1

State Key Laboratory of Rolling and Automation, Northeastern University, NO. 3-11, Wenhua Road, Heping District, Shenyang 110819, Liaoning, China

2

Handan Iron & Steel Group Co., Ltd., No. 232, Fuxing Road, Fuxing Distirct, Handan 056015, Hebei, China

Metals 2018, 8(7), 534; https://doi.org/10.3390/met8070534 - 11 Jul 2018

Cited by 26 | Viewed by 4876

Abstract

We have studied here the evolution of inclusions in ladle furnace (LF), Ruhrstahl & Heraeus furnace (RH), and simulated welded samples during Ti-Mg oxide metallurgy treatment and the mechanical properties of the heat-affected zone (HAZ) after high heat input welding. The study indicated

[...] Read more.

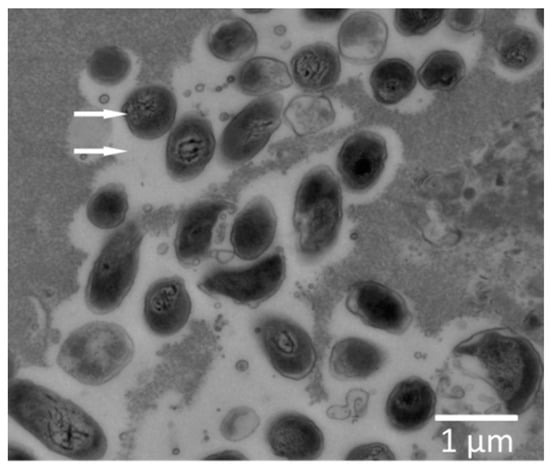

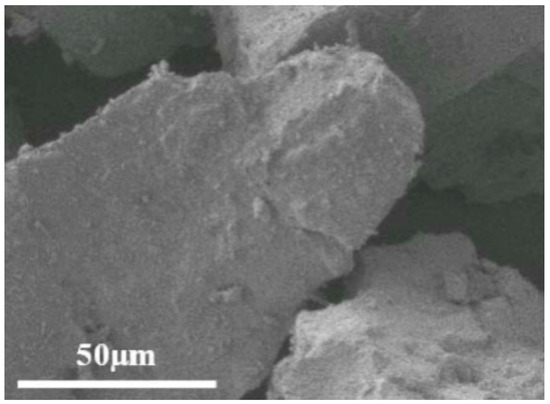

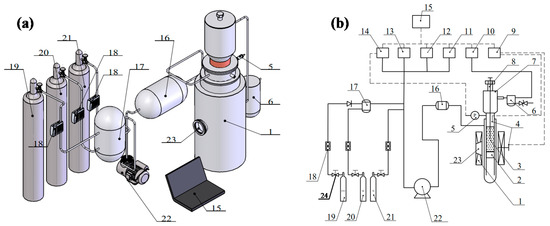

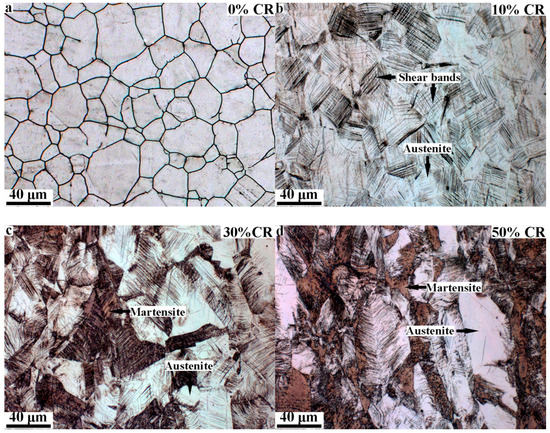

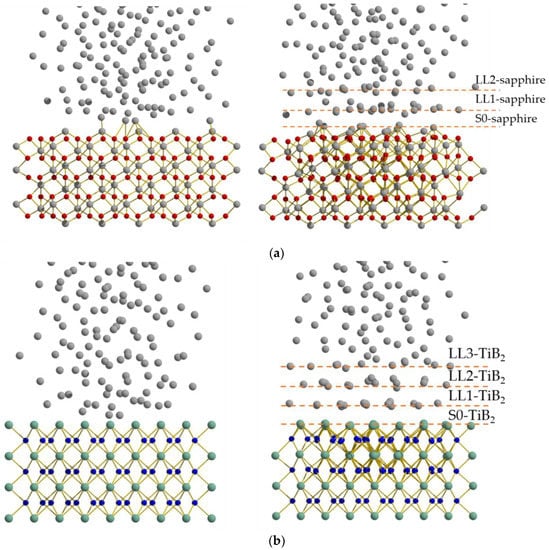

We have studied here the evolution of inclusions in ladle furnace (LF), Ruhrstahl & Heraeus furnace (RH), and simulated welded samples during Ti-Mg oxide metallurgy treatment and the mechanical properties of the heat-affected zone (HAZ) after high heat input welding. The study indicated that inclusions in an LF furnace station are silicomanganate and MnS of size range ~0.8–1.0 μm. After Mg addition, fine Ti-Ca-Mg-O-MnS complex oxides were obtained, which were conducive to the nucleation of acicular ferrite (AF). The corresponding microstructure changed from ferrite side plate (FSP) and polygonal ferrite (PF) to AF, PF, and grain boundary ferrite (GBF). After a simulated welding thermal cycle of 200 kJ/cm, disordered arrangements of acicular ferrite plates, fine size cleavage facets, small inclusions, and dimples all promoted high impact toughness.

Full article

(This article belongs to the Special Issue 5th UK-China Steel Research Forum)

▼

Show Figures