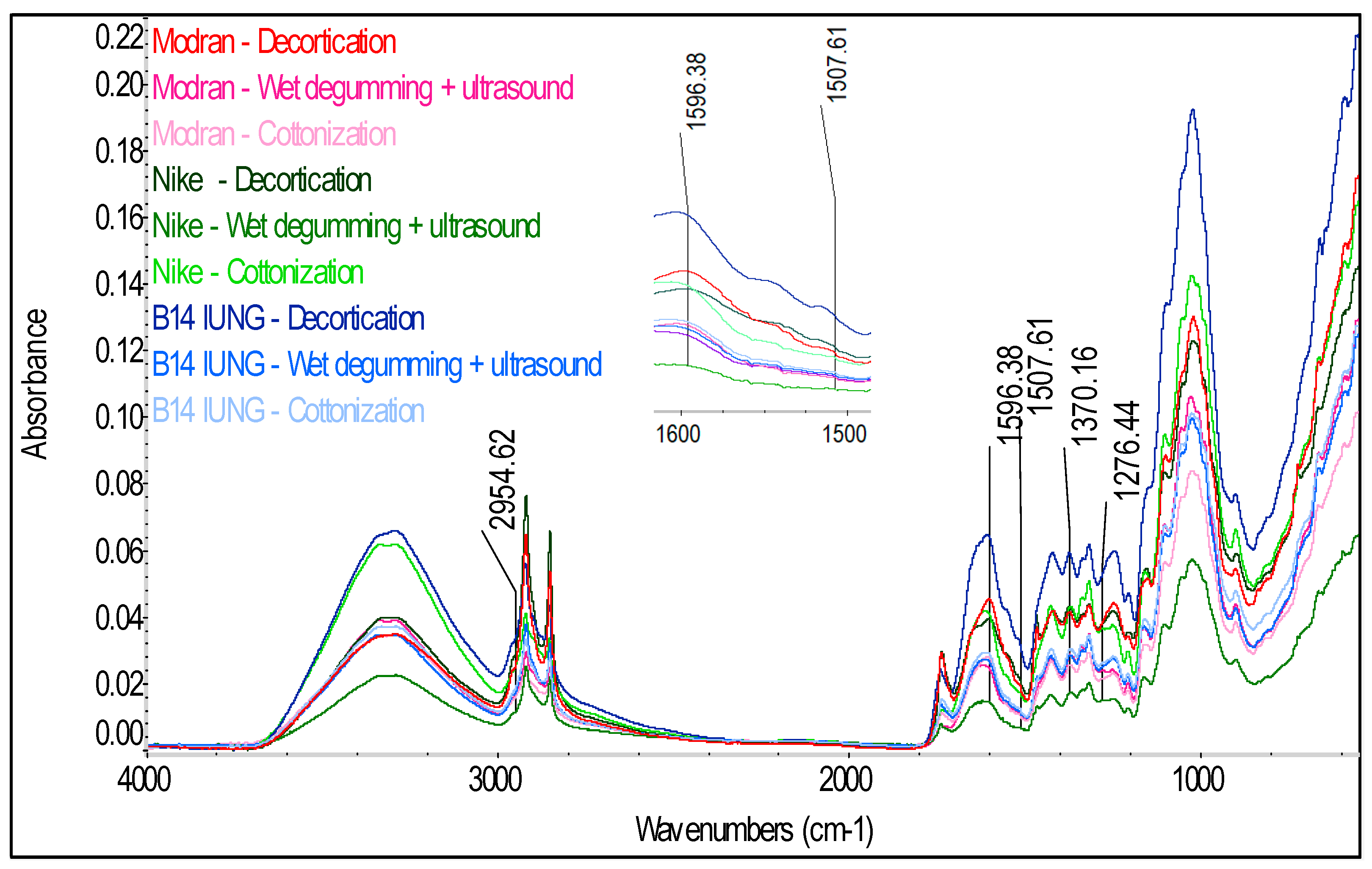

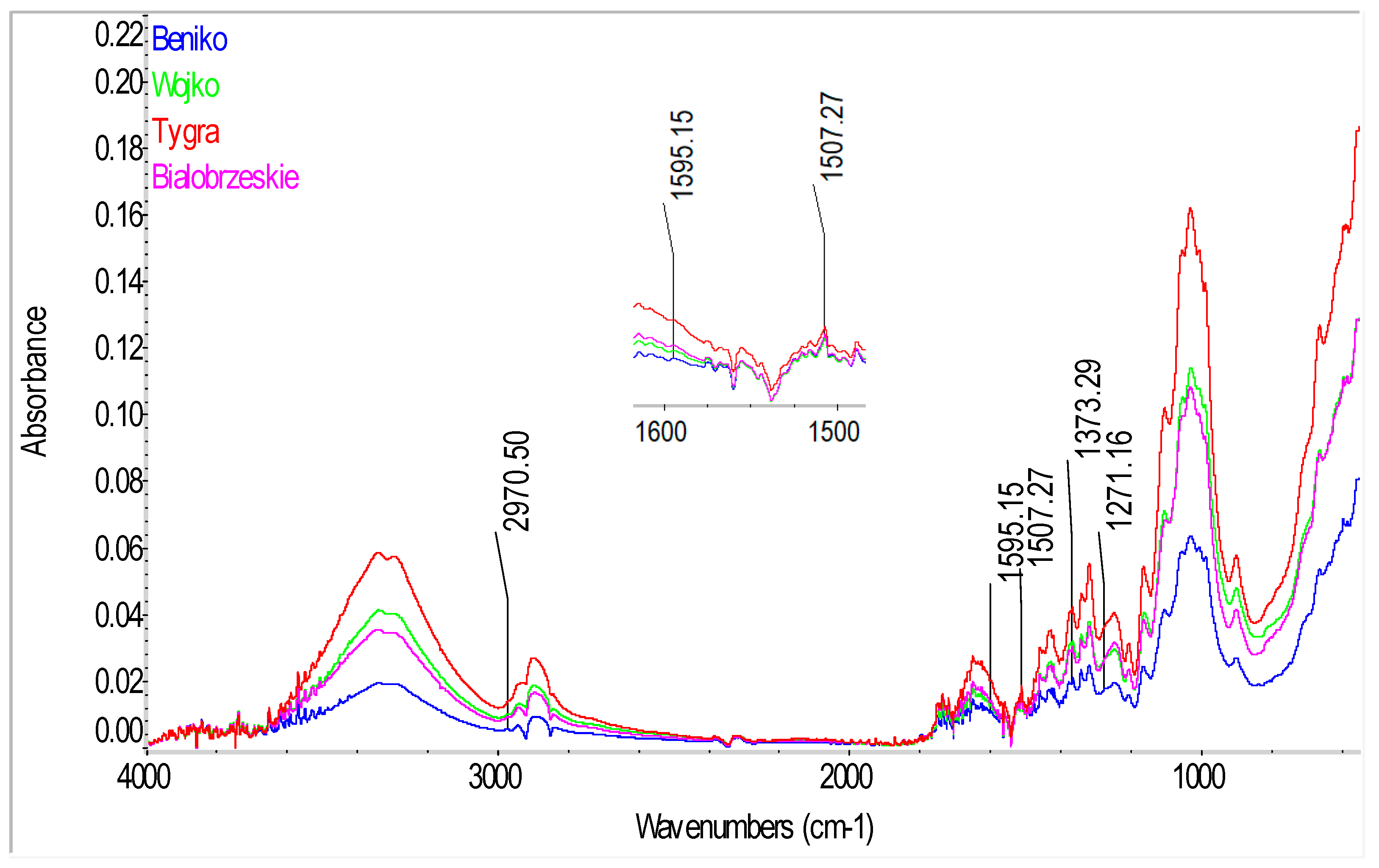

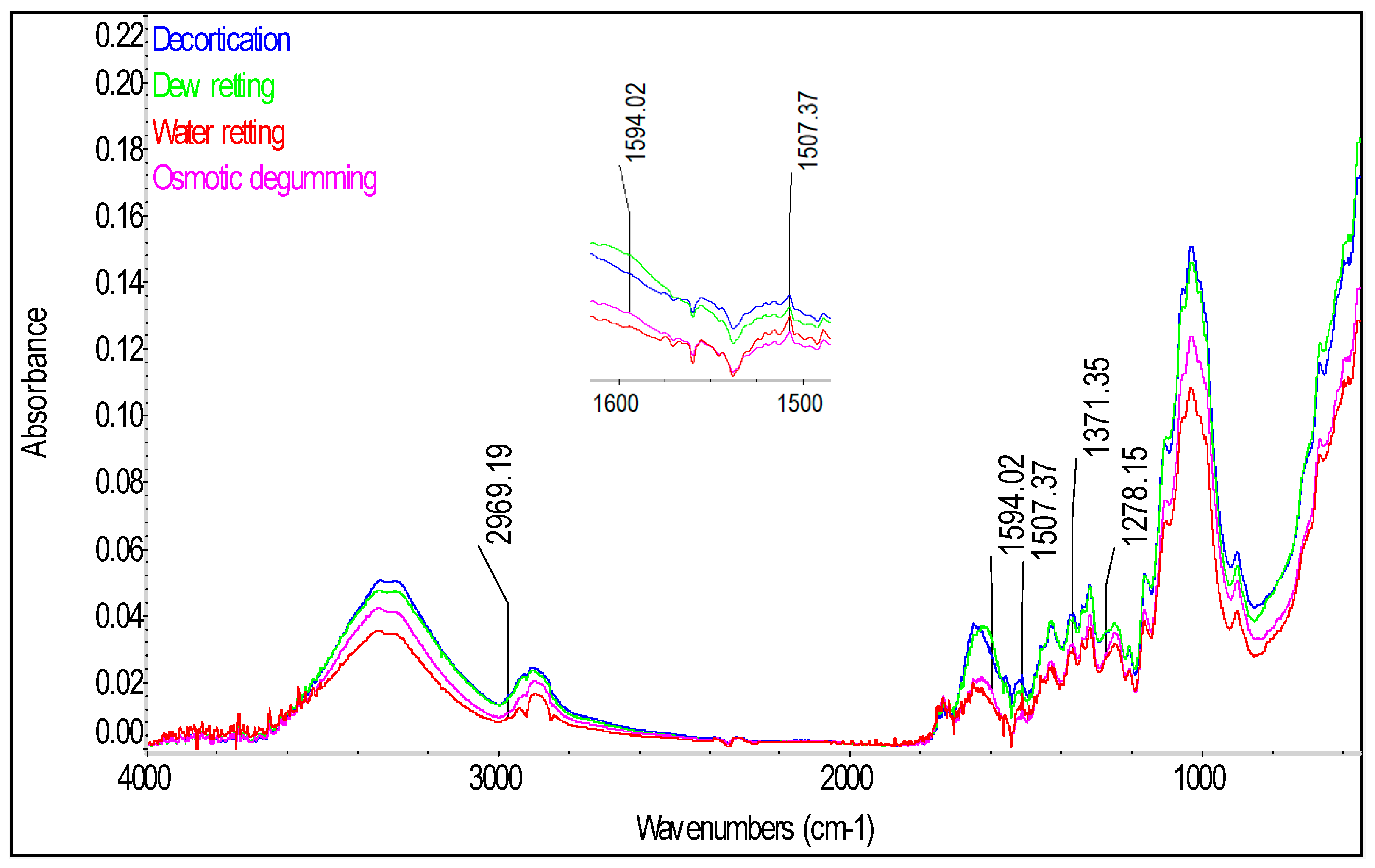

2.3. ATR-FTIR Analyses of Fiber

3. Materials and Methods

3.1. Materials

3.2. Methods of Fiber Extraction

- Flax: Modran, Nike, B14 IUNG varieties (decorticated fiber, wet degummed with ultrasounds and cottonized fiber)

- Hemp: Białobrzeskie (water retted, dew retted, decorticated, osmotically degummed fiber)

- Hemp: Beniko, Wojko, Tygra, Białobrzeskie (water retted fiber).

3.3. Antioxidant Activity

3.3.1. Sample Preparation

3.3.2. Chemicals

3.3.3. Determination of the Ferric Reducing Antioxidant Power (FRAP)

3.3.4. Determination of the 2, 2-Diphenyl-1-picrylhydrazyl (DPPH) Radical Scavenging Activity

3.4. Determination of Phenolic Acids

3.4.1. Sample Preparation

3.4.2. Chemicals

3.4.3. HPLC-DAD Analyses

3.5. Chemical Analyses

- ▪

- Cellulose content (%) in flax and hemp fiber was measured according to the Polish Standard no. PN-92/50092. The cellulose content was measured by dissolving lignins and other substances present in the fiber with a mixture of acetylacetone and dioxane, acidified with hydrochloric acid.

- ▪

- Hemicelluloses content (%) in the flax end hemp fiber was determined according to the Polish Standard BN-77/7529-02. The hemicellulose content was measured by dissolving the hemicellulose present in the fiber with a 1% solution of sodium hydroxide, filtering off the residue after dissolution, drying it and weighing. Then the hemicelluloses were calculated from the mass loss of the sample.

- ▪

- Lignin content (%) was determined according to the Polish Standard BN-86/7501-11. The lignin content was measured by dissolving cellulose, hemicellulose and pectins with a mixture of concentrated sulfuric and ortho phosphoric acids, followed by draining off the remaining insoluble lignin.

- ▪

- Pectin content (%) tests were conducted by a gravimetric method according to a method developed at INF&MP. The percent share of pectins was determined by dissolving them in ammonium citrate and then precipitated from the solution with calcium chloride and by measuring the weight of the calcium pectinate precipitated from the solution.

- ▪

- Waxes and fats content (%) was measured according to the Polish Standard no. BN-86/7501-10. The percentage content of wax and fat substances was determined by extracting them with an organic solvent (petroleum ether) in a Soxhlet extractor (Institute of Natural Fibers & Medicinal Plants) and weighing the residues after vaporization of the solvent.

3.6. ATR-FTIR Analysis

3.7. Statistical Analyses

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zimniewska, M.; Pawlaczyk, M.; Krucinska, I.; Frydrych, I.; Mikolajczak, P.; Schmidt-Przewozna, K.; Komisarczyk, A.; Herczynska, L.; Romanowska, B. The influence of natural functional clothing on some biophysical parameters of the skin. Text. Res. J. 2018. [Google Scholar] [CrossRef]

- Zimniewska, M. Antioxidant Activity of Fibers Originating from Traditional Varieties of Polish Flax Plants. Fibers Text. East. Eur. 2015, 23, 41–47. [Google Scholar]

- Wilska-Jeszka, J. Struktura i wlasciwosci przeciwutleniajace polifenoli. PL. Mat. II Konf. Nauk. „Zywnosc a zdrowie” Lodz 1999, 27–35. [Google Scholar]

- Graf, E. Antioxidant potential of ferulic acid. Free Radic. Biol. Med. 2000, 28, 1249–1256. [Google Scholar] [CrossRef]

- Pouillot, A.; Polla, L.L.; Tacchini, P.; Neequaye, A.; Polla, A.; Polla, B. Natural Antioxidants and their Effects on the Skin. In Formulating, Packaging, and Marketing of Natural Cosmetic Products, 1st ed.; Dayan, N., Kromidas, L., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; Chapter 13; pp. 239–257. [Google Scholar]

- Love, G.D.; Snape, C.E.; Jarvis, M.C.; Morrison, M. Determination of Phenolic Structures in Flax Fiber by Solid-State 13C NMR. Phytochemistry 1994, 35, 489–491. [Google Scholar] [CrossRef]

- Gorshkova, T.A.; Salnikov, V.V.; Pogodina, N.M.; Chemikosova, S.B.; Yablokova, E.V.; Ulanov, A.V.; Ageeva, M.V.; Vandam, J.E.G.; Lozovaya, V.V. Composition and Distribution of Cell Wall Phenolic Compounds in Flax (Linum usitatissimum L.) Stem Tissues. Ann. Bot. 2000, 85, 477–486. [Google Scholar] [CrossRef]

- Kozlowski, R.; Konczewicz, W.; Kaniewski, R.; Dochia, M.; Pernevan, M.S. The Methods of Degumming Bast Fibrous Plants. Sci. Bull. Escorena 2011, 4, 17–31. [Google Scholar]

- Duchemin, B.; Thuault, A.; Vicente, A.; Rigaud, B.; Fernandez, C.; Eve, S. Ultrastructure of cellulose crystallites in flax textile fibers. Cellulose 2012, 19, 1837–1854. [Google Scholar] [CrossRef]

- Day, A.; Ruel, K.; Neutelings, G.; Cronier, D.; David, H.; Hawkins, S.; Chabbert, B. Lignification in the flax stem: Evidence for an unusual lignin in bast fibers. Planta 2005, 222, 234–245. [Google Scholar] [CrossRef] [PubMed]

- Akin, D.E. Linen Most Useful: Perspectiveson Structure, Chemistry, and Enzymes for Retting Flax. ISRN Biotechnol. 2013, 2013, 186534. [Google Scholar] [CrossRef] [PubMed]

- Akin, D.E.; Gamble, G.R.; Morrison, W.H., III; Rigsby, L.L.; Dodd, R.B. Chemical and structural analysis of fiber and core tissues from flax. J. Sci. Food Agric. 1996, 72, 155–165. [Google Scholar] [CrossRef]

- Gamble, G.R.; Snook, M.E.; Henriksson, G.; Akin, D.E. Phenolic constituents in flax bast tissue and inhibition of cellulose and pectinase. Biotechnol. Lett. 2000, 22, 741–746. [Google Scholar] [CrossRef]

- Cotoras, M.; Vivanco, H.; Melo, R.; Aguirre, M.; Silva, E.; Mendoza, L. In vitro and in vivo evaluation of the antioxidant and prooxidant activity of phenolic compounds obtained from grape (Vitis vinifera) pomace. Molecules 2014, 19, 21154–21167. [Google Scholar] [CrossRef] [PubMed]

- Eyre, J.V.; Nodder, C.R. An experimental study of flax retting. I.—The development of acidity during the retting of flax: Its interpretation and technical significance. J. Text. Inst. Trans. 1924, 15, 237–272. [Google Scholar] [CrossRef]

- Morrison, W.H., III; Archibald, D.D.; Sharma, H.S.S.; Akin, D.E. Chemical and physical characterization of water- and dewretted flax fibers. Ind. Crops Prod. 2000, 12, 39–46. [Google Scholar] [CrossRef]

- Chen, C. Sinapic Acid and Its Derivatives as Medicine in Oxidative Stress-Induced Diseases and Aging. Oxid. Med. Cell. Longev. 2016, 2016, 3571614. [Google Scholar] [CrossRef] [PubMed]

- Moura, C.A.S.; Gomes, D.J.C.; de Souza, N.C.; Silva, J.R. Photoresponsive Wettability in Monolayer Films from Sinapinic Acid. Sci. World J. 2013, 2013, 915237. [Google Scholar] [CrossRef] [PubMed]

- Lozovaya, V.V.; Gorshkova, T.; Yablokova, E.V.; Rumyantseva, N.; Valieva, A.; Ulanov, A.; Widholm, J. Cold alkali can extract phenolic acids that are ether linked to cell wall components in dicotyledonous plants (buck wheat, flax and soybean). Phytochemistry 1999, 50, 395–400. [Google Scholar] [CrossRef]

- Konczewicz, W.; Zimniewska, M.; Valera, M.A. Selection of a retting method for extraction of bast fibers as response to challenges in composite reinforcement. Text. Res. J. 2017. [Google Scholar] [CrossRef]

- Marchessault, R.H. Application of infra-red spectroscopy to cellulose and wood polysaccharides. Pure Appl. Chem. 1962, 5, 107–129. [Google Scholar] [CrossRef]

- Fan, M.; Dai, D.; Huang, B. Fourier transform infrared spectroscopy for natural fibers. In Fourier Transform—Materials Analysis; Salih, S.M., Ed.; InTechOpen: Rijeka, Croatia, 2012; pp. 45–68. ISBN 978-953-51-0594-7. [Google Scholar]

- Bacic, A.; Harris, P.J.; Stone, B.A. Structure and function of plant cell wall. In The Biochemistry of Plants; Academic Press: New York, NY, USA, 1988; pp. 297–371. [Google Scholar]

- Zimniewska, M.; Zbrowski, A.; Konczewicz, W.; Majcher, A.; Przybylski, J.; Matecki, K.; Wiśniewski, M.; Kicińska-Jakubowska, A.; Mańkowski, J. Cottonization of decorticated flax fibers. Fibers Text. East. Eur. 2017, 3, 26–33. [Google Scholar]

- Jóźwik, W.; Kozioł, S.; Matecki, K.; Neska, M.; Przybylski, J.; Wiśniewski, M.; Zbrowski, A.; Zimniewska, M.; Konczewicz, W.; Kicińska-Jakubowska, A.; et al. A prototype of a technological line for processing decorticated flax fiber. J. Mach. Constr. Maint. Probl. Eksploat. 2017, 1, 73–79. [Google Scholar]

- Konczewicz, W. Physical phenomena occurring in the process of physical-mechanical degumming of fiber from flax straw. Text. Res. J. 2015, 85, 380–390. [Google Scholar] [CrossRef]

- Konczewicz, W.; Wojtysiak, J. The effect of physical factors on the process of physical-mechanical degumming of flax fibers. Text. Res. J. 2015, 85, 391–403. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The Ferric Reducing Ability of Plasma (FRAP) as a Measure of “Antioxidant Power”: The FRAP Assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.; Ou, B.; Prior, R.L. The chemistry behind antioxidant capacity assays. J. Agric. Food Chem. 2005, 53, 1841–1856. [Google Scholar] [CrossRef] [PubMed]

- Katalinic, V.; Milos, M.; Kulisic, T.; Jukic, M. Screening of 70 medicinal plant extracts for antioxidant capacity and total phenols. Food Chem. 2006, 94, 550–557. [Google Scholar] [CrossRef]

- Qian, H.; Nihorimbere, V. Antioxidant power of phytochemicals from Psidium guajava leaf. J. Zhejiang Univ. Sci. 2004, 5, 676–683. [Google Scholar] [CrossRef] [PubMed]

- Liu, A.H.; Li, L.; Xu, M.; Lin, Y.H.; Guo, H.Z.; Guo, D.A. Simultaneous quantifi-cation of six major phenolic acids in the roots of Salvia miltiorrhiza and four related traditional Chinese medicinal preparations by HPLC–DAD method. J. Pharm. Biomed. Anal. 2006, 41, 48–56. [Google Scholar] [CrossRef] [PubMed]

- Gryszczyńska, A.; Opala, B.; Lowicki, Z.; Dreger, M.; Gorska-Paukszta, M.; Szulc, M.; Kaminska, E.; Litwin, E.; Struzik, P.; Dyr, W.; et al. Bioactive compounds determination in the callus and hydroalcoholic extracts from Salvia miltiorrhiza and Salvia przewalskii—Preliminary study on their anti-alcoholic activity effects. Phytochem. Lett. 2015, 11, 399–403. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds, samples of tested fibers are available from the authors. |

| Degumming Method | Variety | Content of: | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Waxes and Fats (n = 3) | Pectin (n = 5) | Lignin (n = 3) | Cellulose (n = 3) | Hemicellulose (n = 3) | |||||||

| % | ±SD | % | ±SD | % | ±SD | % | ±SD | % | ±SD | ||

| HEMP | |||||||||||

| Water retting | Beniko | 0.23 a | 0.01 | 1.47 | 0.09 | 2.81 a | 0.29 | 71.31 a | 1.32 | 15.03 a | 0.02 |

| Wojko | 0.24 a | 0.04 | 0.67 a | 0.02 | 3.02 a | 0.31 | 72.53 a | 0.11 | 16.67 | 0.24 | |

| Tygra | 0.25 a | 0.04 | 0.56 | 0.00 | 2.78 a | 0.28 | 70.79 a | 0.13 | 15.00 a | 0.28 | |

| Białobrzeskie | 0.34 | 0.02 | 0.67 | 0.02 | 2.38 a | 0.22 | 72.03 a | 0.22 | 14.37 | 0.29 | |

| Decortication | 0.47 a,b | 0.02 | 2.00 | 0.09 | 5.55 | 0.17 | 66.02 a | 0.46 | 21.25 | 0.05 | |

| Dew retting | 0.56 a | 0.14 | 3.68 | 0.19 | 4.31 a | 0.04 | 66.16 a | 0.48 | 21.72 | 0.12 | |

| Water retting | Białobrzeskie | 0.34 b | 0.02 | 0.67 | 0.02 | 2.38 | 0.22 | 72.03 | 0.22 | 14.37 | 0.29 |

| Osmotic degumming | 0.44 a,b | 0.04 | 2.82 | 0.22 | 4.03 a | 0.09 | 67.81 | 0.52 | 16.29 | 0.03 | |

| FLAX | |||||||||||

| Decortication | 1.26 | 0.00 | 4.62 a | 0.16 | 4.00 a | 0.16 | 68.89 | 1.91 | 29.35 | 0.16 | |

| Wet degumming + ultrasound | Modran | 0.69 | 0.07 | 4.41 a | 0.50 | 4.20 a | 0.16 | 75.54 a | 1.18 | 19.62 | 0.15 |

| Cottonization | 0.97 | 0.10 | 4.72 a | 0.39 | 4.26 a | 0.15 | 73.51 a | 0.98 | 16.44 | 0.23 | |

| Decortication | 1.47 | 0.07 | 4.11 | 0.38 | 8.60 | 0.30 | 64.57 | 0.85 | 29.38 | 0.08 | |

| Wet degumming + ultrasound | NIKE | 0.76 | 0.00 | 3.56 | 0.27 | 4.46 a | 0.48 | 77.44 | 1.58 | 16.43 | 0.25 |

| Cottonization | 0.95 | 0.05 | 2.39 | 0.22 | 4.87 a | 0.51 | 74.25 | 0.20 | 13.84 | 0.06 | |

| Decortication | 1.47 a | 0.07 | 4.11 | 0.38 | 8.60 | 0.30 | 64.57 | 0.85 | 29.38 | 0.08 | |

| Wet degumming + ultrasound | B14 IUNG | 1.33 a | 0.01 | 5.43 | 0.28 | 6.69 a | 0.48 | 75.04 | 0.46 | 23.92 | 0.02 |

| Cottonization | 1.72 | 0.09 | 3.57 | 0.23 | 6.10 a | 0.01 | 72.20 | 0.47 | 20.41 | 0.09 | |

| Degumming Method | Variety | Content of Acids: | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Syringic [mg/100 g] | Sinapinic [mg/100 g] | p-Coumaric [mg/100 g] | Ferulic [mg/100 g] | ||||||

| Result | ±SD | Result | ±SD | Result | ±SD | Result | ±SD | ||

| HEMP | |||||||||

| Water retting | Beniko | 0.031 a | 0.001 | -* a | - | 0.722 a,b | 0.019 | -* a | - |

| Wojko | 0.046 | 0.001 | 0.048 | 0.002 | 0.741 a | 0.006 | 0.027 a | 0.001 | |

| Tygra | 0.036 | 0.001 | 0.100 | 0.003 | 0.695 b | 0.034 | 0.572 | 0.031 | |

| Białobrzeskie | 0.033 a | 0.001 | -* a | - | 0.024 | 0.006 | -* a | - | |

| Decortication | 0.224 | 0.011 | 0.672 | 0.023 | 0.746 | 0.008 | 2.082 | 0.036 | |

| Dew retting | 0.079 | 0.003 | -* a | - | 0.717 | 0.008 | 0.039 a | 0.004 | |

| Water retting | Białobrzeskie | 0.033 | 0.001 | -* a | - | 0.024 | 0.006 | -* a | - |

| Osmotic degumming | 0.094 | 0.003 | -* a | - | 1.111 | 0.011 | 0.625 | 0.009 | |

| FLAX | |||||||||

| Decortication | 0.235 | 0.008 | -* a | - | 0.995 | 0.024 | 5.749 | 0.159 | |

| Wet degumming + ultrasound | Modran | -* | - | -* a | - | -* a | - | 0.041 | 0.002 |

| Cottonization | 0.035 | 0.002 | -* a | - | -* a | - | 1.206 | 0.053 | |

| Decortication | -* a | - | -* a | - | -* a | - | 1.485 | 0.034 | |

| Wet degumming + ultrasound | NIKE | -* a | - | -* | - | -* a | - | 0.054 | 0.001 |

| Cottonization | -* a | - | -* a | - | -* a | - | 1.035 | 0.020 | |

| Decortication | 0.125 | 0.060 | -* a | - | 0.904 | 0.009 | 3.146 | 0.106 | |

| Wet degumming + ultrasound | B14 IUNG | 0.052 a | 0.002 | -* a | - | 0.027 | 0.008 | 2.525 | 0.106 |

| Cottonization | 0.040 a | 0.001 | -* a | - | 0.756 | 0.034 | 1.736 | 0.045 | |

| Degumming Method | Variety | FRAP [μmol/L] | Inhibition of DPPH [%] | ||

|---|---|---|---|---|---|

| Result | ±SD | Result | ±SD | ||

| HEMP | |||||

| Water retting | Beniko | 140.34 | 4.75 | 11.30 a | 0.92 |

| Wojko | 156.75 | 2.31 | 10.04 a | 0.49 | |

| Tygra | 165.76 | 1.62 | 32.55 | 0.32 | |

| Białobrzeskie | 76.62 | 1.33 | 3.09 | 0.18 | |

| Decortication | 230.22 | 1.55 | 18.03 | 0.63 | |

| Dew retting | 124.09 | 1.93 | 5.31 | 0.25 | |

| Water retting | Białobrzeskie | 76.62 | 1.33 | 3.09 a | 0.18 |

| Osmotic degumming | 93.71 | 0.69 | 3.94 a | 0.19 | |

| FLAX | |||||

| Decortication | 523.00 | 2.08 | 33.85 | 0.17 | |

| Wet degumming + ultrasound | Modran | 129.45 | 1.28 | 5.80 | 0.14 |

| Cottonization | 70.69 | 2.31 | 3.29 | 0.24 | |

| Decortication | 519.75 | 2.69 | 29.76 | 0.15 | |

| Wet degumming + ultrasound | NIKE | 140.79 | 1.16 | 7.64 | 0.16 |

| Cottonization | 78.84 | 1.59 | 5.10 | 0.36 | |

| Decortication | 485.84 | 2.11 | 37.71 | 0.14 | |

| Wet degumming + ultrasound | B14 Iung | 195.79 | 2.23 | 11.05 | 0.11 |

| Cottonization | 119.42 | 4.55 | 6.82 | 0.23 | |

| Tested Parameters | Values of the Pearson Correlation Coefficient | |||

|---|---|---|---|---|

| Content of Ferulic Acid | Content of p-Coumaric Acid | Content of Syringic Acid | Content of Sinapinic Acid | |

| Hemp variety | ||||

| Lignin content | 0.11 | 0.93 | 0.66 | 0.43 |

| FRAP | 0.54 | 0.96 | 0.46 | 0.72 |

| DPPH | 0.96 | 0.54 | 0.02 | 0.89 |

| Method extraction of hemp | ||||

| Lignin content | 0.81 | 0.67 | 0.91 | 0.76 |

| FRAP | 0.91 | 0.28 | 0.96 | 0.96 |

| DPPH | 0.94 | 0.21 | 0.97 | 0.99 |

| Variety of flax—MODRAN | ||||

| Lignin content | −0.91 | −0.98 | −0.94 | Not identified |

| FRAP | 0.95 | 0.99 | 0.97 | Not identified |

| DPPH | 0.96 | 1.00 | 0.98 | Not identified |

| Variety of flax—NIKE | ||||

| Lignin content | 0.80 | Not identified | Not identified | Not identified |

| FRAP | 0.65 | Not identified | Not identified | Not identified |

| DPPH | 0.68 | Not identified | Not identified | Not identified |

| Variety of flax—B14 IUNG | ||||

| Lignin content | −0.53 | −0.89 | −0.85 | Not identified |

| FRAP | 0.92 | 0.46 | 1.00 | Not identified |

| DPPH | 0.89 | 0.53 | 1.00 | Not identified |

| Bond | Vibration Type | Wavenumber [cm−1] | Remarks |

|---|---|---|---|

| O-H | Stretching | 3100–3600 | Cellulose, hemicellulose, lignin, pectin |

| C-H3 | Stretching | 2954–2970 | Lignin |

| C-H, C-H2 | Stretching | 2915–2923; 2895–2897; 2841–2848 | Cellulose, hemicellulose, lignin, pectins, waxes and fats |

| C=O | Stretching | 1730–1736 | Carboxylic acids, aldehydes, esters (pectin, lignin, waxes and fats) |

| O-H | Stretching | 1615–1645 | Adsorbed water |

| C=C Aromatic | Symmetrical Stretching | 1593–1595; 1507–1508 | Peaks characteristic of lignin |

| O-H and C-H3 and C-H2 | Bending and Deforming | 1461–1463 and 1461–1463; 1472–1473 | Adsorbed water and Lignin and cellulose, hemicellulose, pectins, waxes and fats |

| COO | Stretching | 1418–1420; 1424–1426 | Acids (pectins) |

| C-H3 | Symmetrical Deformation | 1370–1373 | Lignin |

| O-H | Bending | 1332–1338 | Cellulose, hemicellulose, lignin, pectin |

| CH2 | Scissoring (bending) | 1312–1314 | Cellulose, hemicellulose |

| C-H | Bending | 1271–1278 | Peak characteristic for lignin |

| C-O | Stretching | 1244–1246 | Hemicellulose, pectins |

| C-H | Bending | 1201–1204 | Flax, hemp |

| C-O-C | Bending | 1156–1161; 1051; 1020–1028 | Cellulose, hemicellulose, pectin |

| C-O | Stretching | 910–1125 | Cellulose, hemicellulose, pectin |

| Β-Glycosidic bond | Stretching | 893–897 | Cellulose, hemicellulose, pectin |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zimniewska, M.; Rozańska, W.; Gryszczynska, A.; Romanowska, B.; Kicinska-Jakubowska, A. Antioxidant Potential of Hemp and Flax Fibers Depending on Their Chemical Composition. Molecules 2018, 23, 1993. https://doi.org/10.3390/molecules23081993

Zimniewska M, Rozańska W, Gryszczynska A, Romanowska B, Kicinska-Jakubowska A. Antioxidant Potential of Hemp and Flax Fibers Depending on Their Chemical Composition. Molecules. 2018; 23(8):1993. https://doi.org/10.3390/molecules23081993

Chicago/Turabian StyleZimniewska, Malgorzata, Wanda Rozańska, Agnieszka Gryszczynska, Barbara Romanowska, and Anna Kicinska-Jakubowska. 2018. "Antioxidant Potential of Hemp and Flax Fibers Depending on Their Chemical Composition" Molecules 23, no. 8: 1993. https://doi.org/10.3390/molecules23081993