1

Department of Computer Science, University of Verona, Strada le Grazie 15, 37134 Verona, Italy

2

Department of Sciences, University of Basilicata, V.le dell’Ateneo Lucano 10, 85100 Potenza, Italy

3

Department of Chemistry, Sapienza University of Rome. P.le Aldo Moro 5, 00185 Rome, Italy

Polymers 2016, 8(3), 68; https://doi.org/10.3390/polym8030068 - 1 Mar 2016

Cited by 22 | Viewed by 6801

Abstract

A large number of nano-sized oxides have been studied in the literature as fillers for polymeric membranes, such as Nafion®. Superacidic sulfated oxides have been proposed and characterized. Once incorporated into polymer matrices, their beneficial effect on peculiar membrane properties has

[...] Read more.

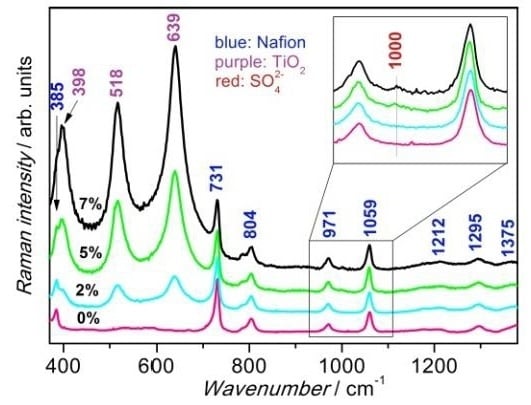

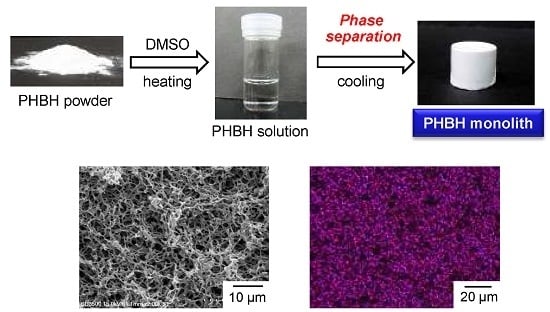

A large number of nano-sized oxides have been studied in the literature as fillers for polymeric membranes, such as Nafion®. Superacidic sulfated oxides have been proposed and characterized. Once incorporated into polymer matrices, their beneficial effect on peculiar membrane properties has been demonstrated. The alteration of physical-chemical properties of composite membranes has roots in the intermolecular interaction between the inorganic filler surface groups and the polymer chains. In the attempt to tackle this fundamental issue, here we discuss, by a multi-technique approach, the properties of a nanosized sulfated titania material as a candidate filler for Nafion membranes. The results of a systematic study carried out by synchrotron X-ray diffraction, transmission electron microscopy, thermogravimetry, Raman and infrared spectroscopies are presented and discussed to get novel insights about the structural features, molecular properties, and morphological characteristics of sulphated TiO2 nanopowders and composite Nafion membranes containing different amount of sulfated TiO2 nanoparticles (2%, 5%, 7% w/w).

Full article

(This article belongs to the Special Issue Nano- and Microcomposites for Electrical Engineering Applications)

▼

Show Figures